Dual air conditioner for vehicle

A technology for air conditioners and vehicles, applied in the direction of air conditioning systems, vehicle components, applications, etc., can solve the problems of complex pipeline laying routes, unstable refrigerant flow, increased number of components and manufacturing processes, etc., to achieve simple pipelines Effects of laying work, quantity reduction, and simplification of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

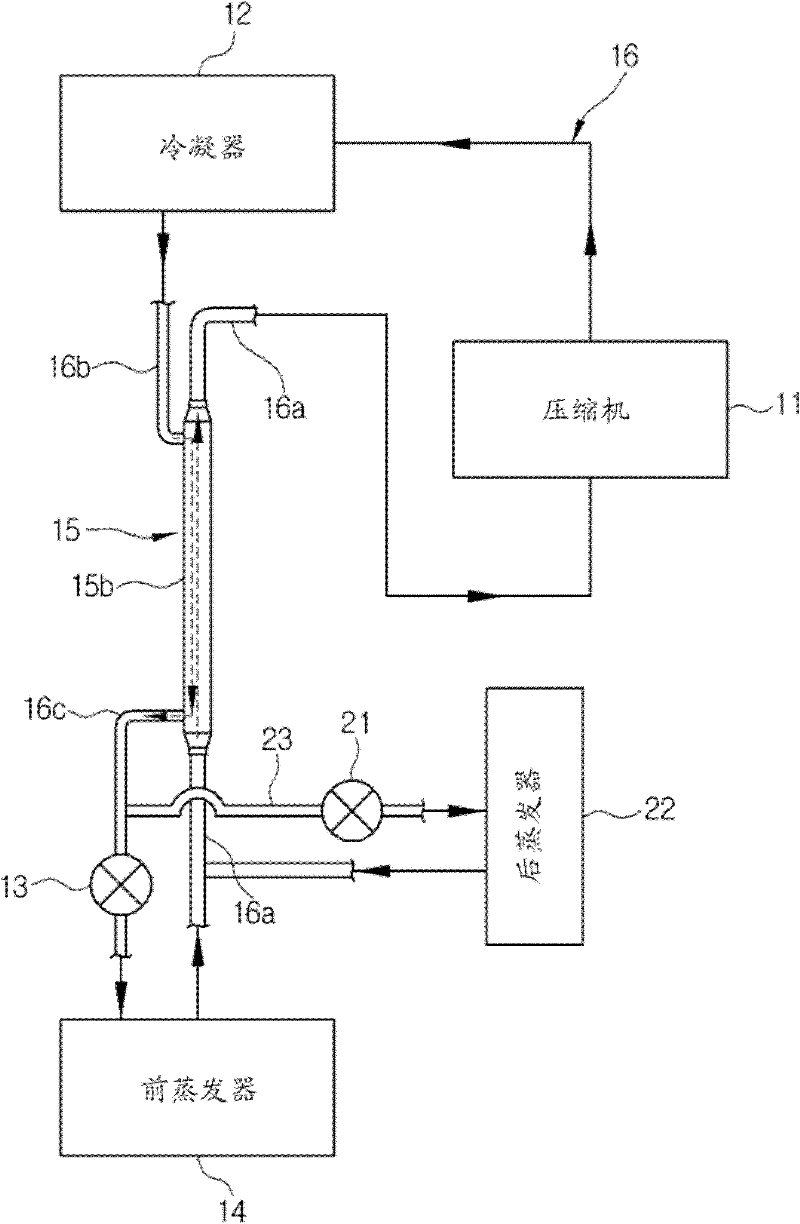

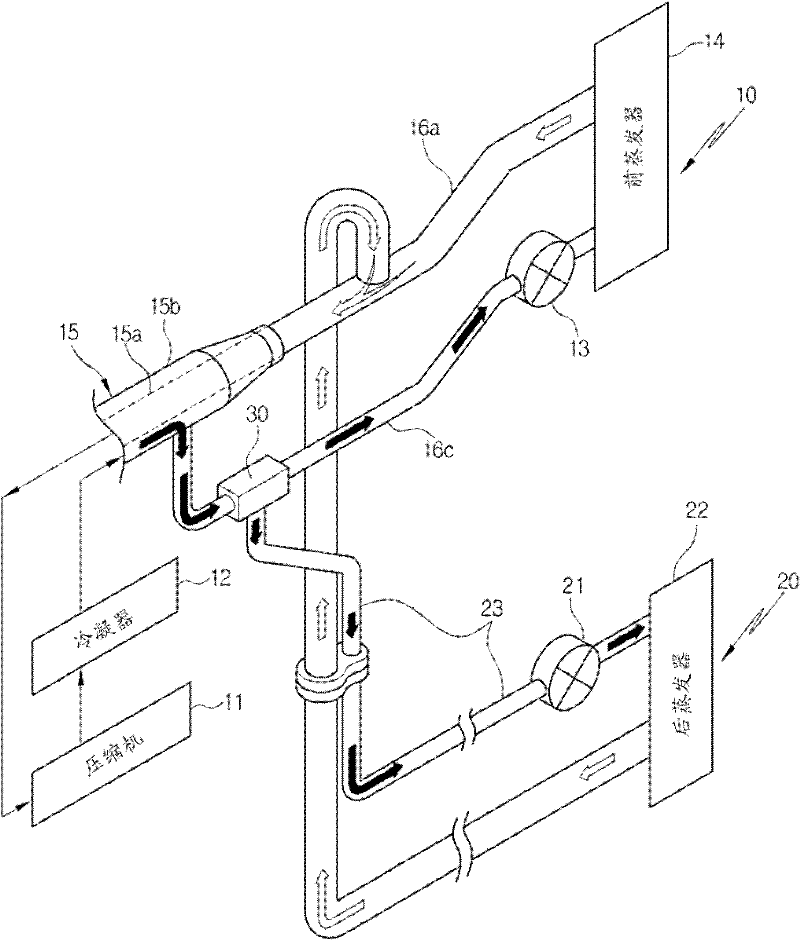

[0047] The dual air conditioner 100 for a vehicle according to the present invention includes a front air conditioner 200 installed in the engine compartment of the vehicle and a rear air conditioner 300 installed on the rear side of the vehicle and supporting the front air conditioner. The refrigerant circulating in the device 200 is divided.

[0048] First, the front air conditioner 200 has a refrigeration cycle including a compressor 210 , a condenser 220 , a double-pipe internal heat exchanger 250 , a front expansion valve 230 , and a front evaporator 240 connected to each other in sequence via a pipe P.

[0049] The compressor 210 operates by receiving a driving force from a power source (an engine, a motor, or others), thereby sucking and compressing a gas-phase low-temperature and low-pressure refrigerant discharged from the front evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com