Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195results about How to "With slow release function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly road surface ice and snow melt coating material, preparation method thereof and using method thereof

ActiveCN102199398AEnsure Snowmelt RequirementsPrevent loose grainsIn situ pavingsOther chemical processesSnow removalSnowpack

The invention relates to an environment-friendly road surface ice and snow melt coating material, a preparation method thereof and a using method thereof. Serious consequences such as traffic jam and the like can be caused by snow accumulation in winter; and at present, a snow removal method comprises passive snow removal and active snow removal, wherein in the passive snow removal, the operating efficiency of manual snow removal is low, mechanical snow removal is incomplete relatively in clearing, and for the spreading of a snow melt agent, substances with the snow melt effect are mixed simply only, so the spreading is non-uniform, and the snow melt agent dispersed to peripheral air has the major influence on environment; and the active snow removal is high in cost, and has a certain damage to structures of road surfaces, so the service life of roads is shortened. In the environment-friendly road surface ice and snow melt coating material, after being loaded on a carrier material, the snow melt substances are mixed with emulsified asphalt, water-soluble epoxy resin and a curing agent and sprayed on the road surfaces to form an ice and snow melt coating, so that the roads have the function of melting snow actively. By the environment-friendly road surface ice and snow melt coating material, an ice point of water is reduced to between -5 and -20 DEG C so as to clear the ice and snow of the roads, and the coating material has the sustained-release function, is high in coating adhesivity and wear-resisting effect, low in cost and convenient to maintain, and can prolong the life of the road surfaces effectively.

Owner:CCCC CIVIL ENG SCI & TECH

Growth factor slow-release type double-layered artificial skin

ActiveCN101716376AImprove waterproof performanceImprove breathabilitySkin implantsMicrospherePolyethylene glycol

The invention relates to a growth factor slow-release type double-layered artificial skin which is used for repairing injured skin with related growth factor slow-release functions and a preparation method thereof. The artificial skin is divided into two layers of an epidermal layer and an enderonic layer, wherein the epidermal layer is constituted by a micropore double-layered thin film with the functions of water proofing, ventilation and enderonic protection; the materials of the upper layer which contacts with air is polyurethane, or silicon rubber, or polyethylene glycol, or ethylene terephthalate and other medical materials; the lower layer which contacts with the dermis is a natural biological macromolecule thin film which is constructed by silk fibroin and chitosan; the enderonic layer of the artificial skin is constituted by collagen, polysaccharide and microspheres carrying growth factors related to skin regeneration and repairing; the microspheres have good slow-release function, and the slow-release period is equal to or slightly longer than the degradation period of the collagen and polysaccharide and can be matched with the skin regeneration and repairing period; and the thickness of the artificial skin is in a range of 0.5-1.5mm and can be regulated according to requirements.

Owner:SHENZHEN QIKANG MEDICAL DEVICES

Artificial skin prepared from purely natural materials and having gradient hole structure and property

ActiveCN101716375AImprove waterproof performanceImprove breathabilitySkin implantsMedicineMicrometer

The invention relates to artificial skin prepared from purely natural materials and having gradient hole structure and property and a preparation method thereof. The artificial skin comprises an epidermal layer and an enderonic layer, wherein the epidermal layer and the enderonic layer both have the gradient in the structure and the property simultaneously and the thicknesses of the epidermal layer and the enderonic layer are between 0.5 millimeters and 1.5 millimeters and can be regulated as required; the epidermal layer is a thin film which has the functions of water prevention, air permeation and enderon protection and has compacter structure, and the dimensions of holes are smaller than 5 micrometers; the epidermal layer has degradability, degrading period between four months and six months and good elasticity and ductility; the enderonic layer of the artificial skin is prepared from collagen and polysaccharide in a simulating way, in a sponge shape, porous and mutually communicated, the dimensions and the distribution of the holes are in gradient distribution from top to bottom, and apertures are increased from 20 micrometers to 300 micrometers; the enderonic layer has different degrading periods from top to bottom and is also in the gradient distribution, degrading speed is increased from top to bottom, and the degrading periods are accelerated from four months to two weeks; and the dimensions and the distribution of the holes and the gradient of degradation are controlled by the component transformation and a multi-layer overlying processing technology.

Owner:SHENZHEN QIKANG MEDICAL DEVICES

Synthesis of urea-formaldehyde controlled releasing fertilizer

InactiveCN1506335AAvoid excessive cross-linking reactionsImprove effectivenessUrea compound fertilisersFertilizer mixturesVegetable oilFORMALDEHYDE SOLUTION

The synthesis process of urea-formaldehyde controlled releasing fertilizer includes mixing gelatinized starch and urea, adding the mixture of polymer water absorbing resin and formaldehyde solution, adding vegetable oil, organic matter including turf and stalk and adsorbent including zeolite, adding sulfuric acid for acidifying to obtain solid product, and final drying, crushing and sieving to obtain the product. The said process avoids excessive crosslinking of polymer to raise the utility of nitrogen, avoids volatizing of formaldehyde during reaction to raise environment quality and production efficiency, and adds zeolite and other inorganic stuffing to raise product quality and provide water maintaining and fertilizer maintaining function and trace elements. In addition, phosphate fertilizer and potash fertilizer may be also added to produce re-compounded fertilizer.

Owner:北京市农林科学院植物营养与资源研究所

Slowly-released filter stick essence microcapsule and preparation method thereof

InactiveCN101972038AHave mechanical strengthImprove particle size uniformityTobacco preparationEssential-oils/perfumesPolymer sciencePolymer chemistry

The invention discloses a slowly-released filter stick essence microcapsule and a preparation method thereof. The slowly-released filter stick essence microcapsule is prepared from the following raw materials in parts by weight: 12-18 parts of sodium alginate, 6-12 parts of Arabic gum, 15-25 parts of emulsifier and 10-15 parts of filter stick essence. The preparation method comprises the following steps: firstly, respectively preparing an Arabic gum solution and a sodium alginate solution; then, injecting the sodium alginate solution into the Arabic gum solution proportionally to obtain a mixed wall material solution; in the stirring process, successively adding the emulsifier and the filter stick essence to obtain emulsion; standing; and carrying out high-voltage electrostatic treatment after foam is eliminated to obtain the microcapsule. The slowly-released filter stick essence microcapsule prepared by the invention has the advantages that the embedding rate is more than 80%, the particle diameter uniformity is good, the essence retention rate is more than 85% after the microcapsule is stored for 6 months at 20 DEG C, and the release rate of the essence microcapsule at 40 DEG C is about 6 times of the release rate of the essence microcapsule at 20 DEG C.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Humic acid synergistic slow-release compound fertilizer and preparation method thereof

ActiveCN104276906ASmall molecular weightWith slow release functionAlkali orthophosphate fertiliserExcrement fertilisersUreaHumic acid

The invention discloses a humic acid synergistic slow-release compound fertilizer and a preparation method thereof and belongs to the technical field of slow-release compound fertilizers. The fertilizer is prepared from the following raw materials in parts by weight: 15-45 parts of nitrogen fertilizer, 15-35 parts of phosphorus fertilizer, 10-25 parts of potassium fertilizer, 1-10 parts of medium trace elements, 5-15 parts of biological humic acid and a controlled-release agent, wherein the nitrogen fertilizer raw material comprises urea which accounts for 8-25% of total weight, the addition of the controlled-release agent is 0.7-0.9% the weight of urea, the controlled-release agent is prepared by mixing an urease inhibitor and a nitrification inhibitor in a weight ratio of 1 to (0.5-1), and biological humic acid is prepared by fermenting crushed bagasse and animal waste by using a special microbial agent. Biological humic acid which has the advantages of small molecular weight, strong activity, good solubility and the like is added into the compound fertilizer, and the controlled-release agent and biological humic acid are combined by using a method of combining amino acid granulation and urea-based guniting, so that the fertilizer conserving and supply condition of soil is improved while the utilization rate of the fertilizer is improved.

Owner:HUBEI XIANGYUN GROUP CHEM

Preparation method of buckwheat flavone microcapsule and its product

InactiveCN102334685AHigh mechanical strengthHigh activityFood preparationPolygonum fagopyrumSolubility

The invention provides a preparation method of a buckwheat flavone microcapsule, which comprises the following steps: 1) pretreating: drying buckwheat grain, buckwheat shell, buckwheat husk or buckwheat stem leaf, sieving after crushing for standby to obtain buckwheat powder; 2) extracting; 3) separating and purifying; 4) preparing a capsule emulsion: uniformly mixing a core material, a wall material and an emulsifier to prepare a buckwheat flavone microcapsule emulsion; 5) spray drying to obtain the buckwheat flavone microcapsule. The invention has the advantages that: 1, the activity of an active component flavone substance in buckwheat is protected; 2, the buckwheat flavone is prevented from damage of gastric acid, has certain targeting after microencapsulation, and has good enteric solubility but insolublility in stomach; 3, the bitter taste of buckwheat is covered; 4, the release speed is controlled, the flavone substance can not be stored in vivo, and the concentration of the flavone substance is rapidly increased in vivo after taking and rapidly decreasing due to metabolism degradation effect, the microencapsulation enables a slow release function and releases functional factors in certain time and scope.

Owner:SHAANXI UNIV OF SCI & TECH

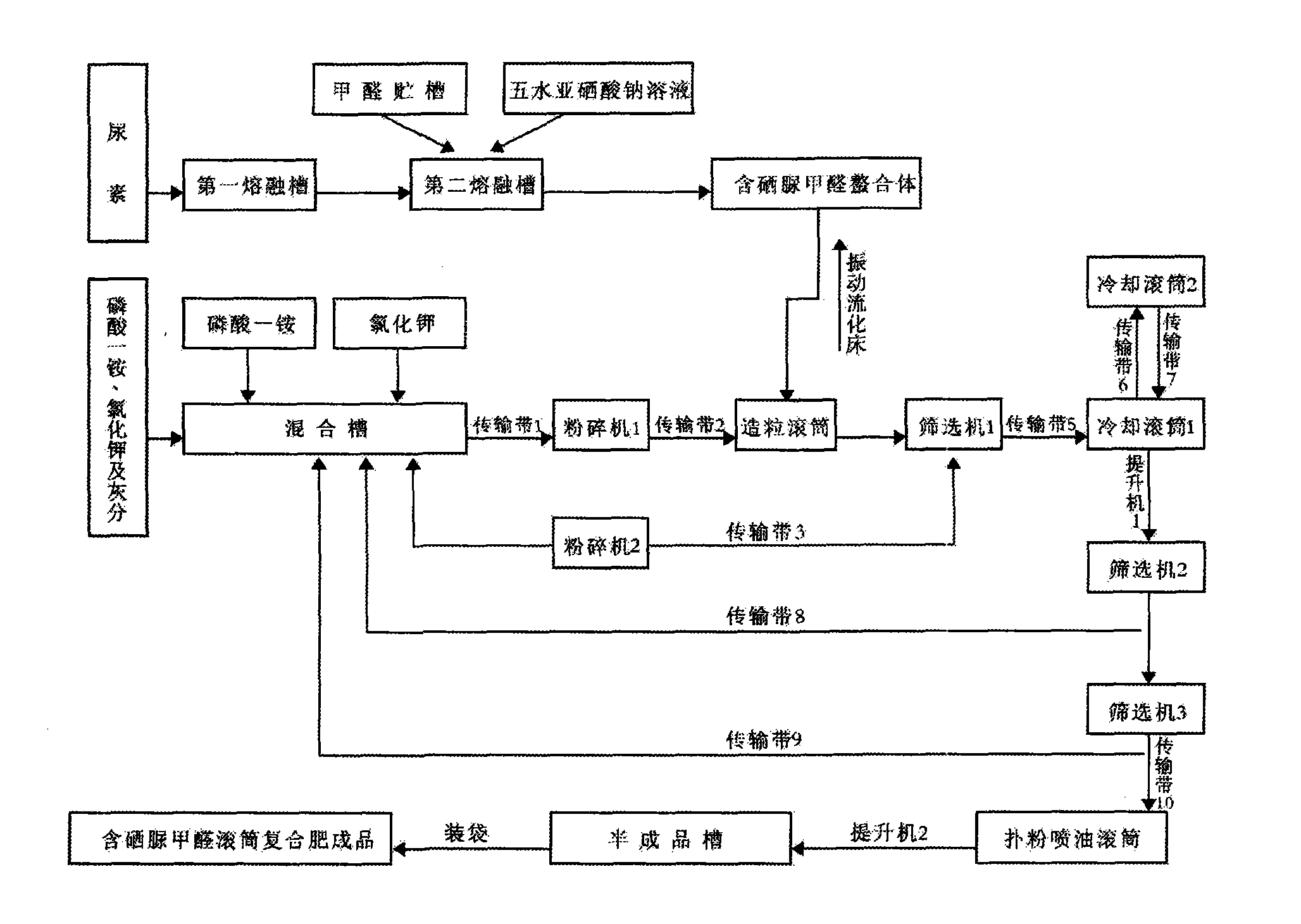

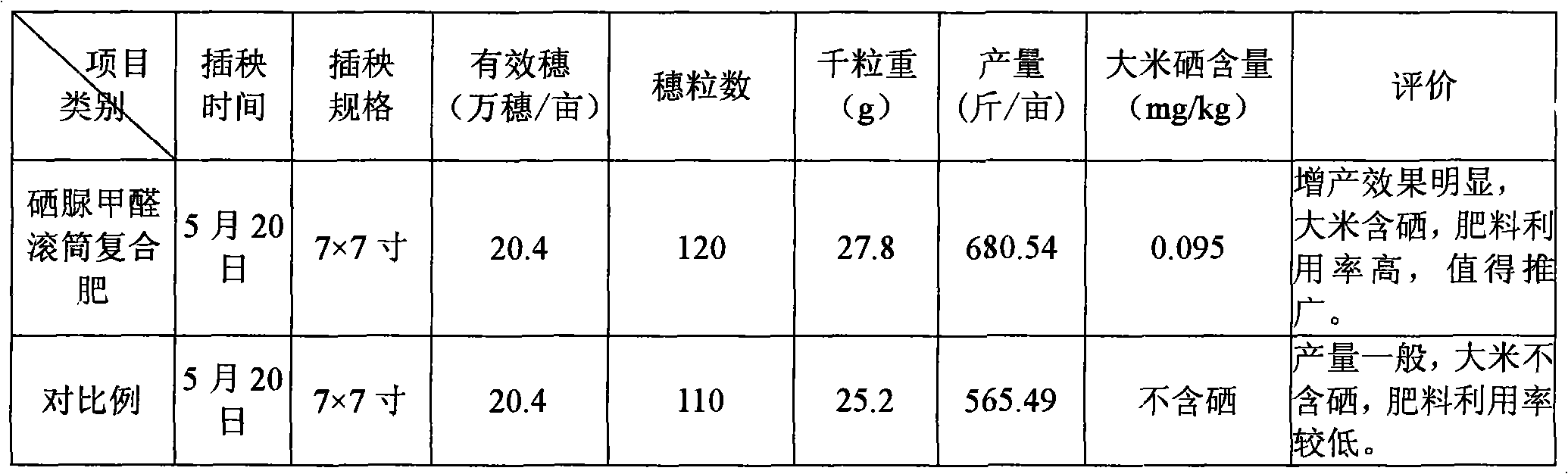

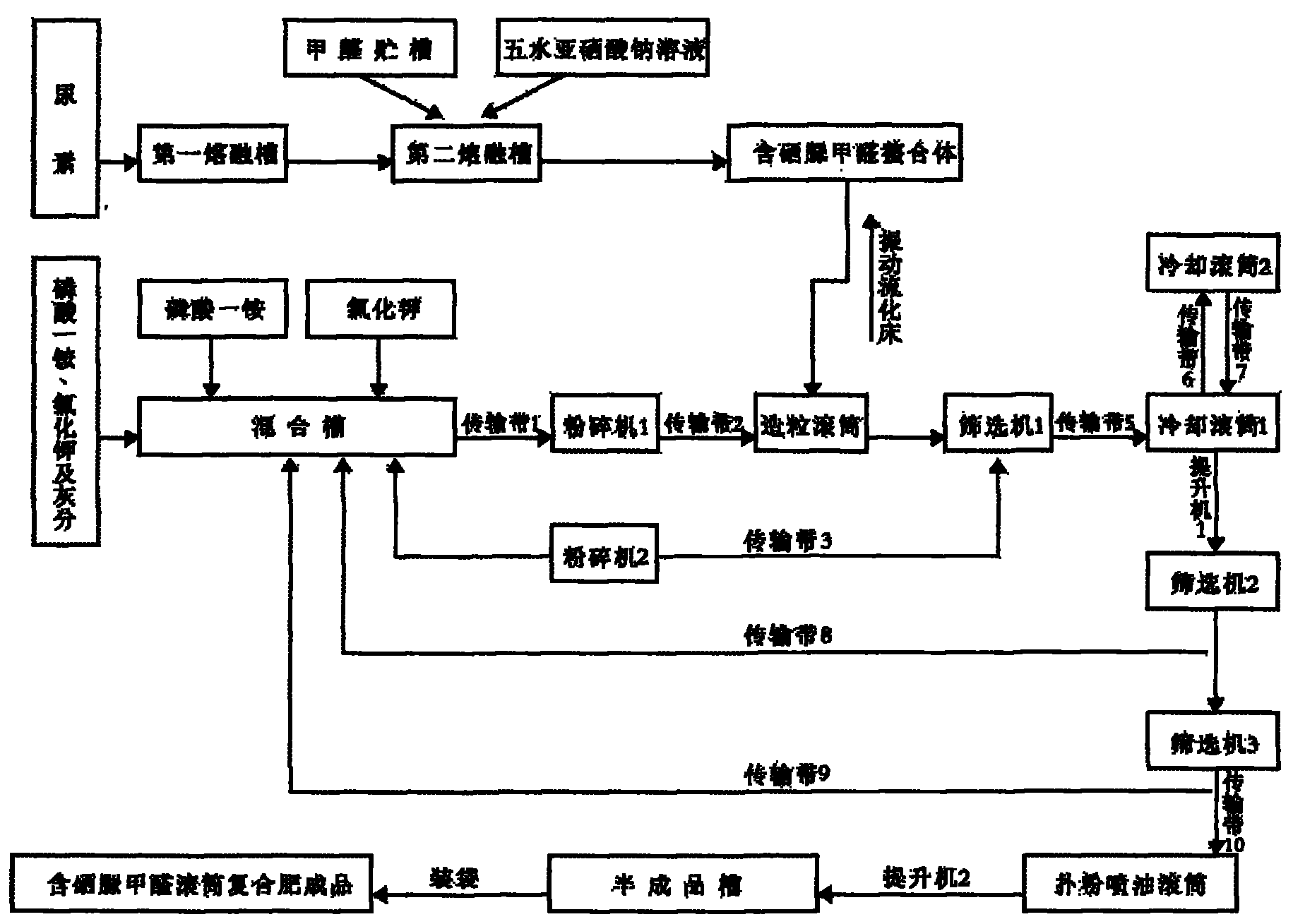

Selenium urea formaldehyde roller pelleting compound fertilizer and production method thereof

ActiveCN101993268AFertilizer effect time is longProvide crop yieldAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersWater contentFertilizer

The invention relates to a fertilizer, in particular to a selenium urea formaldehyde roller pelleting compound fertilizer and a production method thereof. After selenium urea formaldehyde is added into the compound fertilizer, agricultural products enriched in selenium cannot only be produced; because a nitrogen element and a selenium element in the selenium urea formaldehyde are chelated, the selenium urea formaldehyde roller pelleting compound fertilizer has a certain release function, and the fertilizer efficacy time is long so as to improve the yield of the crops. On the other hand, the compound fertilizer adopts circulation cooling in the production process and the cooling process, so that fertilizer particles are fully cooled, along with the adhesion of the selenium urea formaldehyde, so that the particle hardness of the compound fertilizer product is high, less water content is introduced into the production without drying, so as to greatly save energy sources.

Owner:STANLEY AGRI GRP CO LTD

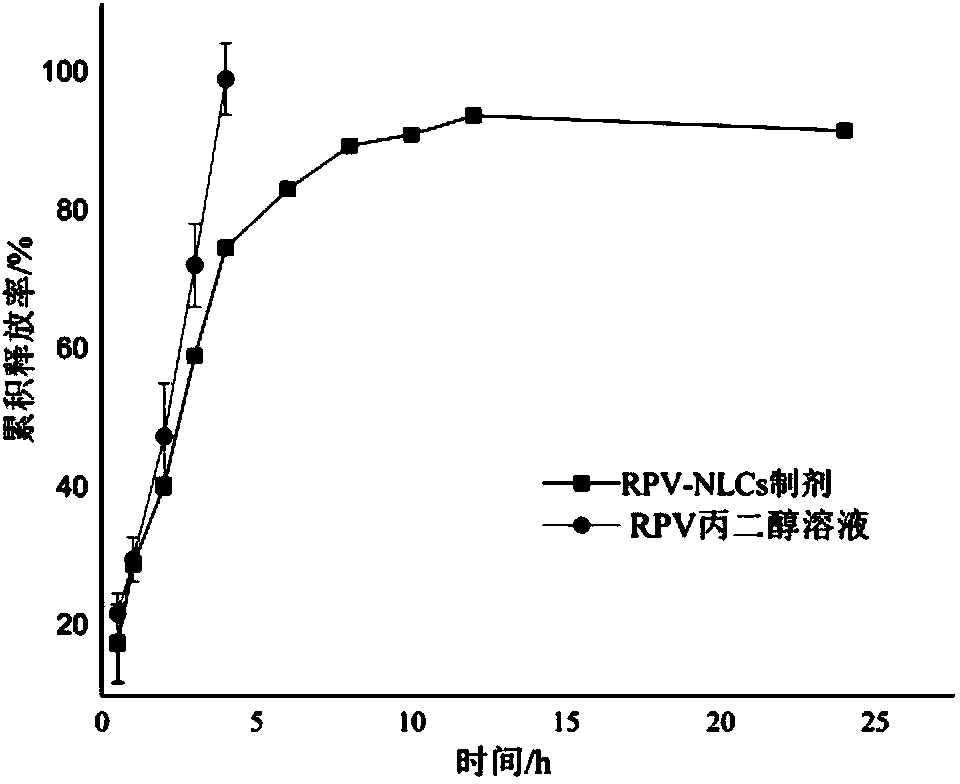

Ropivacaine nanometer lipid carrier temperature-sensitive in-situ gel and preparation method thereof

InactiveCN103816111AImprove solubilityReduce releaseAerosol deliveryOintment deliveryLipid formationBiocompatibility Testing

The invention belongs to the technical field of medicinal preparations and specifically to a ropivacaine nanometer lipid carrier temperature-sensitive in-situ gel and a preparation method thereof. The ropivacaine nanometer lipid carrier temperature-sensitive in-situ gel disclosed by the invention mainly comprises bulk drug ropivacaine, a solid lipid material, a liquid lipid material, a surfactant, a cosurfactant, a gel matrix and injection water. The preparation method is a high-temperature emulsification low-temperature setting and cold melt method. The ropivacaine nanometer lipid carrier temperature-sensitive in-situ gel prepared in the invention is applied through transdermal drug delivery and has the advantages of a slow release function, a high transdermal permeation rate, a high entrapment rate, high drug loading capacity, good biocompatibility and good stability.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Slow-release collapse-preventing type polycarboxylic water reducing agent and preparation method thereof

The invention discloses slow-release collapse-preventing type polycarboxylic water reducing agent and a preparation method thereof, and belongs to the field of preparation of the water reducing agent. The slow-release collapse-preventing type polycarboxylic water reducing agent consists of methyl allyl polyoxyethylene ether, acrylic acid, methyl acrylic polyethylene glycol monoester, imide, initiator, vitamin C, chain transfer agent and deionized water. The preparation method comprises the following steps of: preparing macromonomer methyl allyl polyoxyethylene ether, acrylic acid, methyl acrylic polyethylene glycol monoester, imide and vitamin C; under the action of the polymerization initiator and the chain transfer agent, dissolving the methyl allyl polyoxyethylene ether into deionized water, rising temperature to 40 DEG C for dissolving, adding the initiator, then respectively dripping water solution A prepared by dissolving the chain transfer agent, the acrylic acid, the methyl acrylic polyethylene glycol monoester and the imide in the deionized water and V.C water solution B, and after the dripping is finished, carrying out insulation, cooling and neutralization to obtain a finished product. The slow-release collapse-preventing type polycarboxylic water reducing agent disclosed by the invention has the advantages that the loss and the evaporation of water in concrete due to long-time transportation and higher temperature are effectively prevented, and the difficulty of excessively-fast slump loss of the concrete in engineering is solved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

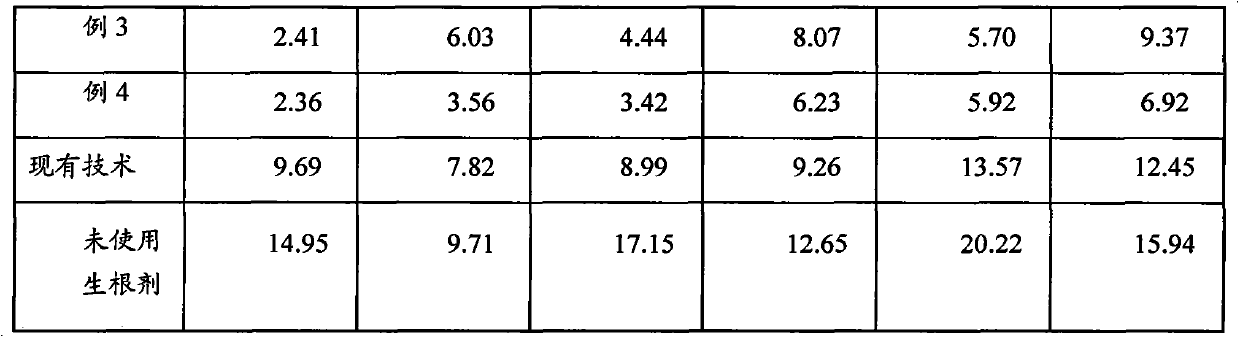

Seed coating agent for ecological remediation of desertified land, coating method and coated seed

ActiveCN110622967AEasy sowingImprove seedling ratePlant growth regulatorsBiocideAdhesivePlant growth

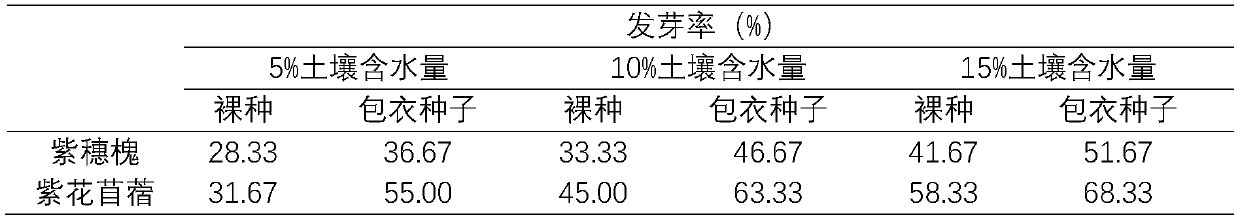

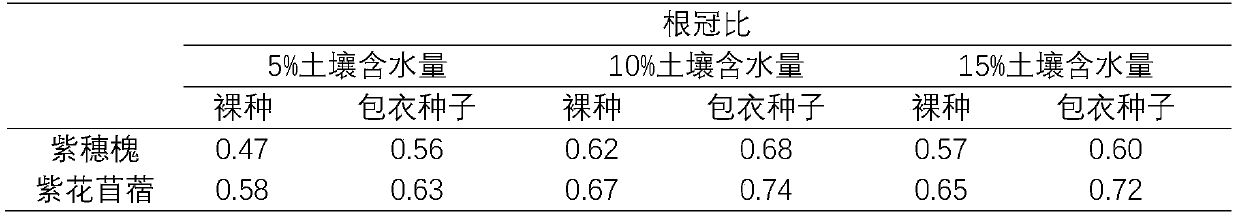

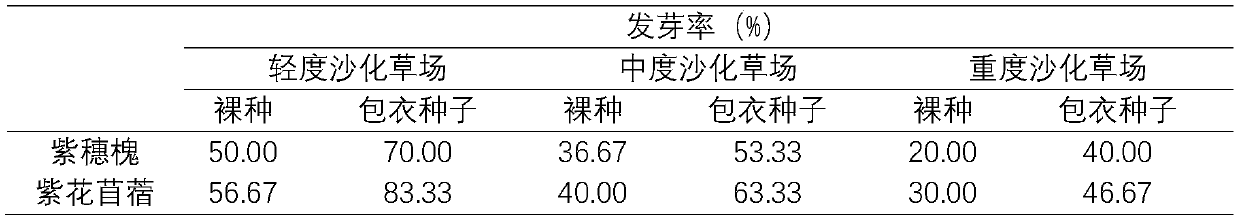

The invention provides a seed coating agent for ecological restoration of desertified land. The seed coating agent comprises the following raw materials by mass: 80-110 parts of filler, 1-4 parts of super absorbent resin, 0.03-0.11 part of a plant growth regulator, 10-15 parts of humic acid and 0.5-1 part of a rhizosphere microbial strain, and also includes an adhesive, wherein the total mass of the filler, the super absorbent resin, the plant growth regulator, humic acid and the rhizosphere microbial strain and the massic volume of adhesive are in a ratio of (3-8):1, preferably 6.25:1 or 5:1.The germination rate of seeds coated with the seed coating agent is obviously increased, and the root cap ratio of seedlings is obviously increased, therefore the seed coating agent can be applied toagricultural production.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

Dentoidin sponginum and preparation method thereof

ActiveCN102309523ALarge doseImprove plasticityPeptide/protein ingredientsSkeletal disorderAtrophyBone tissue

The invention belongs to the field of pharmacy and medical technology and relates to a dentoidin sponginum and a preparation method thereof. The sponginum provided by the invention comprises 80-99wt% of dentoidin and 1-20wt% of collage sponge matrix, wherein the dentoidin is fixed on the collagen sponge through crosslinking in different weight ratios. The sponginum provided by the invention ensures that the dentoidin is filled into ill parts with bone defects, nonunion of bone, bone tissue atrophy, bone fracture, poor bone healing and the like, so that the dentoidin plays roles in inducing bone formation, promoting bone repair and promoting wound convergence.

Owner:深圳市光明创博生物制品发展有限公司

Original form dechroming method for chrome leather fragment, and application of product thereof in fertilizer aspect

ActiveCN103143551AReduce manufacturing costReduced chromium contentSolid waste disposalPlant growthCalcium oxide

The invention relates to an original form dechroming method for chrome leather fragment, and application of a product thereof in fertilizer aspect. The method comprises the following steps of: adding water and calcium oxide, soaking at 20-40 DEG C for 1-4 days, washing by water and filtering; adding water, acid and salt into the filter residue, dechroming at 20-30 DEG C for 2-4 hours, washing by water and filtering; continuing to add water, salt and alkaline into the filter residue, keeping the temperature and dechroming for 30-60 min, regulating the pH to be neutral, washing by water and filtering; obtaining an original form dechromed product of chrome leather fragment; mixing and crushing the original form dechromed product of chrome leather fragment with plant ash, pelleting, and thus containing an agricultural composite fertilizer. The composite fertilizer not only has low chrome content and is rich of potassium element and organic nitrogen, but also has certain slow release function, and can effectively promote growth of plants.

Owner:王全杰

Method for preparing micro-spheres using modified ploylactic acid material as shell material

InactiveCN1935127ASmall particle sizeParticle size controllableBiocidePharmaceutical non-active ingredientsMicrosphereWater soluble

The present invention relates to a microphere preparation method using modified polylactic acid material as capsule material. Said preparation method includes the following steps: firstly, the capsule core material can be dissolved or dispersed in the water, the modified polylactic acid material is dissolved in the solvent which can be mixed with water-phase; then the aqueous solution of capsule core material is added into the solution of modified polylactic acid material or the solution of modified polylactic acid material is added into the aqueous solution of capsule core material or said two solutions are simultaneously added into the solvent capable of dissolving polylactic acid material or their mixed solution is added into the solvent capable of dissolving modified polylactic acid material, then they are stirred so as to obtain microsphere solution, filtered to obtain microspheres.

Owner:CHONGQING UNIV

Taxol nano targeting slow-release long-circulating liposome and preparation method thereof

InactiveCN101780042AImprove stabilityHigh drug loading rateOrganic active ingredientsPharmaceutical non-active ingredientsPolyethylene glycolTarget tissue

The invention relates to a taxol nano targeting slow-release long-circulating liposome and a preparation method thereof. The taxol nano targeting slow-release long-circulating liposome of the invention mediates the structure of polyethylene glycol modificatory chitosan derivative by folate receptor; and the invention utilizes the chitosan derivative as an auxiliary material to prepare a novel taxol preparation by a reverse phase evaporation method or film dispersion method, and the prepared taxol nano targeting slow-release long-circulating liposome has the grain size smaller than 100nm, can freely run in the blood, penetrates the endothelial cell of a target tissue, can be uptaken by a tumor cell to enter the cell, releases the contained taxol in the cell, and greatly improves the utilization efficiency of medicaments. In addition, the surface of the prepared taxol nano targeting slow-release long-circulating liposome is also covered by a layer of polyethylene glycol (PEG) which can prolong the dwell time of liposome in the blood, reduce the uptaken amount of liposome by liver and spleen reticuloendothelial systems, and is beneficial to the absorption of tumor tissues and lesion parts.

Owner:TIANJIN UNIV

Antibacterial and mold-proof essential oil composition and packaging paper prepared by applying same

The invention relates to the field of antibacterial and mold-proof technologies, in particular to an antibacterial and mold-proof essential oil composition and packaging paper prepared by applying the same. The antibacterial and mold-proof essential oil composition is prepared from, by weight, 30-40parts of horseradish essential oil, 10-20parts ofcinnamon oil, 20-30parts ofbasic oil, 1-5parts ofpreservative and 2-8parts ofessence, and 10-15 parts of garlic essential oil and 10-15parts ofchili oil can be also added. The essential oil composition adopts multiple types of extracted natural plant essential oil, is harmless to human body health, free of environmental pollution and high in safety, hasfreshness-retaining, antibacterial and mold-proof effects and the like, has a slow-release function, can prolong a preservation and storage period, is long in preservation effect, delays the rotting and mildewing situation, is suitable for freshness-retaining and mold-proof package of vegetables, fruits and other foods and can be used for antibacterial and mold-proof packaging and storage of clothes, shoes, quilts, bags and suitcases and other articles.

Owner:东莞市隆威实业有限公司

Essence micro-capsule wall material and essence micro-capsule

InactiveCN104263513AUniform particlesDense wallEssential-oils/perfumesMicroballoon preparationFuranChemistry

The invention relates to an essence micro-capsule wall material and an essence micro-capsule. The essence micro-capsule wall material is a mixed product of whey protein-glucose prepared by performing Maillard reaction on whey protein and glucose in a mass ratio of 1:(2-3). The invention also provides a method for preparing an essence micro-capsule by using the essence micro-capsule wall material. According to the essence micro-capsule wall material and the essence micro-capsule disclosed by the invention, a whey protein-glucose mixture is used as the wall material of the essence micro-capsule, heterocyclic compounds with aromatic flavor such as pyrazine and furan can be generated in food heating processes such as boiling and deep-frying processes, and aroma components can be compatible with foods, so that adverse effects caused by adding a conventional wall material into the foods can be avoided. Moreover, the essence micro-capsule prepared from the wall material has the advantages of uniform particles, compact capsule wall, high embedding rate, good stability, good release performance and the like.

Owner:TIANJIN CHUNFA BIO TECH GRP

Two-layer coated seeds, and processing tech. therefor

InactiveCN1559166AReduce virus infectionNot easy to loseSeed arrangmentsFood preparationAdhesiveBiology

A seed between two filmes is prepared through uniformly arranging the coated seeds on a lower paper film and sticking an upper paper film on said coated seeds by use of the adhesive containing agricultural chemical, so arranging the coated seeds between two paper film for omitting ground film.

Owner:唐高民

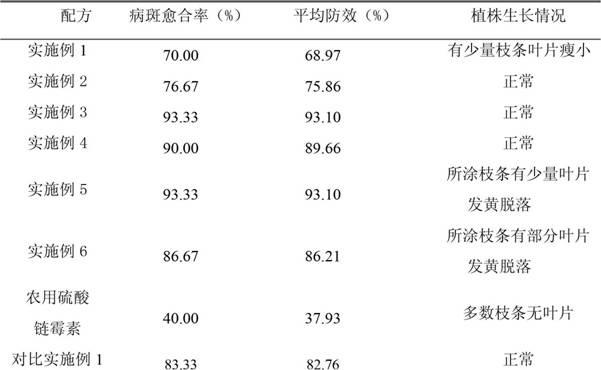

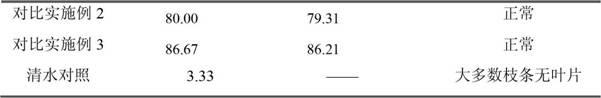

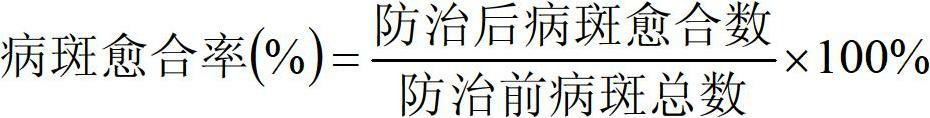

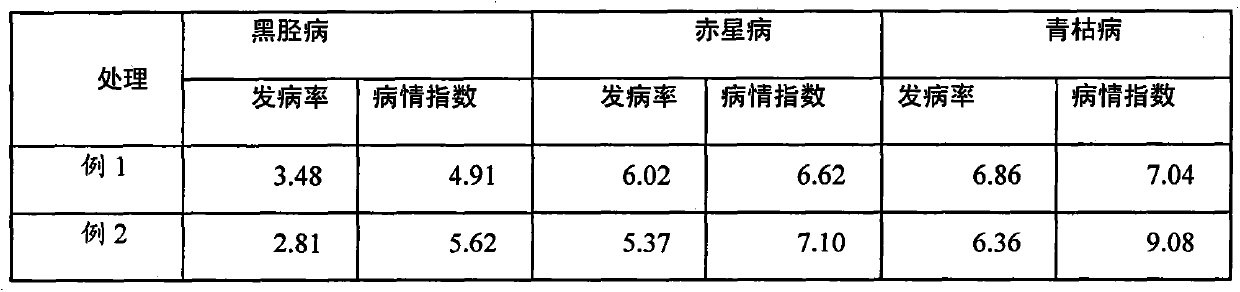

Smearing preparation for preventing and controlling kiwifruit bacterial canker

InactiveCN102669128AImprove self-healing abilityReduce infestationBiocidePlant growth regulatorsActinidiaMedicine

The invention relates to a smearing preparation, in particular to a smearing preparation for preventing and controlling kiwifruit bacterial canker. Bromothalonil as a low-toxicity medicament is used as an active ingredient of the smearing preparation, and smearing is used as the using way of the smearing preparation, so that no liquid medicine drifting problem exists. More importantly, the smearing preparation provided by the invention is a gel liquid and can automatically form a uniform coating at the wound part of a kiwifruit after being used, so that infection of foreign germs to a wound of a plant and water evaporation of the plant can be effectively reduced, influences of the wound to the growth of the kiwifruit can be reduced, and the aims of preventing and controlling the kiwifruitbacterial canker for a long term can be achieved.

Owner:SICHUAN AGRI UNIV

Anti-seepagesustained-release fertilizer for planting potato and preparation method thereof

InactiveCN101386557AWith slow release functionGood anti-seepage functionFertilizer mixturesFertilizerChemistry

The invention discloses an anti-seepage slow release fertilizer for potato planting and a preparation method thereof. The anti-seepage slow release fertilizer mainly comprises clay, starch, nutritional components and high water-absorption resin. A composite system has obvious functions of storing water, preventing seepage and slowing releasing the fertilizer in soil, greatly improves the utilization ratio of water and fertilizer, and increases potato yield in sandy soil by more than 50 percent. The anti-seepage slow release fertilizer has the advantages that the fertilizer is fast to take effect and easy to popularize, effectively solves the problem about the excessive infiltration of moisture in sandy land, and has obvious economic, social and ecological benefits when used in the sandy land.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Sugar-vitrified essential oil capsule prepared based on extrusion method and preparation method thereof

ActiveCN103242961ACompact and stable structureEffective dispersionEssential-oils/perfumesMicroballoon preparationSucroseSoybean Lecithin

The invention relates to a sugar-vitrified essential oil capsule prepared based on an extrusion method and a preparation method thereof. Essential oil is instable in nature, high in volatility, poor in water solubility and easy to deteriorate under high-temperature conditions. The preparation method comprises the following steps: preparing soya bean lecithin, water and essential oil into a pasty emulsion; mixing sucrose, modified starch and maltodextrin at a high speed, adding the emulsion, mixing according to a dry method, feeding into an extruder through a screw feeder, and extruding to prepare the essential oil capsule. The capsule prepared by the invention has a more compact and stable structure; the capsule hermetically packaged in a moisture-proof material can be stored for a long time under room temperature conditions; and the stability is greatly improved, no antioxidant needs to be used, and the capsule has a certain slow release function in application.

Owner:广州市珍馨香精香料有限公司

Preparation method for multifunctional hydrogel used for 3D printing

ActiveCN105770998AWith slow release functionPromote hyperplasiaAdditive manufacturing apparatusProsthesisO carboxymethyl chitosanFiltration

The invention provides a preparation method for multifunctional hydrogel used for 3D printing.Raw herbal materials of radix angelica sinensis and radix astragali are mixed and smashed, and then a water-extraction and alcohol-precipitation method is used for extracting radix angelica sinensis and radix astragali polysaccharides; radix angelica sinensis and radix astragali polysaccharide powder is added into a dry reaction kettle, then ethyl alcohol is added, NaIO4 with the mass 0.4-0.6 time that of the radix angelica sinensis and radix astragali polysaccharides is dissolved in 200 ml of water, and the solution is added into a reaction system for reacting for 8 h in a lucifugal state; glycol is added, absolute ethyl alcohol with the volume about 2 times that of the reaction system is added into the reaction system, stirring is carried out for 10 min before suction filtration, then a dialysis bag with the molecular cut-off of 3,500 is used for dialysis for 72 h, drying is carried out for 12 hours at the temperature of 50 DEG C, and oxidized radix angelica sinensis and radix astragali polysaccharides are obtained; the oxidized radix angelica sinensis and radix astragali polysaccharides are weighed and dissolved in distilled water according to the mass-to-volume ratio of 1:20, N,O-carboxymethyl chitosan with the mass 1-3 times that of the oxidized radix angelica sinensis and radix astragali polysaccharides is weighed and dissolved in distilled water according to the mass-to-volume ratio of 1:10, the two solutions are mixed in an isovolumetric mode, standing is carried out for 10 min at room temperature, and the multifunctional radix angelica sinensis and radix astragali polysaccharide gel is obtained.

Owner:甘肃中科博瑞生物工程有限公司

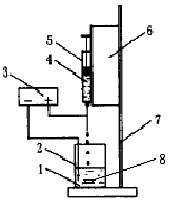

Large grained fertilizer granulation equipment

At present, fertilizers are granulated mostly through the following processes: granulating by a rotary drum, granulating through slurry spraying, granulating by a high tower, granulating through ammonification, granulating through extrusion and the like; however, large grained fertilizers with the grain diameters of more than 2 cm are very difficult to manufacture through the processes. The invention provides large grained fertilizer granulation equipment. Raw materials are adopted to be fused into liquid at a high temperature, liquid fertilizers fused at the high temperature, which are loaded in a bunker trolley, are filled in dies on a machine in sequence so as to conduct the cooling formation, and the dies are opened by a die closing frame system to eject the formed fertilizer particles to be conveyed outside the machine. Spherical, square and cylindrical large grained fertilizers with the grain sizes of more than 2 cm can be manufactured by the large grained fertilizer granulation equipment. The fertilizers manufactured by the large grained fertilizer granulation equipment has the advantages that the rate of finished products is high, the drying operation is omitted, the appearance is attractive, the compression strength is high, the resistant transportation capability is achieved, and no soil hardening phenomenon exists.

Owner:CHONGQING JINMANDI FERTILIZER

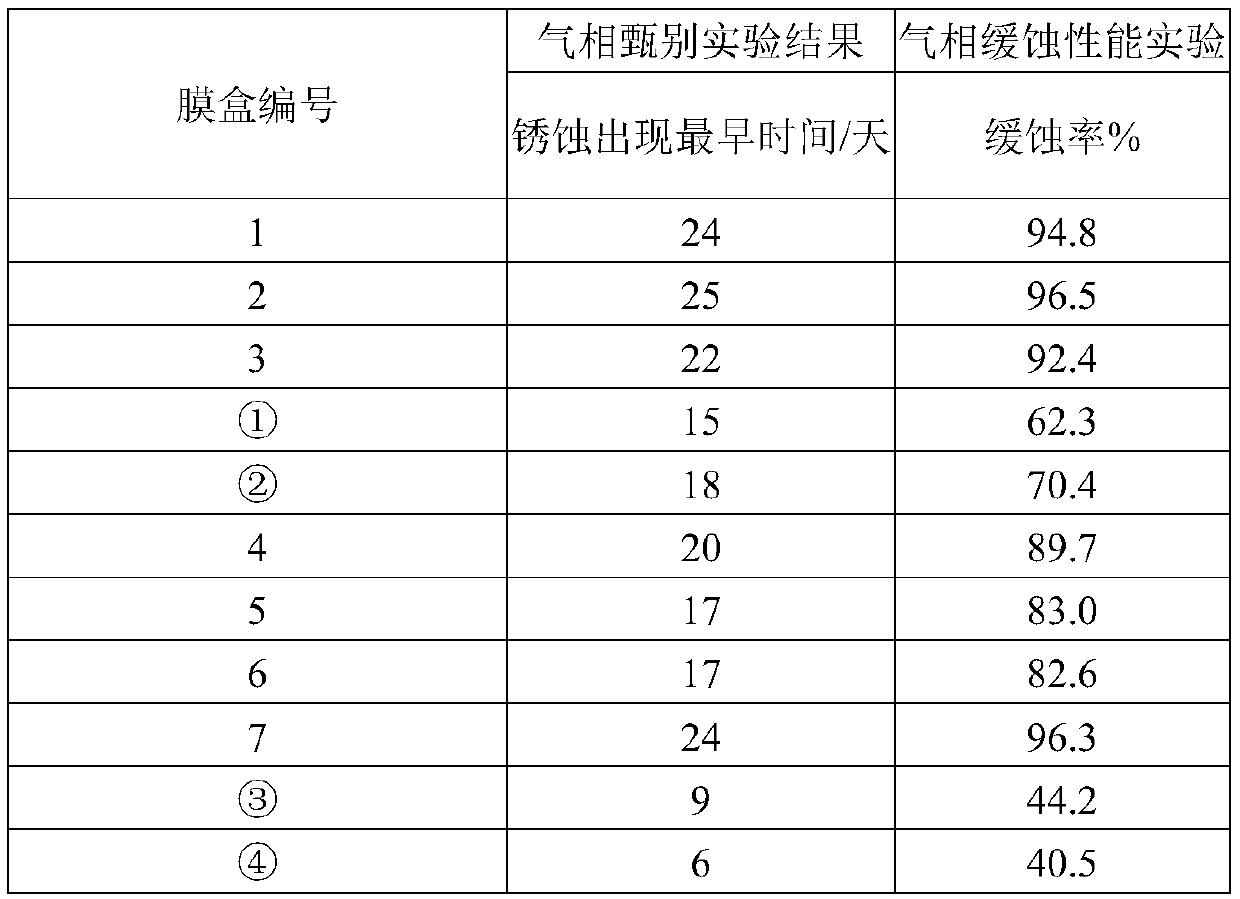

Gas-phase rust inhibitor and slow release gas-phase rust inhibiting film box containing same

The invention discloses a gas-phase rust inhibitor and a slow release gas-phase rust inhibiting film box containing the same. The gas-phase rust inhibitor comprises rust inhibiting components, polyvinyl alcohol and solvent wit a weight ratio of (60-70): (10-20): (10-20); and the rust inhibiting components comprise 40-50 parts of first aliphatic amino acid, 20-25 parts of organic amine, 5-10 parts of second amino acid alkyl ester, and 5-20 parts of benzoate. A gas-phase rust inhibiting diaphragm with a slow release function of the film box is matched with the gas-phase rust inhibitor for use; the volatile gas-phase rust inhibiting components are slowly and uniformly volatilized, and can be slowly corroded permanently; on the basis of guaranteeing the rust inhibition, the life of the film box is further prolonged through the diaphragm, and the medicine change frequency is reduced; and the film box is simple in shape, and can be recycled.

Owner:中电保力(北京)科技有限公司

Water-soluble nitro-compound fertilizer anti-blocking agent as well as preparation and using method thereof

InactiveCN104671989AEasy to operateEase of industrial productionFertilizer mixturesAgricultural engineeringWater soluble

The invention discloses a water-soluble nitro-compound fertilizer anti-blocking agent. The water-soluble nitro-compound fertilizer anti-blocking agent comprises the components in percentage by mass: 8-40 percent of sodium tripolyphosphate, 10-35 percent of lauryl sodium sulfate, 15-35 percent of sodium dodecyl benzene sulfonate and 8-30 percent of polyacrylamide. A preparation method of the water-soluble nitro-compound fertilizer anti-blocking agent comprises the following steps: grinding the formula raw materials of the anti-blocking agent to be 300 meshes to obtain anti-blocking agent powder. A using method of the water-soluble nitro-compound fertilizer anti-blocking agent comprises the steps that when used, the water-soluble nitro-compound fertilizer anti-blocking agent is fully mixed with a compound fertilizer through a coating machine, 2-8kg of water-soluble nitro-compound fertilizer anti-blocking agents are added in the compound fertilizer per ton. The water-soluble nitro-compound fertilizer anti-blocking agent is easy and convenient to operate, convenient for industrial production, less in using amount and low in cost, moreover, and the pollution to environment is avoided; in addition, the water-soluble nitro-compound fertilizer anti-blocking agent has a good anti-blocking effect, and the loose degree of the powder soluble fertilizer reaches 90 percent or more.

Owner:YANSHAN UNIV

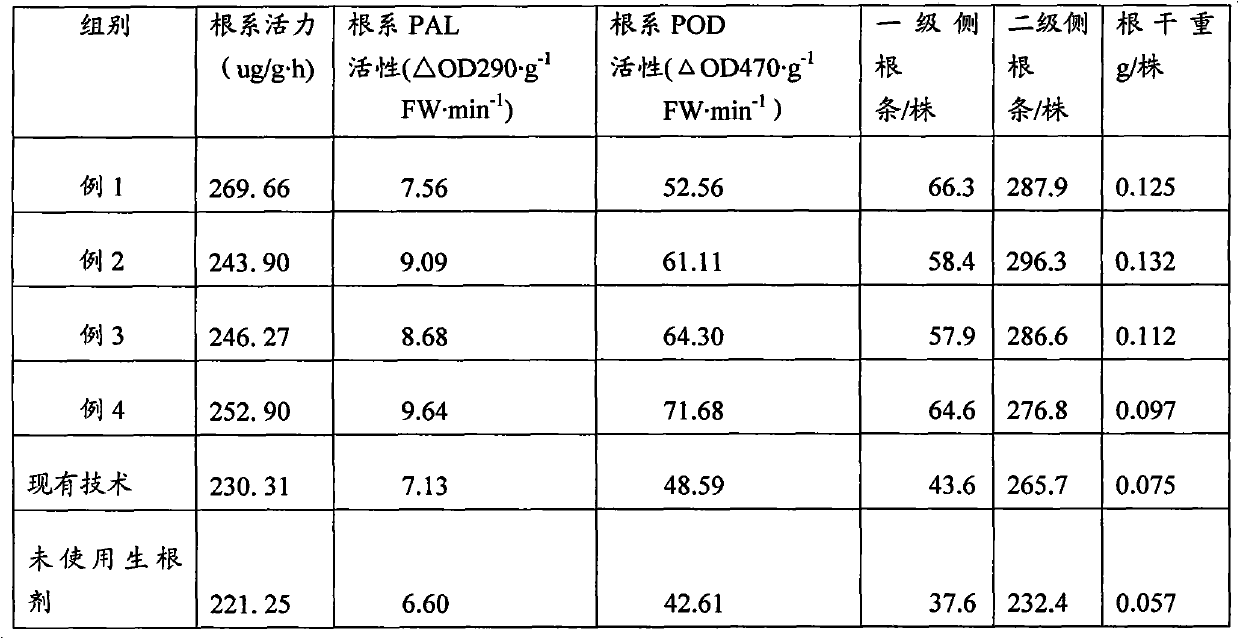

Rooting agent used for transplanting tobacco crops and playing role in resisting diseases and promoting growth

InactiveCN103271096ASolve the problem of long seedling periodSolving activityPlant growth regulatorsBiocideDiseaseNicotiana tabacum

The invention discloses a rooting agent used for transplanting tobacco crops and playing a role in resisting diseases and promoting growth. The rooting agent comprises the following ingredients in parts by weight: 40-45 parts of a compound microorganism bacterium agent, 20-25 parts of fulvic acid potassium, 40-50 parts of fulvic acid and 1-2 parts of sodium alginate. The rooting agent is simple in process, reasonable in composition proportion and convenient to use, can effectively solve various problems of long seedling returning period, lowering of root activity and the like after tobacco seedlings are transplanted, and can prevent plant diseases and insect pests and improve the drought resistance of the crops. The ingredients of the rooting agent for transplanting does not contain artificially synthesized hormone. Compared with a traditional transplanting method, the rooting agent for transplanting has the advantages that the seedling returning period of large fields is shortened, the growth of lateral roots is promoted, the active absorbing area of the roots is increased, the physiological metabolism strength in the roots can be improved, the disease resistance of tobacco seedlings is improved, and the transplanting survival rate is enhanced.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Preparation method for garlic oil essence microcapsules

InactiveCN104312727AUniform particlesDense wallEssential-oils/perfumesFood ingredientsRevolutions per minuteEmulsion

The invention relates to a preparation method for garlic oil essence microcapsules. The preparation method comprises the following steps: an essence microcapsule wall material is dissolved in water to form a wall material solution; garlic oil is added after stirring, and the mass ratio of the garlic oil and the wall material is 1 to 6-9; shearing is carried out for 5 to 8 minutes through a high-speed emulsification homogenizer under the condition of 12,000 to 15,000 revolutions per minute, so as to obtain a coarse emulsion; the coarse emulsion is further treated for 3 to 5 times through an ultrahigh-pressure microjet homogenizer under a homogenization pressure of 20 to 50 Mpa, and each treatment lasts for 8 to 10 minutes; an emulsion is prepared after stirring; the obtained emulsion is finally treated through a freezer dryer for 18 to 24 hours within a temperature range of minus 40 to minus 20 DEG C, and obtained substances are crushed through a grinder to obtain the garlic oil essence microcapsules. The garlic oil essence microcapsules prepared through the invention have the advantages of uniform particles, compact capsule walls, high embedding rate and stability, good release performance, etc.

Owner:TIANJIN CHUNFA BIO TECH GRP

Slow release type testis prosthesis and its application

InactiveCN1947802AWith slow release functionOrganic active ingredientsSexual disorderProsthesisSilicon rubber

A slow-release artificial testis for slowly releasing androgen is prepared from silicon rubber and testosterone in weight ratio of (2-4):1. It can be used to replace human testis for androgen therapy.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

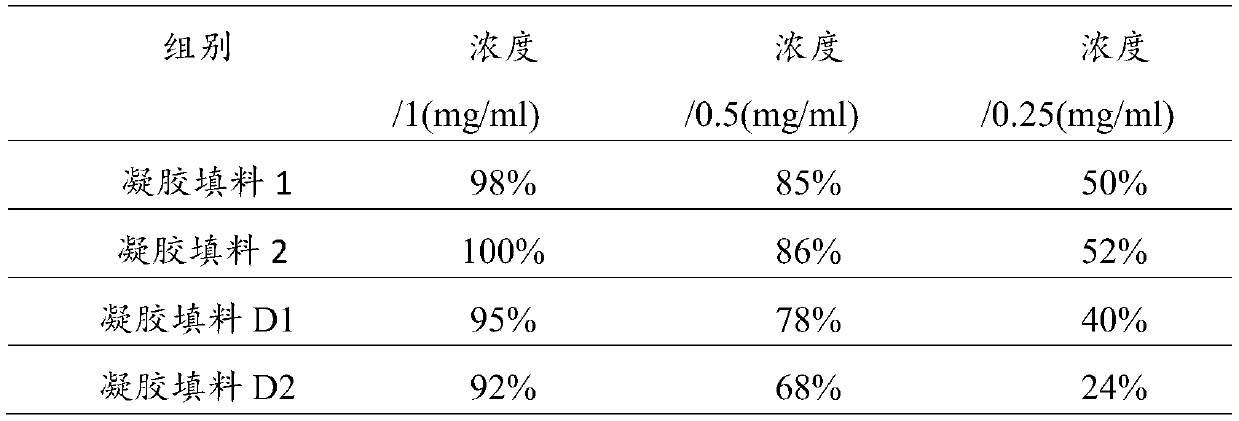

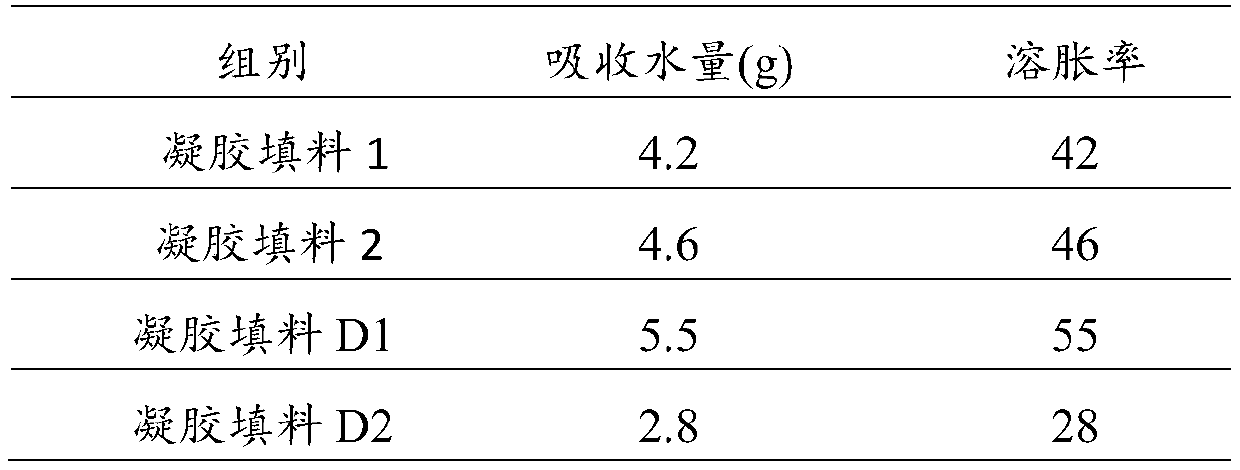

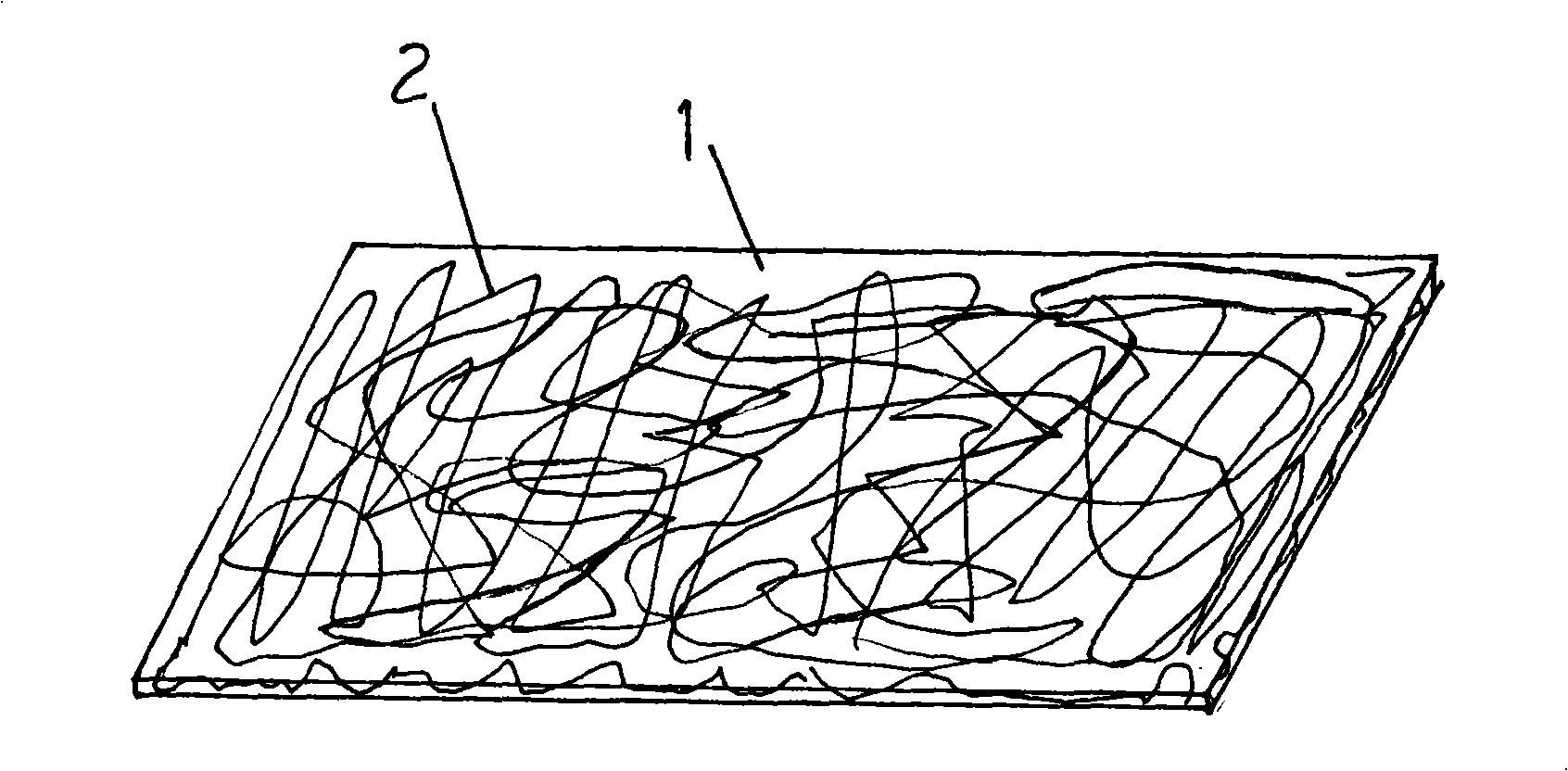

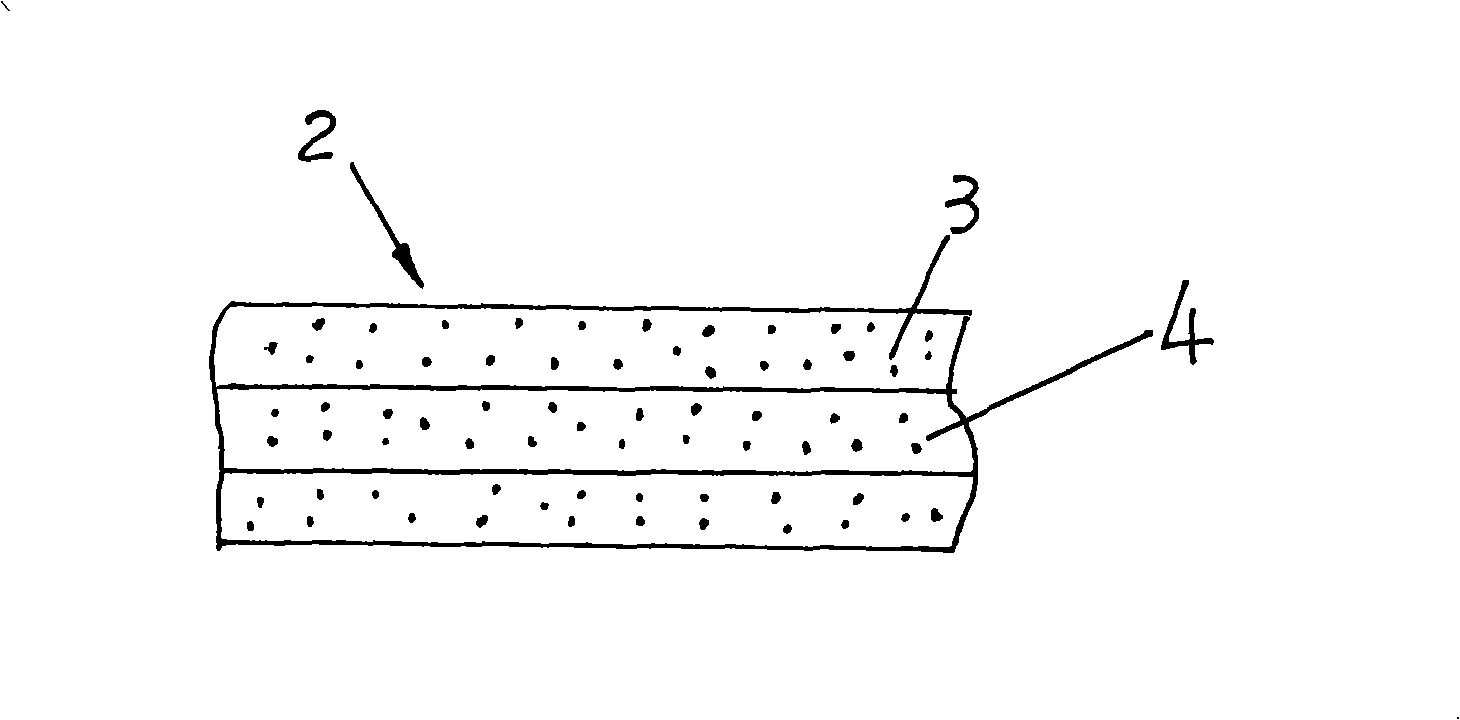

Swelling medical biogel filler based on portulaca oleracea polysaccharide and flavone extract

InactiveCN110124082AImprove anti-inflammatory and antibacterial effectWith slow release functionSurgeryPharmaceutical delivery mechanismComponent LoadPhosphorite

The invention relates to swelling medical biogel filler based on portulaca oleracea polysaccharide and flavone extract. The swelling medical biogel filler comprises a collagen gel component modified by compound polysaccharide, a swelling compound polysaccharide gel component and a nano hydroxy phosphorite component loaded with portulaca oleracea flavone extract and calcium ion. The swelling medical biogel filler is a framework supporting polysaccharide filling material integrating effects of absorbing seepage, stopping bleeding, filling and promoting healing and has antibacterial and antipyrotic characteristics. Portulaca oleracea is rich in source, and polysaccharide is low in preparation cost, so that the swelling medical biogel filler is suitable for industrial production.

Owner:NANJING XIAOZHUANG UNIV

Antimicrobial superfine fibre nonwoven cloth embedded with nano silvery

InactiveCN101301488APromote healingImprove the bactericidal effectAbsorbent padsBandagesWound healingPolymer science

The invention discloses an anti-bacterial superfine fiber non-woven fabric of an embedded nano-silver, which is weaved with the superfine fibers of the embedded nano-silver. The each superfine fiber consists of an outer layer and an inner core, the material of the outer layer is biocompatible polymer material, the material of the inner core is nano-silver. The diameter of the fiber is 200 nanometers to 10 microns, the diameter of the inner core is 1 / 3 to 2 / 3 of the diameter of superfine fiber , the size of the nano-silver particle is 5 to 30 nanometers. The invention has a significant effect on sterilization, inhibiting bacteria, diminishing inflammation and promoting wound healing, can be directly applied on the affected areas and is particularly suited for the burn and scald treatment; the biocompatible polymer material of the outer layer can be degraded. After treatment, the applied layer is no longer needed to be taken off, which saves the taking off step, and also avoids the bleeding phenomenon during the taking off process and the pain of patients; also has releasing function.

Owner:吉林邦安宝医用设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com