Gas-phase rust inhibitor and slow release gas-phase rust inhibiting film box containing same

A rust inhibitor and gas-phase technology, applied in the field of gas-phase rust inhibitors and slow-release gas-phase rust-inhibiting capsules containing it, can solve the problem of excessive volatilization of the active components of rust inhibitors, time-consuming and labor-intensive replacement of rust inhibitors, and obstacles to smart grids Development and other issues, to achieve the effect of reducing the frequency of dressing changes, prolonging life, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

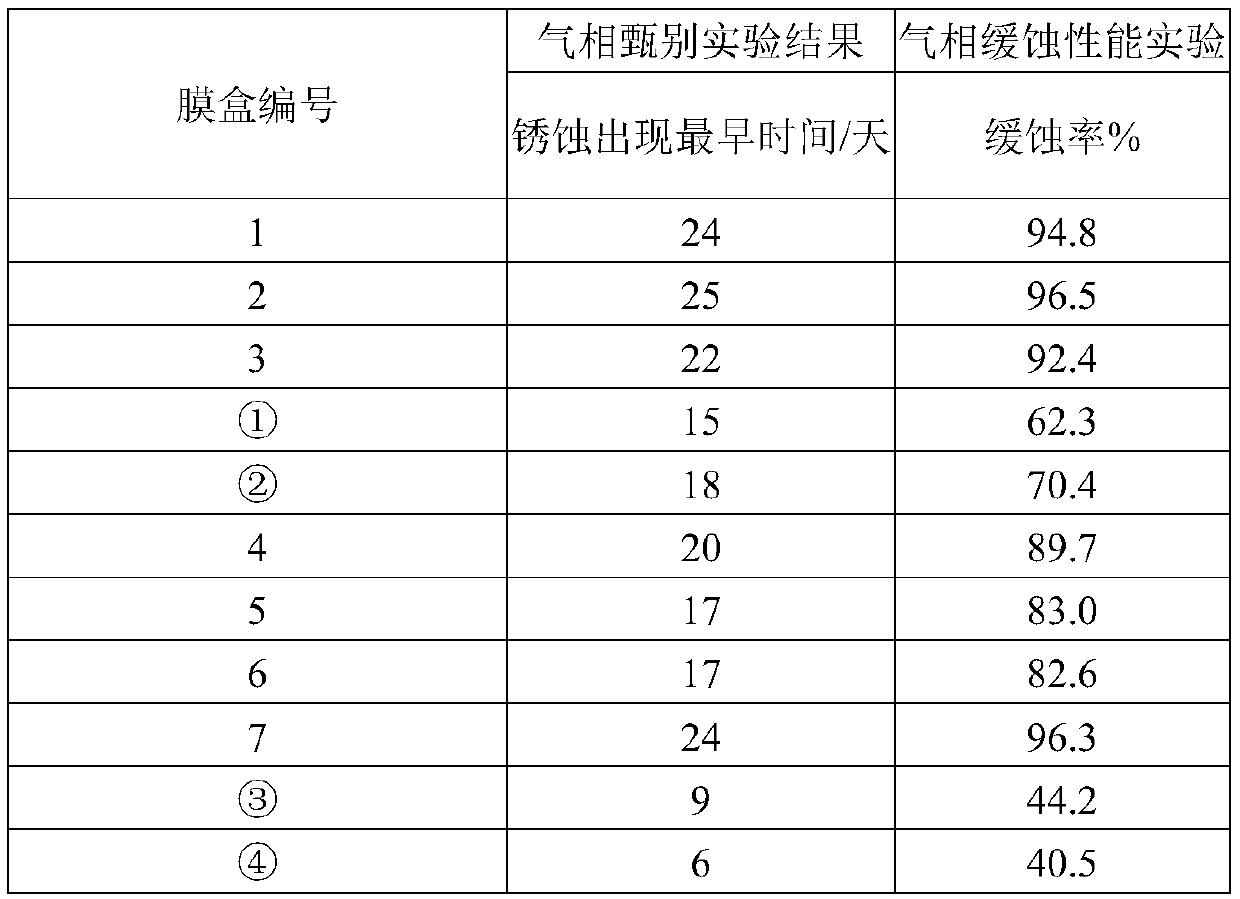

Examples

preparation example Construction

[0040] The preparation method of the gas-phase rust-inhibiting diaphragm comprises the following steps:

[0041](1) Dissolve 20-40 parts by weight of polyvinylidene fluoride in 50-150 parts by weight of dimethylformamide, stir for 5-12 hours and heat in a water bath at 30-40°C, then keep the temperature in the water bath for 1.5-5 hours to form a stable mixed solution , and add 3-7 parts by weight of the additive, the additive contains polyvinylpyrrolidone and 2-mercaptoethanol, the mass percentage of 2-mercaptoethanol in the additive is 2-15wt%, let stand for 2-6h, realize complete defoaming Obtain the film liquid precursor; Preferred additives are polyethylene glycol, ethanol, polyvinylpyrrolidone, poly(meth)acrylate and 2-mercaptoethanol, and the weight ratio is 33-48:8-15:15-25 :5-40: 4-7.

[0042] (2) Pouring the film liquid precursor obtained in step (1) on the non-woven fabric, and using a scraper to scrape the liquid film to form a film with a thickness of 100-450 μm....

preparation example 1

[0048] formula:

[0049] Vapor-phase rust inhibitor consists of 60 parts of rust inhibitor, 15 parts of polyvinyl alcohol and 20 parts of solvent;

[0050] Antirust ingredients include glutamic acid, triethanolamine, tert-butyl glycine and sodium benzoate, with a weight ratio of 40:25:5:15;

[0051] The solvent is a mixed solvent of ethanol and water, and the weight ratio is 15:85.

[0052] Preparation:

[0053] (1) Take amino acid alkyl ester and add in ethanol and stir and mix evenly;

[0054] (2) Add polyvinyl alcohol, glutamic acid and sodium benzoate into water in proportion, stir and mix evenly;

[0055] (3) Mix the mixture obtained in step (1) and step (2) until uniform;

[0056] (4) Weigh triethanolamine and add it to the mixture obtained in step (3) for mixing to finally obtain the desired vapor phase rust inhibitor.

preparation example 2

[0058] Others are the same as Preparation Example 1, except that the antirust ingredients glutamic acid, triethanolamine, tert-butyl glycine and sodium benzoate in the formula are in a weight ratio of 45:20:8:20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| bubble point pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com