Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Sufficient duration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

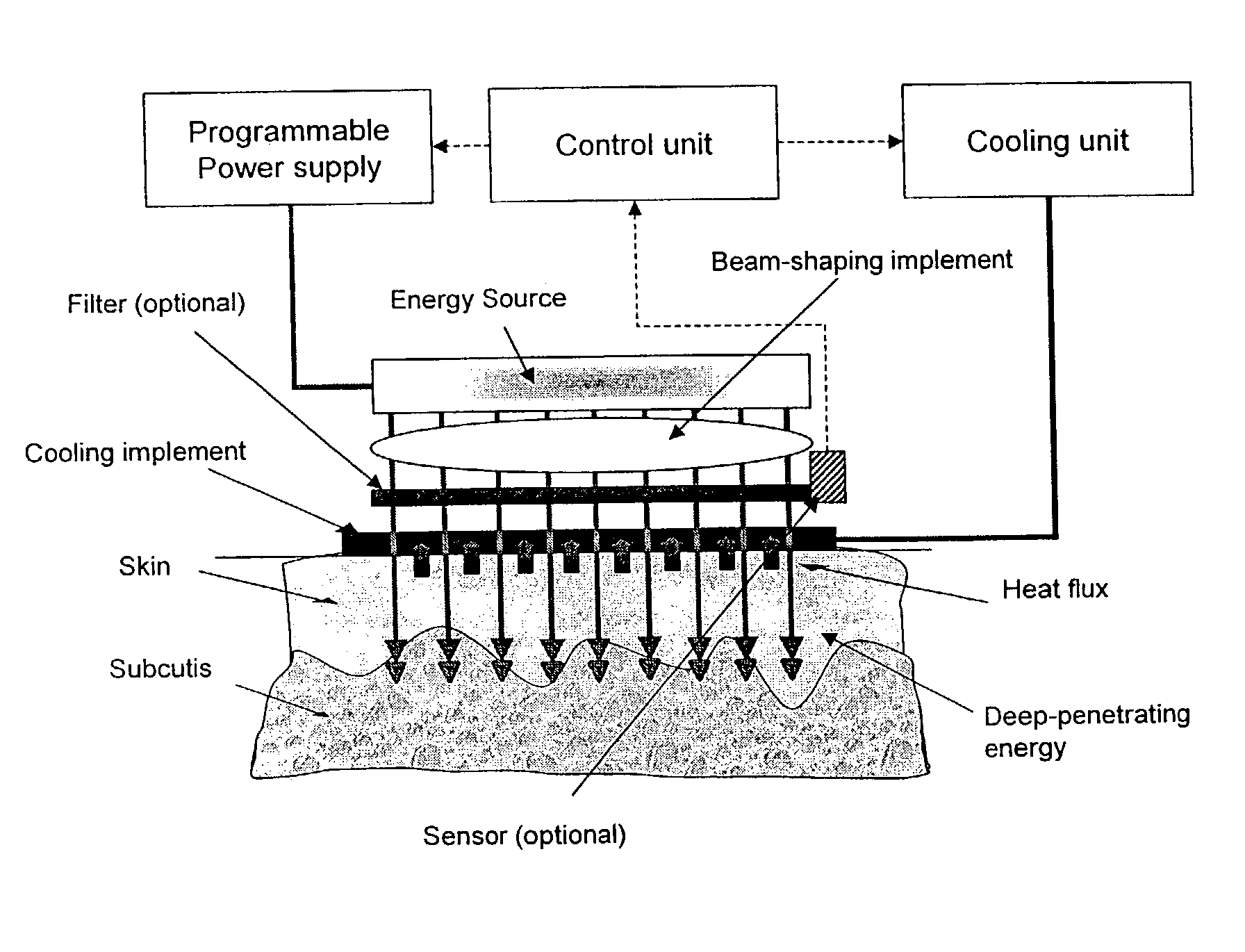

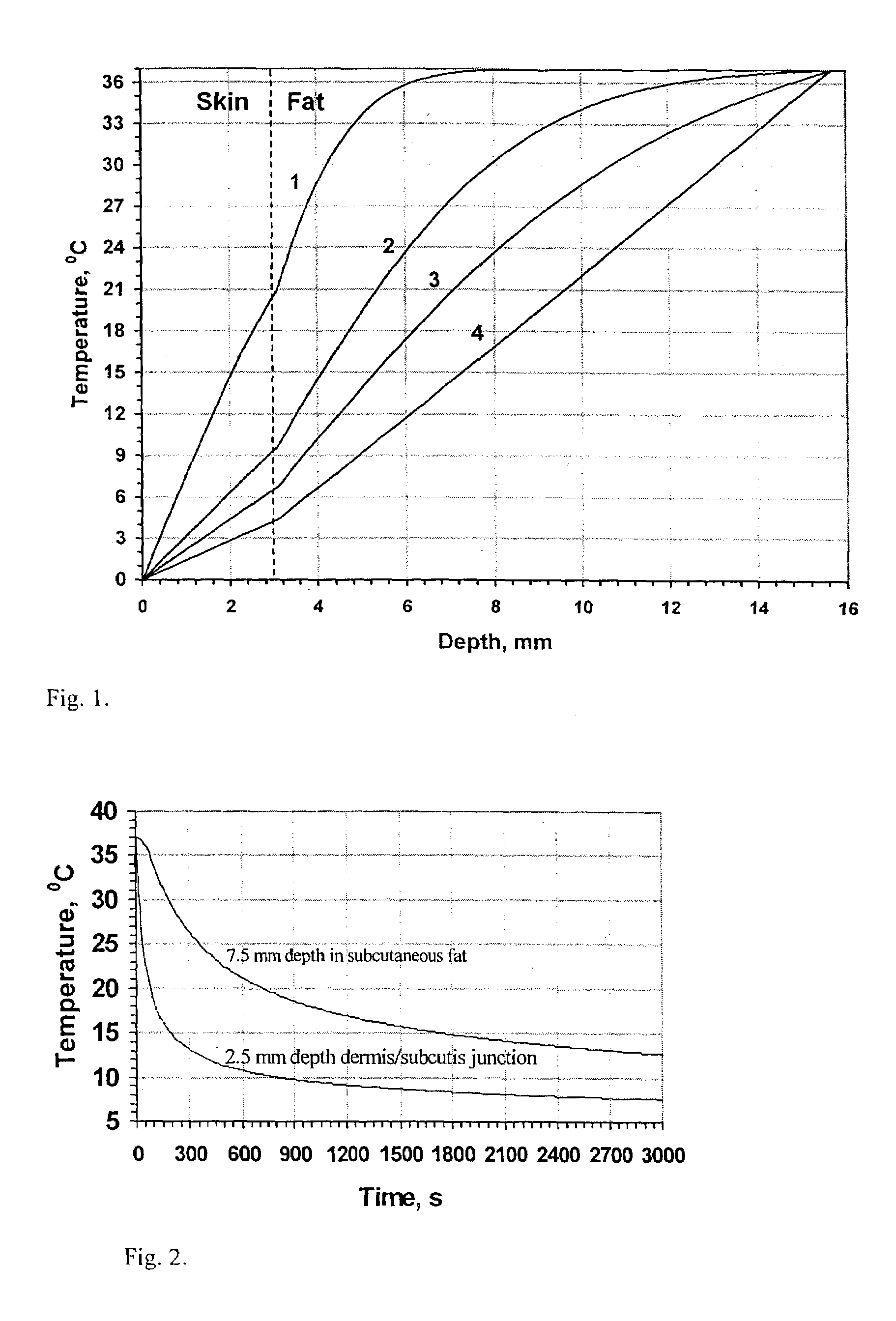

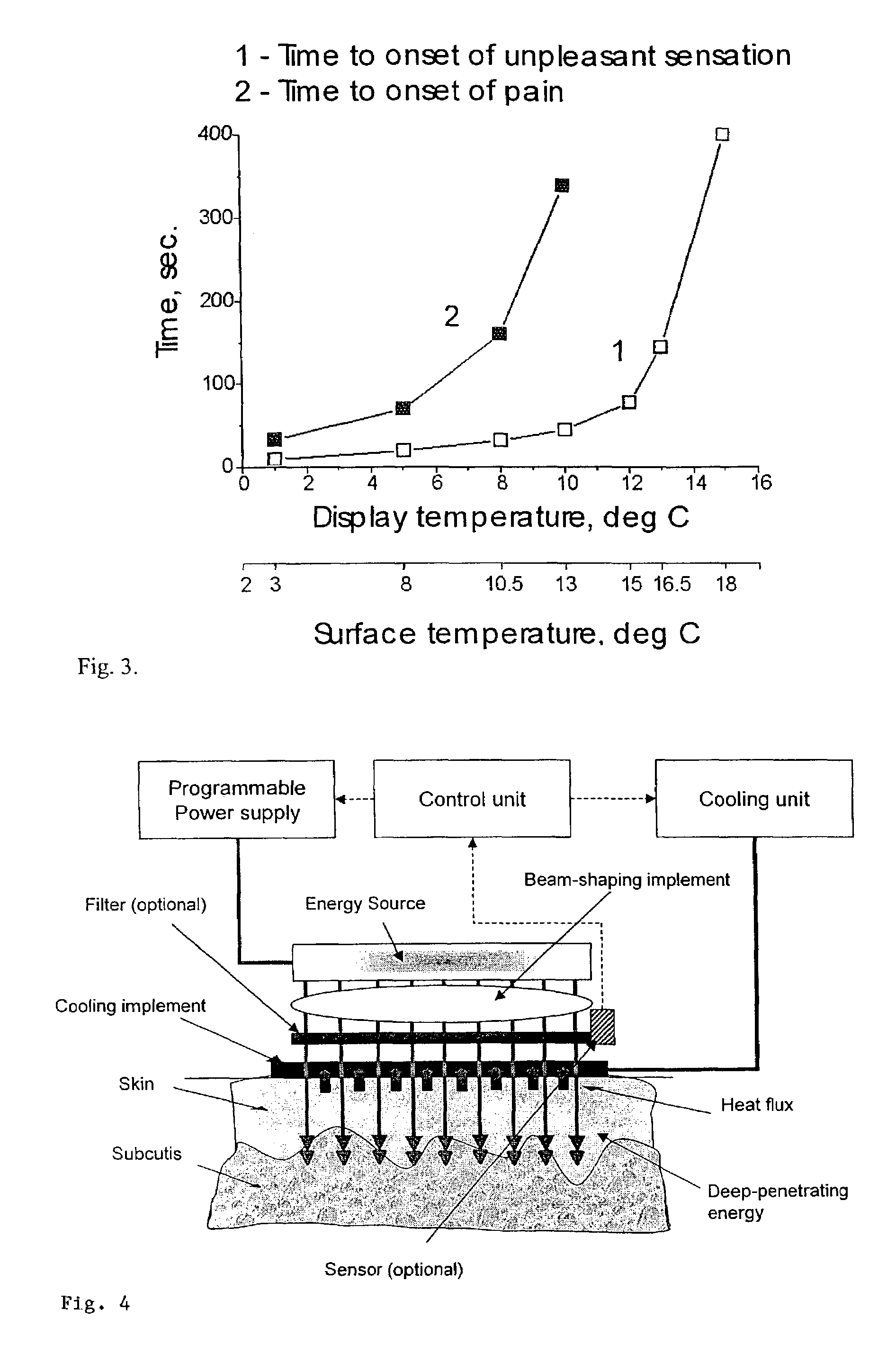

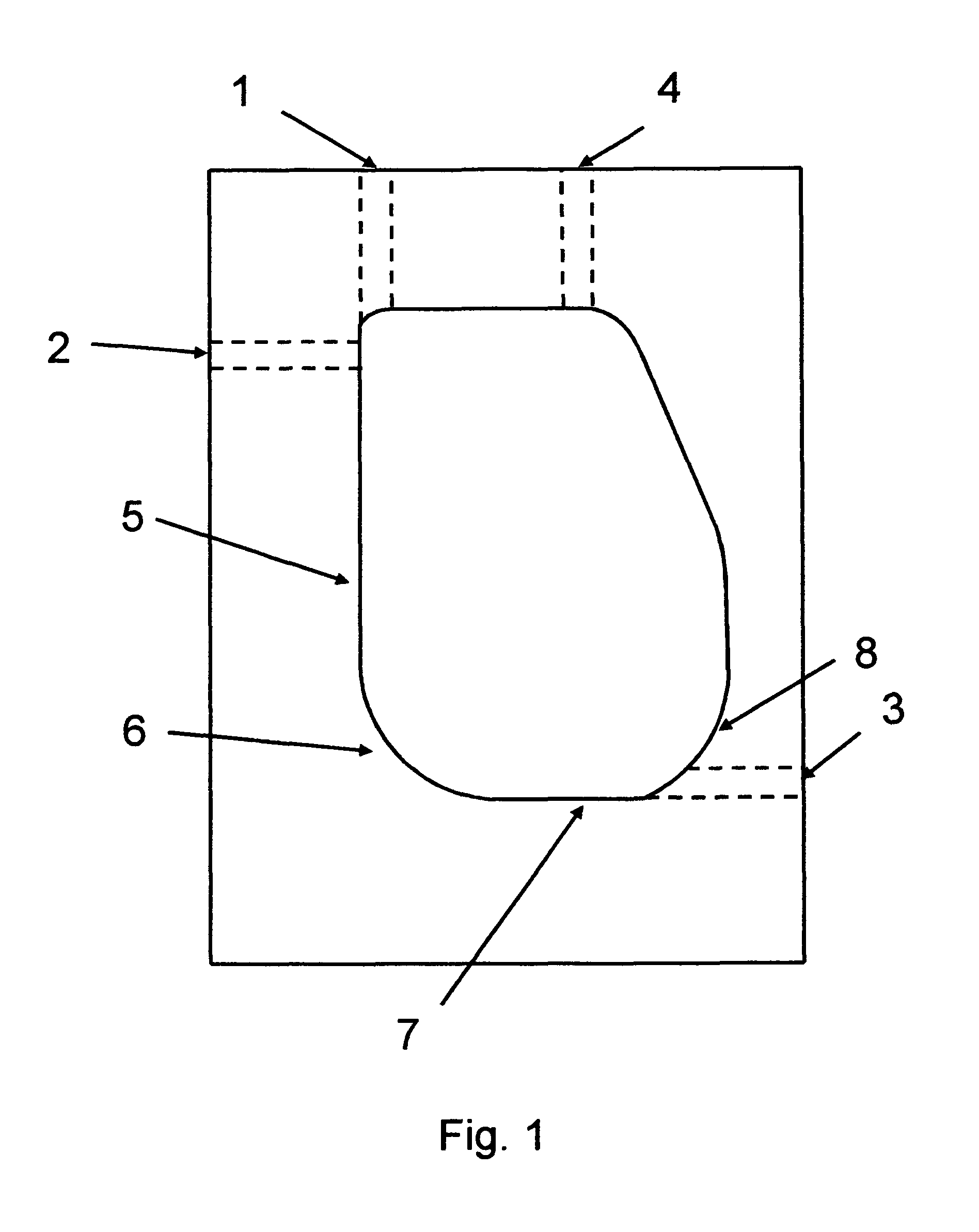

Method and apparatus for treatment of cutaneous and subcutaneous conditions

ActiveUS7276058B2Sufficient durationSufficient powerUltrasound therapyElectrotherapyElectrical stimulationsTarget tissue

The present invention provides method and apparatus for treating tissue in a region at depth while protecting non-targeted tissue by cyclically applying cooling to the patients skin, and preferably to the region, and by applying radiation to the patient's skin above the region to selectively heat tissue during and / or after cooling is applied. At least one of cooling and radiation my be applied by successivly passing a continuous output applicator over the patient's skin. Treatment may also be enhanced by applying mechanical, acoustic or electrical stimulation to the region.

Owner:PALOMAR MEDICAL TECH

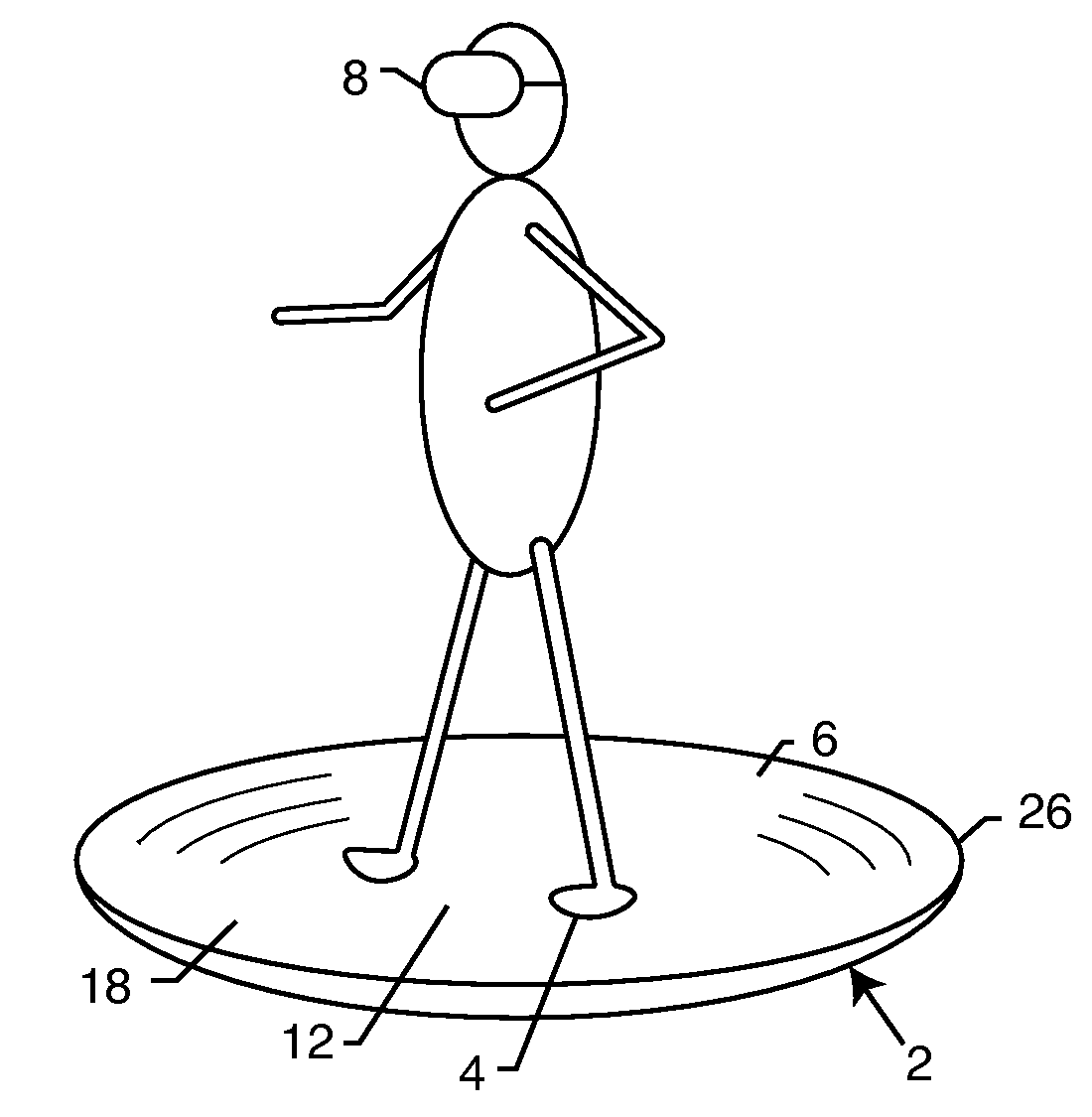

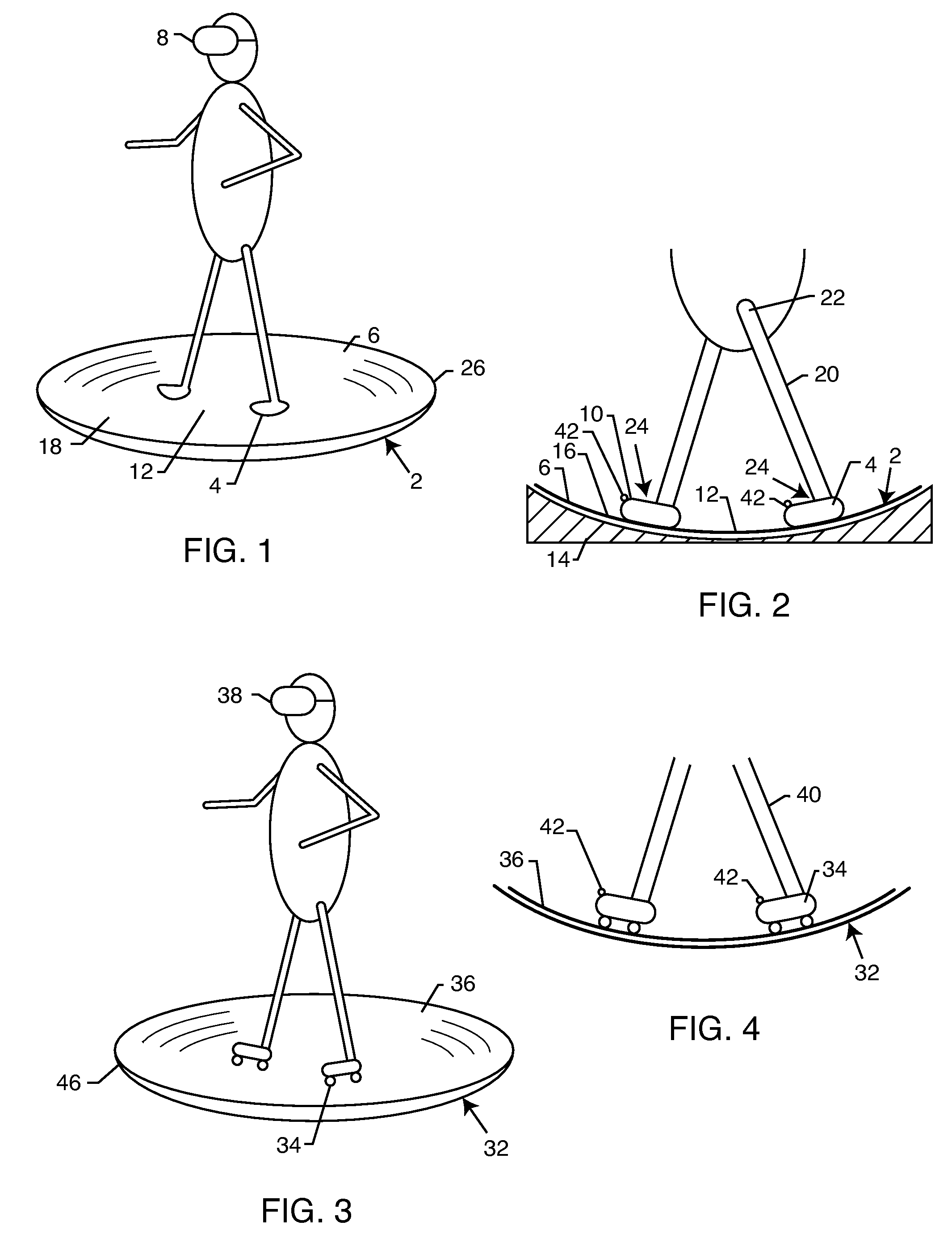

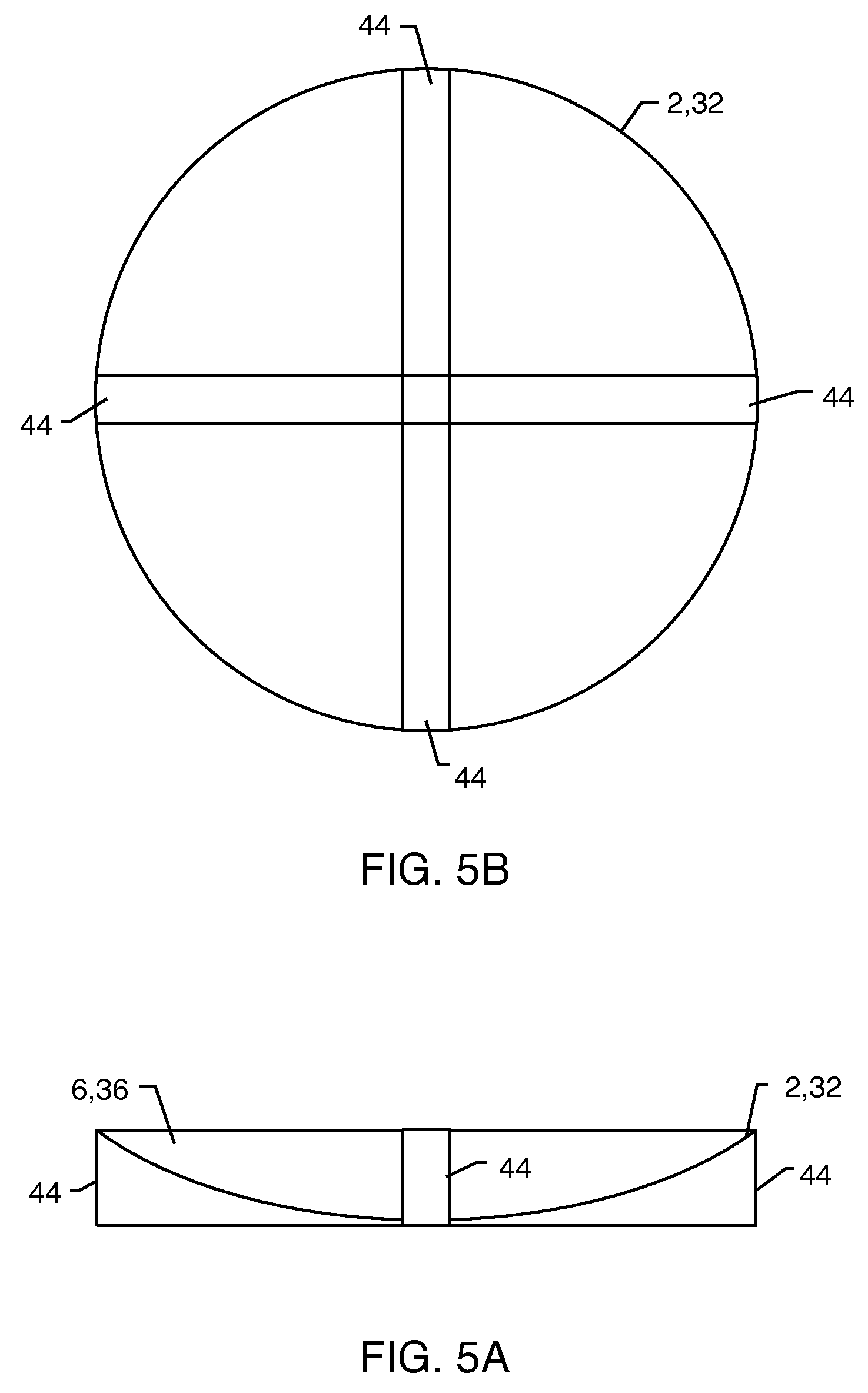

Walk simulation apparatus for exercise and virtual reality

InactiveUS20090111670A1Reduce frictionEasy to manufactureInput/output processes for data processingMovement coordination devicesEngineeringDual reality

A locomotion platform device enables a user to perform a simulation of various motions including walking and running. The device comprises a locomotion platform having a concave upward facing surface. The platform and / or the user's footwear incorporate a mechanism to reduce friction between the user and the surface of the platform in order to allow the user's feet to move freely.

Owner:WILLIAMS JULIAN D

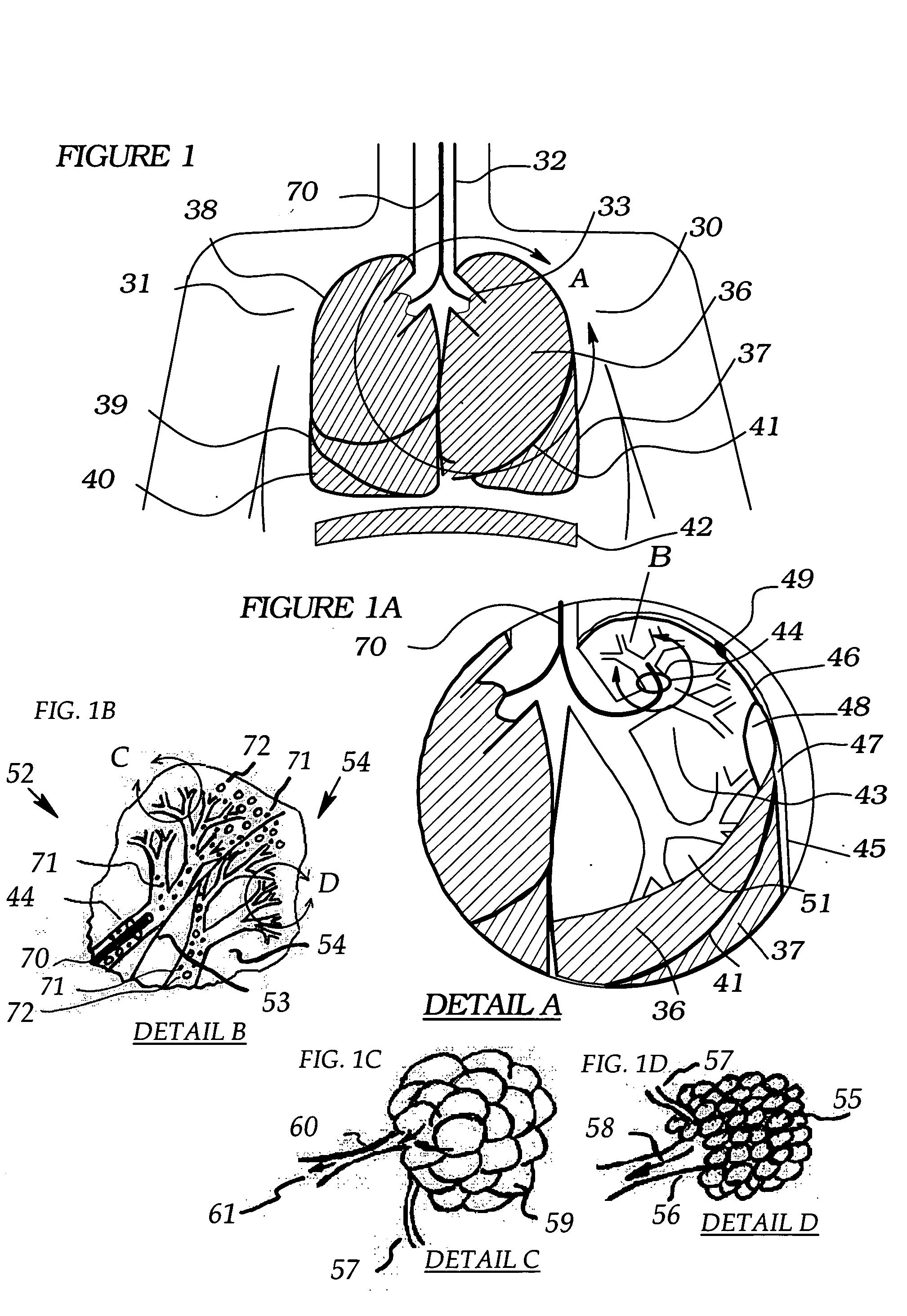

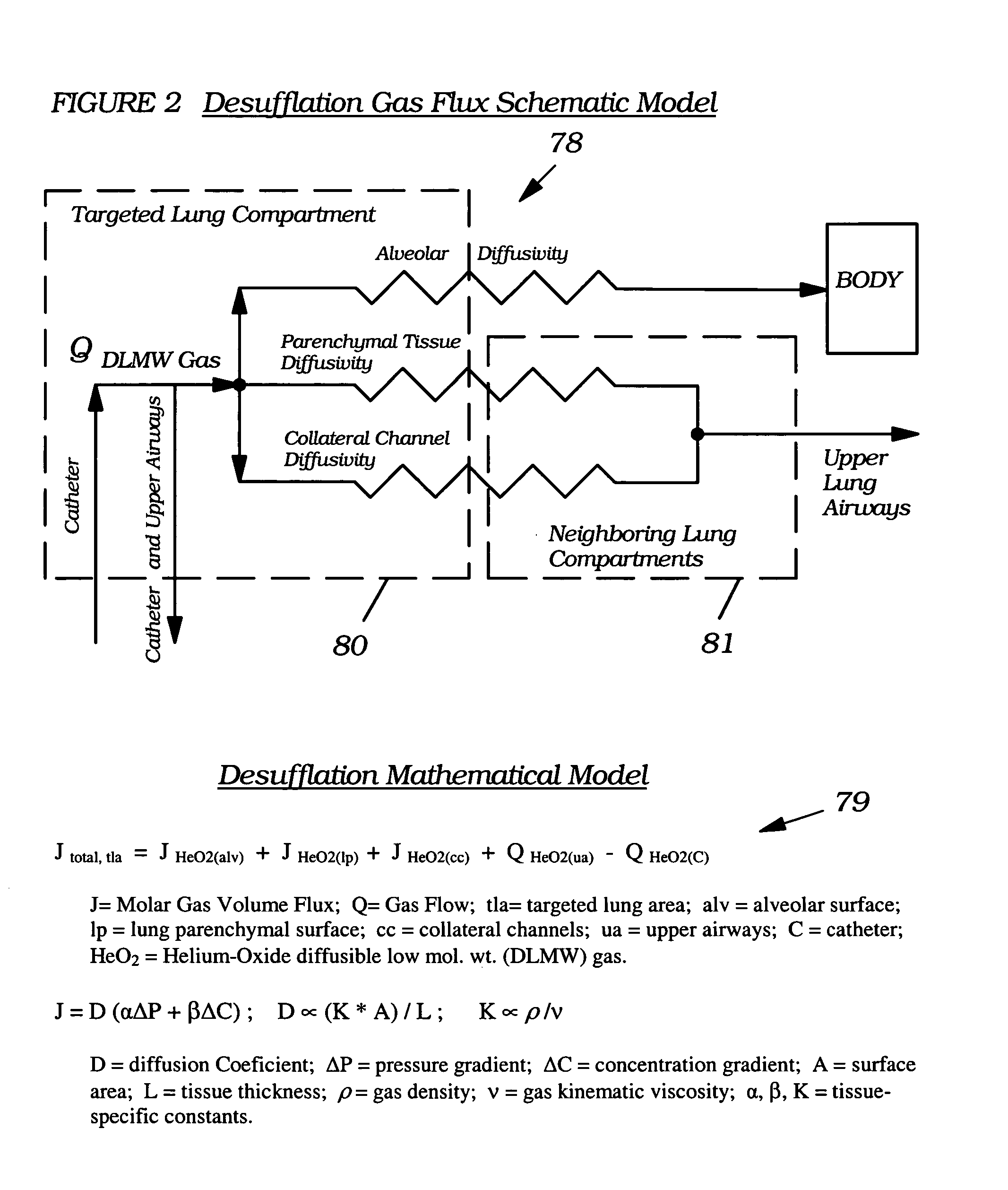

Methods, systems and devices for desufflating a lung area

InactiveUS20050022809A1Lower the volumeOut diffusionTracheal tubesBreathing masksCOPDPositive pressure

Methods, systems and devices are described for temporarily or permanently evacuating stagnating air from a diseased lung area, typically for the purpose of treating COPD. Evacuation is accomplished by displacing the stagnant CO2-rich air with a readily diffusible gas using a transluminal indwelling catheter specially configured to remain anchored in the targeted area for long term treatment without supervision. Appropriate elevated positive gas pressure in the targeted area is then regulated via the catheter and a pneumatic control unit to force under positive pressure effusion of the diffusible gas out of the area into neighboring areas while inhibiting infusion of other gases thus effecting a gradual gas volume decrease and deflation of the targeted area.

Owner:WONDKA ANTHONY DAVID

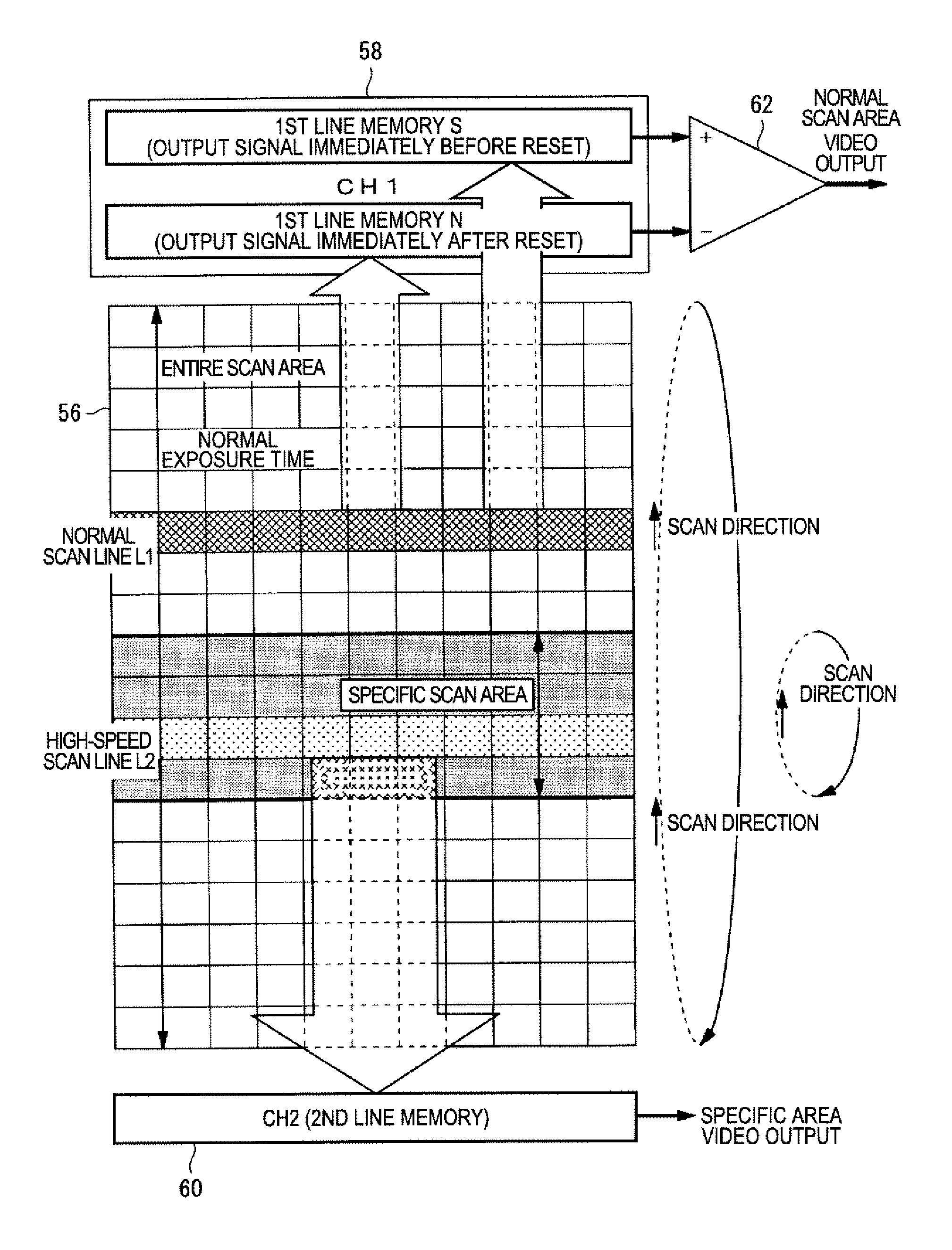

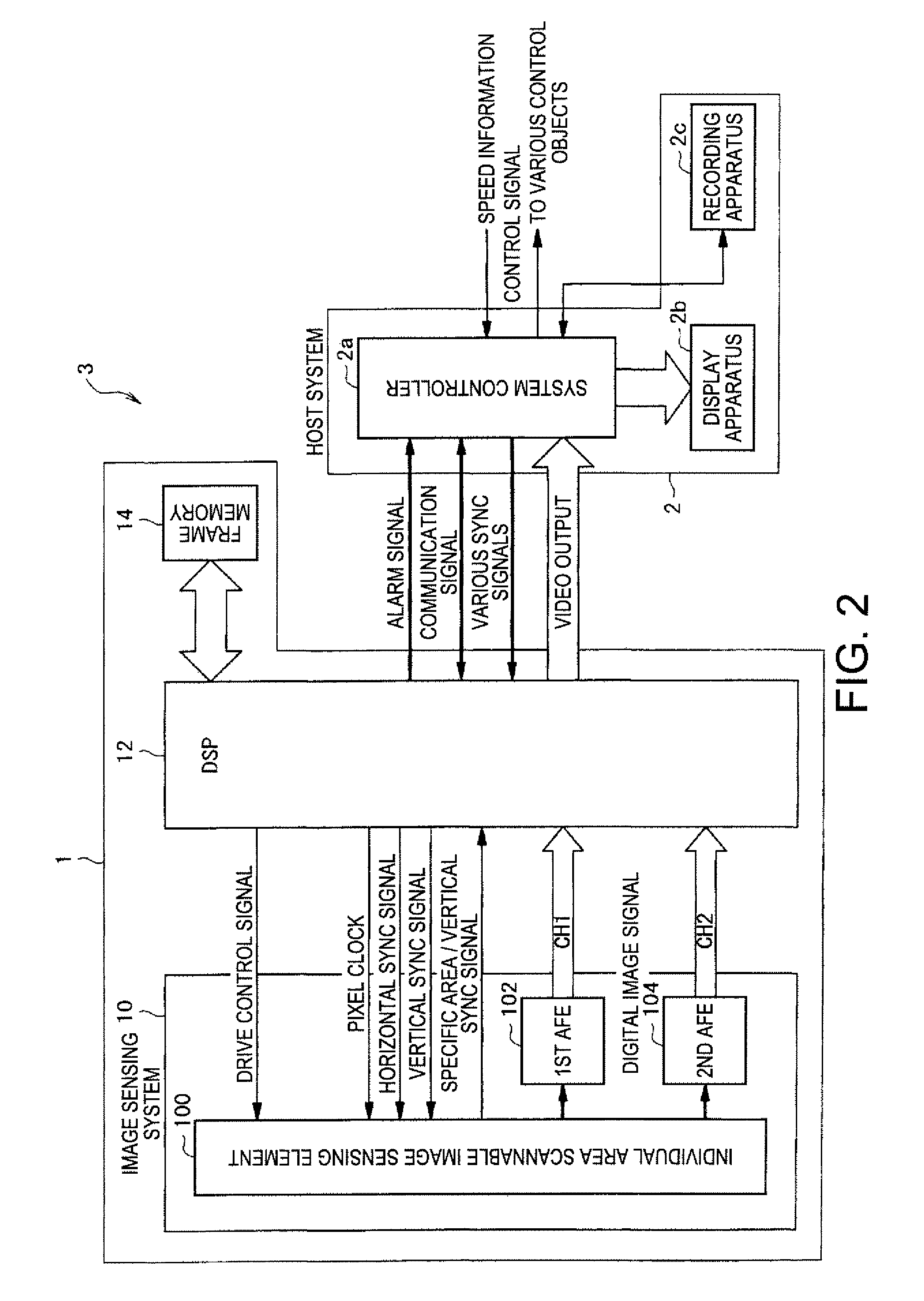

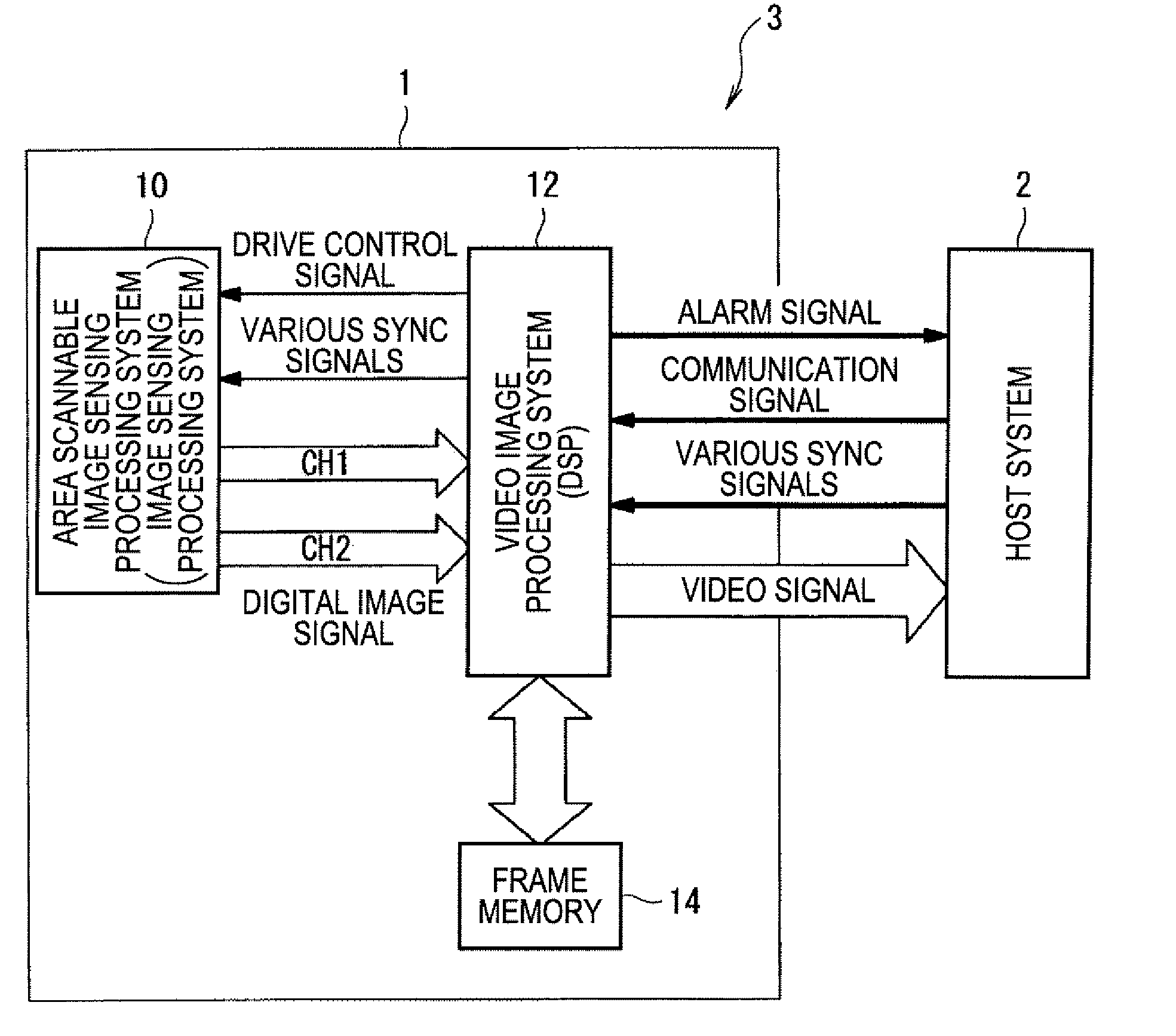

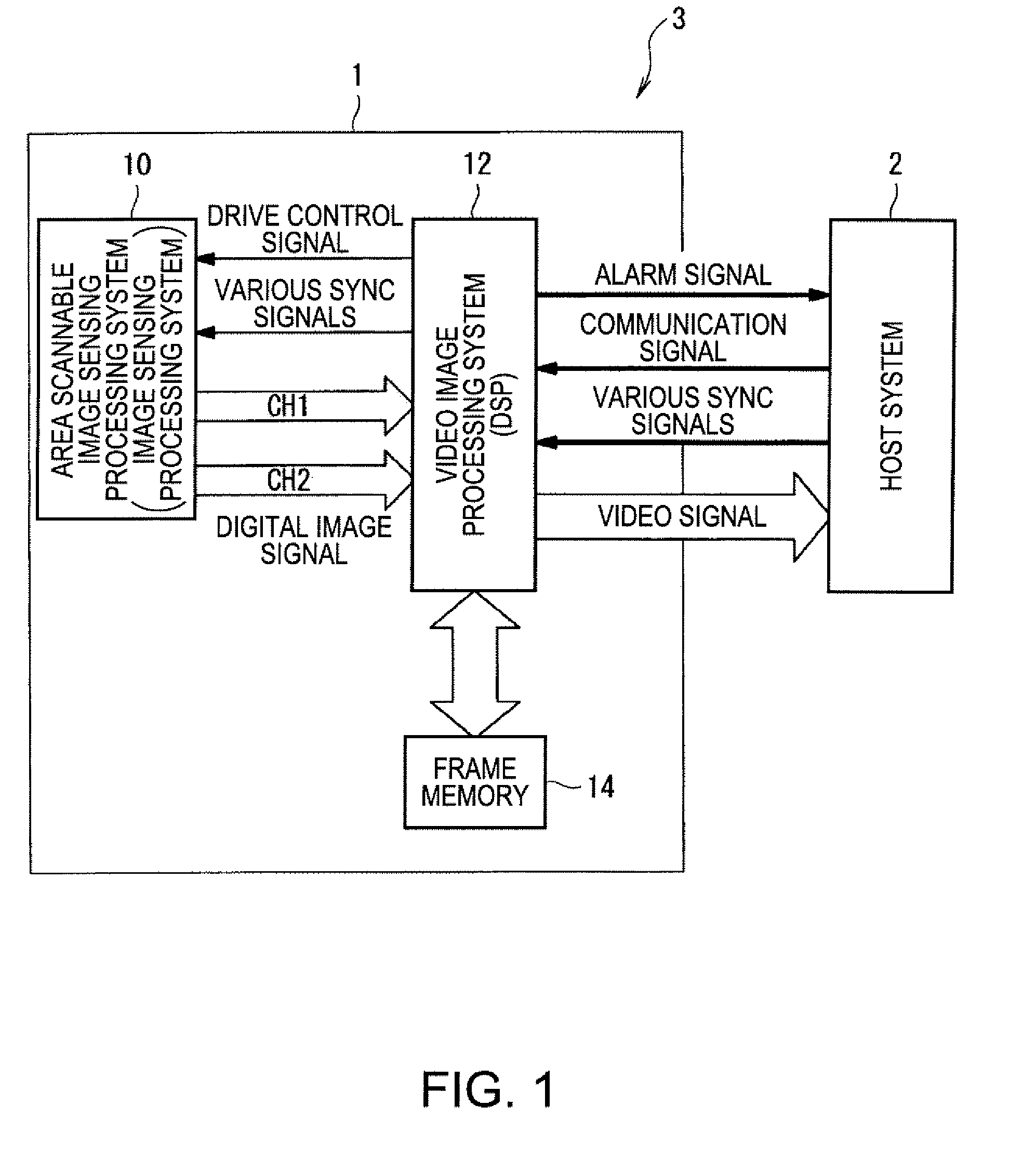

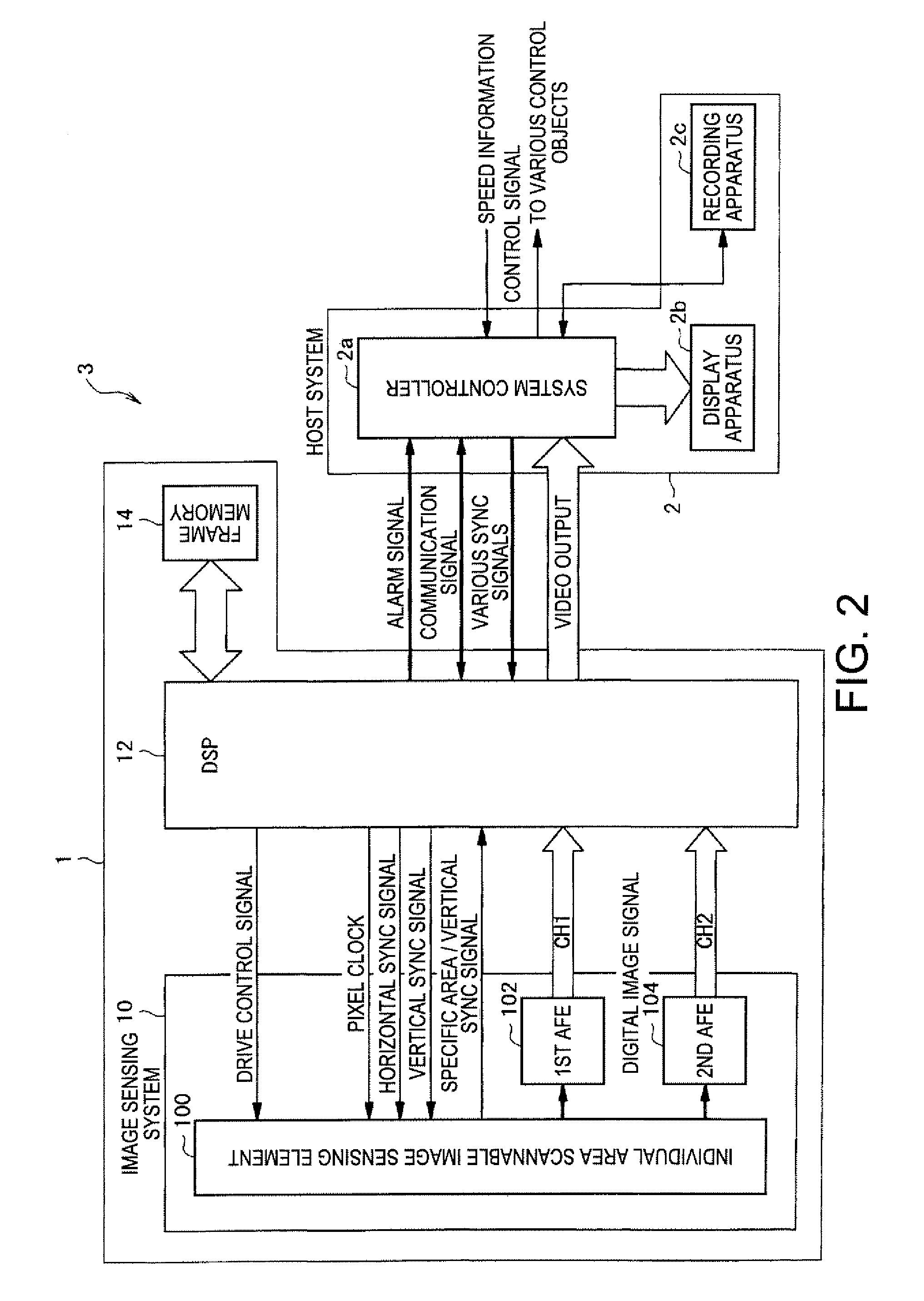

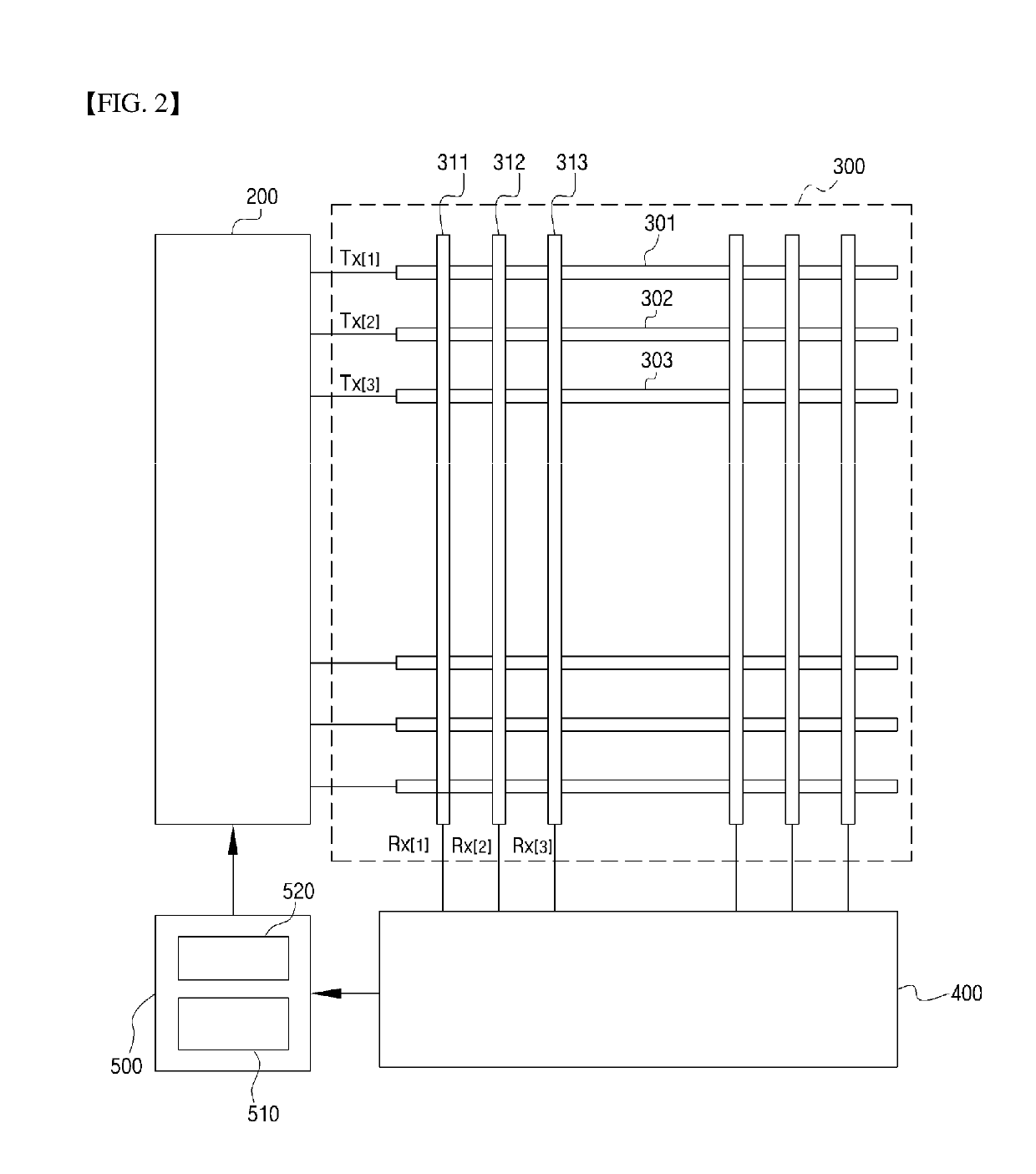

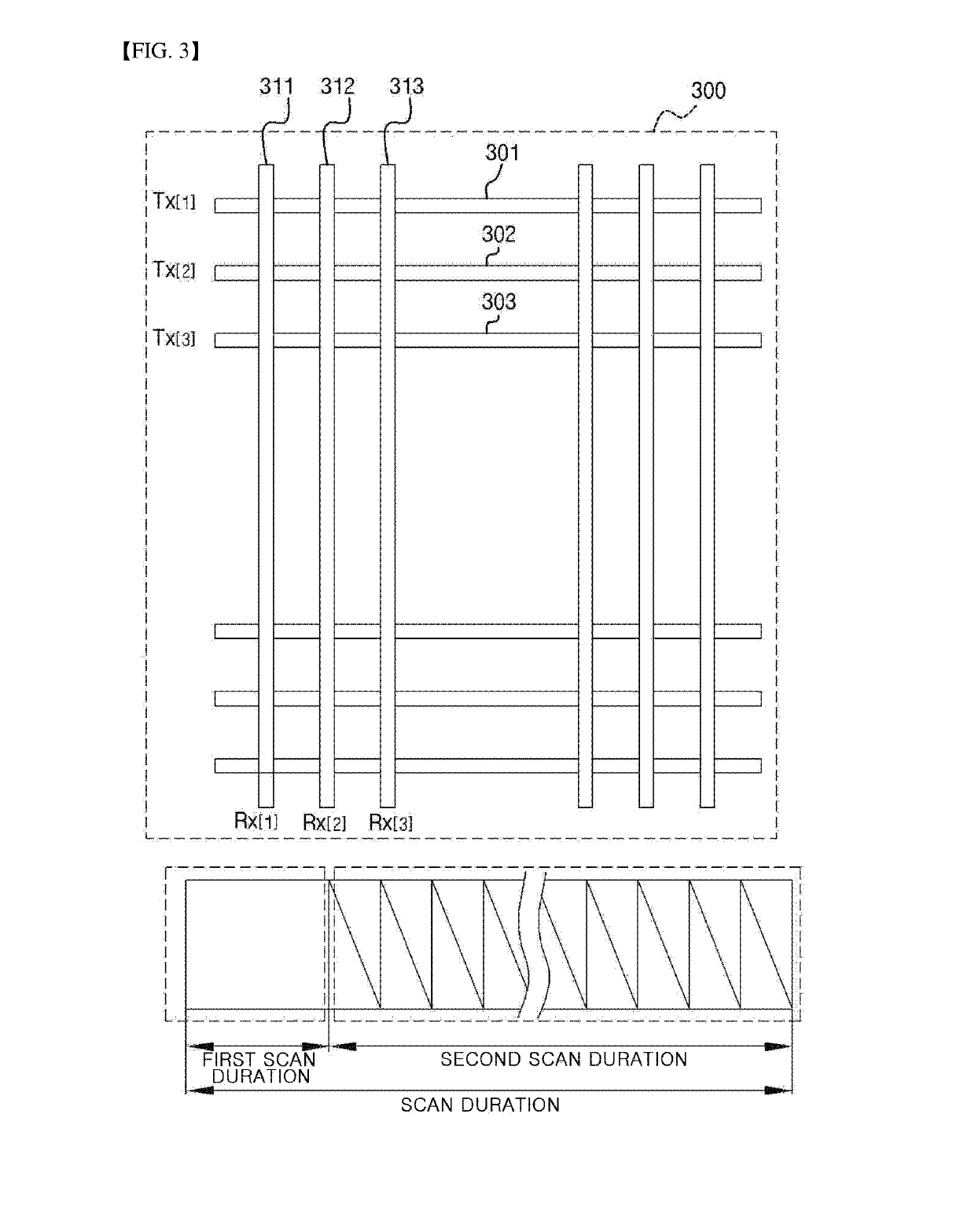

Image sensing apparatus, image sensing system, and image sensing method

InactiveUS7834922B2Sufficient durationTelevision system detailsTelevision system scanning detailsEngineeringPhotoelectric conversion

There is provided an image sensing apparatus. The image sensing apparatus includes a photoelectric conversion unit constituted by a plurality of photoelectric conversion elements converting exposed light into charge and accumulating the charge therein, and an exposure time control function for controlling an exposure time of the photoelectric conversion elements, the apparatus including: a first readout unit that reads out charge from pixels composed of the photoelectric conversion elements of the photoelectric conversion unit, the charge being accumulated in the pixels as a result of exposure for a predetermined exposure time; a second readout unit that reads out charge from pixels of a specific area in a predetermined area of the photoelectric conversion unit over a plurality of times, in a period when the first readout unit is reading out charge from the pixels of the predetermined area of the photoelectric conversion unit; an image data generation unit that generates an image data on the basis of a first pixel data composed of the charge read out by the first readout unit; and a predetermined data generation unit that generates a predetermined data on the basis of a second pixel data composed of the charge read over the plurality of times by the second readout unit.

Owner:COLUMBIA PEAK VENTURES LLC

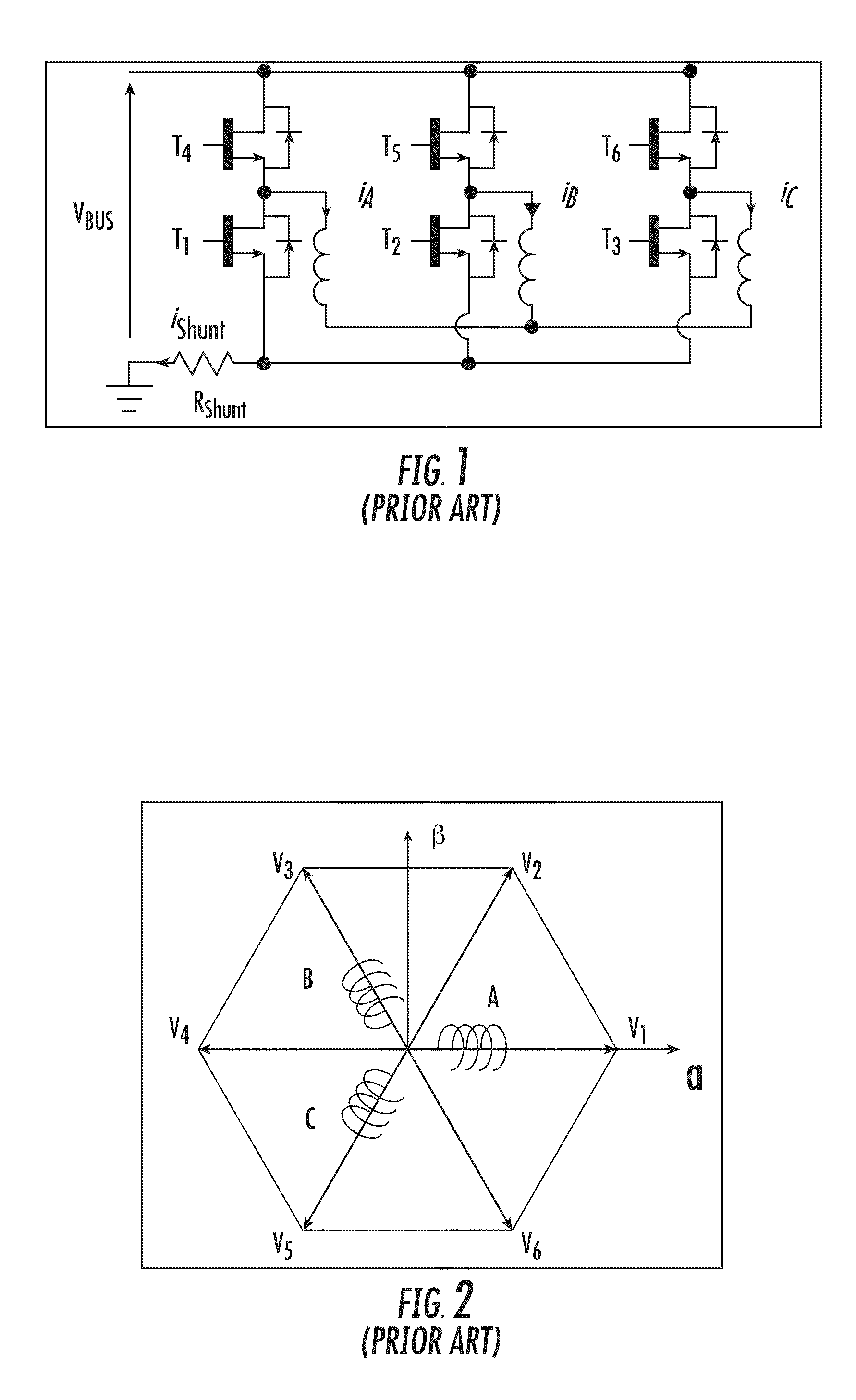

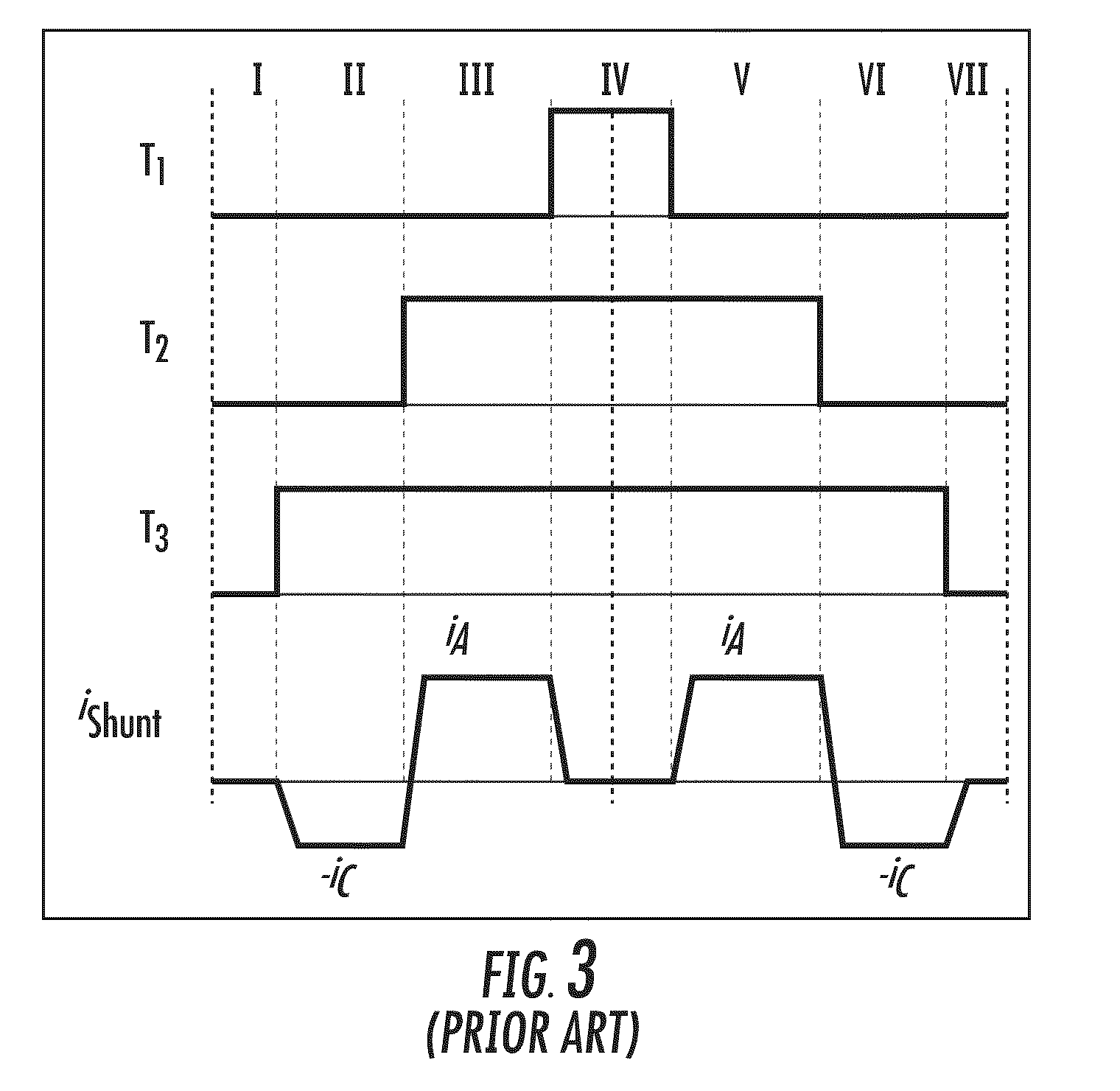

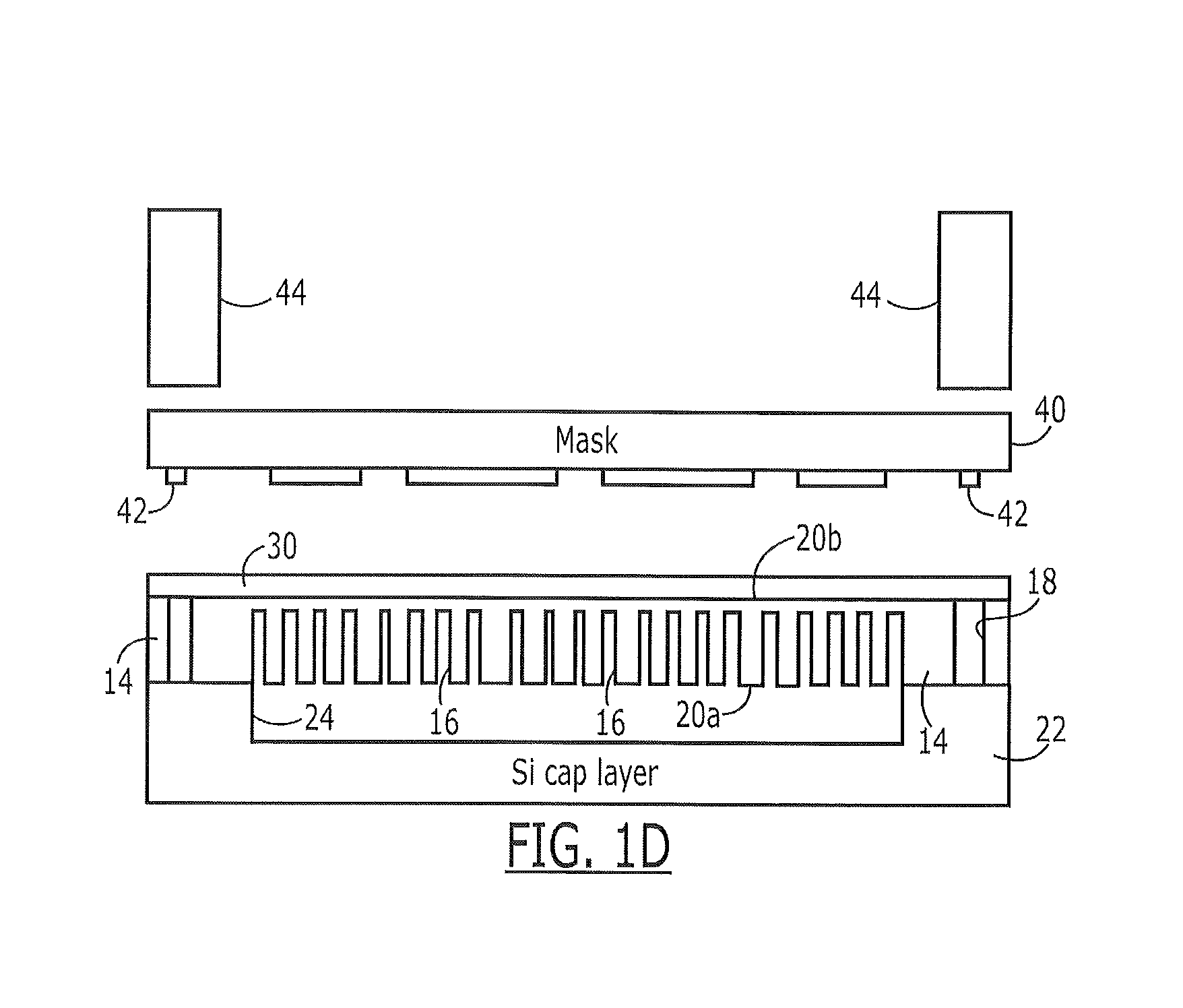

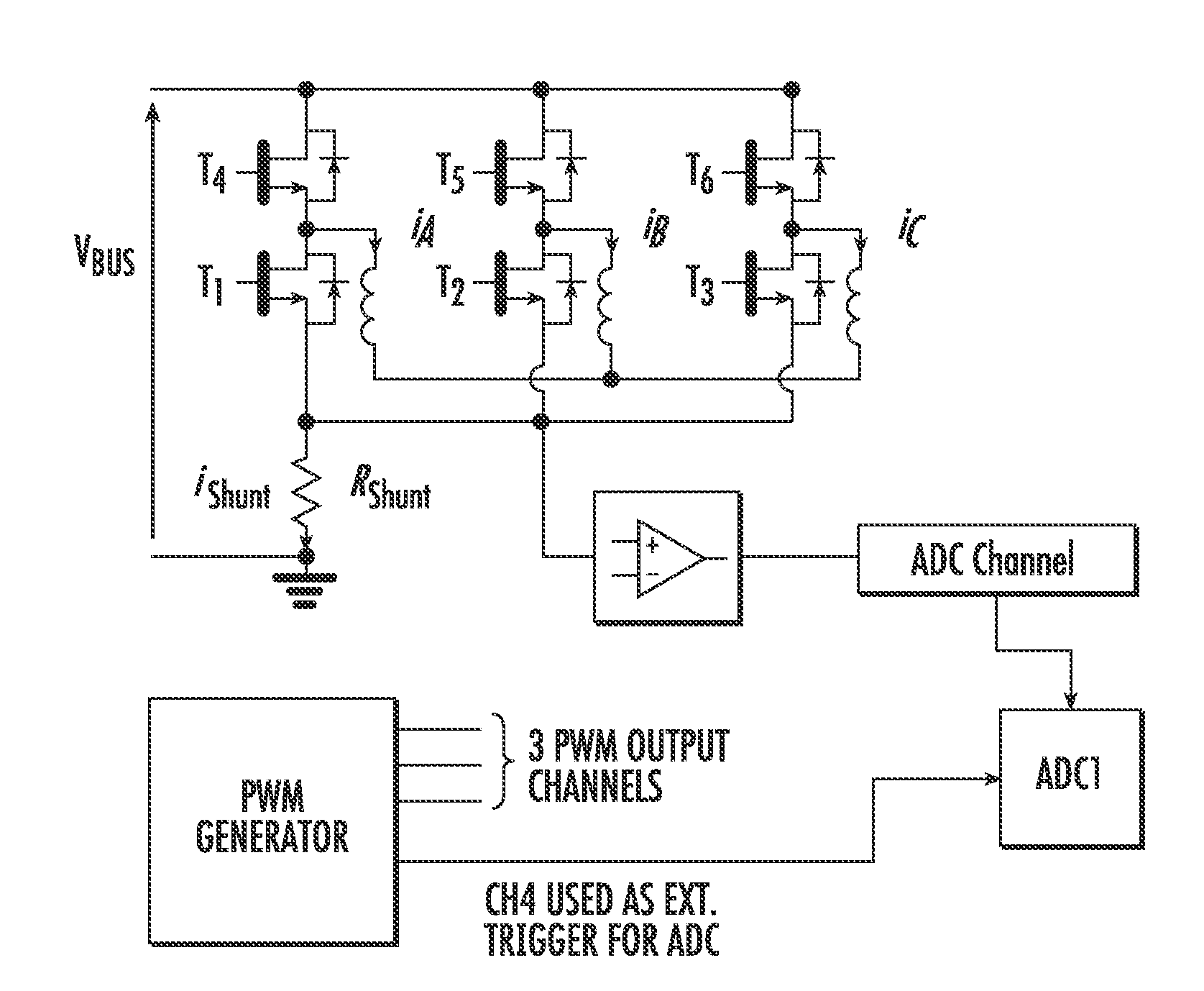

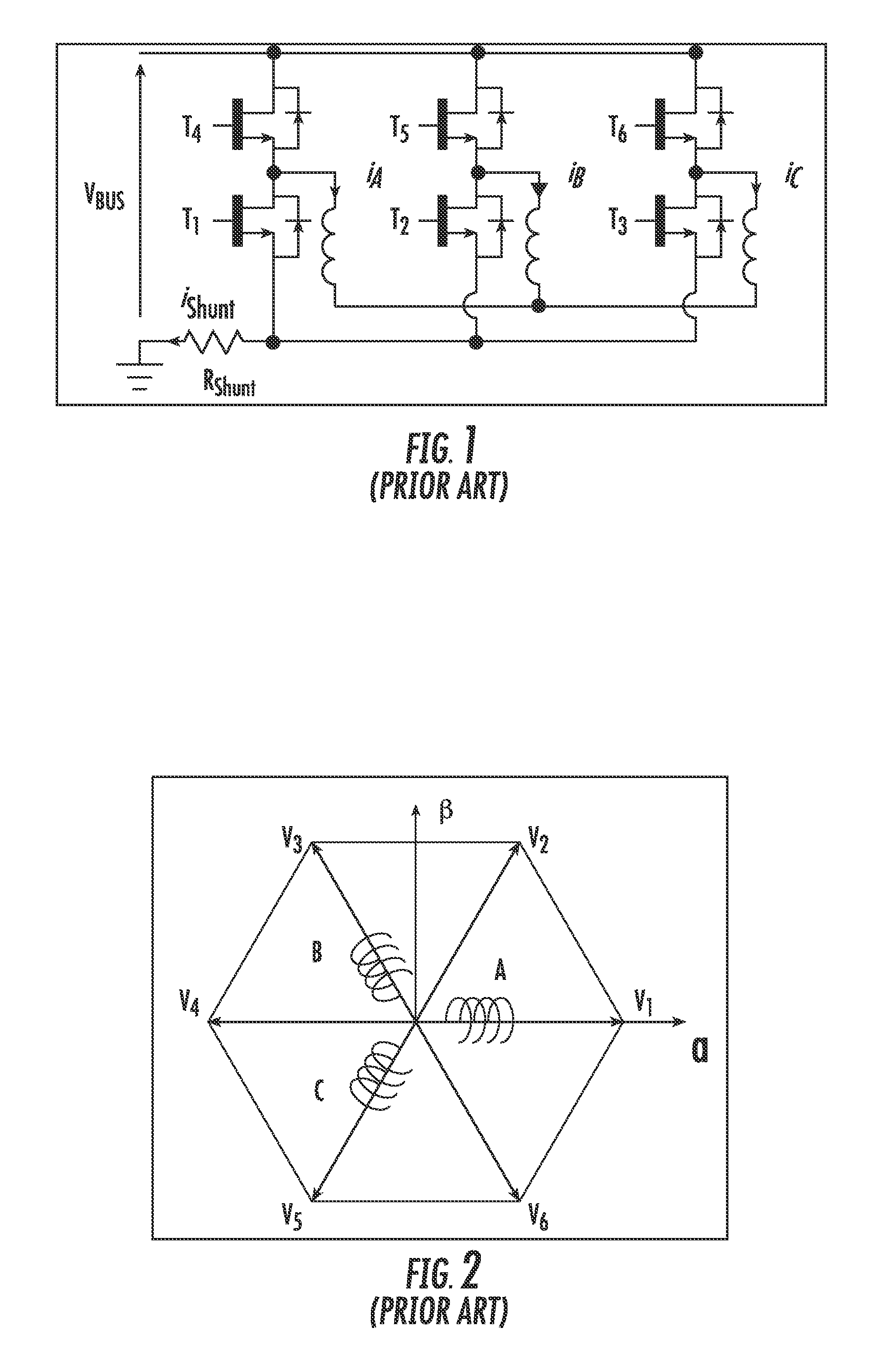

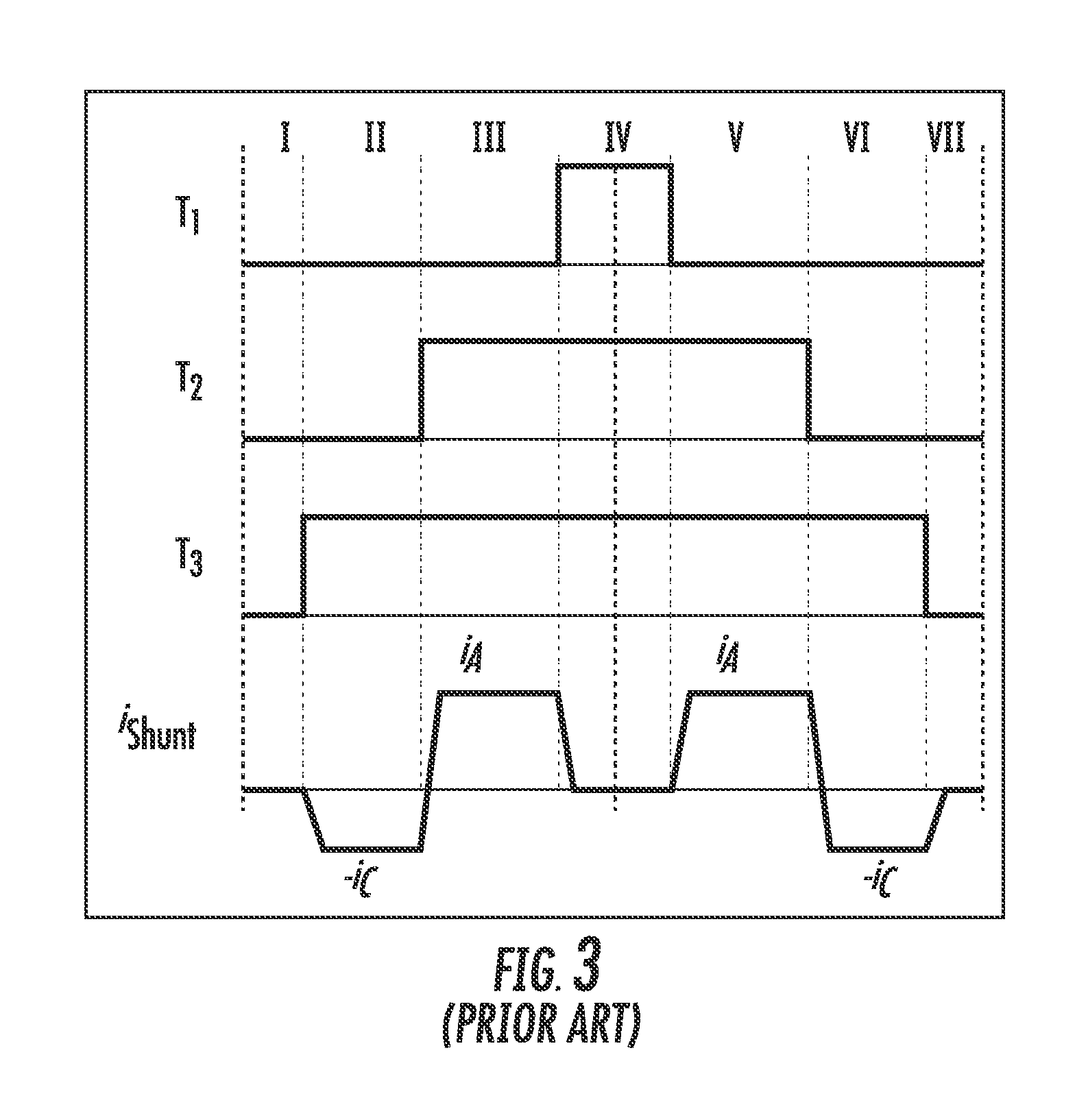

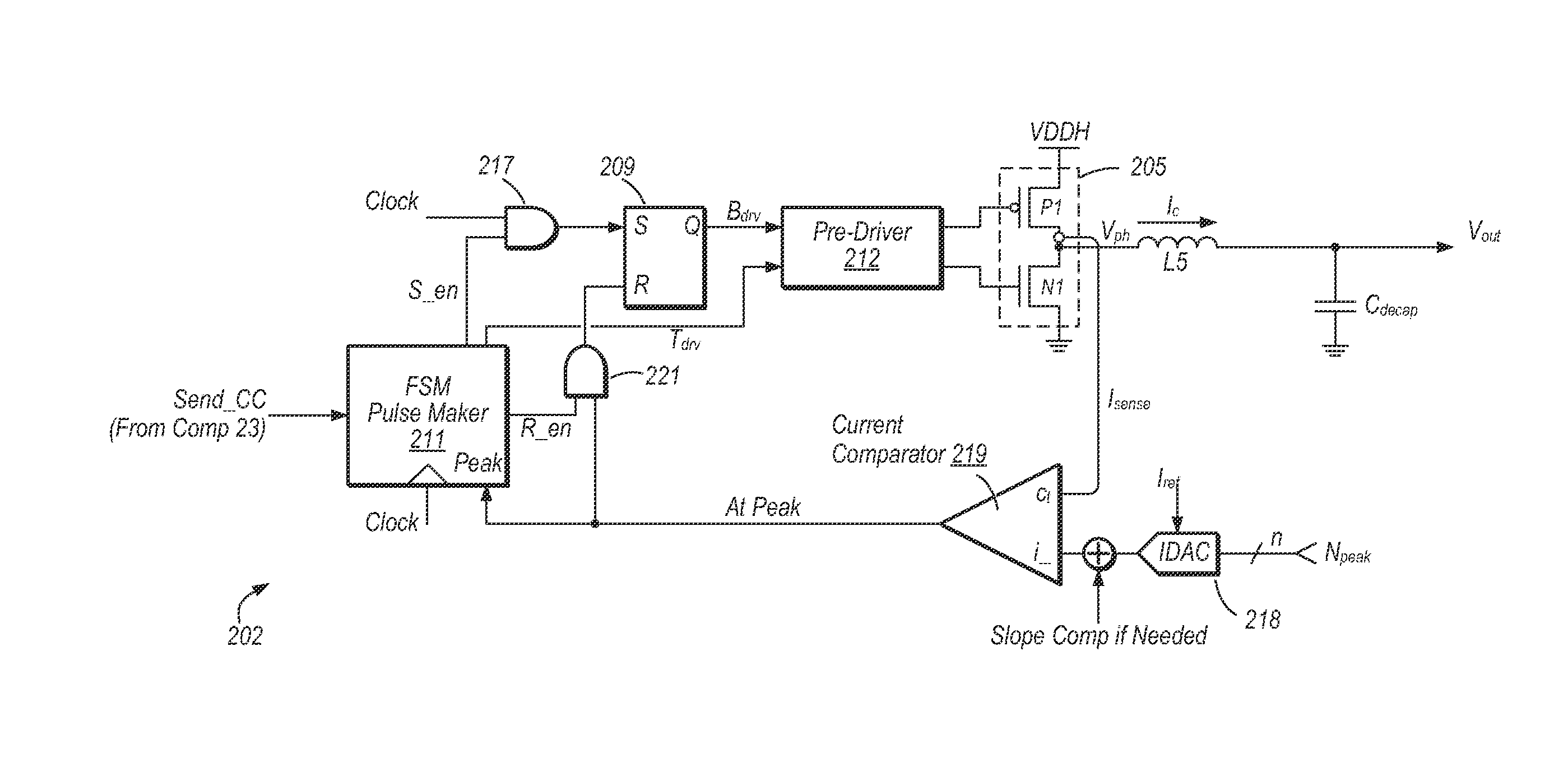

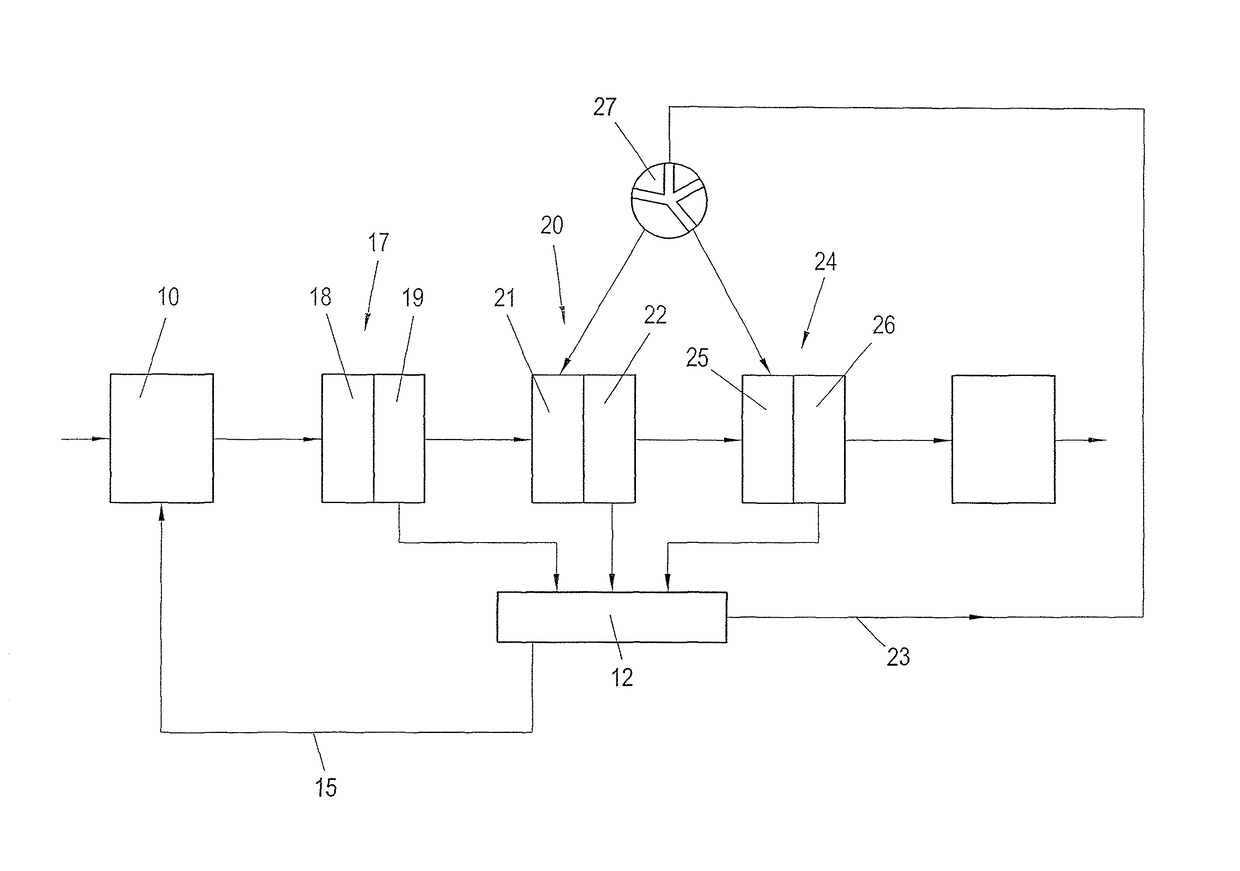

Phase current measurements in a three phase inverter using a single common dc-link current sensor

ActiveUS20090284194A1Sufficient durationImprove performanceSynchronous motors startersAC motor controlPhase currentsCurrent sensor

A method for measuring current in each phase of a three-phase inverter driven motor is based on the three-phase inverter being controlled in a PWM mode by three PWM signals including the use of a common DC-link current sensing resistor. The current on the sensing resistor is intermittently sampled. The method includes determining a modulation index for the voltage demand set by a motor controller. Based on specific mutual duty cycle conditions of the three PWM phase driving signals, sampling windows of sufficient duration are created for allowing distinct sampling of two of the phase currents.

Owner:STMICROELECTRONICS SRL

Image sensing apparatus, image sensing system, and image sensing method

InactiveUS20070222877A1Increase frame rateSufficient durationTelevision system detailsTelevision system scanning detailsPhotoelectric conversionEngineering

There is provided an image sensing apparatus. The image sensing apparatus includes a photoelectric conversion unit constituted by a plurality of photoelectric conversion elements converting exposed light into charge and accumulating the charge therein, and an exposure time control function for controlling an exposure time of the photoelectric conversion elements, the apparatus including: a first readout unit that reads out charge from pixels composed of the photoelectric conversion elements of the photoelectric conversion unit, the charge being accumulated in the pixels as a result of exposure for a predetermined exposure time; a second readout unit that reads out charge from pixels of a specific area in a predetermined area of the photoelectric conversion unit over a plurality of times, in a period when the first readout unit is reading out charge from the pixels of the predetermined area of the photoelectric conversion unit; an image data generation unit that generates an image data on the basis of a first pixel data composed of the charge read out by the first readout unit; and a predetermined data generation unit that generates a predetermined data on the basis of a second pixel data composed of the charge read over the plurality of times by the second readout unit.

Owner:COLUMBIA PEAK VENTURES LLC

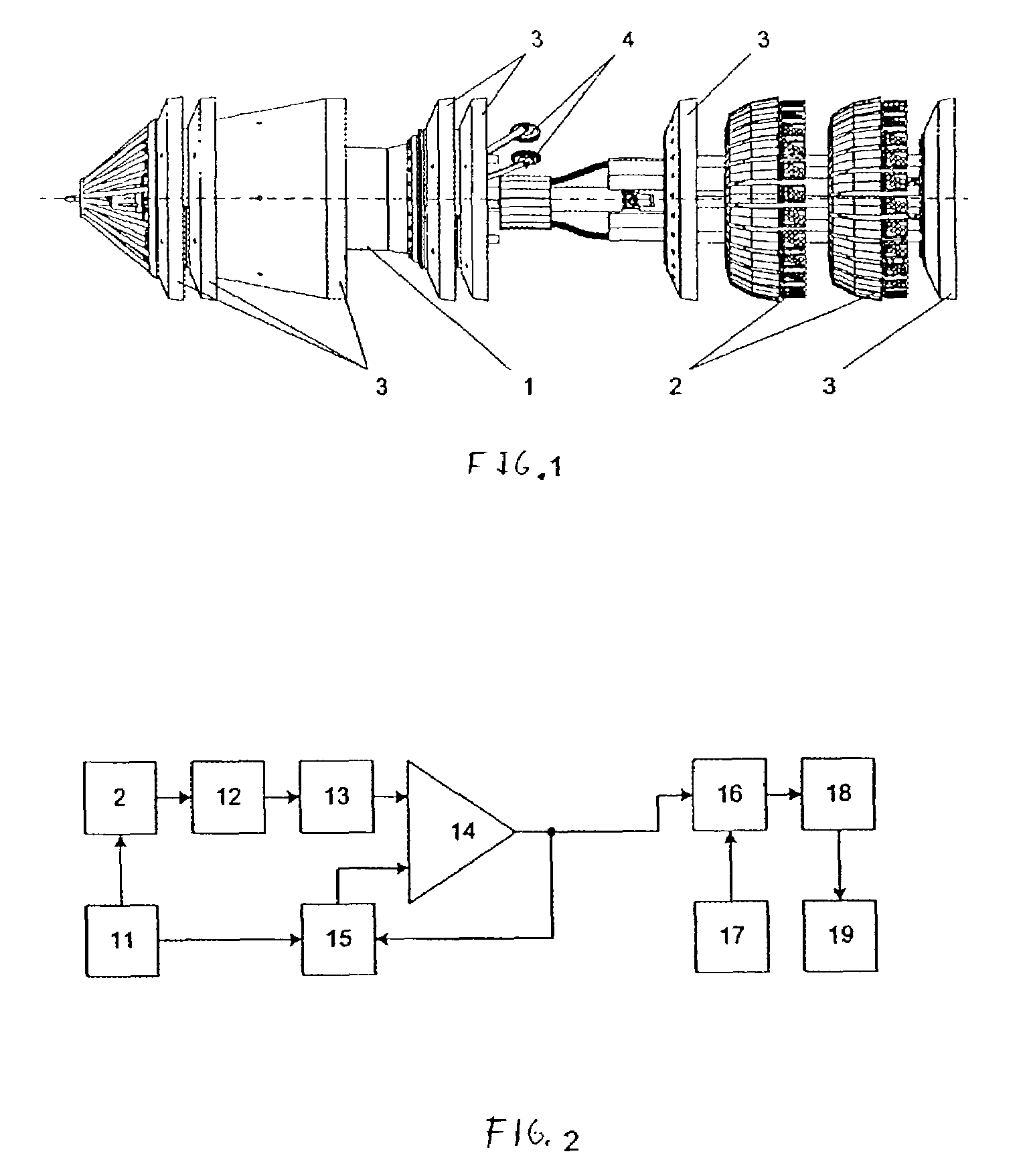

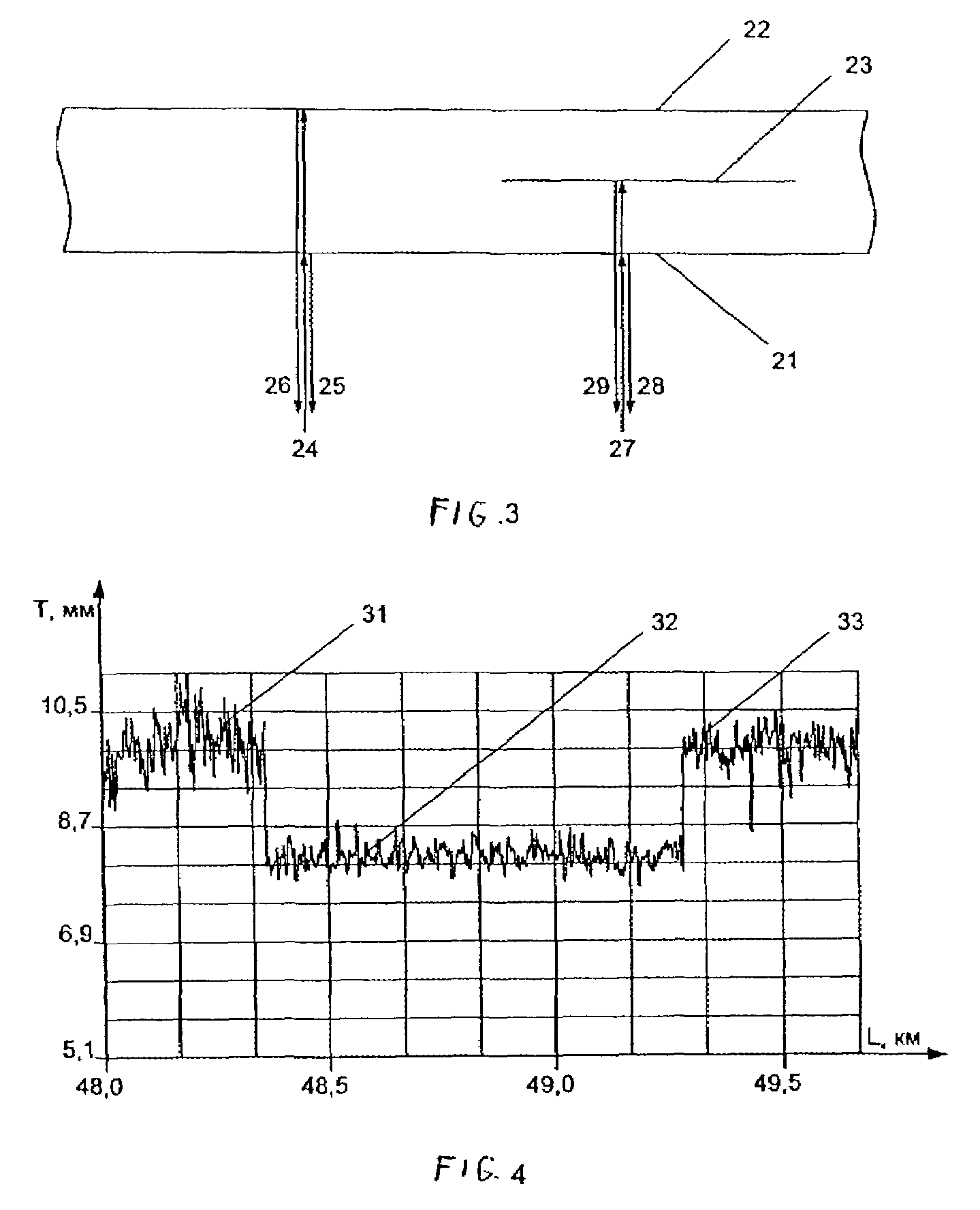

In-tube ultrasonic device for wall thickness metering

InactiveUS7111516B2Increase of distance controlledHigh measurement accuracyUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesOne passEngineering

What is claimed is an inspection device for in-tube monitoring of main pipelines by the method of ultrasonic wall thickness metering realized in a device traveling inside the pipeline and performing measurements, acquisition of measurement data and their interpretation. The device comprises a probing pulse generator, an ultrasonic transducer, an amplifier, a comparator with an analog input, a digital timer, a processor and a data storage module, and a controlled reference voltage source connected in series. The output of said reference voltage source is connected to the reference voltage input of the comparator, said reference voltage source being capable of setting at least two different voltages at its output.The comparator output is connected to one of the control inputs of the reference voltage source that allows one to switch threshold values in the comparator, when recording the ultrasonic pulses, to use one threshold value to record the moment of reception of the ultrasonic pulse reflected from the internal wall of the pipeline using another threshold value of the comparator to record the moment of reception of the ultrasonic pulse reflected from the external wall of the pipeline using the other threshold value. Thus, the operator can perform direct measurements of the transit time of the ultrasonic pulses in the pipe wall allowing him to increase the distance monitored per one pass of the device, and to increase the accuracy of measurements and the rate of hardware data processing compared to the prototypes known in the art.

Owner:WEATHERFORD TECH HLDG LLC +1

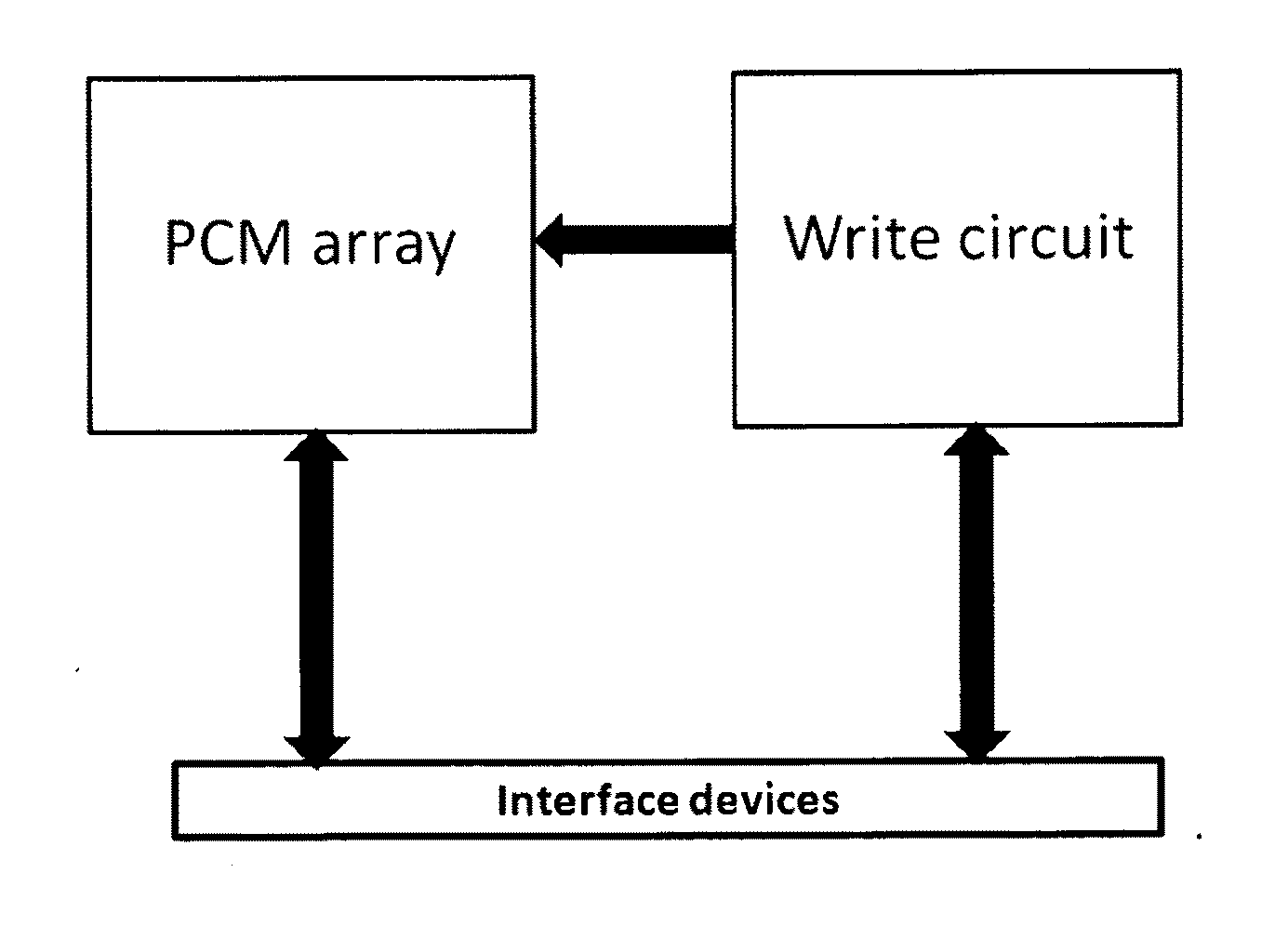

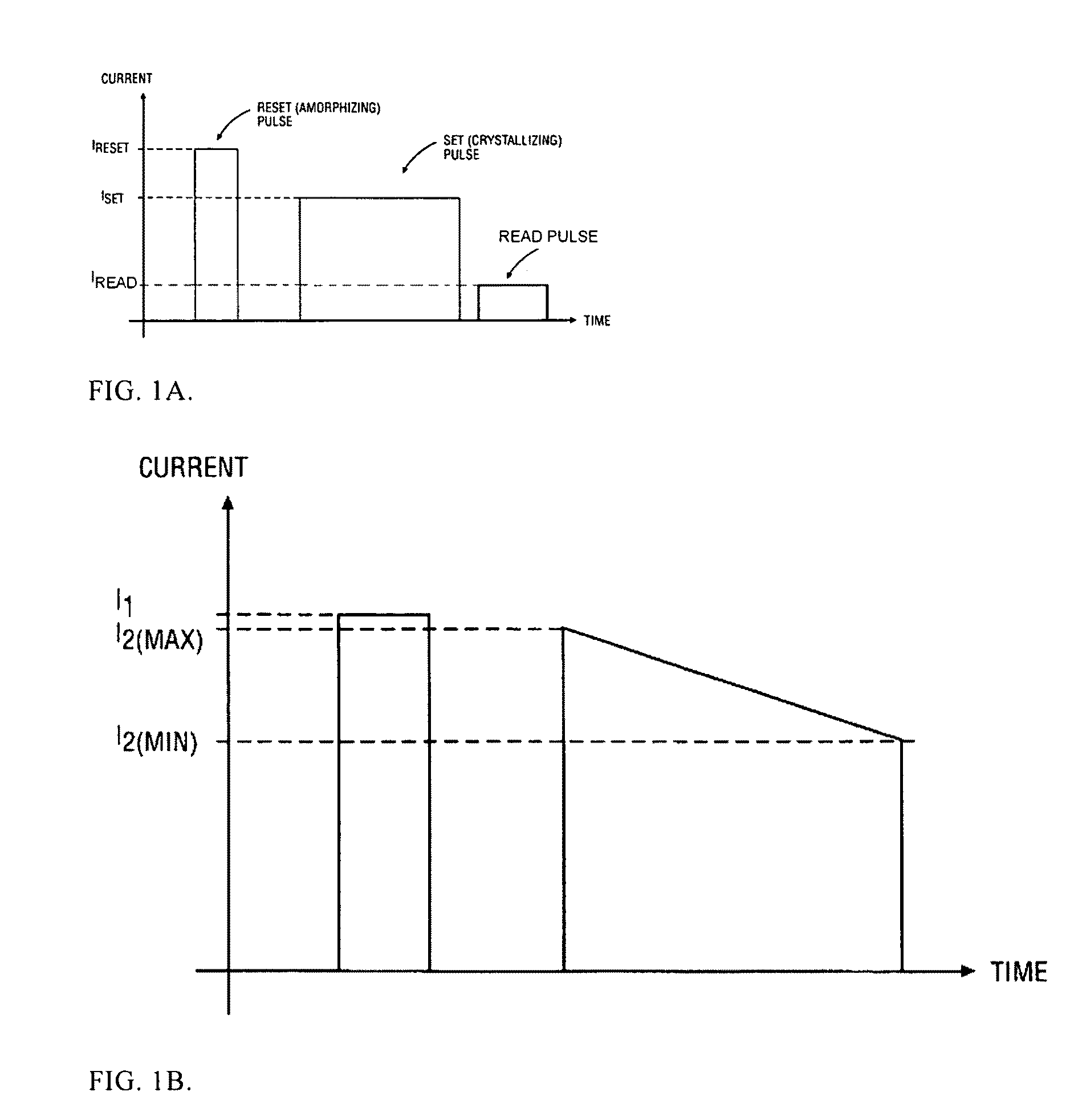

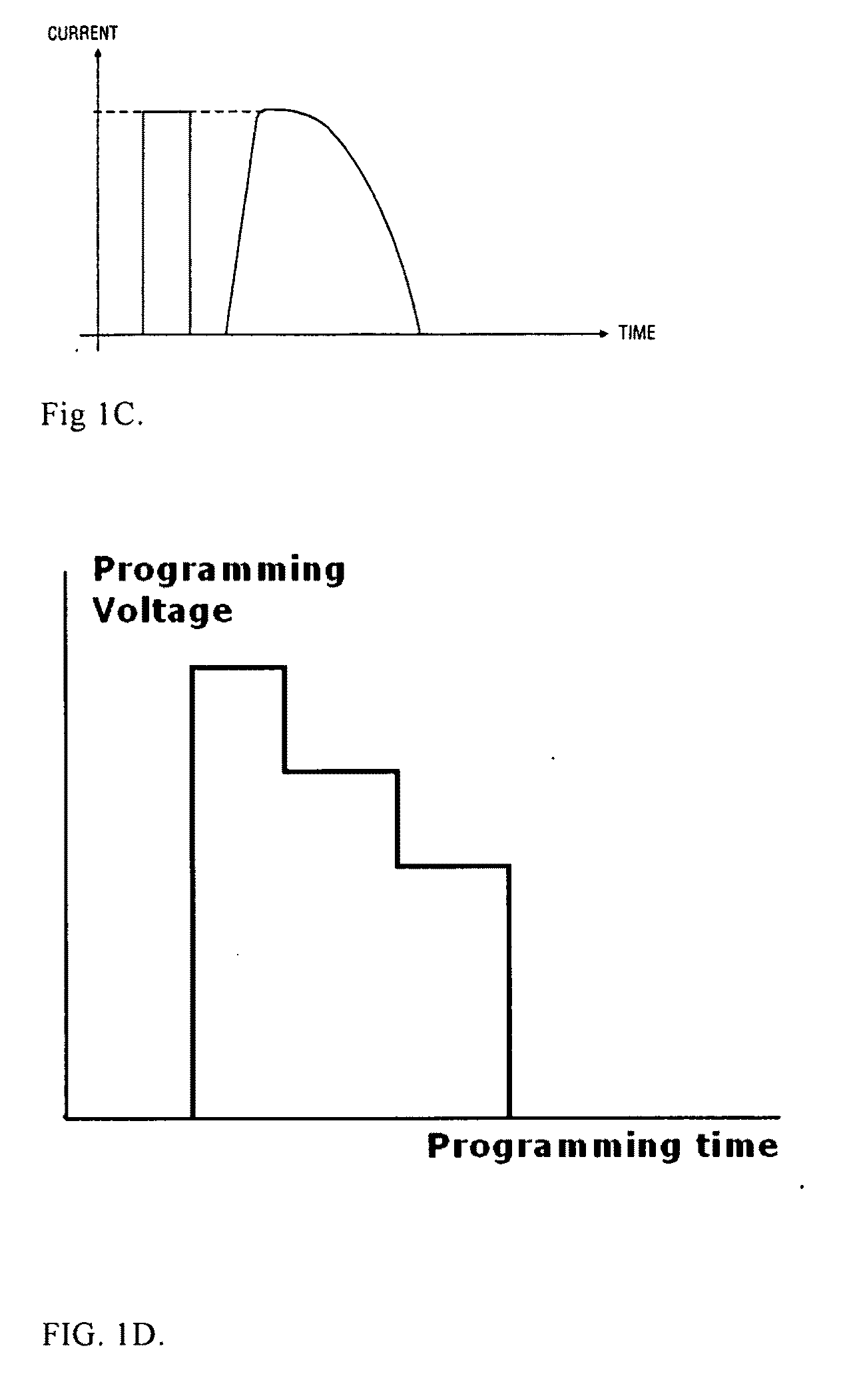

Programming methods for phase-change memory

InactiveUS20100226168A1Without deterioration enduranceSolve the large consumptionDigital storagePhase-change memoryAlloy

Set pulses with finite rise time that heat up phase change alloy between about nucleation temperature and about average of crystallization and melting temperatures are proposed for programming phase change memory from reset to set state in order to minimize energy during this transition and to achieve uniform set state distribution. Non-square reset pulses with finite rise time that heat up phase change alloy at or above melting temperature are proposed for programming phase change memory from set to reset state in order to improve cell endurance.

Owner:SAVRANSKY SEMYON D

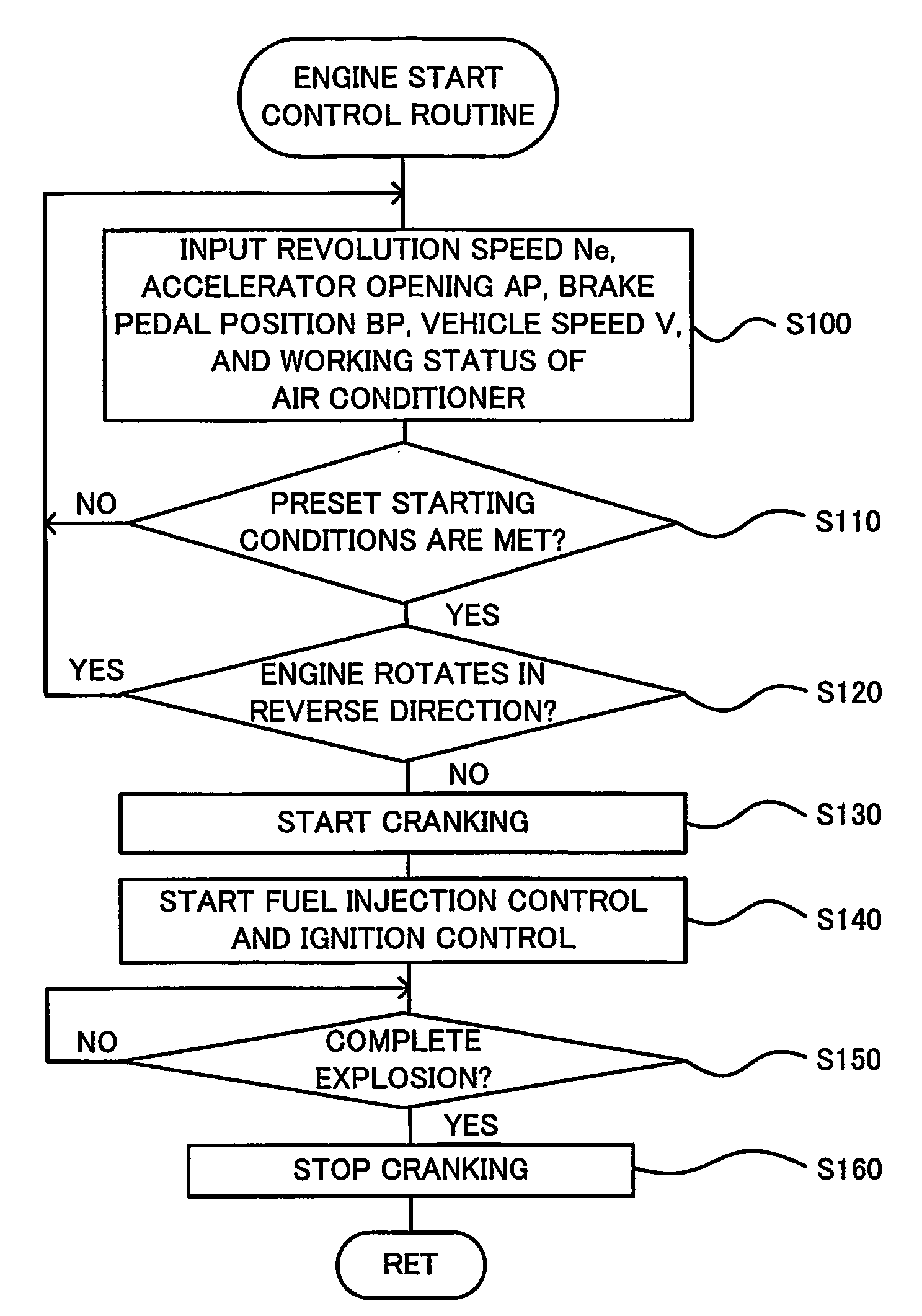

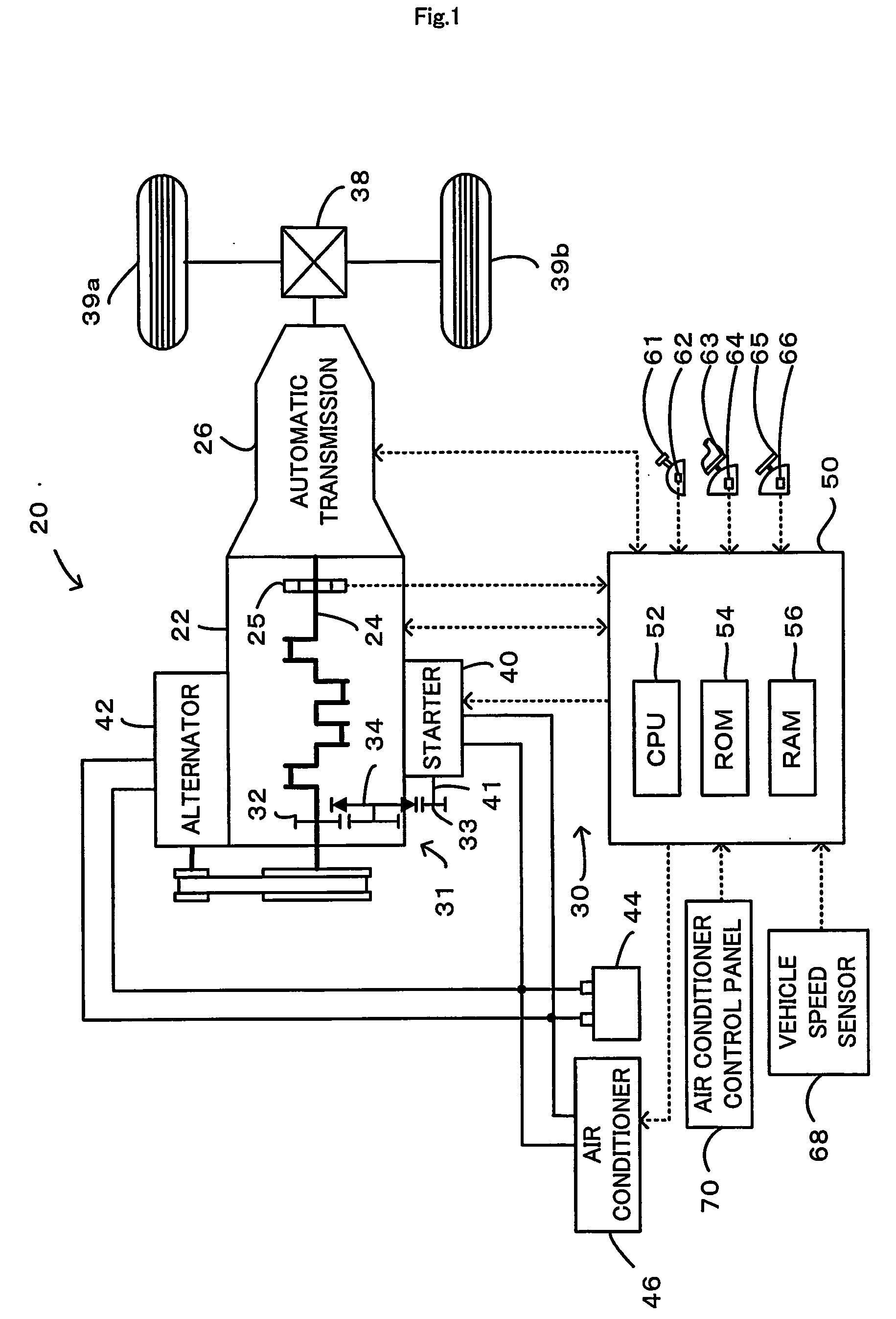

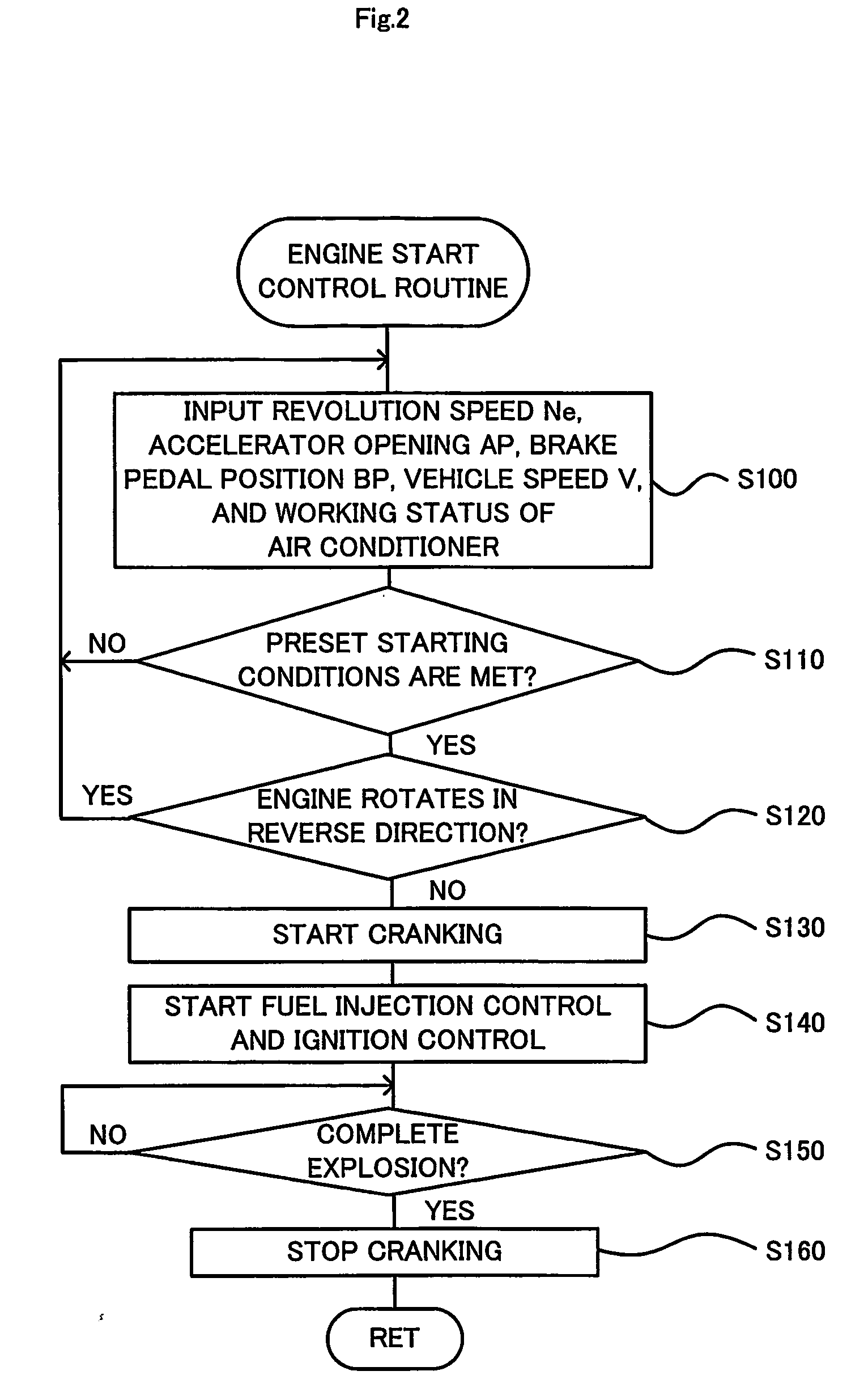

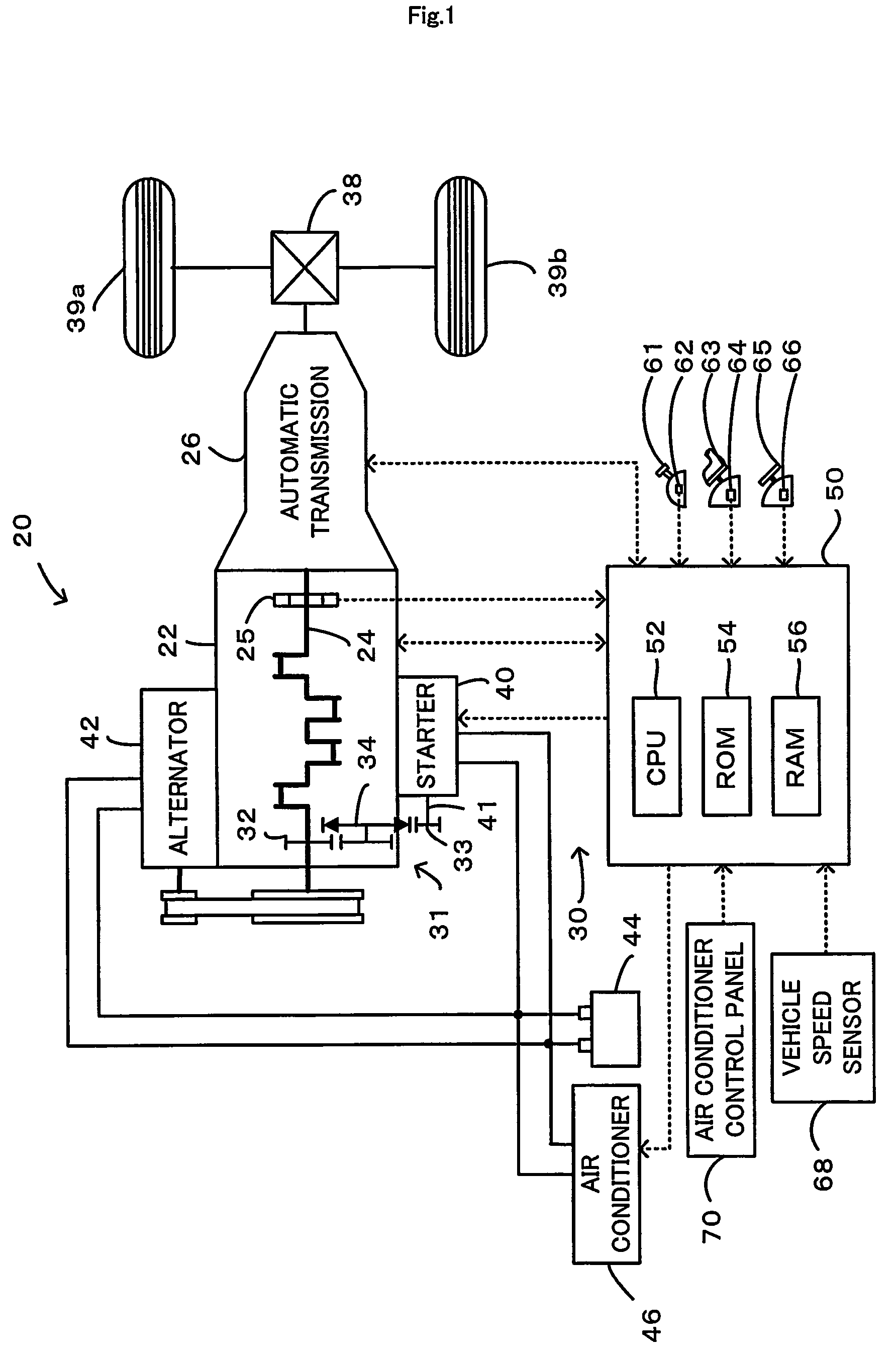

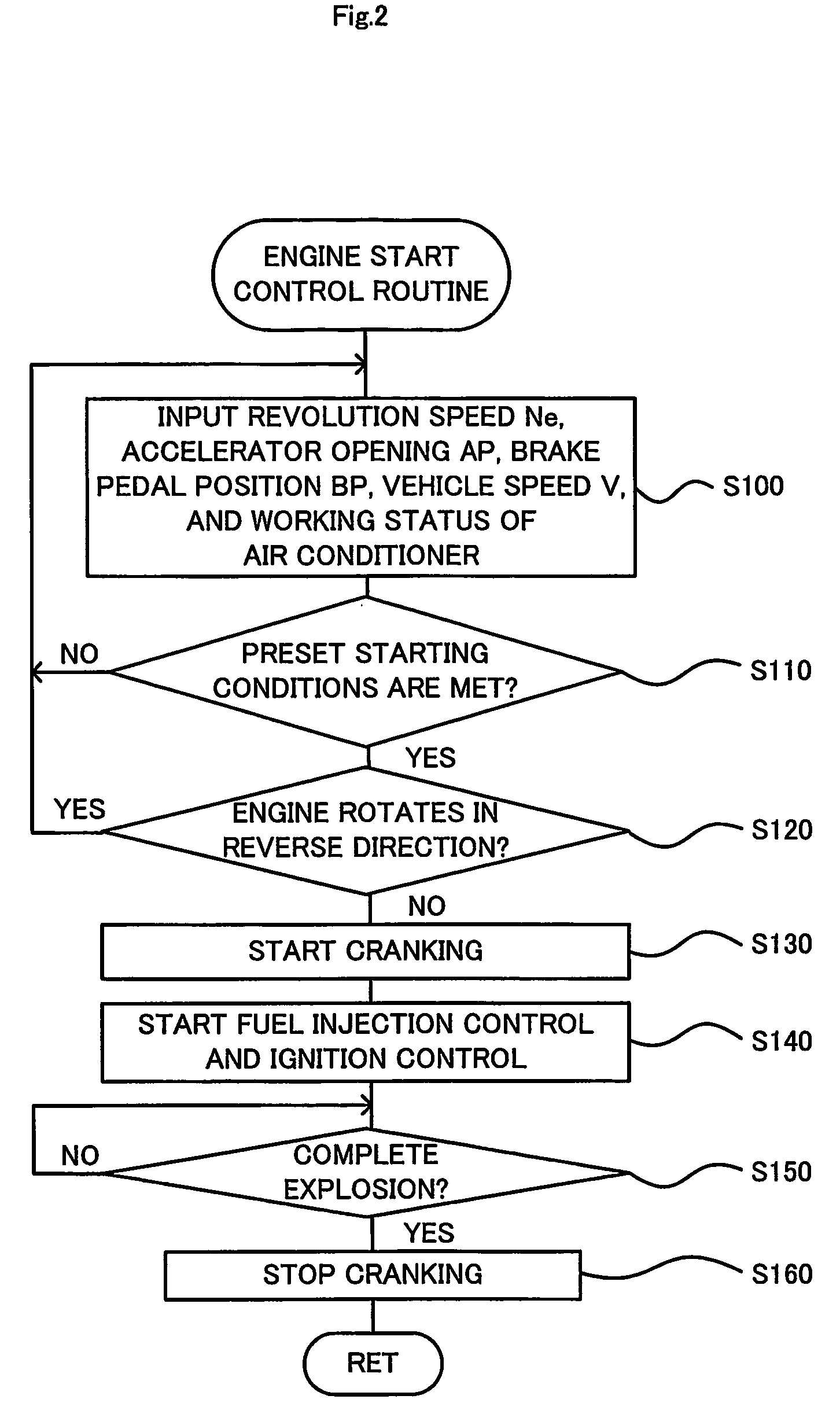

Starting apparatus for internal combustion engine and automobile

InactiveUS20070084429A1RestrictsReduce weightAnalogue computers for vehiclesPower operated startersEngineeringIdle speed

An idling stop control of the invention attains an auto start and an auto stop of an engine. At a time point t1, pre-set stop conditions are met to cut off a fuel supply to the engine. Preset starting conditions may be met at a time point t2 when the engine still continues rotating in a normal direction by the inertial force. In this state, the idling stop control starts cranking the engine. The preset starting conditions may be met at a time point t4 when a piston does not complete a compression cycle immediately before a stop of the engine but is pressed back by the compressed air to rotate the engine in a reverse direction. In this state, the idling stop control waits until cancellation of the reverse rotation of the engine and then starts cranking the engine. The arrangement of the invention desirably ensures a quick start of the engine, while effectively preventing an excess stress from acting on a gear mechanism, which connects a starter motor to the engine.

Owner:TOYOTA JIDOSHA KK

Starting apparatus for internal combustion engine and automobile

InactiveUS7681545B2Load moreReduce weightAnalogue computers for vehiclesPower operated startersEngineeringIdle speed

Owner:TOYOTA JIDOSHA KK

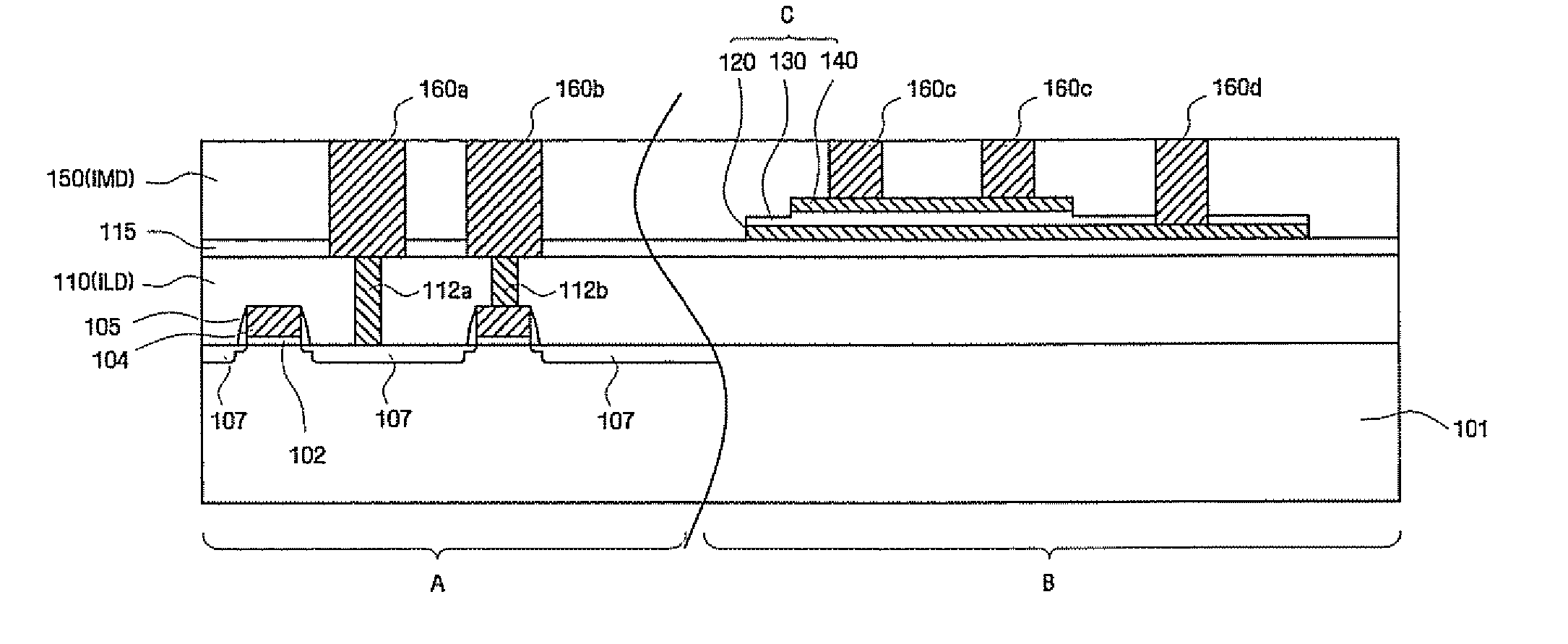

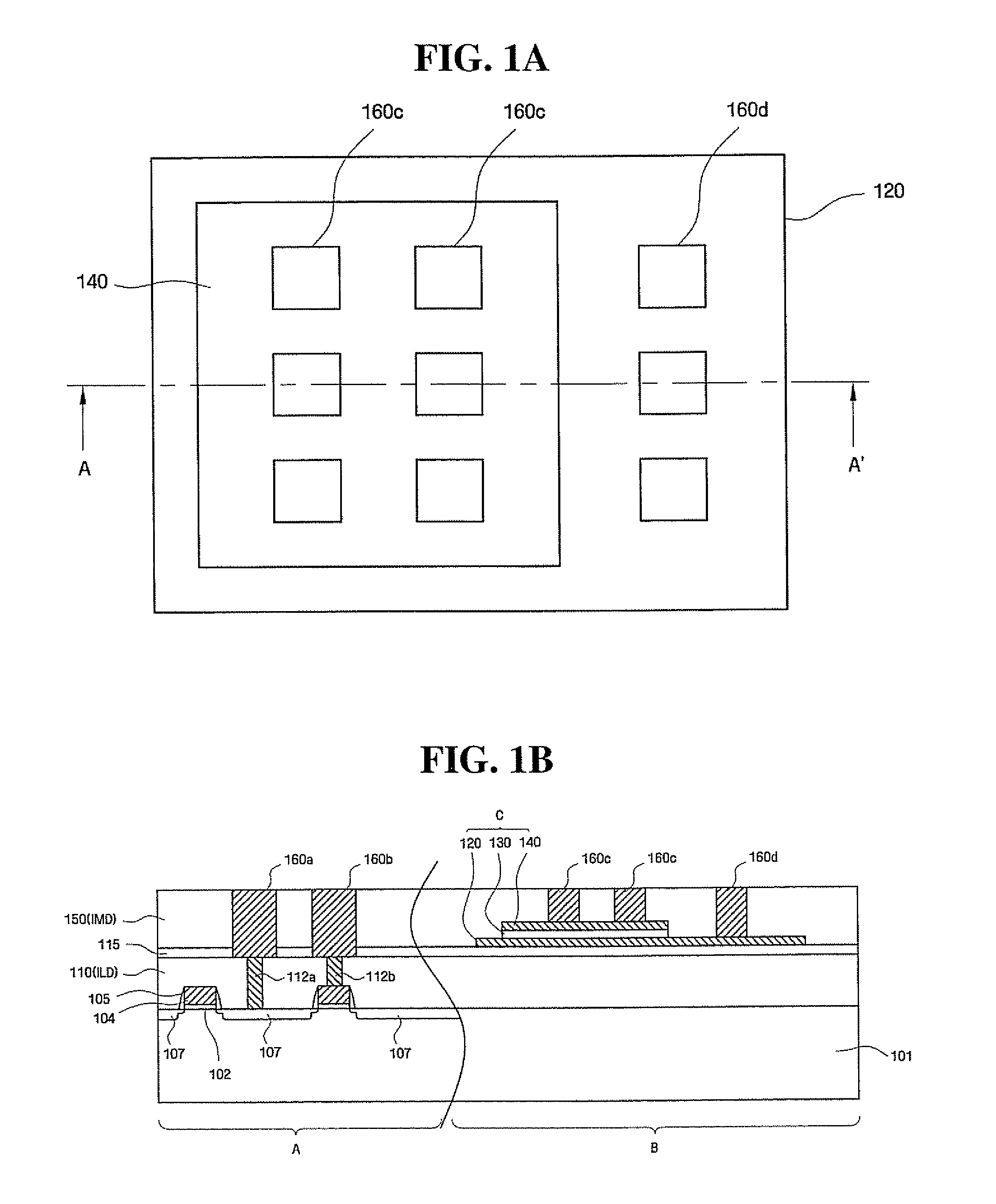

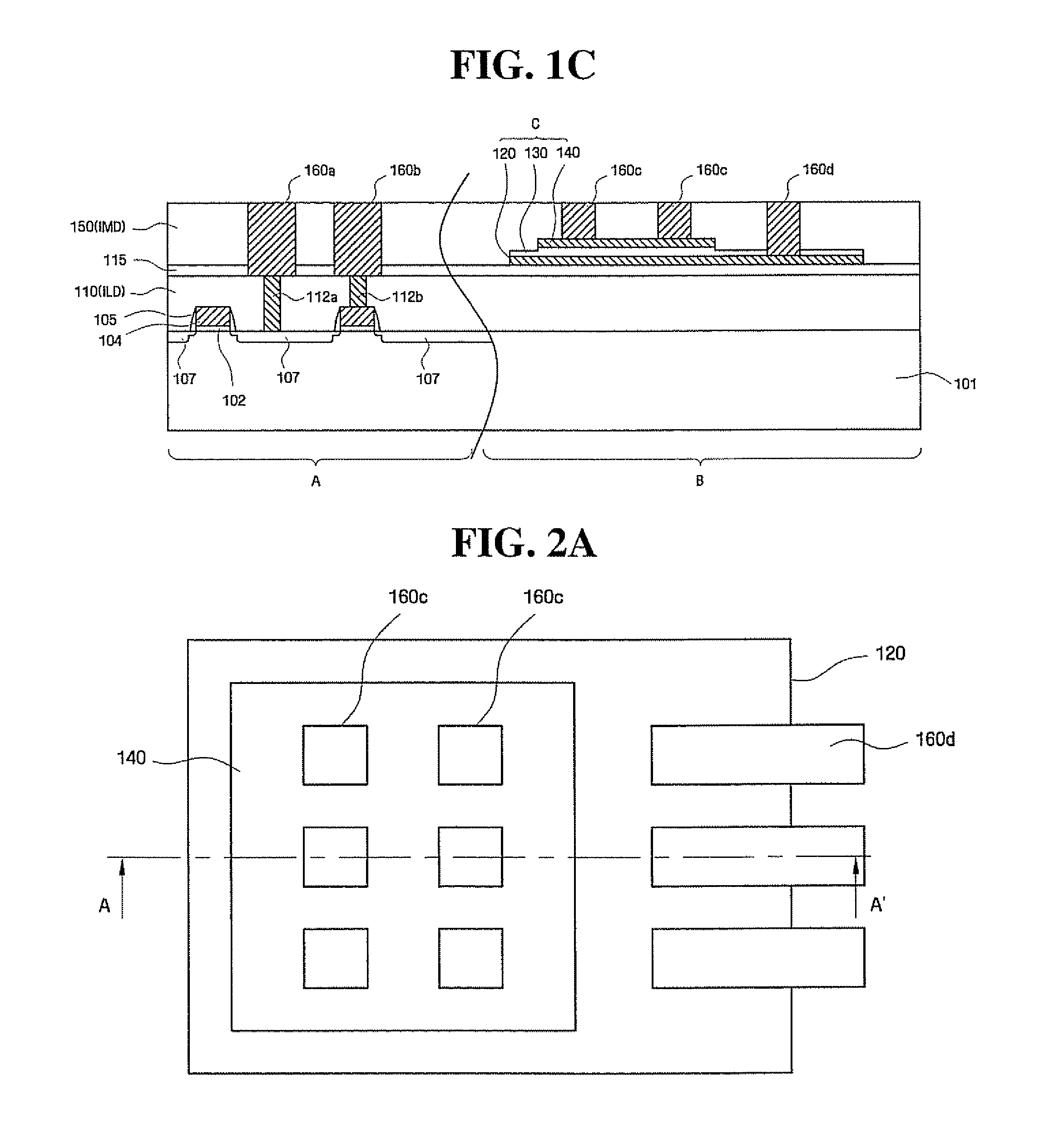

Metal-Insulator-Metal (MIM) Capacitors Formed Beneath First Level Metallization and Methods of Forming Same

InactiveUS20070034988A1Improve leakage current characteristicSufficient durationSemiconductor/solid-state device detailsSolid-state devicesMetal-insulator-metalMetal

A metal-insulator-metal (MIM) capacitor for an integrated circuit may be provided on the interlayer insulating layer and covered by a inter-metal dielectric (IMD) layer. This IMD layer has at least a first opening therein that exposes an upper surface of a first electrode of the MIM capacitor. This first opening is filled with a first copper damascene interconnect pattern, which may in some embodiments be part of a dual-damascene copper interconnect structure associated with a first and lowermost level of metallization (e.g., M1 wiring layer). This first copper damascene interconnect pattern may have an upper surface that is planar with an upper surface of the IMD layer and a bottom surface that is in contact with the upper surface of the first electrode of the MIM capacitor.

Owner:SAMSUNG ELECTRONICS CO LTD

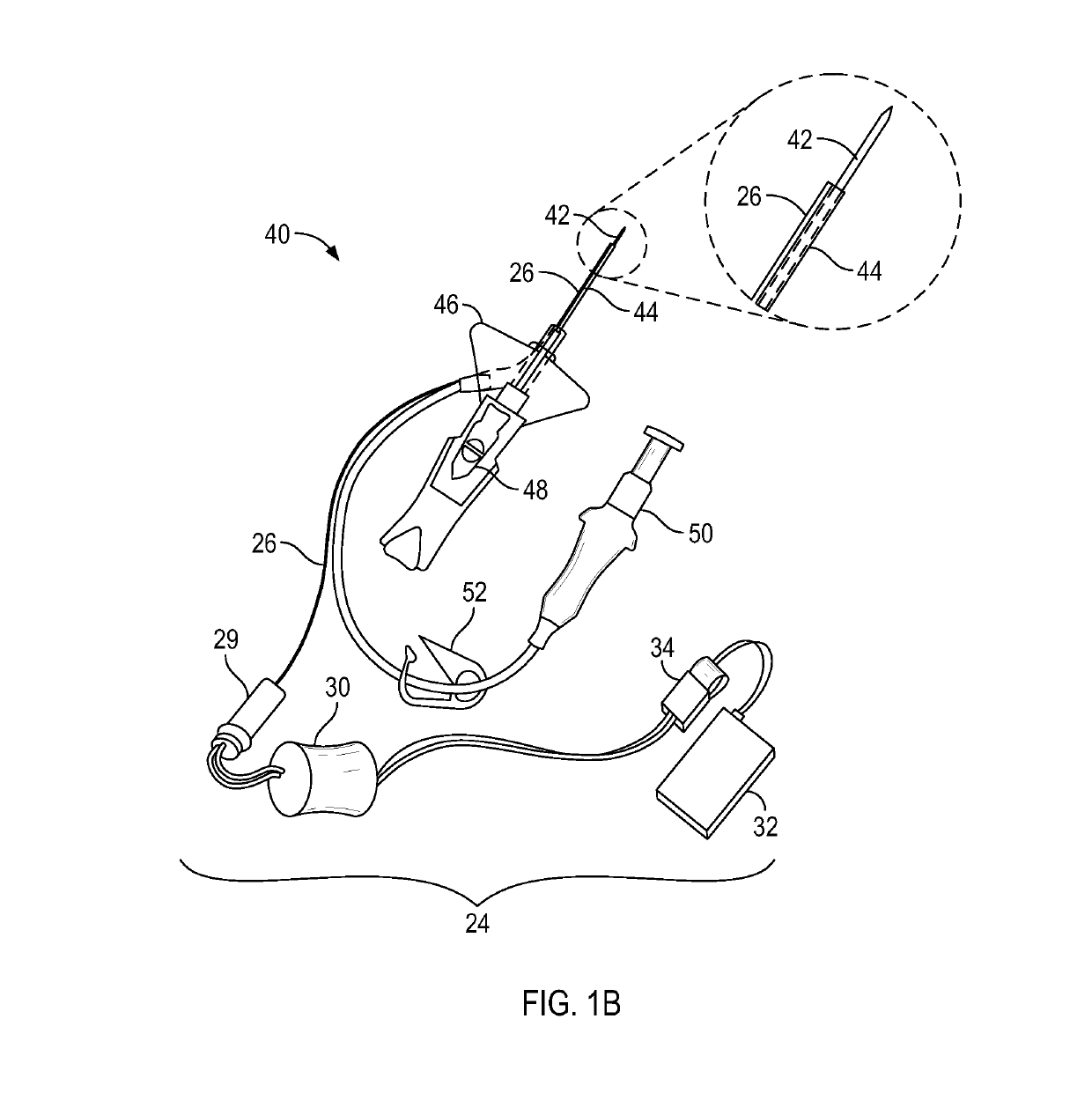

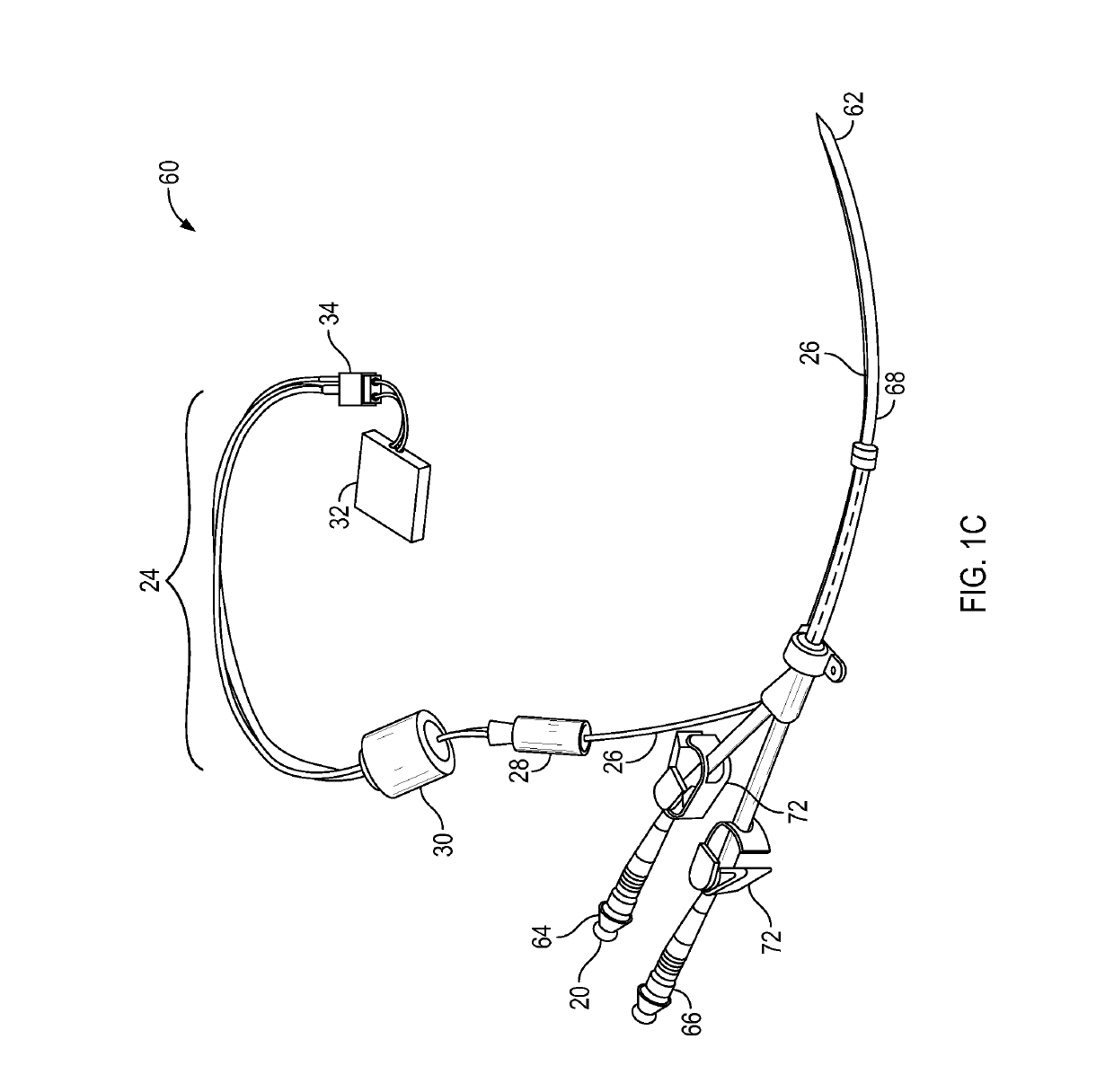

Method, system, and devices of safe, antimicrobial light-emitting catheters, tubes, and instruments

PendingUS20190168023A1Safe to expose to human tissueReduce the risk of infectionBalloon catheterMedical devicesPhotodynamic therapyUltraviolet

A light-emitting, antimicrobial tuber, instrument or catheter includes a thin, flexible tube having an optically transparent wall; and a light transmitter configured and arranged to emit light through the tube, which may be ultraviolet C (UVC) irradiation, photodynamic therapy (PDT), violet-blue light therapy, and other light-based therapies. In one embodiment, violet-blue light from 400-500 nm in wavelength, such as 405 nm, for instance, is used. The device is used on a patient and a therapeutic amount of light is administered to the patient, thereby reducing the risk of infections being transmitted from the instrument, tube or catheter to the patient, generally. The device may be configured for use in the urinary tract or as intravascular, and may be indwelling or temporary. Light may be administered for the duration of use or another time period effective to halt, inhibit, or reduce microbial or fungal growth.

Owner:LUMEN CATHETERS LLC

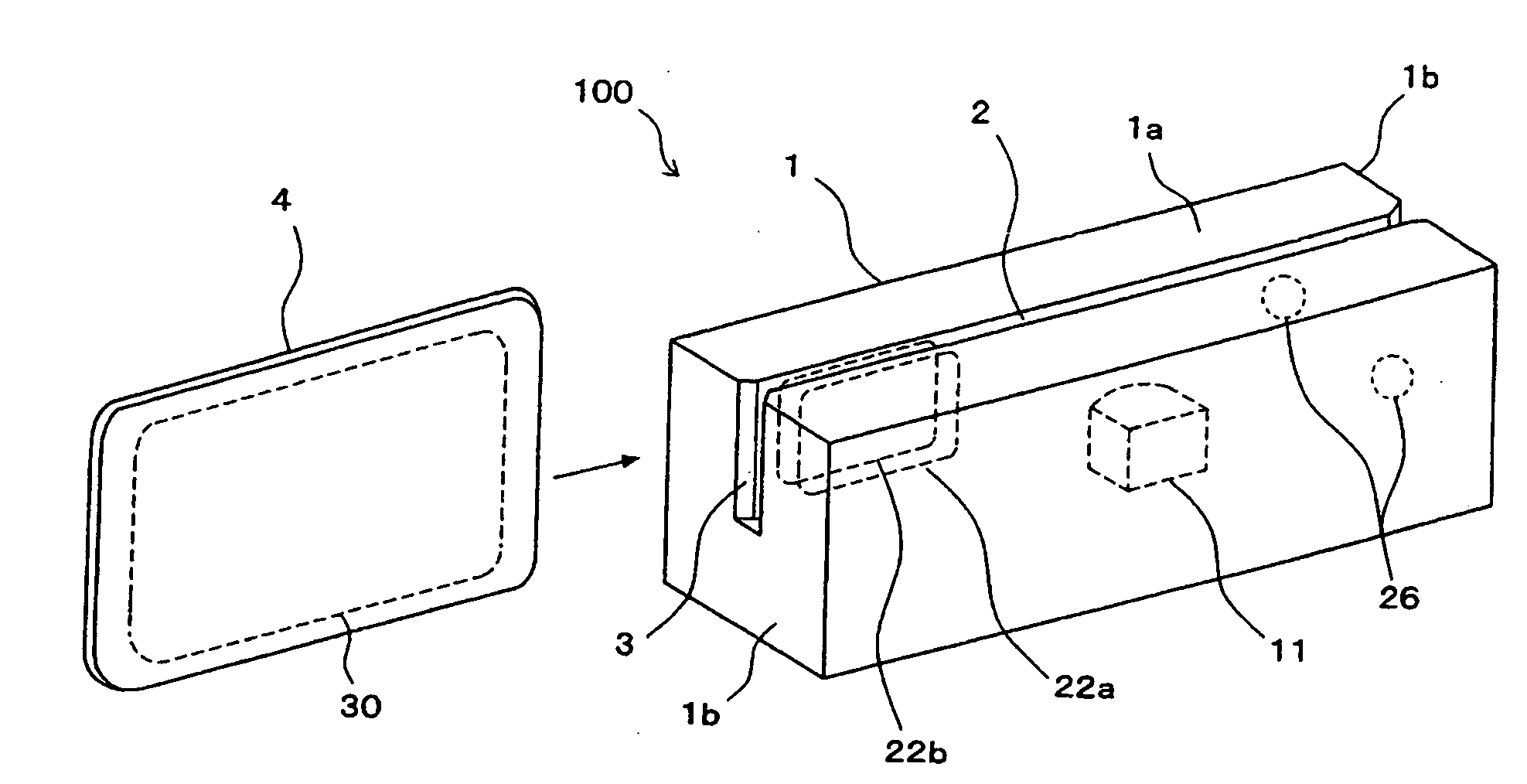

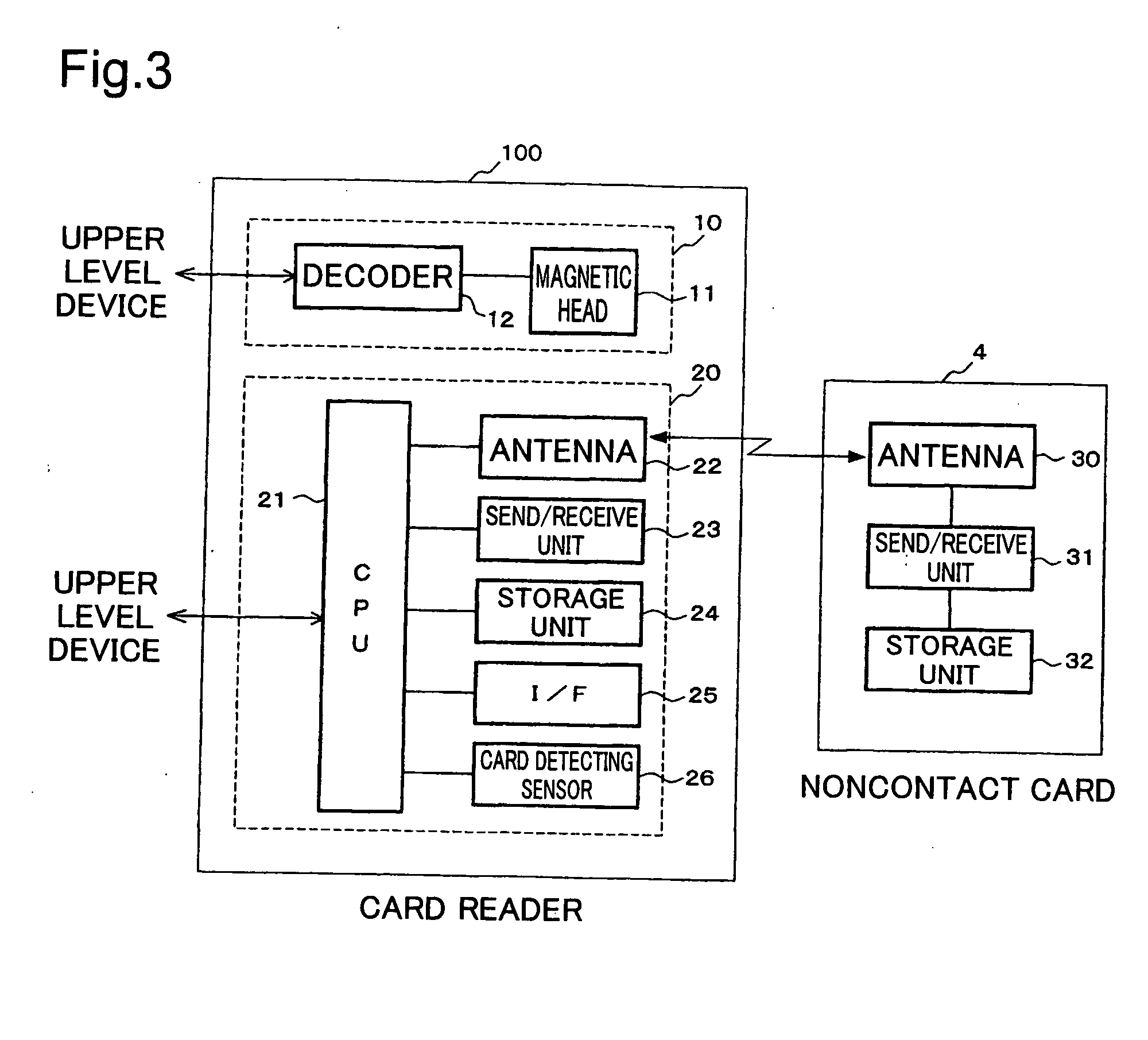

Manual noncontact IC card reader

InactiveUS20080203163A1Accurately readAvoid attenuationConveying record carriersSensing detailsMagnetic fluxEngineering

A technology that is applicable generally to manual noncontact card readers regardless of whether they are of insertion or swipe type, and realizes stable communication even with antennas of small size is provided. A pair of loop antennas 22a, 22b is located in opposition to either side of a transport path 2, in proximity to a card insertion slot 3 of the transport path 2. A magnetic circuit 40 which connects the loop antennas 22a, 22b together is located so as to not lie exposed in the transport path 2, so that, of the magnetic fluxes produced in two directions with respect to the noncontact card from the loop antennas 22a, 22b, one of these will be diverted through the magnetic circuit 40 without interlinking to the card.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

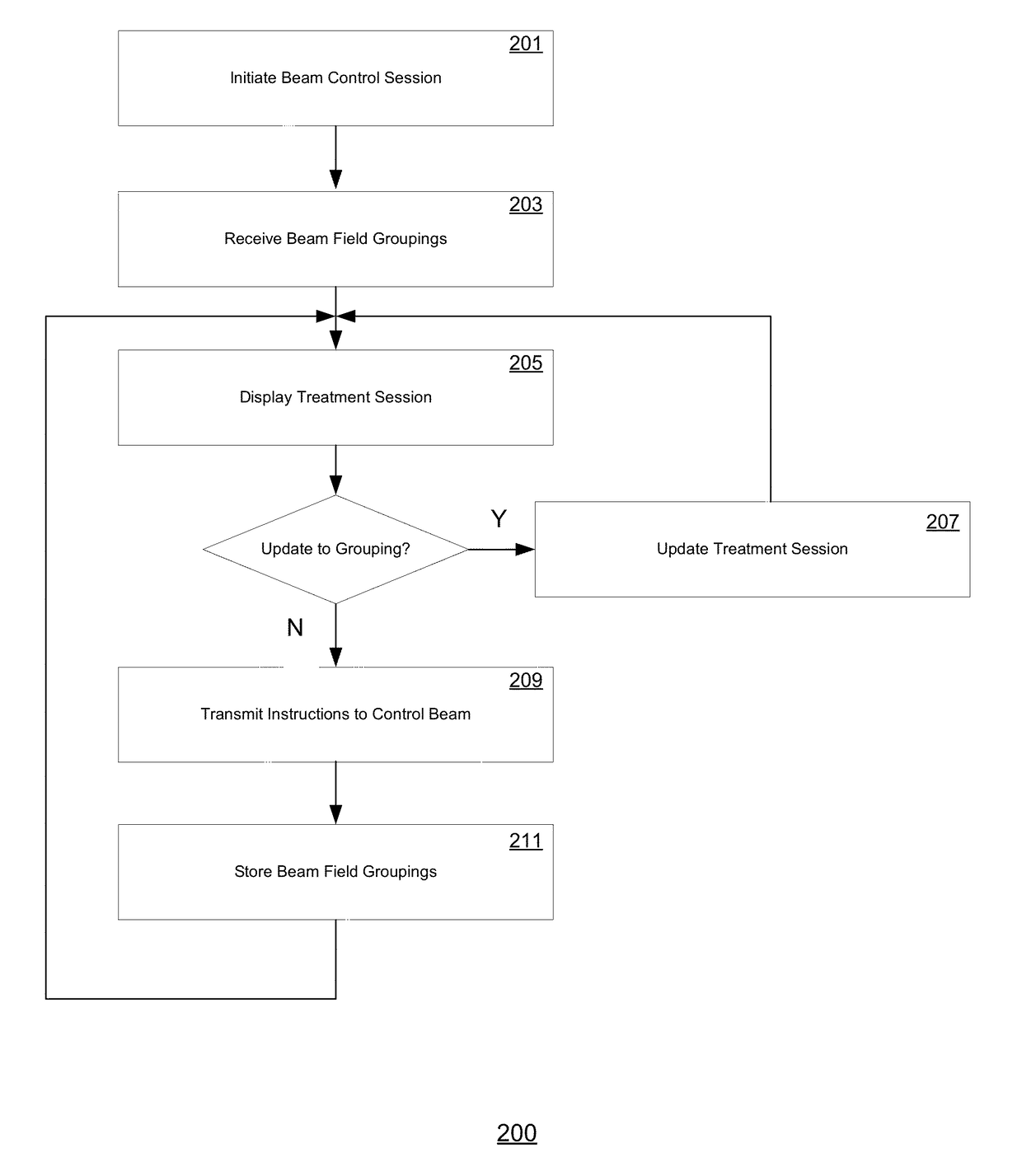

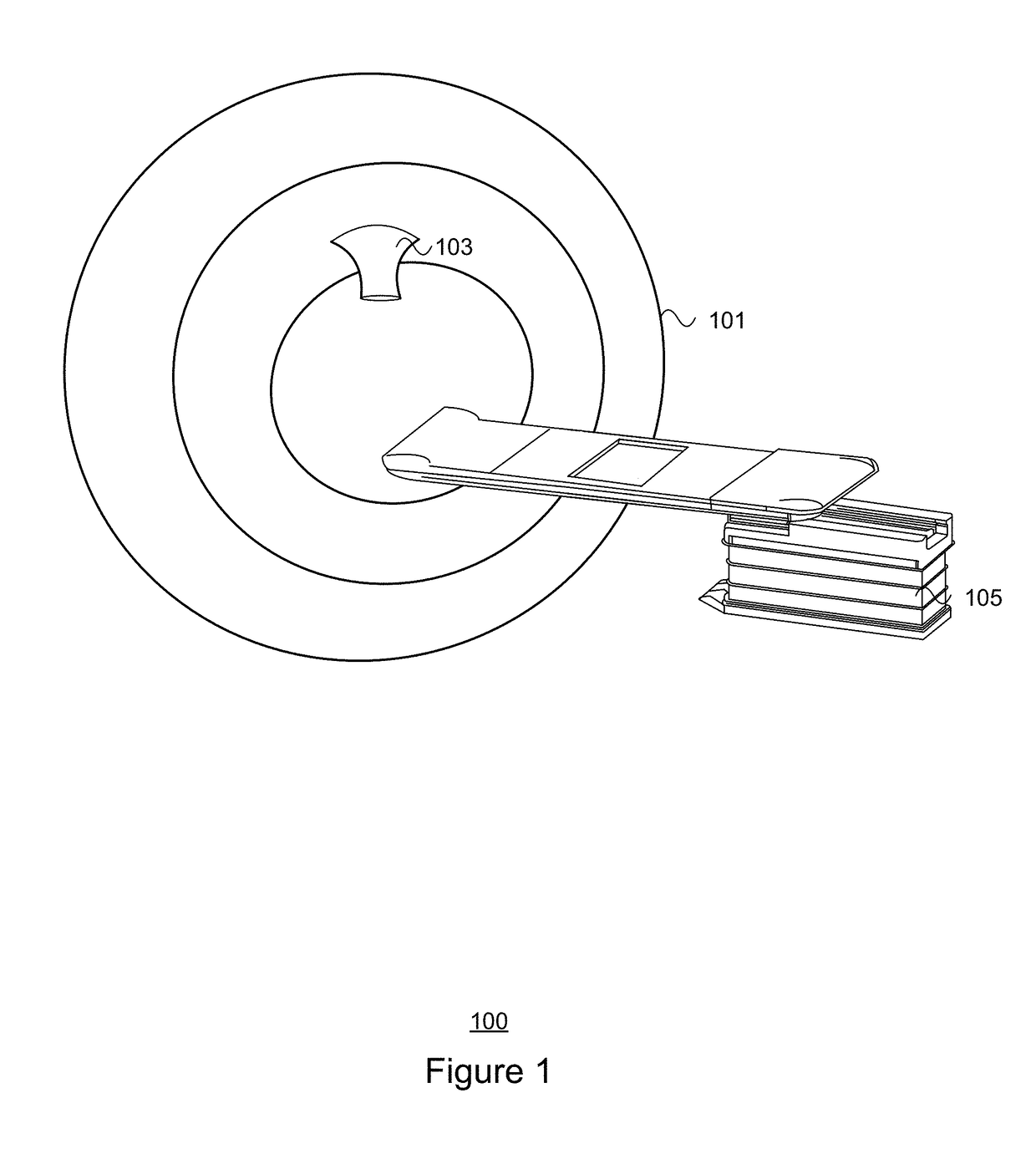

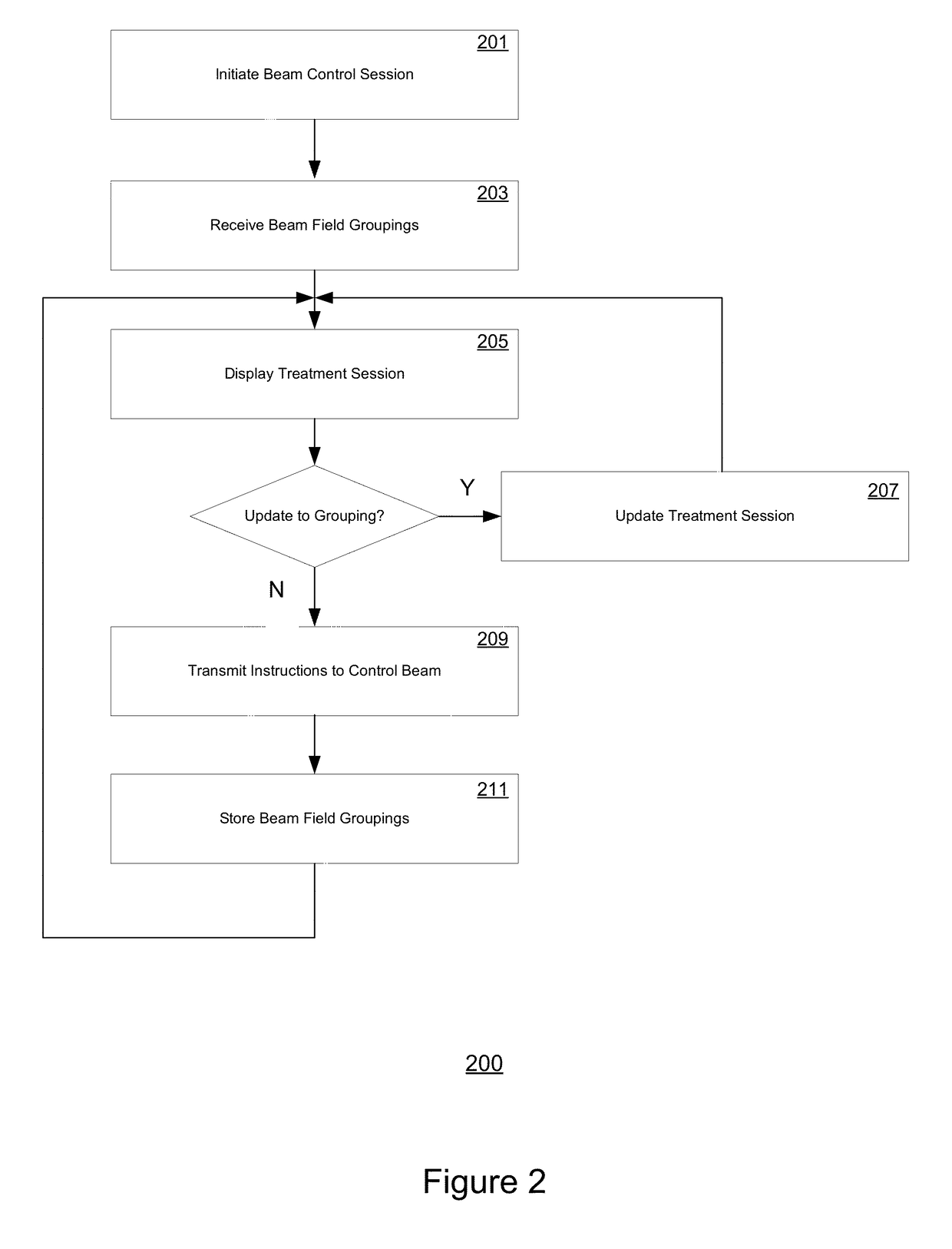

Method and device for efficiently irradiating a target from multiple irradiation angles in a particle therapy system

ActiveUS9764163B2Overcome difficultiesReduce needX-ray/gamma-ray/particle-irradiation therapyGraphicsControl system

Owner:VARIAN MEDICAL SYSTEMS +1

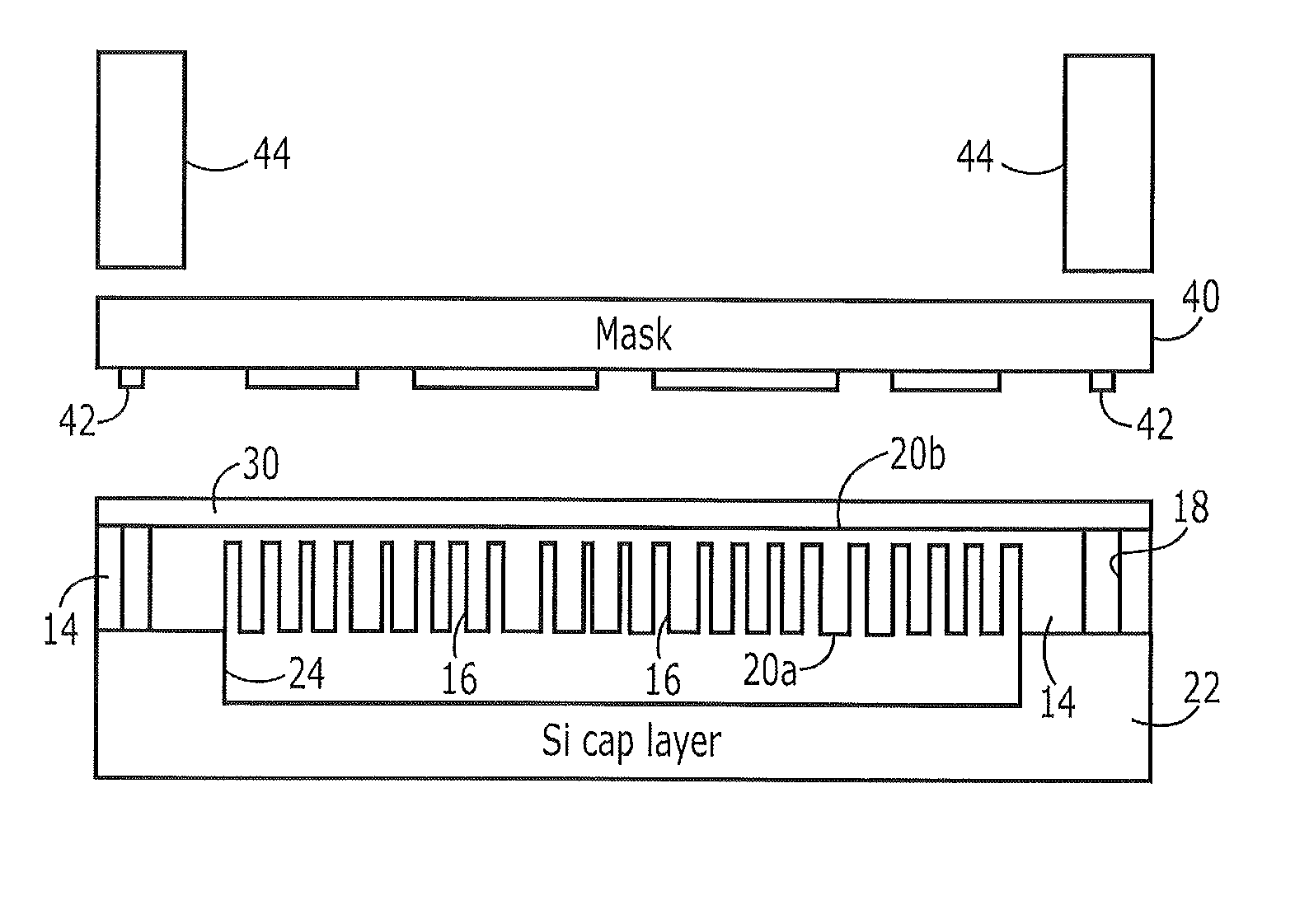

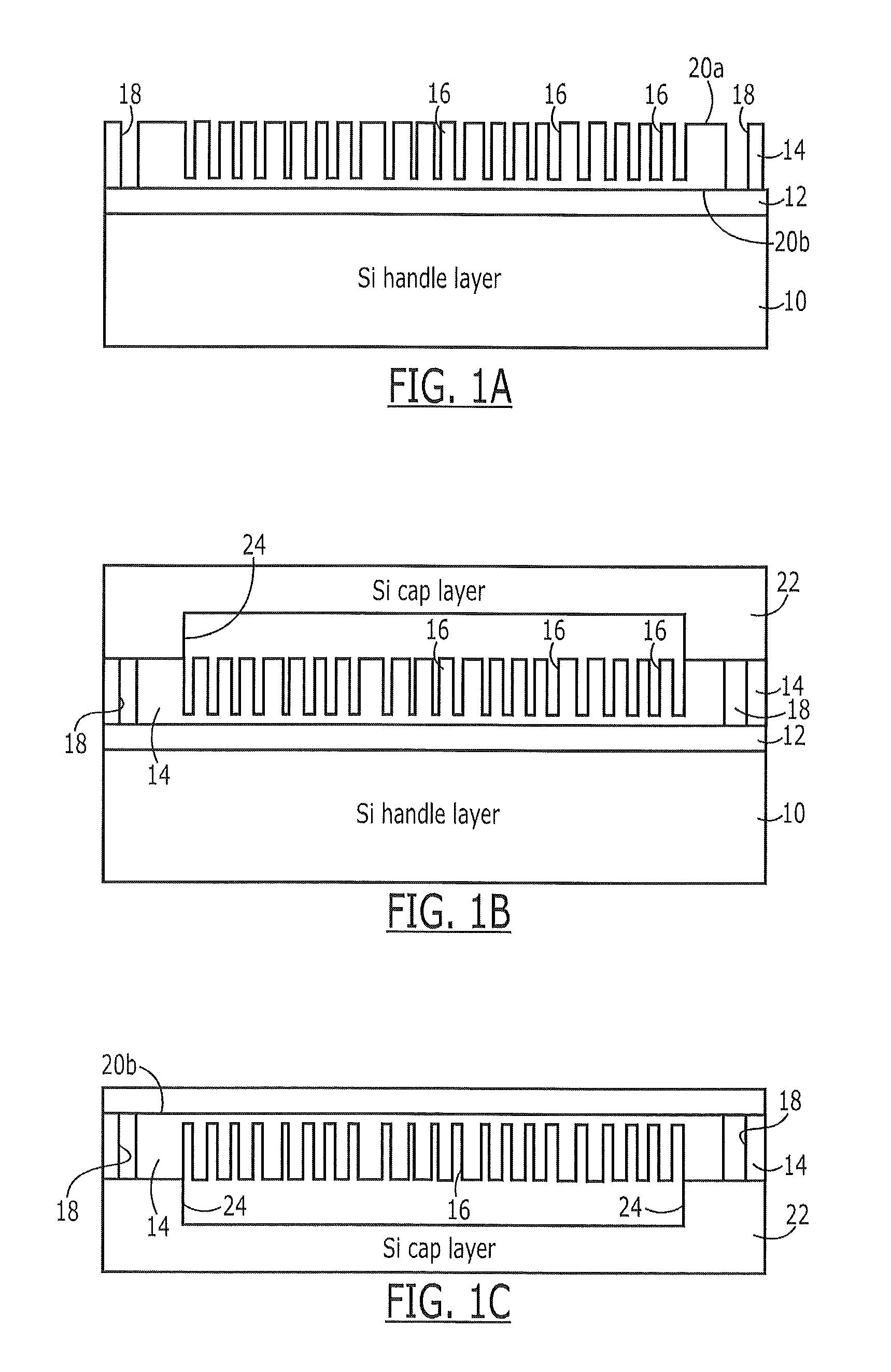

Methods of forming microdevice substrates using double-sided alignment techniques

ActiveUS8283256B1Sufficient durationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringPhotolithography

Methods of forming substrates having two-sided microstructures therein include selectively etching a first surface of the substrate to define a plurality of alignment keys therein that extend through the substrate to a second surface thereof. A direct photolithographic alignment step is then performed on a second surface of the substrate by aligning a photolithography mask to the plurality of alignment keys at the second surface. This direct alignment step is performed during steps to photolithographically define patterns in the second surface.

Owner:INTEGRATED DEVICE TECH INC

Phase current measurements in a three phase inverter using a single common DC-link current sensor

ActiveUS8134327B2Sufficient durationElectronic commutation motor controlMotor/generator/converter stoppersPhase currentsCurrent sensor

Owner:STMICROELECTRONICS SRL

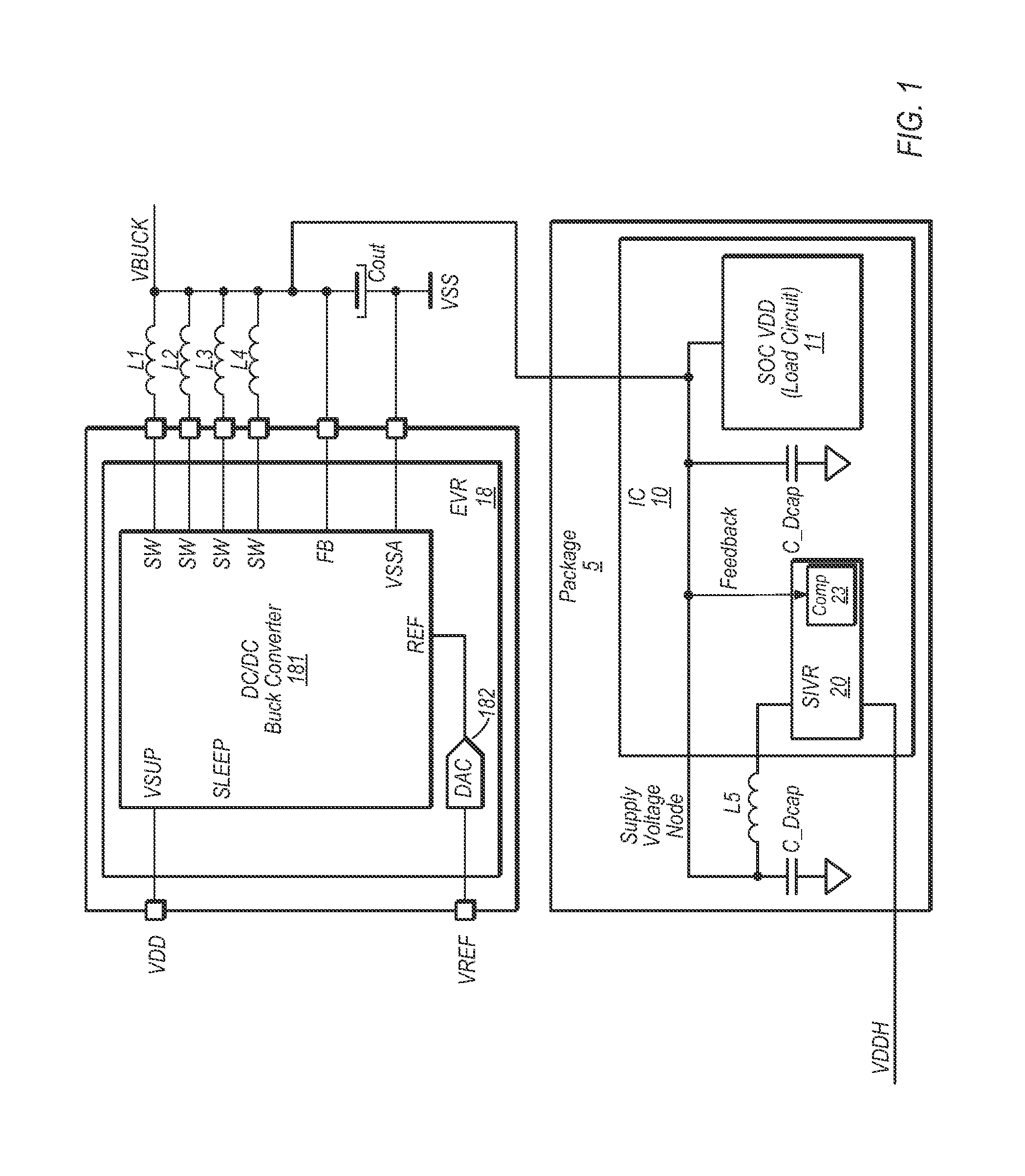

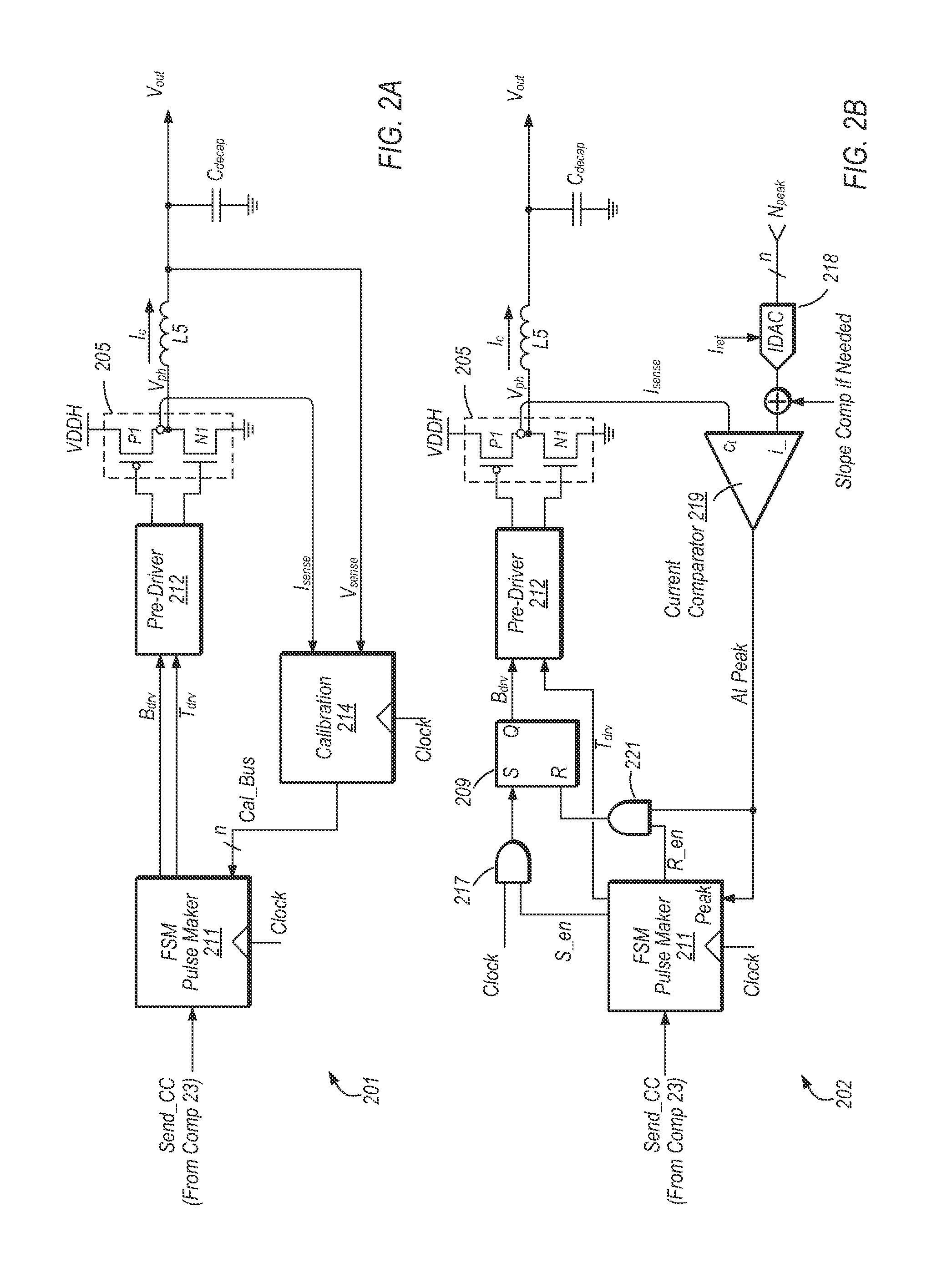

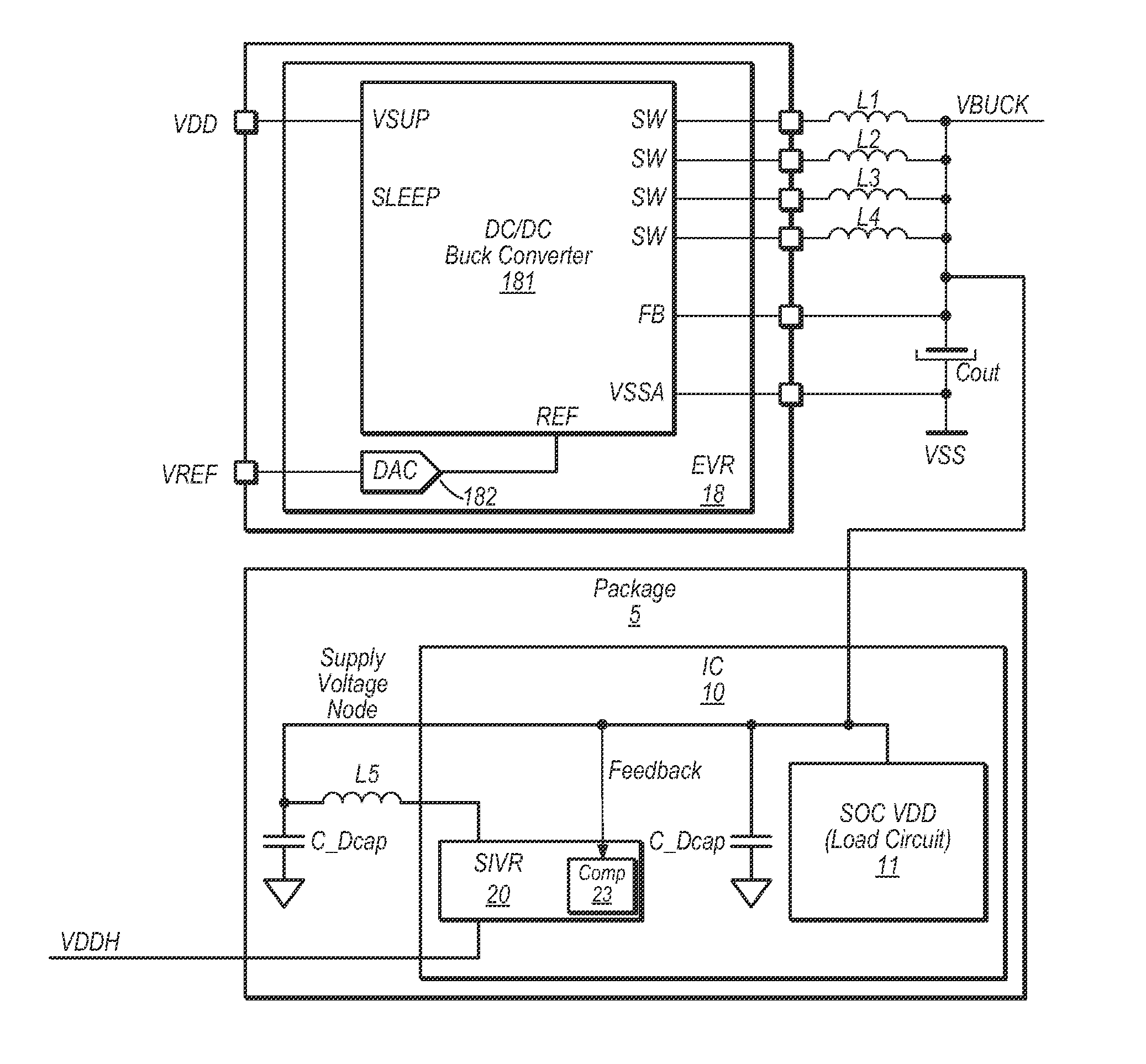

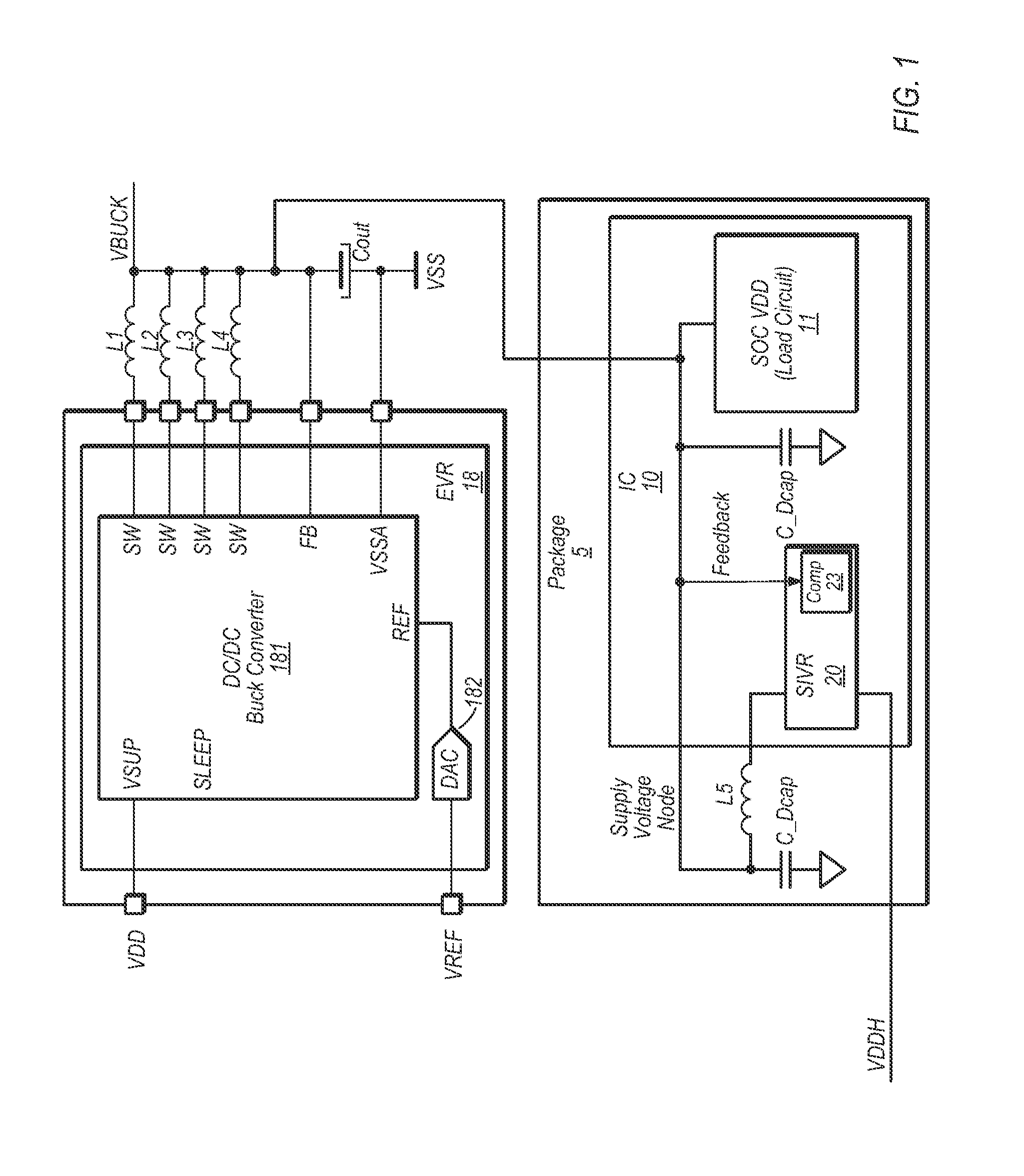

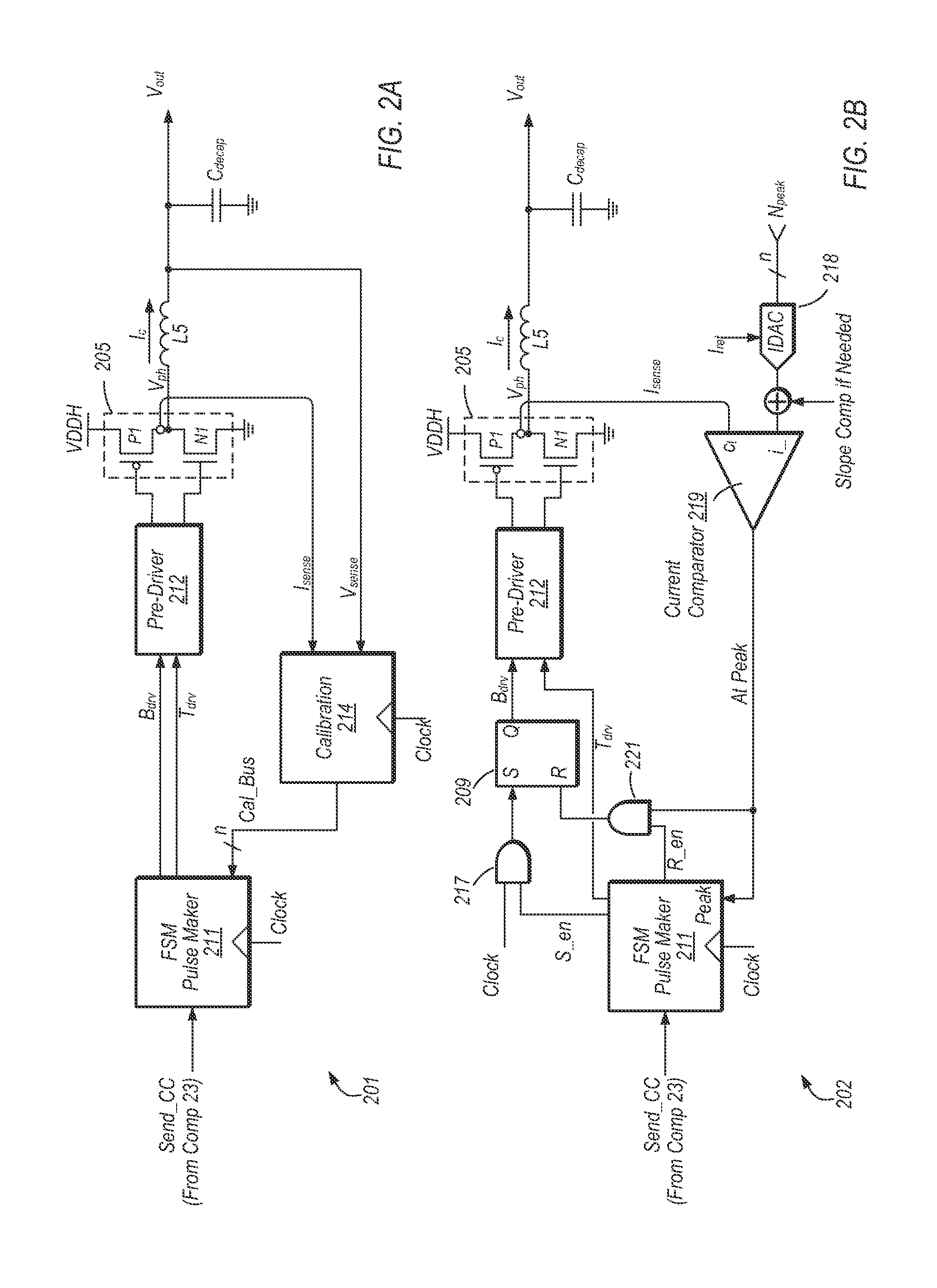

Shunt Integrated Voltage Regulator

ActiveUS20150222182A1Minimize magnitude and durationMinimize magnitudeEfficient power electronics conversionDc-dc conversionVoltage regulationIntegrated circuit

A method and apparatus for augmenting an external voltage regulator with a shunt integrated voltage regulator is disclosed. In one embodiment, an integrated circuit (IC) includes a load circuit coupled to a supply voltage node. The supply voltage node is electrically coupled to receive a supply voltage from an external voltage regulator. The IC also includes a shunt integrated voltage regulator coupled to the supply voltage node and implemented on the same IC die as the load circuit. If the supply voltage falls below a specified value (e.g., to increased current demand), the integrated voltage regulator may begin supplying current to the load. This may cause the supply voltage to return to within its specified range of the specified value, while allowing the external voltage regulator sufficient time to respond to the increased current demand. Thus, voltage droops on the supply voltage node may be minimized.

Owner:APPLE INC

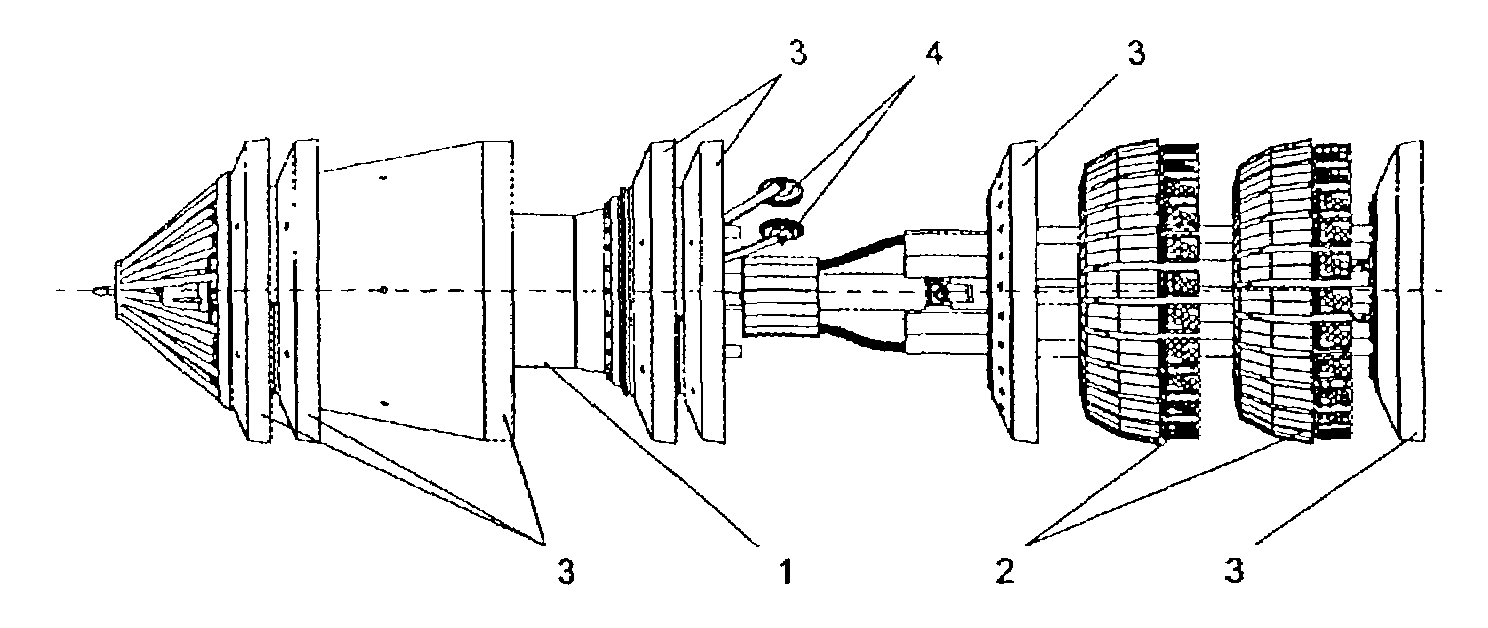

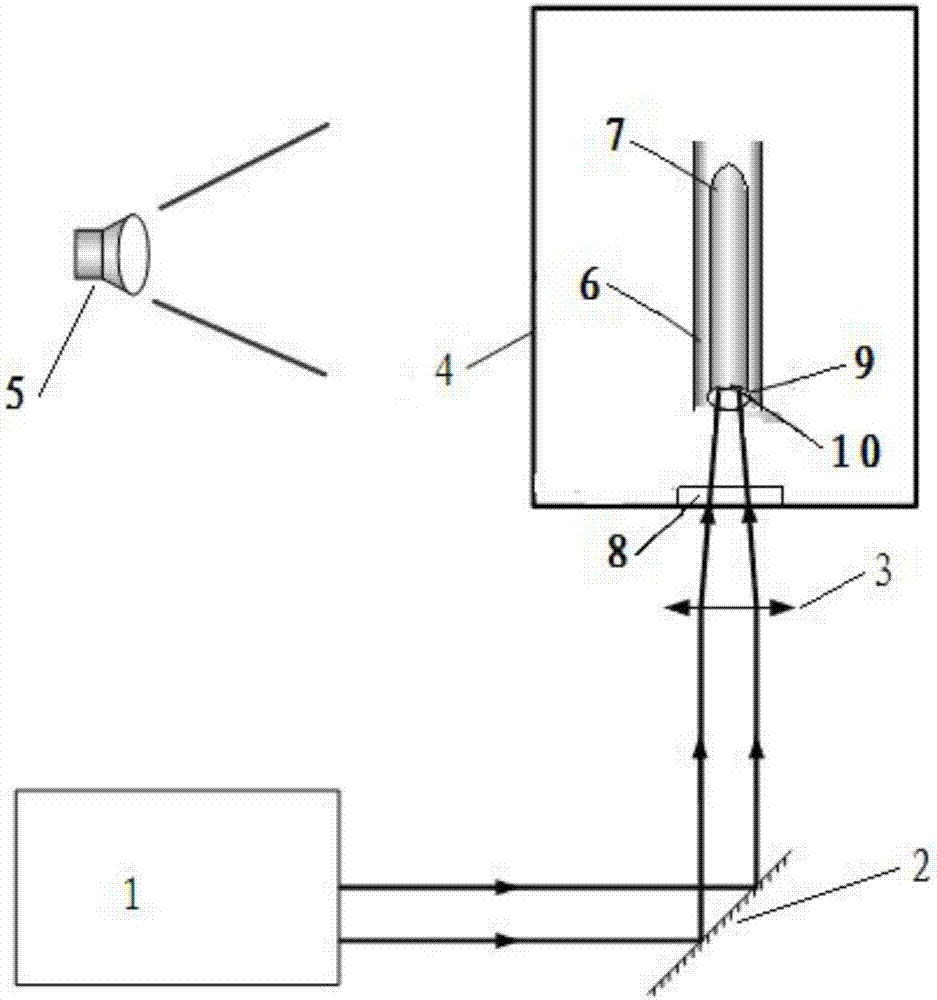

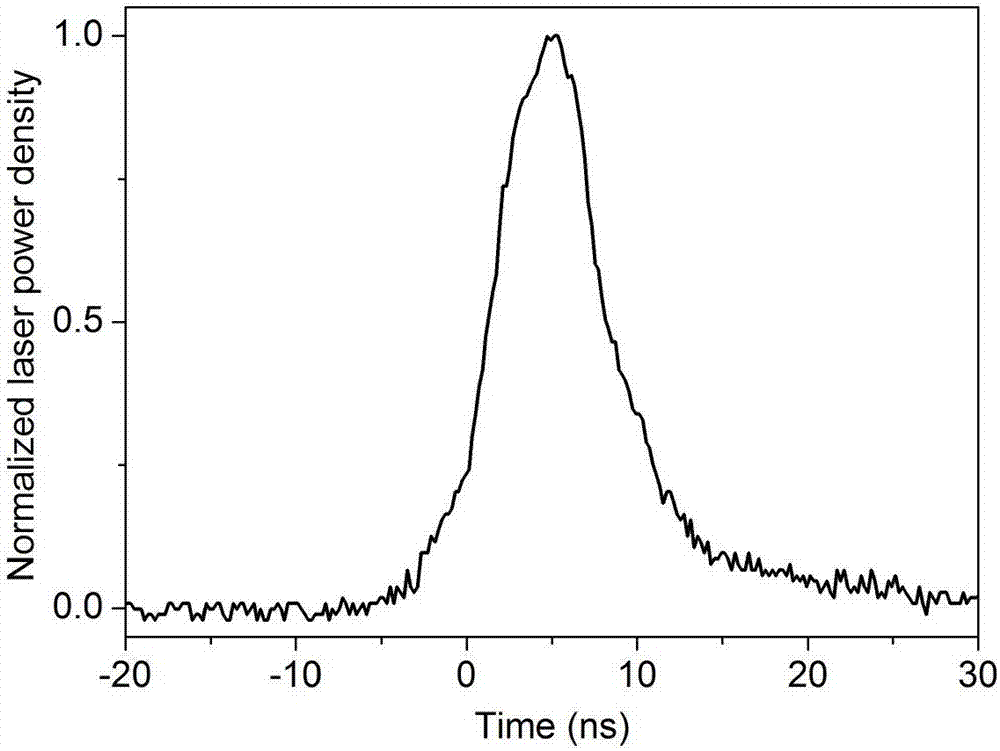

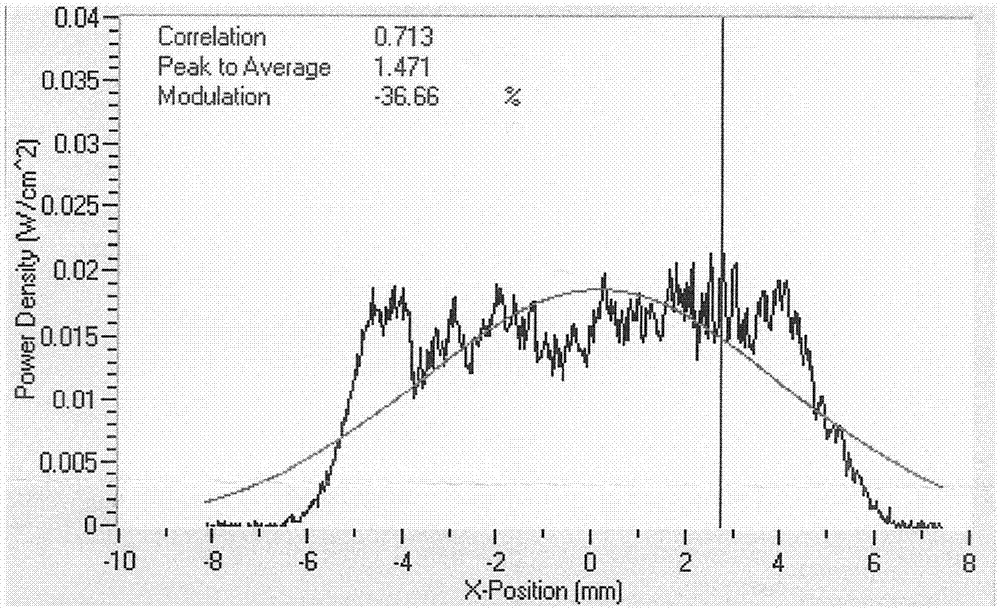

Laser underwater explosion emission propulsion method in tube

InactiveCN107221231AAchieve vertical launch out of the tubeMeet the energy requirements of the launch tubeEducational modelsUnderwater explosionDetonation

The present invention discloses a new method for emission and tube exit of navigation body through laser underwater explosion emission propulsion in a tube. High-energy laser is focused to the tail portion of a model to generate detonation wave and high-temperature and high-pressure product bubbles, and detonation wave propagation and bubble pulsation are performed to generate thrust in the emission tube constraint condition so as to realize tube exit of the navigation body through vertical emission. The laser underwater explosion energy is intensively effected on the motion of the navigation body so as to greatly reduce the energy dissipation, provide enough thrust effect and duration and reach the energy requirement of tube exit of the navigation body. Compared to a current chemical fuel emission propulsion method, the laser underwater explosion emission propulsion method in a tube can realize effective separation of the fuel, the propeller and the navigation body so as to effectively reduce the total weight of the navigation body and realize the effect of increasing the effective load.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

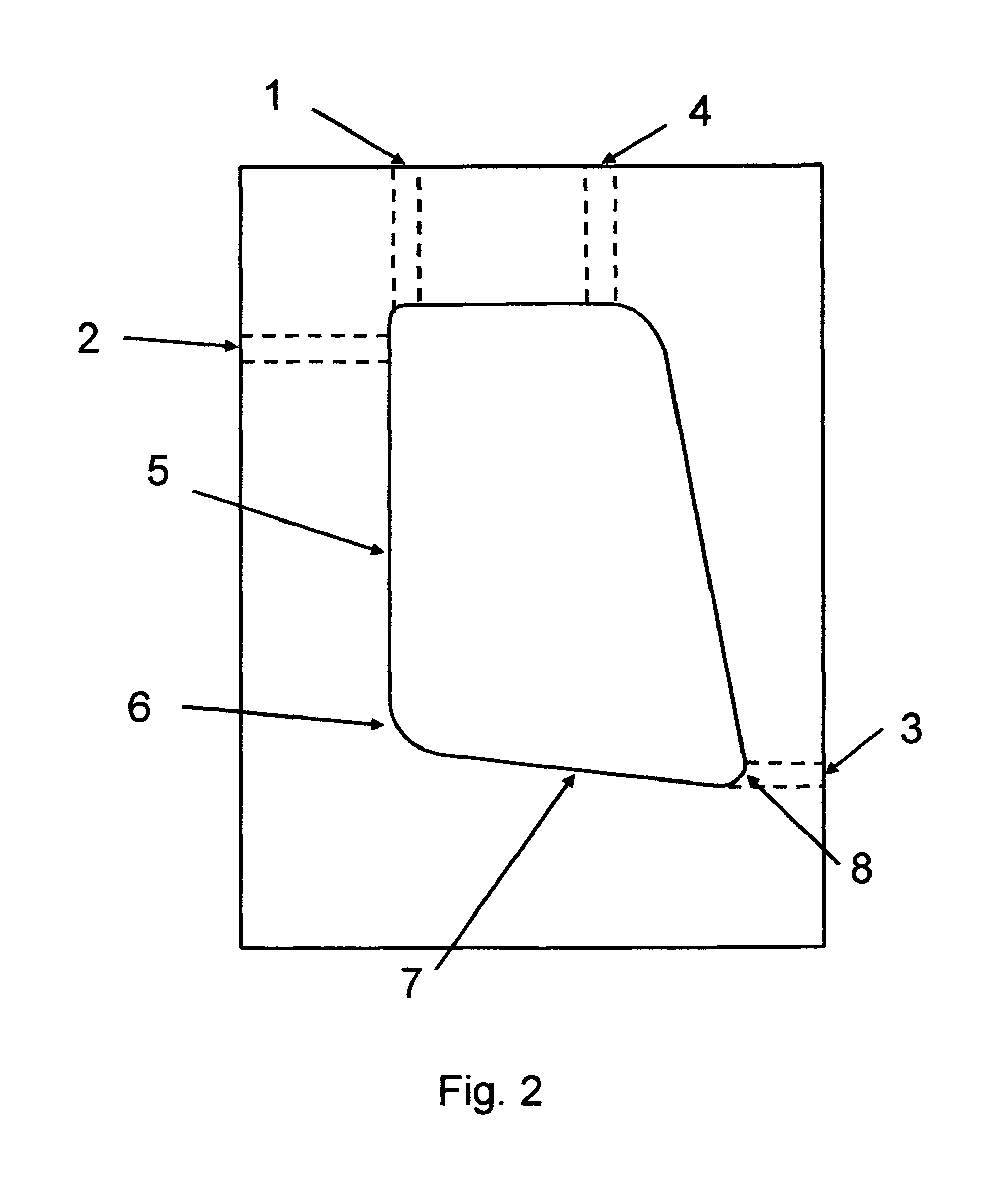

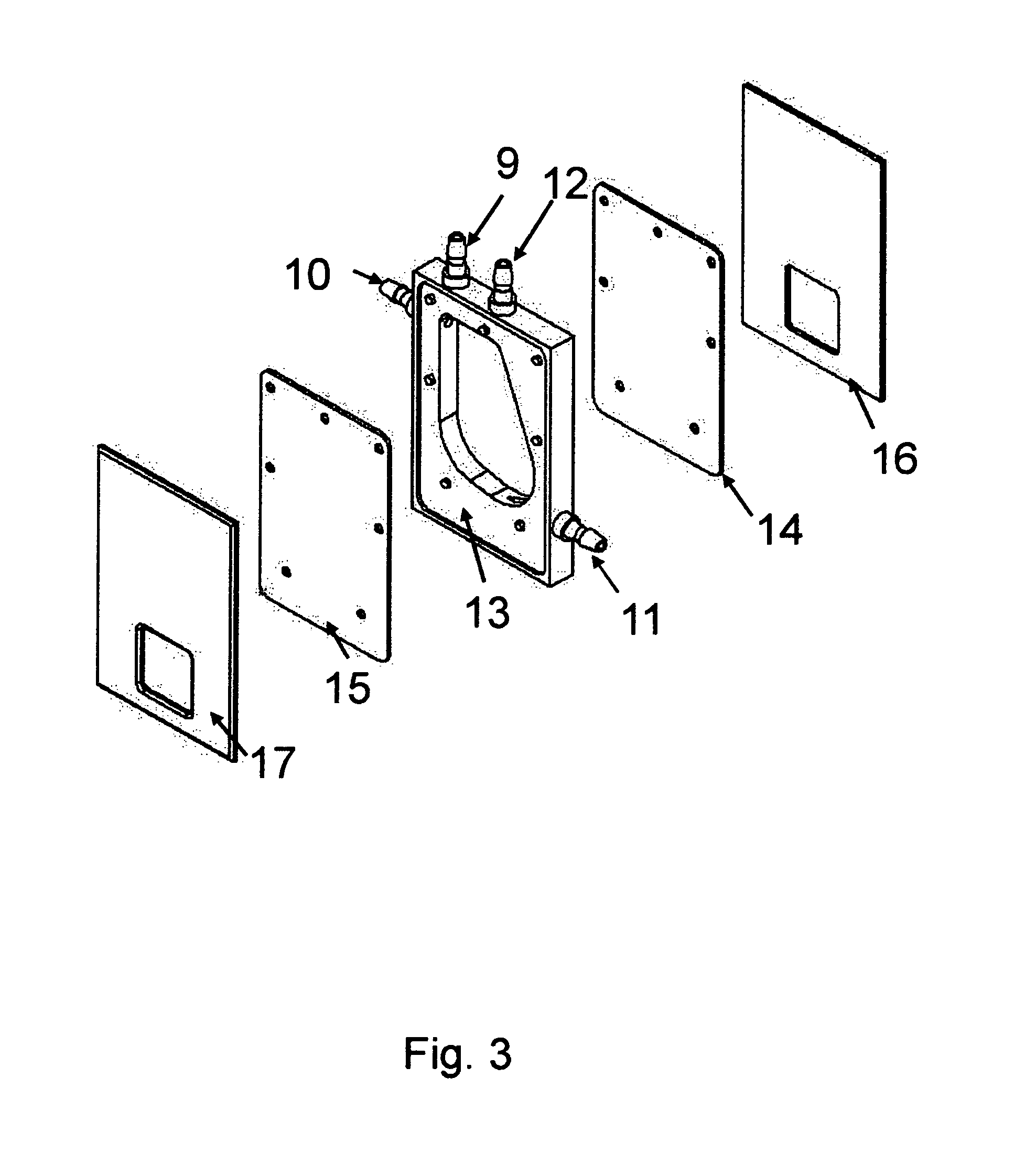

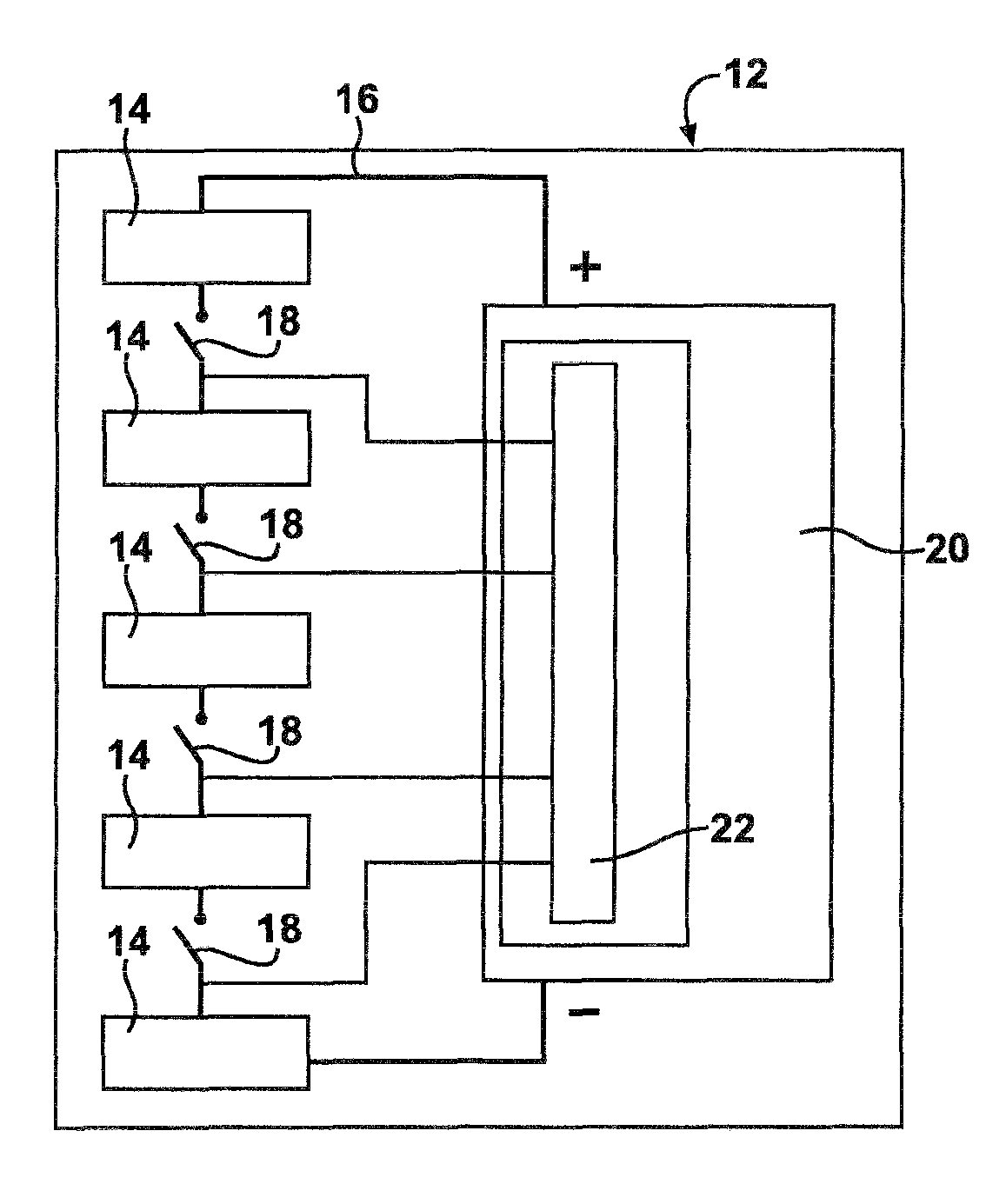

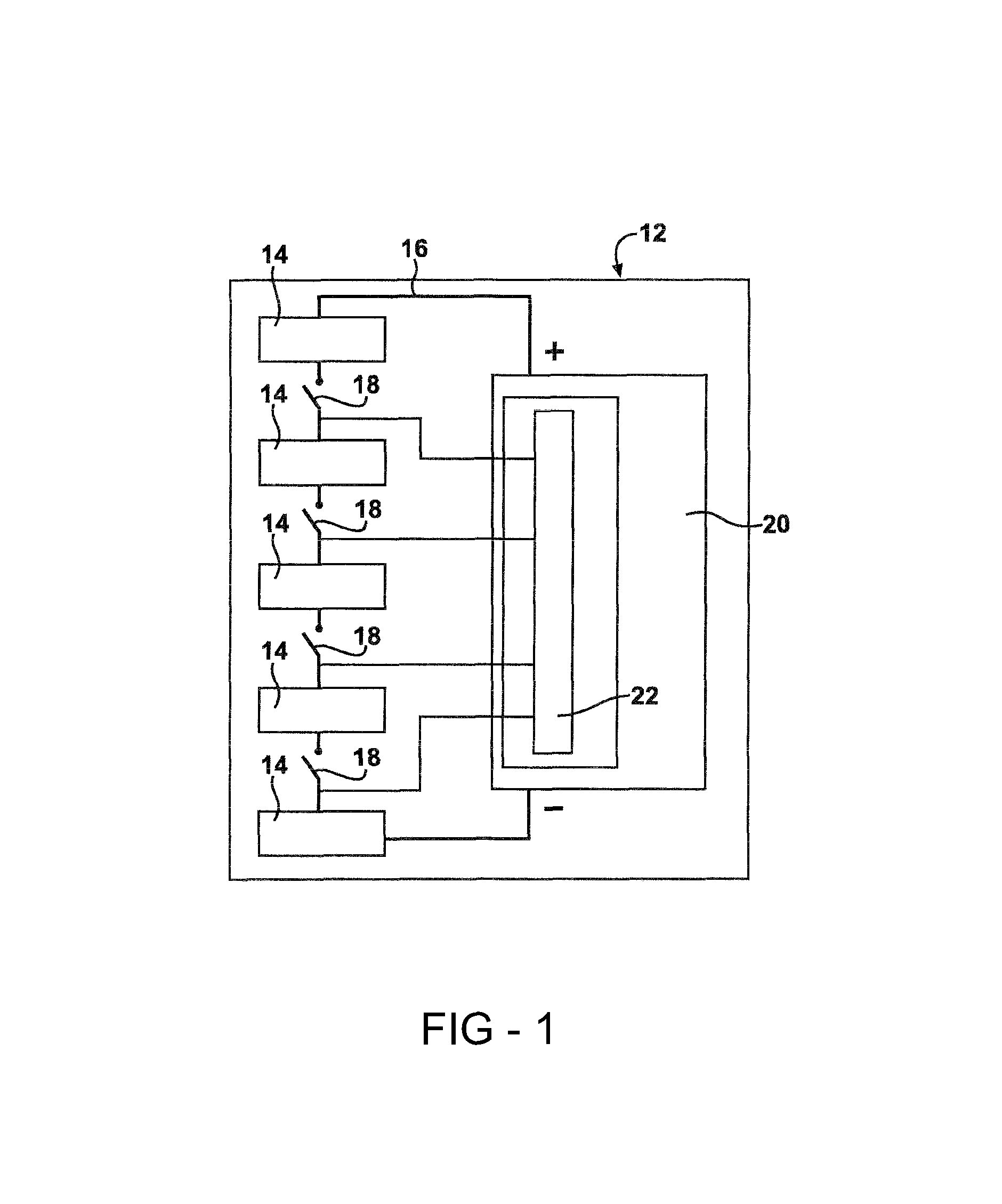

Dynamic mixing and electroporation chamber and system

ActiveUS20140220665A1Well mixedPrevent degradationBioreactor/fermenter combinationsBiological substance pretreatmentsWater basedElectroporation

The present invention relates to an apparatus for mixing cells and exogenous material for delivery of the exogenous material into cells using electroporation in a manner that preserves cell viability and integrity of the exogenous material. The exogenous material can be polynucleotides, peptides, proteins or other pharmaceutical molecules. It further provides a chamber that can be used to electroporate the contents of the chamber after mixing. In accordance with the invention, cell suspensions that may be contaminated with degrading enzymes are stored separately from water-based liquids that contain the exogenous material. Contact of the two water-based liquids (cell suspension and exogenous material) first occurs within the chamber. The chamber of the present invention has two or more inlet ports to allow separate entrance of water-based liquids. Two other ports are vent and exit ports. The inside of the chamber allows flow of all water-based liquids down the same side of the chamber and curved corners for redirecting flow direction and gently mixing water-based liquids. The chamber also includes electrodes as chamber walls for electroporation of chamber contents.

Owner:CELLECTIS SA

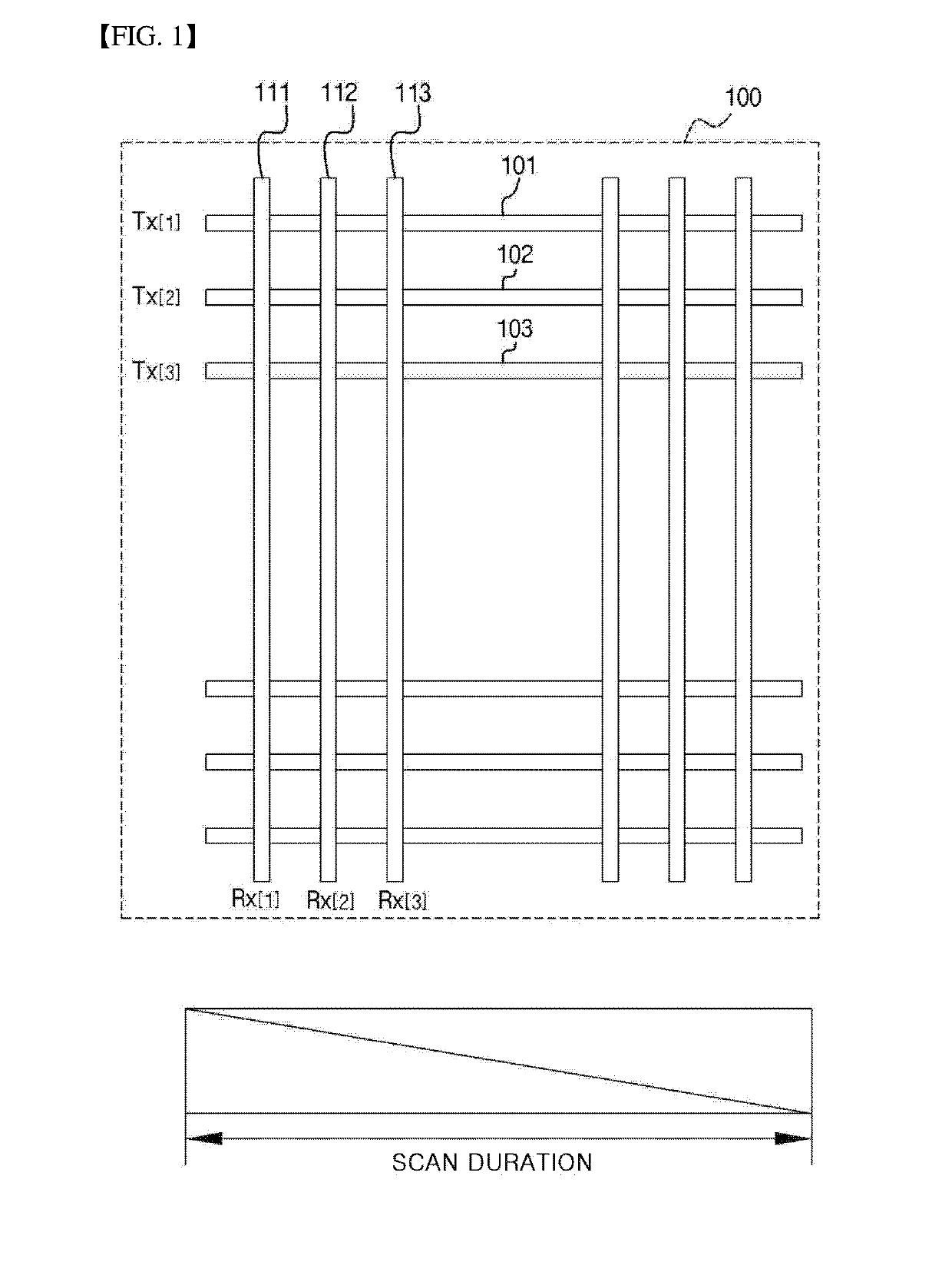

Method and device for operating capacitive touch panel

ActiveUS20190138148A1Shorten the construction periodSufficient durationInput/output processes for data processingEngineeringTouch panel

In the touch panel device and the operating method for the same according to the present invention, an entire scan is divided into a first scan and a second scan for determining a touch position. In the first scan, a plurality of transmission electrodes are configured into groups, and a signal is applied sequentially or simultaneously such that a first analysis position is determined. In the second scan, since a signal is sequentially or simultaneously applied only to the first analysis position, a plurality of sampling durations can sufficiently be provided such that a second analysis position, which is the exact touch position, can be determined.

Owner:MIRAENANOTECH

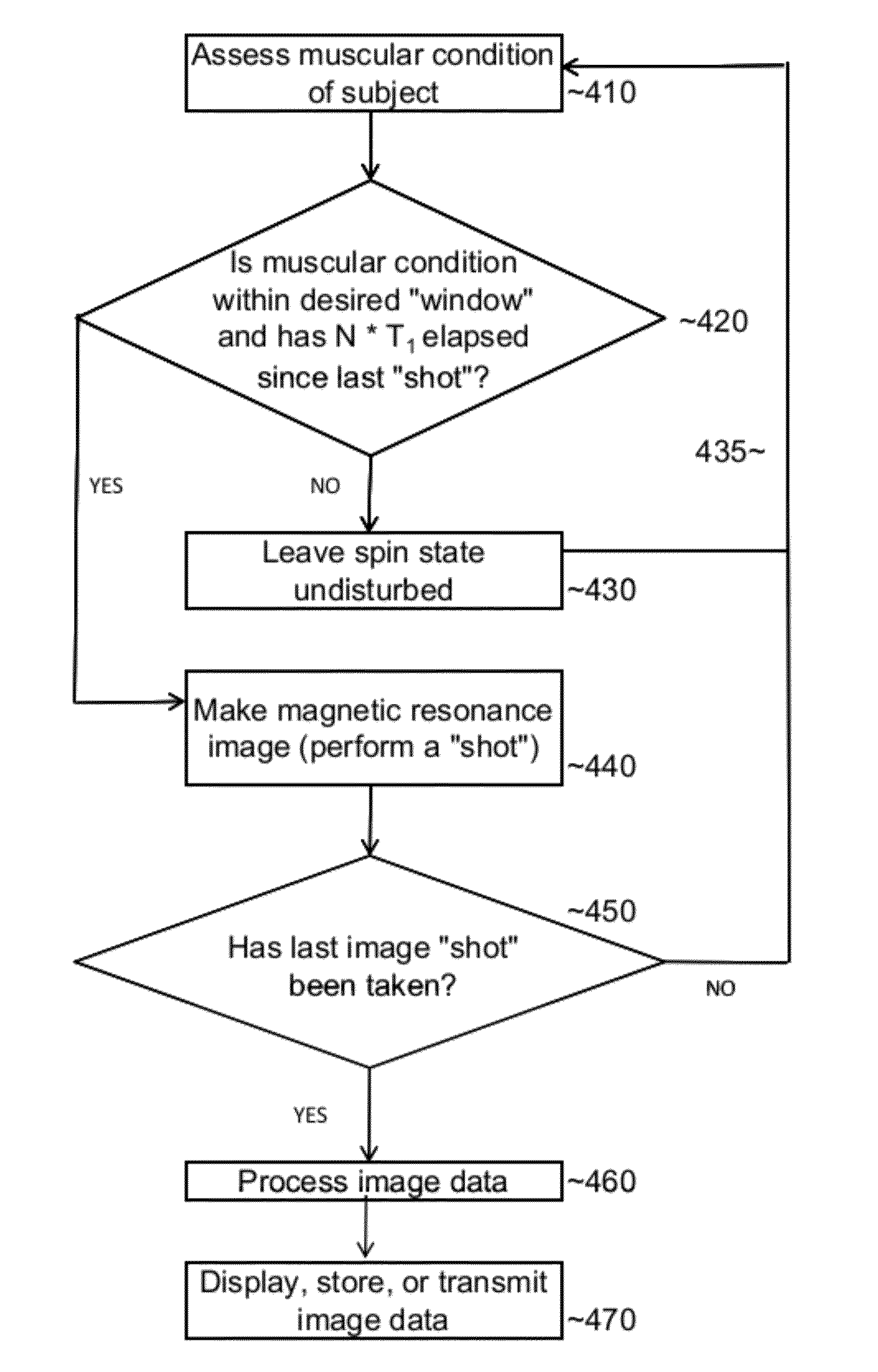

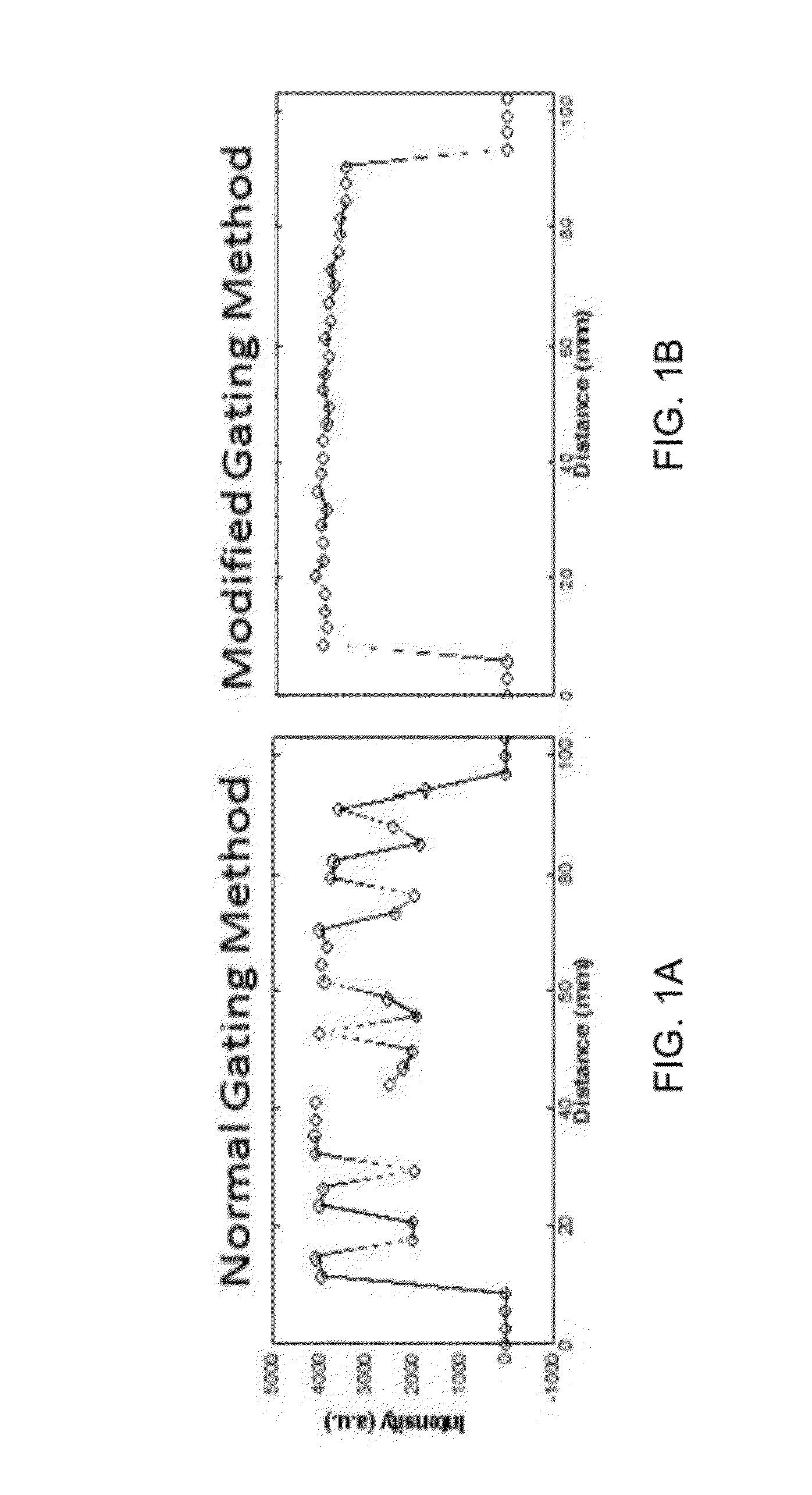

Relaxation-corrected ecg-triggering and navigator-gating technique

A system and method for recording magnetic resonance images with reduced relaxation-related artifacts. The system and method improve the conventional methods for acquiring magnetic resonance images of in vivo tissue by augmenting the procedures for eliminating artifacts caused by motion with procedures for eliminating artifacts caused by spin of the magnetic resonance-active nuclei in the specimen of interest. One procedure to eliminate such spin inhomogeneities is to require a delay defined by the time N*T1, where N is a numerical value greater than or equal to 5 and T1 is the characteristic time constant for decay of spins back to the equilibrium longitudinal state. Another procedure uses a value of N less than 5.

Owner:UNIV OF MASSACHUSETTS

Lithium titanate cell with reduced gassing

InactiveUS8168330B2Sufficient durationAvoid decompositionAlkali titanatesFinal product manufacturePhysical chemistryElectrolyte

Owner:ENERDEL

Shunt integrated voltage regulator

ActiveUS9397567B2Minimize magnitudeMinimize durationEfficient power electronics conversionDc-dc conversionShunt DeviceLoad circuit

A method and apparatus for augmenting an external voltage regulator with a shunt integrated voltage regulator is disclosed. In one embodiment, an integrated circuit (IC) includes a load circuit coupled to a supply voltage node. The supply voltage node is electrically coupled to receive a supply voltage from an external voltage regulator. The IC also includes a shunt integrated voltage regulator coupled to the supply voltage node and implemented on the same IC die as the load circuit. If the supply voltage falls below a specified value (e.g., to increased current demand), the integrated voltage regulator may begin supplying current to the load. This may cause the supply voltage to return to within its specified range of the specified value, while allowing the external voltage regulator sufficient time to respond to the increased current demand. Thus, voltage droops on the supply voltage node may be minimized.

Owner:APPLE INC

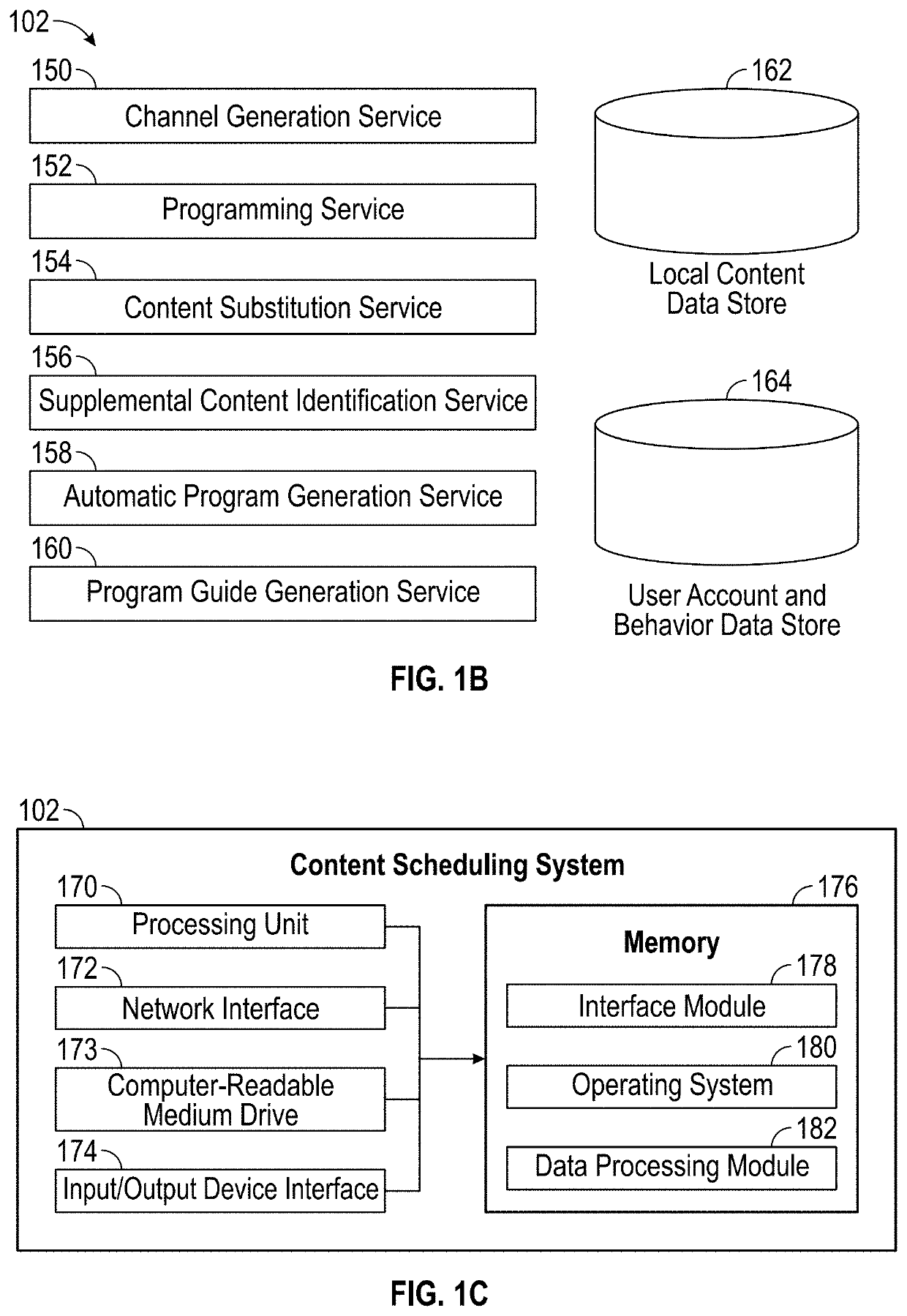

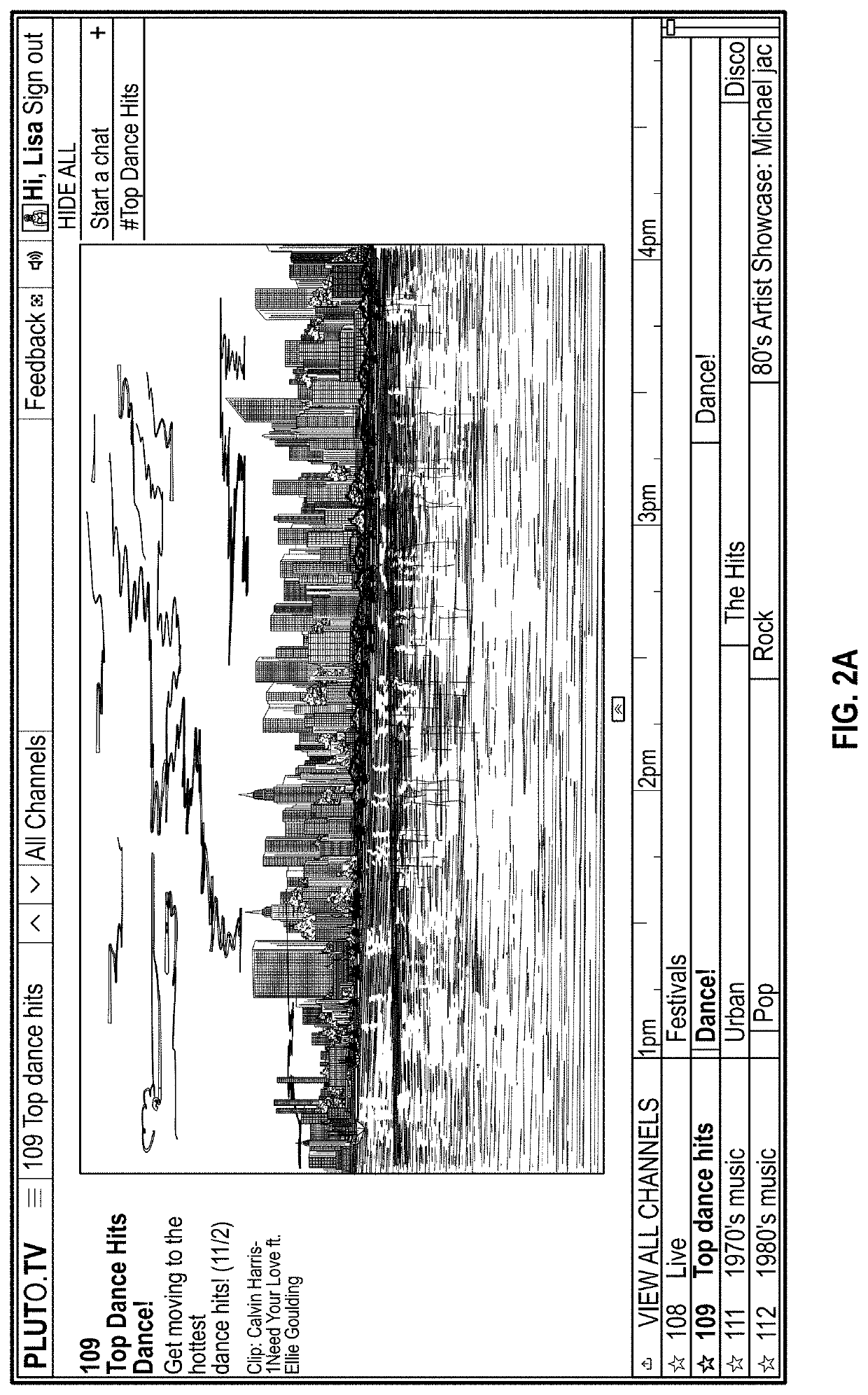

Methods and systems for generating and providing program guides and content

ActiveUS20220046302A1Enhancing prediction modelEasy to predictSelective content distributionStart timeTransmission channel

Systems and methods are configured to manage streaming video content. A first time length specification for a content pod is accessed. If a determination is made that a response to a request for ancillary content of a duration corresponding to the first time length of the content pod includes ancillary content of insufficient duration to populate the first time length of the content pod, the content pod time length is reduced. Ancillary content items associated with the response to the request are streamed to a user device as part of a streaming channel comprising primary content having scheduled start times. A primary content item, having a scheduled start time, is streamed to the user device after the items of ancillary content, and earlier than the scheduled start time of the item of primary content.

Owner:PLUTO

Efficient lipid delivery to human tear film using a salt-sensitive emulsion system

InactiveUS20130150324A1Sufficient amountEffective dosageBiocideSenses disorderLipid formationEmulsion

A salt-free emulsion for the treatment of dry eye and other ocular conditions is disclosed which contains castor oil and does not contain olive oil which prolongs TBUT and provides superior comfort.

Owner:ALLERGAN INC

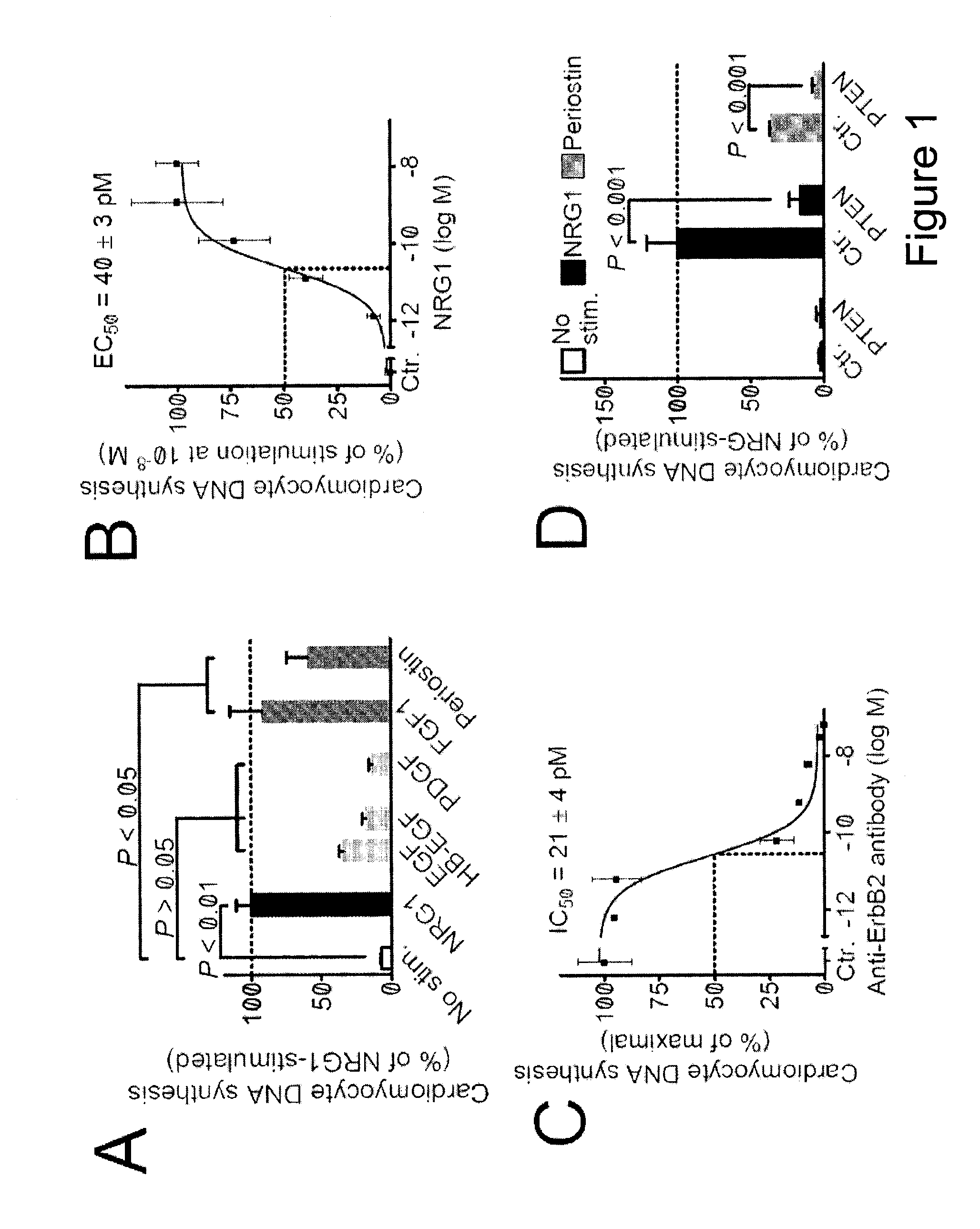

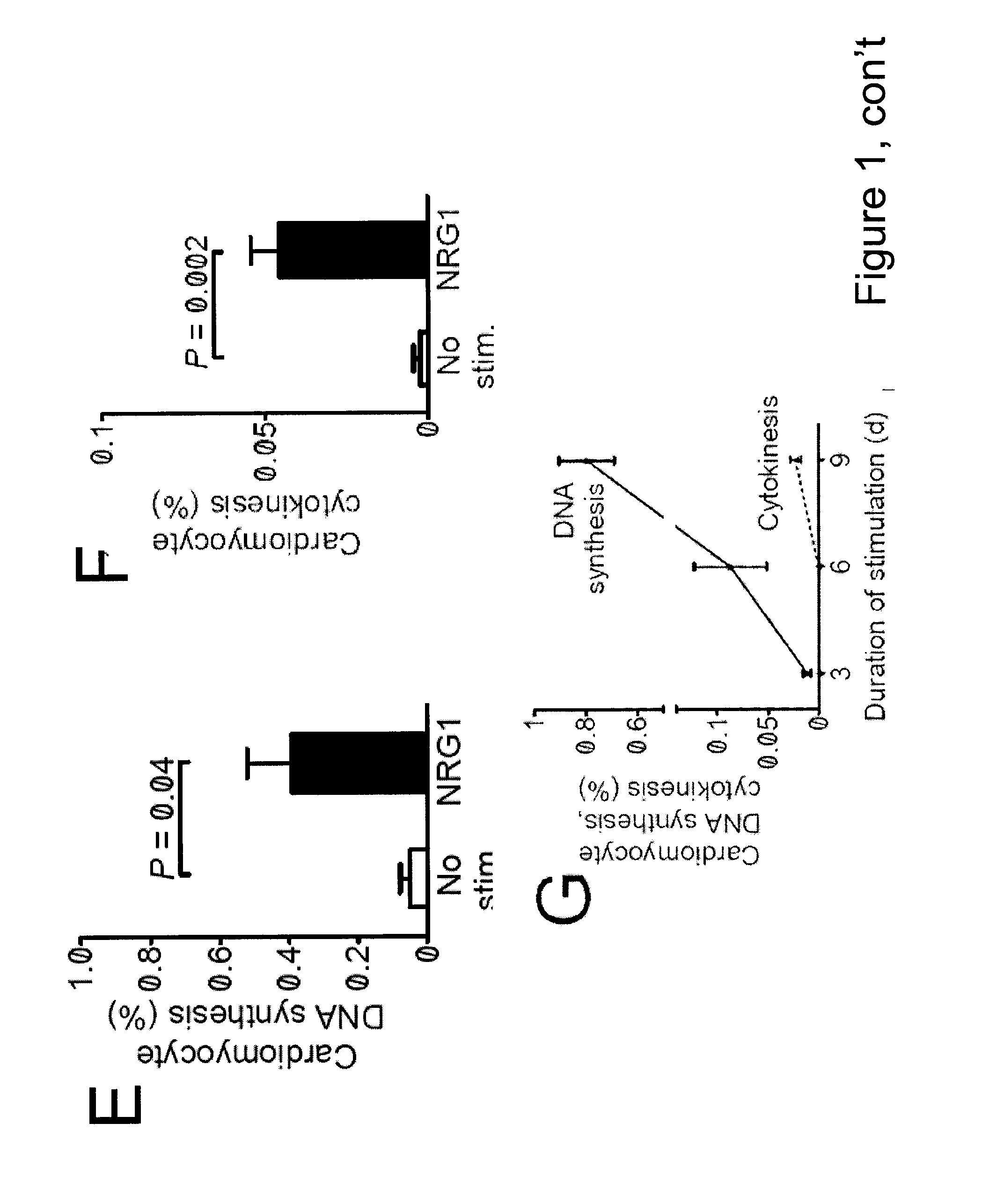

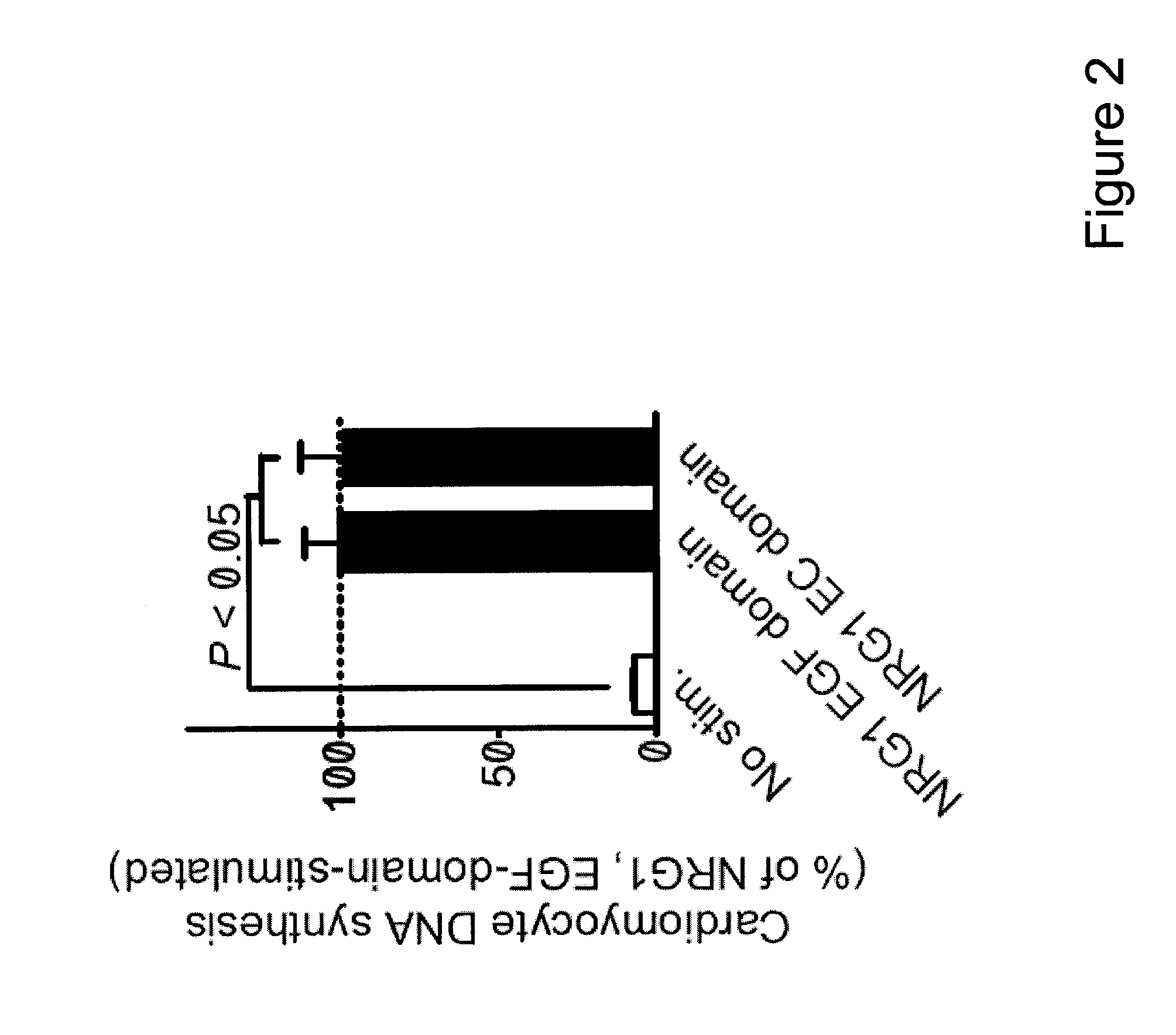

Neuregulin induced proliferation of cardiomyocytes

InactiveUS20120121557A1Slow and reduce and prevent and treat onsetIncreased proliferationBiocidePeptide/protein ingredientsNeuregulinChronic ischemic heart disease

The present invention provides methods for inducing division of postmitotic mammalian differentiated cardiomyocytes. The invention can be used to repair heart tissue damaged by, for example, myocardial ischemia, hypoxia, stroke, myocardial infarction or chronic ischemic heart disease in vivo. In addition, the methods of the invention can be used to induce heart muscle cells to divide in vitro, in vivo and / or ex vivo, which can then be used in heart tissue repair.

Owner:CHILDRENS MEDICAL CENT CORP

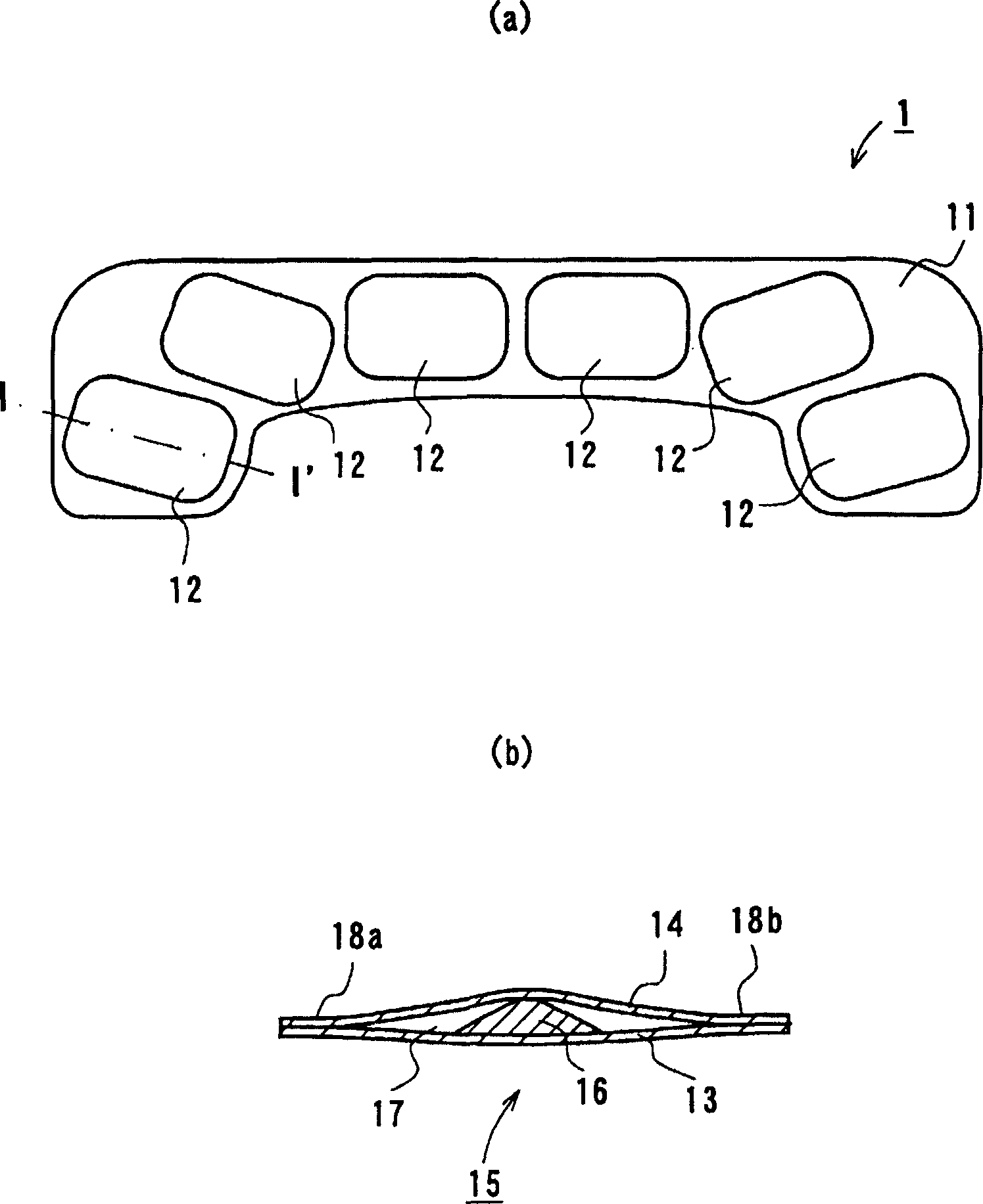

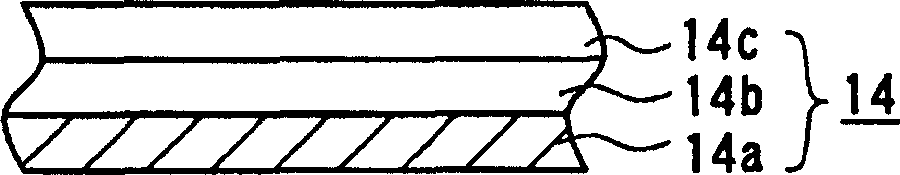

Thermotherapy device

ActiveCN1819807AFit closelyImprove conductivityTherapeutic coolingTherapeutic heatingBand shapeOxygen

To provide a band-like thermotherapy device capable of relieving the stiffness of shoulder and lumbago. The thermotherapy device (1) comprises a plurality of heating parts (12) on a flexible band-shaped body (11). The heating part (12) further comprises a bag-like storage part (15) formed between a base material sheet (13) and an oxygen permeable sheet (14) forming the flexible band-like body (11) and an oxidative heating type heating compound (16) filled in the storage part (15). The filling ratio R of the heating compound (16) in the storage part (15) meets the requirement of the following expression (1) and is less than 0.7, and the heating amount of the heating compound (16) in the storage part (15) is 0.26 kcal / cm<2> or more for each plan view area of the storage part. R <= -0.016S + 0.94 Expression (1) Where S is the plan view area of the heating compound storage part (unit:cm<2>), and R can be expressed by the following expression. R = (Mass of heating compound in storage part) / (Mass of heating compound chargeable in storage part.

Owner:KOBAYASHI PHARMA CO LTD

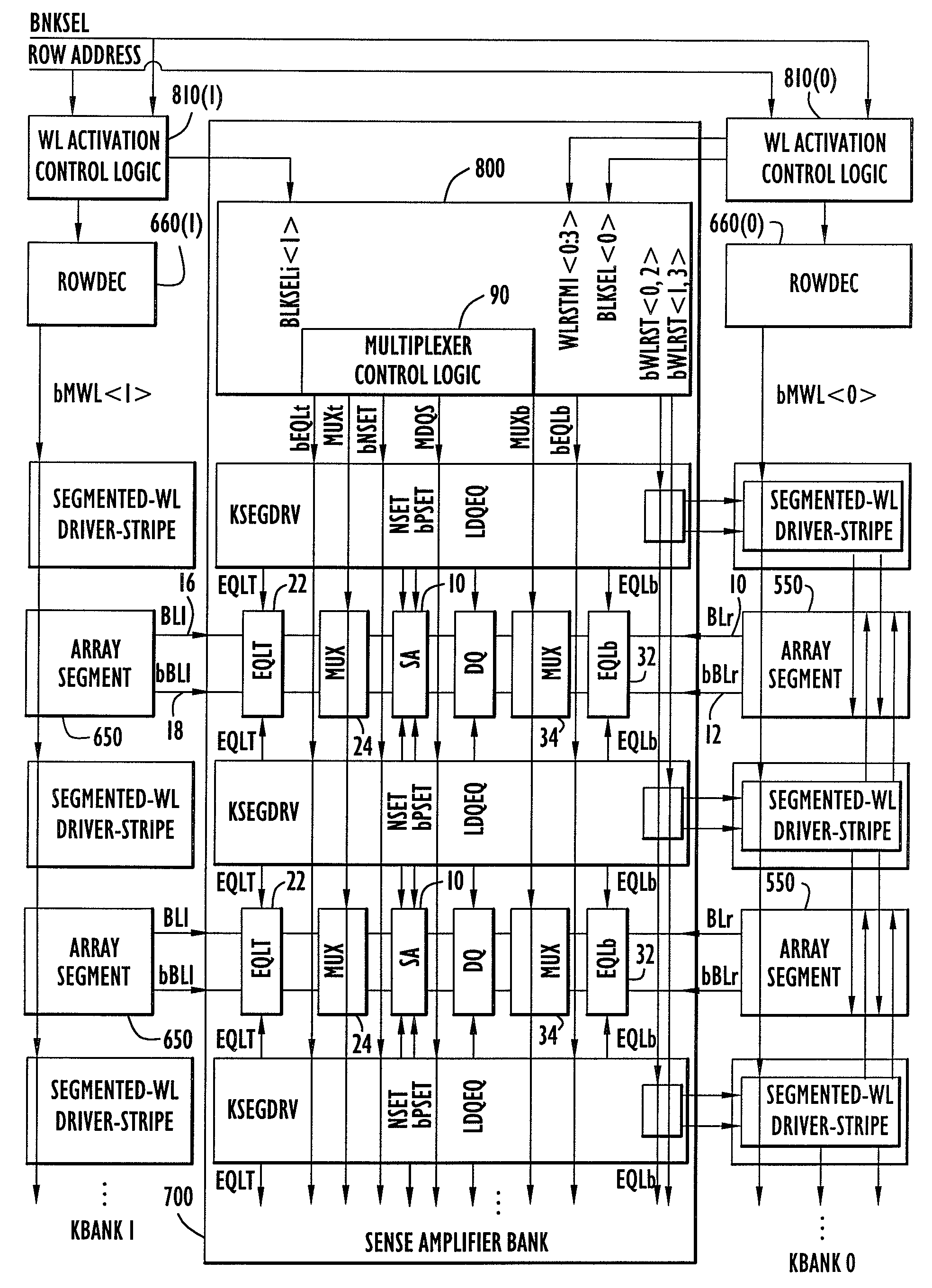

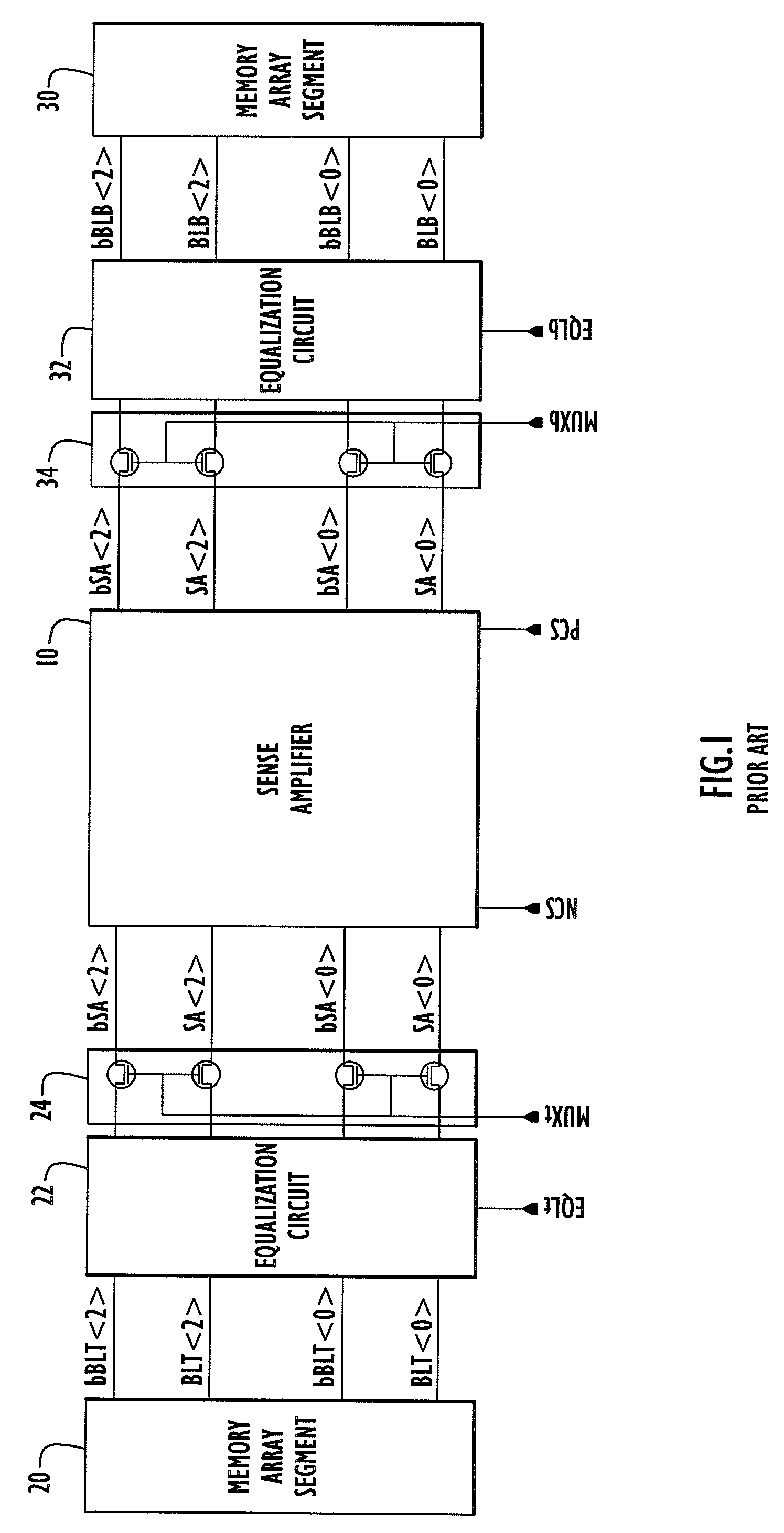

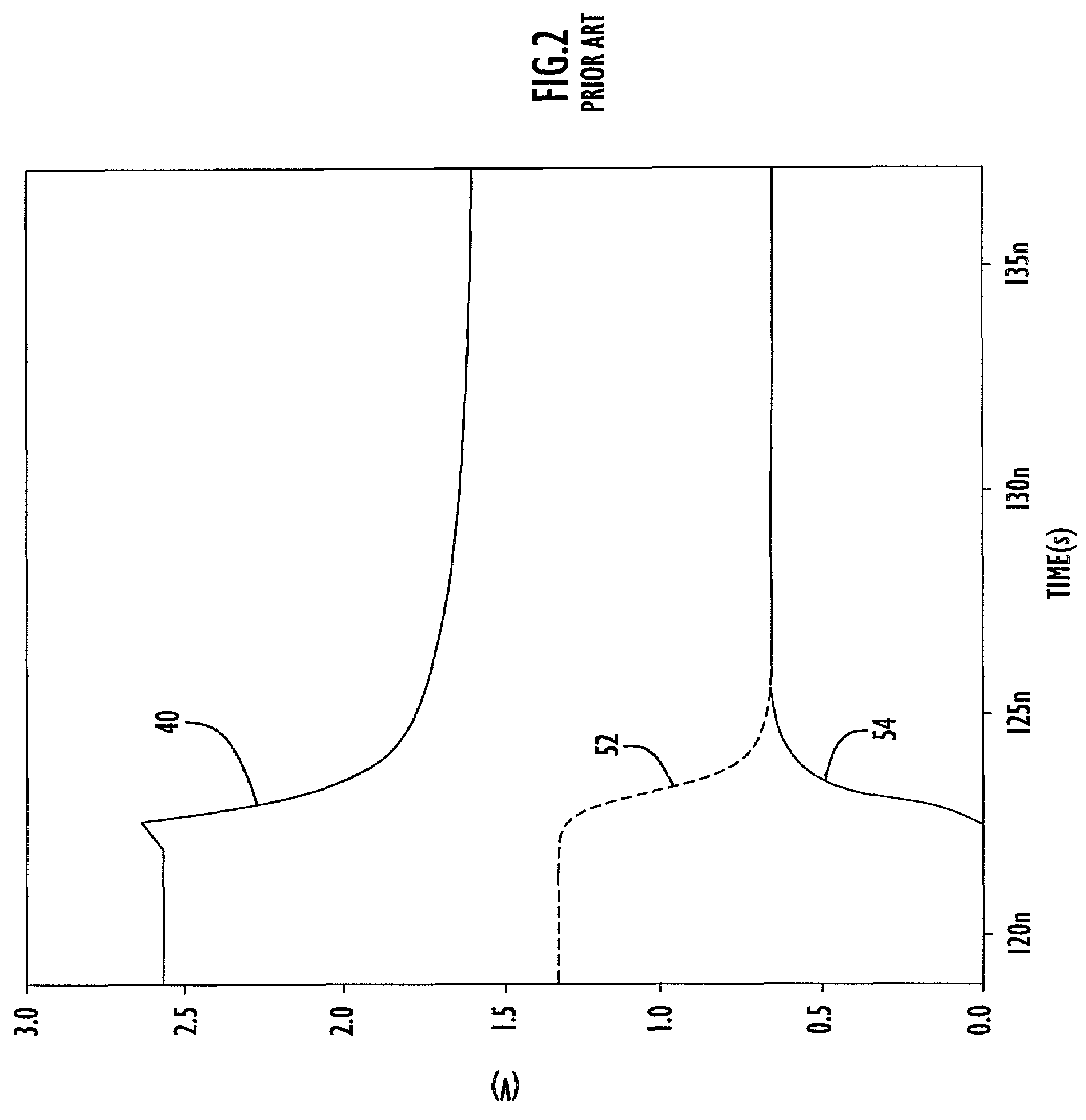

Delayed sense amplifier multiplexer isolation

InactiveUS7663955B2Evenly goodIsolation of the sense amplifier from the memory array segment is delayedDigital storageBit lineAudio power amplifier

Methods and circuit arrangements are provided for improving equalization of sense nodes of a sense amplifier in a semiconductor memory device. When a memory array segment on a side a sense amplifier has a bitline leakage anomaly for which the sense amplifier is to be isolated when that memory is in an unselected state, isolation of the sense amplifier from the memory array segment is delayed when transitioning from a selected state of the memory array segment to an unselected state of the memory array segment. The duration of the delay is sufficient to allow time for equalization of the sense nodes of the sense amplifier before isolating the sense amplifier from the memory array segment.

Owner:POLARIS INNOVATIONS LTD

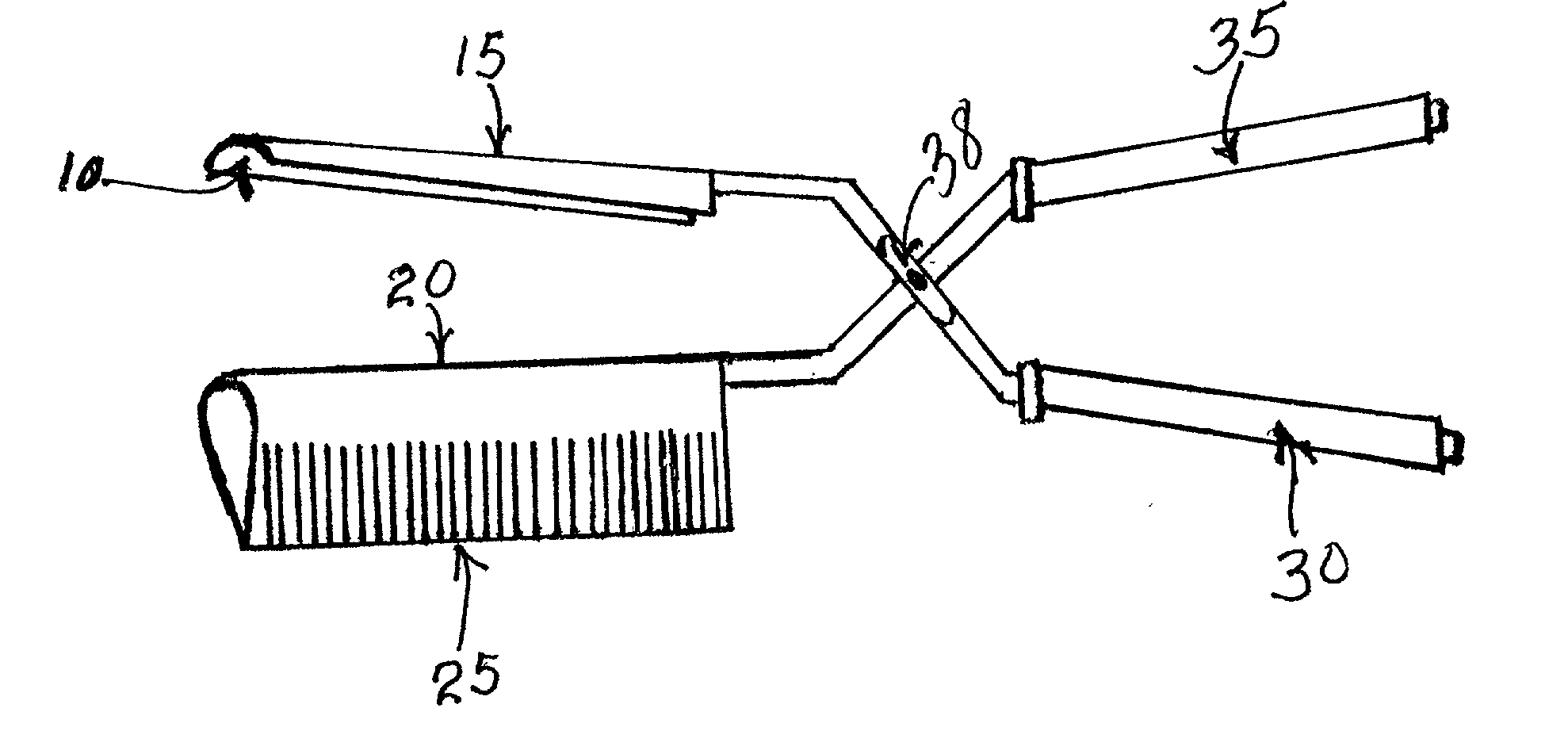

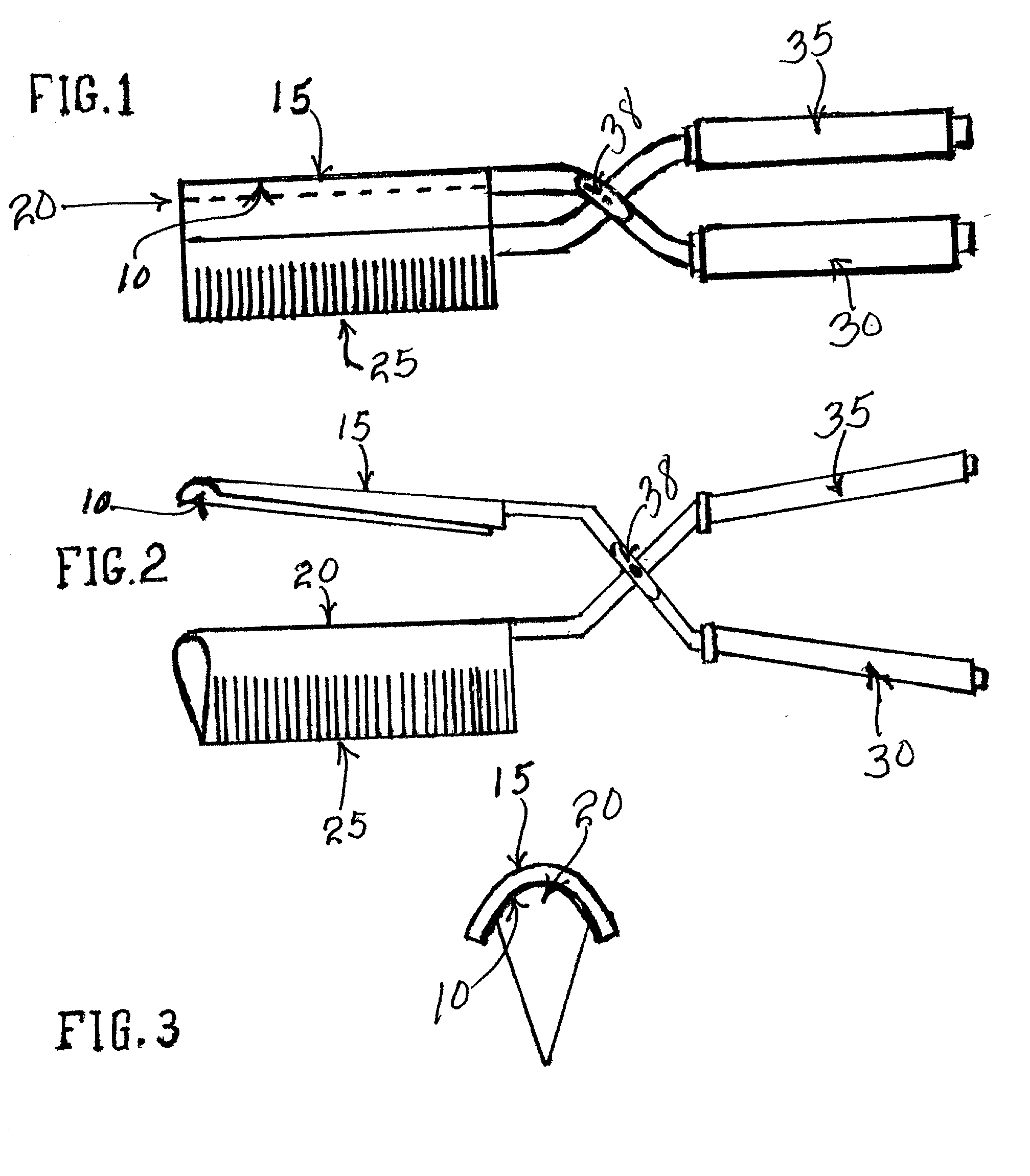

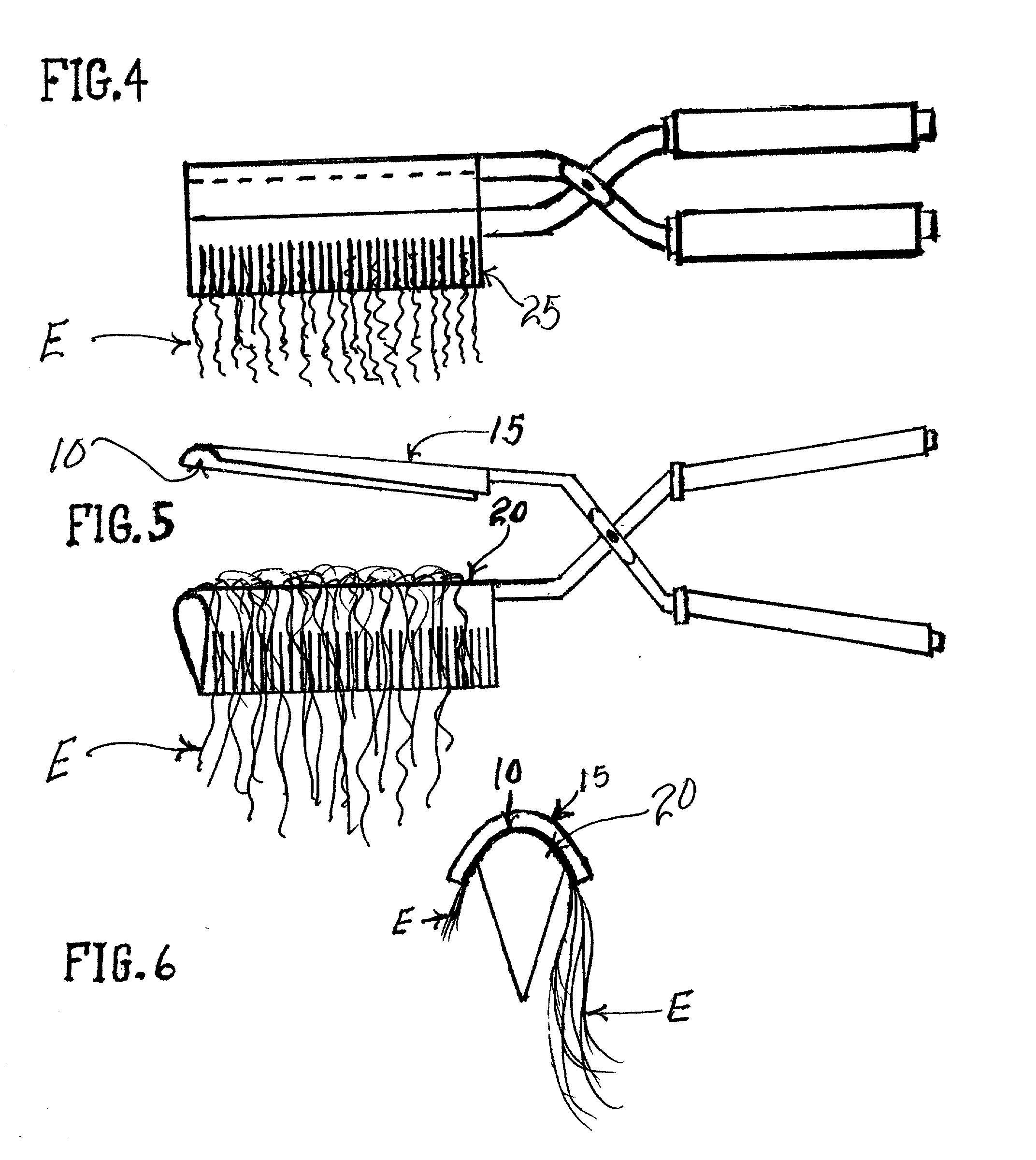

Thermal smoother and comb

Disclosed is an article to enable a cosmetologist to thermally comb wave pattern from the hairshaft. Including is a comb shelf portion to place hair upon to further smooth the outer surface of the hairshaft, with the smoothing shell and having dual handles to manipulate movement.

Owner:COOK CHARLES J

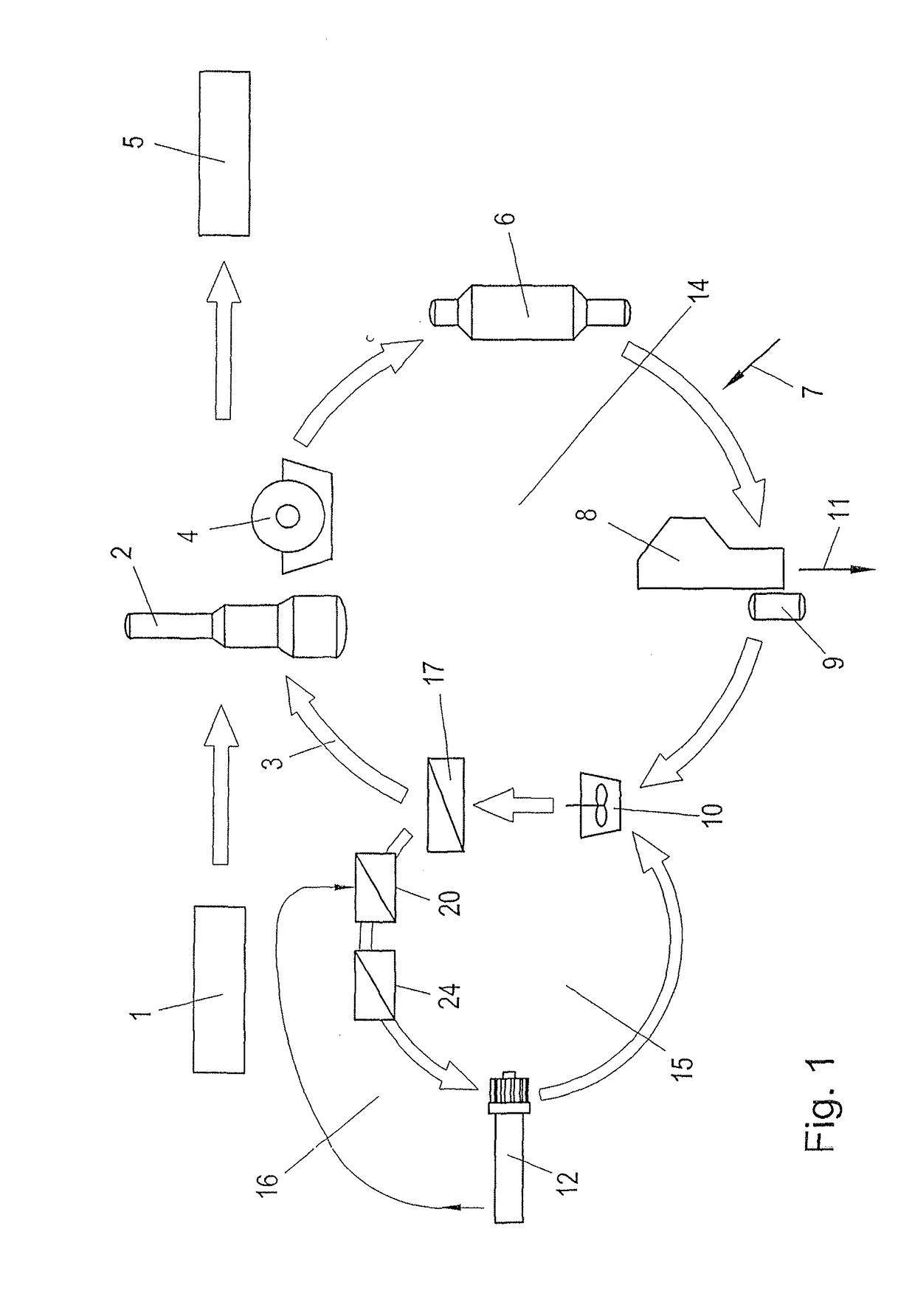

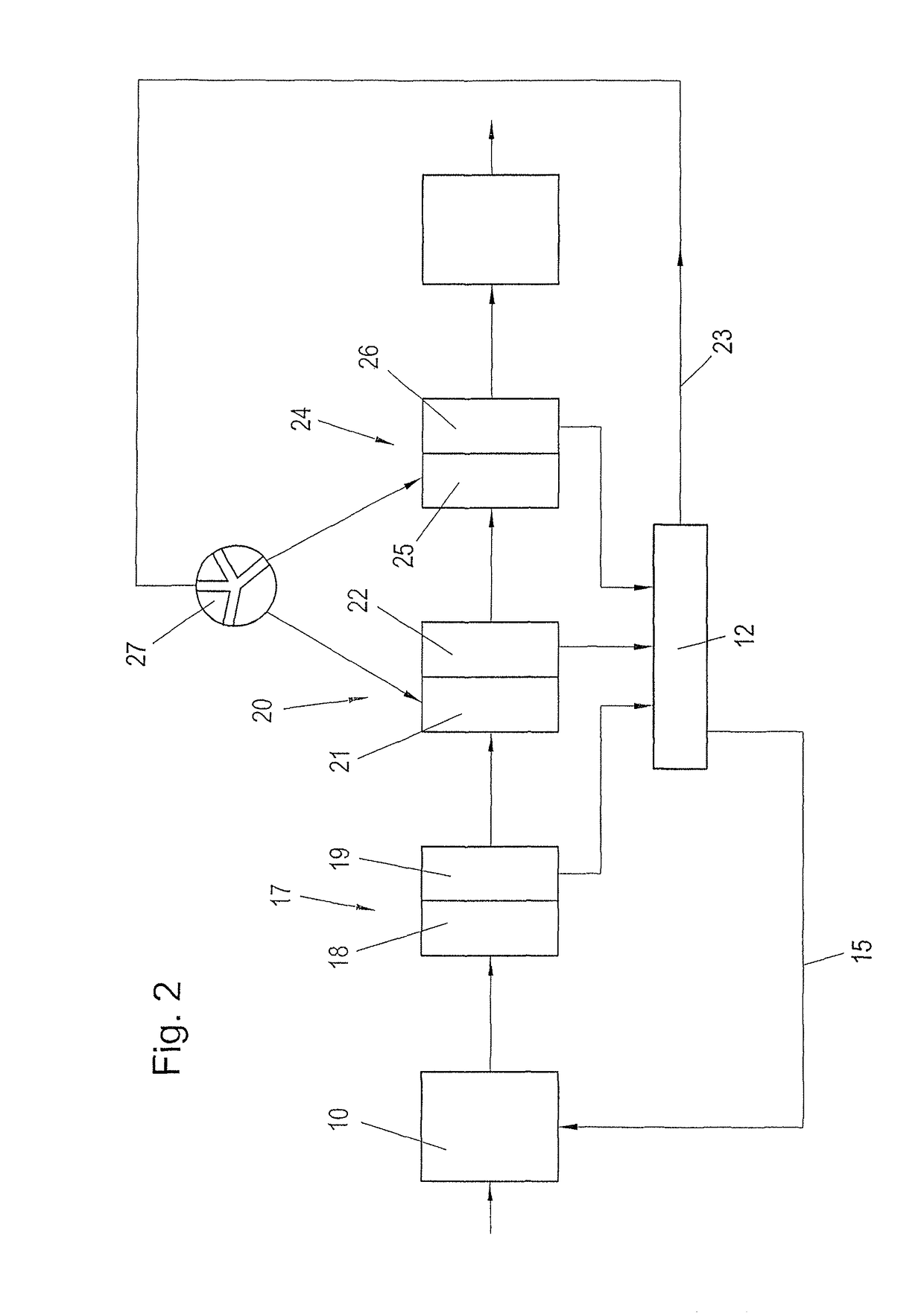

Process for recausticizing green liquor

ActiveUS10011948B2Improve filtering effectHigh crystallinityPulp liquor regenerationLime productionKraft processSulfate

A process for recausticizing green liquor in a sulphate or Kraft process for wood pulp production, in which a green liquor consisting of an aqueous solution of sodium carbonate as the major component and sodium sulphide is admixed with calcium oxide in a slaker and undergoes a reaction in a recausticizer to form an aqueous suspension containing sodium hydroxide and calcium carbonate as the major components, which suspension is filtered on a first filter and subsequently, after dilution with water in a dilution vessel, is fed over further filters two or three times and filtered to separate solids suspended therein, characterized in that after a first separation of calcium carbonate as the major component and calcium oxide as the minor component, carbon dioxide is added to the aqueous suspension at least during dilution in a dilution vessel and in particular in the dilution vessel (s) upstream of a second and / or a third filter.

Owner:MONDI GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com