Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Speed up the production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

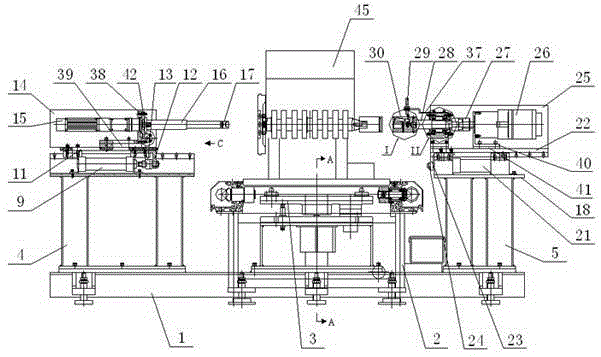

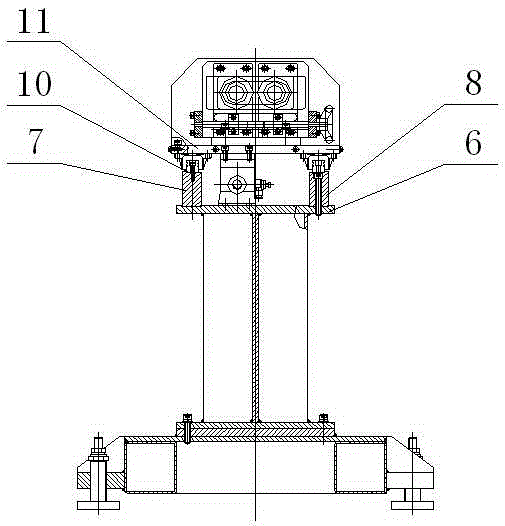

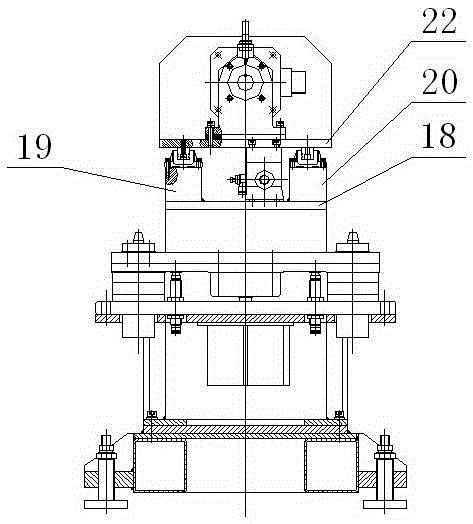

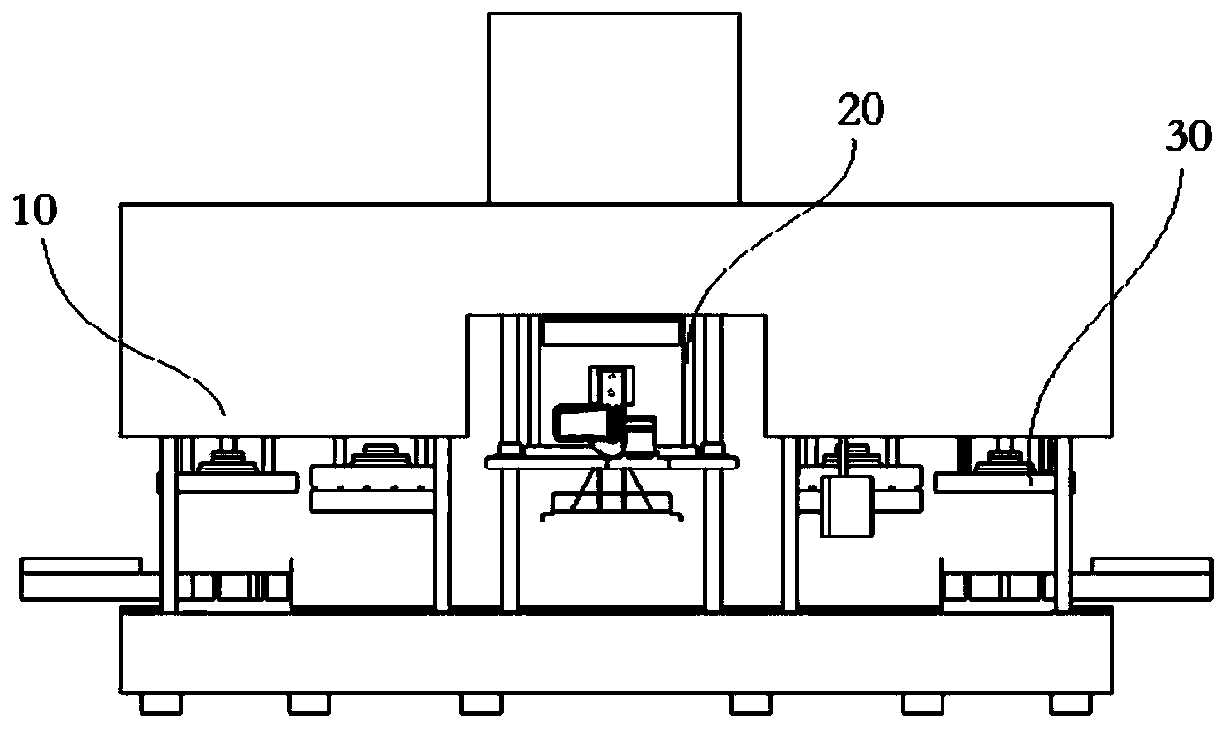

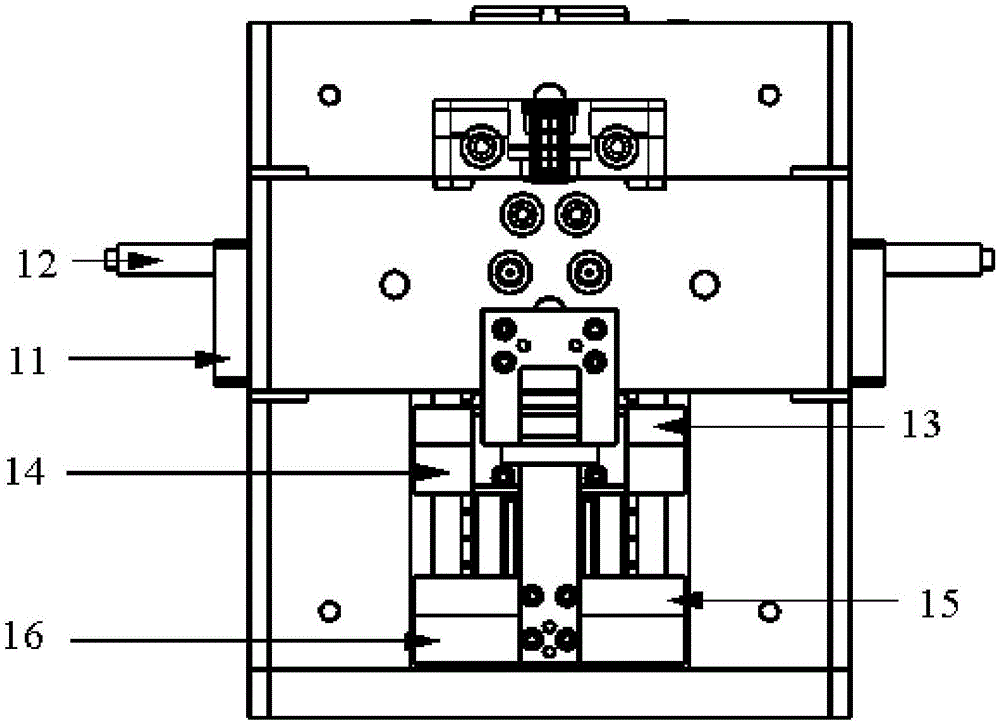

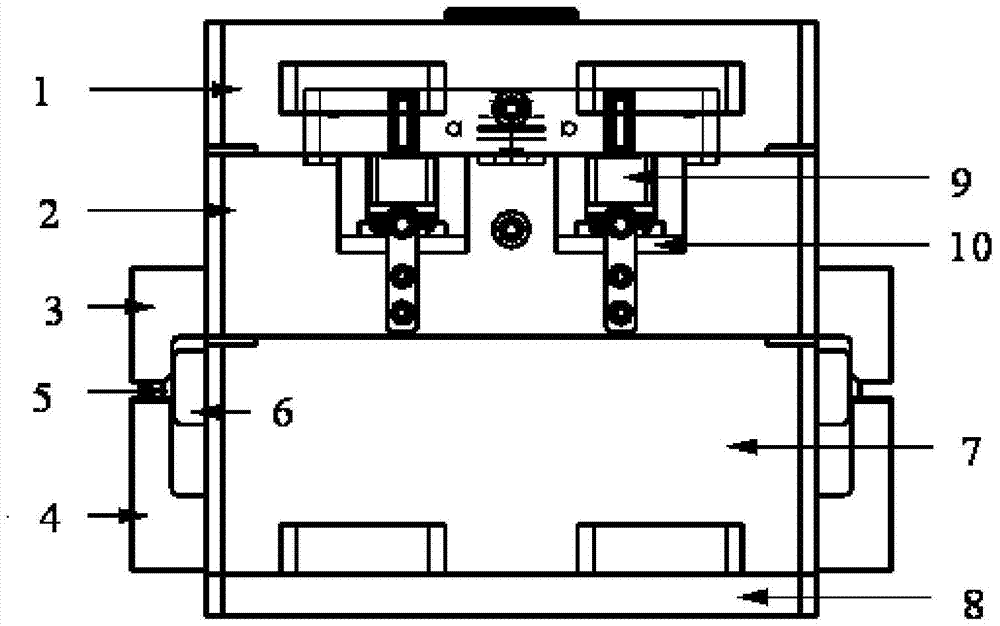

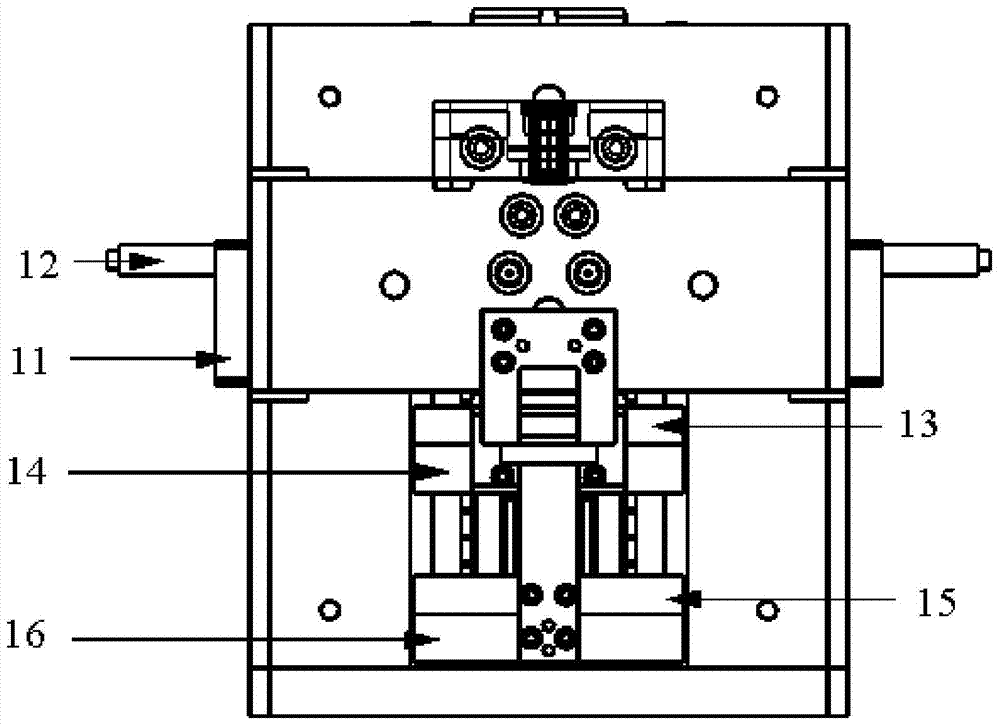

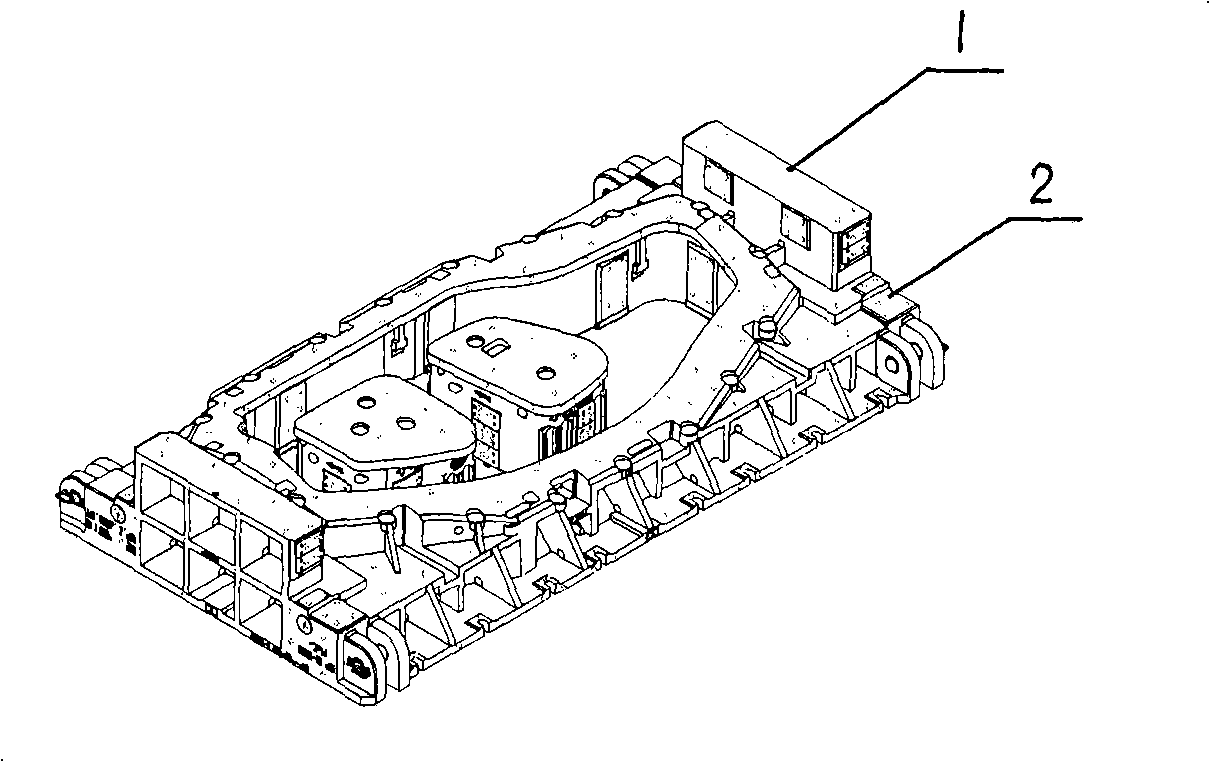

Bolt screwing machine for automobile engine flywheel

InactiveCN105269309AReduce the burden onHigh degree of automationVehicle componentsMetal working apparatusFreewheelEngineering

The invention discloses a bolt screwing machine for an automobile engine flywheel. The bolt screwing machine comprises a base. A lifting installing frame is fixed to the middle of the base. A lifting device is arranged on the lifting installing frame. A first machine base and a second machine base are fixed to the two sides of the base respectively. A first supporting plate is fixed to the first machine base. A first sliding rail cushion plate and a second sliding rail cushion plate are arranged on the two sides of the first supporting plate respectively. A first air cylinder is installed in the middle of the first supporting plate. Linear sliding rails are arranged on the first sliding rail cushion plate and the second sliding rail cushion plate respectively. A first installing plate is in sliding connection with the first sliding rail cushion plate and the second sliding rail cushion plate. A first air cylinder push plate is connected to the bottom of the first installing plate. One side of the first air cylinder push plate is fixed to the first installing plate. The other side of the first air cylinder push plate is connected with a first floating connector fixed to an output shaft of the first air cylinder. The bolt screwing machine is high in automation degree and has high pertinence; and in addition, the installing error is reduced, and the part installing precision and the part production efficiency are improved.

Owner:CHONGQING TECH & BUSINESS INST

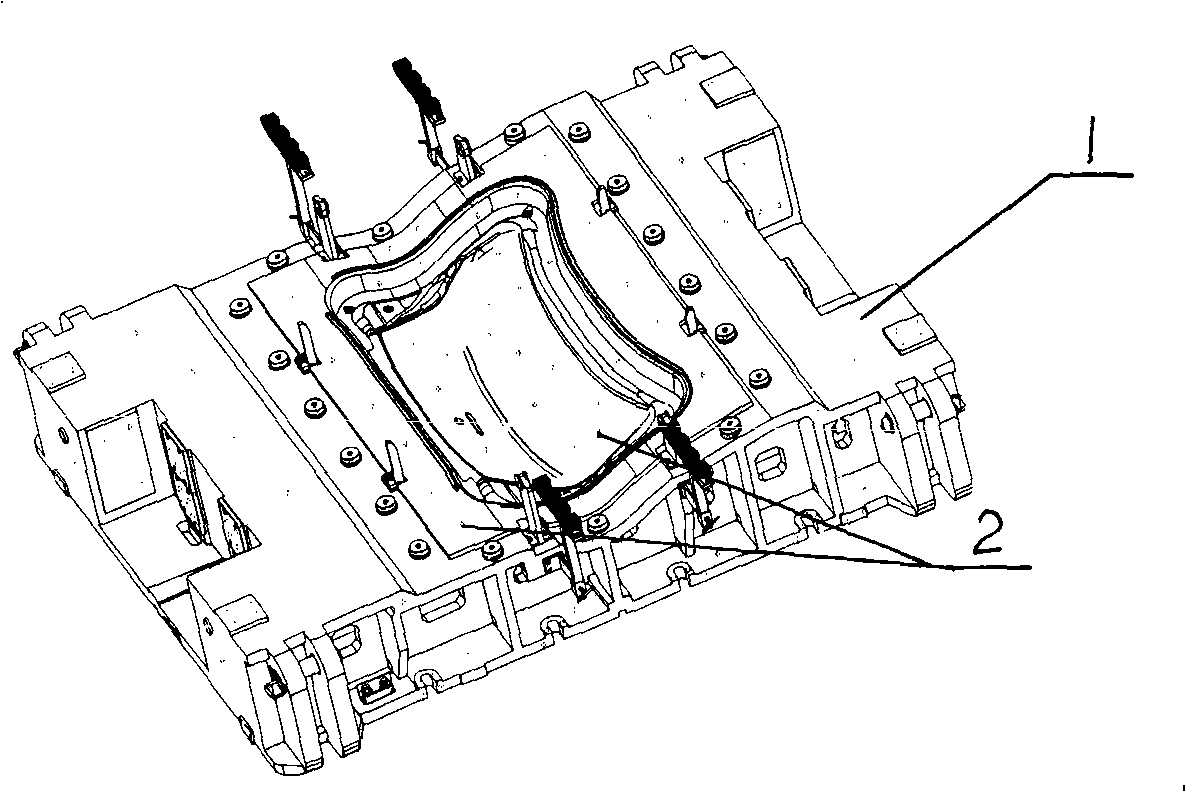

Method for detecting optical photograph of large mold casting blank

InactiveCN101514891AAccurately determineImprove work efficiencyUsing optical meansNumerical controlData acquisition

The invention relates to a method for detecting an optical photograph of a large mold casting blank. The method is characterized in that a lug boss and a peripheral unfinished surface formed by a workpiece are subjected to bulge application; all processing molding surfaces are subjected to data acquisition; a system is established for acquired 3D points, and is compared with the prior theory three-dimensional design data; finally, a digital control processing alignment standard report is released. Under a report chart environment, each direction required in digital control processing is standardized, generally, display of the standard is required to be determined by trial cutting on a machine tool, and theoretical coordinate values, offset directions and dimensions of the coordinates are displayed to be used for digital control processing alignment and standard determination. The method accurately determines the digital control processing standard, reduces load of the machine tool and time for aligning the center by digital control equipment, and accelerates cycle of cast output. A digital control programming staff can reasonably program a digital control processing program through allowance deviation data, thereby improving effective operation time of the digital control machine tool, reducing consumption of cost, improving working efficiency of digital control processing while ensuring the quality of digital control processing, and accelerating the output cycle of cast blank.

Owner:CHINA FIRST AUTOMOBILE +1

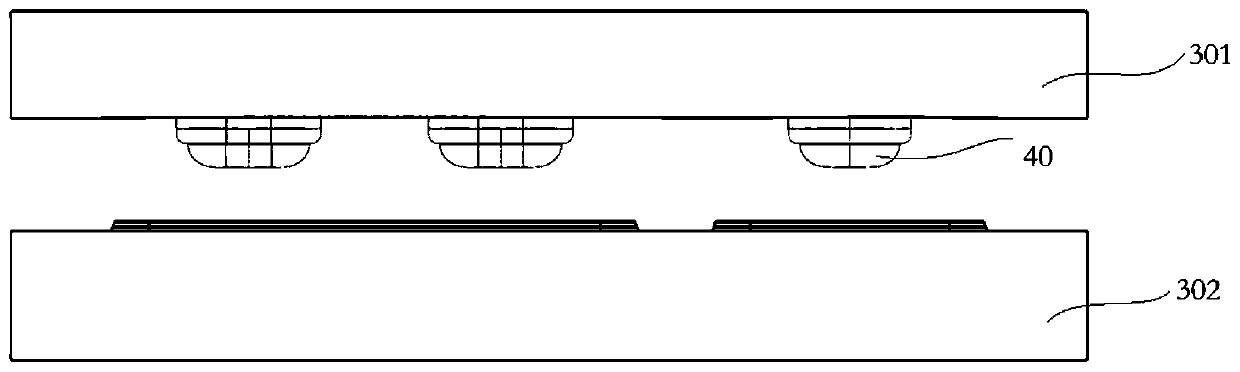

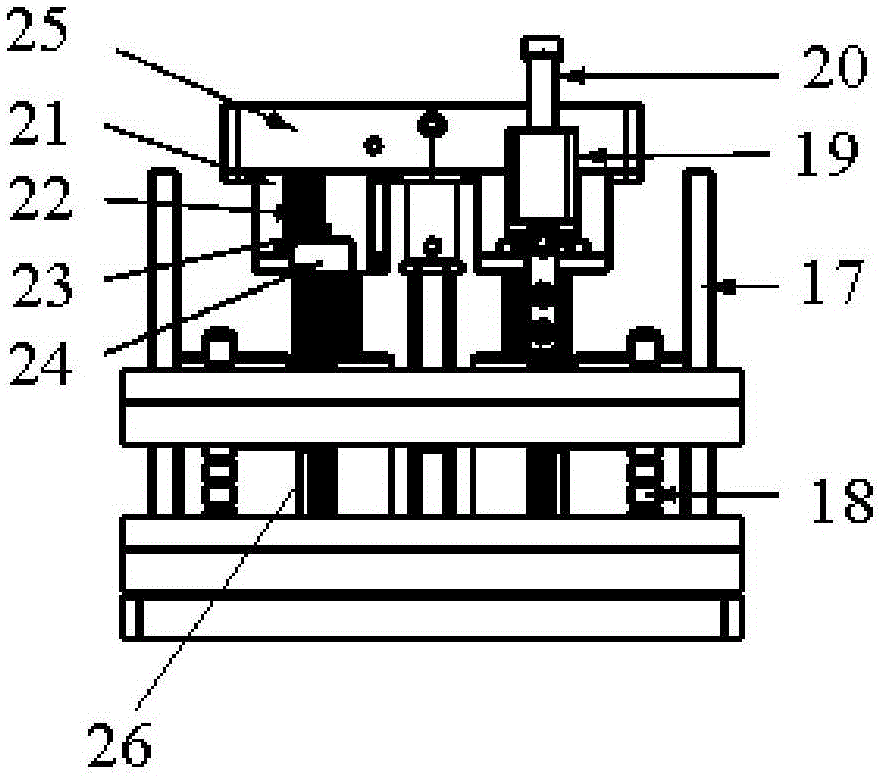

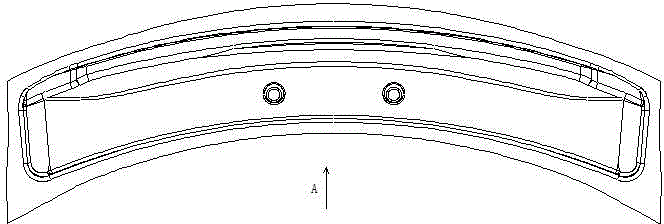

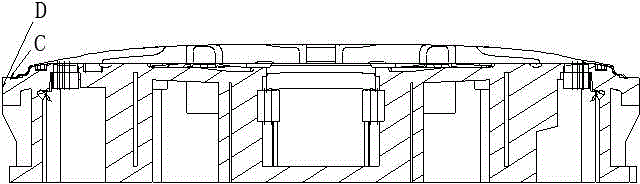

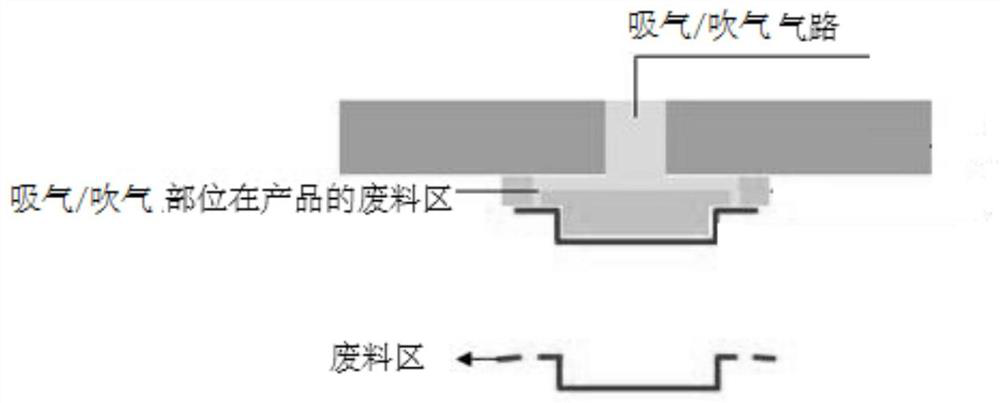

Double-side high-smoothness pulp molding product shaping system and shaping method

The invention discloses a double-side high-smoothness pulp molding product shaping system, which successively includes a pulp sucking mold comprising, successively according to the order of preparation of the pulp molding product, a front side cavity and a back side cavity of the pulp molding product; a hot-pressing mold includes, corresponding to the pulp sucking mold, a hot-pressing upper die and a hot-pressing lower die, wherein the contact surfaces between the hot-pressing upper die and hot-pressing lower die and a to-be-pressed green body are high-gloss surfaces; the hot-pressing upper die can be moved up and down in the vertical direction, while the hot-pressing lower die can be moved left and right in the horizontal direction. When the hot-pressing lower die is moved to a position vertically corresponding to the hot-pressing upper die, the hot-pressing treatment is carried out. The shaping system can be used for manufacturing the double-side high-smoothness pulp molding productwith uniform thickness. The invention also provides a shaping method, which can be used for producing the pulp molding product having uniform thickness, having high smoothness totally and being free of rough surface by using the shaping system. The method is simple in operation, reduces operation time of the equipment during shaping and increases the cycle period of the equipment for manufacturingthe pulp molding product.

Owner:永发(江苏)模塑包装科技有限公司

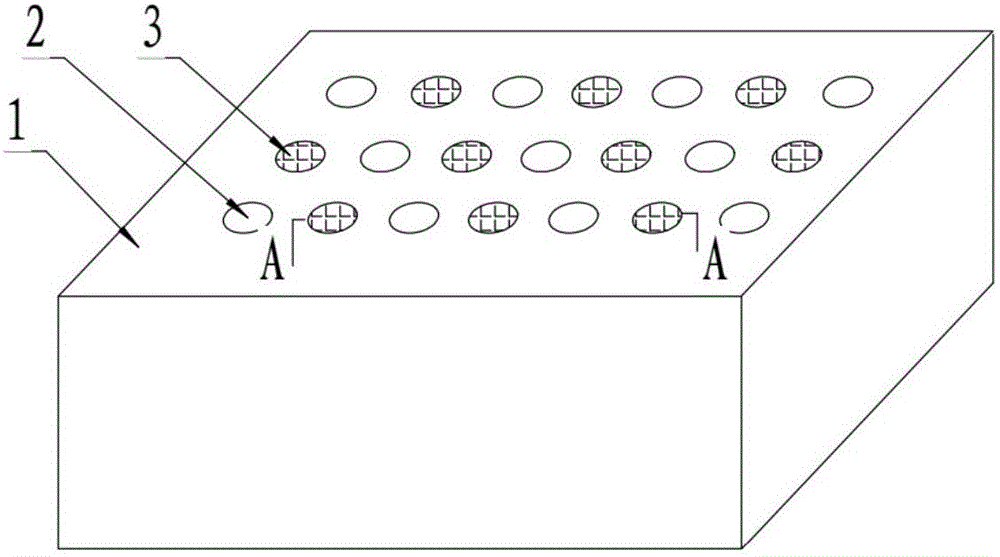

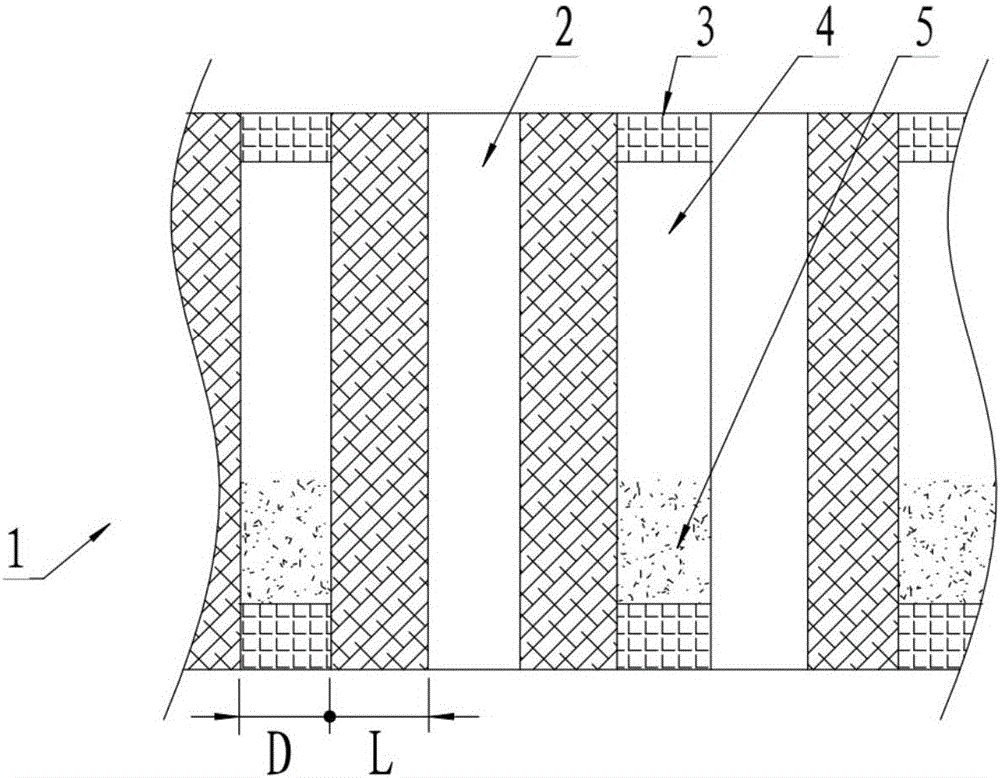

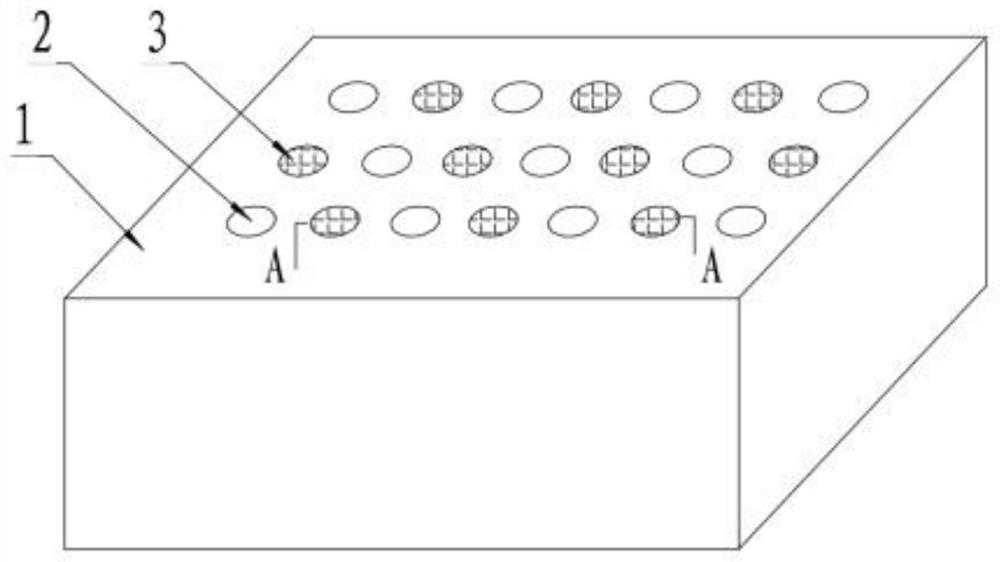

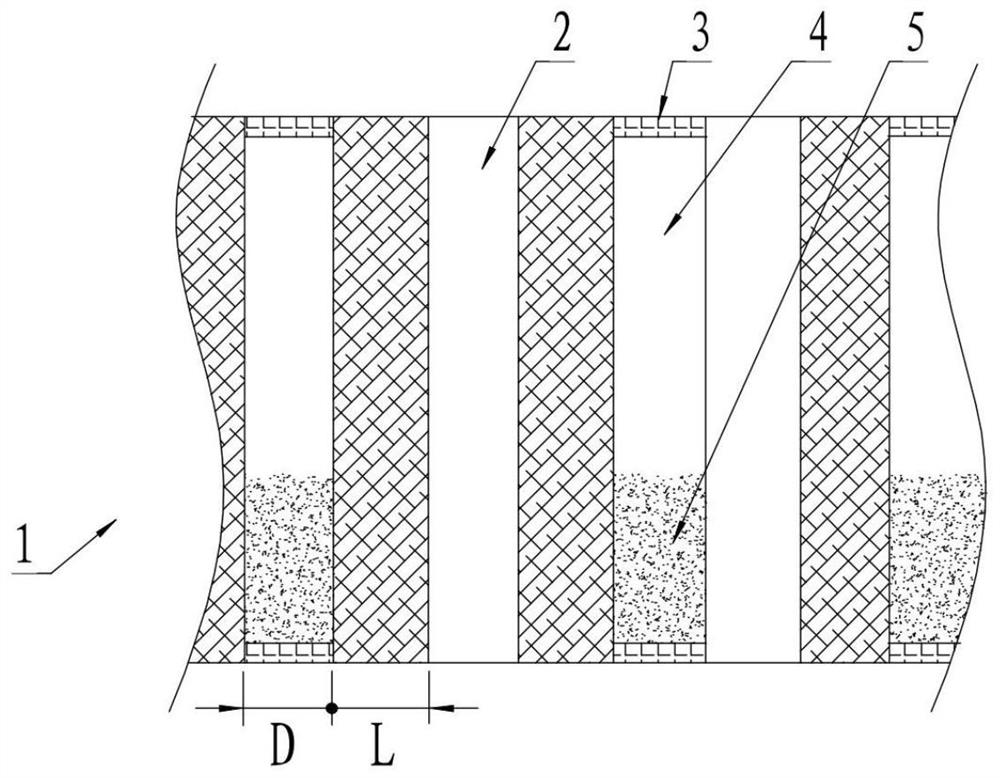

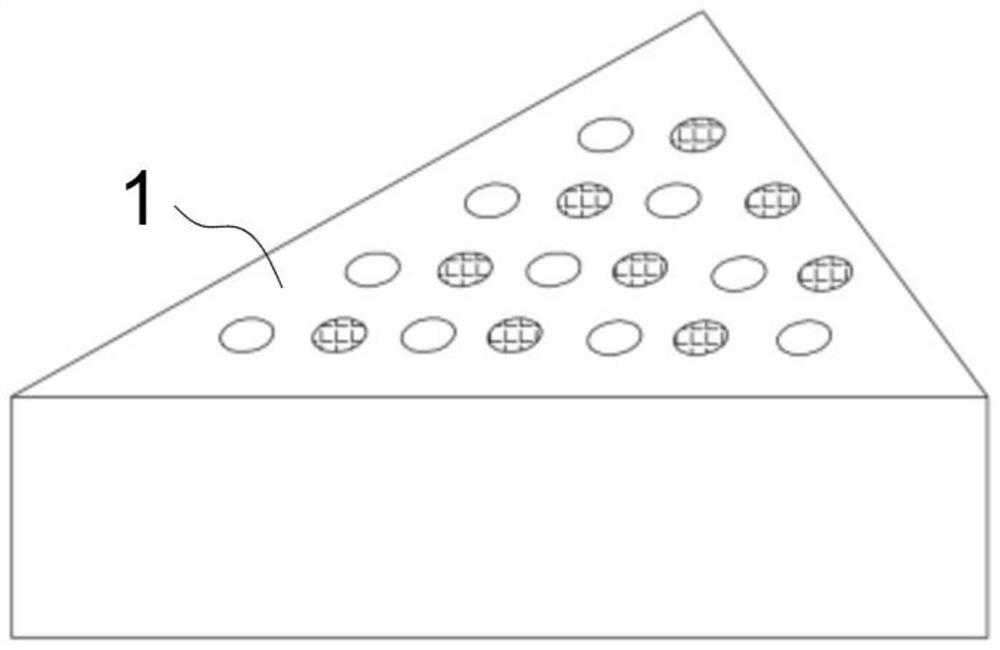

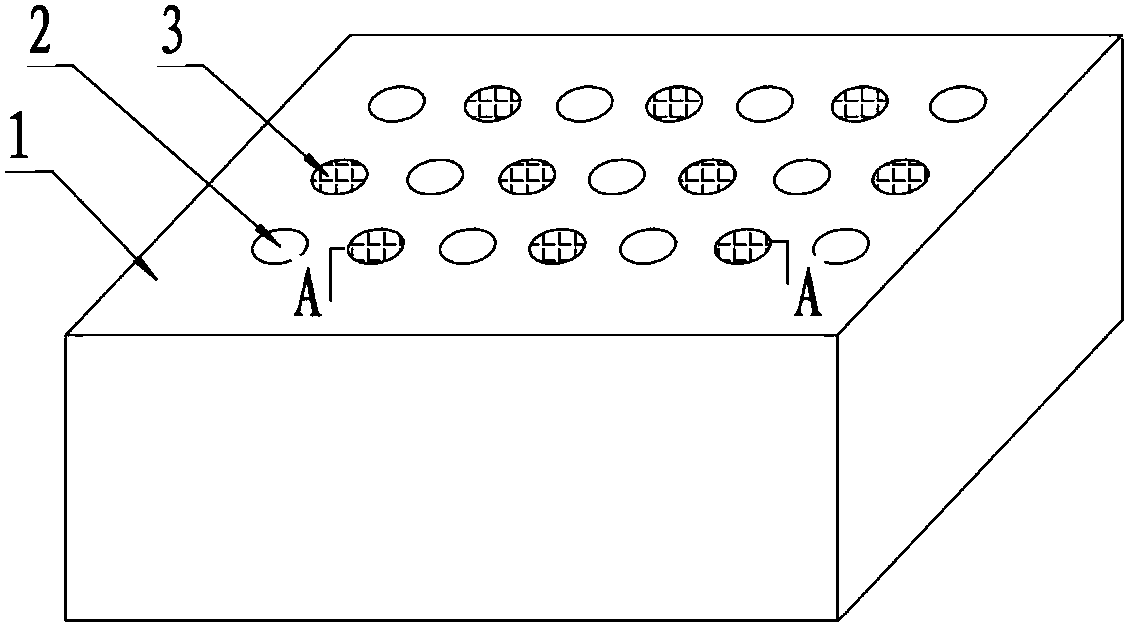

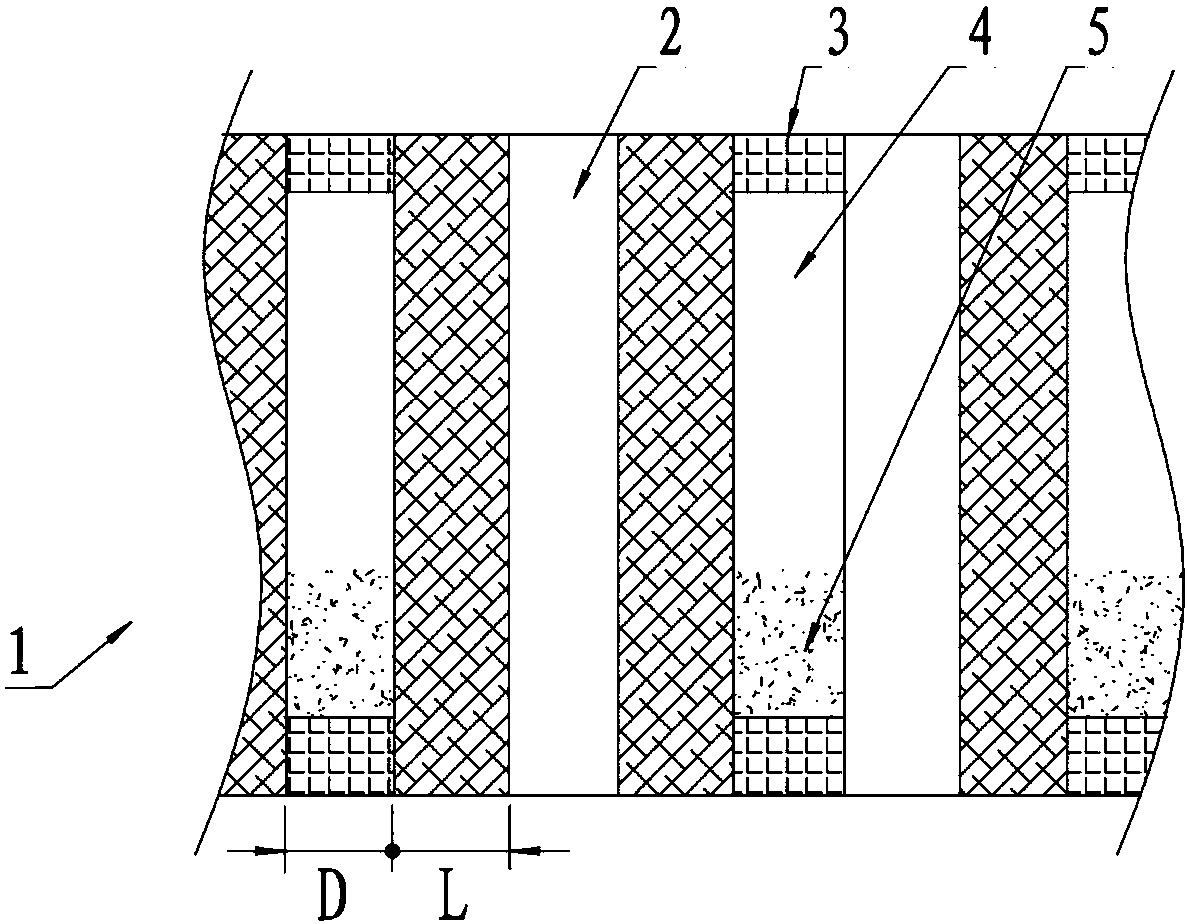

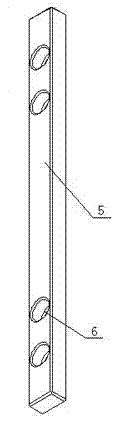

Composite heat retainer and preparation method

ActiveCN105841536ASimple manufacturing processIncrease filling volumeHeat storage plantsCeramicwareLatent heat storageHeat conducting

The invention discloses a composite heat retainer and a preparation method. The composite heat retainer comprises a silicon carbide-based composite ceramic base body and phase-change materials. The silicon carbide-based composite ceramic base body is in a regular geometrical shape and provided with holes. The phase-change materials are charged in parts of the holes. The two ends of each hole filled with the phase-change materials are subjected to hot melting sealing through sealing bodies. The holes which are not filled with the phase-change materials are heat conducting holes which are of communication structures. The preparation method comprises the steps of silicon carbide-based composite ceramic base body preparing, sealing body preparing, phase-change material charging and the like. The composite heat retainer can enable the quantity of the phase-change materials contained by the silicon carbide-based composite ceramic base body to be easy to control; and in the heat storage process, sensible heat storage of the silicon carbide-based composite ceramic base body and latent heat storage of the phase-change materials are organically combined, so that the purposes of improving the heat storage efficiency and optimizing the heat storage process are achieved. The preparation method is capable of simplifying the manufacturing process, reducing the manufacturing cost and accelerating the manufacturing period.

Owner:沧州渤海新区元大自然能源有限公司

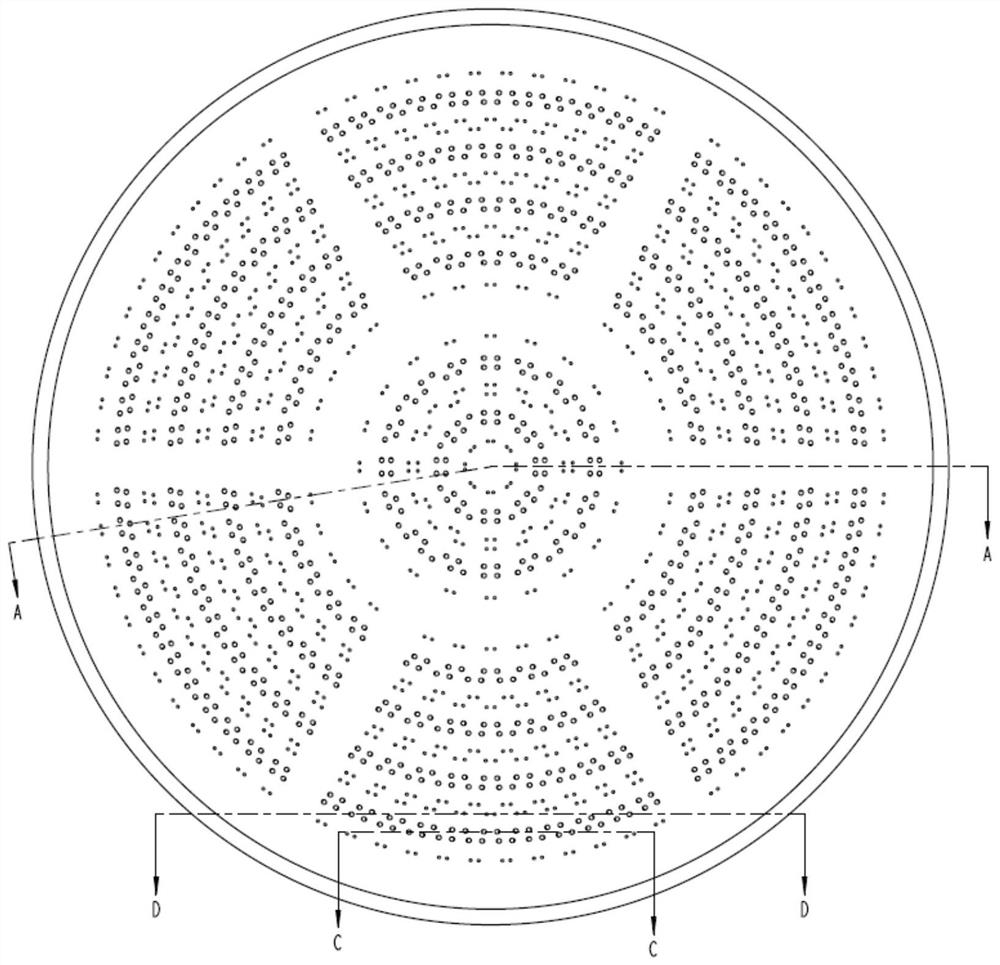

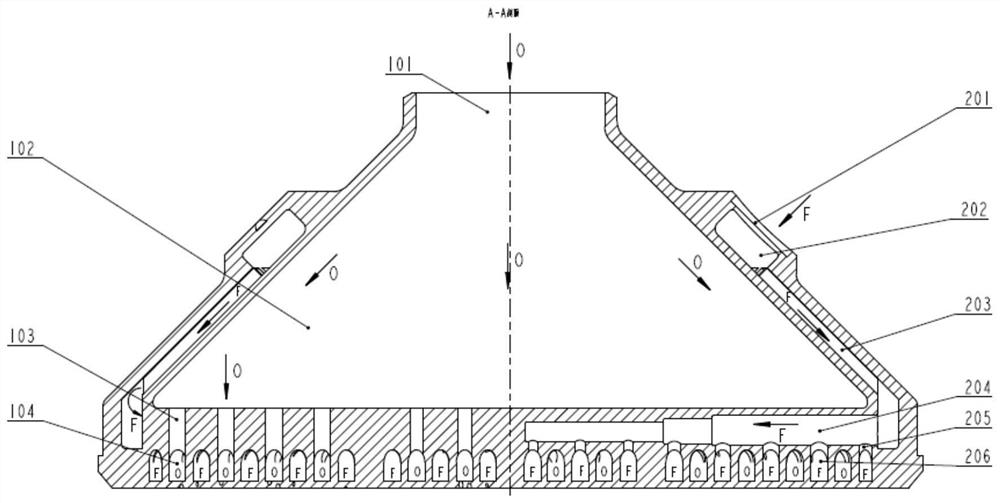

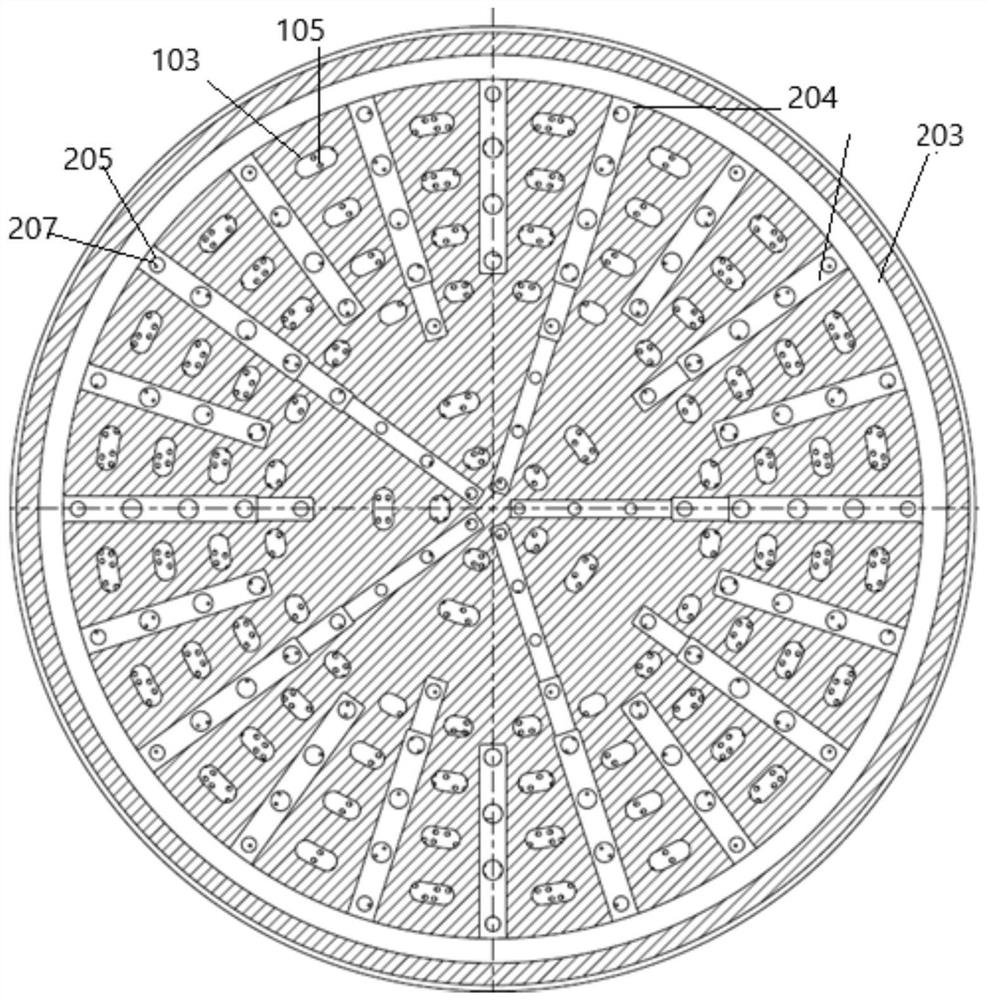

Integrated structure injector for rocket engine

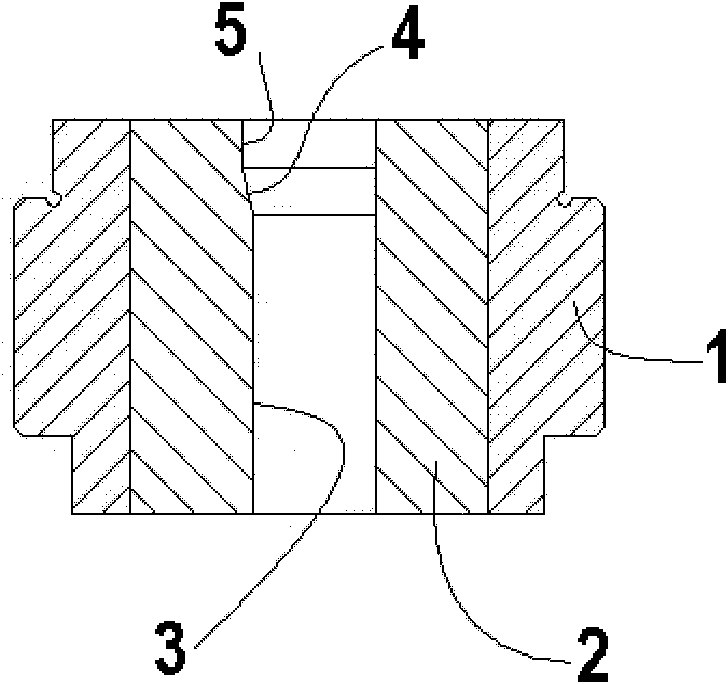

InactiveCN112196697ASpeed up the production cycleReduce in quantityRocket engine plantsFuel distributionEngineering

The invention provides an integrated structure injector for a rocket engine. The integrated structure injector comprises an oxidizing agent inlet, an oxidizing agent liquid collecting cavity, oxidizing agent distribution channels, oxidizing agent annular cavities and oxidizing agent injection holes; and a fuel inlet, a fuel liquid collecting cavity, a fuel conveying channel, fuel distribution channels, fuel annular cavities and fuel injection holes are formed, and each propellant flows through the corresponding channel, then enters the corresponding annular cavity and enters the correspondinginjection hole. According to the machining method, the number of parts is effectively reduced, the machining process is simplified, the manufacturing period of the injector is shortened, the machiningcost is reduced, and meanwhile the product reliability is improved. According to the machining method, the oxidizing agent annular cavities and the fuel annular cavities are arranged in a circle andcorrespond to the injection ports correspondingly, so that the oxidizing agents and fuel are injected correspondingly; and the injection holes form injection pairs, oxidizing agent mist fans and fuelmist fans are formed through mutual impact, and mutual infiltration and mixing between the oxidizing agent mist fans and the fuel mist fans are achieved, so that it is guaranteed that the oxidizing agents and the fuel can be evenly mixed in proportion, and the combustion efficiency is improved.

Owner:北京天兵科技有限公司

Method for manufacturing serialized sofa

InactiveCN102166076ADecrease stockSpeed up the production cycleSofasCouchesComputer scienceStandardization

The invention provides a method for manufacturing a serialized sofa, comprising the following steps of: a, establishing a standard part library, wherein the standard parts library comprises part identification numbers and first corresponding relations between the part identification numbers and sofa types, wherein the part identification numbers are used for indicating standardized parts; b, determining a sofa type to be manufactured; c, determining the part identification number according to the sofa type and the first corresponding relation; and d, assembling the standardized parts indicated by the part identification numbers into a sofa. In the invention, parts in reserve can be directly looked up from a standardized part database through establishing the standardized part database after the sofa is designed, and thereby the making period of the sofa from design to a finished product is shortened; meanwhile, because the standardized parts are adopted, the part inventory can be reduced and the cost is further reduced.

Owner:SHANGHAI BAIYI DECORATION ENG DESIGN

Method for pressing tank-type bulkhead using three rollers rolling machine

InactiveCN101249536BReduce in quantityReduce workloadShaping toolsIndustrial engineeringOil pressure

Owner:江苏新扬子造船有限公司

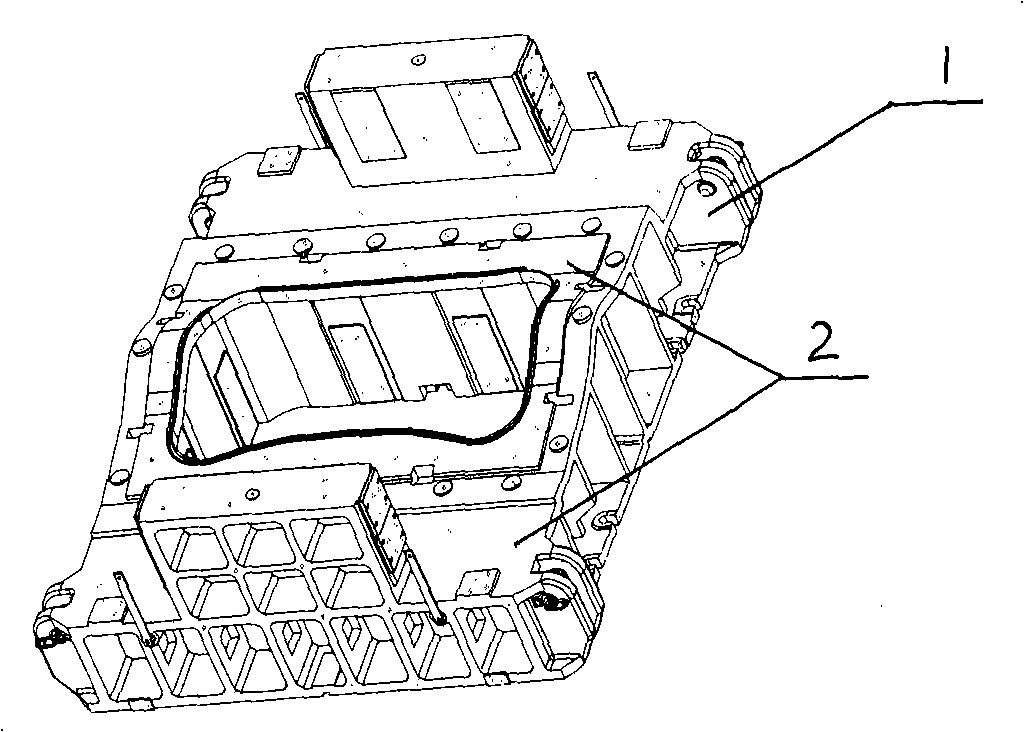

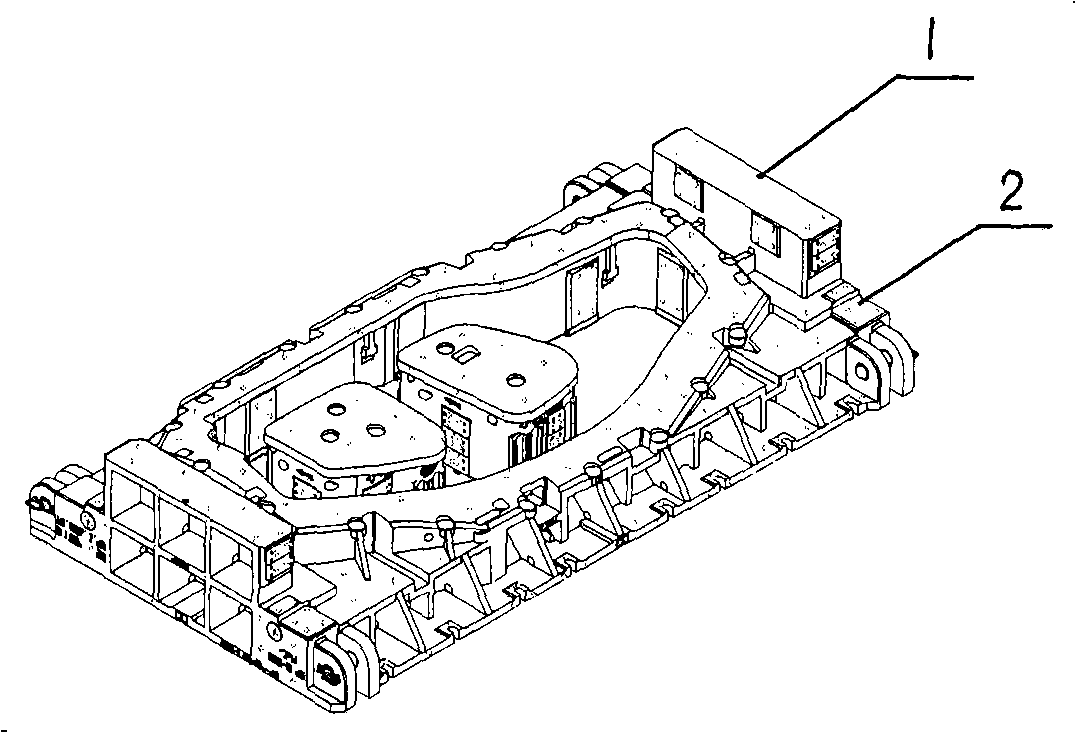

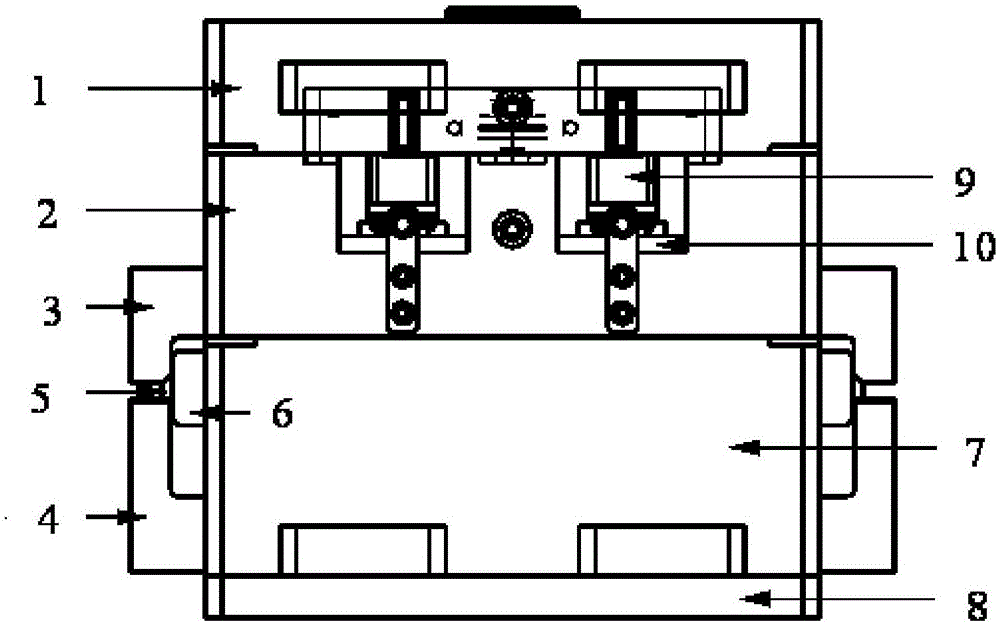

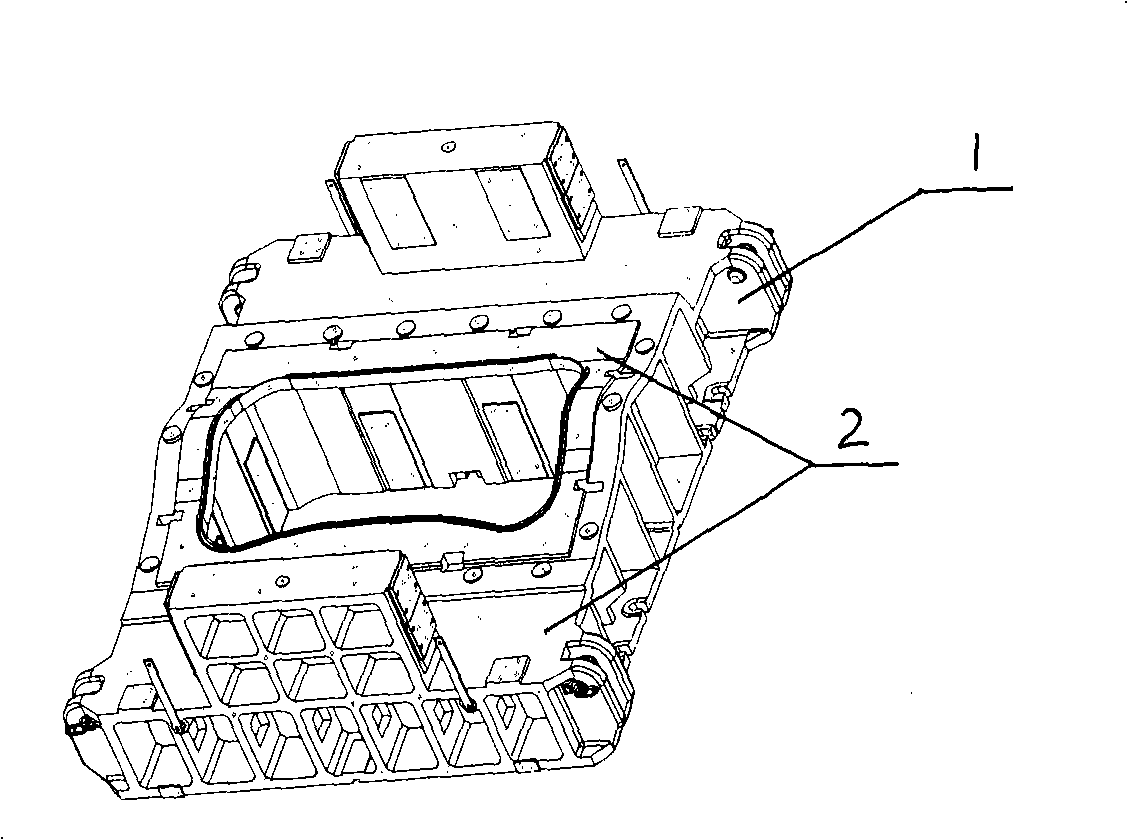

Zinc alloy die-casting die ejection mechanism

The invention discloses a zinc alloy die-casting die ejection mechanism. The zinc alloy die-casting die ejection mechanism comprises a fixed die plate, a moving die plate, a moving die safety bar, a push plate push block, a guide block, a limiting pin and a plug pin, wherein a fixed core is installed on the fixed die plate, a moving core is installed on the moving die plate, a push plate guide post is fixedly installed on the moving die safety bar, a first push plate, a first ejector plate, a second push plate, and a second ejector plate are sequentially arranged on the push plate guide post, the first push plate penetrates through the push plate guide post, the first ejector plate is fixed on the first push plate, the second ejector plate is fixed on the second push plate, and the first push plate, the first ejector plate, the second push plate and the second ejector plate can slide up and down along the push plate guide post. By means of the zinc alloy die-casting die ejection mechanism, the phenomena that the clasp force is large, products are failed to be taken out of the die, die-casting is poor, and spray does not reach the designed position in the product die-casting process, and ejector rods and inserts are broken and pulled crack in the production process are effectively improved.

Owner:FOEHL CHINA CO LTD

A zinc alloy die-casting mold ejection mechanism

ActiveCN105149547BOptimize the internal exhaust mechanismOptimize the exhaust mechanismZinc alloysCasting

The invention discloses a zinc alloy die-casting mold ejection mechanism, which comprises a fixed platen with a fixed mold core, a movable platen with a movable mold core, a movable mold lock plate, a push plate push block, a guide block, a limit pin and The latch, wherein, the movable mold locking plate is fixedly equipped with a push plate guide column, and the first push plate that passes through the push plate guide column is sequentially arranged on the said push plate guide column, and is fixed on the first push plate The first ejector plate on the top, the second push plate, the second ejector plate fixed on the second push plate, the first push plate, the first ejector plate, the second push plate and the The second ejector plate can slide up and down along the push plate guide post. The ejection mechanism of the zinc alloy die-casting mold of the present invention can effectively improve the products in the die-casting process, such as large clinging force, failure of the product to come out of the mold, poor die-casting, insufficient spraying, ejector pins and inserts breaking and cracking during the production process, etc. Phenomenon.

Owner:FOEHL CHINA CO LTD

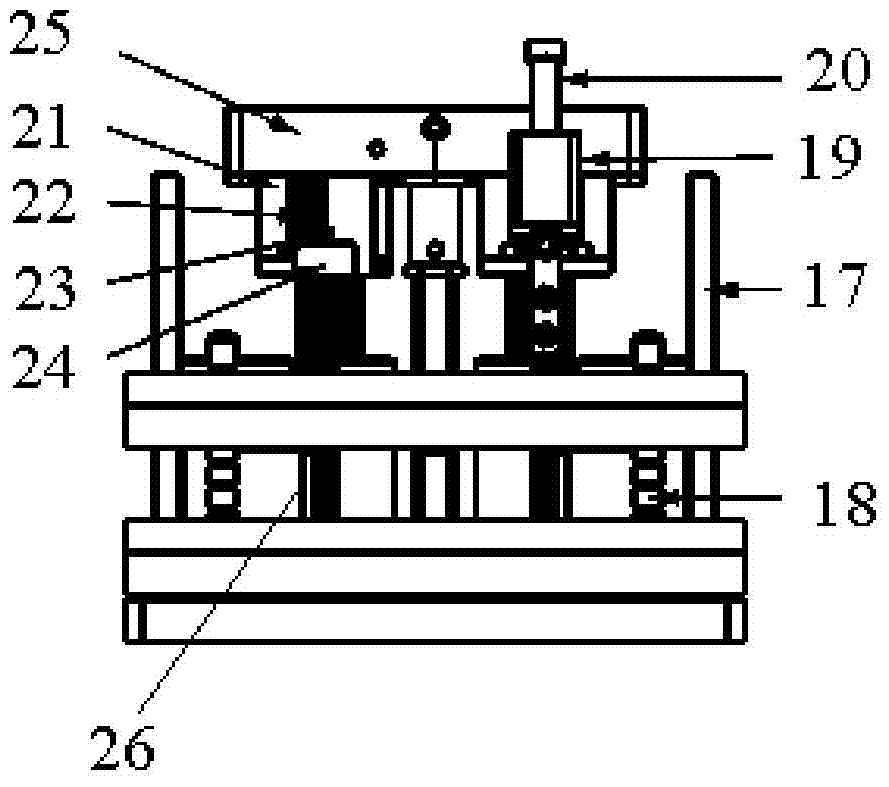

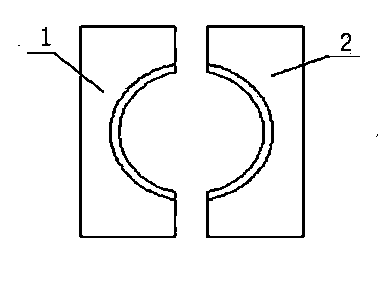

Friction press mould base and mould structure

InactiveCN103769517AChangeover time shortenedShort manufacturing cycleForging/hammering/pressing machinesForgeHole size

Provided are a friction press mould base and mould structure. An upper mould base and a lower mould base are arranged at two ends of a mould seat and can be adjusted movably, and an iron clamping circle clamping mould is arranged in the middle. The structure is characterized in that the iron clamping circle clamping mould is composed of two symmetrical moulds with semicircular mould holes formed in the middle, and the size of the mould holes is adjusted through bolts and wedge blocks on the upper mould base and the lower mould base. The mould replacement time is shortened by a half, the operation is simple and safe, the team yield is increased by 15%, and especially when one team produces a plurality of varieties of forge pieces, the effect is improved by over 50%. In the aspect of mould materials, the weight of workblank material is reduced by over 15% due to the fact that the appearance of the mould is standardized.

Owner:JIANGSU LEAP MACHINE

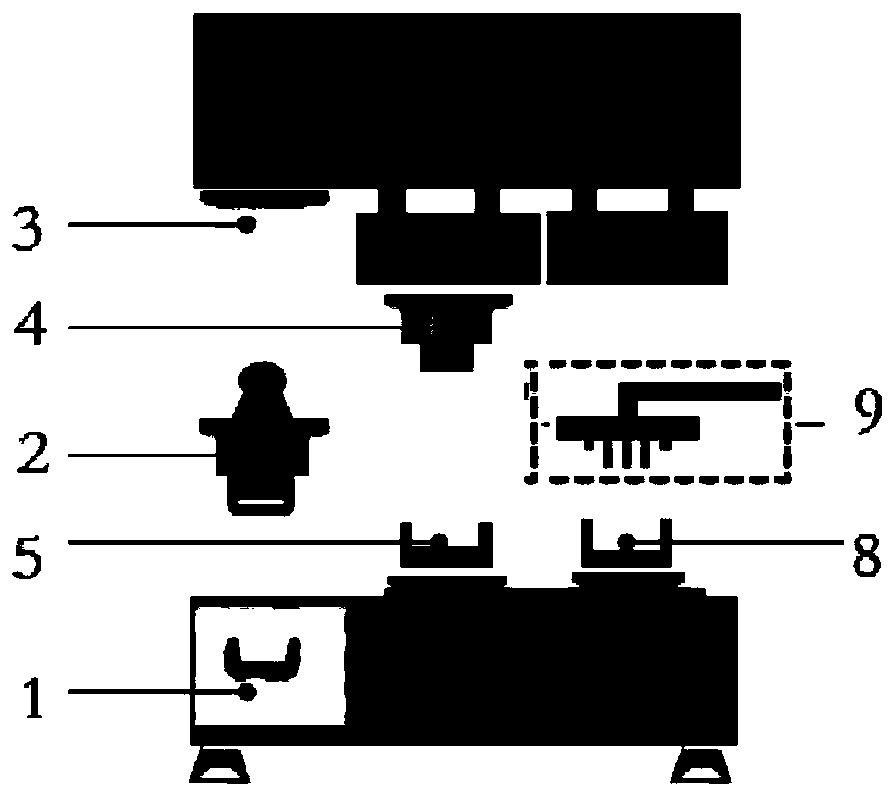

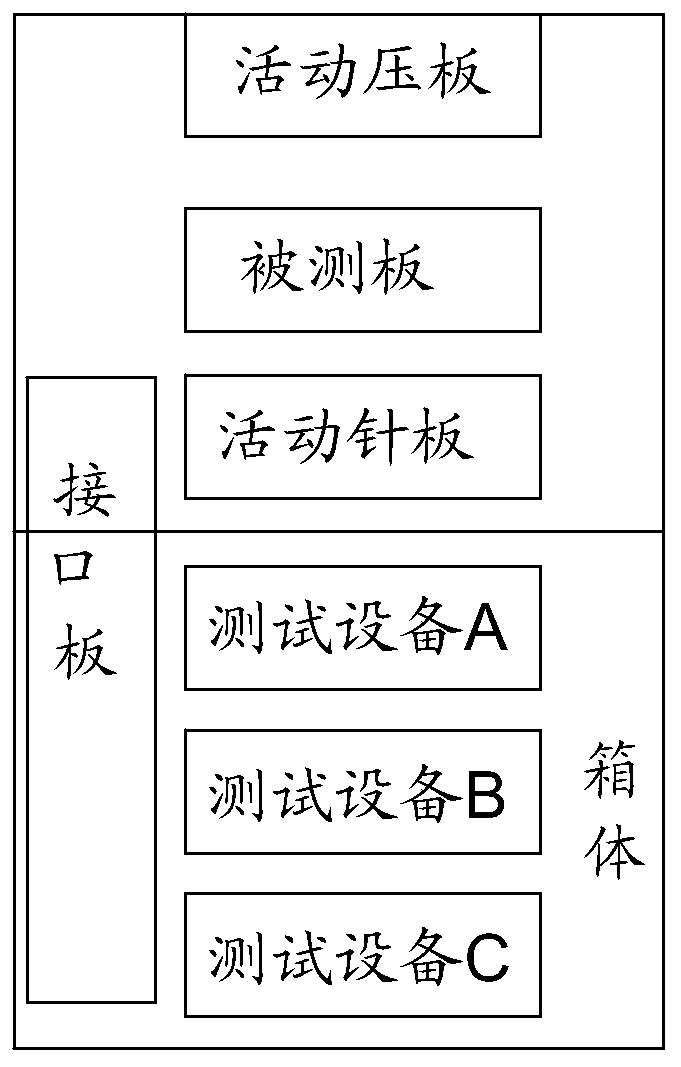

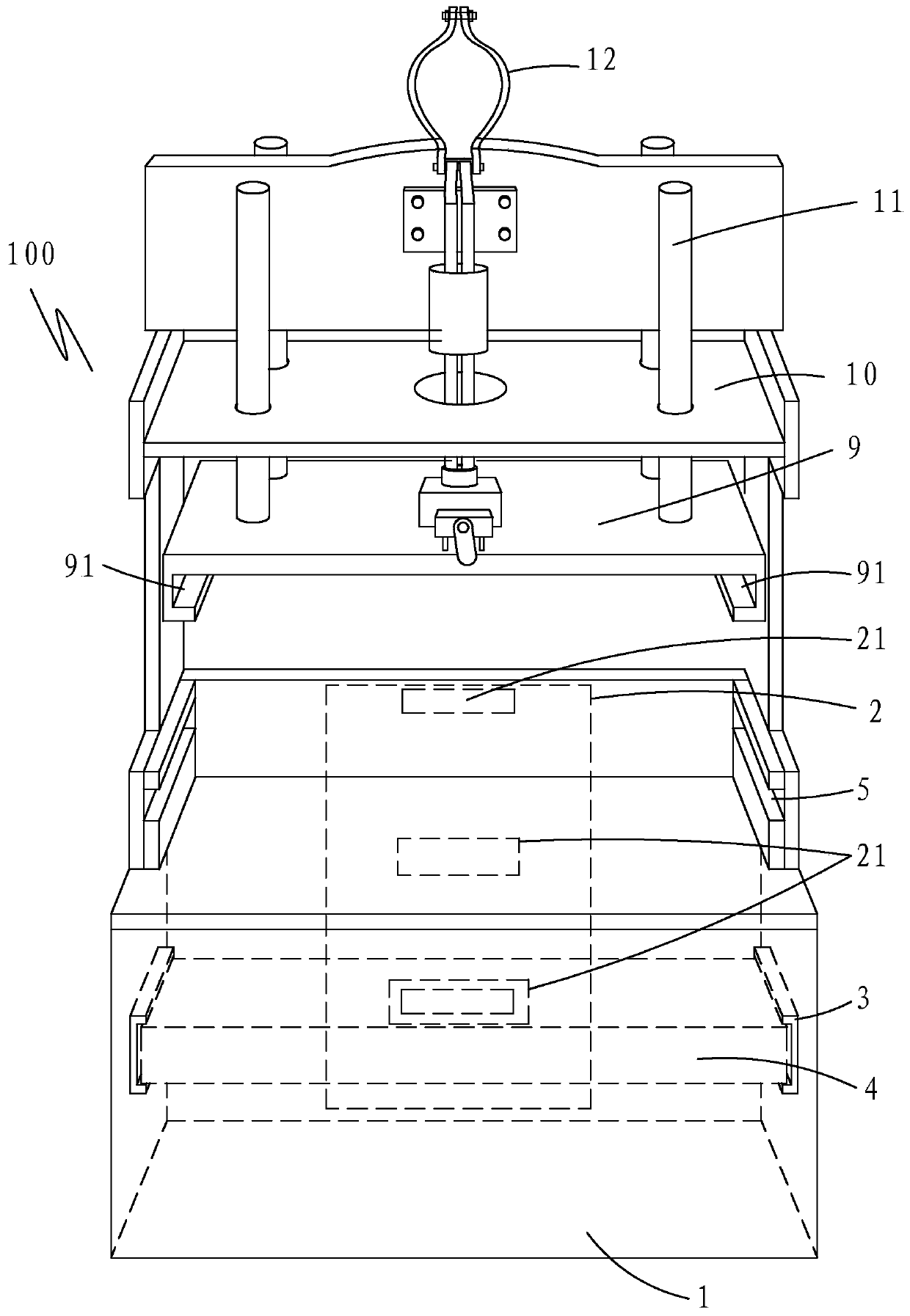

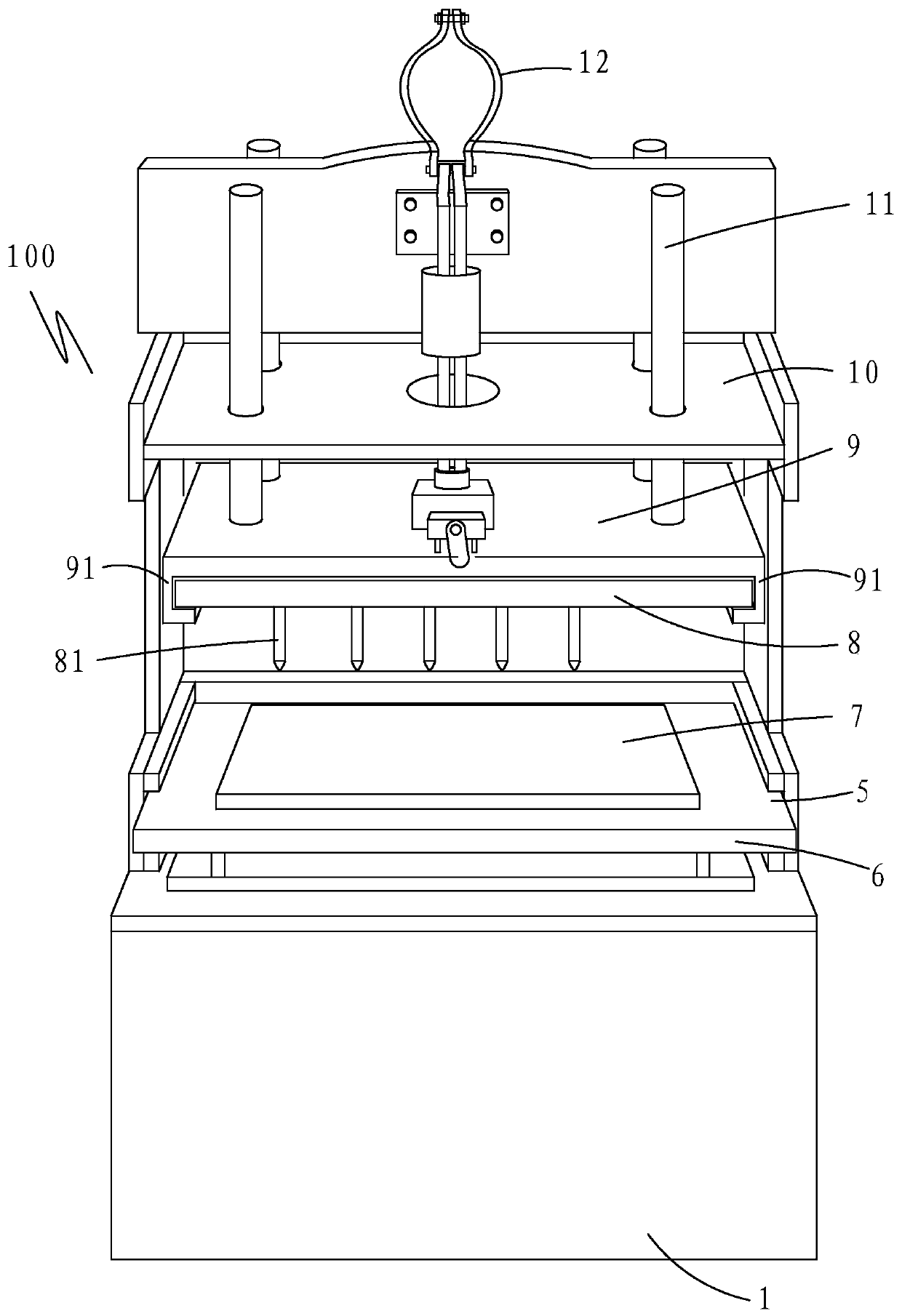

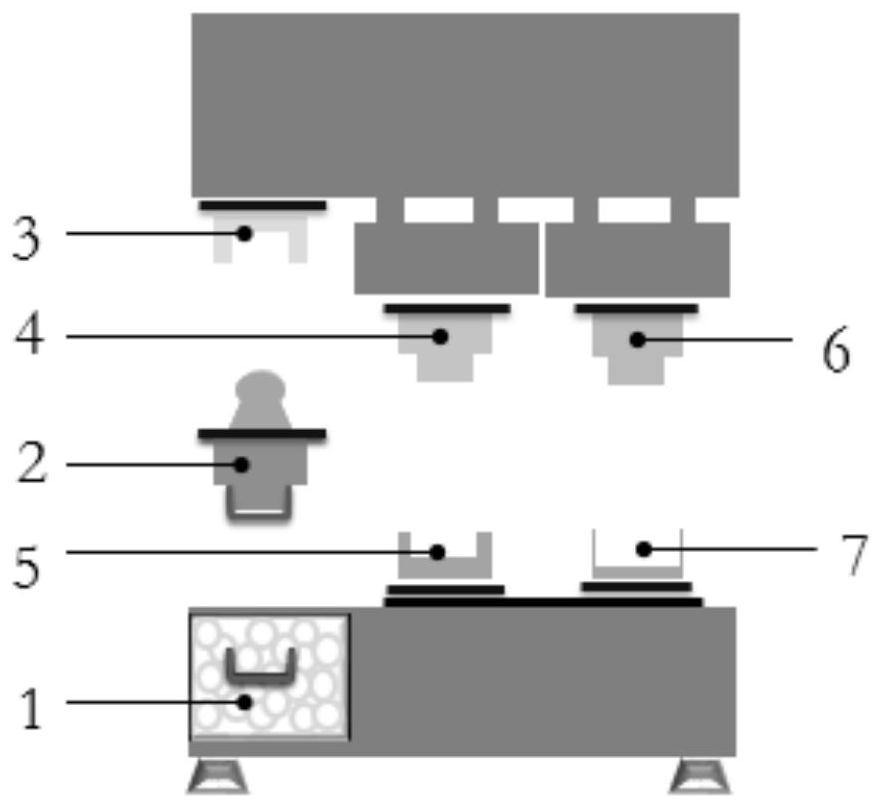

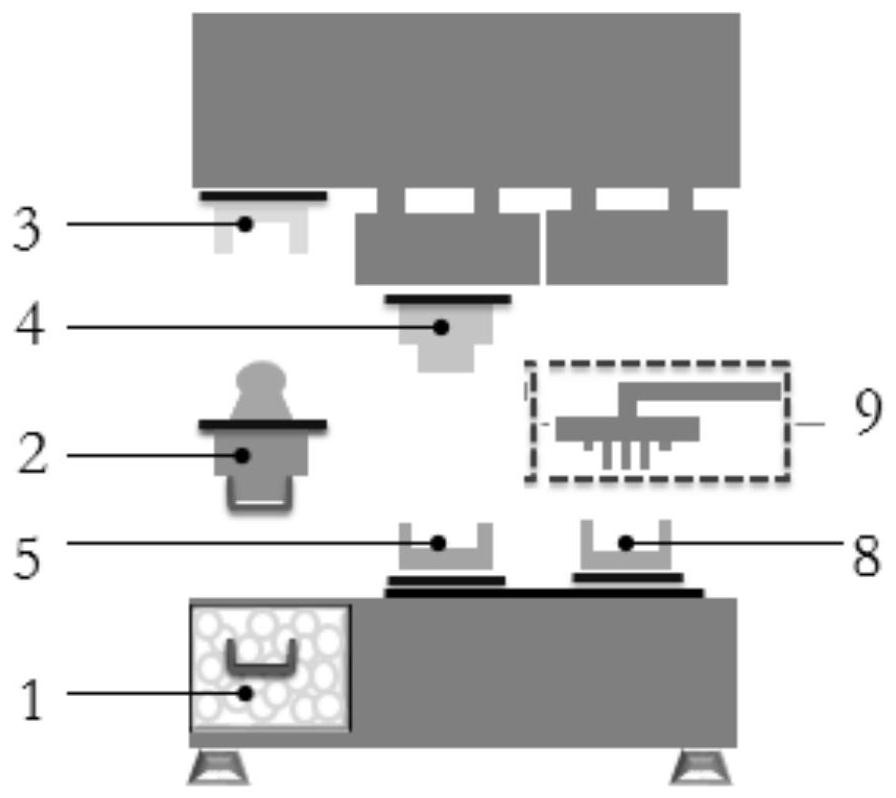

Plug-and-play intelligent testing device without connecting wire

ActiveCN111562454ALower requirementReduce procurement costsElectrical testingMeasurement instrument housingStructural engineeringMechanical engineering

The invention discloses a plug-and-play intelligent testing device without a connecting wire, which comprises a rack, a movable pressing plate, a movable needle plate and testing equipment, wherein apressing plate support is arranged on the upper part of the rack, and the movable pressing plate is arranged on the lower part of the pressing plate support and movably connected with the pressing plate support; a needle plate fixing part is arranged in the middle of the rack and is movably connected with the movable needle plate; a tested plate is placed on the movable needle plate; the lower part of the rack is provided with multiple layers of equipment guide grooves for placing multiple sets of test equipment; an interface circuit board is also arranged at the lower part of the rack; more than two sockets are arranged on the interface circuit board; and the test equipment and the movable needle plate are in butt joint with the sockets of the interface circuit board through plugs. The invention provides a plug-and-play intelligent testing device without a connecting wire, which is simple in test environment building, flexible and efficient in machine type switching, convenient and fast to use and low in cost, and greatly reduces the storage land demand.

Owner:FUJIAN STAR NET EVIDEO INFORMATION SYST CO LTD

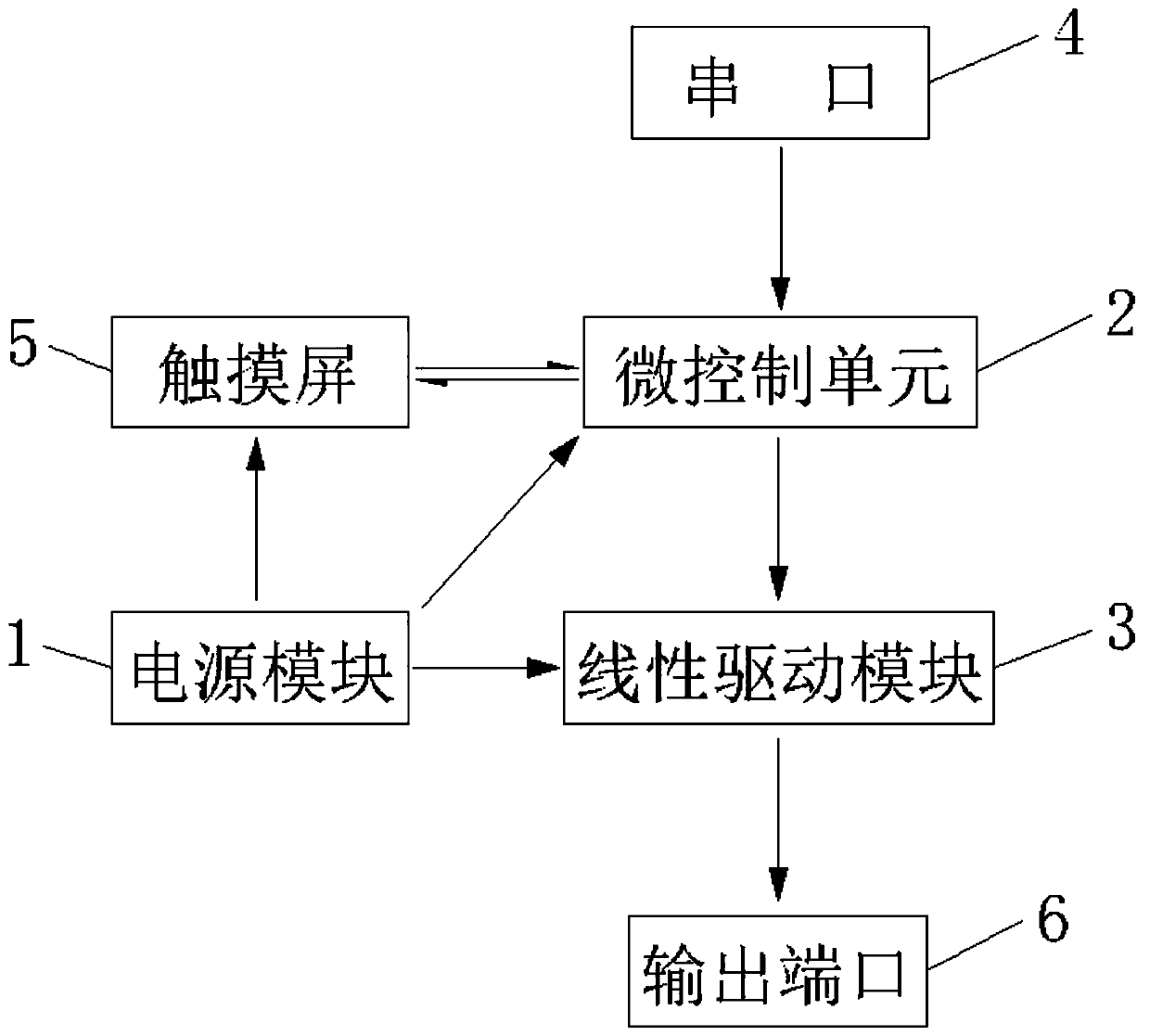

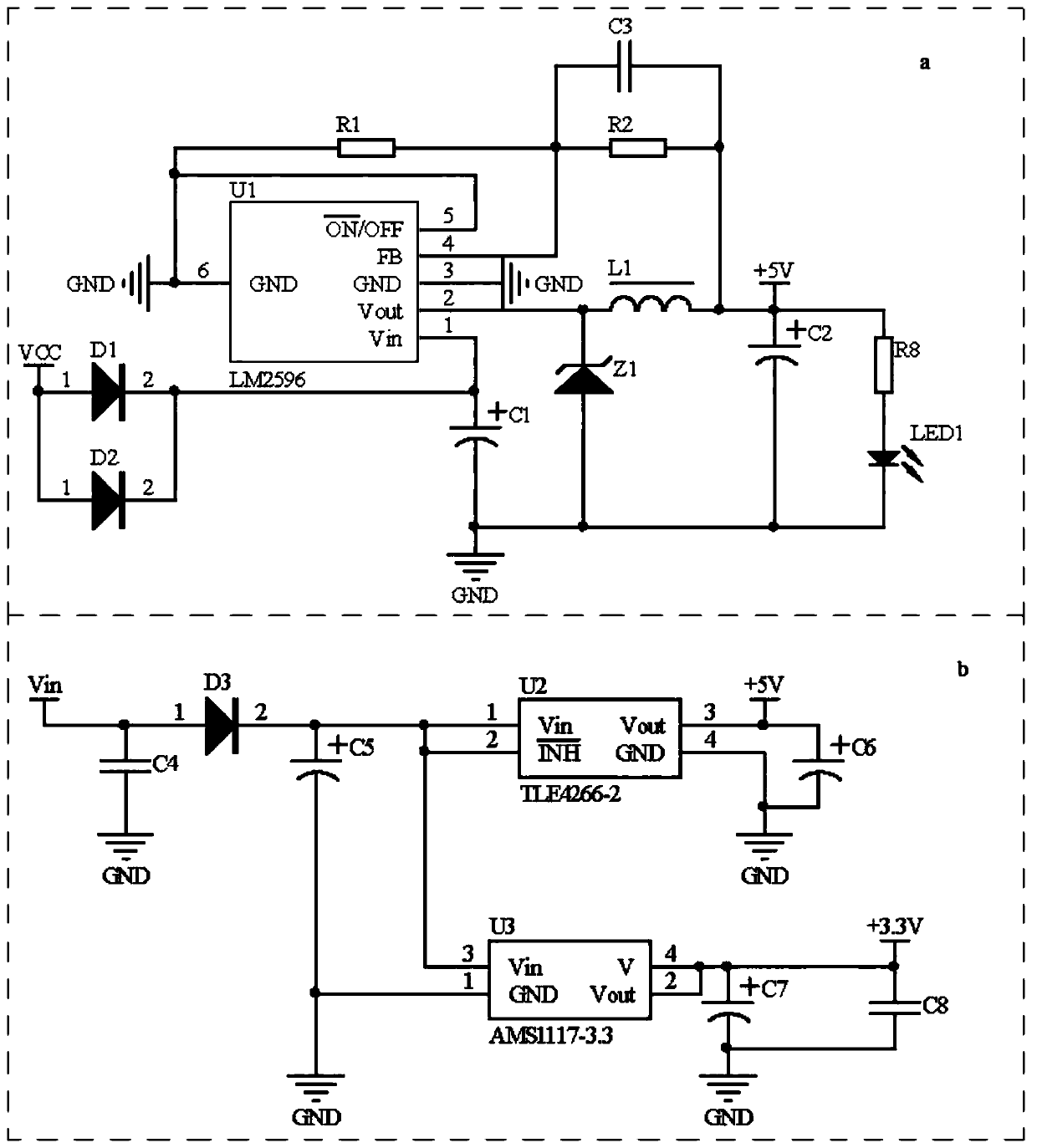

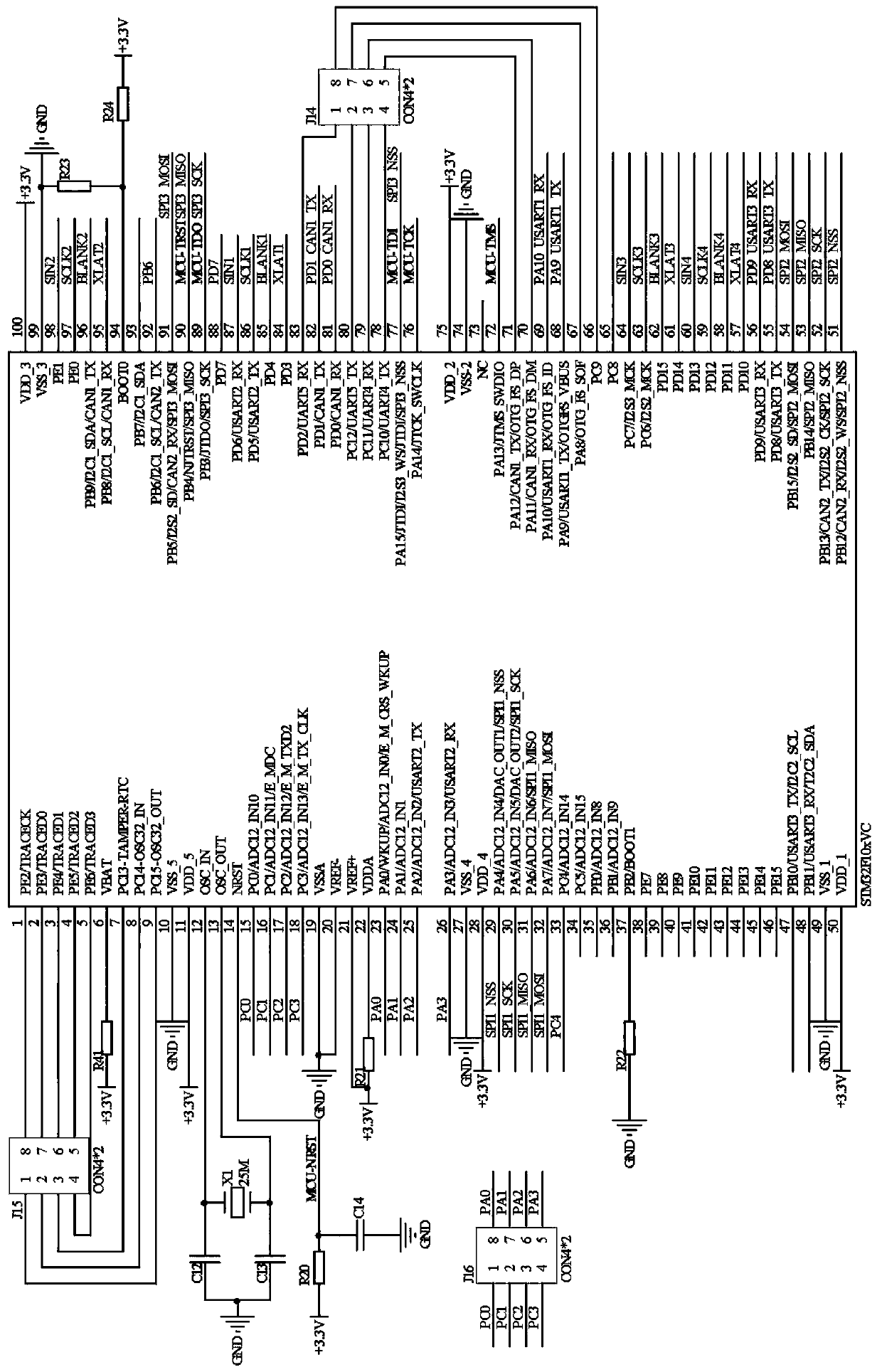

Universal point lamp box

PendingCN109757011AVersatileEasy to adjust and implementElectrical apparatusElectroluminescent light sourcesLinear driveElectricity

The invention relates to the technical field of an automobile signal device, and discloses a universal point lamp box. The universal point lamp box comprises a power module, a microcontrol unit and alinear driving module, wherein the power module is electrically connected with the microcontrol unit and the linear driving module, the microcontrol unit is further electrically connected with the linear driving module and is suitably used for receiving and storing control information of an upper computer and generating a time sequence signal for controlling the linear driving module to work according to the control information, the linear driving module comprises a plurality of linear passages and is suitably used for controlling on / off of each linear passage according to the time sequence signal so as to control on / off of a lamp electrically connected with each linear passage in the lamp and achieve a special animation effect of the lamp. The universal point lamp box can be used for turning on various animation lamps or time sequent lamps and achieving and debugging various animation effects, the debugging cost can be reduced, the fabrication period is shortened, and the satisfactionof a client is favorably enhanced.

Owner:HASCO VISION TECHNOLOGY CO LTD

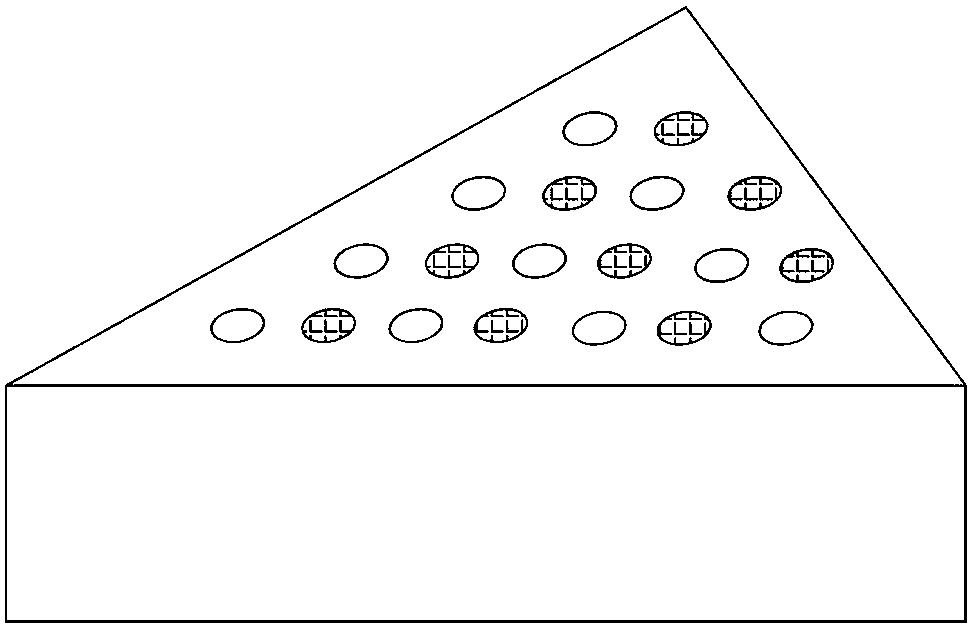

Novel efficient composite heat accumulator and preparation method thereof

PendingCN114184073AIncrease filling volumeImprove heat storage efficiencyHeat storage plantsHeat exchange apparatusCarbide siliconComposite ceramic

The invention relates to the technical field of heat accumulators, in particular to a novel efficient composite heat accumulator and a preparation method thereof. The novel efficient composite heat accumulator comprises a silicon carbide multiphase ceramic matrix, holes are formed in the silicon carbide multiphase ceramic matrix, part of the holes are filled with phase change materials, the two ends of the holes filled with the phase change materials are sealed through hole packaging pieces in a hot melting mode, and the phase change materials are filled with the phase change materials. And the holes which are not filled with the phase change material form heat conduction holes which penetrate through the silicon carbide-based multiphase ceramic matrix structure. According to the novel efficient composite heat accumulator, sensible heat accumulation of the silicon carbide composite ceramic matrix and latent heat accumulation of the phase-change material are organically combined, the purposes of improving the heat accumulation efficiency and optimizing the heat accumulation process are achieved, and compared with an existing sodium chloride silicon carbide heat accumulator, on one hand, the filling amount of the phase-change material can be increased; on the other hand, the manufacturing process can be simplified, the manufacturing cost can be reduced, and the manufacturing period can be shortened.

Owner:天津水务集团华淼规划勘测设计研究院有限公司

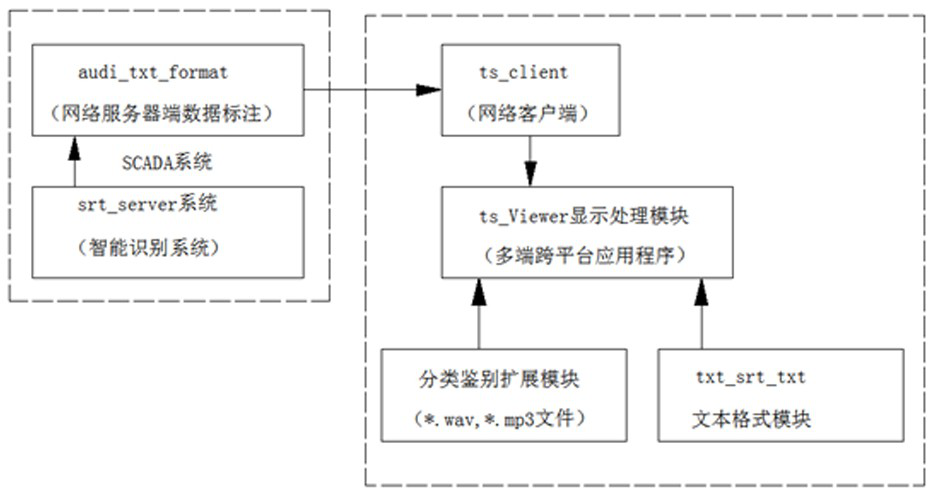

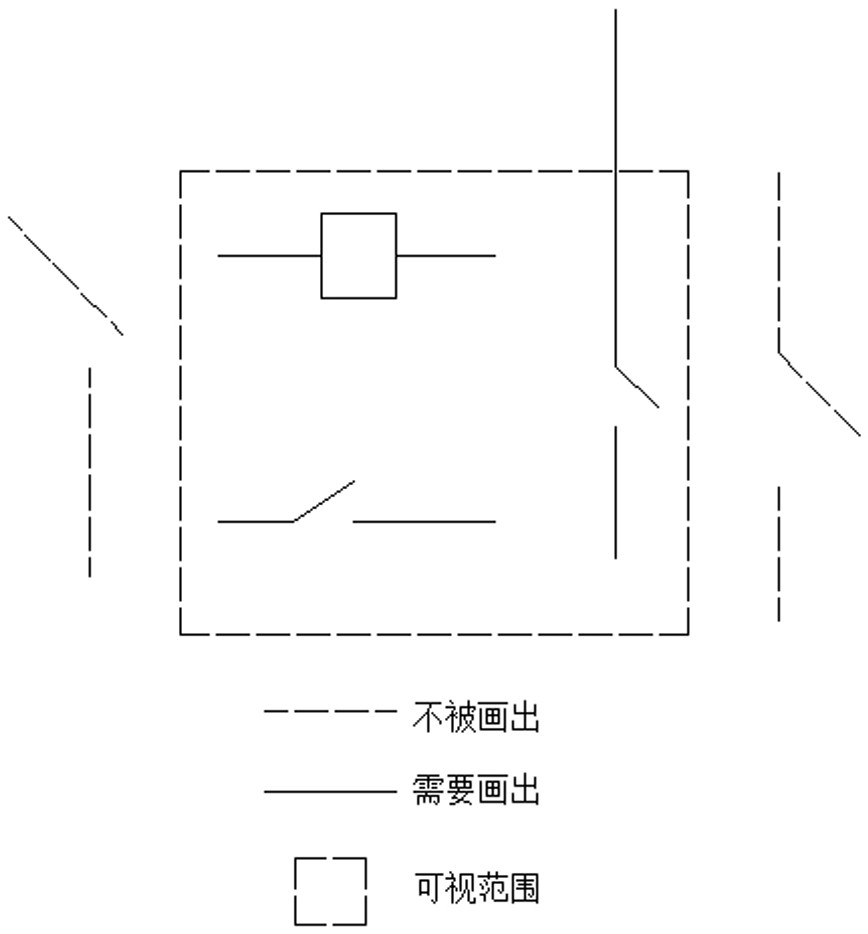

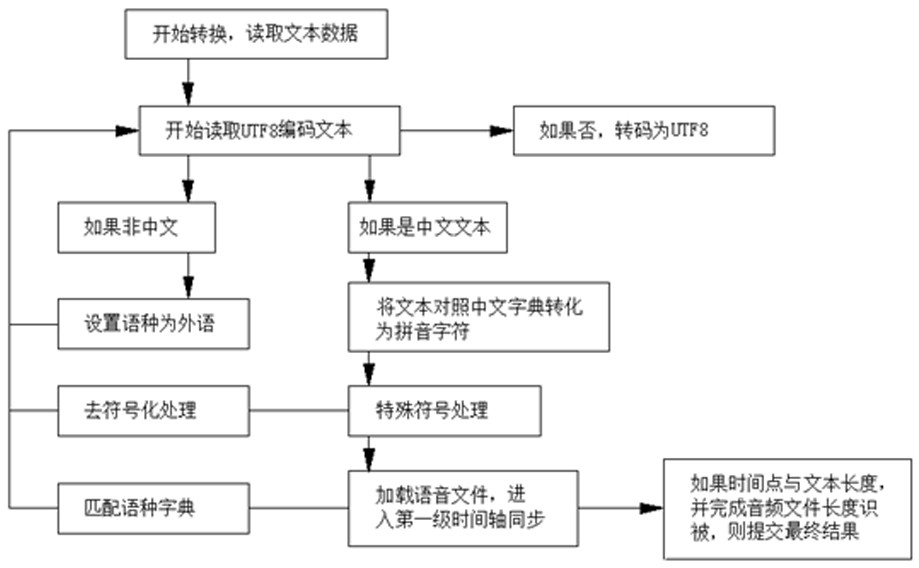

Intelligent film and television work subtitle production method and system

PendingCN113329192ASpeed up the production cycleFully reflect the nature of workTelevision system detailsColor television detailsEngineeringLarge screen

The invention provides an intelligent film and television work subtitle production method and system, and the method comprises the following steps: (S1) data collection: a network server srt_server is connected with a ts database of a production order system, and collects file state data of a production auto_ts intelligent production system; (S2) data storage: a network client ts_client is connected with a network server Ex_ts, receives real-time data sent by the network server Ex_ts and locally stores the data; and (S3) data processing: a Power_ts intelligent production management control end receives a system data change message notification, and a system administrator carries out next processing on order arrangement. According to the method, the terminal subtitle making period of the film and television industry is greatly shortened, the latest artificial intelligence solution is introduced into the film and television production, historical data can be analyzed from an original traditional post-production system, and is displayed on a large screen, a webpage a mobile phone and the like in a graph or table form to be displayed, analyzed and shared by clients, and provides a rich mining space for imagination.

Owner:在身边(北京)广告技术有限公司

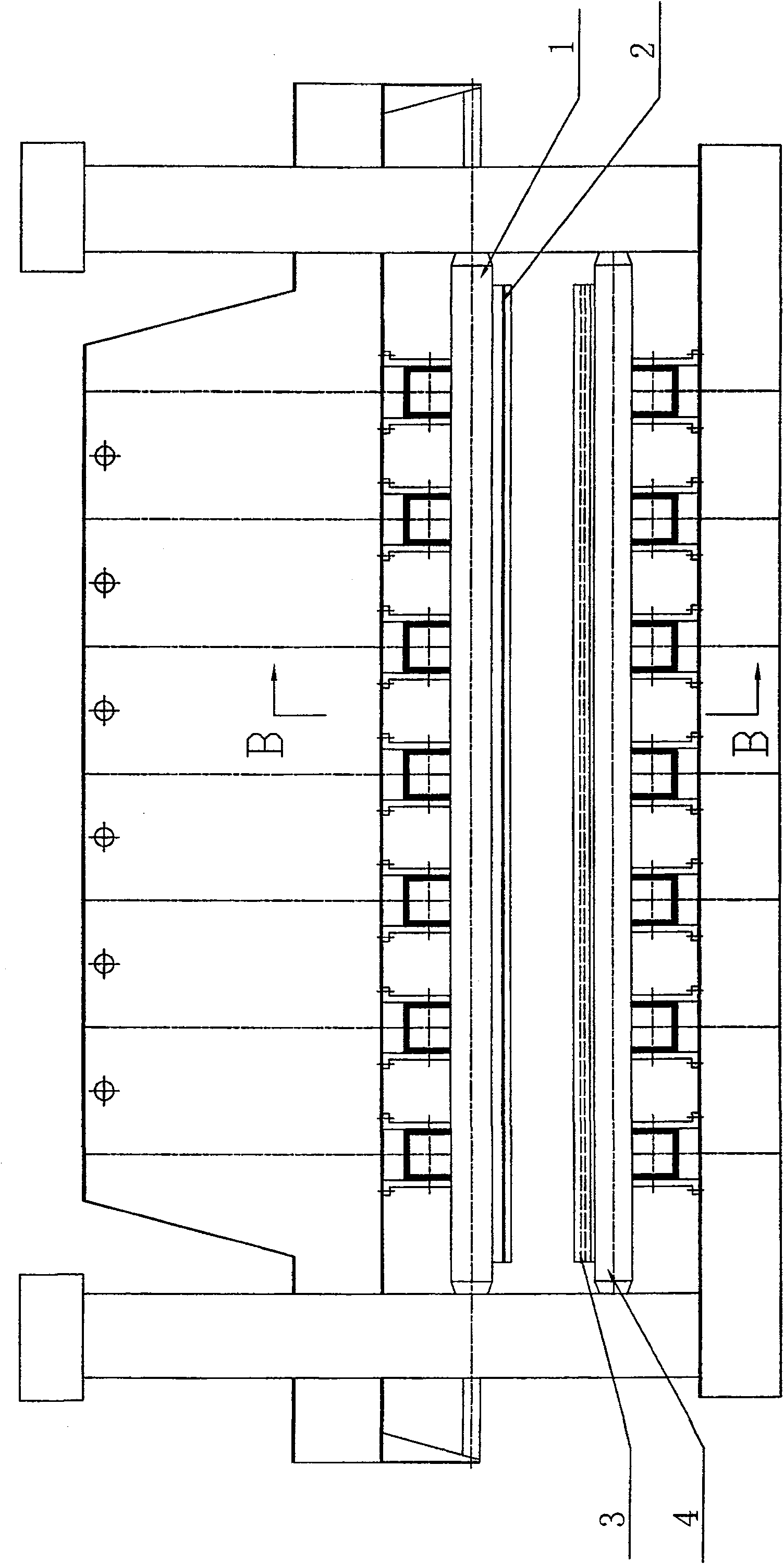

A Variety Expansion Tube Positioning Tool and Its Working Method and Application

ActiveCN104841784BReduce investmentSpeed up the production cycleMetal-working feeding devicesHeat exchange apparatusStructural engineeringHorizontal and vertical

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

A composite thermal storage body and its preparation method

ActiveCN105841536BSimple manufacturing processIncrease filling volumeHeat storage plantsCeramicwareLatent heat storageComposite ceramic

The invention discloses a composite heat retainer and a preparation method. The composite heat retainer comprises a silicon carbide-based composite ceramic base body and phase-change materials. The silicon carbide-based composite ceramic base body is in a regular geometrical shape and provided with holes. The phase-change materials are charged in parts of the holes. The two ends of each hole filled with the phase-change materials are subjected to hot melting sealing through sealing bodies. The holes which are not filled with the phase-change materials are heat conducting holes which are of communication structures. The preparation method comprises the steps of silicon carbide-based composite ceramic base body preparing, sealing body preparing, phase-change material charging and the like. The composite heat retainer can enable the quantity of the phase-change materials contained by the silicon carbide-based composite ceramic base body to be easy to control; and in the heat storage process, sensible heat storage of the silicon carbide-based composite ceramic base body and latent heat storage of the phase-change materials are organically combined, so that the purposes of improving the heat storage efficiency and optimizing the heat storage process are achieved. The preparation method is capable of simplifying the manufacturing process, reducing the manufacturing cost and accelerating the manufacturing period.

Owner:沧州渤海新区元大自然能源有限公司

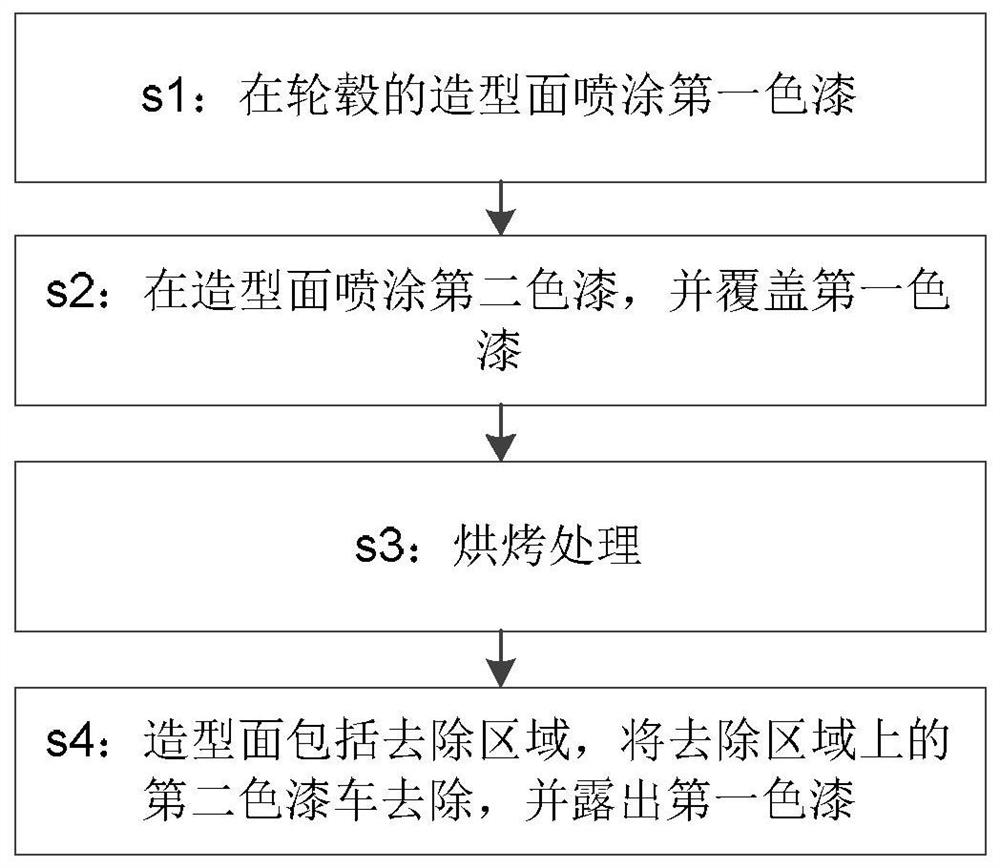

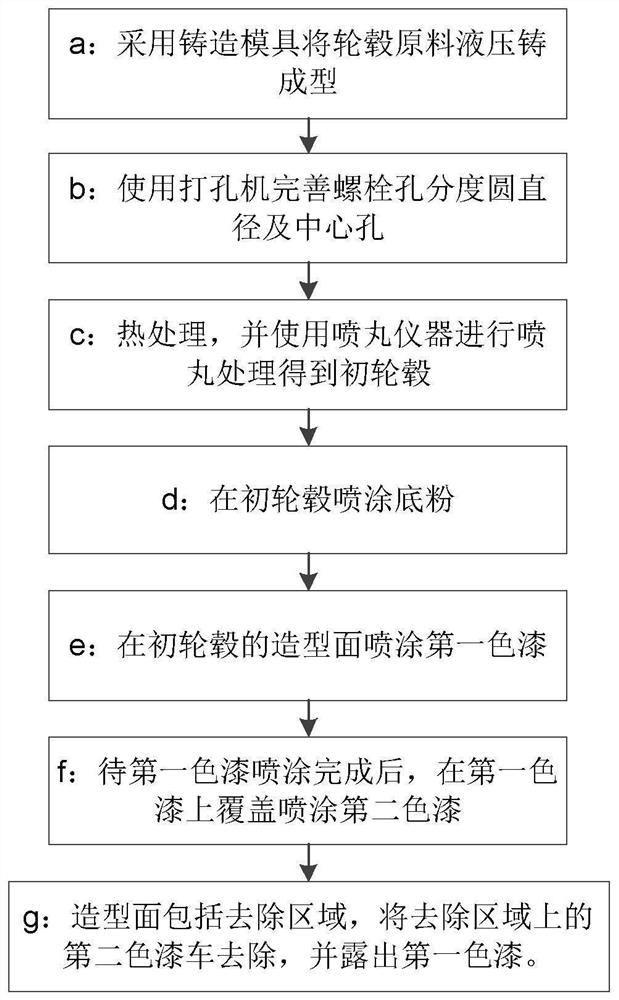

Hub color over-coating method, and manufacture method for hub

InactiveCN111644359AExempt from developmentLow costSpecial surfacesCoatingsStructural engineeringMechanical engineering

The invention provides a hub color over-coating method which comprises the steps that (S1) a shaping face of a hub is sprayed and coated with a first color paint; (s2) the shaping face is sprayed andcoated with a second color paint which covers the first color paint; (s3) baking treatment is carried out; and (s4) the shaping face comprises a removal area, the second color paint on the removal area is removed, and the first color paint is exposed. The solution has the beneficial effects that development of a spraying protection tool is omitted; cost is saved; a manufacture cycle is increased;a border line at a border of two colors is distinct; the method is particularly applicable to color over-coating processing of a special car type which has a plane capable of finish turning; and the solution not only can realize color over-coating of an edge plane of the hub, but can also realize color over-coating of a spoke. The invention also provides a manufacture method for the hub.

Owner:摩登汽车有限公司

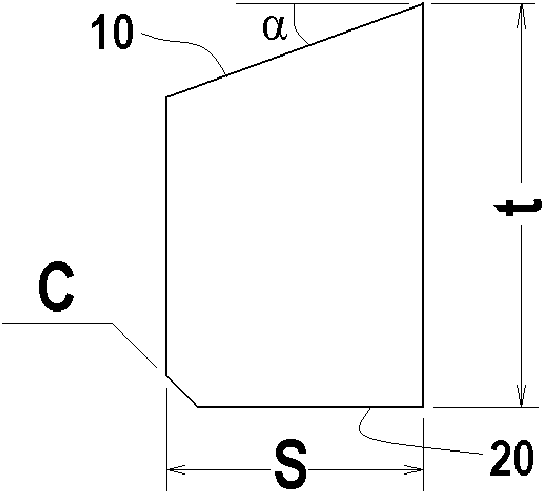

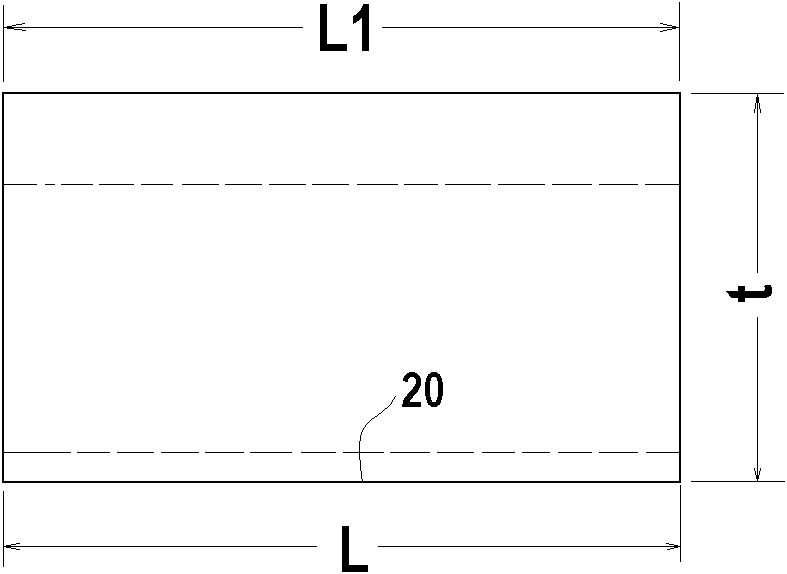

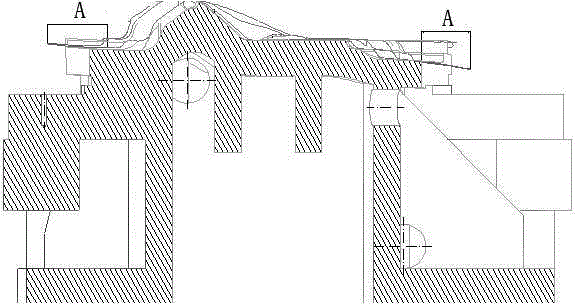

Stamping die and stamping method for hard metal alloy cutting blades

The invention relates to a stamping die for hard metal alloy cutting blades. The stamping die is characterized in that a die hole (3) is rectangular, the longitudinal size of the die hole (3) corresponds to the length (L) of a blank (50), the transversal size corresponds to the thickness (S) of the blank (50), and the stamping height corresponds to the width (t) of the blank (50); a working surface (10) of the blank (50) is formed upwards; the cross section of the die hole (3) is constant; the lower surface of an upper stamping head (101) of an upper die (100) is an inclined surface capable of being tightly attached to the working surface (10), and the cross section of a chamfered bulge corresponds to the blank (50) is arranged on the upper surface of a lower stamping head (201) of a lower die (200). According to the stamping die provided by the invention, the primary percent of pass of products is improved; the unit weight of a manufactured qualified product is 0.5-2g lighter than that of the product of the prior art, therefore a great amount of resources can be saved; and the manufacturing cycle of the dies is accelerated, the processing cost of the dies is reduced, and the production efficiency is improved.

Owner:江西江钨硬质合金有限公司

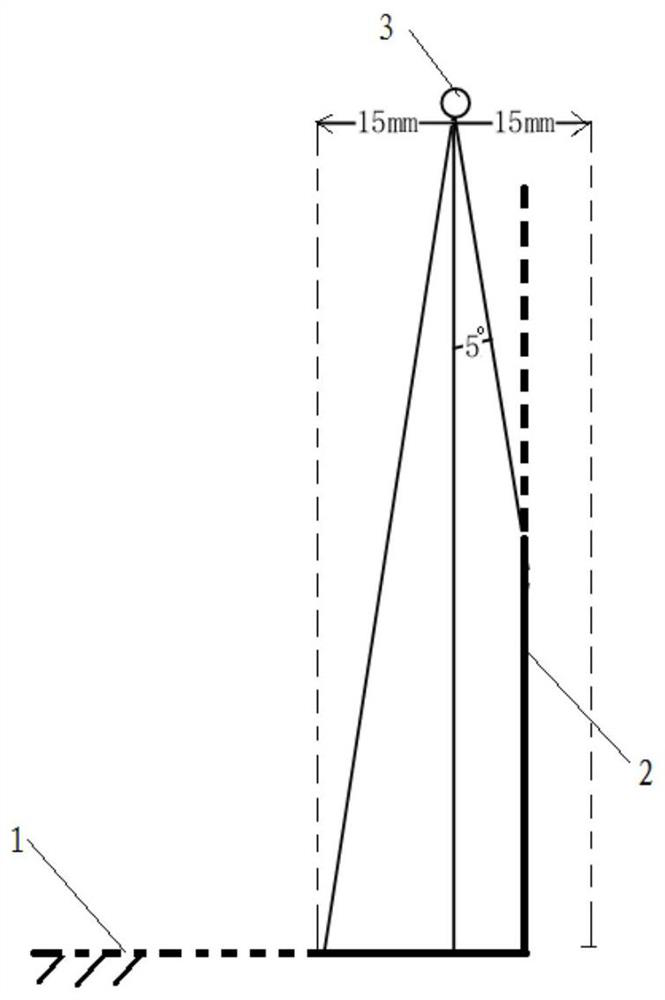

A kind of processing method of server, server chassis and server chassis

ActiveCN111880620BReduce manufacturing costSpeed up the production cycleDigital processing power distributionMechanical engineeringServer

The invention discloses a server, a server case and a processing method for the server case. The server case includes a shell with a bottom plate and a rear window, and components are arranged in the shell, and the components are directed toward the bottom plate and have a preset expansion angle. In the PIS flame area, the rear window is provided with a shield, which is used to shield the PIS flame area, so that the rear window has a shielding part that is not in the PIS flame area; the shielding part is provided with a first cooling hole, and the PIS flame area of the bottom plate A second heat dissipation hole is arranged inside, and the first heat dissipation hole is larger than the second heat dissipation hole. In the present invention, a cover is provided on the rear window, so that the covered part does not belong to the projection range of the PIS flame area. Due to the setting of the cover, the heat dissipation holes on the rear window can maintain the original large-diameter holes, and meet the new standard. Under certain circumstances, the change of the opening size is reduced, the original mold can be continued to be used, and the manufacturing cost of the server chassis is reduced.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Device for machining lacquer painting wood base

InactiveCN106427359ASpeed up the production cycleImprove molding efficiencyDecorative surface effectsSpecial ornamental structuresLacquerMechanical engineering

The invention discloses a device for machining a lacquer painting wood base. The device comprises a working rack and a bracket and is characterized in that the bottom of the working rack is connected with the bracket; the working rack is a rectangular hollowed-out frame; a hopper is arranged on one side above the working rack; a hand scraper is arranged on the other side of the top surface of the working rack; the long sides of the interior of the working rack are each provided with a plurality of lifting guide rods; a transverse guide rod is arranged on the lifting guide rods located on the same side; the two sides of the hopper are connected with a hopper bracket; the two ends of the hand scraper are connected with a scraper bracket; the bottom surface of the scraper bracket is connected with the top surface of the working rack; and the transverse guide rods can longitudinally move on the lifting guide rods. The device for machining the lacquer painting wood base has the advantages of being convenient to operate, safe, reliable, capable of reducing the manual manufacturing cost, shortening the lacquer painting manufacturing period and improving the wood base forming efficiency and the like.

Owner:哈尔滨漆艺之星科技发展有限公司

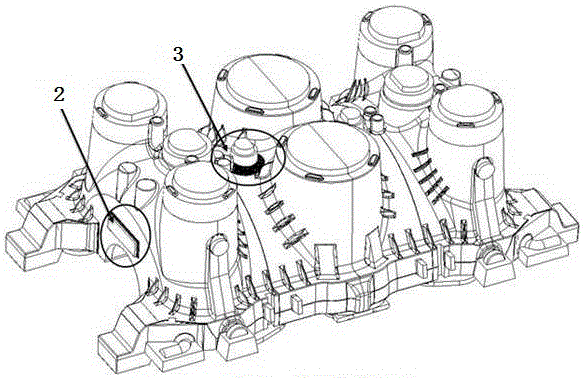

Manufacturing method of mold for car axles

InactiveCN106584041ASpeed up the production cycleReduce the difficulty of productionFoundry mouldsFoundry coresSilicon disulfideAluminium alloy

The invention discloses a manufacturing method of a mold for car axles. The method comprises following steps: drawing a three-dimensional CAD model based on a casting technology map of axle castings and making a resin prototype through rapid prototyping equipment; rolling over the manufactured resin prototype by a normal-temperature silicon sulfide rubber mold to rapidly obtain a mold cavity for manufacturing of the resin casting mold; providing a flat aluminum alloy plate workpiece as an aluminum alloy matrix, melting the flat aluminum alloy plate workpiece and enabling the melted alloy liquid to flow through the mold cavity; cooling the alloy liquid in the flat cavity to obtain the aluminum alloy matrix; and drilling a taper hole in the aluminum alloy matrix. The manufacturing method of the mold for car axles has following beneficial effects: the manufacture period of the mold for the car axles is effectively prolonged; and manufacturing difficulty is reduced.

Owner:JIANGSU YUYAN MOLDING CO LTD

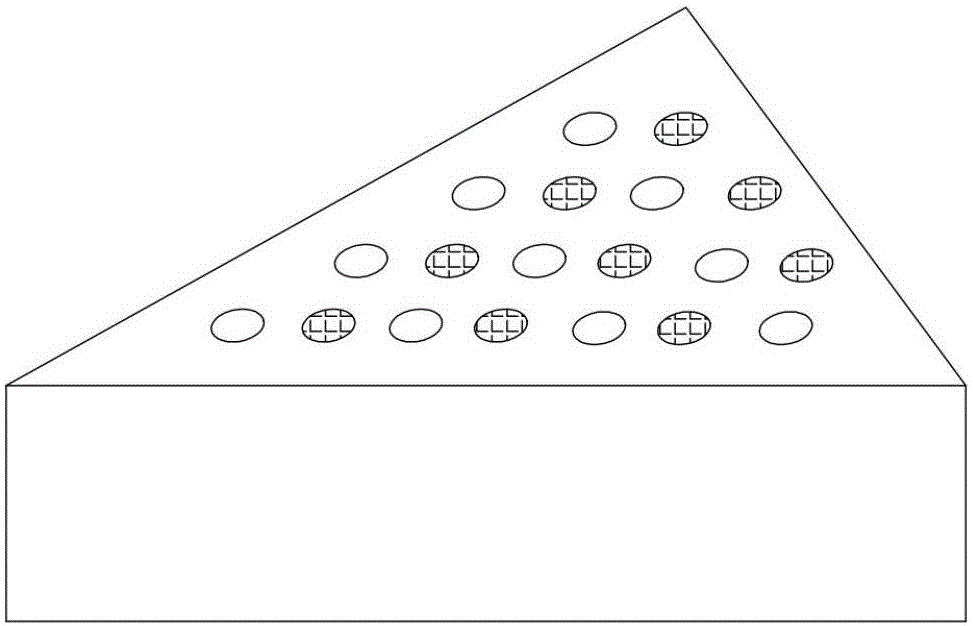

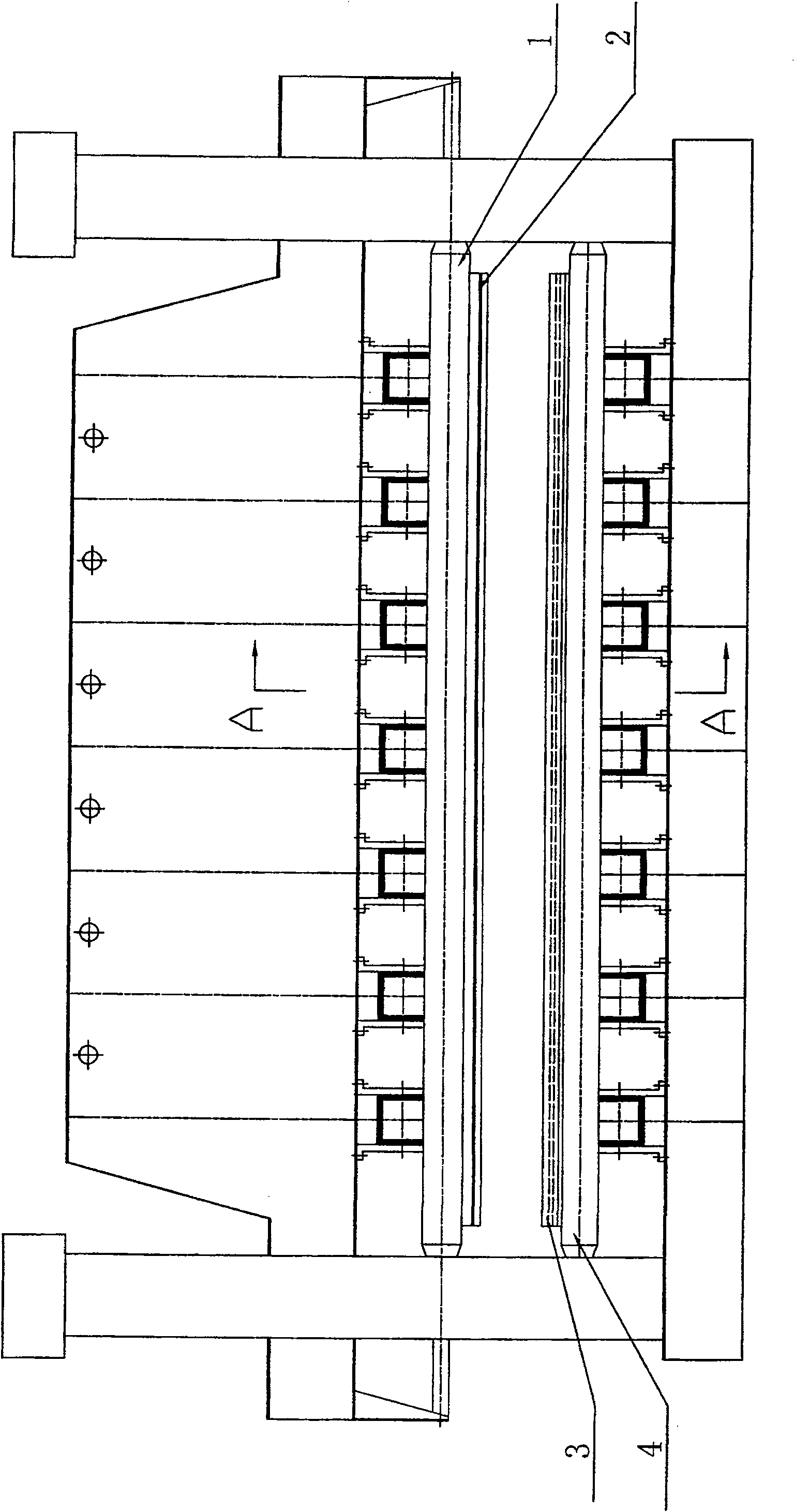

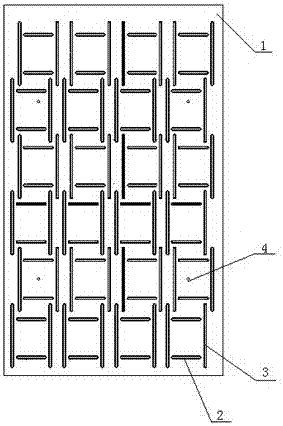

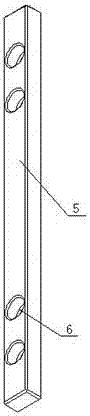

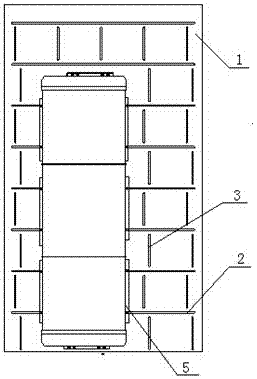

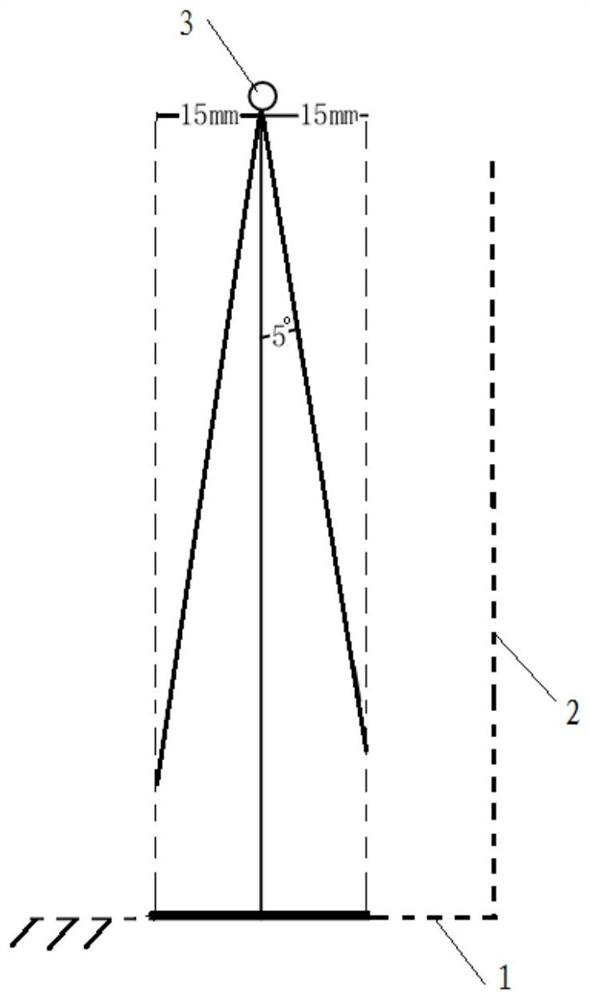

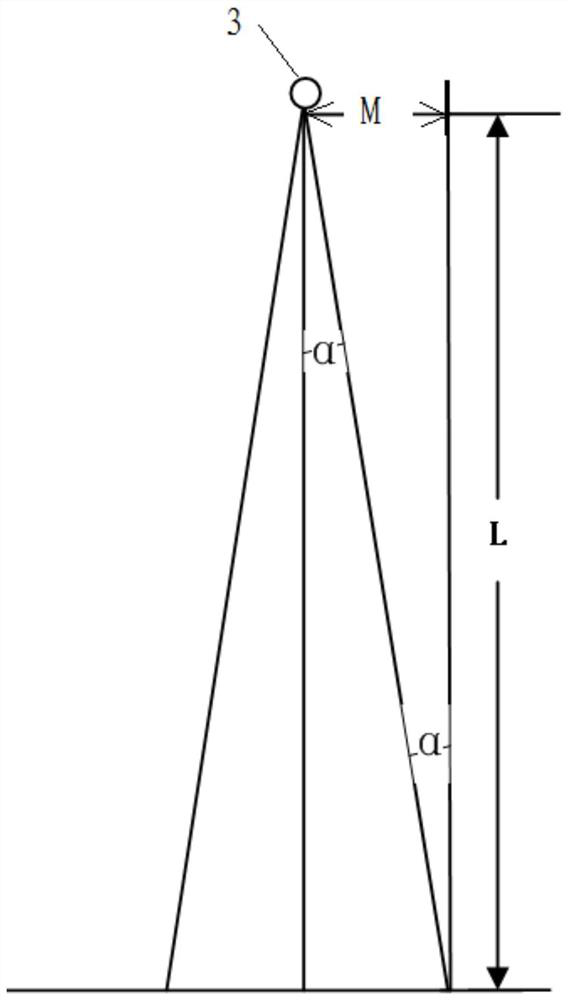

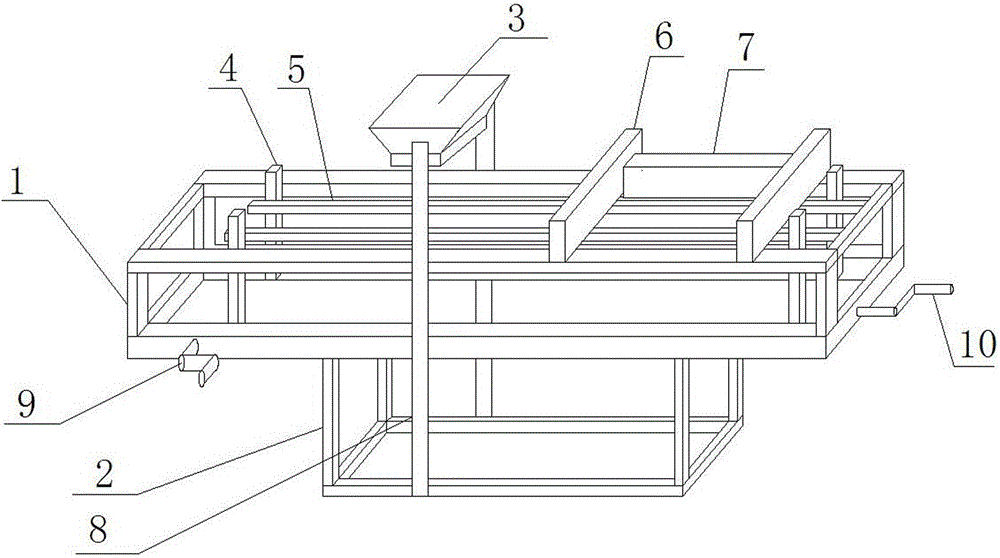

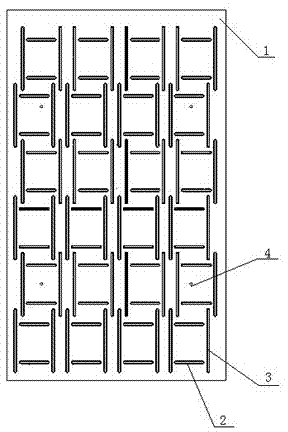

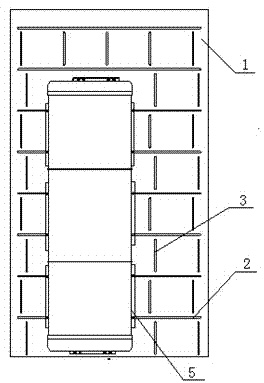

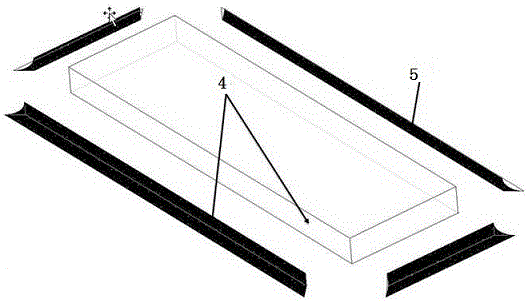

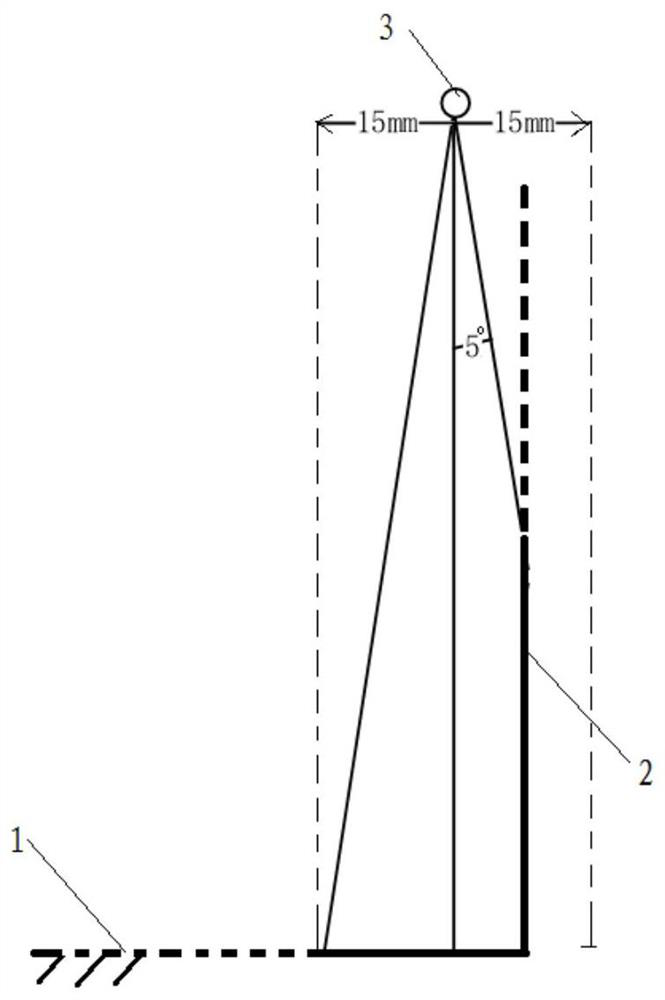

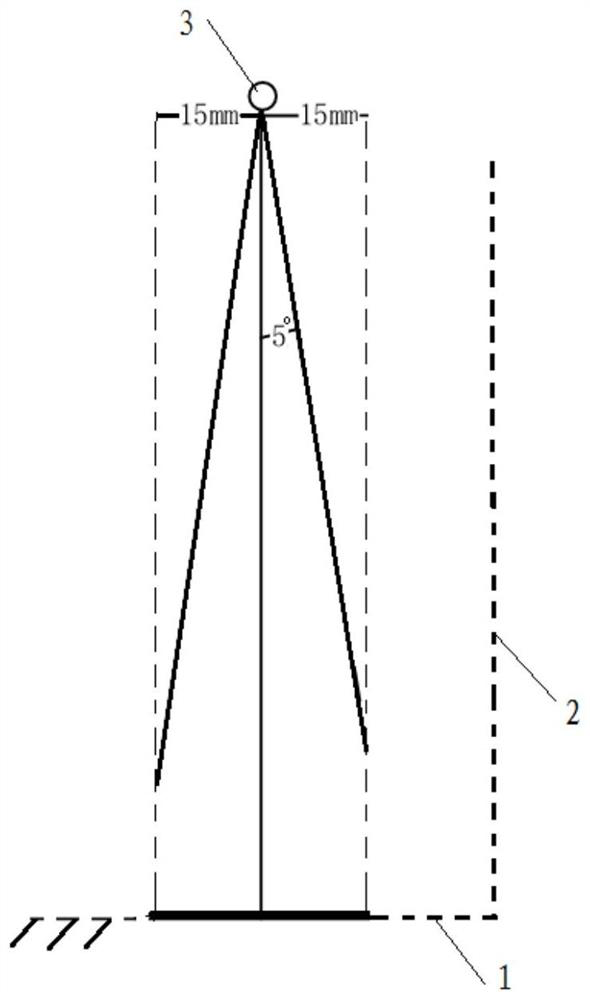

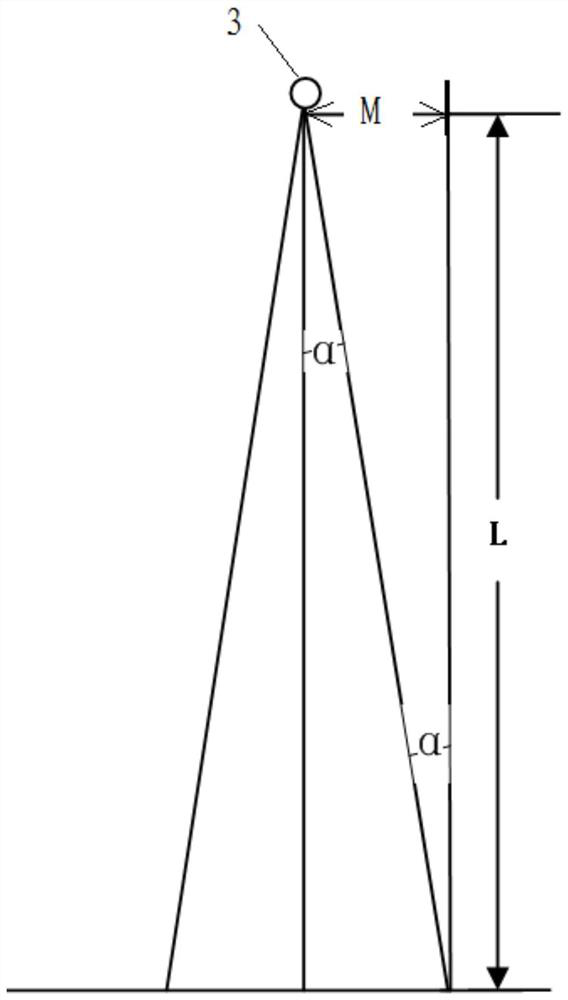

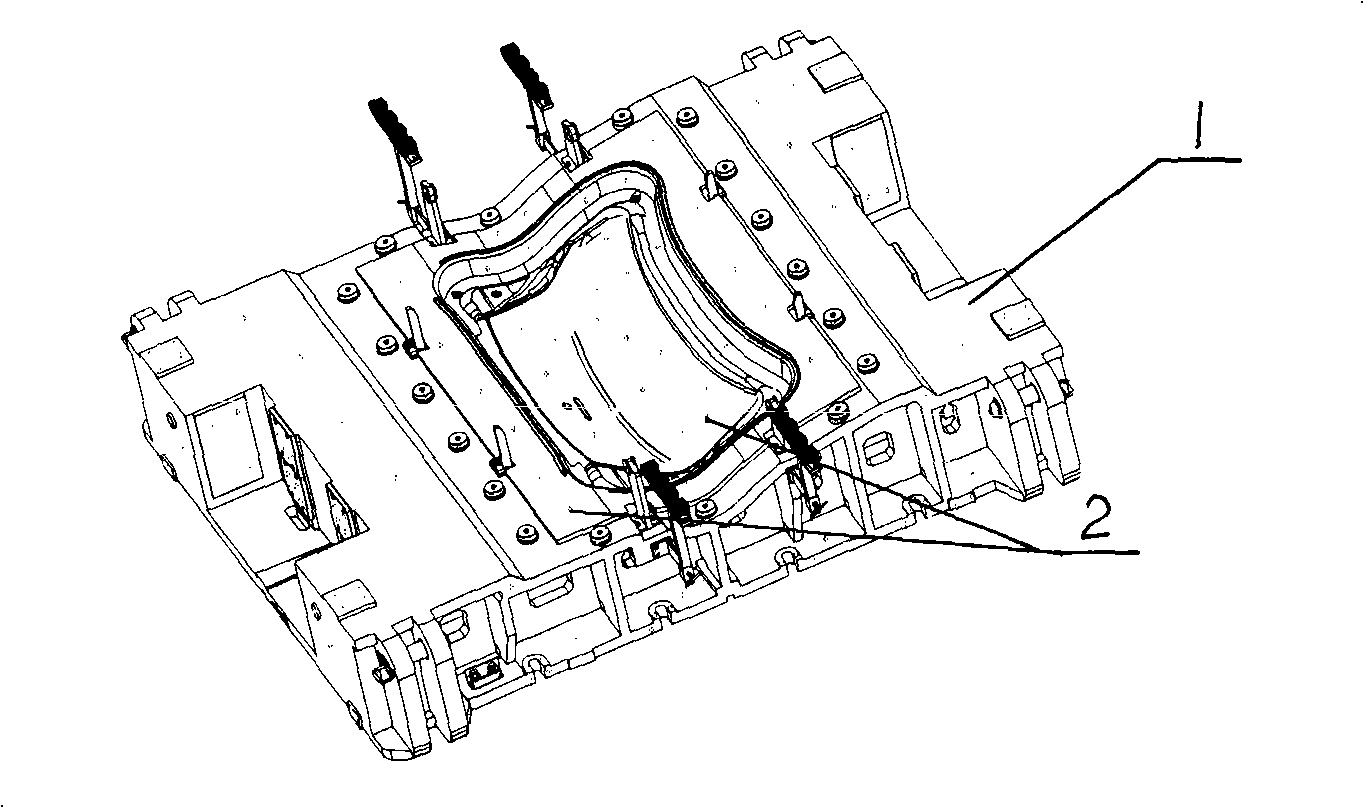

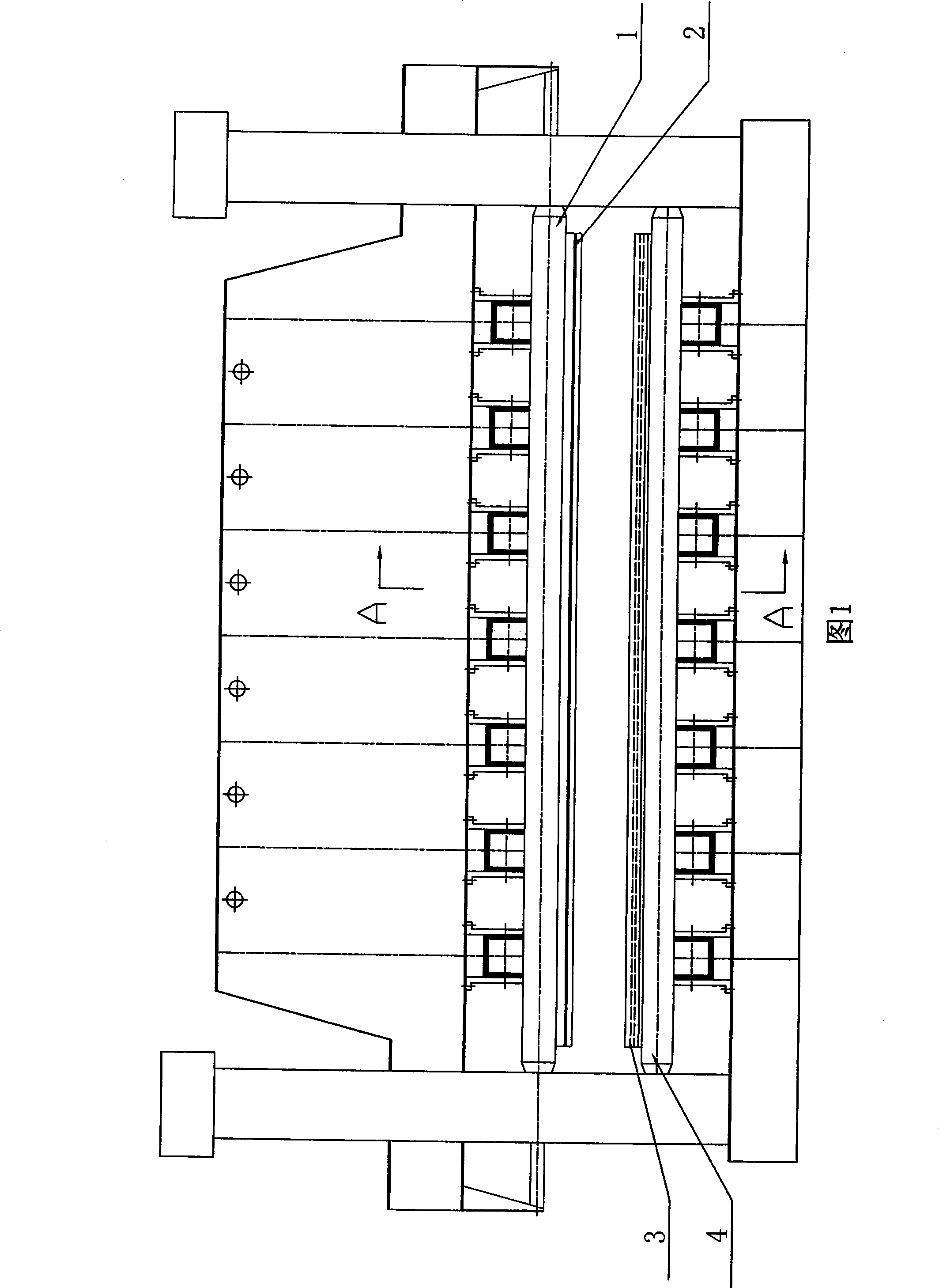

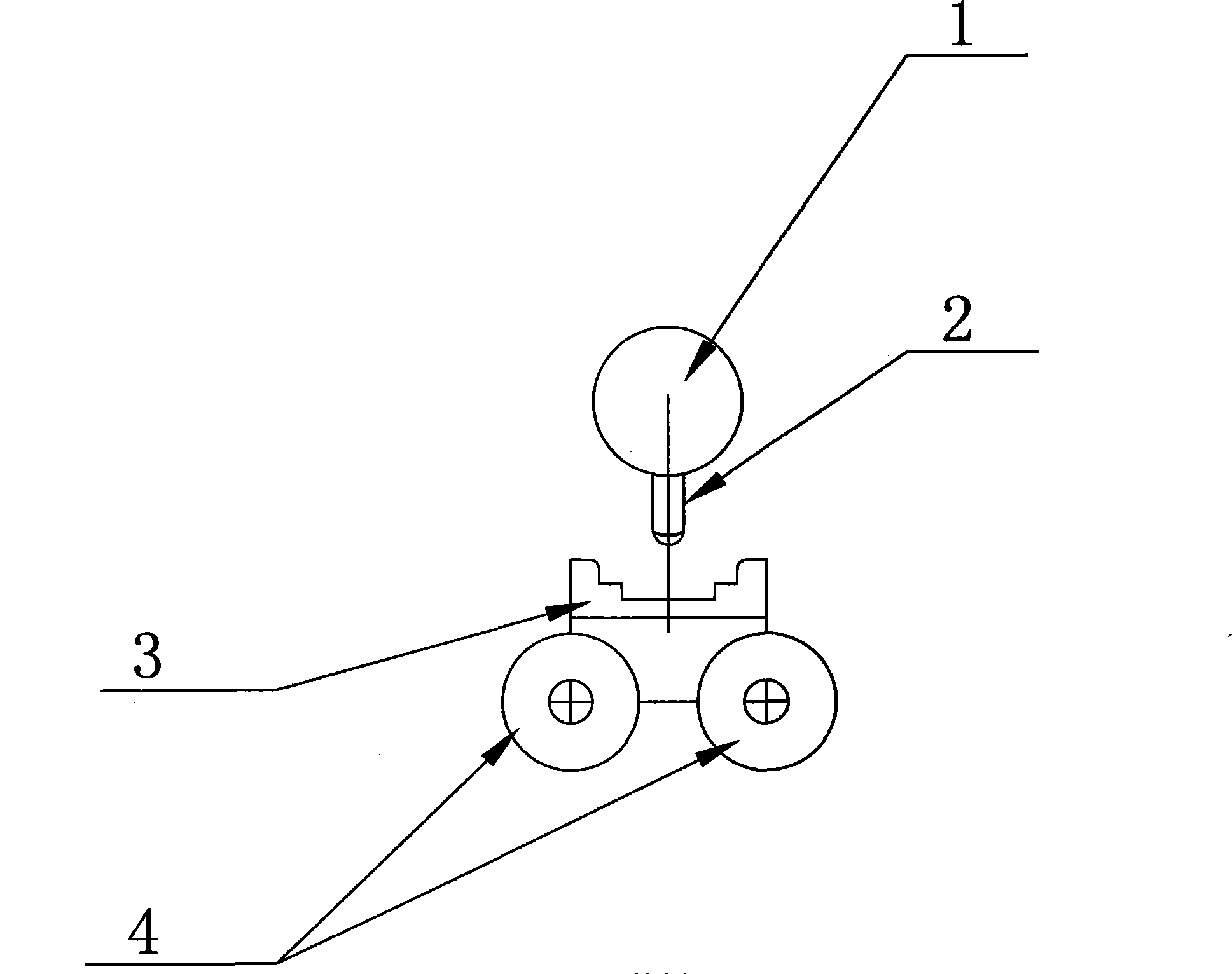

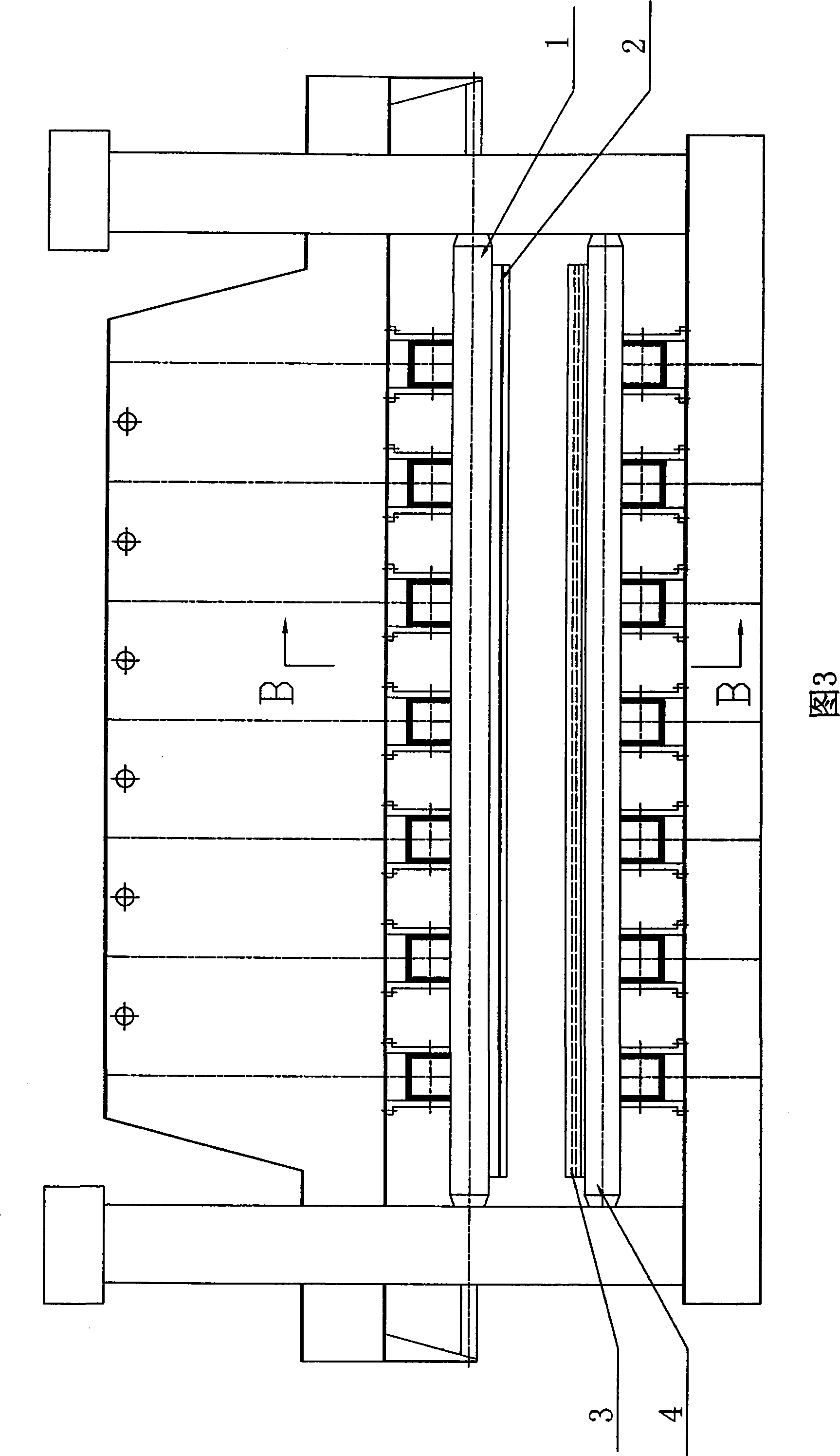

Variable expansion tube positioning tool, and working method and application thereof

ActiveCN104841784AReduce investmentSpeed up the production cycleMetal-working feeding devicesHeat exchange apparatusStructural engineeringHorizontal and vertical

The invention discloses a variable expansion tube positioning tool comprising an expansion tube positioning tool plate. The expansion tube positioning tool plate is fixedly connected to a workbench. A plurality of parallel horizontal positioning strips and a plurality of parallel vertical positioning strips are arranged on the expansion tube positioning tool plate in the horizontal and vertical directions respectively. Workpieces as required are clamped on the expansion tube positioning tool plate through fixing clamp strips according to length and width requirements of the workpieces. Positioning holes are formed in the fixing clamp strips, and bolts are penetrated the positioning holes and the horizontal positioning strips or the vertical positioning strips to cooperate with nuts to fix the fixing clamp strips to the expansion tube positioning tool plate. The variable expansion tube positioning tool is simple and convenient and applicable to positioning of all heat exchanger expansion tubes, tool input of enterprises is reduced, and production cycle of heat exchangers is accelerated to achieve competitive advantages of the heat exchanger industry.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

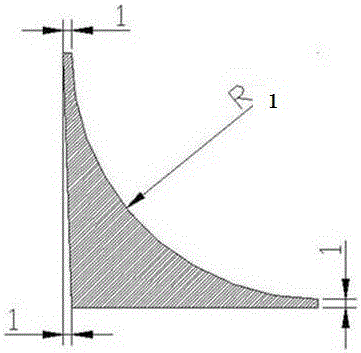

Using method for mold fillet

InactiveCN106738508ASpeed up the production cycleImprove production efficiencyRubber materialToughness

On account of the problems in the prior art, the invention provides a manufacturing technological method for a mold fillet. According to the manufacturing technological method for the mold fillet, rubber materials serving as sectional materials are used for replacing existing resin and putty materials, so that the manufacturing efficiency of the mold fillet is improved, the toughness of the fillet is improved, and the fillet is prevented from being damaged in the using process. The mold fillet need not be polished, and thus pollution to the workshop environment is reduced. Assembling time is shortened, the efficiency of a mold assembling procedure is improved, mold damage is reduced, damage to the mold movable material fillet is reduced, mold quality is improved, and large-scale application prospects are prominent.

Owner:NINGXIA KOCEL MOLD

A kind of manufacturing method of resin plug hole circuit board

ActiveCN106973507BShort manufacturing cycleSpeed up the production cyclePrinted circuit aspectsPrinted element electric connection formationEngineeringRejection rate

The invention discloses a manufacturing method of a resin plug-hole circuit board. The method comprises following steps of drilling through holes in a production board subjected to early-stage press fitting, wherein the through holes comprise holes to be filled with resin, holes to be metalized and non-metalized holes; metalizing the holes to be filled with resin and the holes to be metalized through copper deposition and full-board electroplating working procedures; filling the metalized holes to be filled with resin with resin; using a sand belt to grind plug-holes and removing resin protruding from the board face; manufacturing mask hole graphs on the production board and etching to reduce parts of thickness of copper faces which are not at the holes; retreating films and using the sand belt to grind the reduced copper faces and removing resin protruding from the board faces carrying out secondary copper deposition and full-board electroplating working procedures on the production board; and successively manufacturing an outer layer circuit, a welding resisting layer and silkscreen characters and carrying out surface treatment to manufacture the circuit board. According to the invention, drilling frequency is reduced; manufacturing processes are simplified; production efficiency of the circuit board is improved; and the rejection rate and the production cost are reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for designing post-process die profile machining data by draw piece scanning result

InactiveCN103143633BSpeed up the production cycleReduce manufacturing costProgramme controlShaping toolsPoint cloudEngineering

The invention relates to a method for designing post-process die profile machining data by a draw piece scanning result. The method is characterized by comprising the steps as follows: carrying out white light scanning (photographing) on draw pieces by non-contact type ATOS optical scanning equipment developed by a German GOM company, ending the scanning operation, and calculating the scanning result in a system of the ATOS optical scanning equipment to obtain triangular patch point cloud data; and debugging a drawing die until the drawing die is qualified, making a first trimming die, scanning the qualified draw pieces to generate point cloud data, reversing machining data profiles in Geomagic studio 11 software by utilizing the scanning point cloud data as the theory basis, and converting the machining data profiles of the first trimming die on the basis of the reversed profiles. According to the method, the qualified draw pieces are scanned to generate the point cloud data, the profiles of the draw pieces are reversed in the software by utilizing the scanning point cloud data as the theory basis, and the machining data profiles of the first trimming die after the drawing process are converted on the basis of the reversed profiles.

Owner:CHINA FIRST AUTOMOBILE +1

Server, server case and processing method of server case

ActiveCN111880620AReduce manufacturing costSpeed up the production cycleDigital processing power distributionEngineeringMechanical engineering

The invention discloses a server, a server case and a processing method of the server case. The server case comprises a shell with a bottom plate and a rear window; a component is arranged in the shell, the component is provided with a PIS flame area which faces the bottom plate and has a preset divergence angle; the rear window is provided with a shielding part, and the shielding part is used forshielding the PIS flame area, so that the rear window is provided with a shielding part which is not located in the PIS flame area; first heat dissipation holes are formed in the shielding part, second heat dissipation holes are formed in the PIS flame area of the bottom plate, and the first heat dissipation holes are larger than the second heat dissipation holes. The shielding part is arranged on the rear window, so the shielding part does not belong to the projection range of a PIS flame area; due to the arrangement of the shielding part, part of heat dissipation holes in the rear window can keep original large-diameter holes; under the condition that a new standard is met, the change of the hole forming size is reduced, an original mold can be continuously used, and the manufacturing cost of the server case is reduced.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

A kind of molding equipment and method of pulp molding

ActiveCN109736139BSpeed up the production cycleExtend the production cycleTextiles and paperMolded pulpProcess engineering

The invention discloses a molding equipment for pulp molding. According to the sequence of preparation of pulp molding products, it comprises: a slurry suction mold absorbs slurry from a pulp pool to form a wet embryo; an extrusion mold is arranged above the slurry suction mold, and After the slurry mold is reversed upwards with the wet embryo, it will be squeezed with the extrusion mold for the first time; the hot pressing upper mold can move up and down in the vertical direction; the hot pressing lower mold can move horizontally left and right. When the pressing mold is up and down, the wet embryo is hot-pressed; the hot-pressing upper mold is provided with an air suction structure, and the hot-pressing lower mold is provided with an air-blowing structure; the invention also discloses a pulp molding method , including slurry suction, extrusion, hot pressing, transfer, after the heating is completed, when the hot pressing upper mold and the hot pressing lower mold are separated, the formed molded product is absorbed and transferred by the hot pressing upper mold. The above-mentioned equipment and method reduce the equipment molding movement time and improve the cycle period for equipment to prepare molded products.

Owner:永发(江苏)模塑包装科技有限公司

Method for detecting optical photograph of large mold casting blank

InactiveCN101514891BAccurately determineImprove work efficiencyUsing optical meansNumerical controlData acquisition

The invention relates to a method for detecting an optical photograph of a large mold casting blank. The method is characterized in that a lug boss and a peripheral unfinished surface formed by a workpiece are subjected to bulge application; all processing molding surfaces are subjected to data acquisition; a system is established for acquired 3D points, and is compared with the prior theory three-dimensional design data; finally, a digital control processing alignment standard report is released. Under a report chart environment, each direction required in digital control processing is standardized, generally, display of the standard is required to be determined by trial cutting on a machine tool, and theoretical coordinate values, offset directions and dimensions of the coordinates are displayed to be used for digital control processing alignment and standard determination. The method accurately determines the digital control processing standard, reduces load of the machine tool and time for aligning the center by digital control equipment, and accelerates cycle of cast output. A digital control programming staff can reasonably program a digital control processing program through allowance deviation data, thereby improving effective operation time of the digital control machine tool, reducing consumption of cost, improving working efficiency of digital control processing while ensuring the quality of digital control processing, and accelerating the output cycle of cast blank.

Owner:CHINA FIRST AUTOMOBILE +1

Method and mold pressing tank-type bulkhead using three rollers rolling machine

InactiveCN101249536AReduce in quantityReduce workloadShaping toolsIndustrial engineeringOil pressure

The invention relates to a method for pressing corrugated bulkhead by using a three-roller bending machine in hull construction process and a mold. The method comprises the following steps of: arranging and mechanically fixing lower pressing molds equivalent to the effective work length of lower rollers on two lower rollers of the three-roller bending machine by utilizing the prior configuration of the three-roller bending machine and the effective work length of the roller; arranging and mechanically fixing upper pressing molds equivalent to the effective work length of upper rollers on single upper roller of the three-roller bending machine; setting the length of a slot-shaped component according to the pressing lengths of the upper and the lower molds; loading board material; driving the upper mold by the upper roller of the three-roller bending machine, which is used as a lengthened oil pressure machine, to press-mold the corrugated component by one step through the mutual restriction of the upper and the lower molds. The inventive method can lengthen the process length of the corrugated component by only one three-roller bending machine which is equipped with the special mold, thereby reducing the number of the components. With reduced process and joint workloads, increased production efficiency and improved process precision, the shipbuilding cost is lowed.

Owner:江苏新扬子造船有限公司

Virtual scene generation method and device, storage medium and electronic equipment

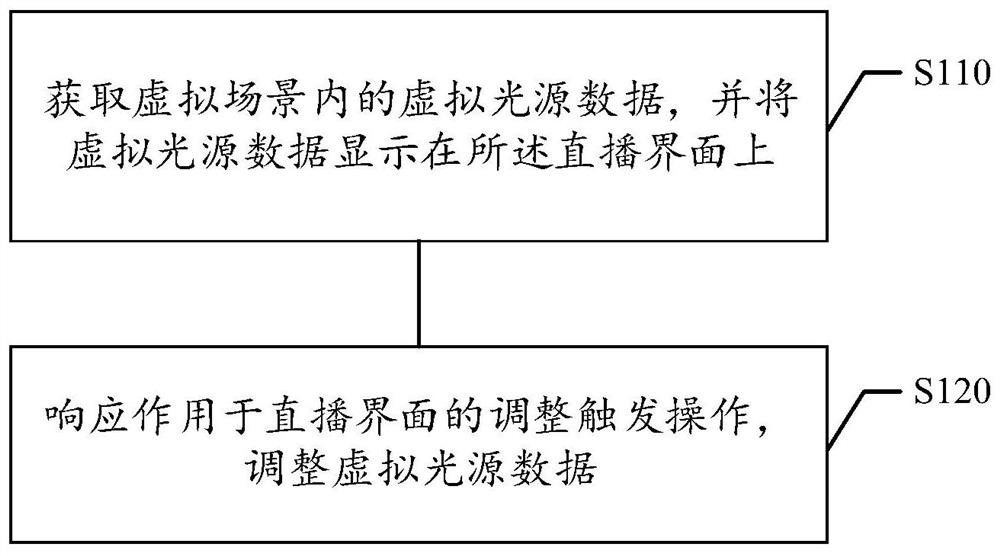

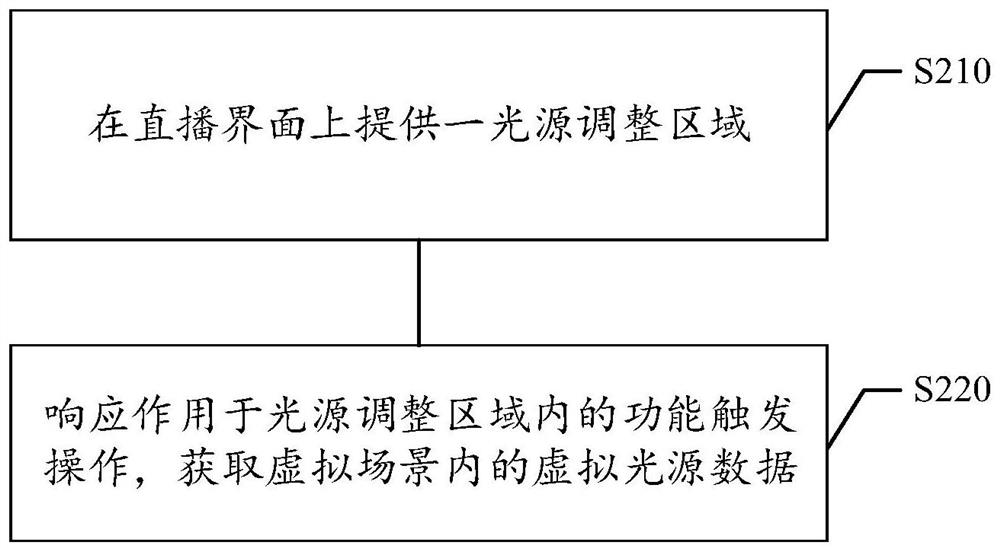

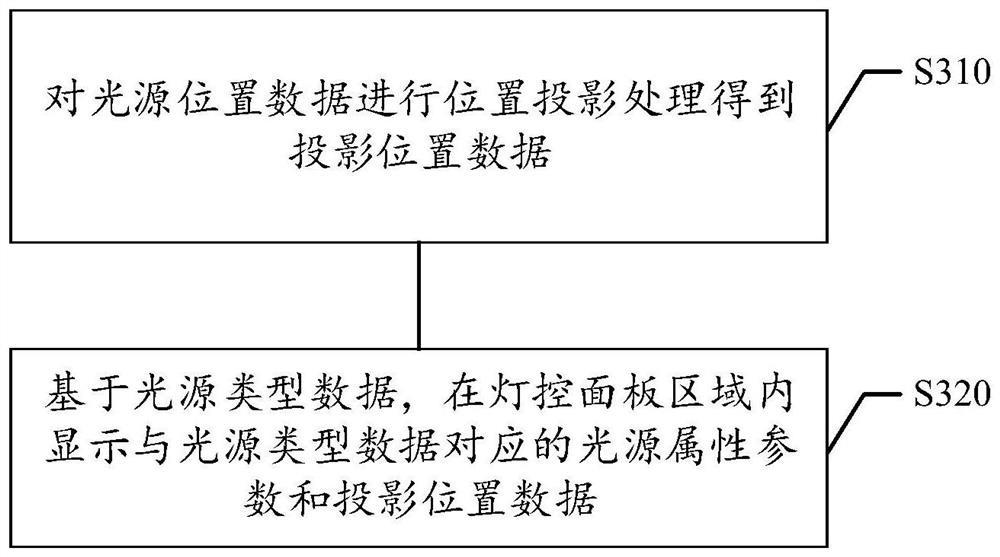

PendingCN113706719AHigh degree of automation and intelligenceSpeed up the production cycleInput/output for user-computer interactionImage data processingPersonalizationLight source

The invention belongs to the technical field of video live broadcast, and relates to a virtual scene generation method and device, a storage medium and electronic equipment. The method comprises the following steps: acquiring virtual light source data in a virtual scene, and displaying the virtual light source data on a live broadcast interface; and adjusting the virtual light source data in response to an adjustment triggering operation acting on the live broadcast interface. According to the invention, the virtual light source data is displayed on the live broadcast interface, the anchor end can view the light source data in the virtual scene, and a data basis is provided for autonomous interaction and personalized setting of the anchor end. Moreover, the virtual light source data in the virtual scene is adjusted according to the adjustment triggering operation, and the anchor interacts to change the lighting effect of the virtual scene, so that customization of the personalized live scene is completed, the automation and intelligence degrees are high, the generation period of the virtual scene is accelerated, the time cost and the labor cost for replacing the virtual scene are reduced, the demands of the user for freshness and diversification of the live broadcast scene are met, and the watching experience of audiences is optimized.

Owner:GUANGZHOU BOGUAN TELECOMM TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com