Plug-and-play intelligent testing device without connecting wire

A plug-and-play, test device technology, applied in the direction of measuring device, measuring device shell, measuring electricity, etc., can solve the problems of occupying a large work surface area, long introduction cycle of new products, and complicated production of test tooling. The effect of shortening the cycle, reducing the environment setup and debugging time, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

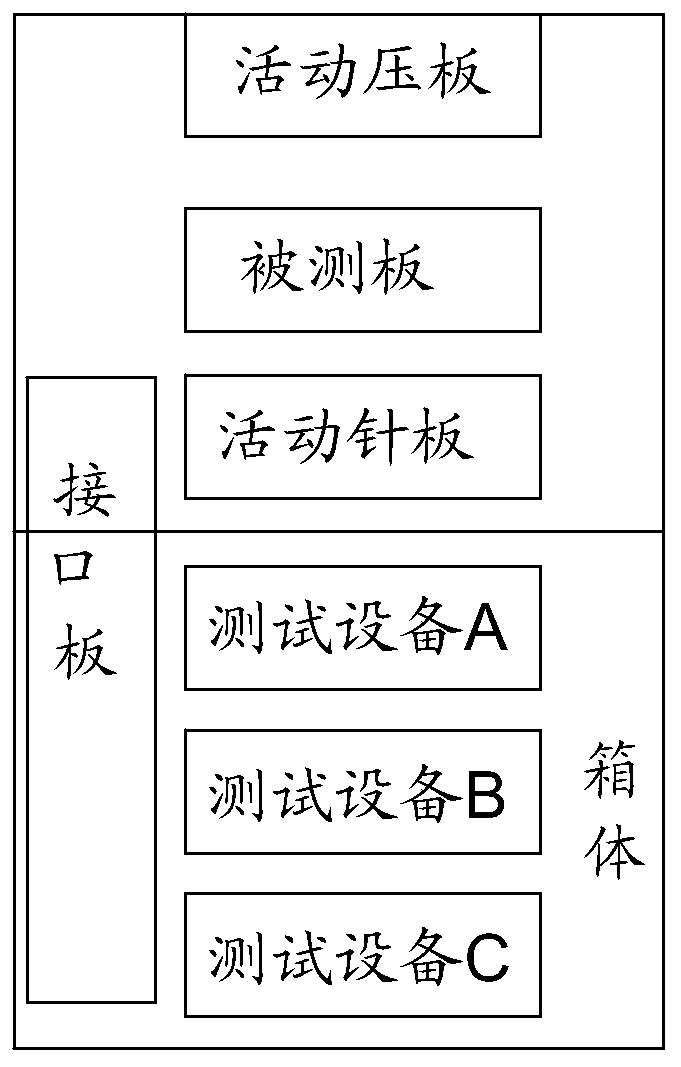

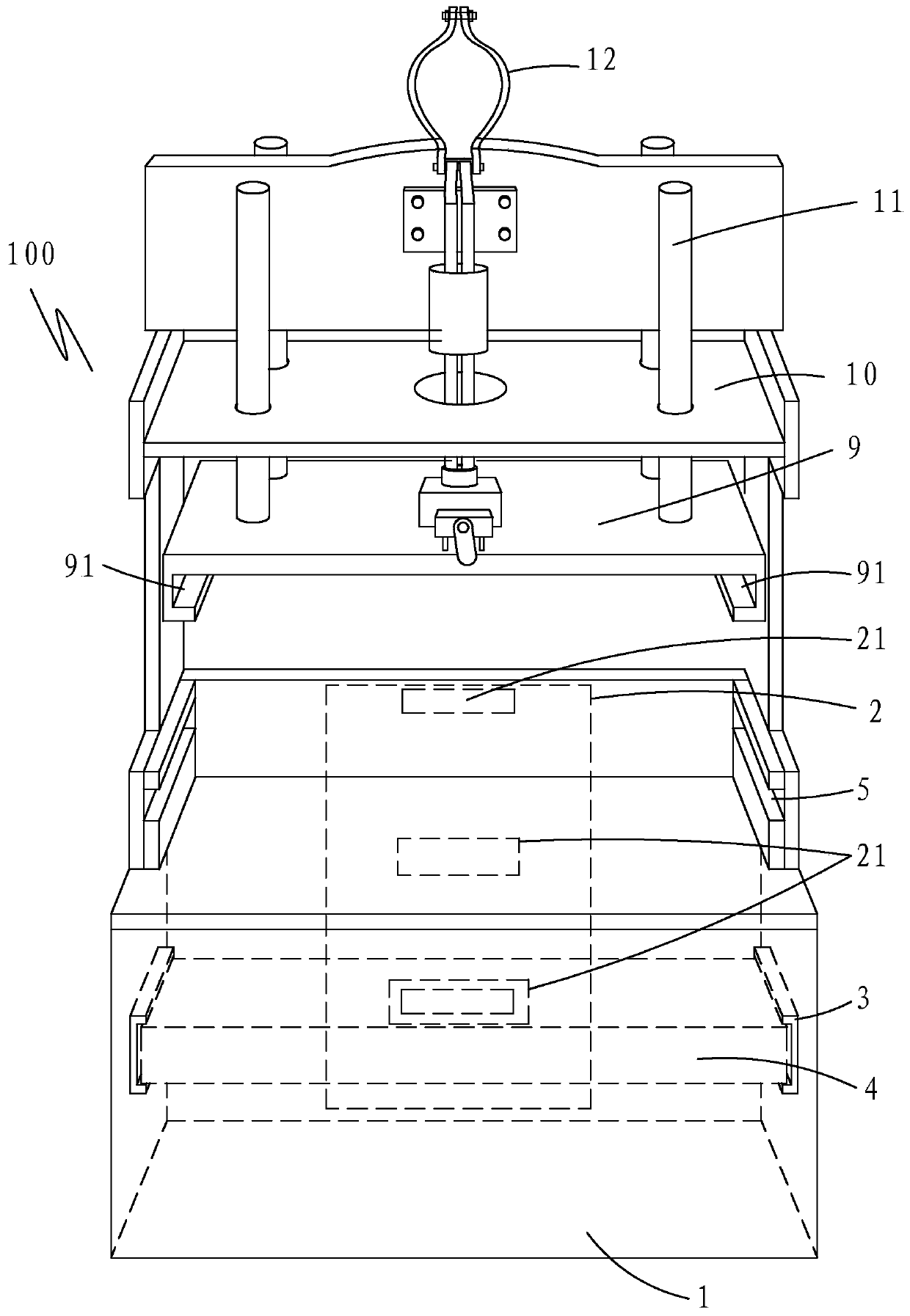

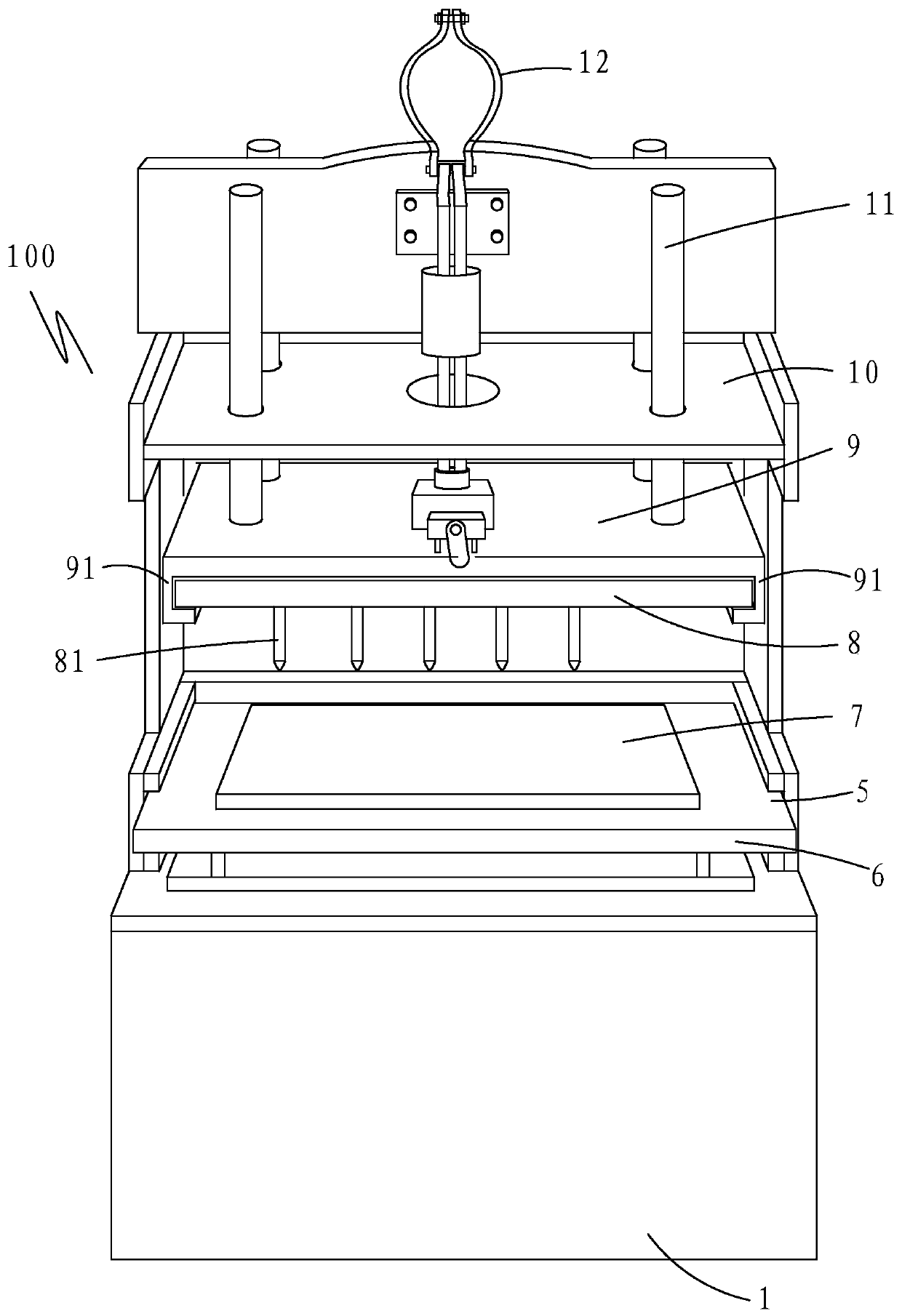

[0026] Such as Figure 1 to Figure 3 As shown, a plug-and-play intelligent test device free of connecting wires, including a frame 100, a movable pressure plate 8, and a movable needle plate 6,

[0027] The upper part of the frame 100 is provided with a pressing plate support 9, and the movable pressing plate 8 is located at the lower part of the pressing plate supporting 9, and is movably connected with the pressing plate supporting 9;

[0028] The middle part of the frame 100 is provided with a needle plate fixing part 5, and the movable needle plate 6 is movably connected with the needle plate fixing part 5;

[0029] The tested board 7 is placed on the movable needle board 6;

[0030] The bottom of the frame 100 is provided with a multi-layer equipment guide groove 3 for placing a plurality of test equipment 4; the bottom of the frame 100 is also provided with an interface circuit board 2, and the interface circuit board 2 is provided with more than two socket 21;

[003...

Embodiment 2

[0039] Such as Figure 1 to Figure 3 As shown, a plug-and-play intelligent test device free of connecting wires includes a frame 100, a movable platen 8, a movable needle plate 6, and a test device 4; the lower part of the frame 100 is provided with a box body 1, and the two sides A pair of needle plate guide grooves 5 are provided, and a press plate support 9 is provided on the upper part; a pair of press plate guide grooves 91 are provided on both sides of the press plate support 9 .

[0040] The needle plate guide groove 5 is used to fix the movable needle plate 6 , the press plate guide groove 91 is used to fix the movable needle plate 8 , and the tested board 7 is placed on the movable needle plate 6 .

[0041] When the quick clamp 12 is turned downwards, under the guidance of the four bearings 11 on the top plate 10, the pressure plate bracket 9 is driven to move vertically downward, and the pressure plate bracket 9 drives the movable pressure plate 8 to move vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com