Integrated structure injector for rocket engine

A rocket engine and injector technology, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complex processing technology and poor permeability, and achieve the goal of simplifying the processing process, reducing processing costs, and reducing the number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

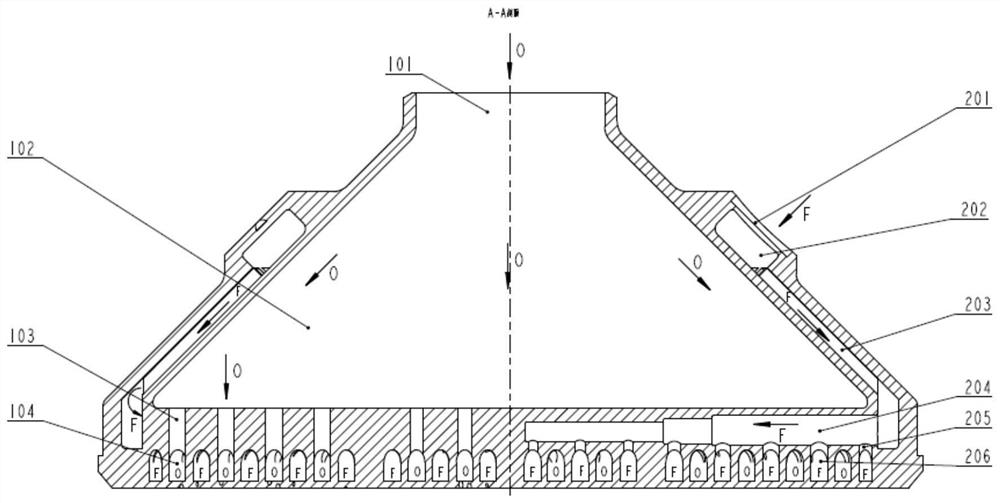

[0045] For the thrust chamber head injector of a 30-ton liquid rocket engine, the maximum diameter is Φ393mm, the height is 188mm, the oxidant (O) is nitrous oxide, the fuel (F) is ethylene, and the propellant mixing ratio is 6.

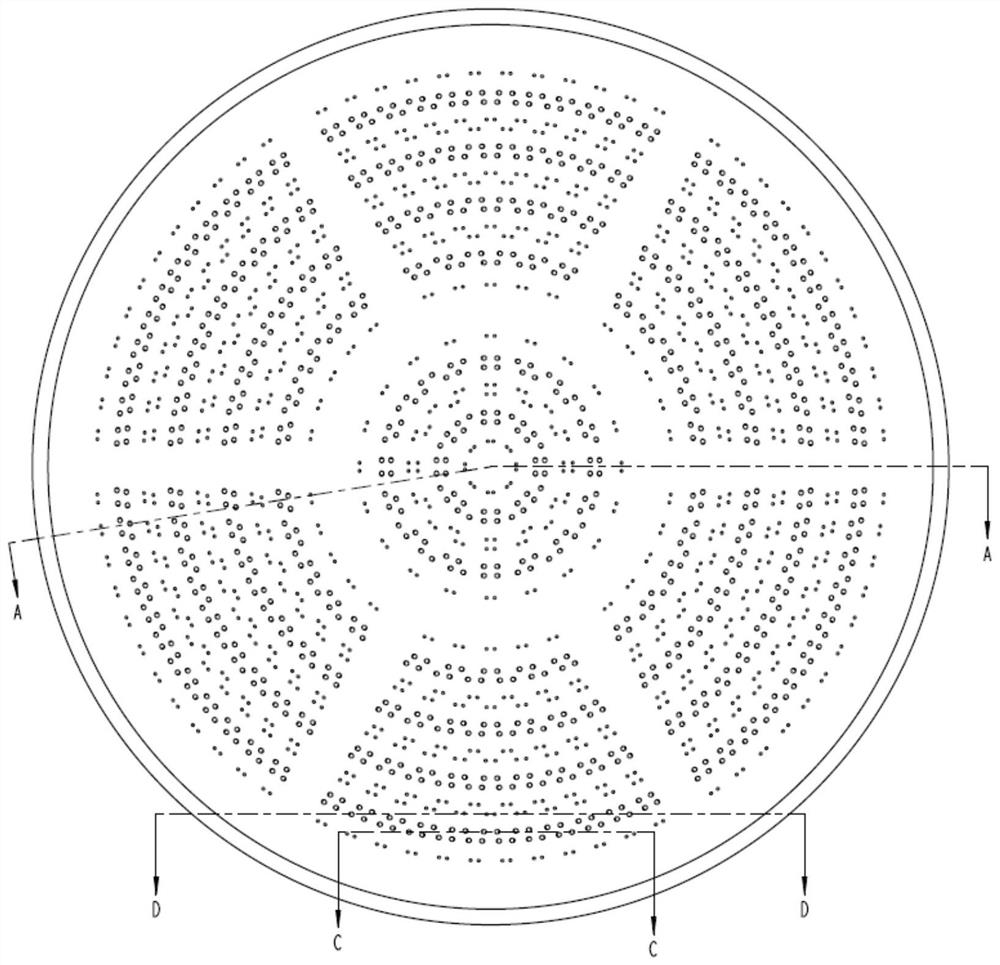

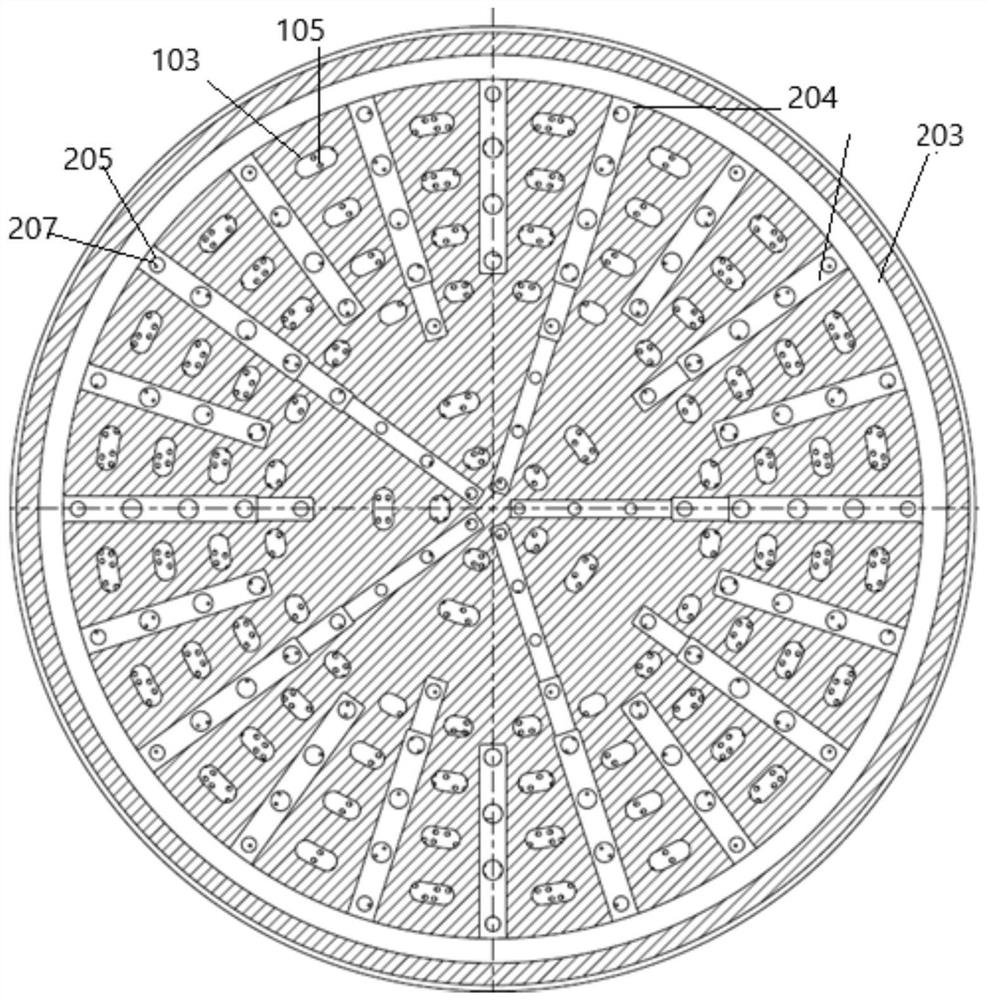

[0046] Such as figure 1 To such as Figure 5 As shown, an injector with an integrated structure provided by the present invention includes according to the fluid flow sequence:

[0047] Oxidant inlet 101, oxidant liquid collection chamber 102, oxidant distribution channel 103, oxidant ring chamber 104 and oxidant injection hole 105;

[0048] A fuel inlet 201 , a fuel liquid collection chamber 202 , a fuel delivery channel 203 , a fuel delivery channel 204 , a fuel distribution hole 205 , a fuel annular cavity 206 and a fuel injection hole 207 .

[0049] The oxidant enters the oxidant liquid collection chamber 102 from the oxidant inlet 101, passes through the oxidant distribution channels 103 arranged in the axial direction, enters six oxidant ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com