Method for detecting optical photograph of large mold casting blank

A technology of optical photography and detection methods, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as tool wear, long inspection time, and decreased precision of processing equipment, so as to reduce cost consumption, speed up production cycle, The effect of improving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

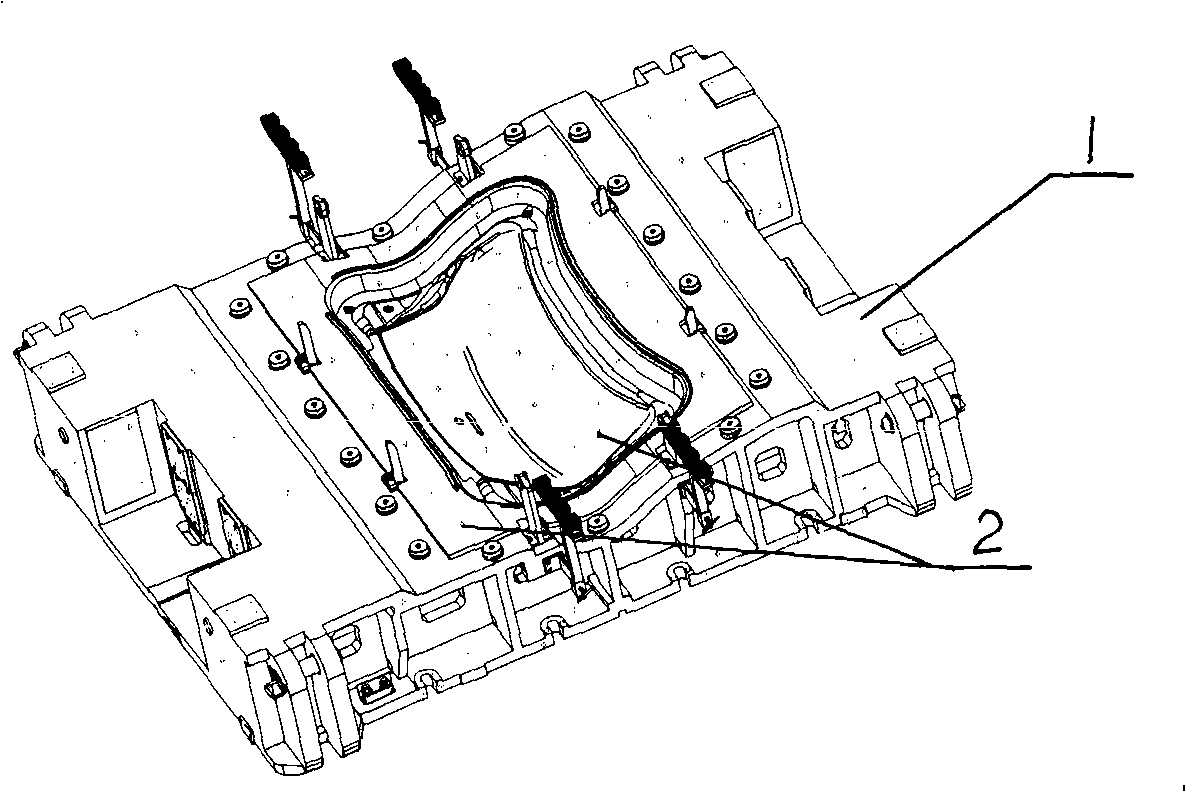

[0012] Such as figure 1 As shown, the entity of casting 1 should be opened before work to fully confirm the shape, size, processing area, non-processing area and related structure positions of the entity. Then paste the processed profile, interference surface, boss formed during the casting process, and peripheral non-processed surface of the workpiece 2; collect data on all processed profiles of the casting blank; ensure that the final data deviation of the collected points is less than 0.5 pixels , The scale deviation is less than 0.15mm, this casting is about 1000 points. After sticking point 2, check the entire casting, and find out if there are any omissions and add them.

Embodiment 2

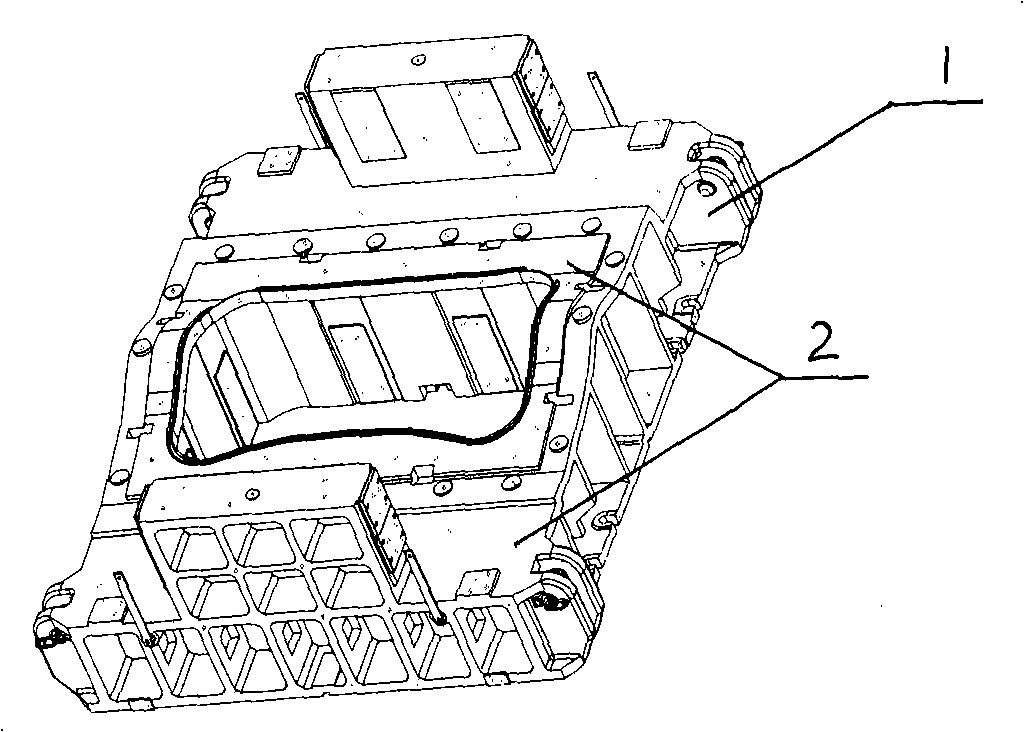

[0014] Such as figure 2 As shown, the entity of casting 1 should be opened before work to fully confirm the shape, size, processing area, non-processing area and related structure positions of the entity. Then paste the processed profile, interference surface, boss formed during the casting process, and peripheral non-processed surface of the workpiece 2; collect data on all processed profiles of the casting blank; ensure that the final data deviation of the collected points is less than 0.5 pixels , The scale deviation is less than 0.15mm, this casting is about 1000 points. After sticking point 2, check the entire casting, and find out if there are any omissions and add them.

Embodiment 3

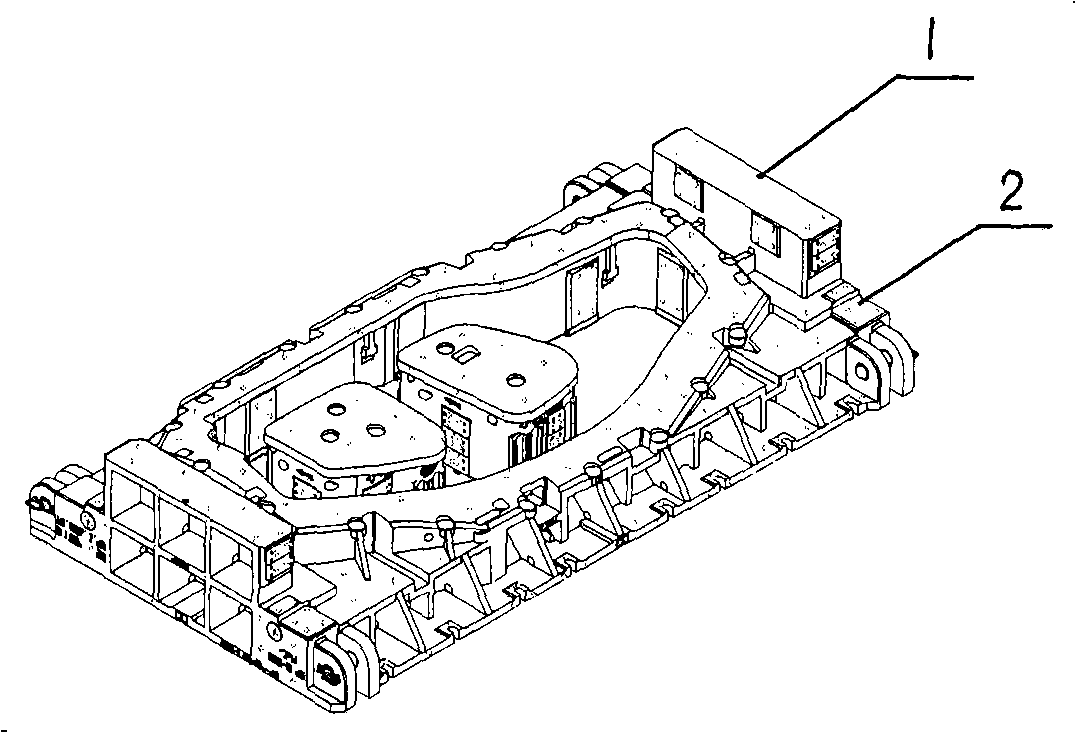

[0016] Such as image 3 As shown, the entity of casting 1 should be opened before work to fully confirm the shape, size, processing area, non-processing area and related structure positions of the entity. Then paste the processed profile, interference surface, boss formed during the casting process, and peripheral non-processed surface of the workpiece 2; collect data on all processed profiles of the casting blank; ensure that the final data deviation of the collected points is less than 0.5 pixels , The scale deviation is less than 0.15mm, this casting is about 1000 points. After sticking point 2, check the entire casting, and find out if there are any omissions and add them.

[0017] Determine the alignment datum for CNC machining, input the CAD data into the alignment environment in the center coordinate system of the die, and ensure the same datum as the CNC machining. Create a coordinate system 3-2-1 for the collected data, and require the bottom surface of the casting to be l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com