Using method for mold fillet

A technology of rounded corners and molds, which is applied in the field of mold rounded corners, can solve the problems of restricting the total cycle of mold production efficiency, affecting the service life of molds, and easily damaged flash fillets, so as to meet the requirements of green sustainable development production and improve The effect of environmental sanitation in the workshop and reduction of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

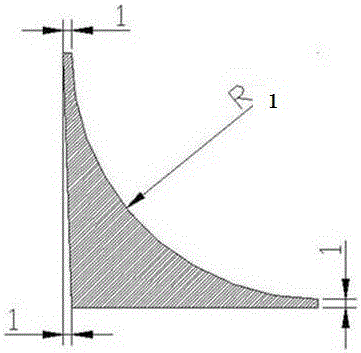

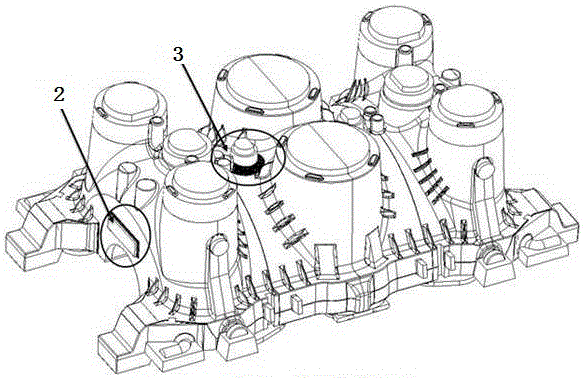

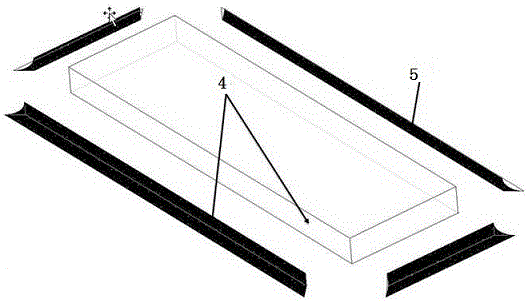

[0021] Aiming at the problems existing in the prior art, the invention provides a method for using mold rounded corners. The use method of the mold fillet provided by the present invention uses rubber material as a profile to replace the existing resin and putty materials, so as to improve the production efficiency of the mold fillet, increase the toughness of the fillet, and prevent the damage of the fillet during use; The rounded corners of the mold do not need to be polished, which reduces the pollution to the workshop environment, improves the environmental sanitation of the workshop, and realizes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com