A composite thermal storage body and its preparation method

A heat storage body and matrix technology, applied in heat storage equipment, lighting and heating equipment, ceramic products, etc., can solve the problems of latent heat storage efficiency to be improved, complex manufacturing process, and limited amount of sodium chloride molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

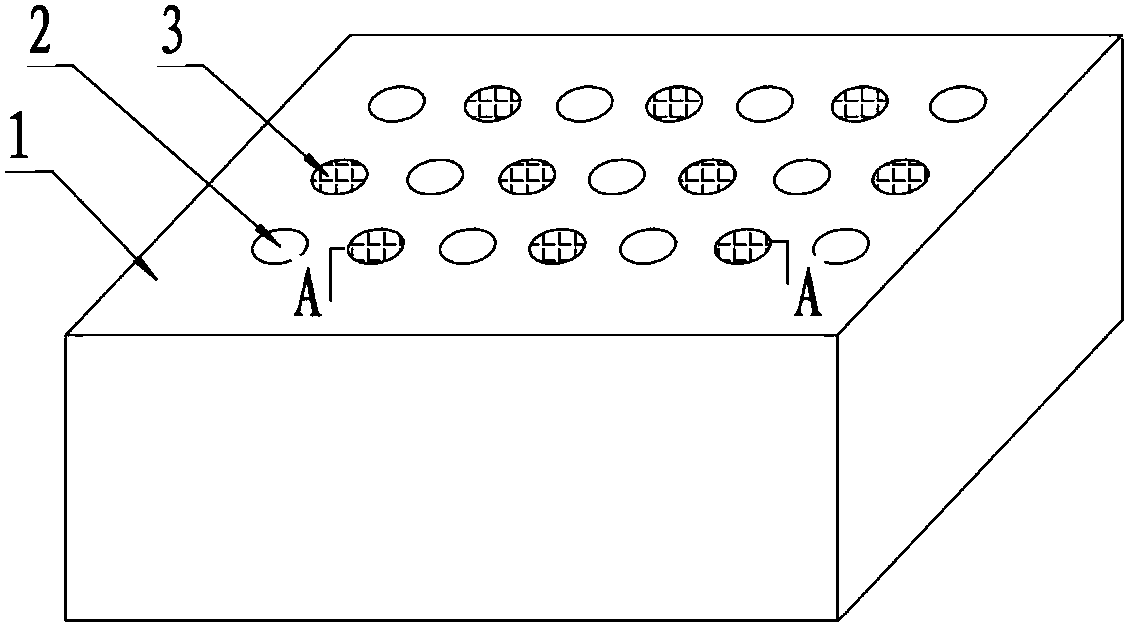

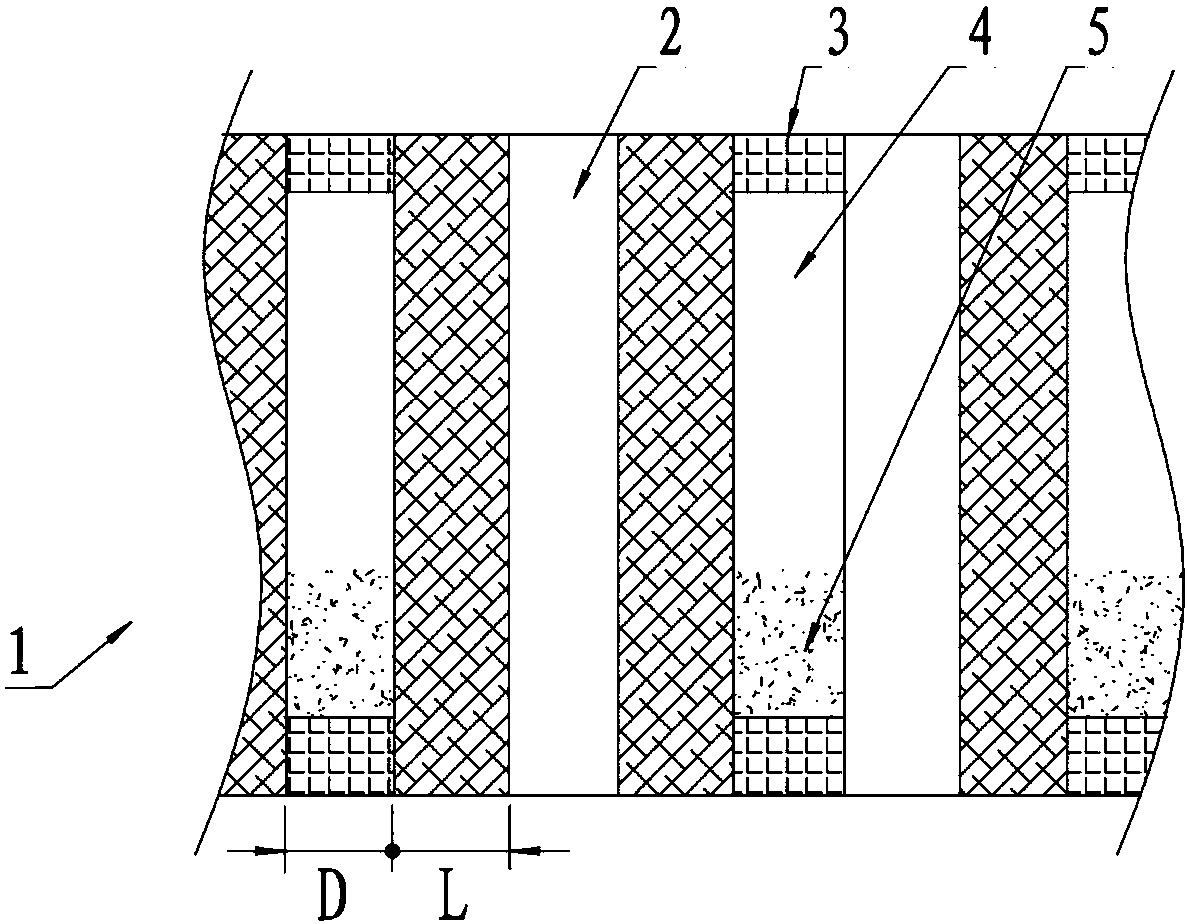

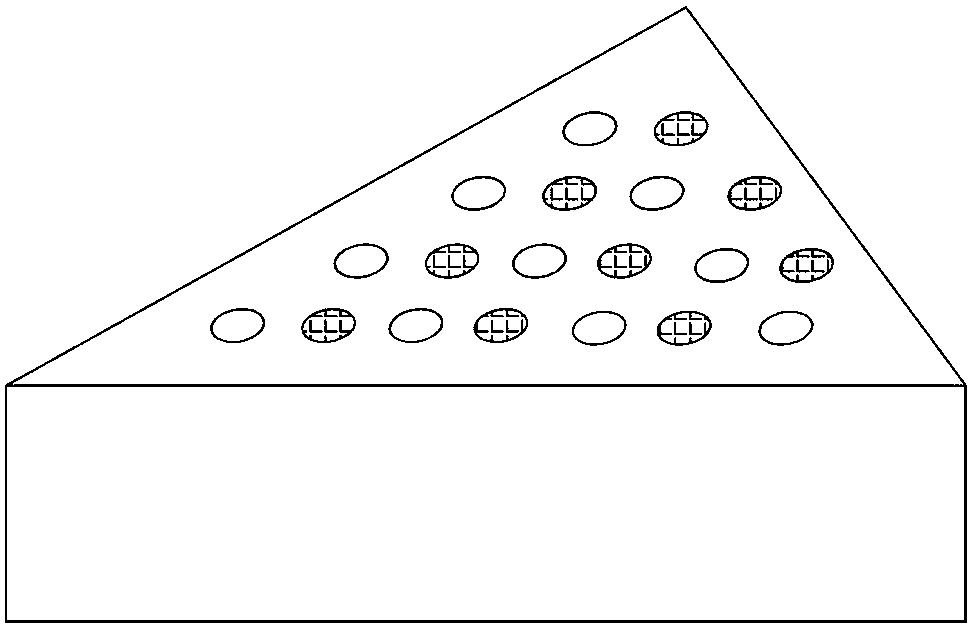

[0027] The preparation method of the composite heat accumulator in the present invention comprises the steps of preparing a silicon carbide multiphase ceramic matrix, preparing an encapsulation body, filling a phase change material, and the like. Among them, in the step of preparing the silicon carbide multiphase ceramic matrix, first weigh the raw materials of the silicon carbide multiphase ceramic matrix according to the following ratio: silicon carbide 78-80, kaolin 8-9, limestone 4-5, mullite 5-7 , cordierite 14-16. The above raw materials are mixed evenly, crushed to 200-300 mesh and set aside. Then configure the plasticizer solution: prepare the plasticizer solution according to the ratio of water to polyvinyl alcohol solution volume ratio of 4:1, mix the polyvinyl alcohol solution with a concentration of 3% and water, leave it for 12-24h, and wait until the two are fully After compounding, stir for 30 minutes to obtain a plasticizer solution. Then mix the pulverized s...

Embodiment 1

[0032] Preparation of silicon carbide multiphase ceramic matrix: Weigh the raw materials of silicon carbide multiphase ceramic matrix: 780g of silicon carbide, 80g of kaolin, 45g of limestone, 55g of mullite, and 150g of cordierite. The above raw materials are mixed evenly, crushed to 200 mesh and set aside. Then configure the plasticizer solution: prepare 370g of plasticizer solution according to the ratio of water to polyvinyl alcohol solution volume ratio of 4:1, add the polyvinyl alcohol solution with a concentration of 3% to the water, let it stand for 12 hours, and wait for the two to fully compound Stir for another 30 minutes to obtain a plasticizer solution. Then mix and stir the pulverized silicon carbide multiphase ceramic matrix raw material and plasticizer solution to make a green body, inject the green body into a mold, solidify at 20°C for 12 hours, and demould to obtain a green body; then After drying the green body, put it into the furnace, calcinate at 1150°C...

Embodiment 2

[0036] Preparation of silicon carbide multiphase ceramic matrix: Weigh the raw materials of silicon carbide multiphase ceramic matrix: 790g of silicon carbide, 85g of kaolin, 50g of limestone, 50g of mullite, and 140g of cordierite. The above raw materials are mixed evenly, crushed to 300 mesh and set aside. Then configure the plasticizer solution: prepare 445g of plasticizer solution according to the ratio of water to polyvinyl alcohol solution volume ratio of 4:1, add the polyvinyl alcohol solution to the water, let it stand for 18 hours, and stir for 30 minutes after the two are fully compounded. That is, a plasticizer solution is obtained. Then mix and stir the pulverized silicon carbide multiphase ceramic matrix raw material and plasticizer solution to form a green body, inject the green body into a mold, solidify at 70°C for 3 hours, and demould to obtain a green body; then After drying the green body, put it into the furnace, calcinate at 1250°C for 1 hour, keep it war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com