Device for machining lacquer painting wood base

A lacquer painting and workbench technology, which is used in special decorative structures, decorative arts, and processes for producing decorative surface effects, etc., can solve the problem of not being able to ensure the quality of wood tire boards well, cumbersome and time-wasting lacquer painting process. , energy and manpower and other issues, to achieve the effect of reducing labor costs, speeding up production cycles, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

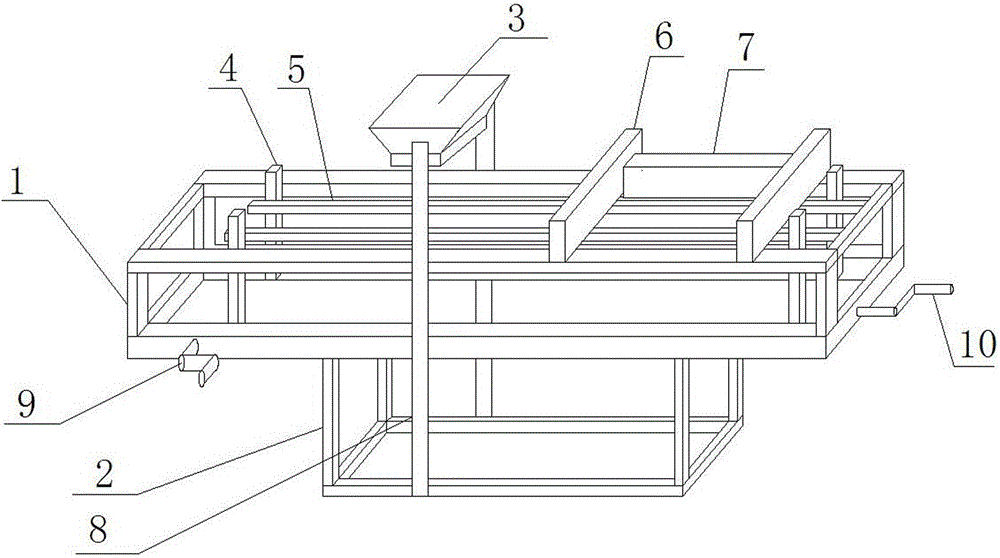

[0020] A device for processing lacquered wooden tires, including a workbench 1 and a support 2; it is characterized in that: the bottom of the workbench 1 is connected to the support 2, and the workbench 1 is a rectangular hollow frame; the workbench 1 A hopper 3 is provided on the upper side, and a manual scraper 7 is provided on the other side of the top surface of the workbench 1; a plurality of lifting guide rods 4 are provided on the inner long side of the workbench 1, and the lifting guide rods 4 on the same side The rod 4 is provided with a transverse guide rod 5; both sides of the hopper 3 are connected to the hopper bracket 8; both ends of the manual scraper 7 are connected to the scraper bracket 6, and the bottom surface of the scraper bracket 6 is connected to the top surface of the workbench 1; The transverse guide rod 5 can move longitudinally on the lifting guide rod 4 .

[0021] The workbench 1 is provided with a lateral control rocker 9 and a longitudinal contr...

Embodiment 2

[0026] The working principle of the present invention: the present invention fixes the wooden tire board between the horizontal guide rods 5 through the clamp, controls the horizontal guide rod 5 to move up and down on the lifting guide rod 4 through the longitudinal control rod, and controls the wooden tire through the horizontal control rocker 9 The board moves laterally between the transverse guide rods 5, which is convenient to fix the wooden base board below the hopper 3 or the manual scraper 7, facilitates adding paint paste to the wooden base board, and also facilitates the removal of excess paint ash on the wooden base board. Impurities are scraped off by the manual scraper 7, which increases the production efficiency of the wooden base board, reduces the manual work strength and lightens the production strength of the lacquer painting simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com