Novel efficient composite heat accumulator and preparation method thereof

A heat storage body and high-efficiency technology, which is applied in heat storage equipment, heat exchange equipment, lighting and heating equipment, etc. The production process of the heat body is complex, and the latent heat storage efficiency needs to be improved, so as to achieve the effect of speeding up the production cycle, improving the heat storage efficiency, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

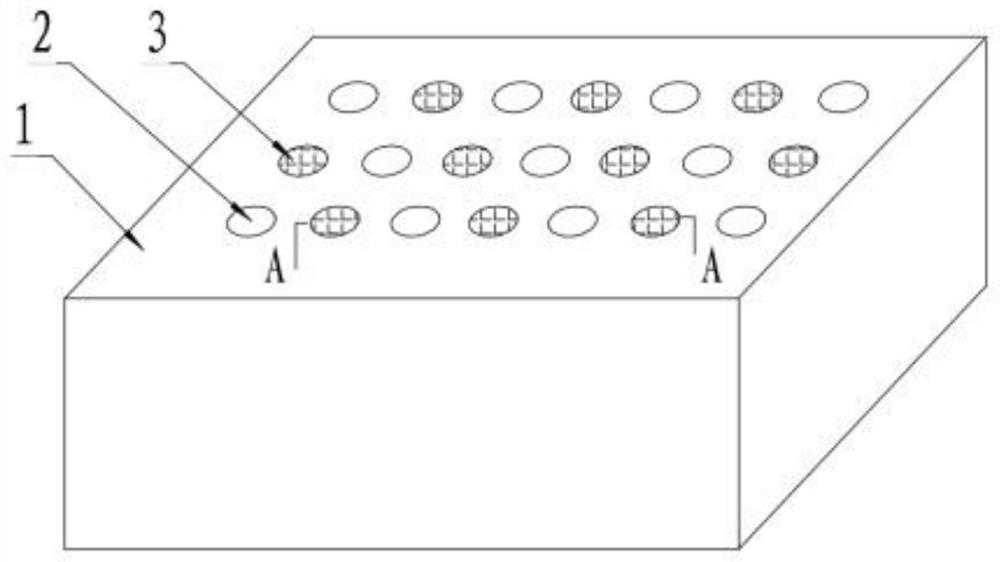

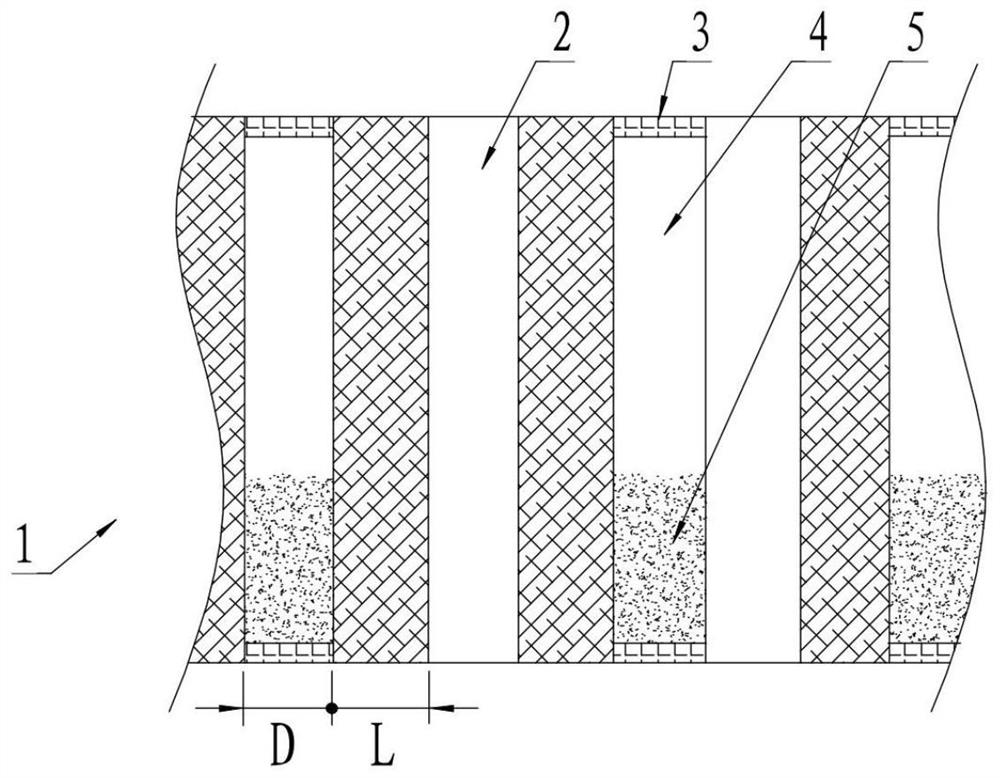

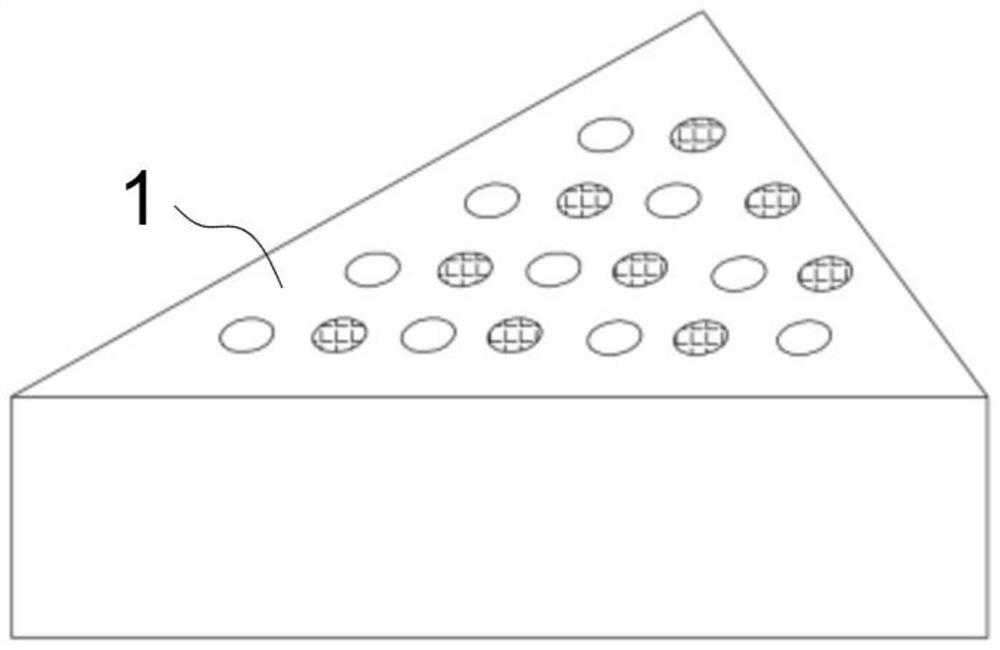

[0037] The preparation method of the novel high-efficiency composite heat accumulator, its specific steps are as follows:

[0038] S1. Preparation of silicon carbide multiphase ceramic substrate: Weigh the raw materials of silicon carbide multiphase ceramic substrate, 780g of silicon carbide, 80g of kaolin, 45g of limestone, 55g of mullite, and 150g of cordierite, mix the above raw materials evenly, and crush them to 200 ready for use;

[0039] S2. Prepare plasticizer solution: Prepare 222g of plasticizer solution according to the ratio of water to polyvinyl alcohol solution volume ratio of 4:1, add polyvinyl alcohol solution to water, let it stand for 12 hours, and stir for 30 minutes after the two are fully compounded , to obtain a plasticizer solution;

[0040] S3. Preparation of silicon carbide multiphase ceramic matrix: mixing and stirring the pulverized silicon carbide multiphase ceramic matrix raw material and plasticizer solution to make a green mud, pouring the green...

Embodiment 2

[0045]S1. Preparation of silicon carbide multi-phase ceramic substrate: Weigh the silicon carbide multi-phase ceramic substrate raw materials, 790g of silicon carbide, 85g of kaolin, 50g of limestone, 50g of mullite, 140g of cordierite, mix the above raw materials evenly, and crush them to 300 ready for use;

[0046] S2. Prepare plasticizer solution: Prepare 223g of plasticizer solution according to the ratio of water to polyvinyl alcohol solution volume ratio of 5:1, add polyvinyl alcohol solution to water, leave it for 18h, and stir for 30min after the two are fully compounded , to obtain a plasticizer solution;

[0047] S3. Preparation of silicon carbide multi-phase ceramic substrate: then mix and stir the pulverized silicon carbide multi-phase ceramic substrate raw material and plasticizer solution to make a green mud, inject the green mud into the mold, and solidify 3 pieces at 70°C After 1 hour, the green body was demoulded to obtain the green body; then the green body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com