Preparation method of iron filled carbon nano tube and reaction device

A carbon nanotube and reactor technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low metal filling rate and complex preparation method, and achieve high filling amount, simple process and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention discloses a method for preparing iron-filled carbon nanotubes and a reaction device. The method for preparing iron-filled carbon nanotubes uses an inorganic covalent compound of iron, anhydrous ferric chloride, as a catalyst precursor, and selects different carbon sources. , Nitrogen-doped iron-filled carbon nanotubes and nitrogen-doped iron-filled carbon nanotubes were prepared by planktonic catalytic chemical vapor deposition. The elemental iron formed after the reduction of the catalyst precursor anhydrous ferric chloride used in the present invention can be filled into carbon nanotubes in large quantities while catalyzing the growth of carbon nanotubes, which breaks through the reaction when ferrocene is used as a catalyst precursor. The maximum iron-to-carbon atomic ratio is only limited to 1:10, and the filling degree of iron in carbon nanotubes can be improved by increasing the amount of anhydrous ferric chloride.

[0037] Specifically, when the car...

Embodiment 1

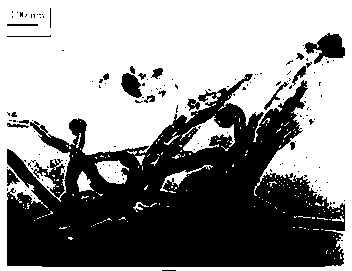

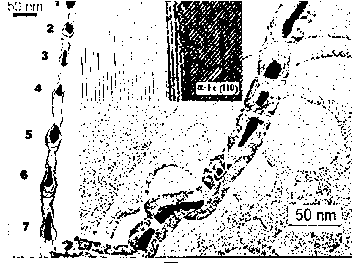

[0058] image 3A schematic structural view of a reaction device for realizing the preparation method of iron-filled carbon nanotubes in Example 1; Figure 4 The transmission electron micrograph of the nitrogen-doped iron-filled carbon nanotubes prepared in Example 1; Figure 8 It is the thermogravimetric curve of embodiment 1, 2 and 3 gained products.

[0059] This embodiment discloses a method for preparing nitrogen-doped iron-filled carbon nanotubes, using image 3 The shown iron-filled carbon nanotube reaction device includes: a tubular resistance furnace 3 with a temperature control device, two porcelain boats 2 for holding solid reactants, and gas inlets 7 and 2 respectively at both ends. The quartz tube reactor 5 of the gas outlet 4, the porcelain boat 2 for holding the solid reactant is placed in the quartz tube reactor 5 near the gas inlet 7, specifically the porcelain boat 2 for holding the solid reactant is placed At 1 / 3 of the total length of the quartz tube reac...

Embodiment 2

[0065] Figure 5 A transmission electron micrograph of the nitrogen-doped iron-filled carbon nanotubes prepared in Example 2;

[0066] This embodiment discloses a method for preparing nitrogen-doped iron-filled carbon nanotubes. Using the same reaction device as in Example 1, the preparation method for nitrogen-doped iron-filled carbon nanotubes includes the following steps:

[0067] Weigh melamine and anhydrous ferric chloride according to a mass ratio of 1:1, place them in two porcelain boats 2, and spread them evenly. Put the two porcelain boats 2 side by side into the quartz tube reactor 5 , and then place the quartz tube reactor 5 in the tubular resistance furnace 3 . Inert protective gas Ar was introduced into the well-sealed quartz tube reactor 5, and at the same time, the temperature of the tubular resistance furnace 3 was programmed to 700 °C, the Ar gas flow rate was adjusted to 200 mL / min, and the quartz tube was pushed to make the ceramic boat enter the tubular re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com