Method for preparing spherical positive pole active material for lithium ion position

A technology for positive active materials and lithium-ion batteries, applied in battery electrodes, electrode heat treatment, active material electrodes, etc., can solve the problems of uneconomical, high energy consumption of pyrolysis, etc., and achieve the effects of reduced energy consumption, high density, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, make a solution of cobalt acetate and lithium acetate, so that Co 2+ with Li + The molar ratio of the solution is 1:1; the solution is spray-dried at an inlet temperature of 300°C and an outlet temperature of 200°C to obtain a precursor powder;

[0025] Then the precursor powder is thermally decomposed in a thermal decomposition furnace, the temperature is controlled at 850°C±5°C, and the powder is collected by cyclone separation;

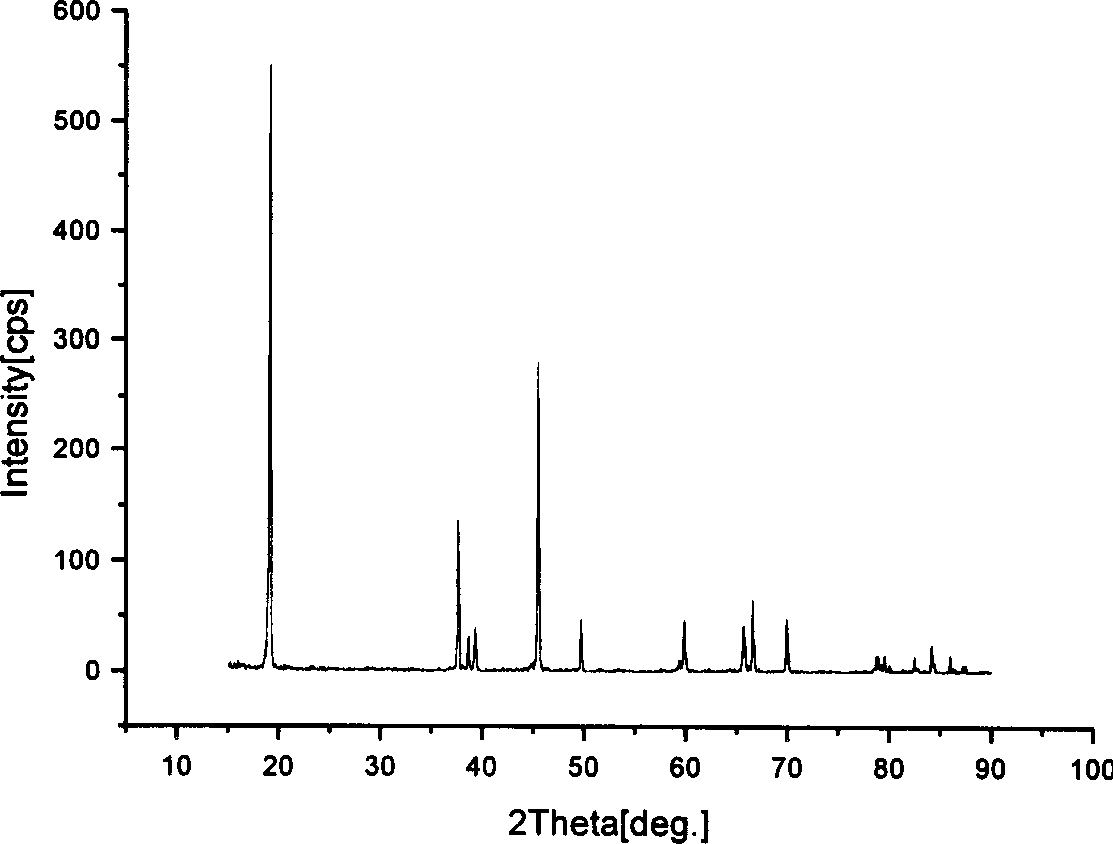

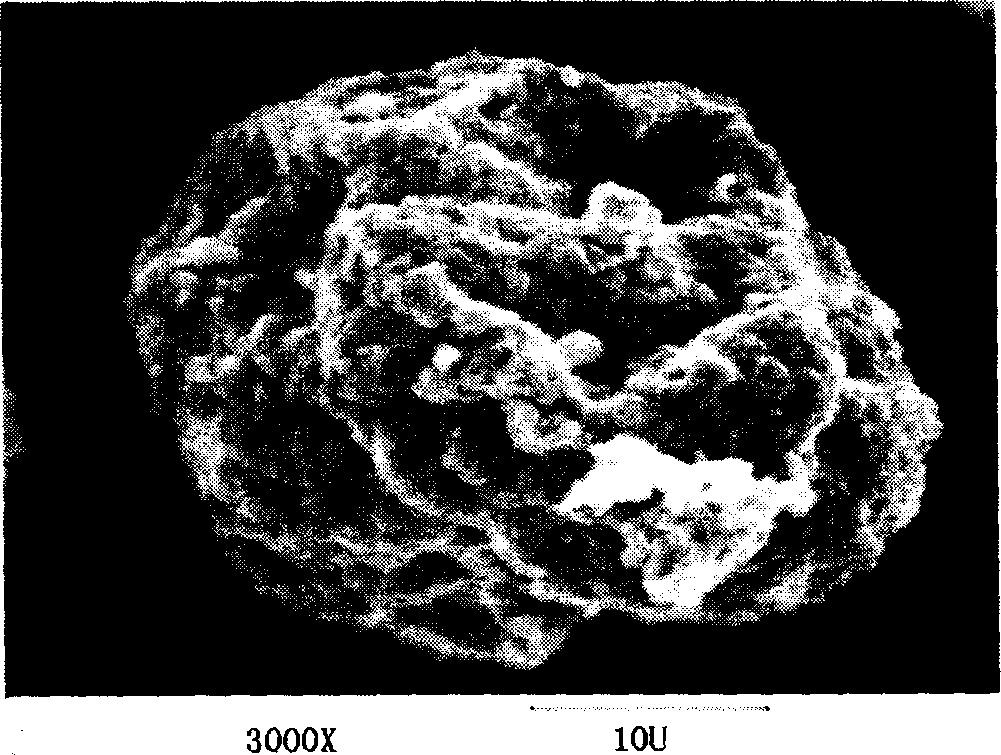

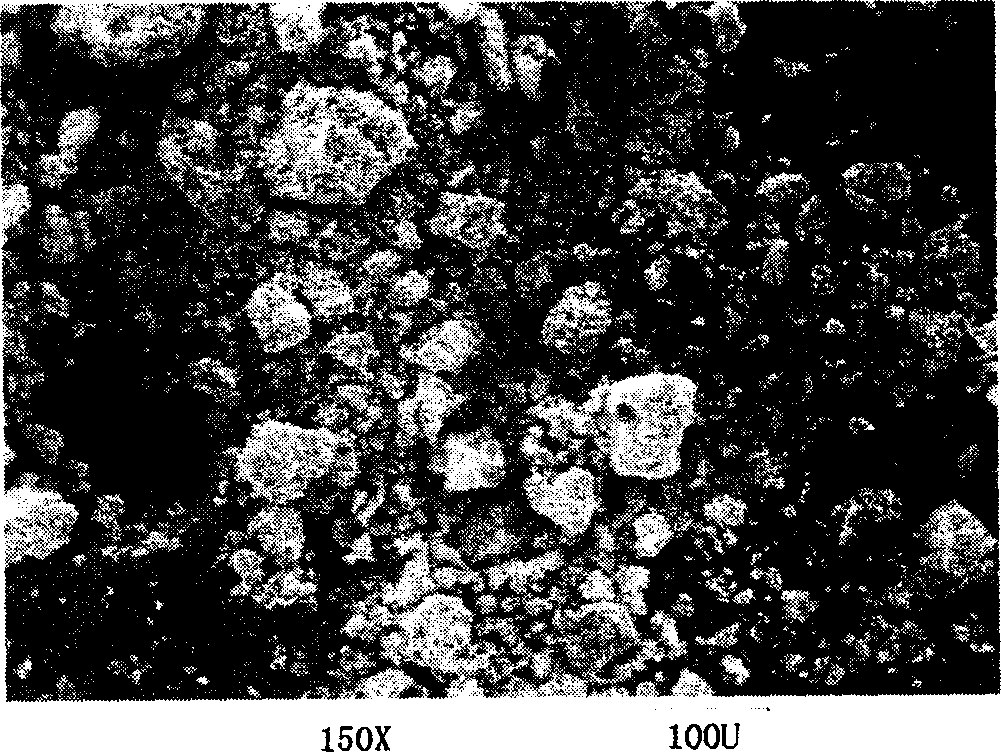

[0026] Finally, the powder was calcined at 800°C for 10 hours under disturbance to obtain the spherical lithium-ion battery cathode active material LiCoO 2 . Its X-ray diffraction spectrum is shown in the attached figure 1 , the scanning electron microscope spectrum is shown in the appendix figure 2 .

Embodiment 2

[0028] First, make a solution of cobalt acetate and lithium acetate, so that Co 2+ with Li + The molar ratio of the solution is 1:1; the solution is spray-dried at an inlet temperature of 430°C and an outlet temperature of 200°C to obtain a precursor powder;

[0029] Then the precursor powder is thermally decomposed in a thermal decomposition furnace, the temperature is controlled at 900°C±5°C, and the powder is collected by cyclone separation;

[0030] Finally, the powder was calcined at 800°C for 8 hours under disturbance to obtain the spherical lithium-ion battery cathode active material LiCoO 2 .

Embodiment 3

[0032] First, make a solution of cobalt nitrate and lithium nitrate to make Co 2+ with Li + The molar ratio of the solution is 1:1; the solution is spray-dried at an inlet temperature of 350°C and an outlet temperature of 200°C to obtain a precursor powder;

[0033] Then the precursor powder is thermally decomposed in a thermal decomposition furnace, the temperature is controlled at 950°C±5°C, and the powder is collected by cyclone separation;

[0034] Finally, the powder was calcined at 800°C for 5 hours under disturbance to obtain the spherical lithium-ion battery cathode active material LiCoO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com