Variable expansion tube positioning tool, and working method and application thereof

A technology for positioning tooling and tube expansion, which is applied to positioning devices, feeding devices, storage devices, etc., can solve the problems of high production cost, no competitive advantage, and difficult management of tube expansion tooling, so as to achieve simple and convenient installation and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

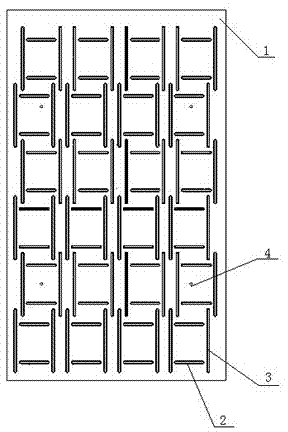

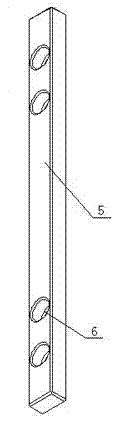

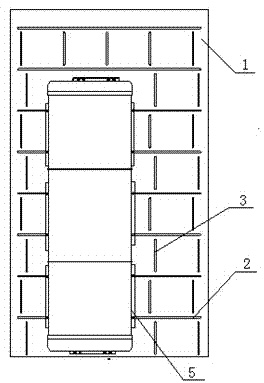

[0016] Such as Figure 1-3 As shown, a variety of expanding tube positioning tooling includes an expanding tube positioning tooling plate 1, the expanding tube positioning tooling plate 1 is fixedly connected to a workbench, and the expanding tube positioning tooling plate 1 is in a horizontal and vertical direction perpendicular to each other. There are several horizontal positioning bars 2 and several longitudinal positioning bars 3 respectively. The horizontal positioning bars 2 are parallel to each other, and the longitudinal positioning bars 3 are parallel to each other. The required workpiece is adjusted according to the workpiece itself through the fixing clamp bar 5 The length and width requirements are clamped on the expansion tube positioning tooling plate 1, the fixing clamp strip 5 is provided with positioning holes 6, and the bolts are passed through the positioning holes 6 and the horizontal positioning strip 2 or the longitudinal positioning strip 3 with nuts to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com