Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce direct production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roadway backfill mining method for coal seams with medium-high thickness

InactiveCN102155226AIncrease profitExtended service lifeUnderground miningSurface miningMining engineeringUltimate tensile strength

Owner:ZIBO WANGZHUANG COAL MINE

Coating for heat sublimation transfer printing and preparation method of coating

The invention relates to a coating for heat sublimation transfer printing and a preparation method of the coating. The coating comprises components in parts by weight as follows: 90-115 parts of cellulose sodium carboxymethyl, 5-8 parts of an inkjet medium adsorbent, 0.5-1.5 parts of an antifoaming agent, 0.5-1.5 parts of polyvinyl chloride resin or calcium carbonate and 800-1,000 parts of water. The preparation method of the coating comprises steps as follows: 800-1,000 kg of water is added to 90-115 kg of cellulose sodium carboxymethyl and is uniformly stirred; 5-8 kg of the inkjet medium adsorbent is added to the diluted cellulose sodium carboxymethyl solution, and the mixed solution is uniformly stirred; 0.5-1.5 kg of polyvinyl chloride resin or calcium carbonate is added to the mixed solution, and the mixed solution is uniformly mixed. The coating and the preparation method are adopted, few materials are consumed, the production is simple, and the production cost is directly saved; meanwhile, according to an actual detection result, the drying speed is increased by 25%, the transfer rate is increased from 80% of the average number of existing coatings to 95% or higher, and the consumption of transfer paper is reduced by 20% during transfer printing.

Owner:浙江卡乐福印花纸有限公司

Cultivation method for interplanting mulberry twig bamboo funguses by simply making shades in leaf mulberry field

The invention discloses a cultivation method for interplanting mulberry twig bamboo funguses by simply making shades in a leaf mulberry field. The cultivation method includes the steps of section of the mulberry field, cutting of mulberries and arrangement of silkworm breeding layout, preparation for raw materials of culture media of the bamboo funguses, settlement of ripple beds in the mulberry field, selective purchasing of cultures, sowing, growth management of hyphae and management of spring silkworm mulberries, simple shade making in the spring and autumn mulberry field and management of fruiting, and harvesting. The cultivation method has the advantages that mulberry twig raw materials are used for cultivation, the stack retting process of the cultivation media is shortened, and labor capacity and labor work hours are saved; a shading net is used to solve the problem of low shady degrees of the mulberry field after leaf picking so that the mulberry field meets the site requirement for growth and development of the bamboo funguses; mulberry twig scraps are used as main cultivation base materials of the bamboo funguses, so that waste mulberry twigs are fully utilized, and economic benefits are produced; the bamboo funguses are directly interplanted in the mulberry field, and remaining materials of the cultivation media are good organic fertilizers in the mulberry field after the cultivation media provide nutrition for growth and breeding of the bamboo funguses, so that fertility of the mulberry field is greatly improved; comprehensive utilization of resources of silkworms and mulberries is achieved.

Owner:JIANGXI SERICULTURE & TEA RES INST

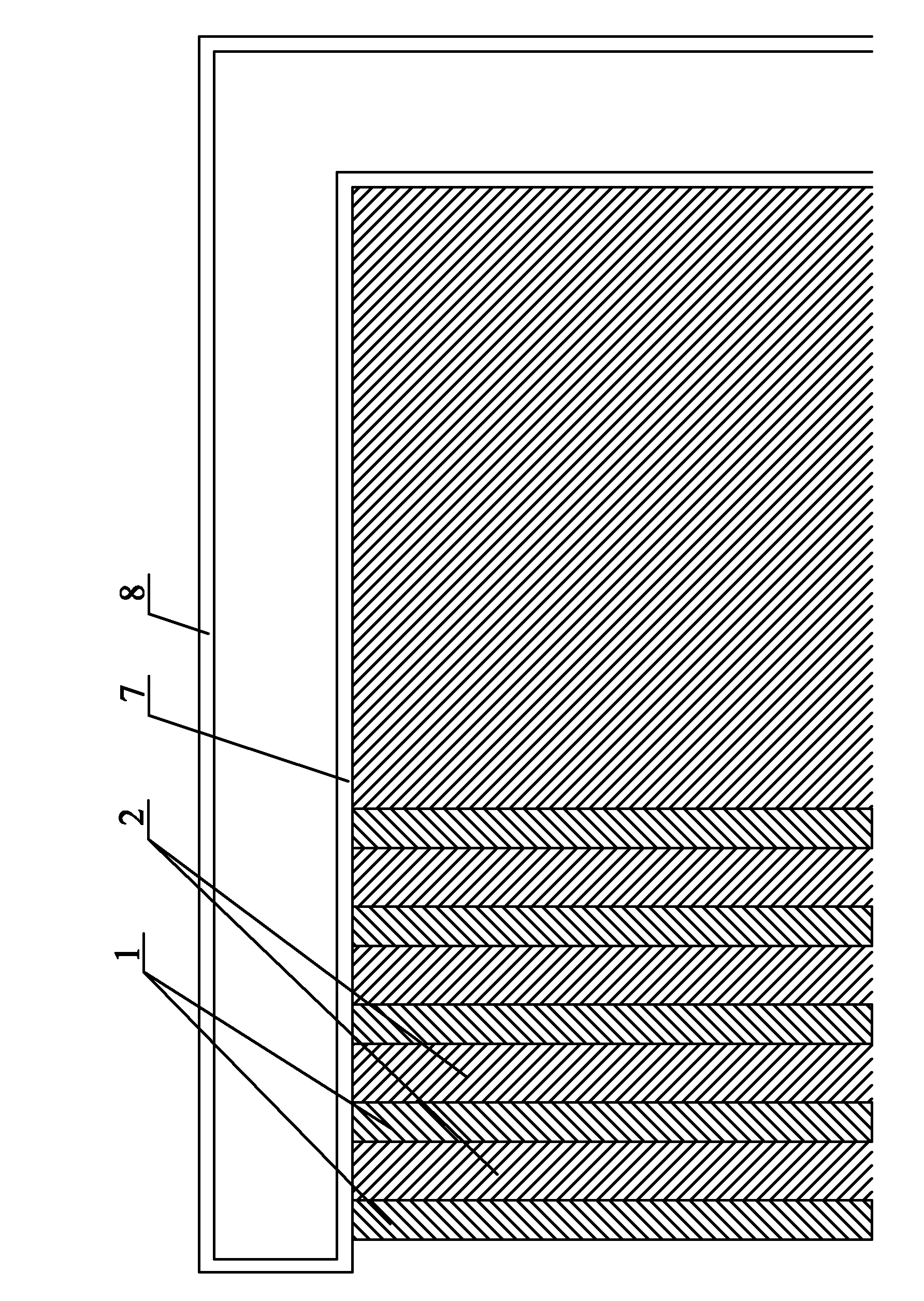

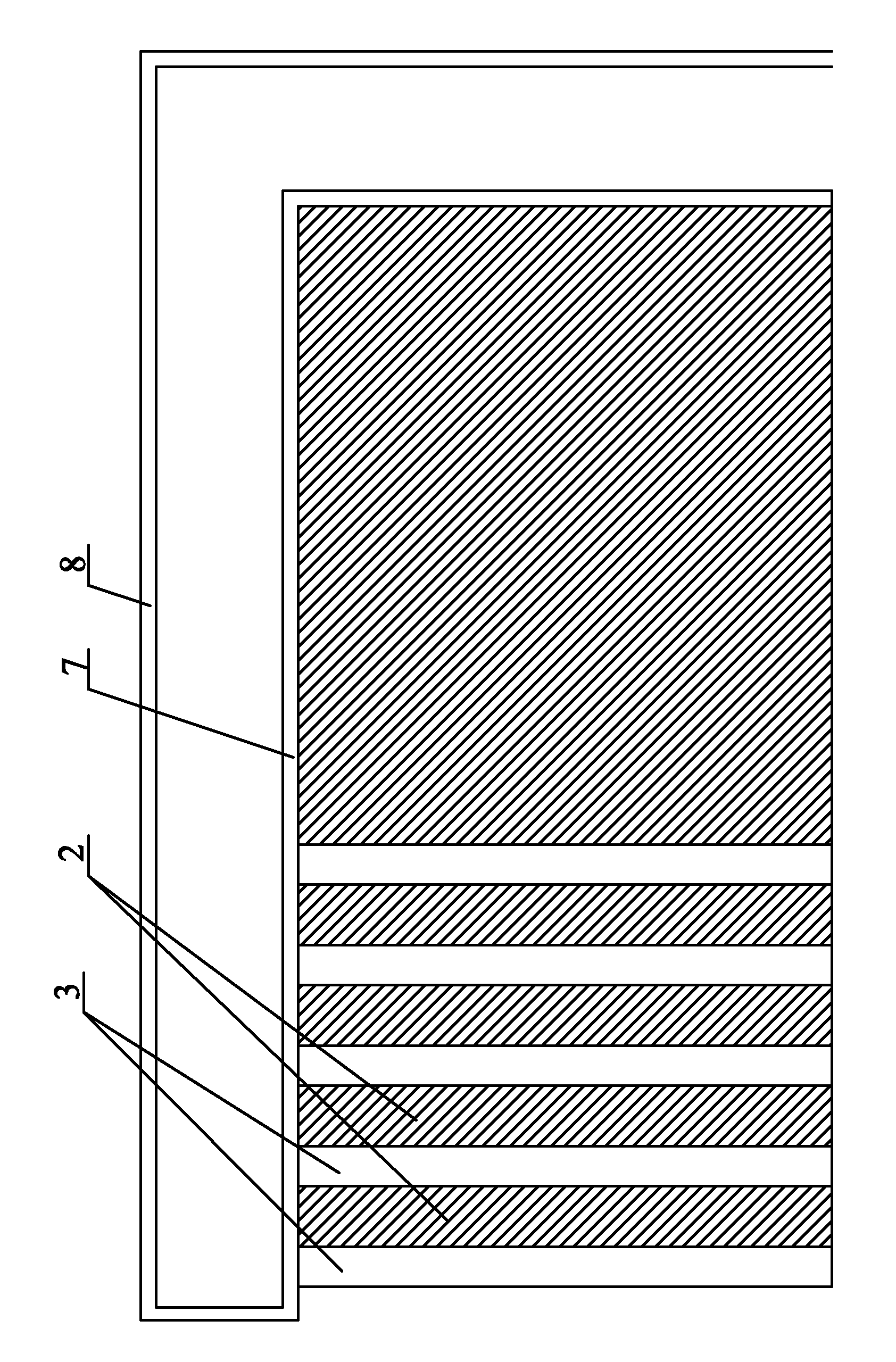

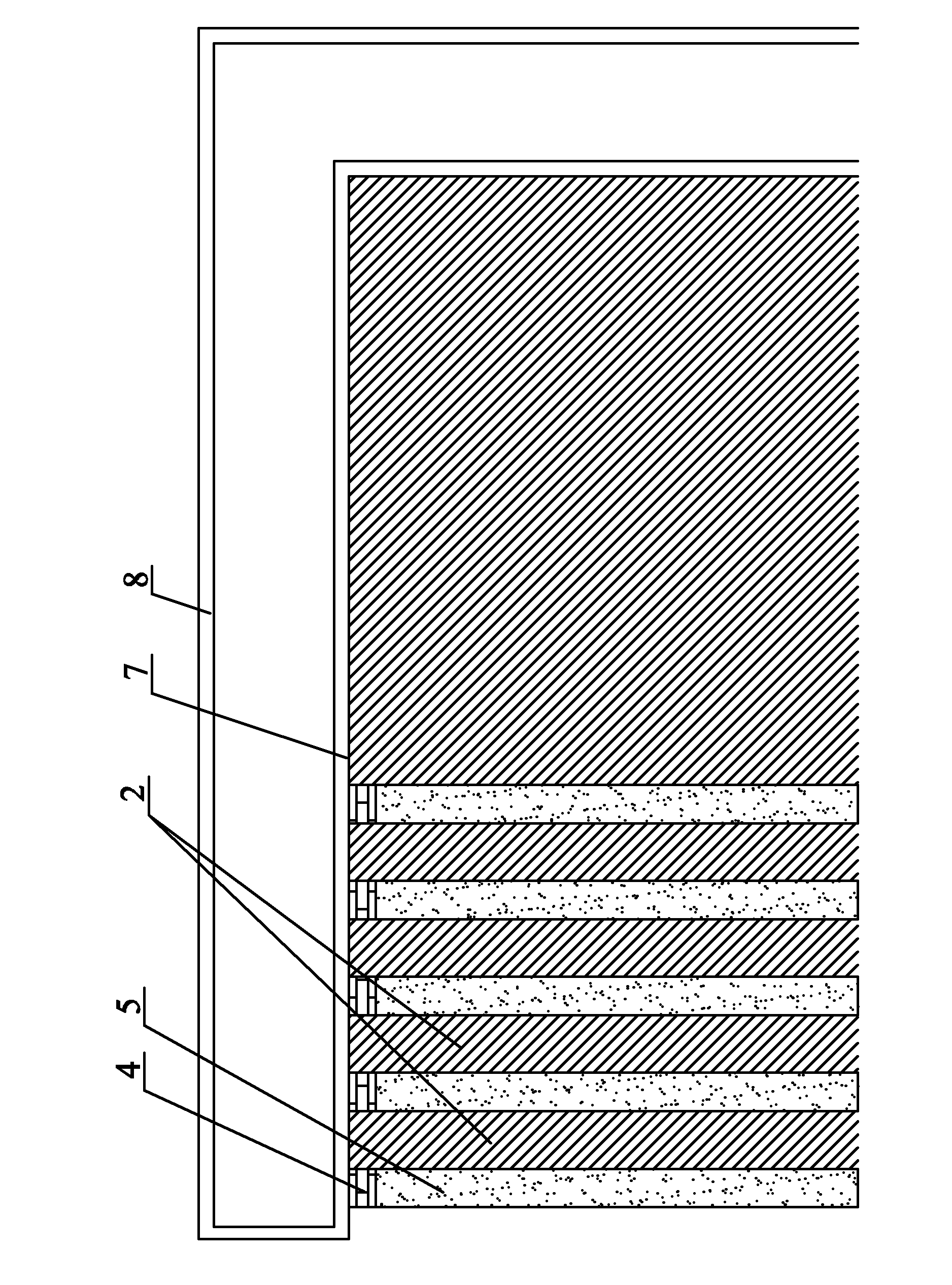

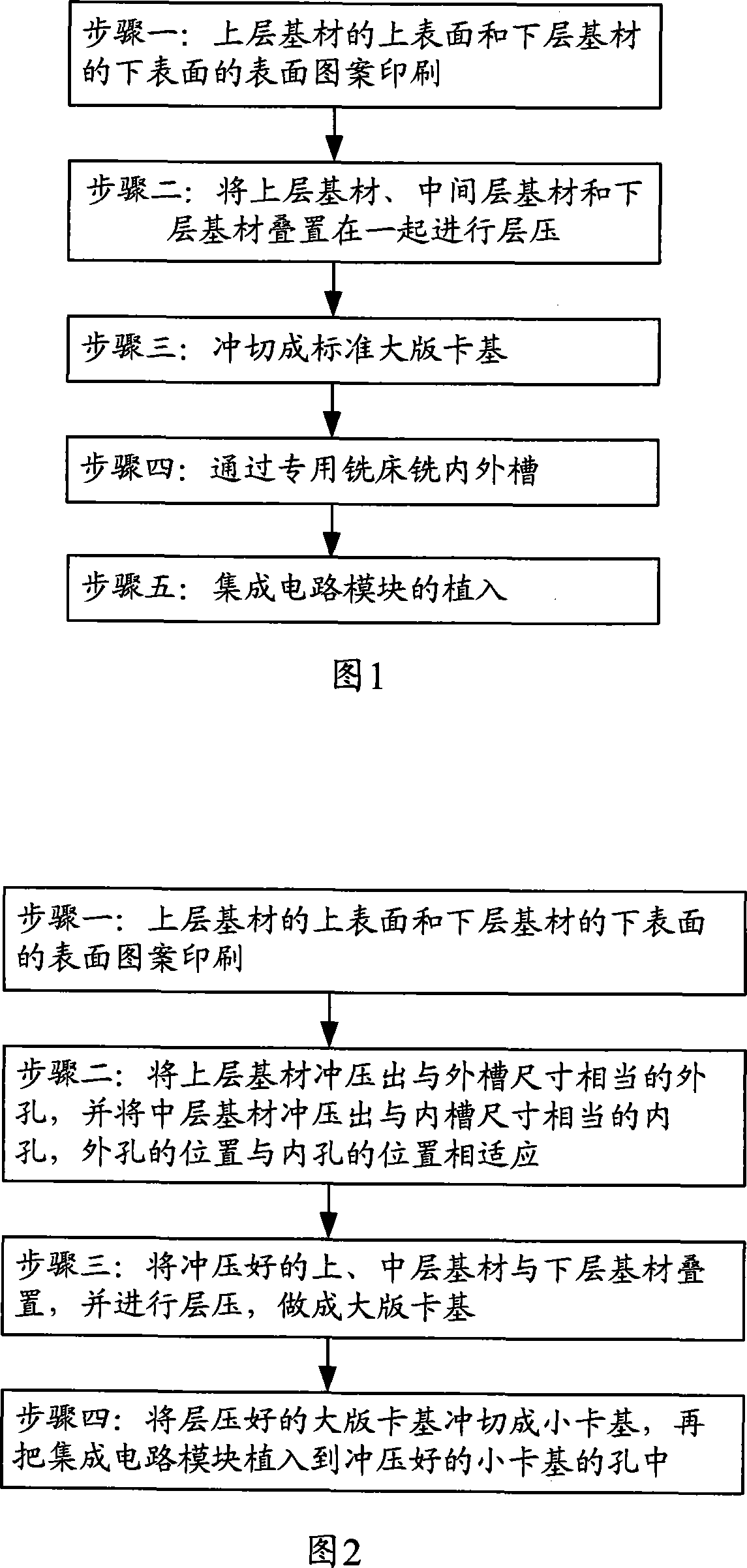

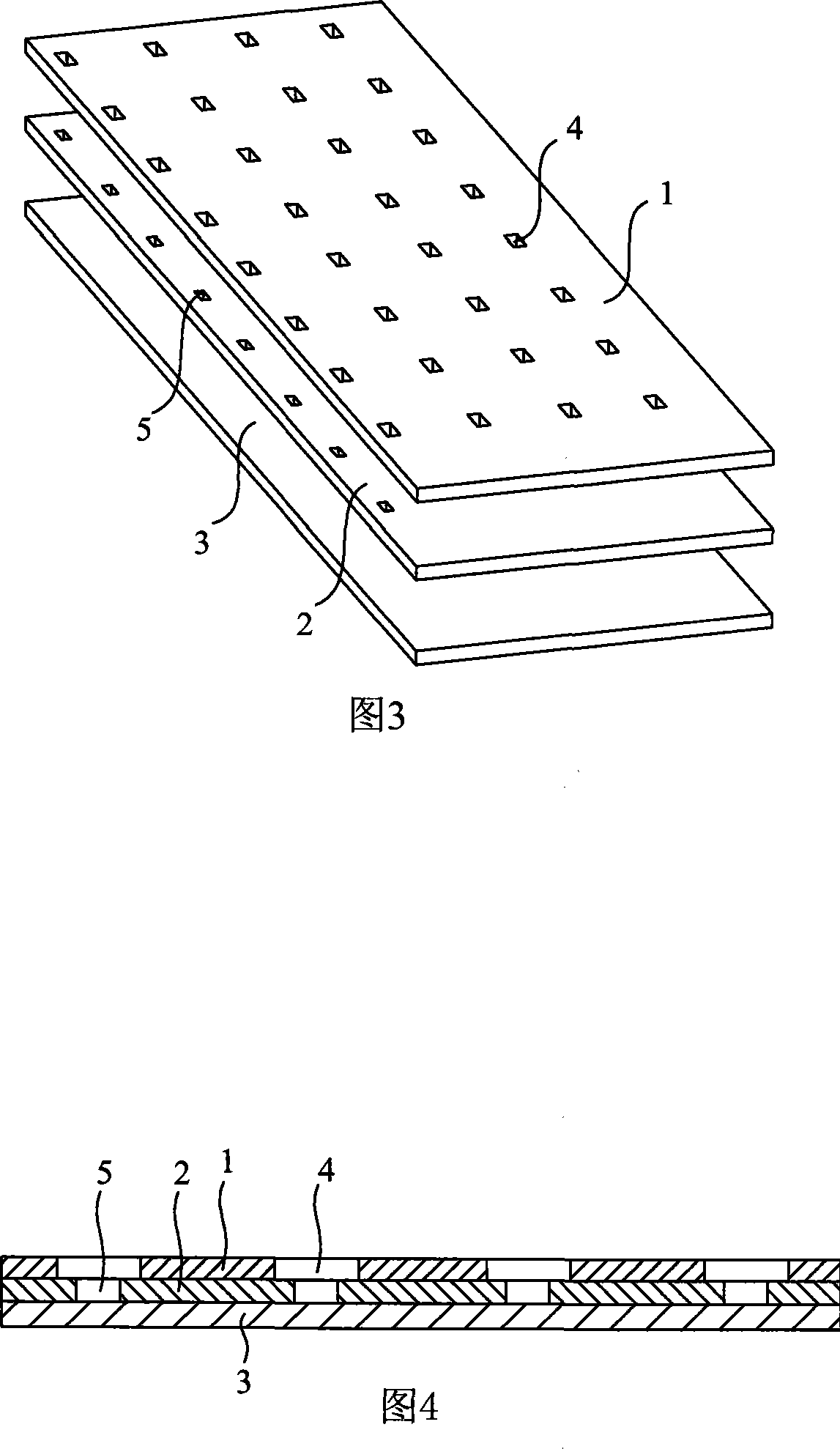

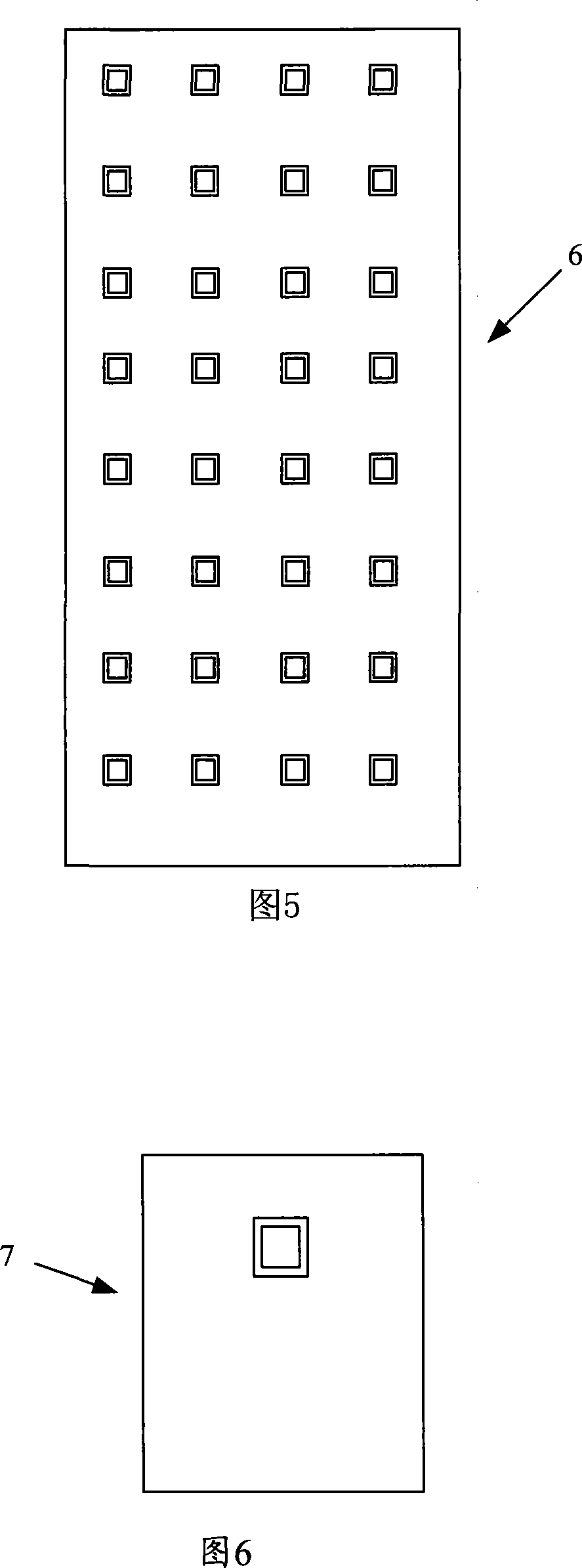

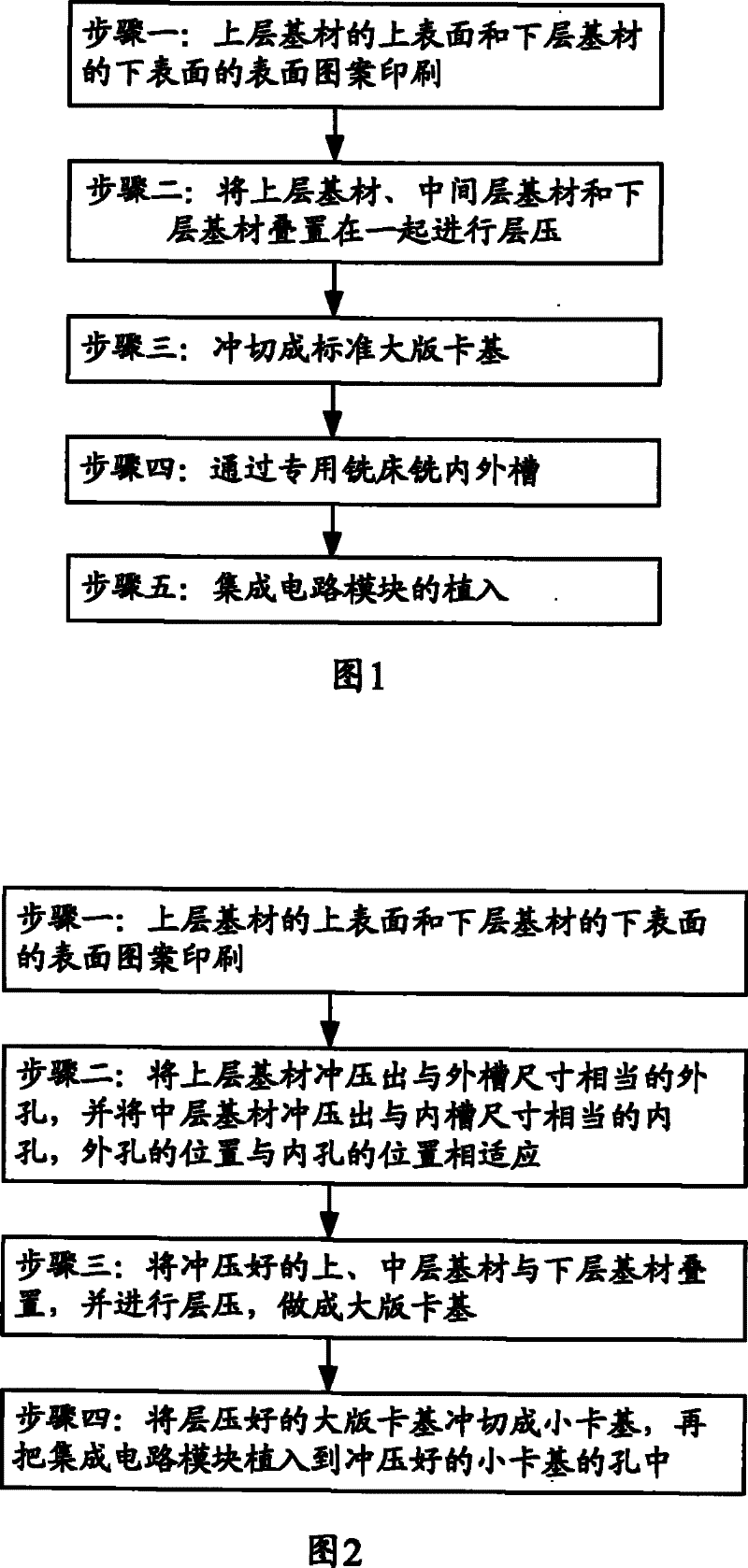

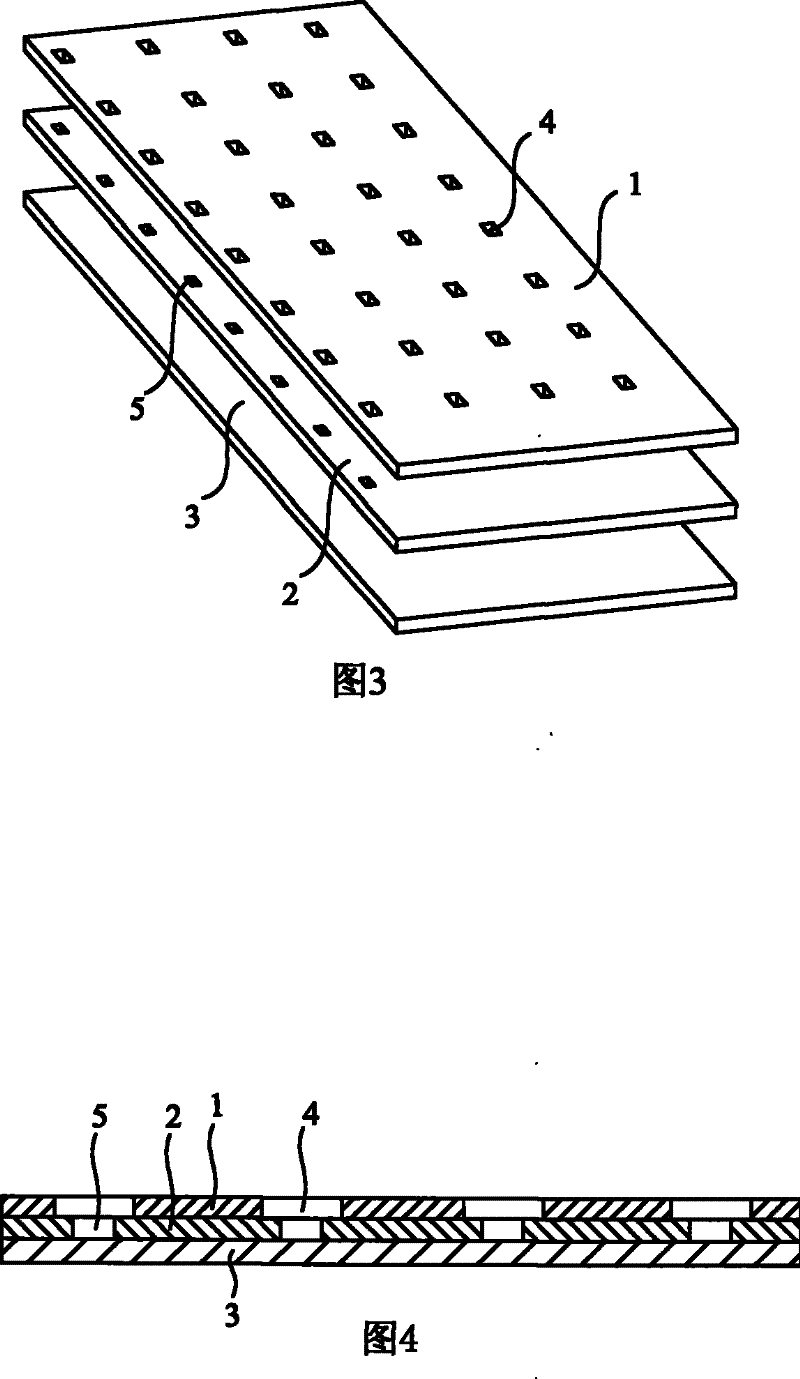

Smart card preparing technique

InactiveCN101183434AQuality controllableQuality improvementRecord carriers used with machinesSmart cardSmall hole

The invention discloses a smart card preparation process, comprising the steps of: 1) punching out an outer hole with a size equal to that of the outer groove on the upper base material, and punching out an inner hole with a size equal to the inner groove on the middle base material, and the position of the outer hole Adapt to the position of the inner hole; 2) Stack the stamped upper and middle base materials with the lower base material and laminate them to make a large card base; 3) Punch the laminated large card base Cut into a small card base, and then implant the integrated circuit module into the hole of the punched small card base. The invention cancels the process step of milling grooves, not only has more operability than the process of milling grooves, greatly improves production efficiency, but also can greatly improve product quality and reduce production costs.

Owner:中电智能卡有限责任公司

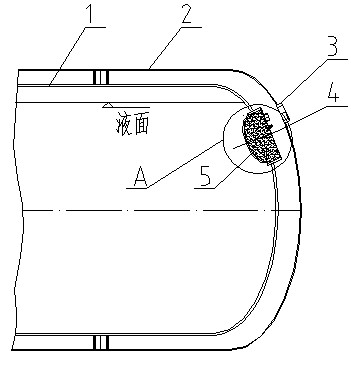

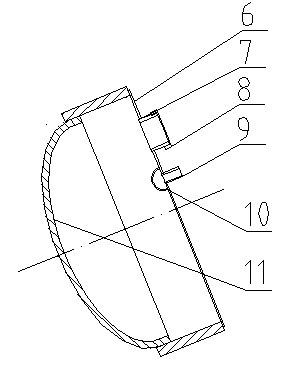

High-vacuum low-temperature container molecular sieve adsorbing device and filling process thereof

ActiveCN102091437AQuality improvementSolve easy-to-occur quality problemsSolid sorbent liquid separationMolecular sieveNitrogen gas

The invention relates to a high-vacuum low-temperature container molecular sieve adsorbing device and a filling process thereof. The high-vacuum low-temperature container molecular sieve adsorbing device comprises an inner container and an outer container, wherein the inner container is provided with a process manhole and the outer container is provided with an anti-explosion hole. The filling process comprises the steps of: charging nitrogen in an adsorbing agent containing container to reach pressure atmosphere, and then opening the anti-explosion hole, connecting a vacuumized rubber pipe, connecting a corrugated pipe with a molecular sieve, starting a vacuum pump, slowly opening a feeding valve, enabling a molecular sieve adsorbing agent to continuously flow into a molecular sieve device under the action of negative pressure, after the molecular sieve adsorbing agent is filled with the molecular sieve device, dismantling the corrugated pipe, then plugging the corrugated pipe with ascrew plug, finally, stopping the vacuum pump, unplugging the vacuum rubber pipe, and closing the anti-explosion hole, and ending the filling of the whole molecular sieve adsorbing agent. The invention has the characteristic of better adsorbing effect, and has the advantages of increasing the load capacity of the whole vehicle, saving the cost, being more convenient for maintenance, improving thewhole quality of a low-temperature container, improving the labor intensity and the operation environment of workers, enhancing the production efficiency, and being convenient and simple in replacingthe molecule sieve.

Owner:江西制氧机有限公司

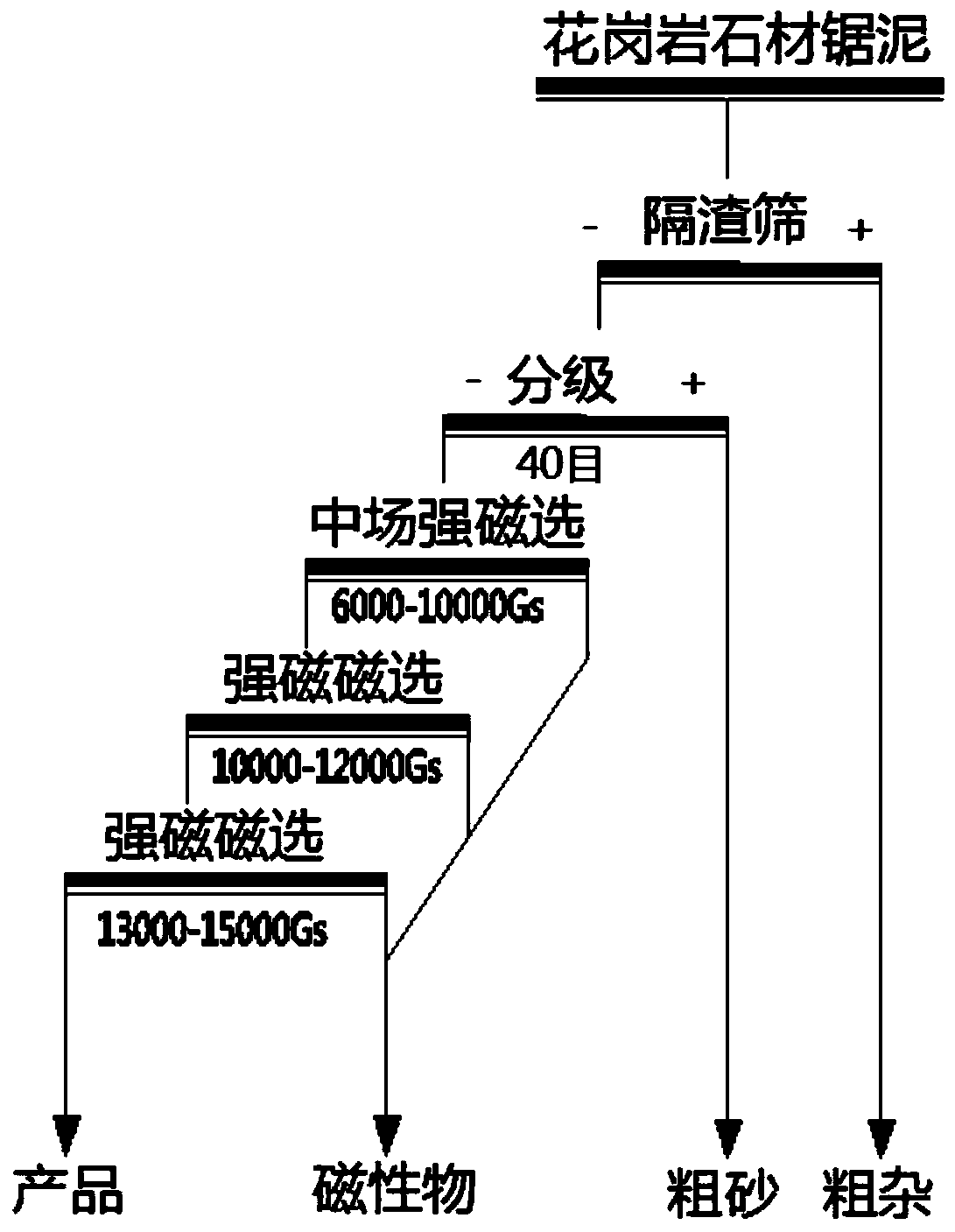

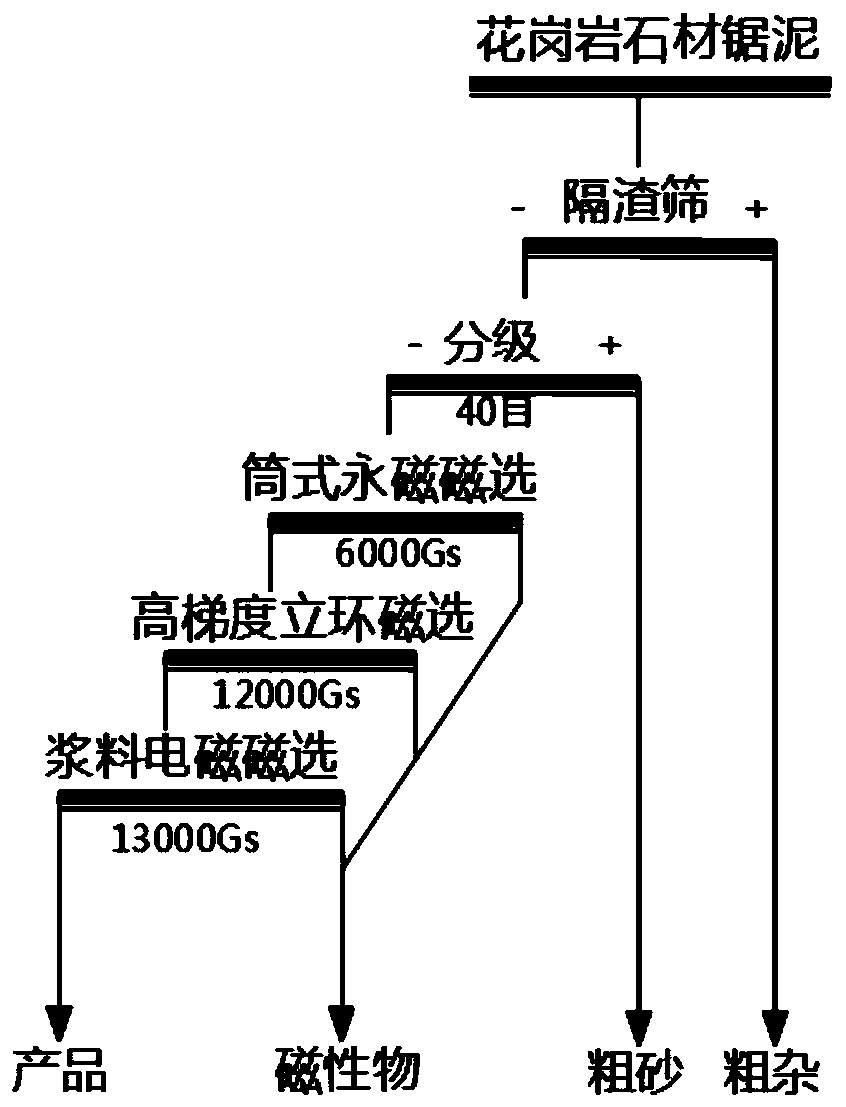

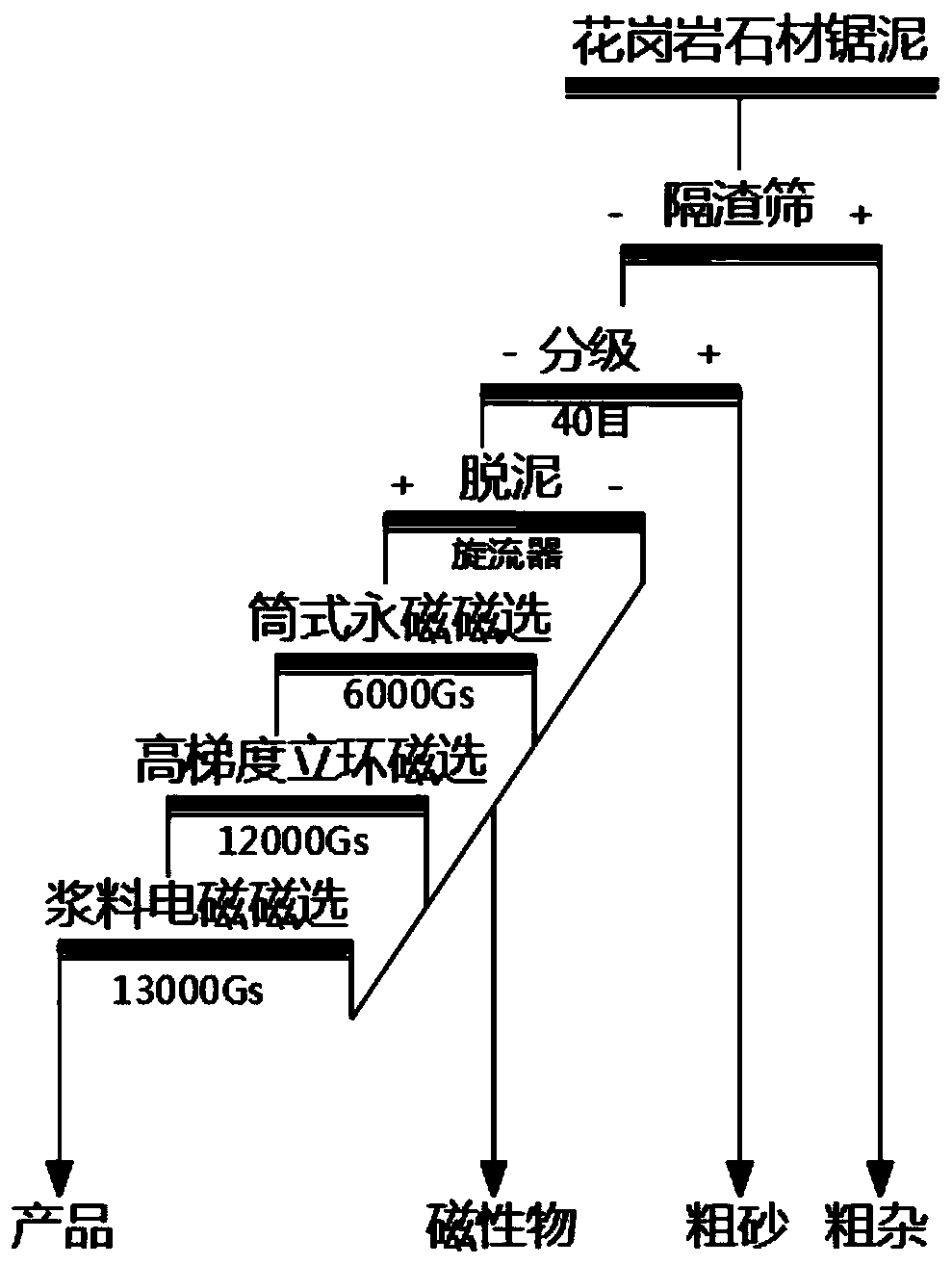

Method for preparing ceramic raw material from granite stone sawing slurry stone powder

ActiveCN110328047AHigh yieldImprove the effect of removing impurities and whiteningSolid separationEnvironmental resistanceSlag

The invention provides a method for preparing a ceramic raw material from granite stone sawing slurry stone powder. The method comprises slag separation, grading and three-section magnetic separationand impurity removal. Three-section magnetic separation and impurity removal comprises medium field intensity magnetic separation and two-section high-gradient intensity magnetic separation. Non-magnetic substances obtained after three-section magnetic separation can be directly subjected to water removal and sold as products. According to the method, pollution-free and environment-friendly physical technology is adopted to realize impurity removal and whitening of the granite stone sawing slurry stone powder used for preparing the ceramic raw material. Compared with a traditional process, themethod is short in process, the raw material does not need to be ground, the direct production cost is reduced by 40%, and the whiteness is up to 60%-68%. Large-scale disposal, harmless treatment andresource utilization of granite sawing slurry solid waste are realized at the same time, so that the general industry-level problems that stone sawing slurry pollutes the environment and is a waste of resources are fundamentally solved. Meanwhile, regeneration resources are used for replacing primary ores, so that the problem of feeding and supply of the ceramic industry is solved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Synchronized production method of reducing leaching and oxidizing deironing of cobalt-copper ore

ActiveCN103060550AHigh recovery rateResolution timeProcess efficiency improvementElectrode potentialReaction temperature

The present invention discloses a synchronized production method of reducing leaching and oxidizing deironing of cobalt-copper ore, including the following steps: crushing and mixing the cobalt-copper ore into cobalt copper slurry, then adding sulfuric acid into the cobalt-copper slurry for leaching with a temperature controlled at 75-85 DEG C, stirring while adding a reducing agent for reducing leaching with an amount of 4-6% of the total cobalt-copper ore, controlling cobalt content in wet residue to be less than 0.2% and copper content less than 0.3%, controlling of the reaction temperature to be 90-95 DEG C and reaction time being 1 to 4 hours, slowly adding alkali to adjust the PH value of the solution to 2.0-3.5, at the same time slowly supplementarily adding cobalt copper slurry for oxidizing deironing according to the content of Fe2+ in solution to make Co3+ and Fe2+ to reach a equilibrium state, and finally performing the solid-liquid separation to obtain qualified leachate. According to the invention, by controlling the electrode potential of the solution, synchronized performance of the reducing leaching process - the oxidizing deironing process is ensured, so direct production cost is significantly reduced, the metal recovery is significantly improved, thus improving production efficiency.

Owner:江苏雄风科技有限公司

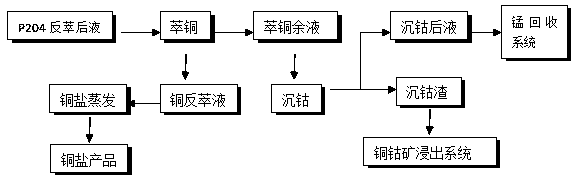

Method for separating and recovering cobalt and copper from P204 reverse extraction liquid in cobalt and copper mine wet method smelting process

PendingCN109487083AHigh recovery rateSolve complexityProcess efficiency improvementCopper sulfatesKeroseneSmelting process

The invention provides a method for separating and recovering cobalt and copper from P204 reverse extraction liquid in a cobalt and copper mine wet method smelting process. The method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process comprises the following steps that a copper extraction agent and sulfonated kerosene are added into the P204 reverse extraction liquid for extraction, a PH value is controlled between 1.5 and 2.0 in the process, and extracted copper residual liquid and extractedcopper organic load are obtained; sulfuric acid is added into the extracted copper organic load for reverse extraction to form a copper sulphate solution, and the copper sulphate solution is fed intoa copper salt vaporization system for vaporization to obtain a copper salt product; and the extracted copper residual liquid is heated to 30-60 DEG C, a precipitating agent is added for precipitation, a final PH value is controlled between 3.0 and 4.0, filter pressing and solid-liquid separation are carried out finally to obtain cobalt slag and precipitating cobalt liquid, the cobalt slag is fedto a copper and cobalt leaching system, and the cobalt and the copper are effectively separated. According to the method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process, the operation process is simple, the production cost is low, the production efficiency is high, and the metal recovery rateis effectively improved.

Owner:江苏雄风科技有限公司

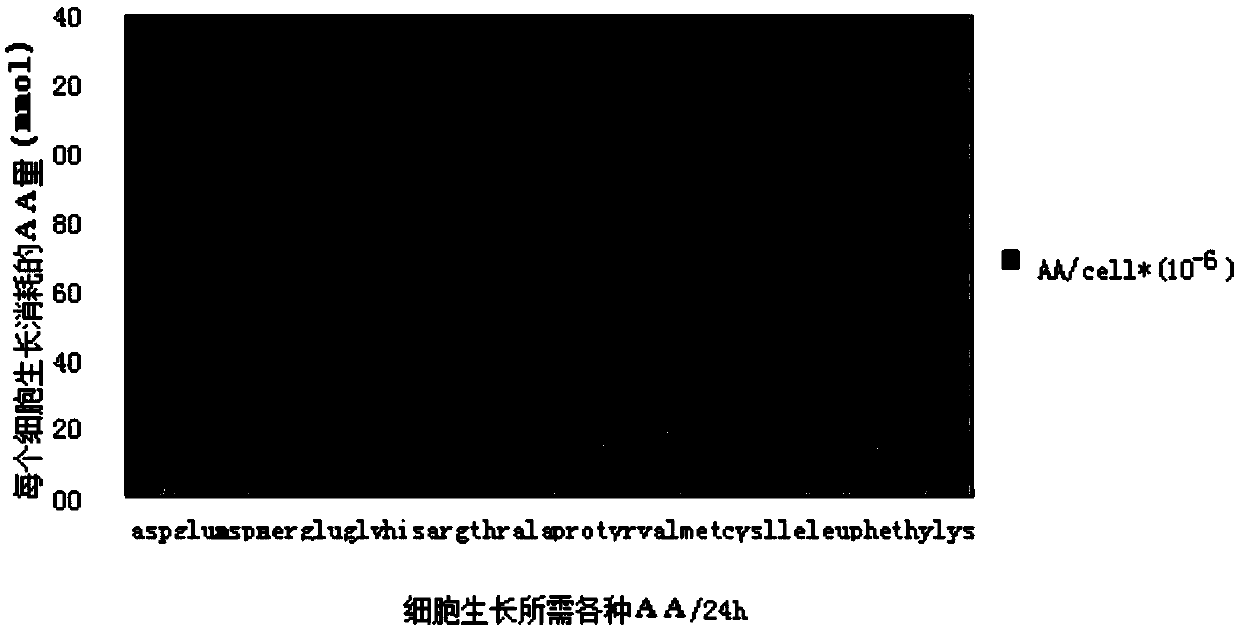

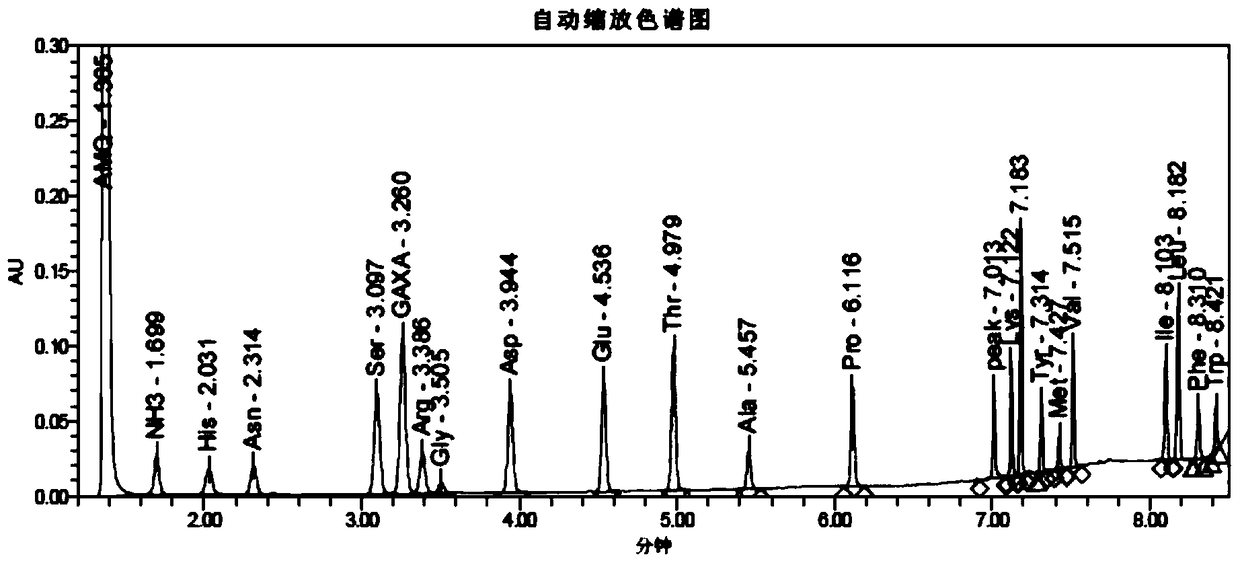

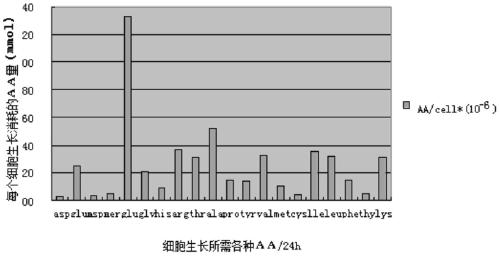

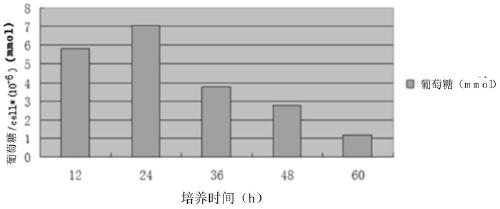

Low-serum culture medium for high-density suspension culture of BHK-21 cells and application of low-serum culture medium in proliferation of FMDVs (foot and mouth disease viruses)

ActiveCN105505853AImprove the training environmentQuality improvementSsRNA viruses positive-senseCulture processHigh cellAntigen

The invention discloses a low-serum culture medium for high-density suspension culture of BHK-21 cells and an application of the low-serum culture medium in proliferation of FMDVs (foot and mouth disease viruses). According to researches on the metabolism level and mutual adjustment of nutritional substances such as glucose and the like in the growth process of the BHK-21 cells, the low-serum culture medium for individual BHK-21 cells is provided and comprises an amino acid part, a vitamin part, a balanced salt part and other additive parts. The culture medium is used for high-density suspension culture of the BHK-21 cells, the effective utilization rate of the nutritional substances by the cells can be greatly increased, the concentration of metabolism byproducts is reduced, and accordingly, the cell culture efficiency is improved; besides, the BHK-21 cells cultured by the culture medium have increased sensitivity for different serums of animals suffering from FMDV, the content of effective antigens 146S of the viruses is substantially increased, the purposes of high cell growth efficiency, cell growth controllability and minimization of the concentration of the metabolism byproducts are achieved, the production efficiency of biological products is higher, the production cost is lower, and the low-serum culture medium has remarkable economic benefits.

Owner:CHINA AGRI VET BIO SCI & TECH +1

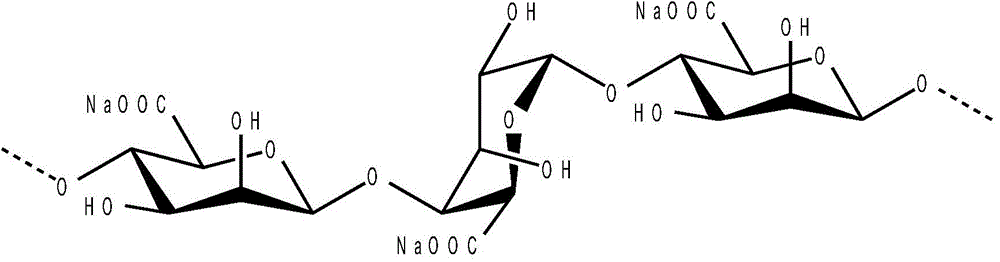

Improved method of traditional sodium alginate production process

The invention relates to the field of algae chemical engineering, in particular to a three-stage separation technology for improvement on the traditional production process of sodium alginate. The method is as below: adding 170-190 tons of tap water in per ton of algae digestive juice for dilution; conducting slag and liquid separation on the diluted digestive juice by a three-stage separation technology; dissolving gas in the digestive juice subjected to three-stage separation; conducting foaming separation on the glue solution subjected to gas dissolution, calcifying under the condition of pH value being 6-9, decalcifying, dehydrating and drying to obtain the sodium alginate. The invention adopts a three-stage separation technology including rotary separation, filtration and spiral sedimentation to separate the fluid suspension after digestion by algae. Solid effect increases from 15% to 58%, the diameter of separation particles increases from no less than 1 mm in bolting-silk filter to no more than 0.05 mm, water consumption is saved by 300 ton for per ton of sodium alginate, the concentration of sodium alginate after dilution increases from 1.2% to 1.75%, the production cost for per ton of products reduces by 650 yuan, and COD emission is reduced to 154 ton.

Owner:SHANDONG JIEJING GROUP CORP

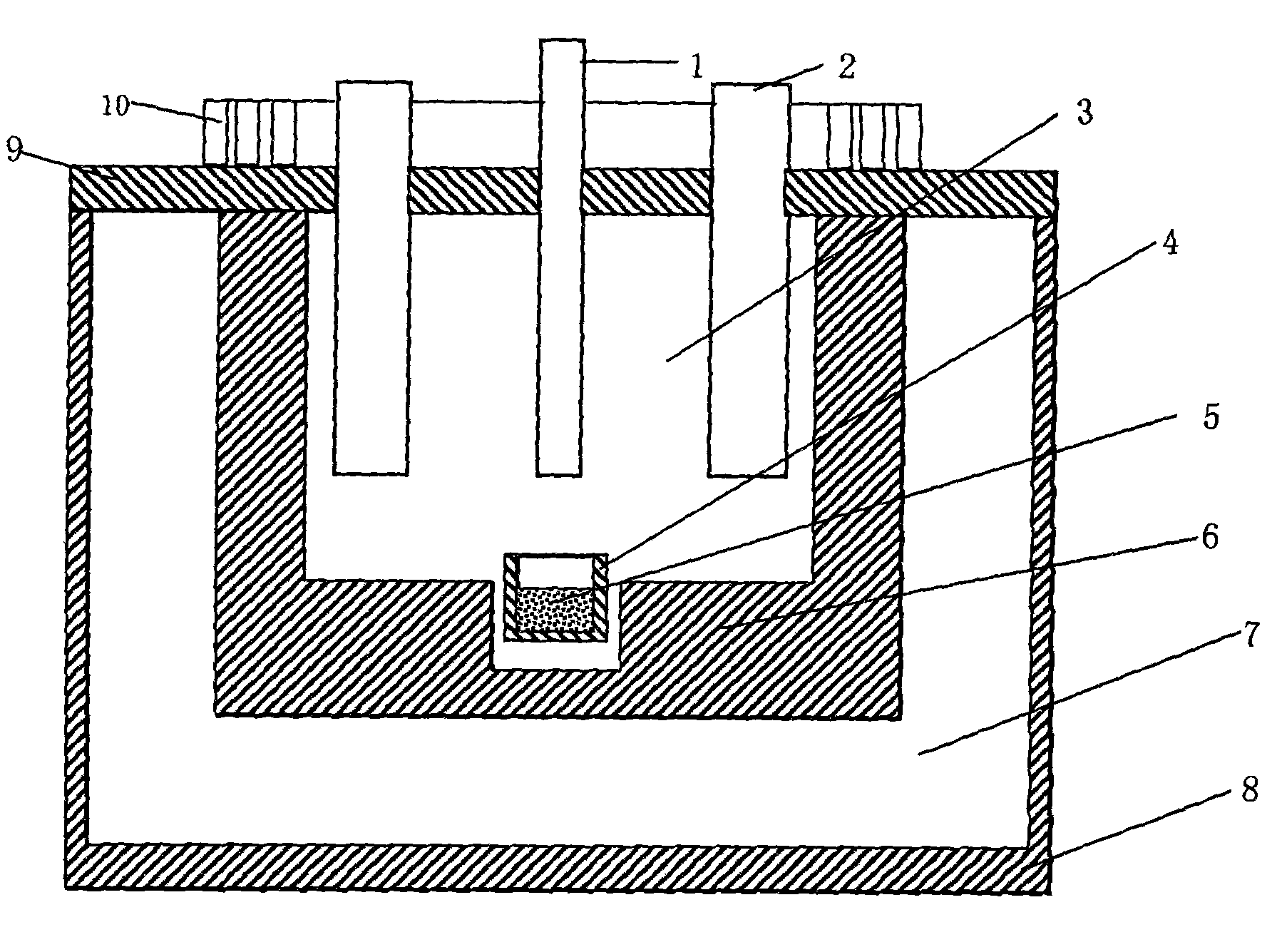

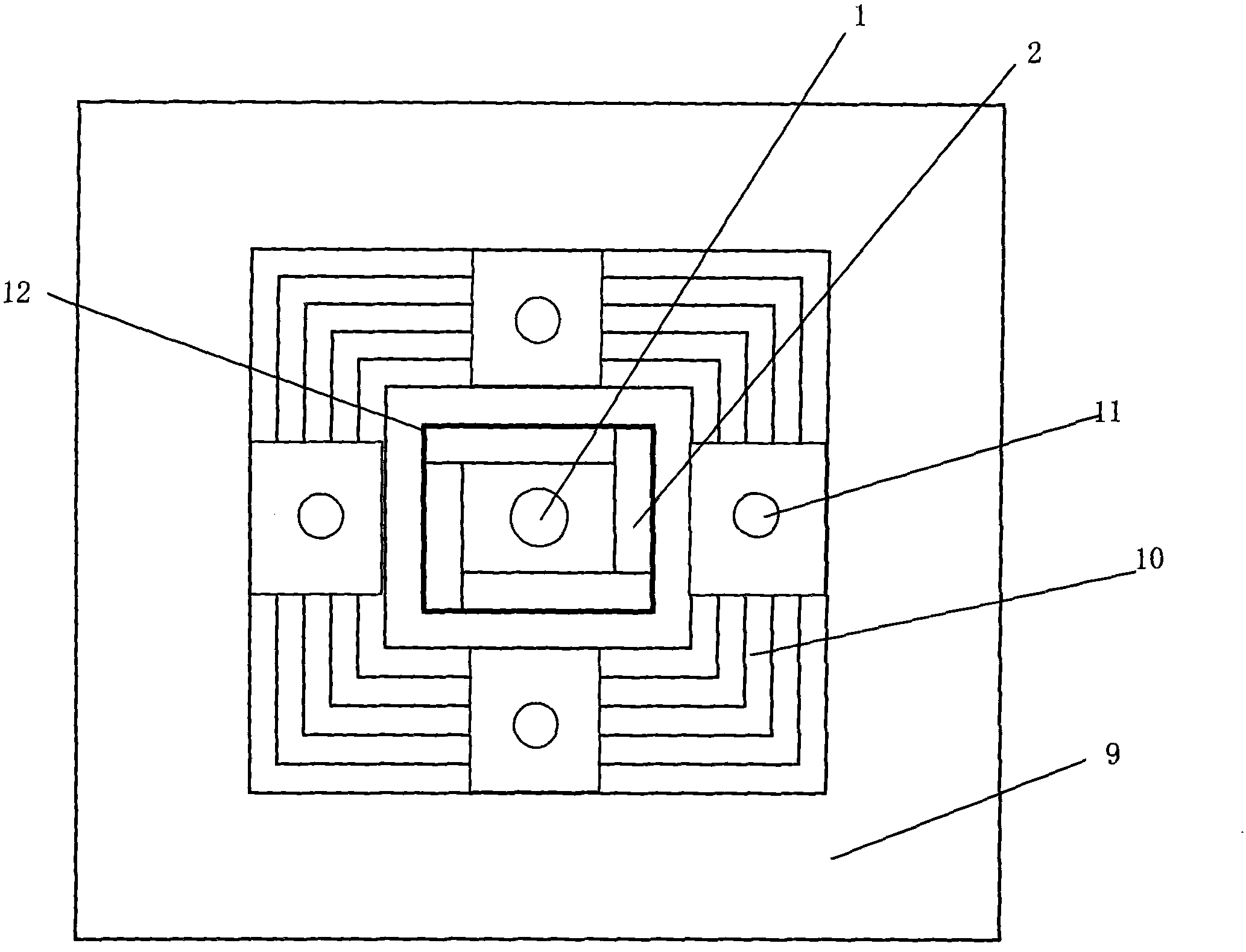

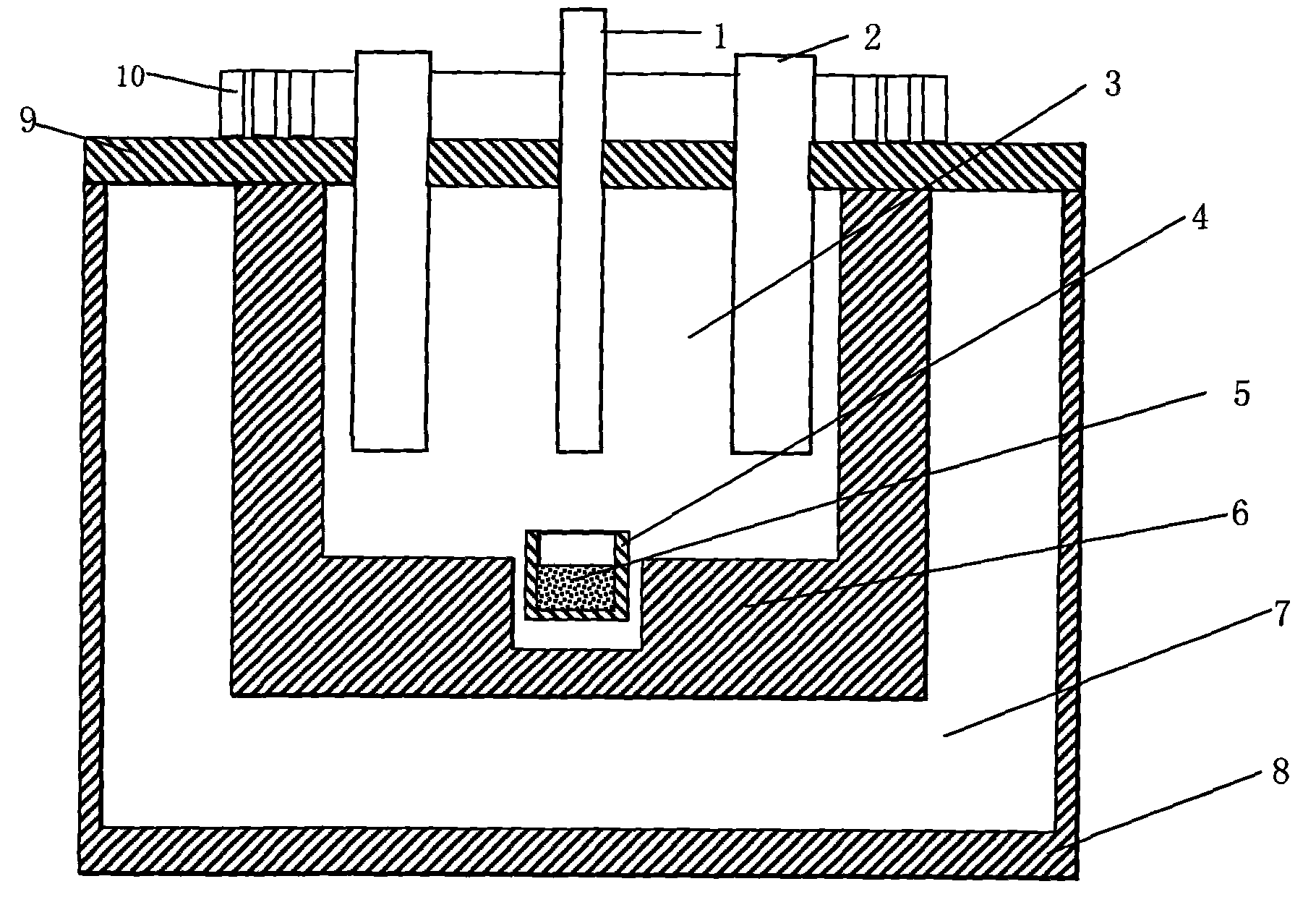

4000A-electrolytic furnace for producing oxide molten salt through electrolysis

The invention relates to a 4000A-electrolytic furnace for producing an oxide molten salt through electrolysis, which comprises a negative electrode, a positive electrode, a molten salt, a crucible, a graphite cuvette, a steel jacket and the like. A packing layer is filled between the graphite cuvette and the steel jacket, a throat opening on a furnace panel is quadrate, and a heat radiator is arranged above the furnace panel to play a role in balancing and stabilizing the furnace temperature. The electrolytic furnace has simple and convenient furnace building process steps and a simple furnace building method, the furnace building materials are few in variety, and part of the materials is low in price and is practical. When the furnace life becomes due, only an inner liner of the graphitecuvette is required to be replaced, and the other parts of the furnace body can be used in a long term. The electrolysis temperature is easy to control, the product quality is high, the electrolysis current can reach 4000A, the product yield is high, and the production operations are easy. The product carbon contents are very easy to control, and produced rare earth products have different electrolysis temperatures due to different varieties so that the carbon contents can be different, but the same point is that all the carbon contents can reach less than 0.03, and the carbon contents of theproducts of most varieties can reach about 0.01.

Owner:カン州晨光希土新材料有限公司

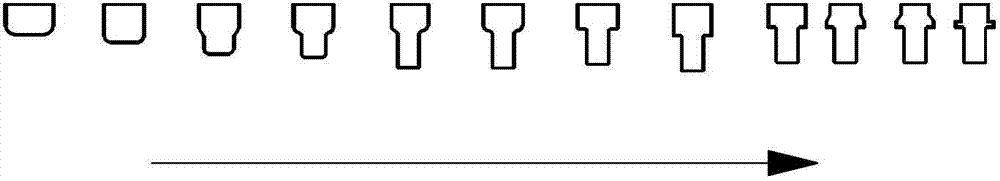

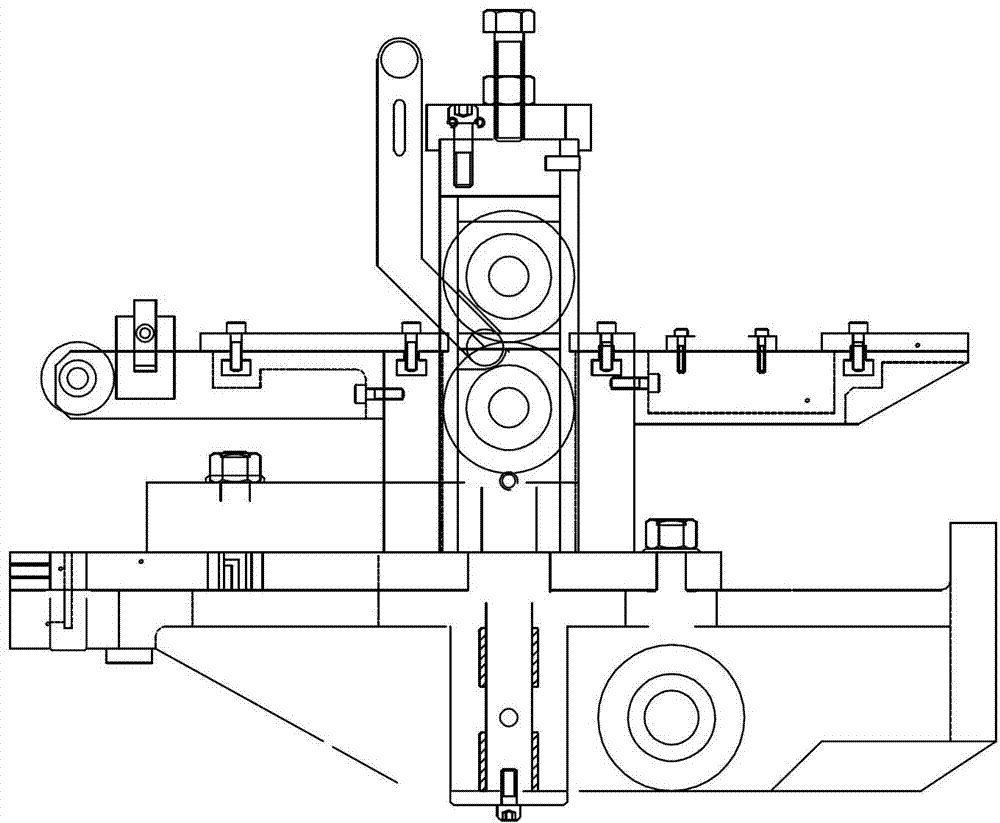

Novel making process of cylindrical pin piece of digital transmission connection pin

ActiveCN102761046BHigh precisionIncrease productivityContact member manufacturingStampingUltimate tensile strength

The invention relates to the field of pin piece manufacturing, in particular to a novel making process of a cylindrical pin piece of a digital transmission connection pin. The process comprises the following steps of: (a) selecting materials: selecting a copper strip with width of 18-27.5 mm and thickness of 0.16-0.22 mm, and placing the copper strip on a swinging feeding device; and (b) high speed precision stamping and deep drawing: feeding the copper strip meeting specifications to a deep drawing progressive die by the swinging feeding device; carrying out continuous deep drawing on the copper strip until an outer pipe finished product meeting the specifications are deeply drawn by a multi-station continuous die. The novel making process provided by the invention has the advantages as follows: the production efficiency is greatly increased, the direct production cost is reduced and high accuracy and stable quality of a product are guaranteed; good mechanical strength and transmission performance are also achieved; it is proved by test that parameters of the product, such as mechanical strength, anti-interference property and the like, all meet specifications and standards in the industry, and compared with a copper rod turned piece, the product has the advantages of more stable performance and strong signal transmission effect.

Owner:CIXI LVLV ELECTRONICS

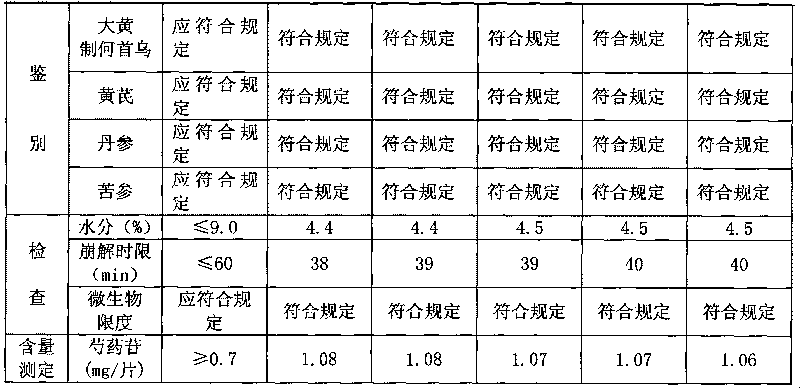

Method for preparing film coating tablet for treating chronic renal failure

InactiveCN101721577AReduce manufacturing costImprove drug stabilityUrinary disorderDrageesRenal functionMagnesium stearate

The invention discloses a method for preparing a film coating tablet for treating chronic renal failure. The method comprises the following steps: proportioning various crude medicines of rhubarb, astragalus root, white mulberry root-bark, kuhseng, radix codonopsis pilosulae, white atractylodes rhizome, tuckahoe, prepared fleece flower root, white peony root, radix salviae miltiorrhizae, rhizoma ligustici wallichii, chrysanthemum, pinellia, plantain, radix bupleuri and licorice according to a conventional method, adding water, decocting, filtering, merging decoction, concentrating, drying and pulverizing to obtain medicinal extract powder; the method is characterized by also comprising the following steps: adding microcrystalline cellulose into the medicinal extract powder, mixing evenly, preparing a soft material by an ethanol water solution, granulating, drying, straightening, adding magnesium stearate, mixing evenly, tabletting to obtain a tablet agent and then coating a film coating by a film coating material; the mass ratio of the medicinal extract powder to the microcrystalline cellulose to the magnesium stearate to the film coating powder is 60-75:20-36:0.5-1.3:2-6; and the conditions of the technical parameters of the coating process for coating the film coating are as follows: the concentration of coating liquid prepared by the film coating material is 10-20wt%, the temperature of a tablet bed is 45-48 DEG C, and the liquid spraying speed of the coating liquid is 4-5ml / min.

Owner:东方药林药业有限公司

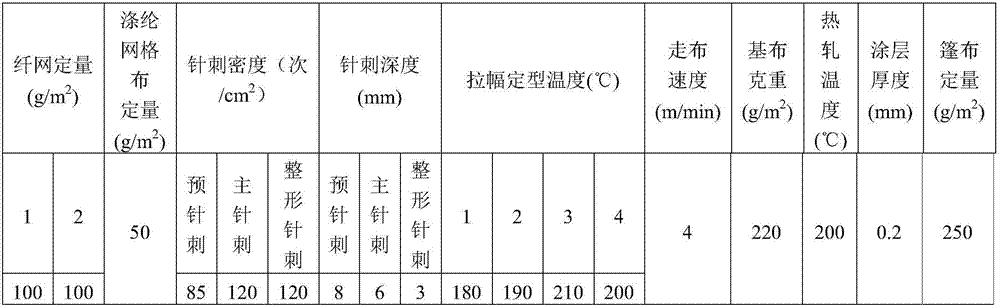

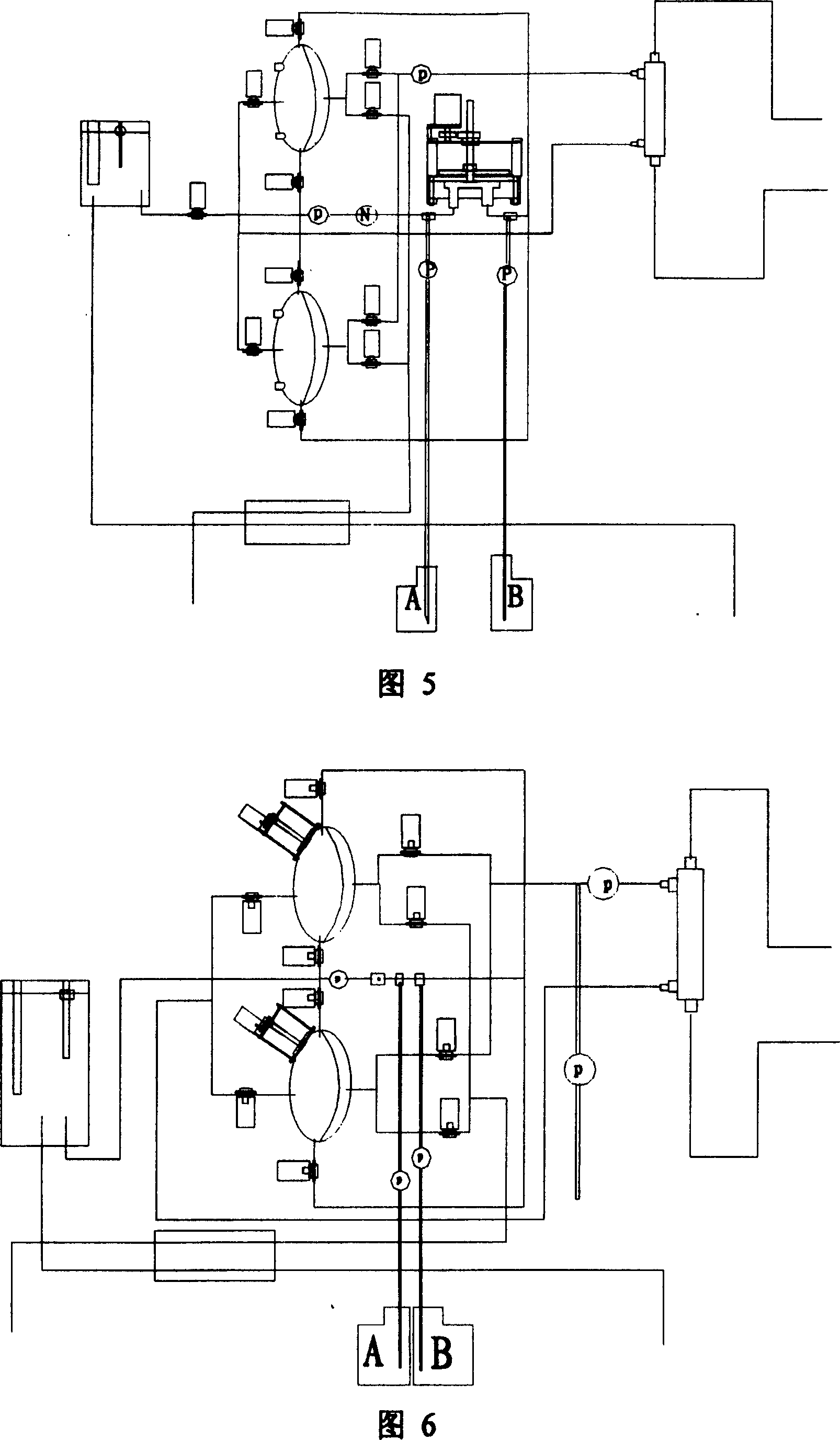

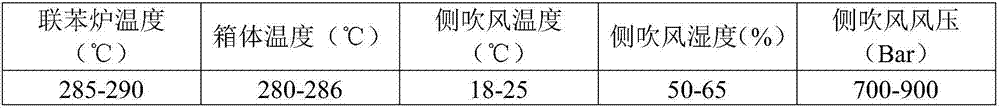

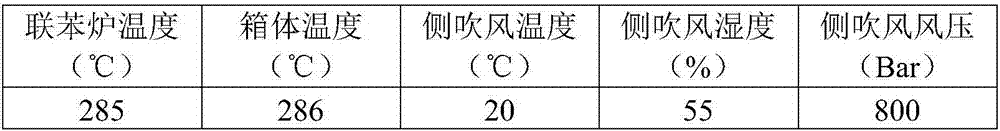

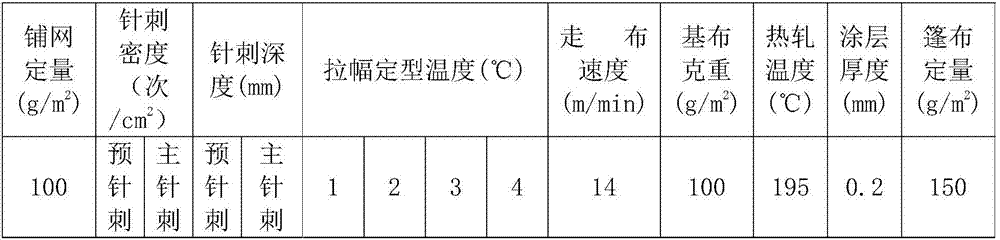

Covering fabric with composite staple fiber non-woven fabric as basic fabric and production method of covering fabric

The invention discloses covering fabric with composite staple fiber non-woven fabric as basic fabric and a production method of the covering fabric. The covering fabric comprises a basic fabric layer and a functional coating layer. The basic fabric layer is a composite layer composed of staple fiber web and polyester fibre mesh fabric; the staple fiber web is made of polyester staple fiber with the fracture strength not less than 5.8CN / dtex and fiber length ranging from 80 mm to 110 mm. The covering fabric using the non-woven fabric as the basic fabric has the advantages of good flexibility and light weight; and as compared with the conventional PE and PVC covering fabric, the covering fabric further has the advantages of high strength, good abrasion resistance, ageing resistance which is much better than that of PE woven coated covering fabric and the like.

Owner:TIANDINGFENG NONWOVENS CO LTD

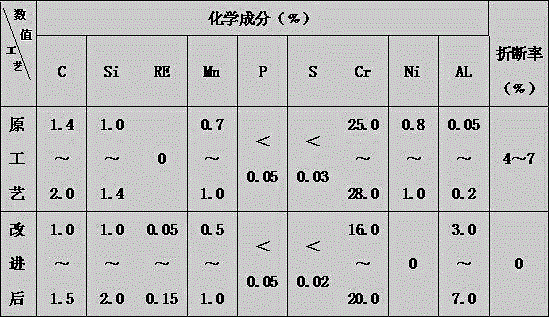

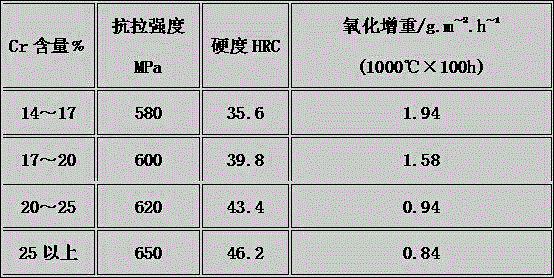

Grate bar material of trolley of sinter machine and production method of grate bar material

InactiveCN104611634AReduce dosageSimple production processFoundry mouldsFoundry coresRare-earth elementChemical composition

The invention discloses a grate bar material of a trolley of a sinter machine. The grate bar material is good in usage effect and low in production cost. The grate bar material is characterized by comprising the following chemical components in percentage by mass: 1-1.5% of C, 1.0-2.0% of Si, 16-20% of Cr, 3.0-7.0% of Al, 0.05-0.15% of rare-earth elements, 0.5-1.0% of Mn, less than 0.02% of S, less than 0.05% of P and the balance of Fe, and the sum of all the components is 100%. The production method comprises the steps of modelling, melting and casting. The service life of grate bars produced by the production method disclosed by the invention is equal to or greater than 12 months, the hardness HBS is equal to or greater than 282, and the fracture rate (when the grate bars drop from a 2-meter-high place) is reduced to 0 from about 5% in orignal. The dosage of precious metal such as chromium and nickel is substantially reduced, and the production technology is simplified, so that the direct production cost is reduced by over 20% than that of an original technology; after about 200 tons of the grate bars are produced and used by users, the response is very good, the economic benefits of enterprises are improved, and the market competitiveness is enhanced.

Owner:桃江新兴管件有限责任公司

Soft-magnetic composite material for magnetic conduction component and process for preparing magnetic conduction component

InactiveCN1700366ASufficient magnetic saturation rateImprove magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMagnetic mediaAlloy

This invention relates to soft magnetic compound materials used in motor magnetic parts, which is characterized by the following: the iron materials and magnetic medium are mixed to get the iron element in the parts with the weight percentage of 85-99.5úÑ, magnetic element of 0.5-15úÑ; the said iron materials and magnetic medium weight percentages are 85íœxa1+ya2íœ99. 5ú”0.5íœxb1+yb2íœ15. The said iron material of iron material and the magnetic materials are the powder alloy to increase the magnetic property.

Owner:罗计添 +2

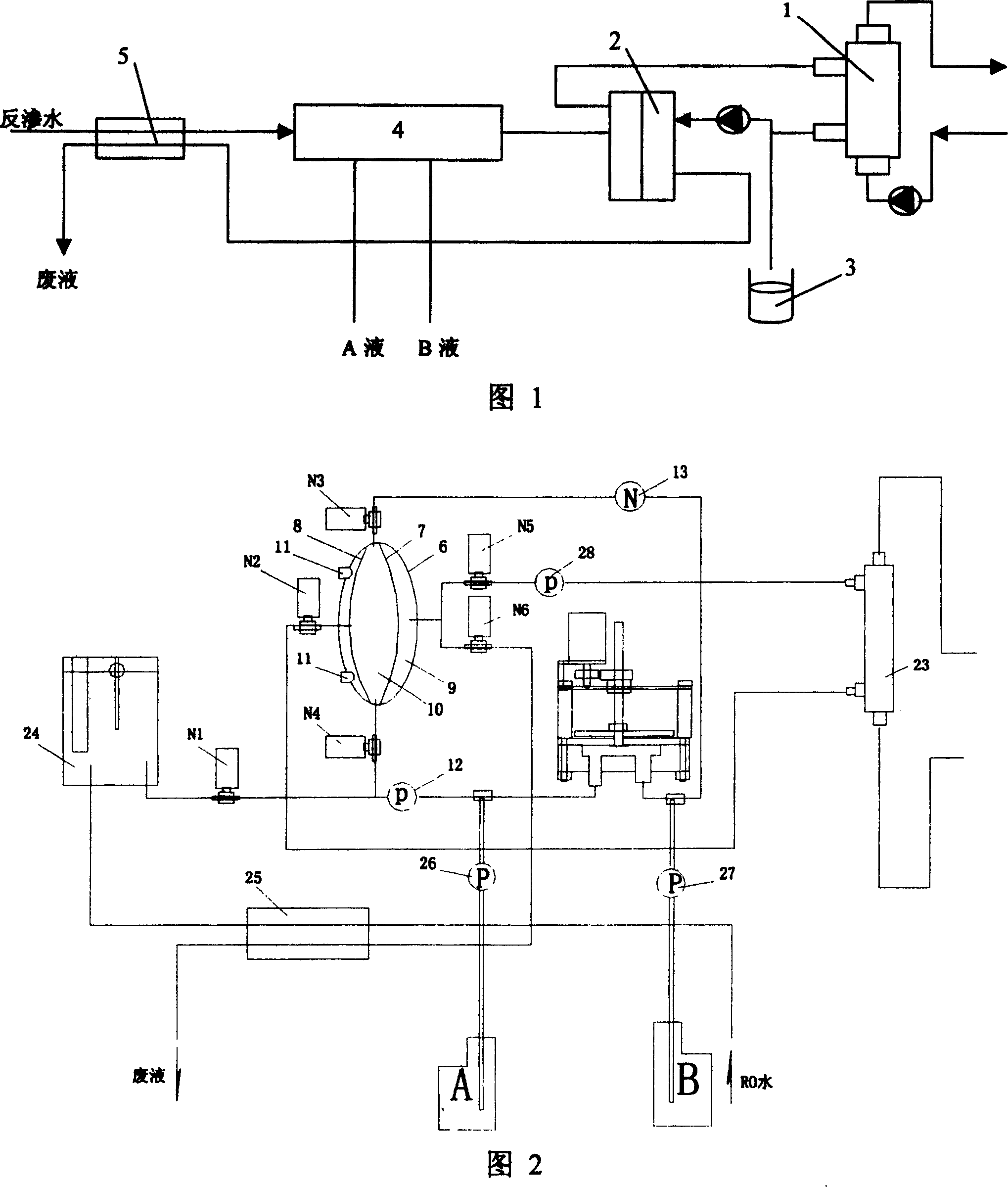

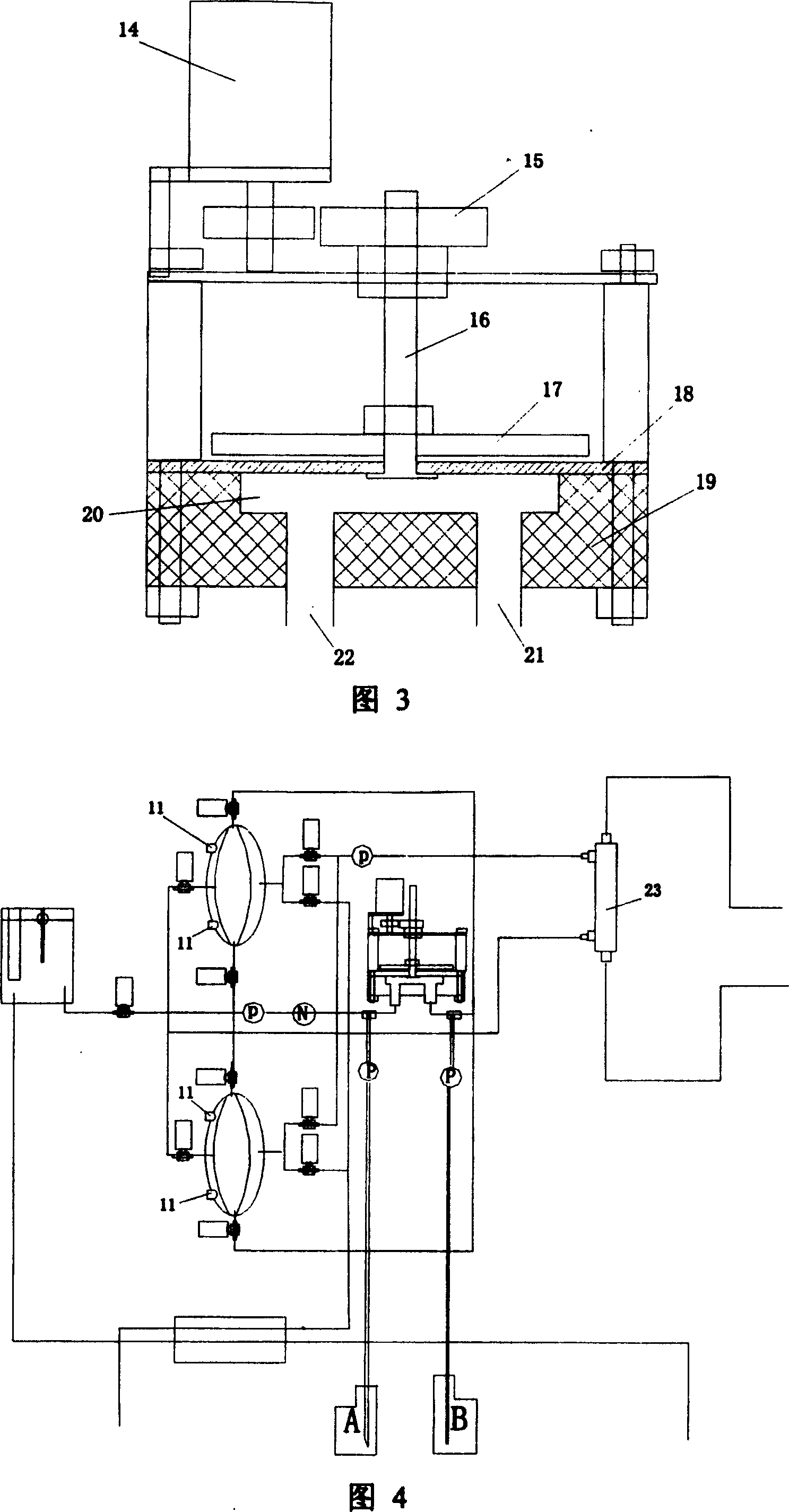

Method and apparatus for dialysate preparation and supply

ActiveCN1327913CSimplify the maintenance processSimple structureDialysis systemsDialysate flowEngineering

A liquid dispensing and feeding method is disclosed. It mainly makes use of a chamber to conduct liquor dispensing and balanced liquor feeding. The liquor dispensing and feeding device comprises a isolated chamber and assembly for dispensing. Inside the chamber, a membrane is provided to separate it at least into two spaces, with one of the space communicated with the liquor dispensing assembly to form a liquor dispensing loop. The invention can regulate the dialysate flow as needed without closing down the machine during dialysis treatment. In addition, it has simple structure, lower production cost, favorable stability.

Owner:JINAN UNIVERSITY

Soft-magnetic composite material for magnetic conduction component and process for preparing magnetic conduction component

InactiveCN1700367ASufficient magnetic saturation rateReduce eddy currentInorganic material magnetismInductances/transformers/magnets manufactureMagnetic mediaAlloy

This invention provides one motor magnetic parts soft magnetic compound materials, which are characterized by the following: comprising iron materials, magnetic medium and additive with their percentage of 82-99.úÑú¼0.5-13úÑú¼0.5-5úÑ; the said iron material is of iron base materials and the magnetic medium is of the powder alloy to increase the part magnetism; the additive is isolation agent or adhesive agent or lubrication or modified agent for lone usage or combination. The magnetic part process comprises the steps of mixing, shaping, solidifying and stainless process.

Owner:罗计添 +2

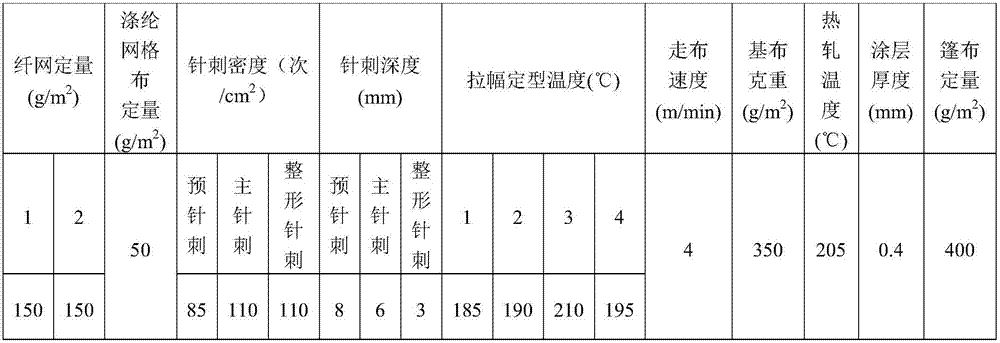

Tarpaulin taking filament spunbond nonwoven fabric as base cloth and production method thereof

InactiveCN106917299AImprove flexibilityLight in massHeating/cooling textile fabricsConstructions elementsWear resistantEngineering

The invention discloses a tarpaulin taking a filament spunbond nonwoven fabric as the base cloth and a production method thereof. The tarpaulin comprises a base cloth layer and a functional coating. The base cloth layer is made of filament spunbond nonwoven fabric, which is prepared from PET with a viscosity of 0.69-0.71. The provided tarpaulin takes nonwoven fabric as the base cloth and has the advantages of good flexibility and lightness. Compared with conventional PE and PVC tarpaulins, the provide tarpaulin has the characteristics of high strength, good wear resistant performance, and better aging resistant performance (compared with a PE woven double membrane tarpaulin).

Owner:TIANDINGFENG NONWOVENS CO LTD

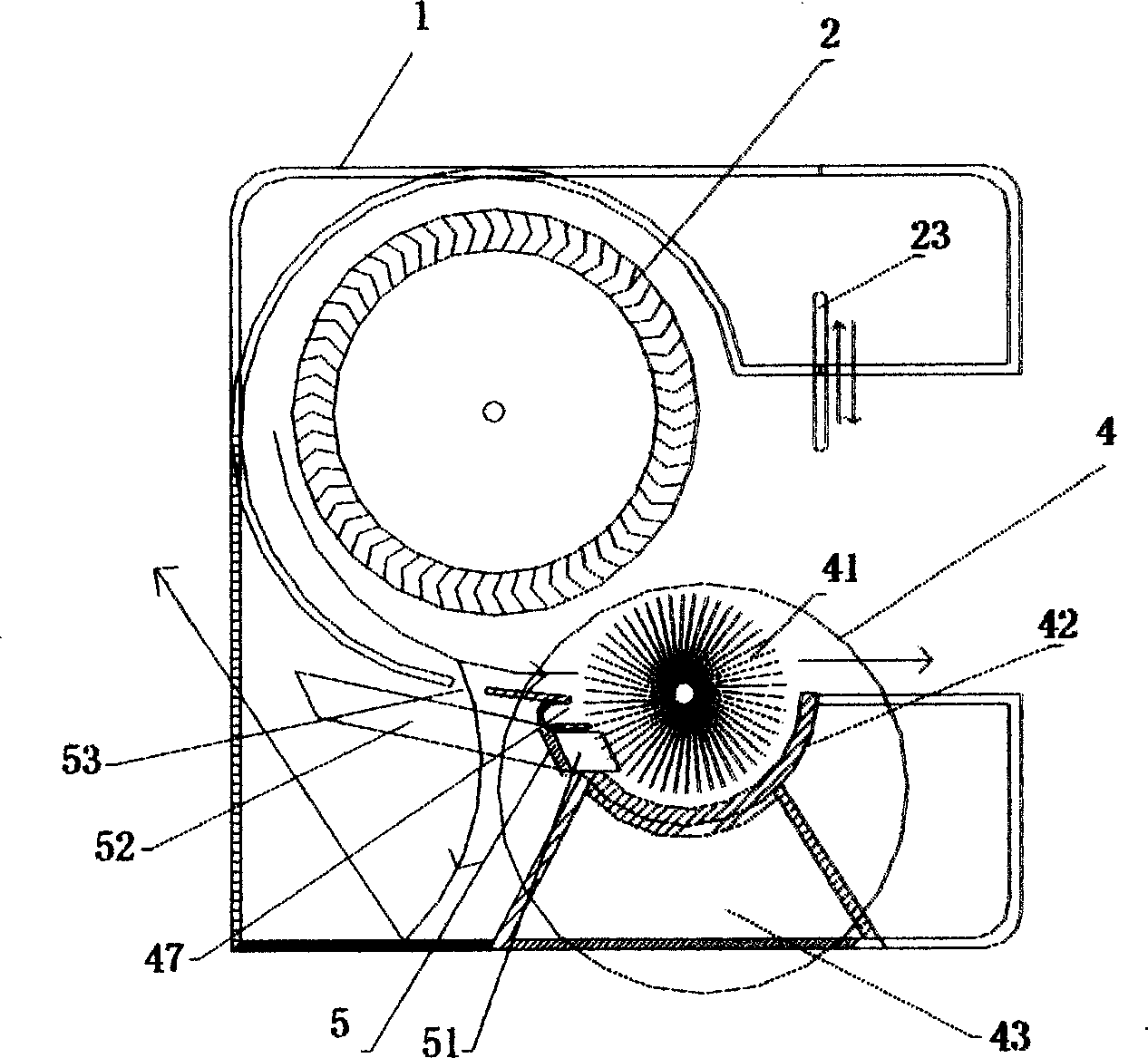

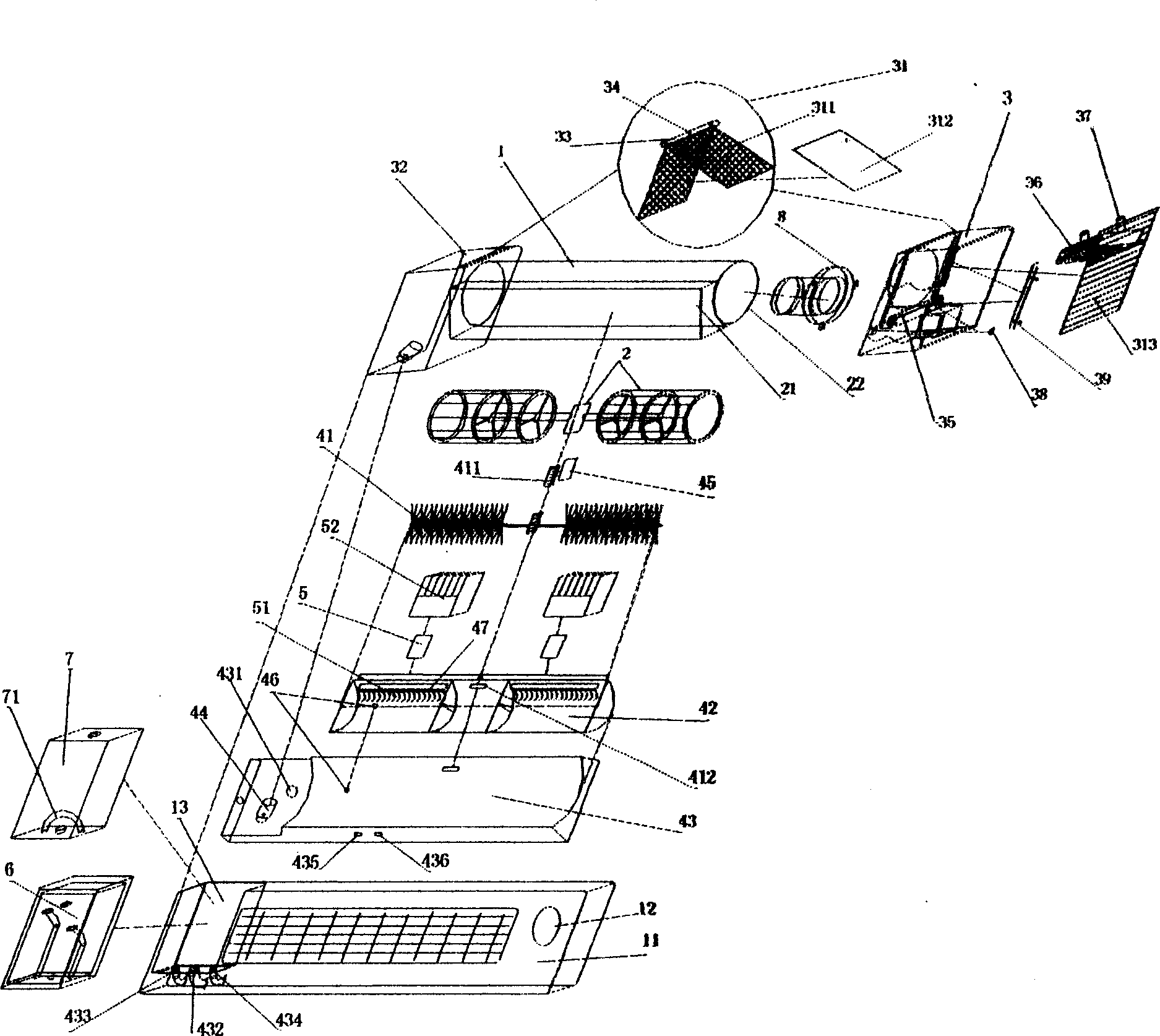

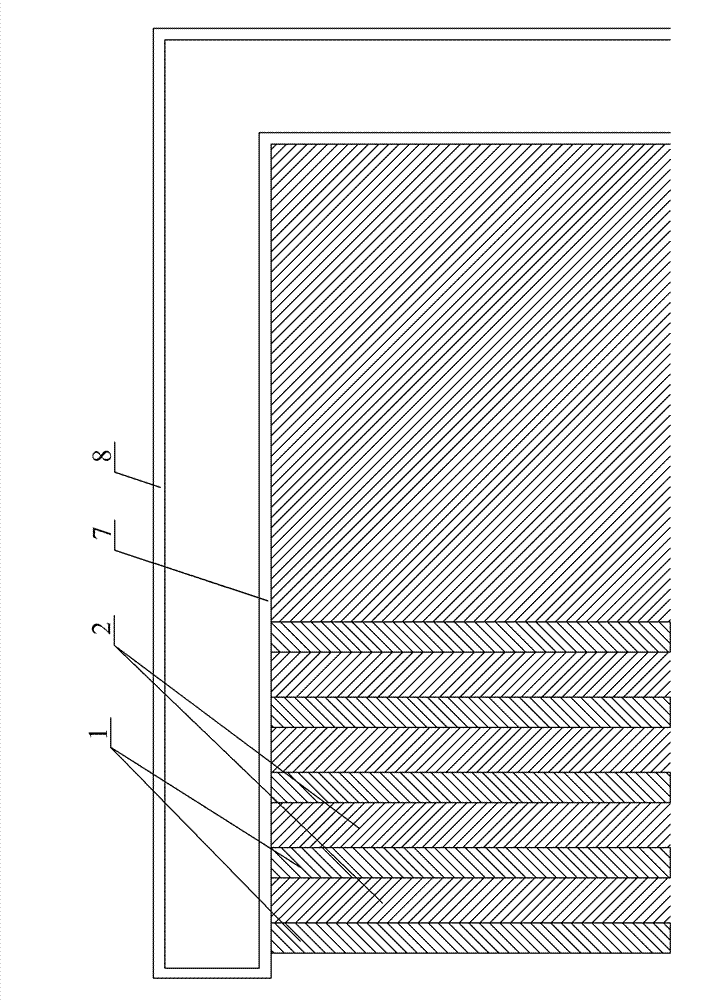

Cold-storage type electronic refrigeration and air conditioning sterilization machine

InactiveCN1566821AReduce dead angleGuaranteed air intakeMachines using electric/magnetic effectsAir conditioning systemsAir cycleAir conditioning

The invention relates to the air disposal field, to be specific, a cold-storage type electronic refrigerating air conditioning sterilizing machine for air filtering, sterilizing, cooling, heating, humidifying and dehumidifying air comprises a casing, a two-wheeled centrifugal fan, a filtering and sterilizing unit, a refrigerating unit and a humidifying device. The two-wheeled centrifugal fan with an air outlet arranged in front of the casing and an air inlet arranged at two sides of the casing is arranged in the casing. The filtering and sterilizing unit is arranged at outer end of the air inlet. The humidifying device arranged outer middle-lower part of the air outlet is a direct contact surface cooler. The refrigerating unit comprises a semiconductor refrigeration assembly and / or an energy storage box. The invention has the following advantages: room air circulation is thorough, filtering and sterilizing effects are good, and refrigeration rate is high.

Owner:高飞

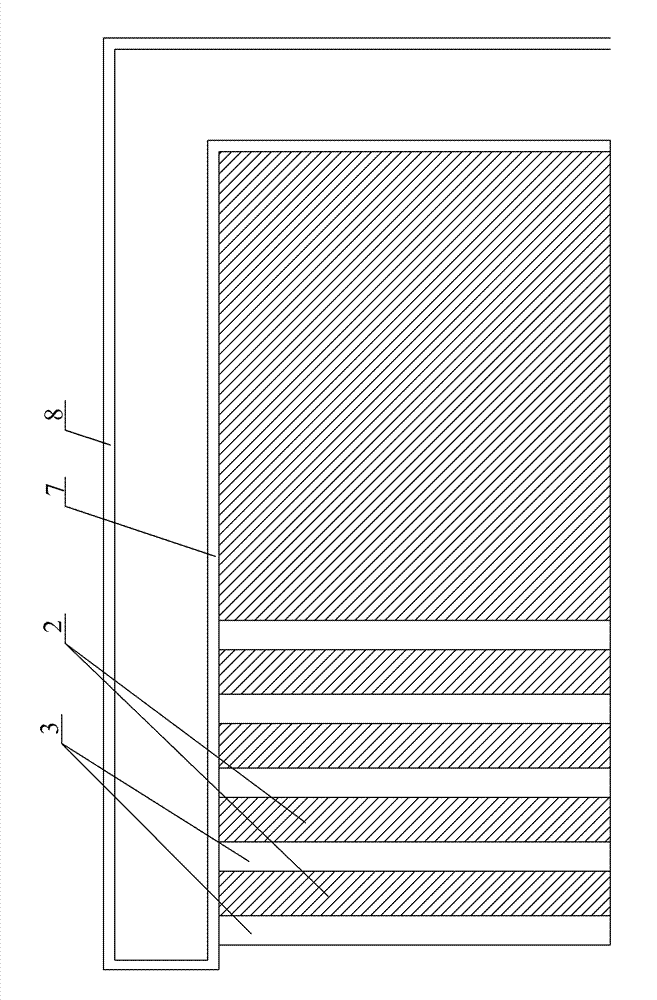

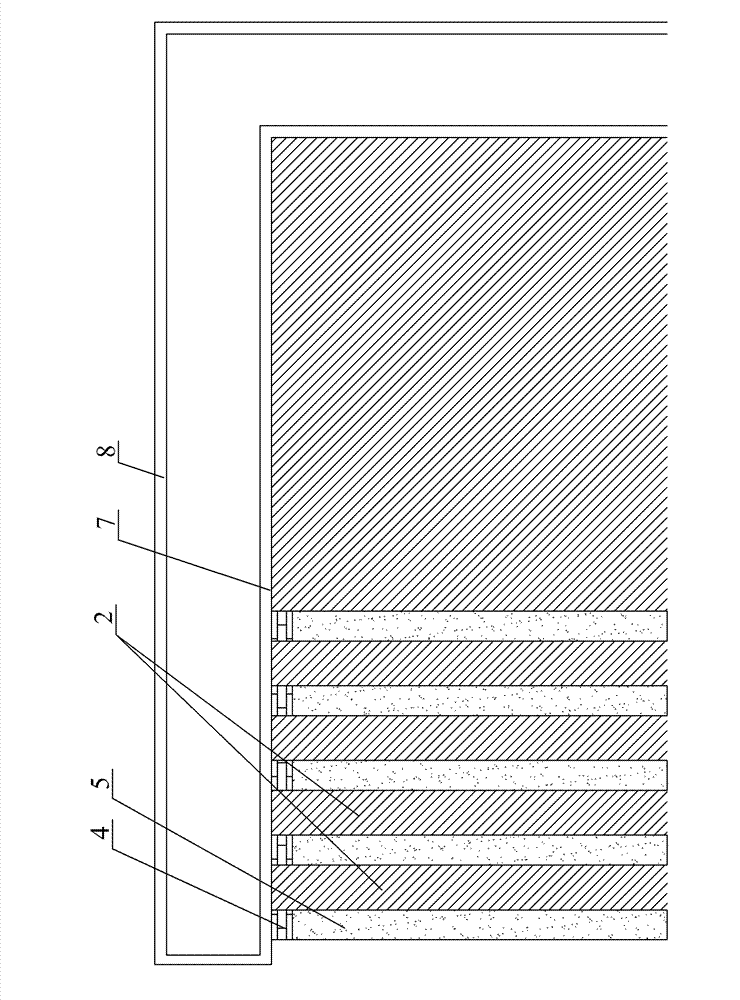

Roadway backfill mining method for coal seams with medium-high thickness

InactiveCN102155226BIncrease profitExtended service lifeUnderground miningSurface miningEngineeringFilling ratio

The invention belongs to the field of coal cutting and filling, in particular to a house pillar type cutting and filling method of the medium coal seam for controlling the movement deformation of the overlying rock, which is suitable for the coal face with the coal seam thickness more than 2 meters. The method comprises the following steps: determining the initial weighting interval L and the periodic weighting interval M of the main roof according to the main roof initial weighting interval theory; arranging the rooms and the coal pillars at intervals; and using the material with high expansibility in water during the filling according to the method comprising the following steps of mining the rooms, filling the empty rooms, mining the coal pillars and filling the empty zones of the coal pillars. The method provided by the invention can determine the most economical filling ratio through controlling the key layer to maximize the benefits; the method provided by the invention can control the movement deformation of the overlying rock absolutely within the allowed range when realizing the pulling without pillars, and realize the extremely small gentle uniform sinking of the ground; and the method provided by the invention can realize the mining of the coal resource with high recovery rate under any condition by using the material with high expansibility in water, and greatly enhance the security of coal face. When the rooms are mined, a plurality of coal face of rooms can be arranged at intervals to enhance the working efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

A low-serum medium for high-density suspension culture of bhk-21 cells and its application in the proliferation of foot-and-mouth disease virus

ActiveCN105505853BQuality improvementIncrease production capacitySsRNA viruses positive-senseCulture processAntigenHigh cell

Owner:CHINA AGRI VET BIO SCI & TECH +1

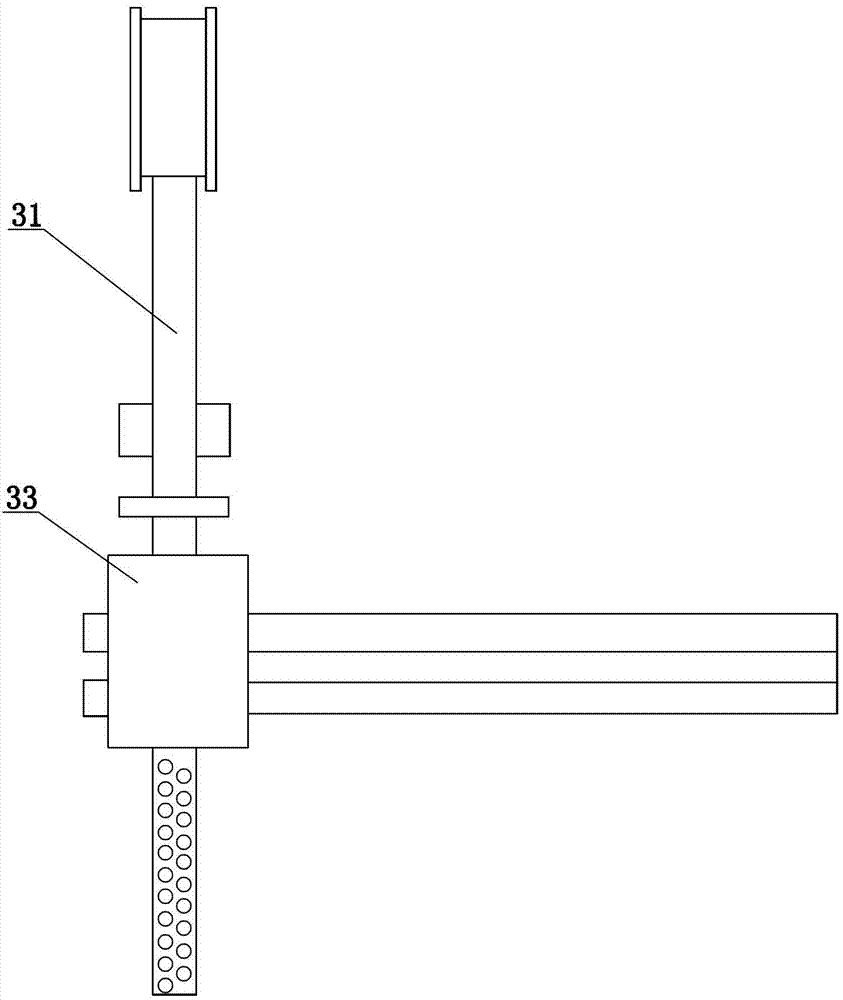

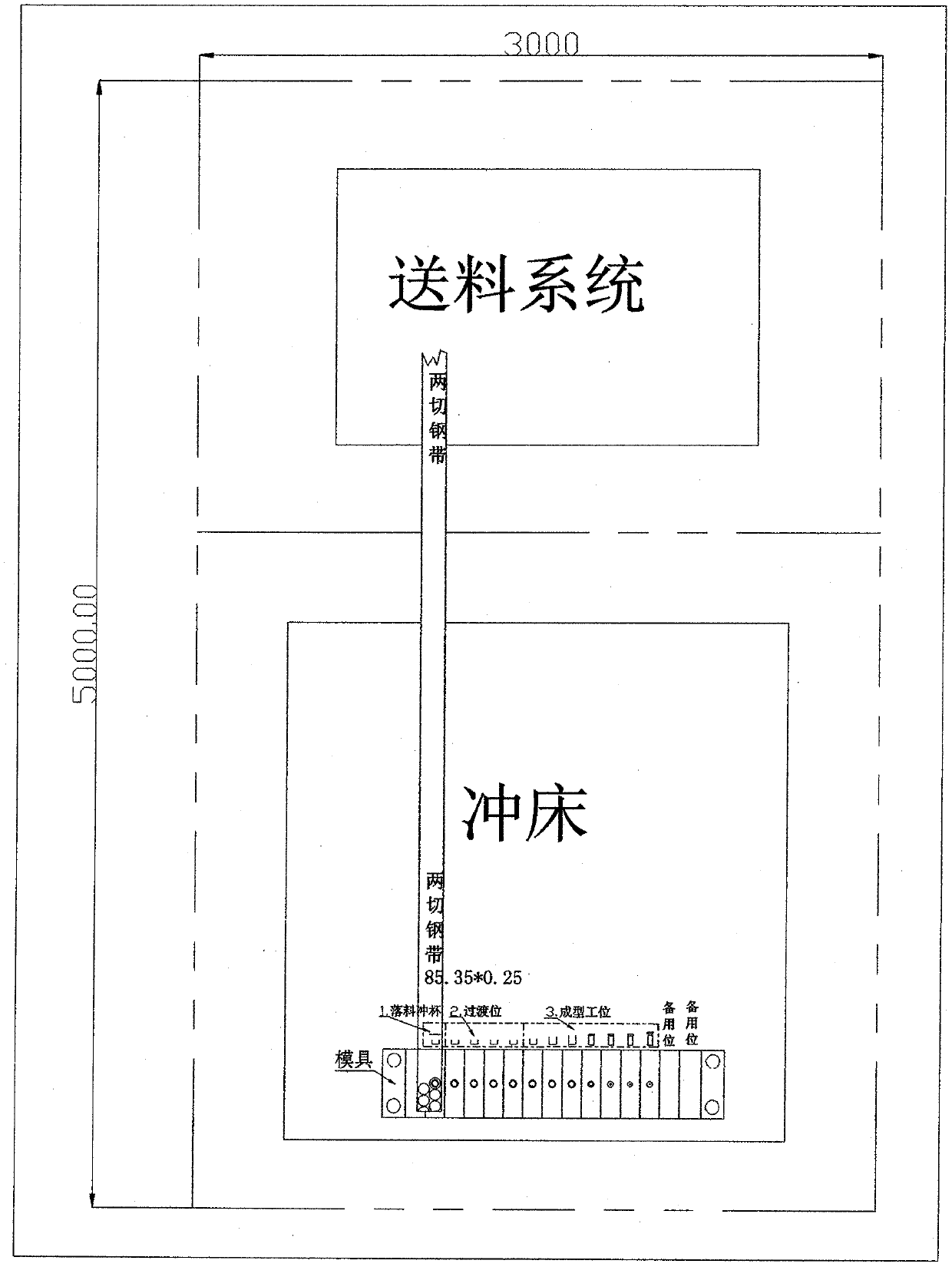

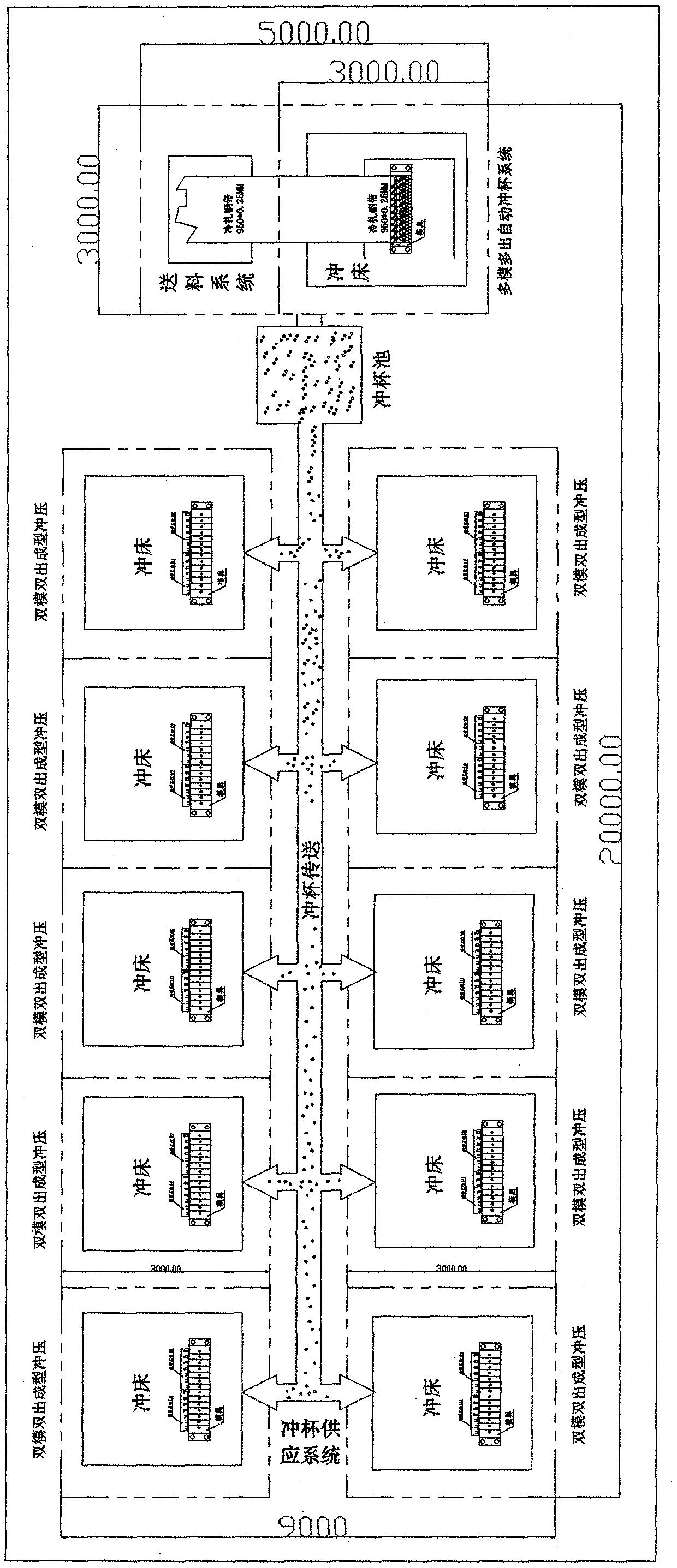

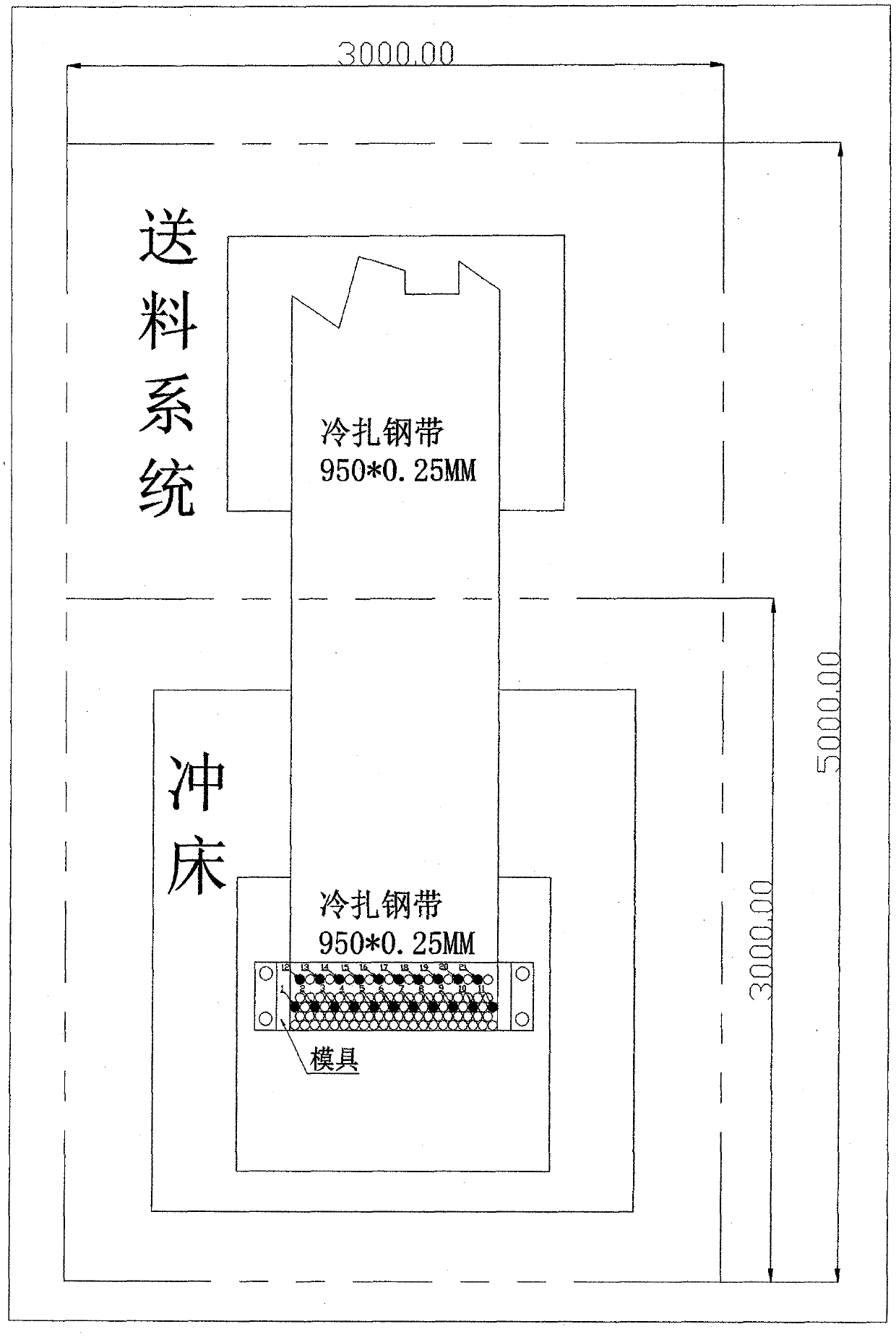

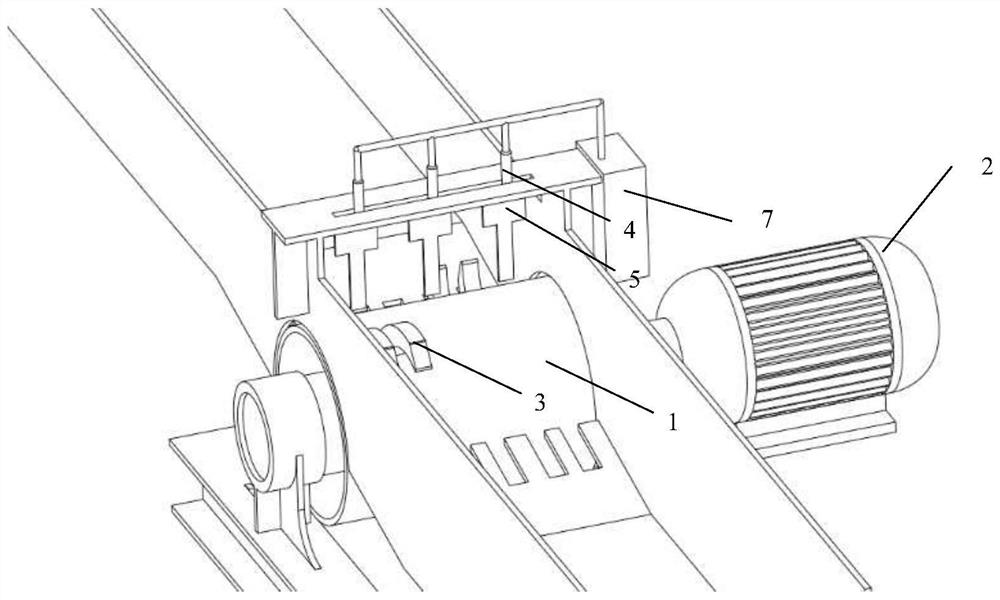

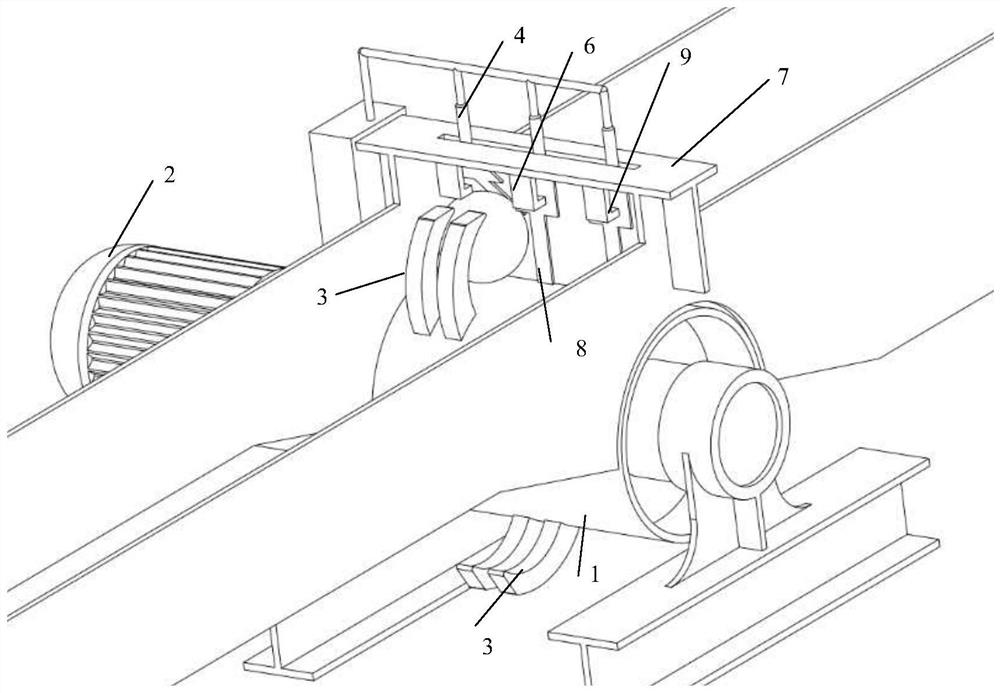

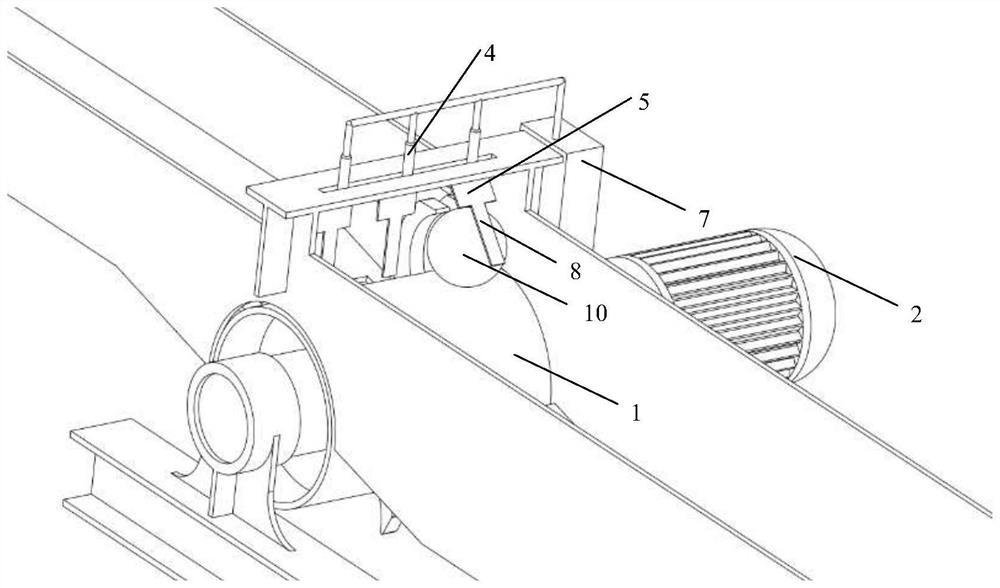

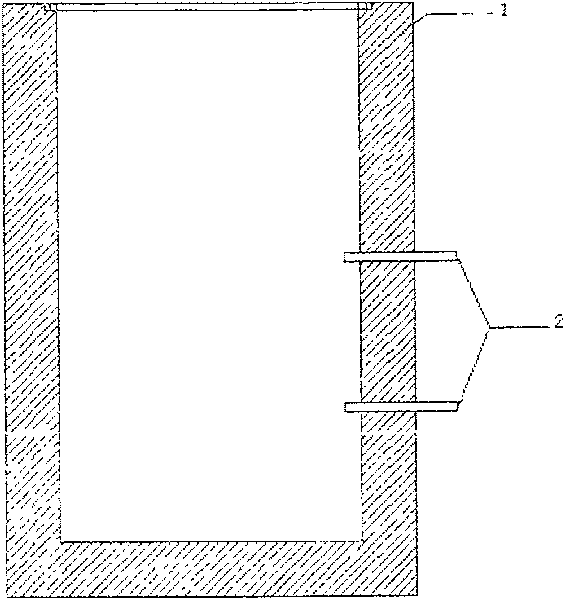

Automatic punching production line for cylindrical battery steel shell

PendingCN110405055AFewer punch failures and product quality issuesReduce manufacturing costFinal product manufactureSmall-sized cells cases/jacketsElectricityManufacturing engineering

The invention relates to the technical field of punching production of battery steel shells, and discloses an automatic punching production line for a cylindrical battery steel shell. The automatic punching production line comprises a multi-mode multi-output automatic cupping system, a cupping supply system and multiple double-mode double-output forming punching machines. Multiple sets of blankingcupping moulds are arranged on a punching machine to realize the centralized multi-mode multi-output automatic blanking cupping, and cupping is supplied to the multiple double-mode double-output punching machines through the cupping supply system to complete forming punching. Compared with the current compound die single-machine single-output automatic punching, the automatic punching productionline for the cylindrical battery steel shell greatly improves the material utilization rate and the production efficiency, the output per machine is doubled, and the product costs, such as the numberof forming punching machines, the area of a production site, direct labor, electricity and oil and other auxiliary materials, are reduced by half.

Owner:李可

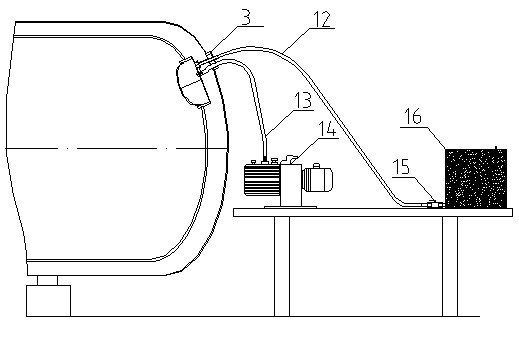

Ball feeder control system based on DCS system platform

PendingCN111983982AAvoid problems that require a lot of manual handlingImprove physical and mental health indexTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention discloses a ball feeder control system based on a DCS platform, belongs to an ore dressing automatic control technology, and particularly relates to an automatic steel ball feeding system of a ball mill. The system comprises a steel ball counting and outputting device and a DCS detection control system. According to the system, a timing period new ore feeding amount automatic calculation unit, a steel ball demand quantity automatic calculation unit, an actual steel ball adding automatic control unit and an automatic period circulation control unit are arranged, the number of thesteel balls needing to be added is calculated, a command is sent out to enable the steel ball output device to add the steel balls into the ball mill, the adding amount is metered, and is fed back tothe actual steel ball adding automatic control unit, and the next adding period is entered after adding is completed. According to the invention, the labor cost is reduced, the safety production indexis improved, the direct production cost is reduced, the system operation difficulty and maintenance difficulty of operators and automation technicians are reduced, and the high efficiency of the steel ball adding system is improved.

Owner:云南迪庆有色金属有限责任公司

Chromizing method by using shaft furnace

InactiveCN101126146BUniform temperatureImprove heat transfer efficiencySolid state diffusion coatingSize differenceHeat transmission

The invention relates to a method applying vertical pit furnace as chromising device; at least two thermoelectric couples are arranged in the furnace to control the temperature in section with a temperature difference less than 5 centigrade. As the parts are placed evenly along the wall of the furnace, the temperature in the furnace is relative even and the heat transmission is in high efficiency, the size differences of the same parts are remarkably reduced after the chromising process; therefore, the usage precision demands of parts are ensured with a pass rate above 96 percent. The vertical pit furnace is equipped with a protective ring and a hanging bracket; the chromising jars are both carried in and out of the furnace with the bridge crane, avoiding the jar to collide the furnace wall and prolonging the life span of furnace, furnace cord and other parts. The power of the vertical pit furnace of the invention is 100kw; the chromising jars are placed in two layers in the furnace chromising 6 jars once, so that the work efficiency is increased at 1 to 2 folds. The invention can also be popularized in the parts process of other similar types.

Owner:NANJING LIMIN MACHINERY

Synchronized production method of reducing leaching and oxidizing deironing of cobalt-copper ore

ActiveCN103060550BHigh recovery rateSolve the disadvantages of excessive consumptionProcess efficiency improvementElectrode potentialReaction temperature

The present invention discloses a synchronized production method of reducing leaching and oxidizing deironing of cobalt-copper ore, including the following steps: crushing and mixing the cobalt-copper ore into cobalt copper slurry, then adding sulfuric acid into the cobalt-copper slurry for leaching with a temperature controlled at 75-85 DEG C, stirring while adding a reducing agent for reducing leaching with an amount of 4-6% of the total cobalt-copper ore, controlling cobalt content in wet residue to be less than 0.2% and copper content less than 0.3%, controlling of the reaction temperature to be 90-95 DEG C and reaction time being 1 to 4 hours, slowly adding alkali to adjust the PH value of the solution to 2.0-3.5, at the same time slowly supplementarily adding cobalt copper slurry for oxidizing deironing according to the content of Fe2+ in solution to make Co3+ and Fe2+ to reach a equilibrium state, and finally performing the solid-liquid separation to obtain qualified leachate. According to the invention, by controlling the electrode potential of the solution, synchronized performance of the reducing leaching process - the oxidizing deironing process is ensured, so direct production cost is significantly reduced, the metal recovery is significantly improved, thus improving production efficiency.

Owner:江苏雄风科技有限公司

A simple cultivation method for making shade and interplanting mulberry branches and bamboo fungus in mulberry field for leaves

InactiveCN103733883BShorten the retting processSkip the stacking procedureHorticultureNutritionHypha

The invention discloses a cultivation method for interplanting mulberry twig bamboo funguses by simply making shades in a leaf mulberry field. The cultivation method includes the steps of section of the mulberry field, cutting of mulberries and arrangement of silkworm breeding layout, preparation for raw materials of culture media of the bamboo funguses, settlement of ripple beds in the mulberry field, selective purchasing of cultures, sowing, growth management of hyphae and management of spring silkworm mulberries, simple shade making in the spring and autumn mulberry field and management of fruiting, and harvesting. The cultivation method has the advantages that mulberry twig raw materials are used for cultivation, the stack retting process of the cultivation media is shortened, and labor capacity and labor work hours are saved; a shading net is used to solve the problem of low shady degrees of the mulberry field after leaf picking so that the mulberry field meets the site requirement for growth and development of the bamboo funguses; mulberry twig scraps are used as main cultivation base materials of the bamboo funguses, so that waste mulberry twigs are fully utilized, and economic benefits are produced; the bamboo funguses are directly interplanted in the mulberry field, and remaining materials of the cultivation media are good organic fertilizers in the mulberry field after the cultivation media provide nutrition for growth and breeding of the bamboo funguses, so that fertility of the mulberry field is greatly improved; comprehensive utilization of resources of silkworms and mulberries is achieved.

Owner:JIANGXI SERICULTURE & TEA RES INST

Smart card preparing technique

InactiveCN101183434BQuality controllableQuality improvementRecord carriers used with machinesSmart cardMechanical engineering

Owner:中电智能卡有限责任公司

A kind of denitrification catalyst and preparation method thereof

ActiveCN108126763BReduce manufacturing costReduce lossDispersed particle separationCatalyst activation/preparationPtru catalystProcess engineering

The invention relates to the technical field of catalyst resource utilization, and particularly relates to a denitration catalyst and a preparation method thereof. The preparation method of the denitration catalyst comprises the following steps: (a) mixing and pulping wastes and waste denitration catalysts during production of the denitration catalyst, and filter-pressing, calcining and grinding,to obtain clinker; and (b) mixing the clinker, carriers, surface treating agents and active components, forming and drying, and calcinating to obtain the catalyst. By specially treating waste generated during production of the denitration catalyst and waste denitration catalyst generated after recycling non-renewable catalysts, fresh raw materials for producing the catalyst can be decreased by 50-70%, the production consumption can be decreased by 60%, the pollution of wastes to environment can be alleviated, and the production cost can be greatly lowered.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

Same-disc pouring process of special-shaped ingot and special-shaped ingot

The invention is suitable for the technical field of steel ingot processing, and provides a same-disc pouring process of a special-shaped ingot and the special-shaped ingot. The same-disc pouring process of the special-shaped ingot comprises the following steps that steel ingot molds with different tonnage specifications are designed, and steel ingots with different weight specifications are produced at the same height; at least two kinds of steel ingots with different weight specifications are taken and are separately subjected to melting treatment to obtain at least two kinds of molten steel; and the at least two kinds of molten steel are placed in the same disc to be poured, and the special-shaped ingot is obtained. According to the same-disc pouring process provided by the embodiment,two or more specifications of steel ingots are poured on the same disc by designing the specific ingot type and matching the weight with the height, so that the consumption of refractory materials isreduced, the residual steel amount is reduced, the product quality is improved, the quality is superior to that of multi-disc pouring steel ingots, the labor intensity of bottom plate masonry and pouring workers is reduced, and the direct production cost is reduced.

Owner:浙江三门太和大型锻造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com