Method for separating and recovering cobalt and copper from P204 reverse extraction liquid in cobalt and copper mine wet method smelting process

A technology of hydrometallurgy and liquid separation, applied in the field of metallurgy, can solve the problems of low metal recovery rate, large amount of precipitated slag, large consumption of auxiliary materials, etc., reduce direct production costs, solve complex production processes, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

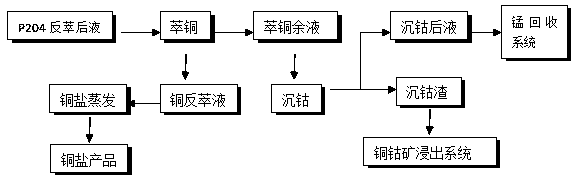

Image

Examples

Embodiment 1

[0016] Take the P204 back-extracted solution, the components of which include: cobalt 15.76g / L, copper 3.78g / L, manganese 14.7g / L, zinc 0.26g / L, iron 0.021g / L, pH 1.0-1.5.

[0017] Mix the mass ratio of 10% Lix984N and 90% sulfonated kerosene, put the above mixed organic liquid into the extraction box, add P204 back-extracted liquid, carry out countercurrent extraction at room temperature, use 20% sodium hydroxide during the extraction process The pH value of the solution is controlled between 1.5-2.0, and the copper-extracting raffinate and the copper-extracting loaded organic are obtained by separation. After extraction, the copper content of the copper extraction raffinate was analyzed to be 0.11g / L.

[0018] Then add 3.5N sulfuric acid to the copper-extracting loading organic to carry out back-extraction to obtain a copper sulfate solution, and send the obtained copper sulfate solution to a copper salt evaporation system for evaporation to produce a copper salt product.

...

Embodiment 2

[0021] Take the P204 back-extracted liquid, its components include: cobalt 10.54g / L, copper 4.56g / L, manganese 25.49g / L, zinc 0.15g / L, iron 0.007g / L, pH 1.0-1.5.

[0022] The mass ratio is 12% Lix984N mixed with 88% sulfonated kerosene, the above mixed organic liquid is put into the extraction box, the P204 back-extracted liquid is added, and countercurrent extraction is carried out at room temperature, and 24% sodium hydroxide is used in the extraction process The pH value of the solution is controlled between 1.5-2.0, and the copper-extracting raffinate and the copper-extracting loaded organic are obtained by separation. After extraction, the copper content of the copper extraction raffinate was analyzed to be 0.055g / L.

[0023] Then add 4.0N sulfuric acid to the copper-extraction-loaded organic medium for back-extraction to obtain a copper sulfate solution, and send the obtained copper sulfate solution to a copper salt evaporation system for evaporation to produce a copper ...

Embodiment 3

[0026] Take the P204 back-extracted solution, in which its components include: cobalt 8.75g / L, copper 5.52g / L, manganese 20.40g / L, zinc 0.11g / L, iron 0.043g / L, pH 1.0-1.5.

[0027] Mix the mass ratio of 15% Lix984N and 85% sulfonated kerosene, put the above mixed organic liquid into the extraction box, add P204 back-extracted liquid, carry out countercurrent extraction at room temperature, use 15% ammonia water to control the pH during the extraction process The value is between 1.5-2.0, and the copper extraction raffinate and the copper extraction loaded organic are obtained by separation. After extraction, the copper content of the copper extraction raffinate was analyzed to be 0.092g / L.

[0028] Then add 4.2N sulfuric acid to the copper-extraction-loaded organic medium for back extraction to obtain a copper sulfate solution, and then send the obtained copper sulfate solution to a copper salt evaporation system for evaporation to produce a copper salt product.

[0029] Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com