Covering fabric with composite staple fiber non-woven fabric as basic fabric and production method of covering fabric

A production method and technology of short fibers, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor flexibility and heavy weight, and achieve the effects of good wear resistance, light weight and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

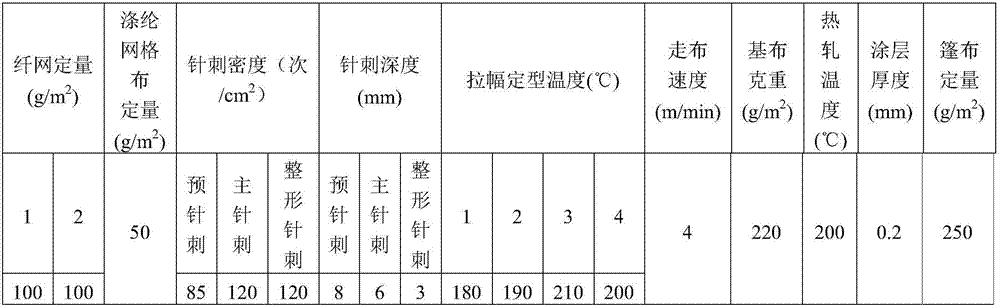

Embodiment 1

[0053] In this embodiment, the selected fiber breaking strength is 6.0CN / dtex. Polyester staple fiber with a model of 3D×108mm is used to produce polyester staple fiber non-woven fabrics, and the basis weight of the laid web is 100g / m 2 , two layers, the weight of polyester mesh cloth is 50g / m 2 ,layer.

[0054] The specific production method is as follows:

[0055] Base fabric processing, polyester staple fiber raw materials are sequentially processed into base fabric through the processes of opening, carding, net laying, polyester grid cloth compounding, acupuncture reinforcement, shaping and tentering;

[0056] Functional coating treatment, the base fabric is made into a tarpaulin through the processes of hot rolling and shaping, functional finishing, knife coating and calender cooling;

[0057] Among them, the card clothing model of the carding machine is: cylinder, V.F-4015-18, doffer, V.K-2510-0.8, working roll and stripping roll, K-5040-0.9-R; the gauge is: working r...

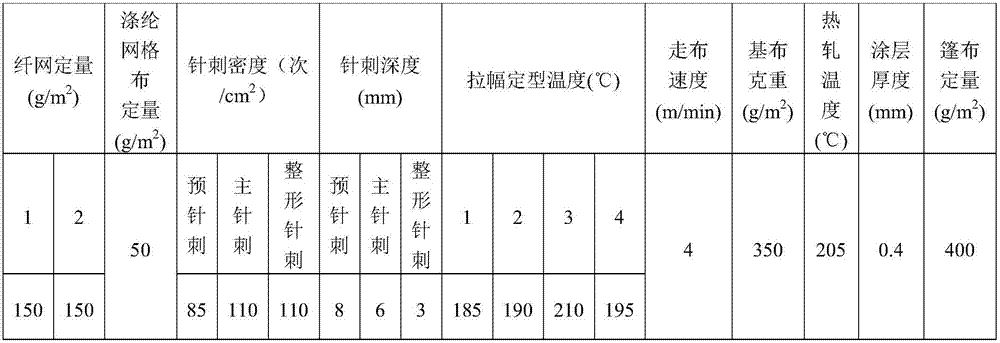

Embodiment 2

[0063] In this embodiment, the selected fiber breaking strength is 6.0CN / dtex. The model is 3D×108mm polyester staple fiber to produce polyester staple fiber non-woven fabric, and the basis weight of the fiber net is 150g / m 2 , two layers, the weight of polyester mesh cloth is 50g / m 2 ,layer.

[0064] The specific production method is as follows:

[0065] Base fabric processing, polyester staple fiber raw materials are sequentially processed into base fabric through the processes of opening, carding, net laying, polyester grid cloth compounding, acupuncture reinforcement, shaping and tentering;

[0066] Functional coating treatment, the base fabric is made into a tarpaulin through the processes of hot rolling and shaping, functional finishing, knife coating and calender cooling;

[0067] Among them, the card clothing model of carding machine is: cylinder, V.F-4015-18, doffer, V.K-2510-0.8, work roll and stripping roll, K-5040-0.9-R, gauge: work roll and stripping Roller, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com