Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Raise material temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

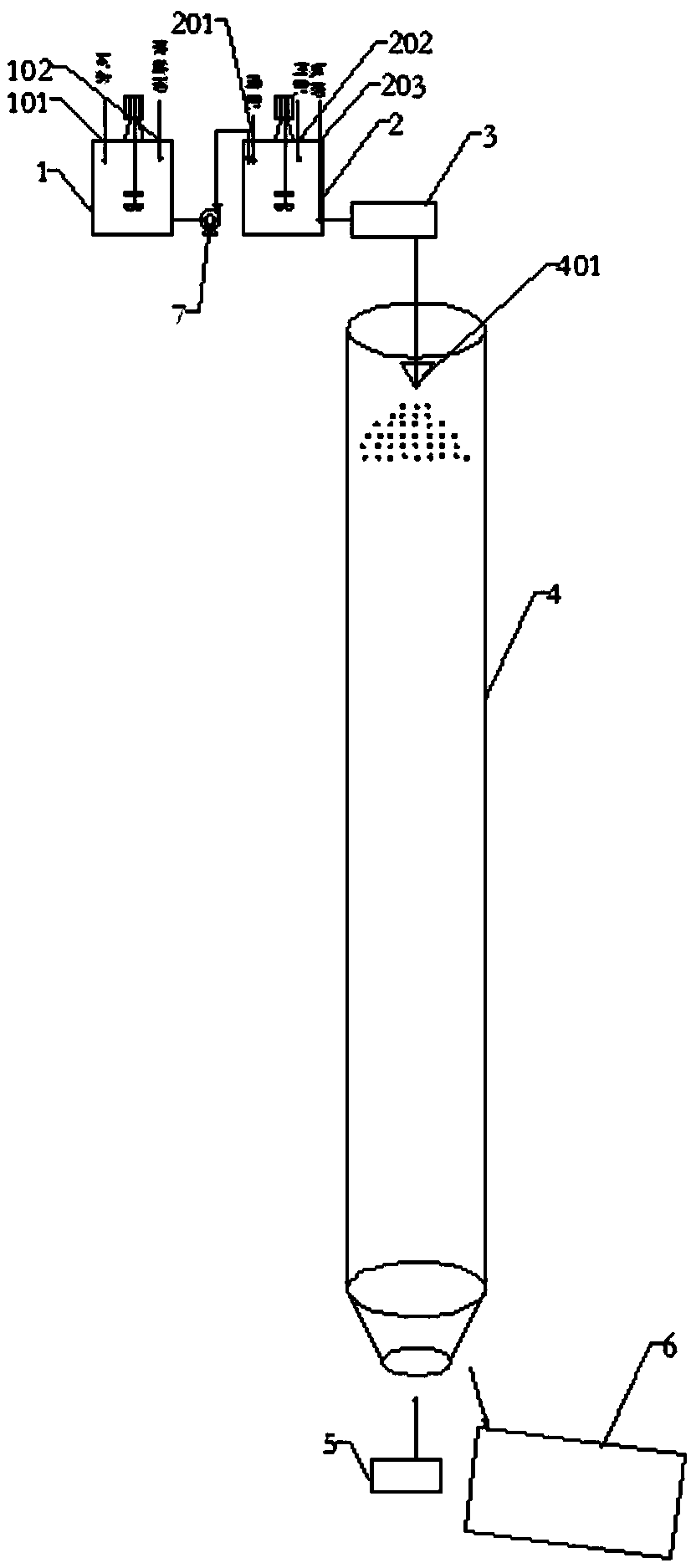

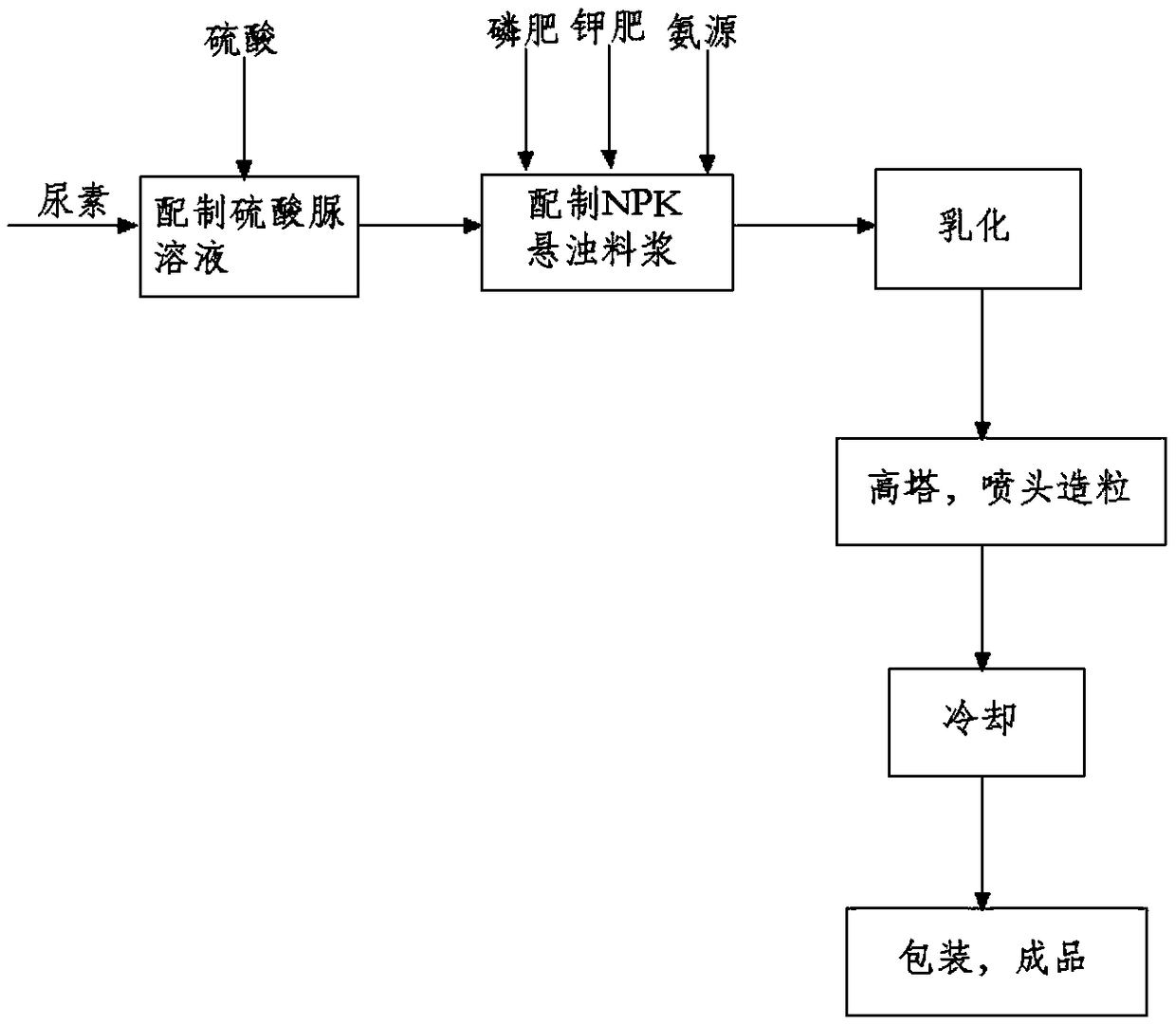

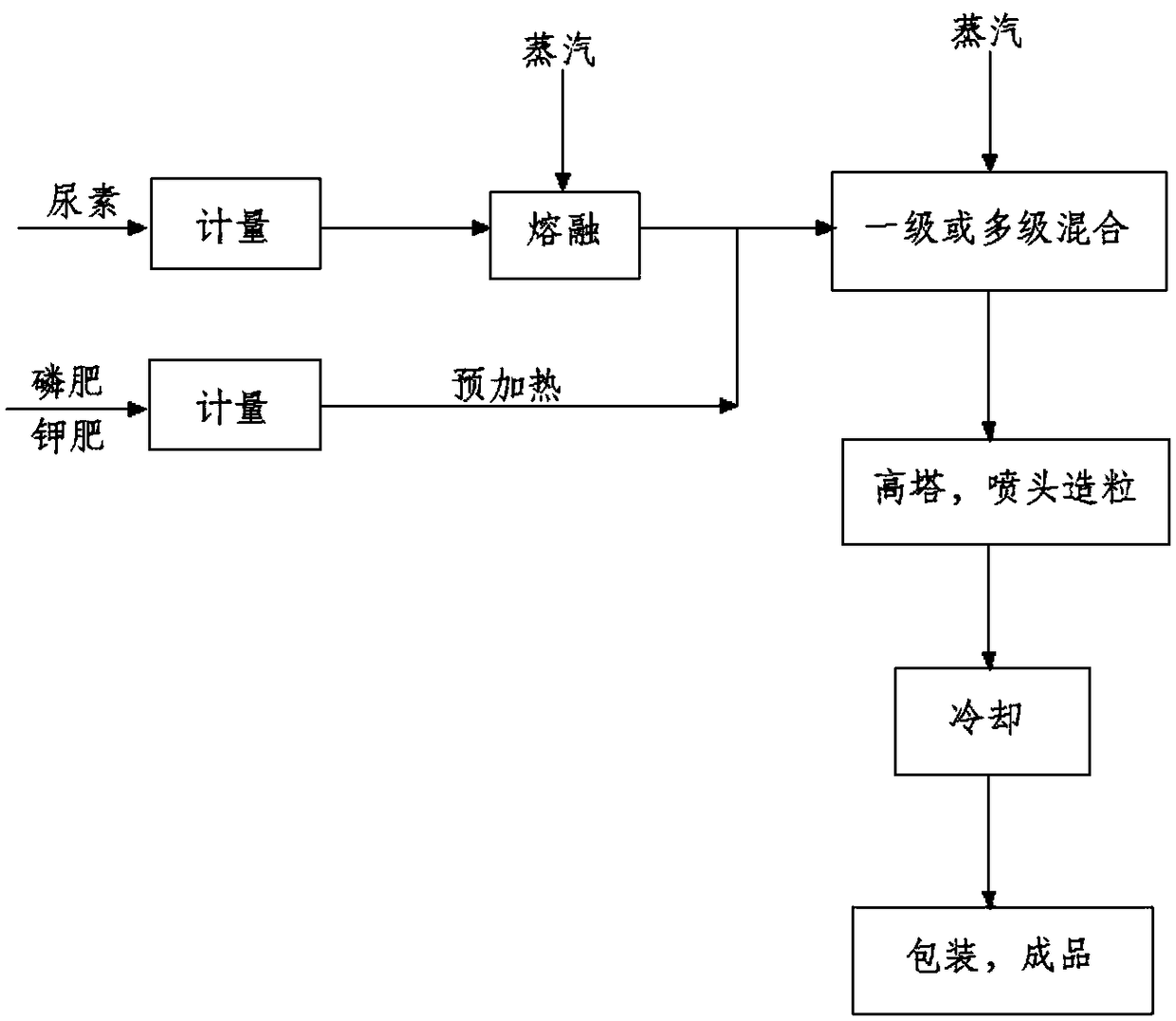

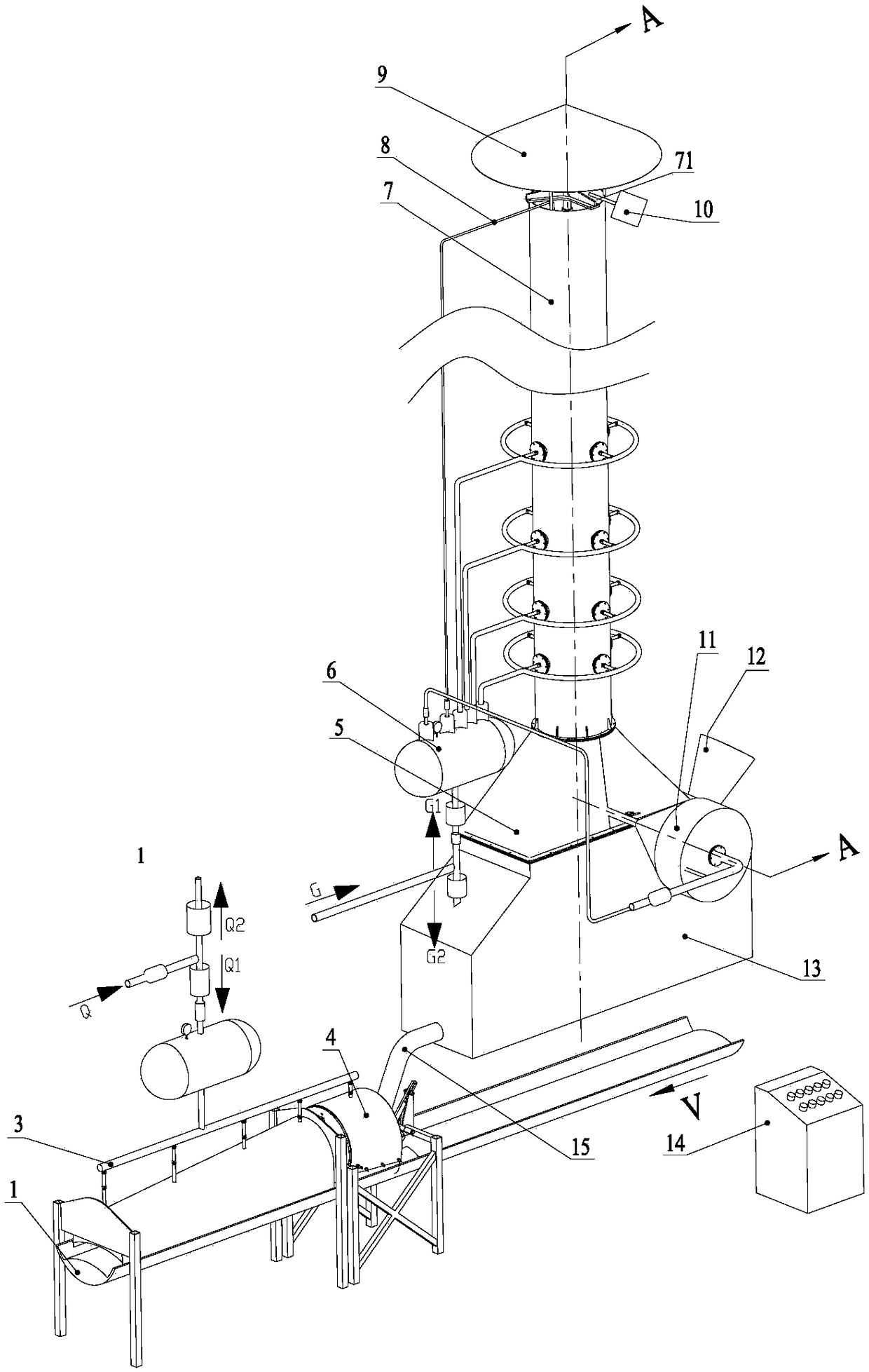

Method for producing compound fertilizer through high-tower granulating, system and compound fertilizer

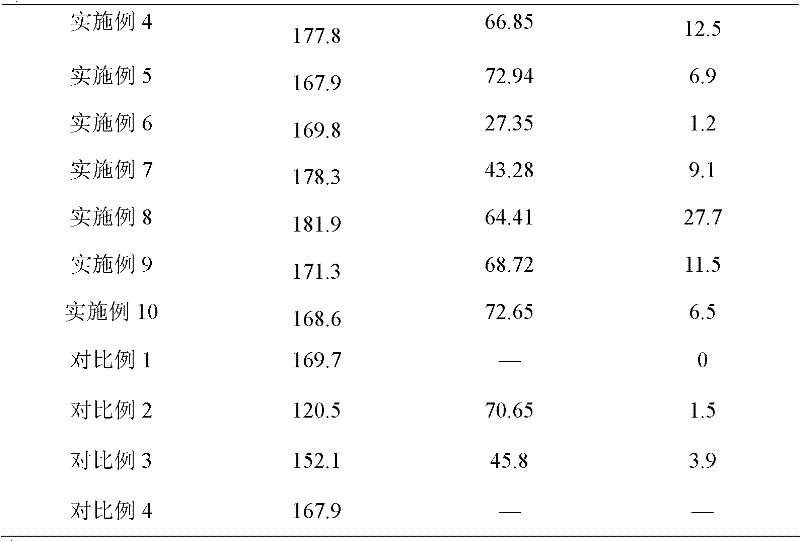

PendingCN108707000AAvoid meltingAvoid heatingGranulation by liquid drop formationFertilizer mixturesSprayerPotassium

The invention belongs to the technical field of compound fertilizers and relates to a method for producing a compound fertilizer through high-tower granulating, a system and the compound fertilizer. The method for producing the compound fertilizer through high-tower granulating, provided by the invention, comprises the following steps: subjecting sulfuric acid and urea to a reaction so as to produce a urea sulfate solution; mixing the urea sulfate solution with an ammonia source, a phosphate fertilizer and a potassium fertilizer so as to form homogeneous-state NPK suspending slurry; spraying the NPK suspending slurry through a granulating sprayer in a high tower, thereby completing granulating in the tower. According to the method, the process is simple, the implementation is easy, the energy consumption and production cost can be greatly reduced, the method is a steam-free melt-free process, and the problems of the existing high-tower granulating processes that the steam consumption is high, the energy consumption is high, the cost is high and the like can be effectively solved.

Owner:秦皇岛农享田生物科技有限公司

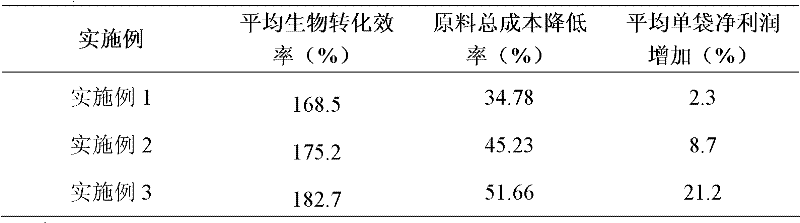

Bamboo fungus cultivation method

InactiveCN104186206AGood insecticide and sterilization effectMaterial temperature rises rapidlyHorticulturePhosphatePotassium

The invention provides a bamboo fungus cultivation method. The raw material formula and the processes are as follows: (1) the raw material formula comprises 500 kilograms of broad-leaved tree wood chips, crop straw or a corncob smashing material, 100 kilograms of bran, rice bran or corn flour, 1.5 kilograms of compound fertilizer, 0.8 kilogram of carbamide, 8 kilograms of lime powder, 4 kilograms of land plaster, 0.6 kilogram of potassium dihydrogen phosphate, 5 kilograms of white sugar and 330-350 kilograms of water; adding 3-5 kilograms of a 'Gymboree edible mushroom leavening agent' produced by the Beijing China Healthhead Science & Technology Co., Ltd; (2) fermenting; (3) conducting sterilization on a fermented material; (4) performing inoculation and cultivation; (5) performing cultivation in workshops or in rural cooperatives. By the skillful application of the biological fermentation technology, fundamental innovation and improvement of the zhijin bamboo fungus raw material and the seed production and cultivation technology are realized, so that the production cost is decreased by more than 50%; the biotransformation rate of the raw material to fresh zhijin bamboo fungus reaches more than 100:50, so that the key technical problem of industrialized cultivation of zhijin bamboo fungus is solved and the market need is fulfilled.

Owner:织金县平远文化园林规划设计中心

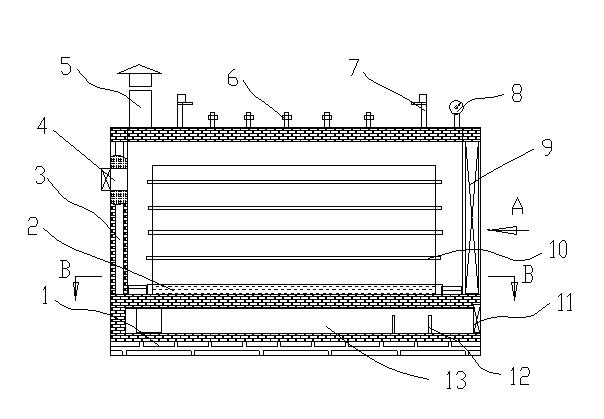

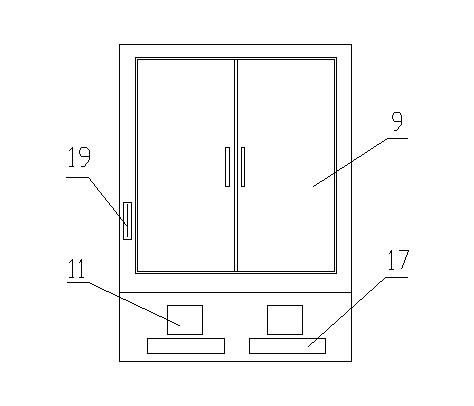

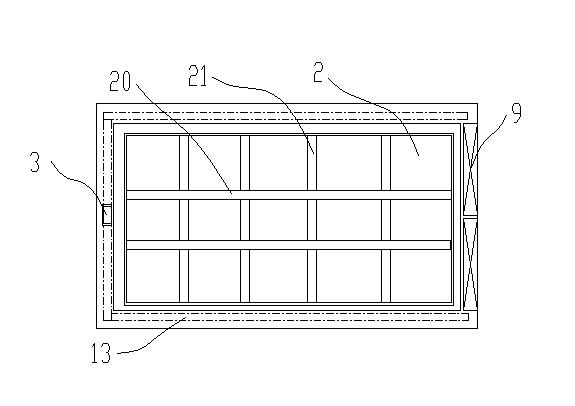

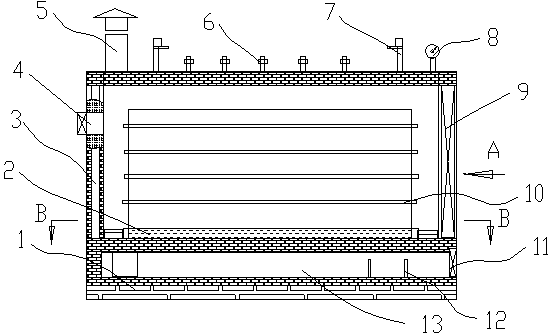

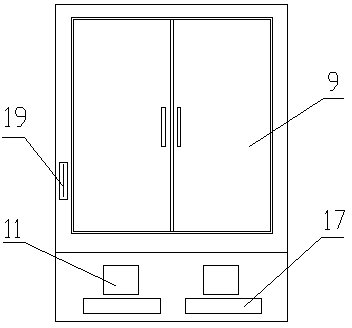

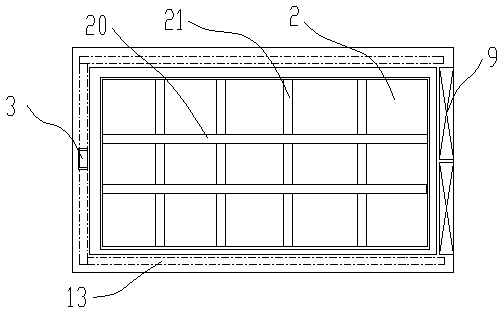

Efficient energy-saving normal pressure sterilization stove for edible fungi

ActiveCN101971765AImprove insulation effectReduce energy consumptionHorticultureProcess equipmentCombustion

The invention relates to the technical field of edible fungi process equipment, in particular to an efficient energy-saving normal pressure sterilization stove, which solves the problems of high comprehensive cost, difficult temperature stabilization and unreliable sterilization effect because the traditional edible fungi sterilization stove stabilizes the internal temperature by mainly adopting an energy dissipation mode. The stove comprises a stove body with an accommodating space and an electric cabinet; one end of a stove body base is provided with a combustion hearth; a horizontal flue is arranged in the stove body base; a plurality of fireproof stop blocks are arranged between the combustion hearth and the horizontal flue and in the horizontal flue; the upper part of the combustion hearth is provided with a trough type steel pot; the upper part of the trough type steel pot is the accommodating space of the stove body; a heat insulation material is arranged in a wall forming the accommodating space; an exhaust port, a deflating valve and a steam safety valve are arranged on the wall forming the accommodating space; and one end, facing the combustion hearth, of the bottom surface of the trough type steel pot is lower than the other end facing the combustion hearth. The stove is supplied with sufficient water at one time, and has the advantages of stable sterilization effect, good heat insulation effect and low energy consumption.

Owner:淳安千岛湖育珍园菇业有限公司

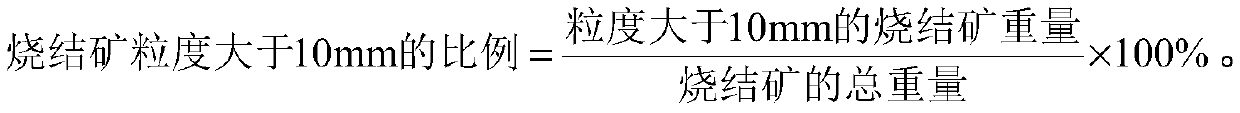

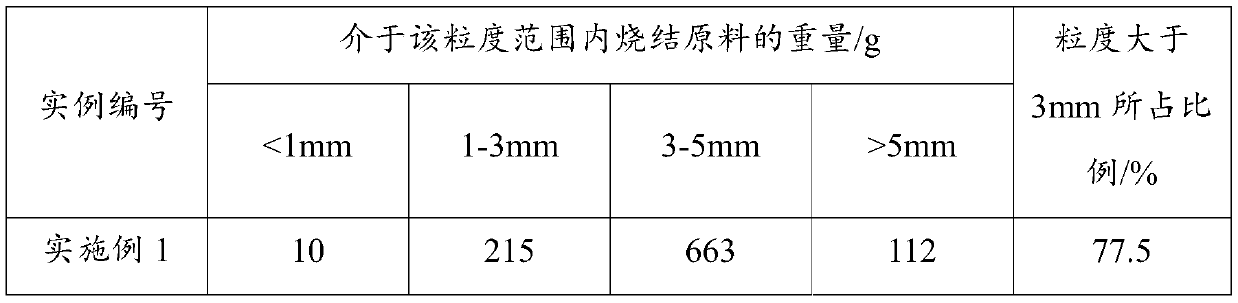

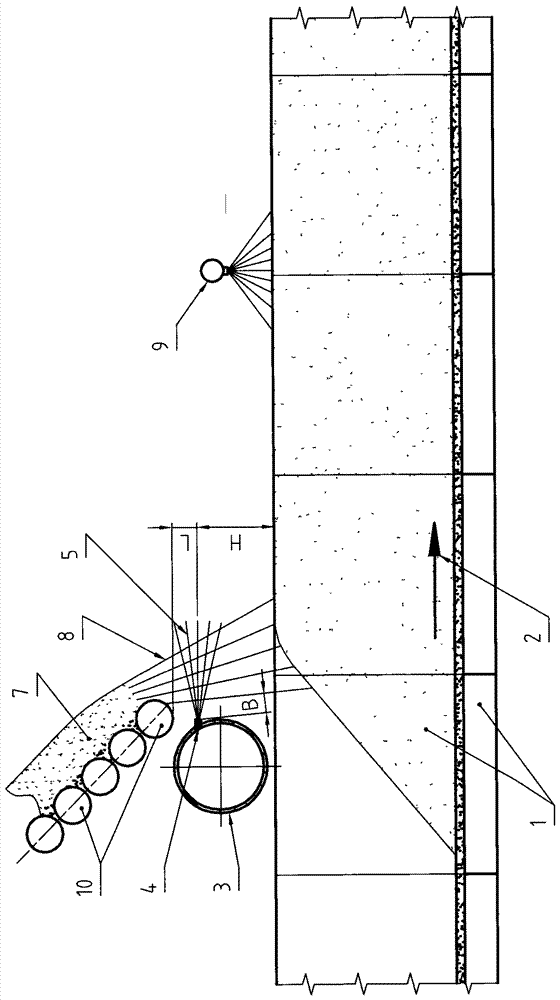

Sintering method of super-thick material layer sinter

The invention provides a sintering method of super-thick material layer sinter. The thickness of a sintering material layer is 920-950mm, the sintering moisture is 6.2-6.4%, and the sintering negativepressure is 14.5-15.5kPa. The sintering method comprises the specific steps of (1) burdening, (2) mixing and pelletizing, (3) mixture preheating, (4) micro-negative pressure ignition, and (5) material loosening. According to the sintering method, through development and application of a low-moisture pelletizing technology, low-pressure steam efficient preheating of a mixture is conducted to increase the material temperature, development and application of a micro-negative pressure ignition technology and transformation and application of three rows of material loosening devices, the thicknessof the material layer is increased, the machine speed of a sintering machine is decreased, the sintering crystallization reaction is promoted, the internal return mine rate is decreased, and the quality and yield of the sinter are improved; the thickness of the material layer is increased to 930mm or above from 730mm, the sintering negative pressure is decreased to 14.5kPa-15.5kPa from 16.0kPa-17.0kPa, low-power-consumption and low-fuel-consumption sintering under the super-thick material layer condition is achieved, and the sintering cost is reduced; and NOx emission of sintering raw flue gas is reduced by about 37%, and efficient process emission reduction of the sintering flue gas NOx is achieved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Edible fungus cultivation medium containing waste feed as major ingredient and preparation method thereof

The invention relates to an edible fungus cultivation medium containing waste feed as major ingredient and a preparation method of the edible fungus cultivation medium containing waste feed as major ingredient, and belongs to the technical field of edible fungus cultivation. The edible fungus cultivation medium containing waste feed as major ingredient contains the following ingredients: waste feed, wood dust or cottonseed hull, calcium superphosphate, urea, lime, magnesium sulfate, Mepartricin and calcium carbonate. The invention also provides the preparation method and the application of the edible fungus cultivation medium. As compared with the conventional cultivation media (such as cottonseed hull, wood dust and corn cob), the application of waste feed as cultivation medium for edible fungus cultivation can save materials and reduce cost.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

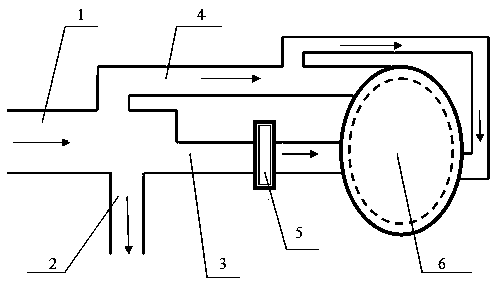

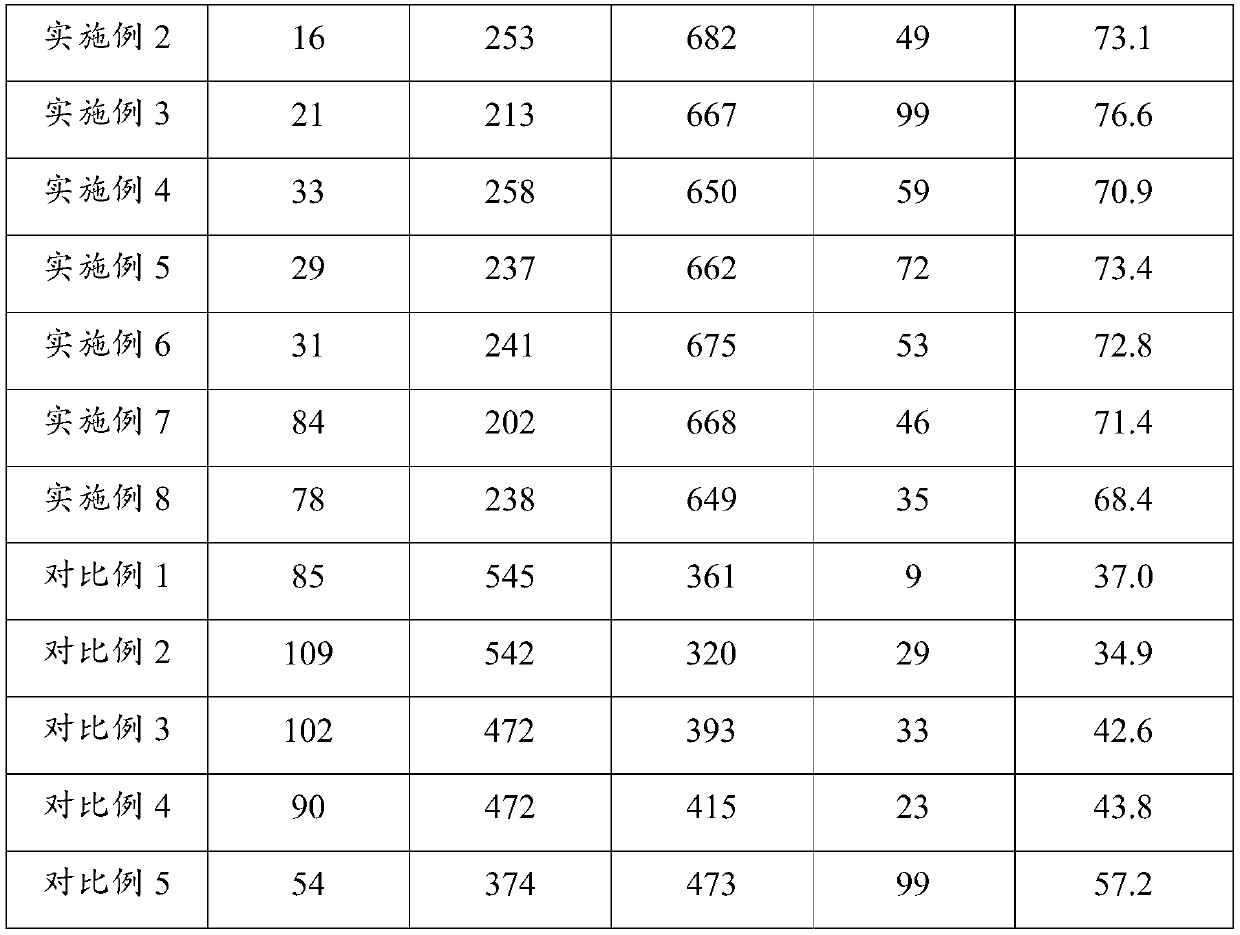

Method for preheating sintering mixture in steel works

InactiveCN109055730AIncrease temperatureRaise material temperatureIncreasing energy efficiencyPreheating chargesMetallurgySolid fuel

The invention relates to a method for preheating a sintering mixture in steel works. The method for preheating the sintering mixture in the steel works includes the steps that low-pressure steam of awaste heat boiler of a ring cooling machine is effectively utilized, the temperature of the mixture is raised to 70 DEG C or more, and the influence of a wet layer in the sintering process is reduced.In order to preheat the sintering mixture, dozens of steam nozzles are installed in a circle around a mixing bunker, and the total sectional area of the steam nozzles must be less than the sectionalarea of a gas supply pipe, the appearance of pressure relief due to the fact that the sum of the diameter and sectional area of the steam nozzles is greater than the sectional area of a main pipe is avoid, so that the nozzles are blocked, and the increase of the temperature of the mixture is affected. The temperature of the mixture is increased, a strong support for sintering of a thick material layer is provided, the sintering solid fuel consumption can be saved, and the sintering mineral quality is improved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Efficient quicklime digestion dust collector

The invention discloses an efficient quicklime digestion dust collector which comprises a quicklime digester, a digester feeding device, a digester discharge device, a conveyer belt, a dust collectioncover, a columnar dust collection pipeline, a tail gas concentration detector, an umbrella-shaped end cover, an electric control device as well as a pipeline dust collection water ejection device, wherein the pipeline dust collection water ejection device is used for supplying water to the columnar dust collection pipeline and the quicklime digester; the pipeline dust collection water ejection device comprises a plurality layers of dust collection water ejection units uniformly and / or non-uniformly distributed in the axial direction of the columnar dust collection pipeline, a first pressure water tank, a dust collection water main pipe and a digestion water main pipe; the water inlet of the dust collection water main pipe is connected with the water inlet of the quicklime digester throughthe digestion water main pipe; dust collection water is directly dropped back into the quicklime digester for digesting quicklime, or is directly dropped back into a sintering mixed material on the conveyer belt and recycled as 'primary mixing' process water; after being 'peeled', dust in steam is directly dropped back into the quicklime digester, is continuously digested, and flows into a next sintering procedure-'primary mixing'.

Owner:武汉净格节能环保设备有限公司

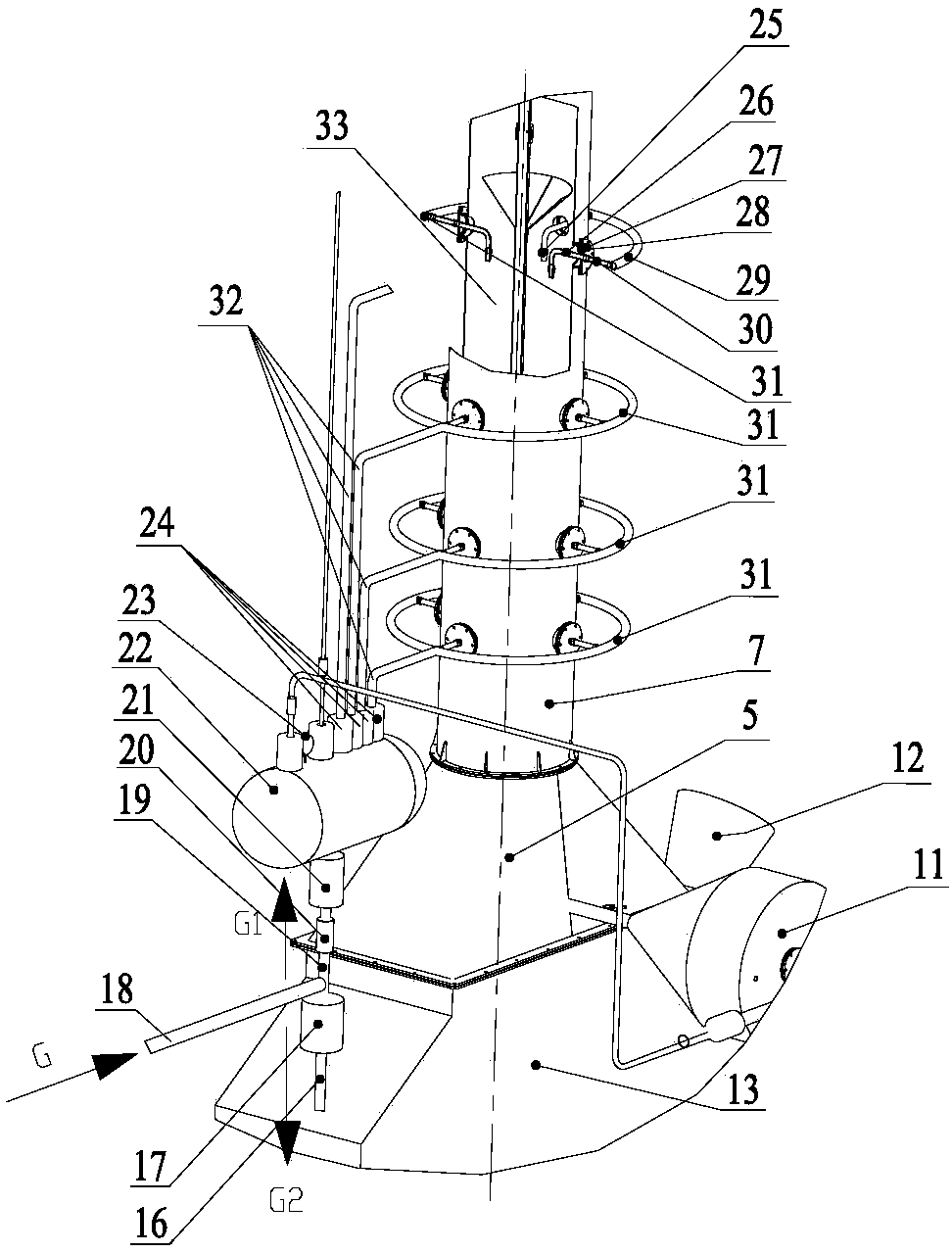

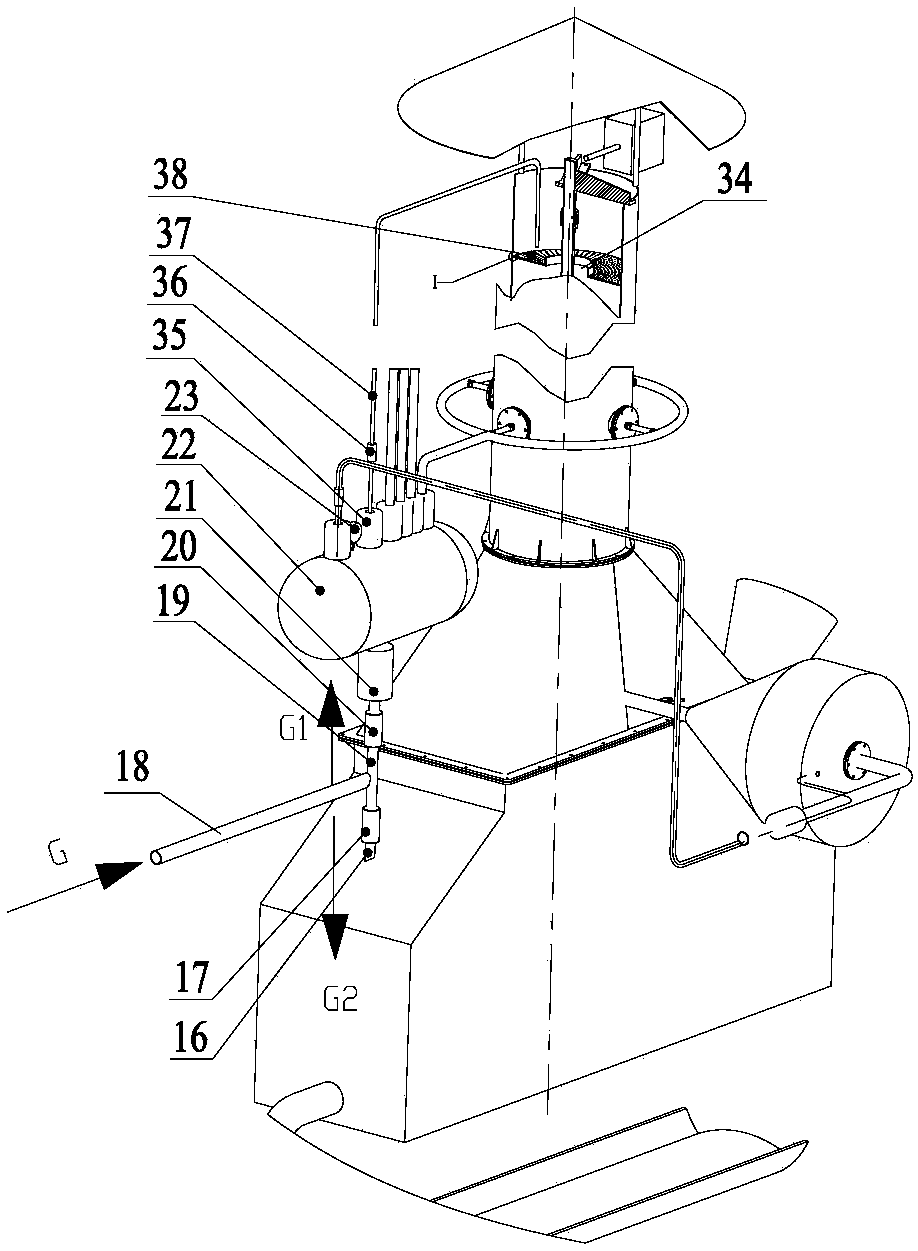

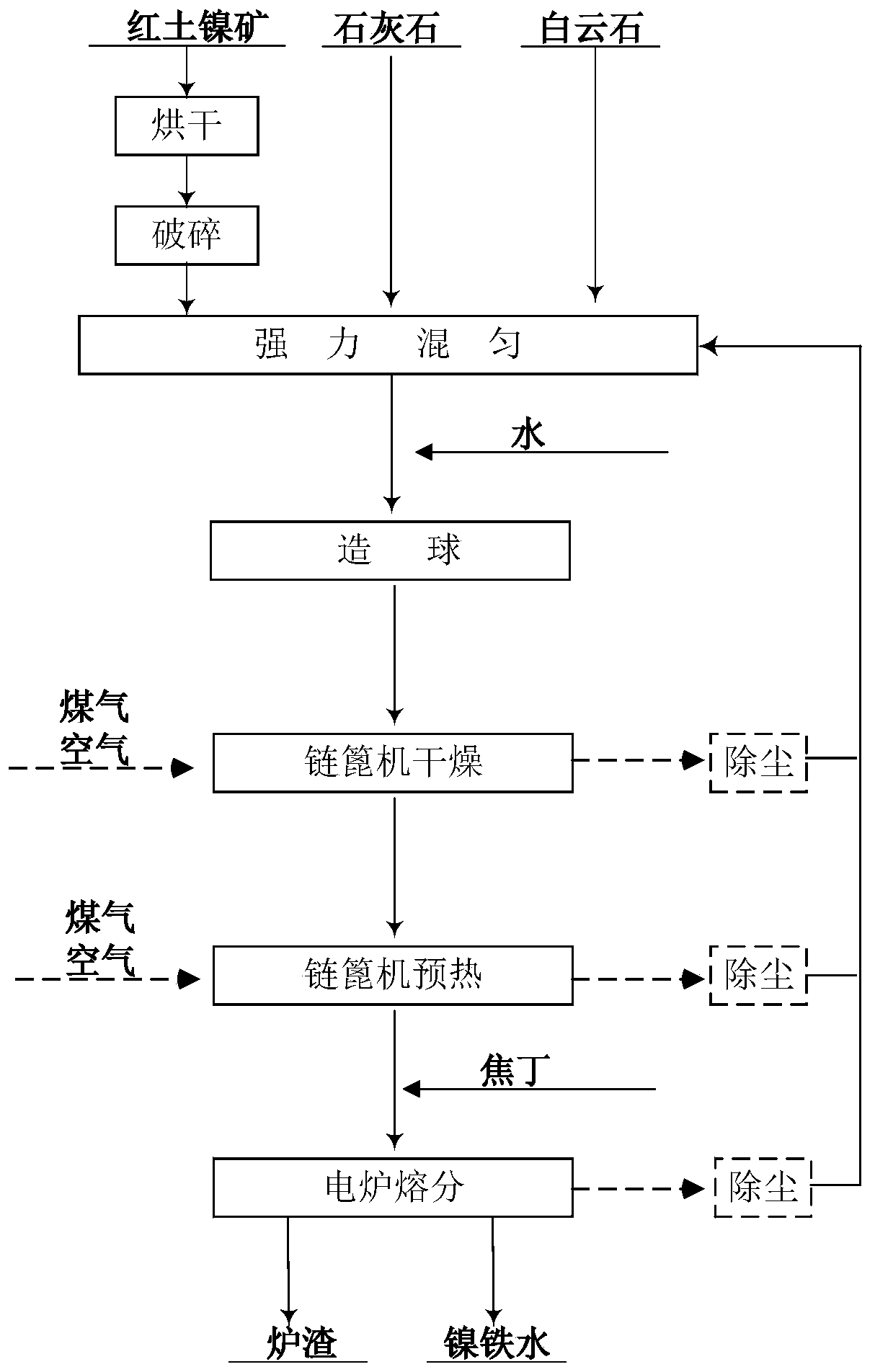

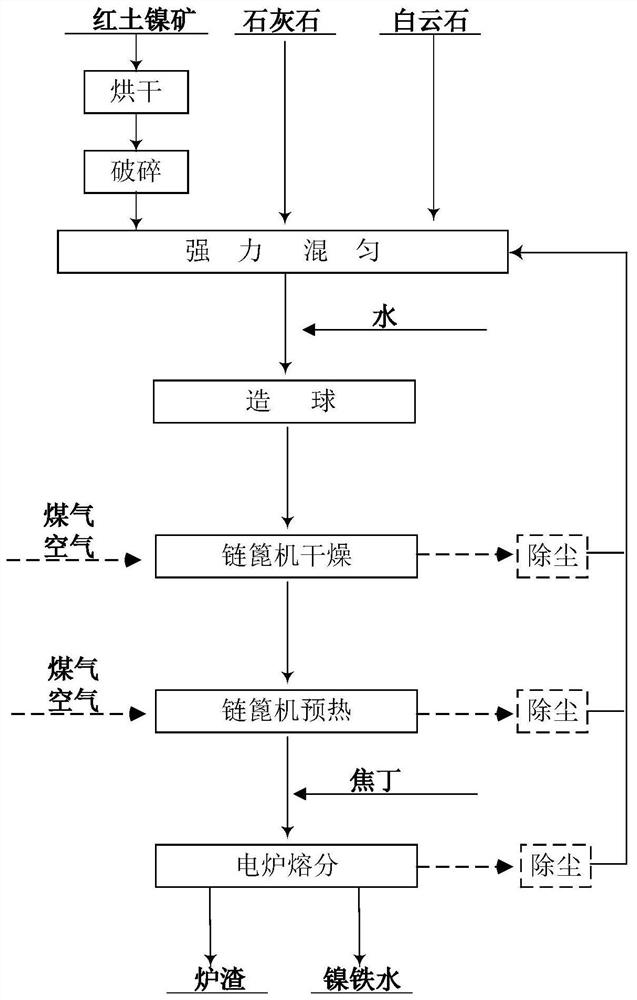

Method for preparing high-nickel molten iron from low-grade laterite-nickel ore by using chain grate machine preheating and electric furnace smelting separation

The invention discloses a method for preparing high-nickel molten iron from low-grade laterite-nickel ore by using chain grate machine preheating and electric furnace smelting separation. The method comprises the following steps that S1, drying pretreatment and crushing are carried out on the laterite-nickel ore to obtain laterite-nickel ore powder; S2, the laterite-nickel ore powder is uniformlymixed with a fusing agent to obtain a uniform mixture, and pelletizing is carried out to obtain green balls; S3, the green balls are fed into a chain grate machine for drying, preheating and roastingto obtain preheated pellets; and S4, the preheated pellets are mixed with a reducing agent, and then are fed into an electric furnace for smelting separation to obtain high-nickel molten iron and furnace slag. According to the production method, the electric furnace burden which is high in strength, uniform in particle size and excellent in quality is prepared, and the high-temperature hot preheated pellets are directly fed into the electric furnace to be subjected to reduction and smelting separation, so that the heat required for re-heating to reach the smelting separation temperature is saved, then the electricity consumption of the electric furnace is reduced, and meanwhile, the metal recovery rate is improved.

Owner:CENT SOUTH UNIV

Preserved beancurd containing functional factor and preparation method thereof

The invention discloses preserved beancurd containing a functional factor, which comprises components of soybean and edible (medicinal) fungi. A preparation method for the preserved beancurd containing the functional factor comprises the following steps: soybean, edulcoration, soaking, soybean grinding, filtering separation, soybean milk, soybean milk cooking, soybean milk curdling, blanking, block division, pehtze preparation fermentation, salted pehtze, filling, ripening, and a finished product. During soybean milk curdling, a mixed solution of an aqueous solution of edible (medicinal) fungi ultra-fine powder and the soybean milk is added, and the soybean milk curdling is realized by the following steps: removing roots of the edible (functional) fungi and carrying out edulcoration on the edible (medicinal) fungi; carrying out ultrafine grinding on the edible (medicinal) fungi after drying or insolating; adding water to dissolve, wherein the ratio of the edible (medicinal) fungi ultra-fine powder to the water is 1:4; adding the soybean milk at 100 DEG C with the same quantity as the aqueous solution of the edible (medicinal) fungi ultra-fine powder into the mixture to dilute after the mixture is stirred fully and evenly; and during filling, the aqueous solution of the edible (medicinal) fungi ultra-fine powder is added. The preserved beancurd is rich in functional factor and multiple nutrients and has the advantages of health care function, tasty mouthfeel and simple processing.

Owner:JIANGSU ANHUI BIO TECH +1

Technology and system for producing iron ore concentrate by iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy

InactiveCN111748684AHigh strengthImproving the quality of magnetization roastingRoastingMetal recycling

The invention relates to a technology and a system for producing an iron ore concentrate by an iron ore chain grate machine-rotary kiln through shallow hydrogen metallurgy. Iron ore of which the granularity is 40 mm or below is divided into three granular classes, wherein coarse-grain iron ore is dried and preheated through the chain grate machine to be added from the material adding end of the rotary kiln, high-volatility lignite is evenly sprayed and blown to be distributed in the length direction of the whole rotary kiln, middle-grain iron ore is sprayed and blown to the front section and the middle section of the shallow hydrogen metallurgy roasting area of the rotary kiln, and fine-grain iron ore is added into the rear section of the shallow hydrogen metallurgy roasting area and is processed through a shallow hydrogen metallurgy process to obtain iron ore concentrate. The chain grate machine is connected in front of a magnetization roasting rotary kiln in series, an early stage oxidizing roasting method and a later-stage reduction roasting method are adopted to further improve hydrogen utilization efficiency, roasting time is shortened, and the roasting quantity of the iron ore, the yield of the iron ore concentrate and a metal recovery rate can be greatly improved.

Owner:JIUQUAN IRON & STEEL GRP

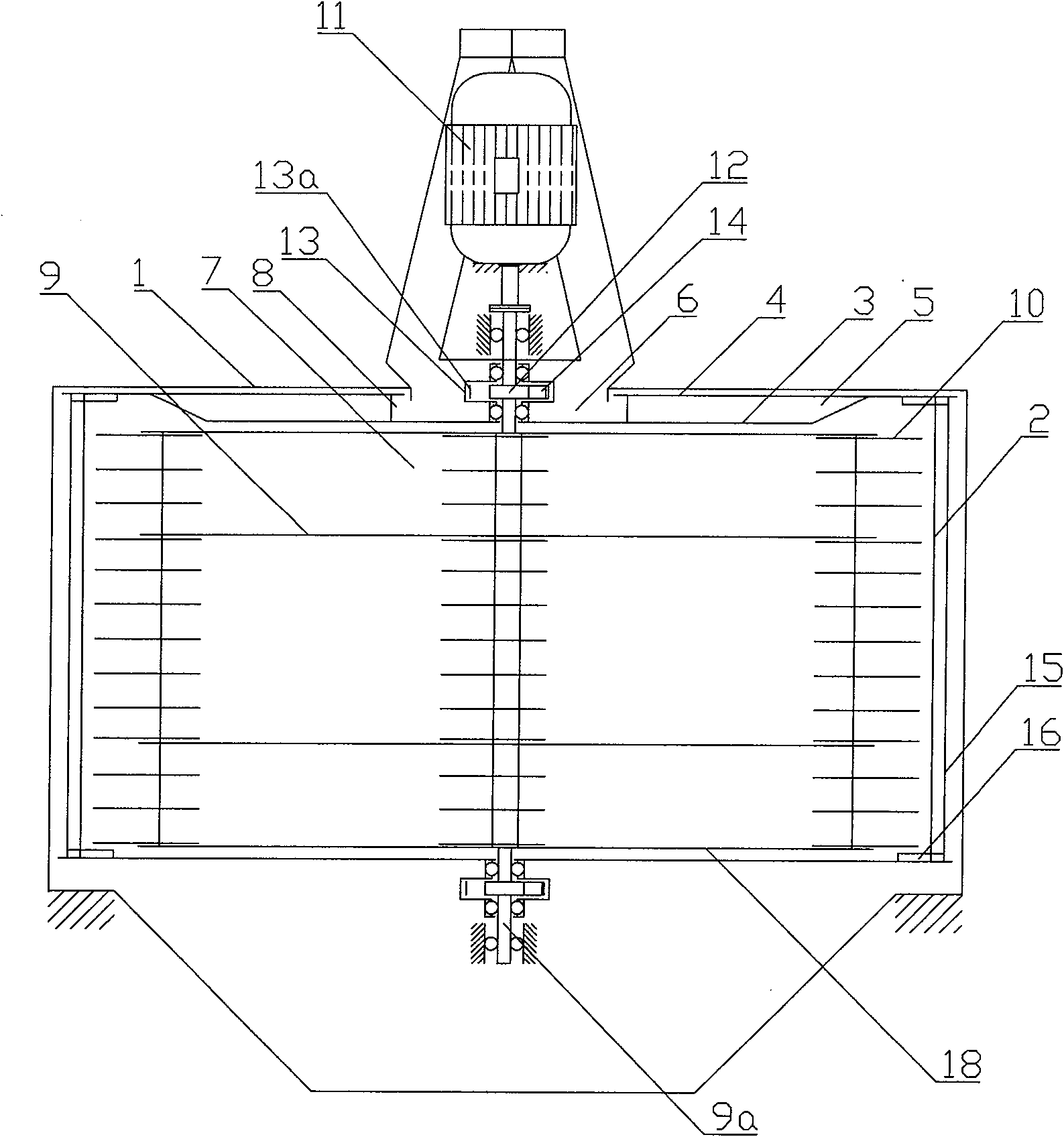

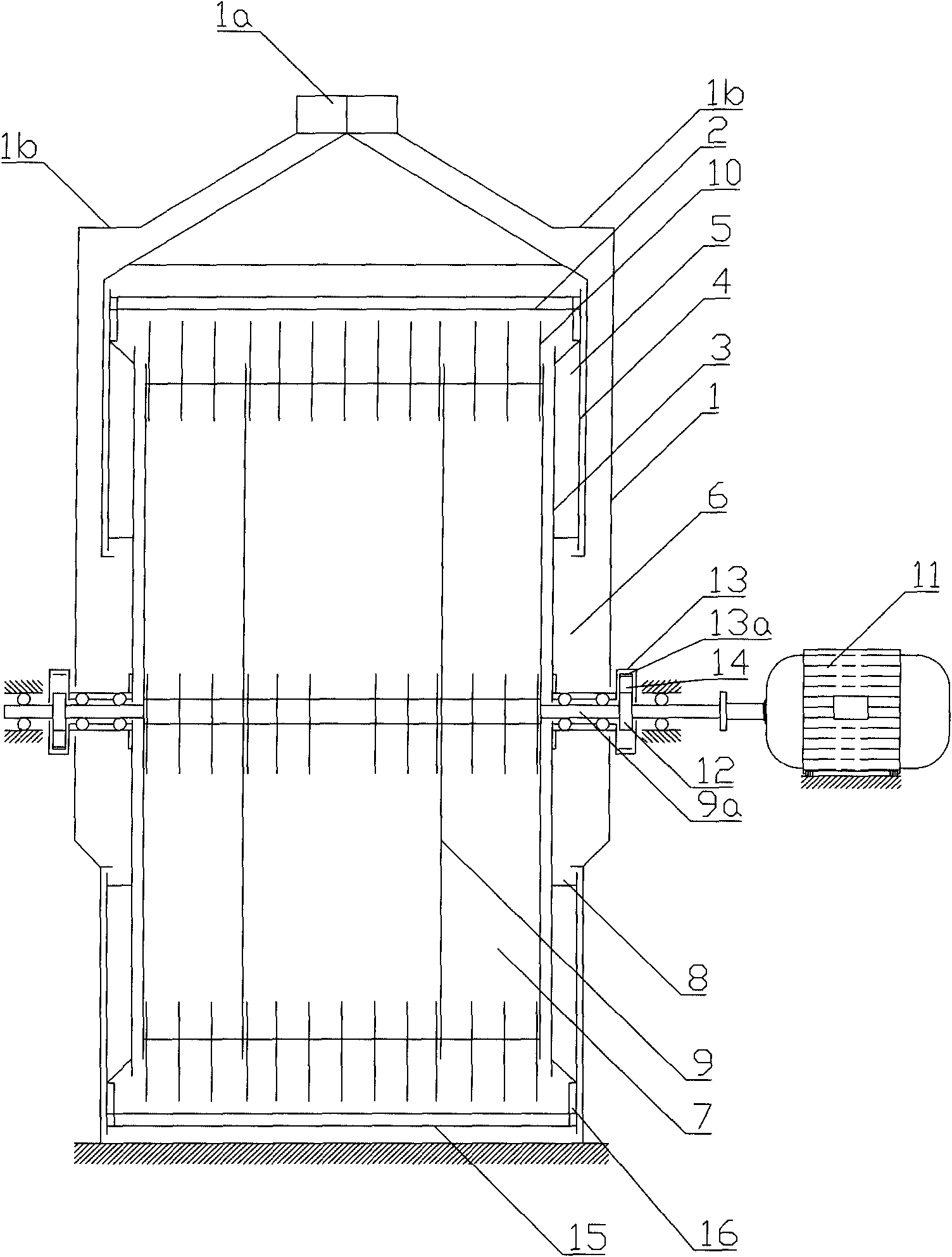

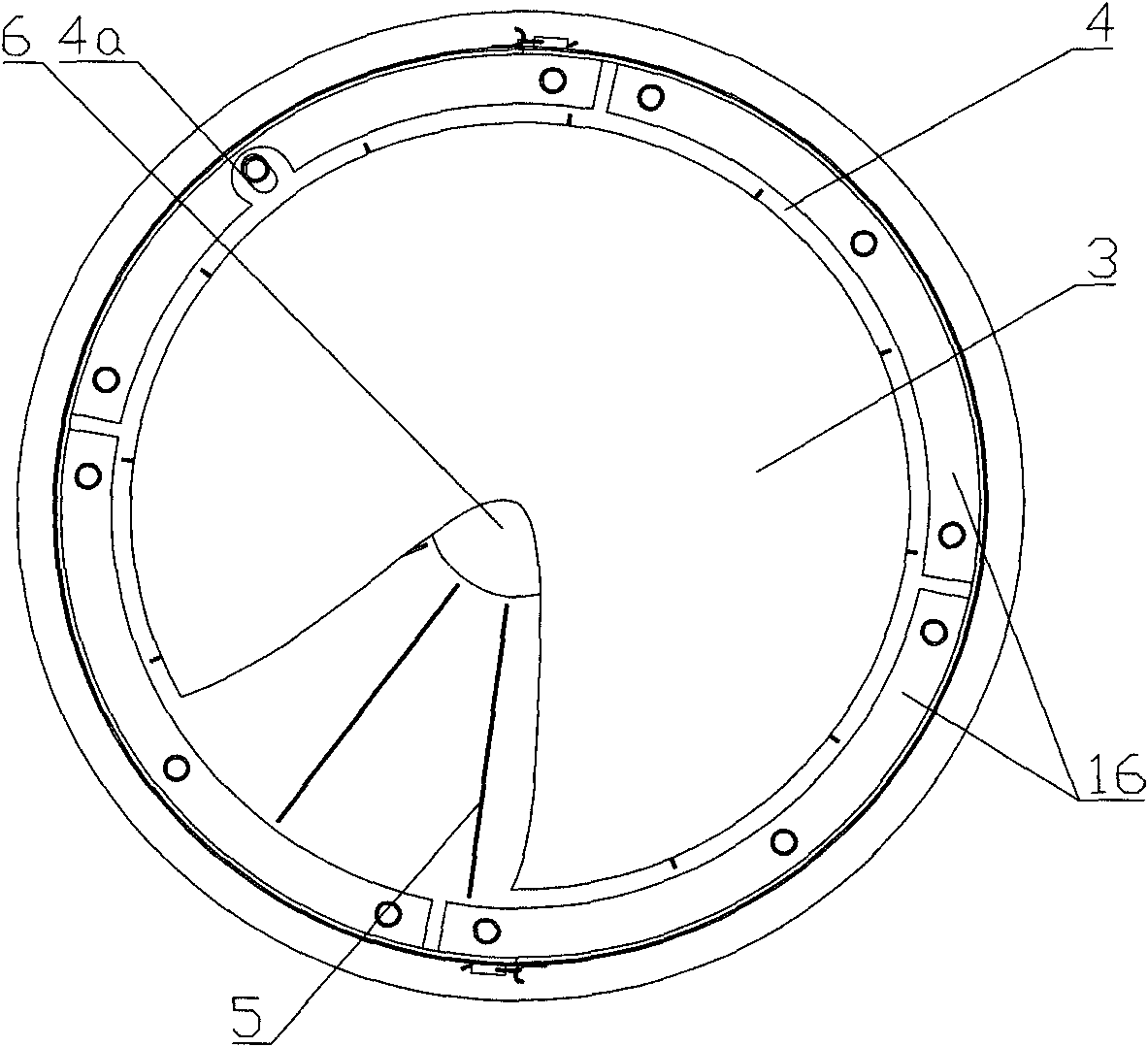

Efficient energy-saving normal pressure sterilization stove for edible fungi

The invention relates to the technical field of edible fungi process equipment, in particular to an efficient energy-saving normal pressure sterilization stove, which solves the problems of high comprehensive cost, difficult temperature stabilization and unreliable sterilization effect because the traditional edible fungi sterilization stove stabilizes the internal temperature by mainly adopting an energy dissipation mode. The stove comprises a stove body with an accommodating space and an electric cabinet; one end of a stove body base is provided with a combustion hearth; a horizontal flue is arranged in the stove body base; a plurality of fireproof stop blocks are arranged between the combustion hearth and the horizontal flue and in the horizontal flue; the upper part of the combustion hearth is provided with a trough type steel pot; the upper part of the trough type steel pot is the accommodating space of the stove body; a heat insulation material is arranged in a wall forming the accommodating space; an exhaust port, a deflating valve and a steam safety valve are arranged on the wall forming the accommodating space; and one end, facing the combustion hearth, of the bottom surface of the trough type steel pot is lower than the other end facing the combustion hearth. The stove is supplied with sufficient water at one time, and has the advantages of stable sterilization effect, good heat insulation effect and low energy consumption.

Owner:淳安千岛湖育珍园菇业有限公司

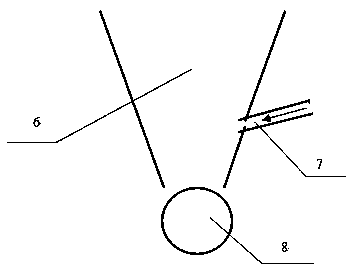

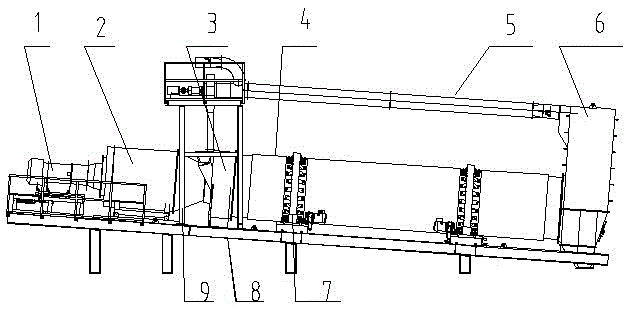

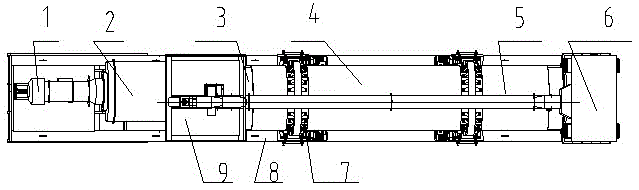

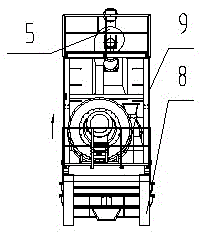

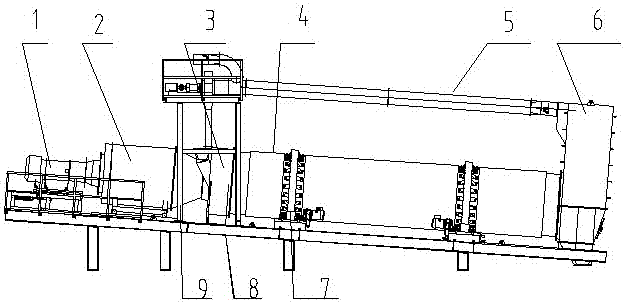

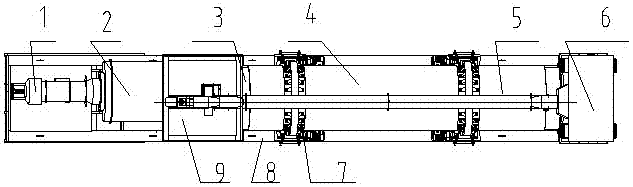

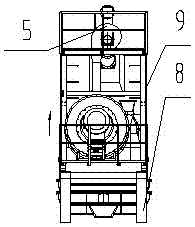

Novel waste pitch heating device

ActiveCN105603853AExtended service lifeRaise material temperatureRoads maintainenceCombustorCombustion chamber

The invention provides a novel waste pitch heating device. The novel waste pitch heating device comprises a base and a combustor and is characterized by further comprising a combustion chamber; the combustor, the combustion chamber and a heating assembly are arranged on the base, the combustor and the combustion chamber are fixedly connected in a sealed mode and fixedly connected with the base through a moving assembly, the two ends of the heating assembly are fixedly connected with the base, and the middle of the heating assembly is fixedly connected with the base; the combustion chamber makes contact with the heating assembly in a sealed mode, a hot air circulating assembly is arranged above the heating assembly and fixedly connected with the base, a first inlet of the hot air circulating assembly is connected with a discharging part in a sealed mode, and a third outlet of the hot air circulating assembly is connected with a feeding part in a sealed mode. During use, combustion hot air enters the heating assembly, normal-temperature waste pitch enters a rotating heating drum from the feeding part, is guided to the bottom of the heating drum through a spiral guiding plate and pushed downwards to a V-shaped plate of a scraping conveying section, moves forwards in a fluctuation mode, is heated by the heating drum, and forms a material curtain for full heat exchange, and the waste pitch is discharged from a discharge port when heated to the needed temperature.

Owner:JILIN PROVINCE ROAD CONSTR MASCH CO LTD

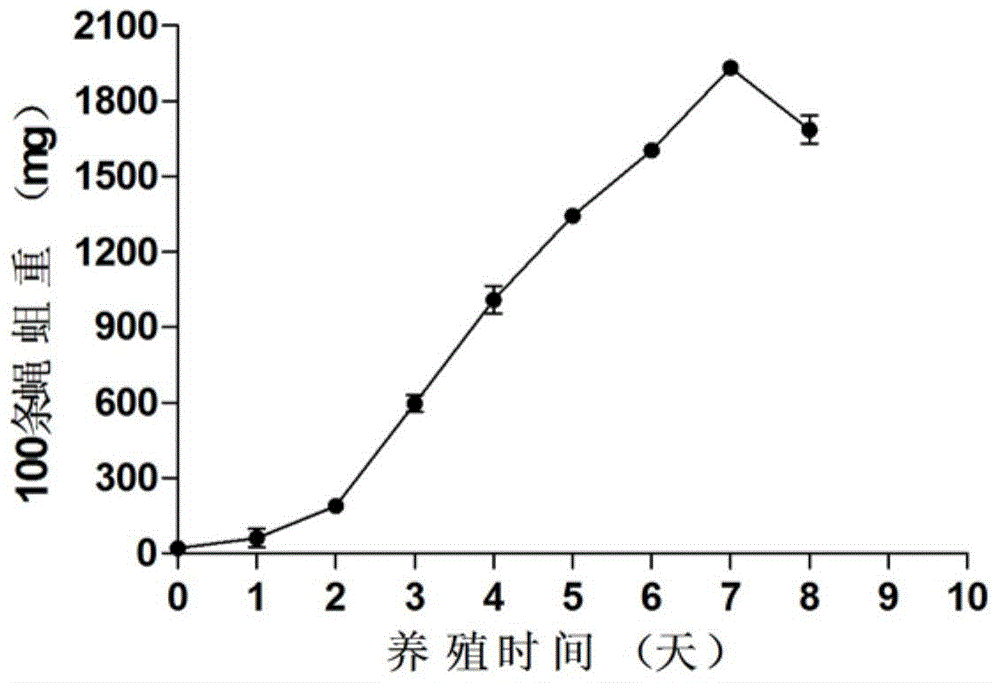

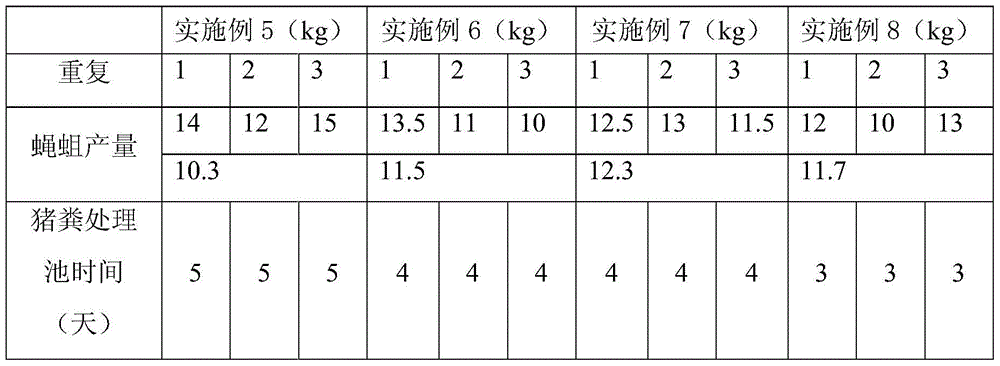

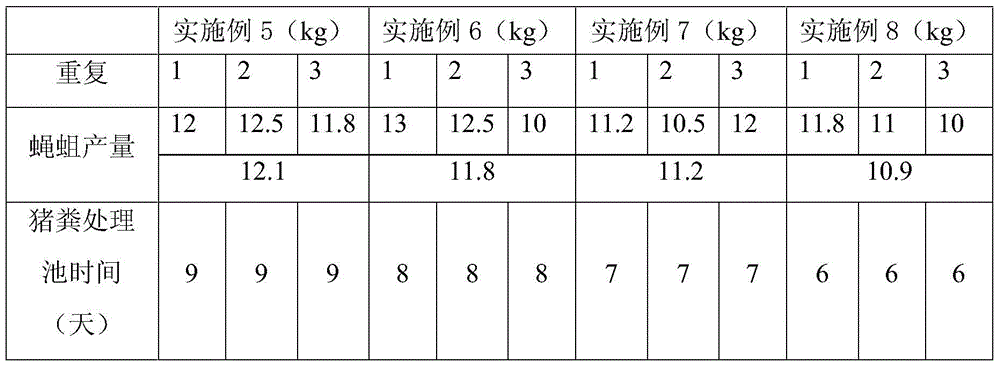

Two-step cultivation method for fly maggots under normal temperature and low temperature conditions

ActiveCN104542497BIncrease breeding densityHigh activityFood processingAnimal feeding stuffTwo stepZoology

The invention relates to a breeding technology of fly maggots and aims to provide a method for breeding fly maggots in two steps under conditions of normal temperature and low temperature. The method is characterized by adding an enhanced treatment stage before the common breeding treatment method and retaining high environment temperature of the former growth period in a manner of increasing the breeding density of larvae of fly maggots, and increasing independent room temperature or providing coverage for the larvae. The enhanced process can be used for improving the features and the nutritional characteristics of the breeding materials; the growth condition of the larvae of fly maggots can be improved; the growth of the fly maggots can be improved; the indoor enhanced process can be used for improving the growth environment of the larvae of fly maggots by increasing the temperature; the relative temperature-increasing cost is low; the larvae of fly maggots after the enhanced treatment are large in larva instar and size and high in resistance to low temperature; the survival rate of the larvae of fly maggots under the condition of the relative low temperature is higher than that of the larvae which are just hatched in 24 hours. The method can be used for increasing the utilization rate of the land; the biomass waste fly maggots such as excrements of livestock can be annually treated; the method has great effects on enterprise benefit and development and quick and effective treatment on the excrements of livestock.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

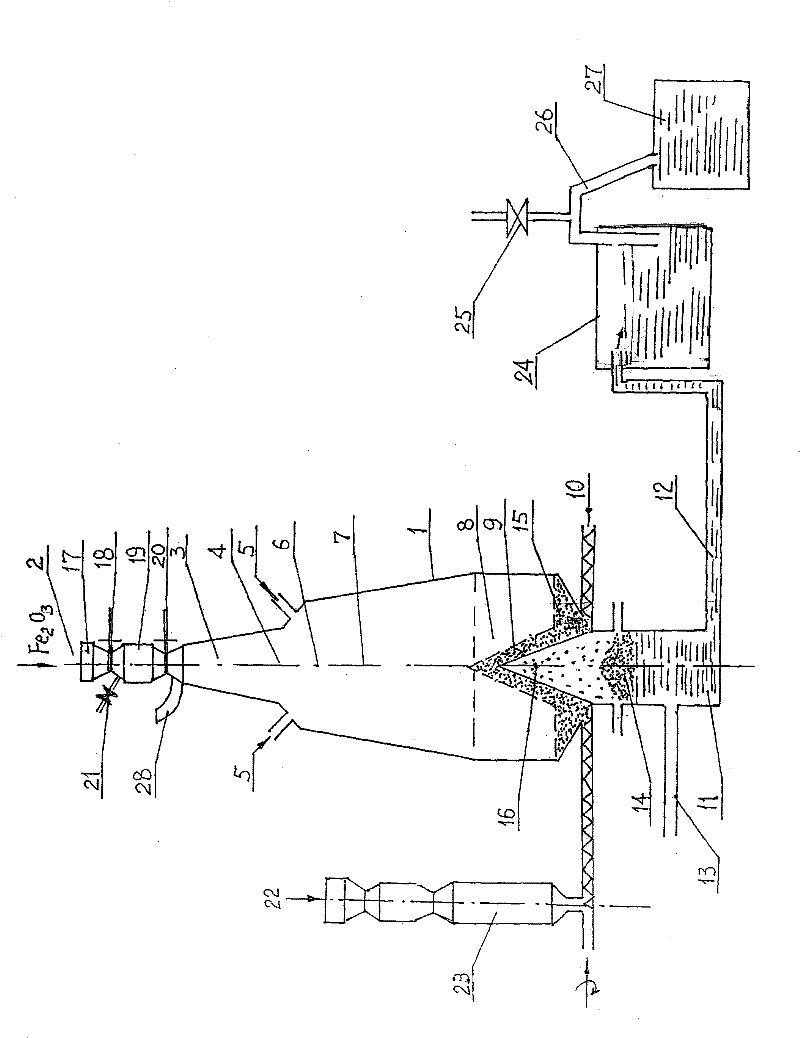

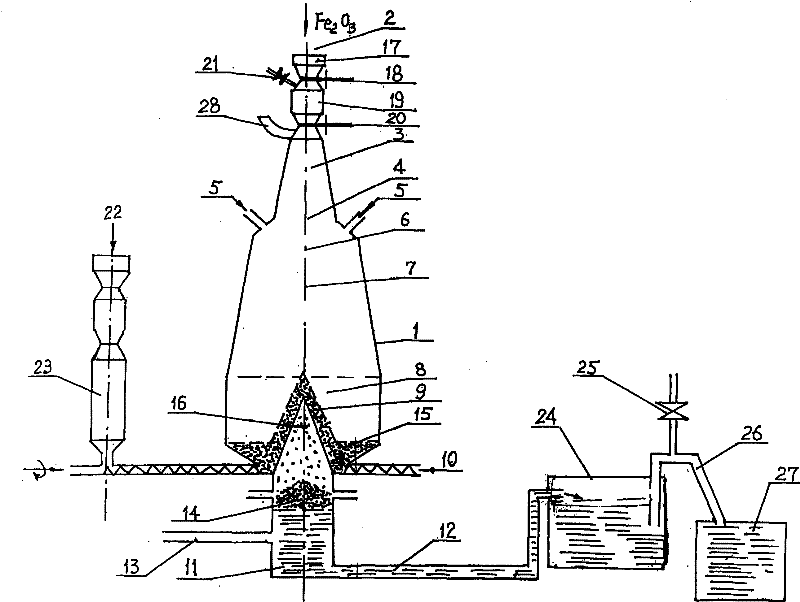

Novel energy-saving and environment-friendly technology for making iron and making iron alloy by using lamp-shaped furnace

The invention relates to a novel energy-saving and environment-friendly method for making iron and making an iron alloy by using a lamp-shaped furnace. Large-air hole pressure-proof type ore is loaded from the top of the furnace by using the lamp-shaped furnace with a small furnace hearth and a hot furnace core, coal oxygen or coal power is jetted from the furnace hearth, high-temperature reduction gas is generated and rises to reduce the type ore, reduced furnace gas is combusted again to preheat the descended type ore, and the utilization rate of CO in the furnace is approximate to 100 percent. The furnace has a small amount of coke, low air displacement, a high material temperature and high smelting speed and does not have nitrogen, so that the utilization coefficient of furnace capacity is improved by more than 10 times compared with that of a blast furnace. The standard coal consumption in each ton of iron is less than 400kg and oxygen consumption is less than 320NM<3>, or coal consumption is less than 270kg, power consumption is less than 1,000 degrees and the oxygen consumption is less than 25NM<3>. The occupied area, investment and employees of a lamp furnace ton iron factory cannot reach one fifth of those of a blast furnace process. The energy consumption of the iron alloy reduced by coal electric furnace charcoal is lowered to a great extent, and the novel method is suitable for updating and leading the conventional energy-saving and emission-reduction technology of large and medium blast furnaces or submerged arc furnaces.

Owner:丁公权 +2

Formula of cultivation material for industrial production of flammulina velutipes and production method

ActiveCN110463510ARich in nutrientsPromote growthCultivating equipmentsMushroom cultivationCalcium carbonateBiology

The invention belongs to the technical field of edible fungi cultivation, and specifically relates to a formula of a cultivation material for industrial production of flammulina velutipes and a production method. The cultivation material for the flammulina velutipes is prepared from the following raw materials in weight percentage: 42%-50% of descurainia sophia, 28%-32% of cottonseed husk, 12%-16%of bran, 5%-10% of soybean meal, 0.5%-2.0% of calcium carbonate, 1.0%-3.0% of lime, and 0.2%-0.5% of magnesium sulfate. By taking the descurainia sophia as the main material, not only is the problemof the cost of the production raw materials of the flammulina velutipes solved, but also the benefit of cultivation is improved, the effective use of descurainia sophia weeds is realized at the same time, and the damage and pollution to the environment are reduced. The production method of the flammulina velutipes achieves the purpose of high efficient production under a factory pattern.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +3

Hammer type crusher internally provided with feeding fan and rotary screen

InactiveCN101816969BIncrease productivityAvoid idling energy consumptionGrain treatmentsEngineeringCrusher

Owner:黄元庆

Automatic fermentation controlling and monitoring system for wine making in wine room

InactiveCN106222005ARaise material temperatureOvercoming unreasonable controlAlcoholic beverage preparationThe InternetEngineering

The invention discloses an automatic fermentation controlling and monitoring system for wine making in a wine room. The system mainly comprises an alcohol concentration detection module, a temperature measurement module, a controller, an air pressure detection module, an Internet of Things communication module, a server, a monitoring platform, a near-field communication module and a client. The controller adjusts the temperature according to a preset value; the alcohol concentration detection module detects the alcohol concentration; the client determines end time of a fermentation process according to a value of the alcohol concentration; information of internal air pressure of fermentation drums is sent to the client through the near-field communication module; the client judges whether the fermentation drums are in air leakage or not; information of the temperature, the alcohol concentration and the air pressure of the fermentation drums is processed by the controller, then sent to the server through the Internet of Things communication module and finally sent to the monitoring platform by the server, and the monitoring platform monitors the fermentation process. Therefore, defects of irrationality in external parameter control, failure in monitoring of airtightness of the fermentation drums, failure in real-time data monitoring and the like in the fermentation process in the prior art can be overcome.

Owner:北海古力酒业股份有限公司

Sintering mixture and mixing method, sintering ore and sintering method

The invention belongs to the technical field of iron ore sintering, and particularly relates to a sintering mixture and a mixing method, sintering ore and a sintering method. The sintering mixture comprises the following components in parts by weight: 90-110 parts of iron ore powder to be sintered, 14-20 parts of returned ore A, 8.5-10.5 parts of returned ore B, 2-4 parts of coke powder, 7-9 partsof quicklime and 6.5-8.5 parts of adhesives, wherein the particle size of the returned ore A is 1-2 mm, and the particle size of the returned ore B is 2.5-5 mm. Through adding the adhesives with an adhesive effect and the returned ore A and the returned ore B with specific particle sizes to the sintered mixture, the particle size and particle structure of the sintering mixture are further improved, so that microparticles with the returned ore as cores are formed, the air permeability of a material layer is greatly improved, the sintering requirement of an ultra-thick material layer of 1000 mmor above is fully met, and the air permeability and the vertical combustion speed of a sintering material layer, and the output and yield of the sintering ore are all improved to various degrees.

Owner:NANKAI UNIV

Water Reduction Method for Sintering Mixture

ActiveCN102676798BReduce wind resistanceReduce processing energy consumptionMoistureEnergy consumption

The invention discloses a method for reducing water of sintered mixture, which belongs to the technical field of sintering process in the metallurgical industry. The main technical problem to be solved by the present invention is to reduce the moisture in the sintering mixture and thereby reduce the energy consumption of the sintering process. The basic technical solution of the present invention is: a water-reducing method for sintered mixture, which includes the process of blowing the sintered mixture in the process of falling through the nozzle and using wind force to make it particle size segregated, characterized in that: the sintered mixture The moisture content is reduced by at least 3.6%. The invention is not only suitable for newly designed sintering machines, but also suitable for the transformation of existing sintering machines.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

A new type of asphalt old material heating device

ActiveCN105603853BExtended service lifeRaise material temperatureRoads maintainenceCombustion chamberCombustor

The invention provides a novel waste pitch heating device. The novel waste pitch heating device comprises a base and a combustor and is characterized by further comprising a combustion chamber; the combustor, the combustion chamber and a heating assembly are arranged on the base, the combustor and the combustion chamber are fixedly connected in a sealed mode and fixedly connected with the base through a moving assembly, the two ends of the heating assembly are fixedly connected with the base, and the middle of the heating assembly is fixedly connected with the base; the combustion chamber makes contact with the heating assembly in a sealed mode, a hot air circulating assembly is arranged above the heating assembly and fixedly connected with the base, a first inlet of the hot air circulating assembly is connected with a discharging part in a sealed mode, and a third outlet of the hot air circulating assembly is connected with a feeding part in a sealed mode. During use, combustion hot air enters the heating assembly, normal-temperature waste pitch enters a rotating heating drum from the feeding part, is guided to the bottom of the heating drum through a spiral guiding plate and pushed downwards to a V-shaped plate of a scraping conveying section, moves forwards in a fluctuation mode, is heated by the heating drum, and forms a material curtain for full heat exchange, and the waste pitch is discharged from a discharge port when heated to the needed temperature.

Owner:JILIN PROVINCE ROAD CONSTR MASCH CO LTD

A method for producing high-nickel molten iron by chain grate machine preheating-electric furnace melting for low-grade laterite nickel ore

The invention discloses a method for preparing high-nickel molten iron from low-grade laterite-nickel ore by using chain grate machine preheating and electric furnace smelting separation. The method comprises the following steps that S1, drying pretreatment and crushing are carried out on the laterite-nickel ore to obtain laterite-nickel ore powder; S2, the laterite-nickel ore powder is uniformlymixed with a fusing agent to obtain a uniform mixture, and pelletizing is carried out to obtain green balls; S3, the green balls are fed into a chain grate machine for drying, preheating and roastingto obtain preheated pellets; and S4, the preheated pellets are mixed with a reducing agent, and then are fed into an electric furnace for smelting separation to obtain high-nickel molten iron and furnace slag. According to the production method, the electric furnace burden which is high in strength, uniform in particle size and excellent in quality is prepared, and the high-temperature hot preheated pellets are directly fed into the electric furnace to be subjected to reduction and smelting separation, so that the heat required for re-heating to reach the smelting separation temperature is saved, then the electricity consumption of the electric furnace is reduced, and meanwhile, the metal recovery rate is improved.

Owner:CENT SOUTH UNIV

Device capable of effectively reducing sintering NOx emission

The invention discloses a device capable of effectively reducing sintering NOx emission. The device comprises a sintering preheating drying furnace and a sintering ignition furnace, the furnace top of the sintering preheating drying furnace is provided with a precast beam, a preheating air channel and a preheating curtain type burner, and the preheating curtain type burner is respectively connected with a gas pipeline and a primary air pipeline; the sintering preheating drying furnace corresponds to a first air bellow and a second air bellow of a sintering air draft air bellow; the sintering ignition furnace corresponds to a third air bellow and a fourth air bellow of the sintering air draft air bellow; and an ignition curtain type burner is arranged at the top of the sintering ignition furnace and connected with the gas pipeline, the primary air pipeline and a secondary air pipeline. According to the device, the stability and uniformity of preheating and drying of a sintering mixture can be achieved, the quality of sintered ore is improved, the strength of the sintered ore is improved, the rate of finished products is increased, reduction reaction with NOx is facilitated, and conversion from fuel nitrogen to NOx is restrained.

Owner:MAANSHAN IRON & STEEL CO LTD

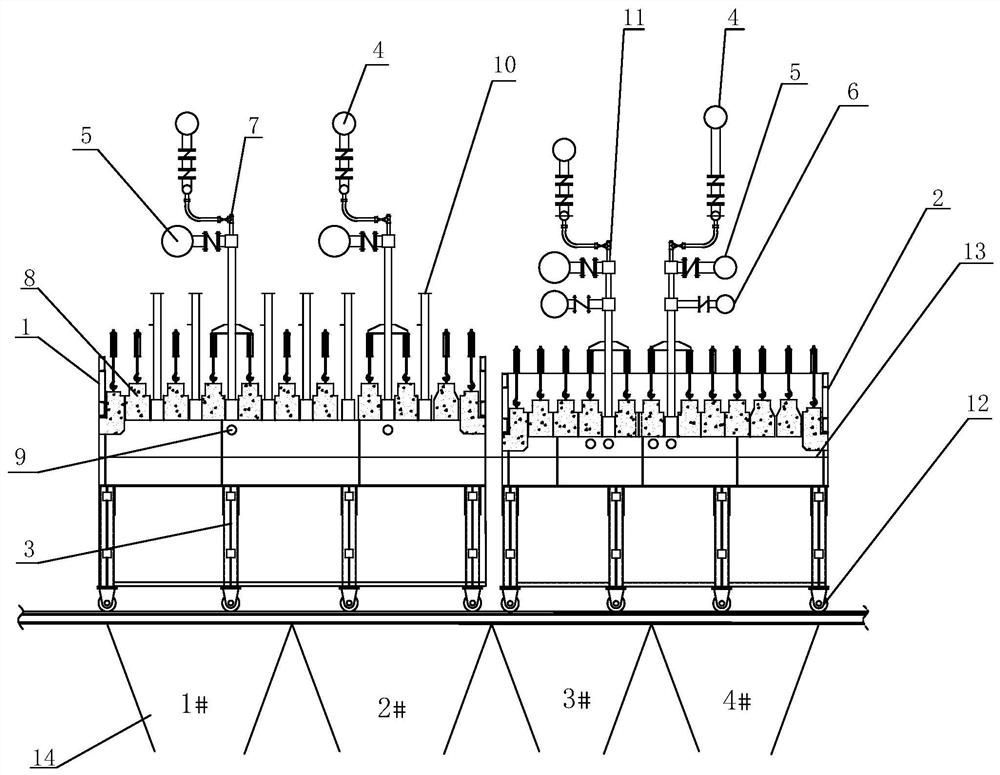

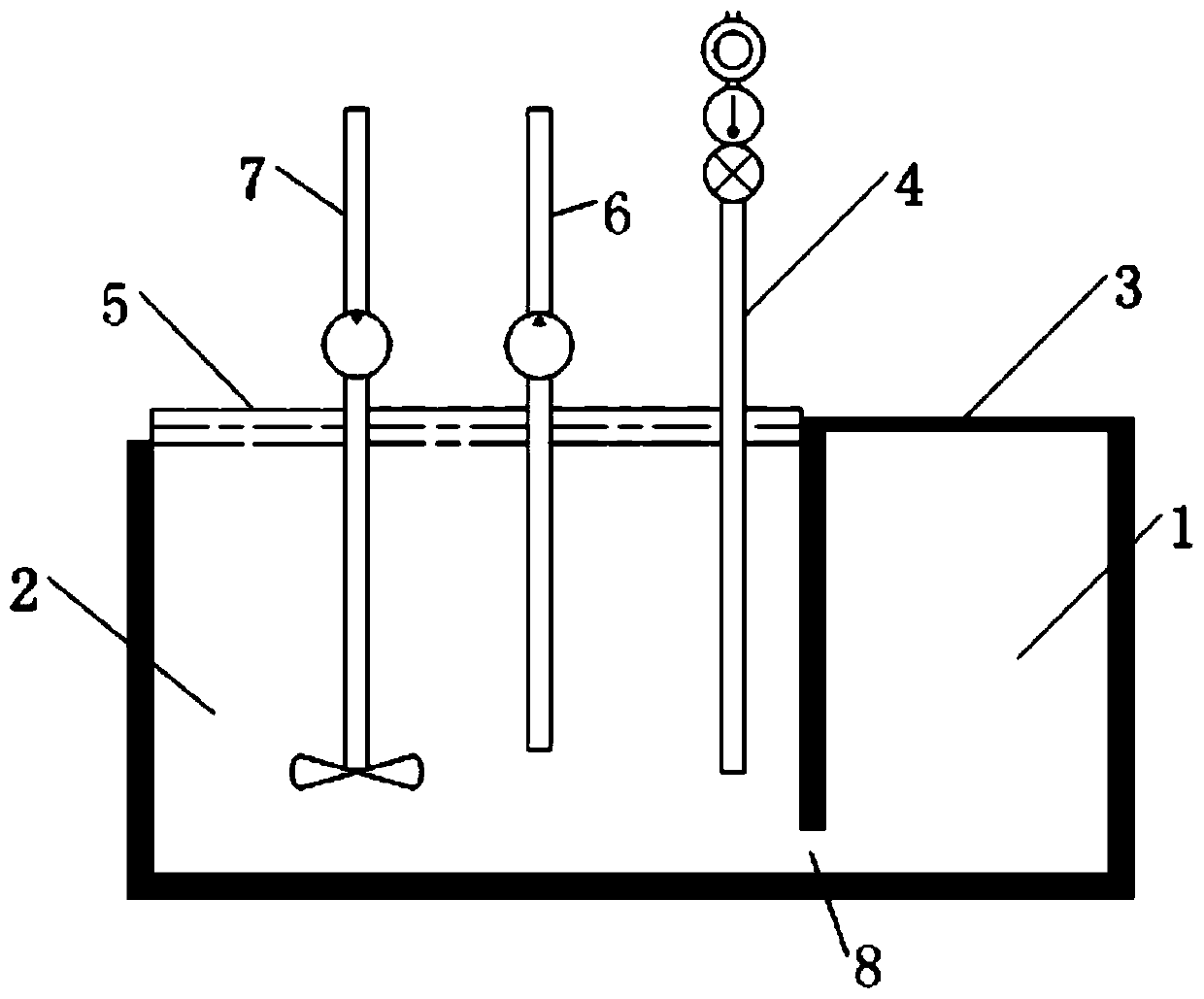

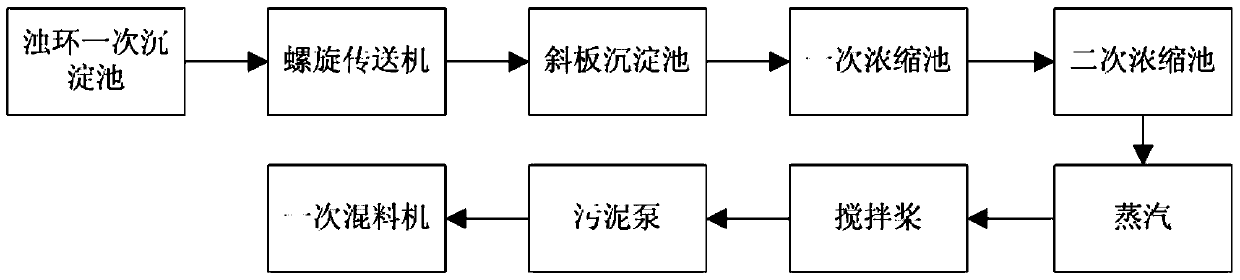

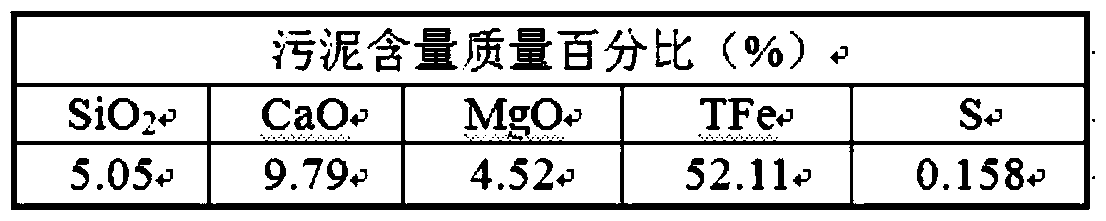

A device for preheating raw materials for sintering by using steam and sludge

A device for preheating to-be-sintered raw materials with steam and sludge belongs to the technical field of sintered ore. The device comprises a primary concentration basin, a secondary concentration basin, a filter screen, a steam pipeline, a lifting platform, a sludge pump, a mud stirring paddle and a through hole, wherein the primary concentration basin and the secondary concentration basin communicate with each other through the bottom through hole; the filter screen is located at the upper part of the primary concentration basin; the steam pipeline is located at the four corners of the secondary concentration basin; the lifting platform is located above the secondary concentration basin; and the sludge pump and the mud stirring paddle are mounted in the middle of the lifting platform. The device has the advantages of simple structure, low site requirement and easiness in implementation. The sludge concentration of equipment with no steam pipeline is about 20%-25% in general, and the concentration is increased to 35%-38% after the steam pipeline is arranged on the equipment.

Owner:QIANAN CITY JIUJIANG WIRE

Automatic fermentation control system for wine making of wine room

InactiveCN106350349ARaise material temperatureOvercome defects such as unreasonable controlAlcoholic beverage preparationAlcoholControl system

The invention discloses an automatic fermentation control system for wine making of a wine room. The automatic fermentation control system for wine making of the wine room mainly comprises an alcohol concentration detecting module, a temperature measuring module, a controller, an air cooler, a fan heater, a near-field communication module and a client side, wherein the temperature measuring module acquires temperature values in real time and transmits the temperature values to the controller; the controller adjusts the temperature according to a preset value; when the temperature is lower than the set value, the controller controls the fan heater to increase external temperature so as to increase the temperature of the material of a fermentation barrel; when the temperature is higher than the set value, the controller controls the air cooler to reduce the external temperature, and the temperature of the material of the fermentation barrel is increased by effect of heat conduction; when the temperature is in a set range, the air cooler and the fan heater are not started; the alcohol concentration detecting module detects alcohol concentration; after being processed by the controller, concentration value of alcohol is transmitted to the client side; and the client side determines end time of a fermentation process according to the concentration value of the alcohol. Therefore, the shortcomings that external parameters in a fermentation process in the prior art are controlled unreasonably and the like can be overcome.

Owner:北海古力酒业股份有限公司

A kind of cultivation material formula and production method of Flammulina velutipes factory production

ActiveCN110463510BRich in nutrientsPromote growthCultivating equipmentsMushroom cultivationHuskEdible mushroom

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +3

A method for mixing raw materials for sintering

ActiveCN110523308BAvoid cloggingReduce the temperatureTransportation and packagingChemical/physical processesBelt conveyorRaw material

The invention discloses a method for mixing raw materials produced by sintering, which comprises the following steps: firstly adding sintered return ore powder and water into a digester for mixing, then adding quicklime into the digester to mix with wet return ore powder and water, and then mixing Good returned ore powder and quicklime are sent to the cylinder mixer for mixing with the iron ore powder, fuel and other materials prepared according to the ratio. The invention can not only avoid the impact on the quality of sintered ore due to incomplete digestion of quicklime, but also avoid problems such as a large amount of dust generated in the process of digesting quicklime with a digester, blockage of the digester, and the like.

Owner:SGIS SONGSHAN CO LTD

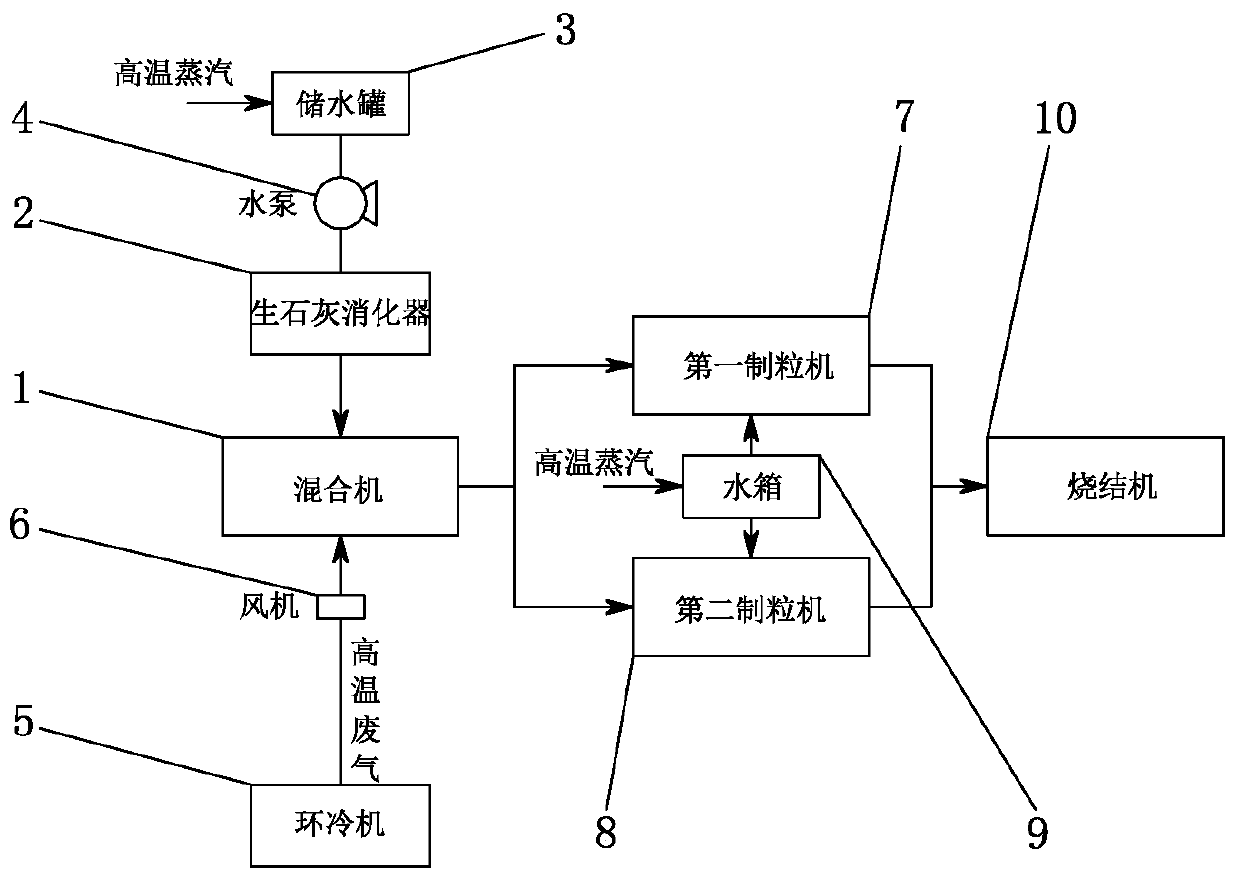

Equipment and method for producing reflective film with microprism structure by extrusion method

The invention discloses a device and a method for producing a reflective film with a microprism structure by an extrusion method. The present invention adopts a special extrusion coating process to extrude and coat transparent thermoplastic resin on the high-temperature-resistant fiber tape attached to the metal roller through the hot extrusion die head without stretching, and through the pressure and rolling of the roller and the roller, The plastic melt is extruded and flowed in the mold belt, thereby filling each sunken microprism unit to achieve the purpose of molding replication, and then enters the cooling zone for cooling and peeling. The equipment of the invention is easy to manufacture, and the mold belt has a long service life; the reflective film produced by it has high retroreflection coefficient, uniform brightness and good weather resistance.

Owner:田武学 +1

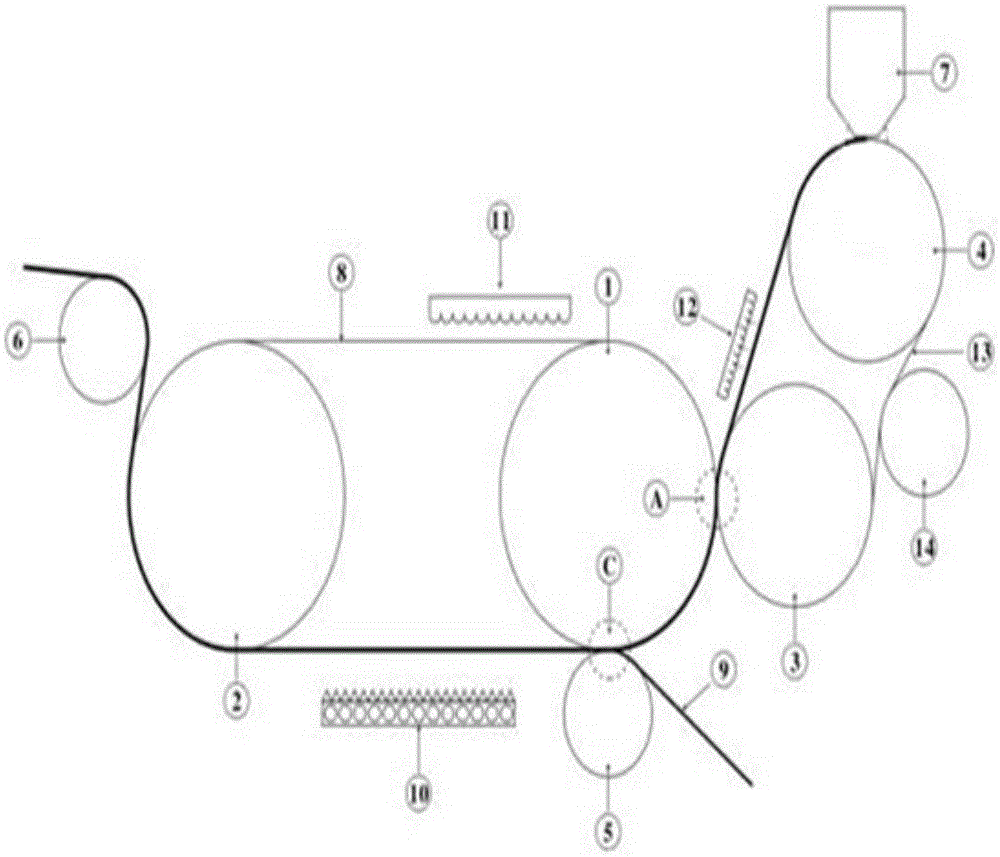

High-temperature sintering method of vanadium-titanium ore mixture

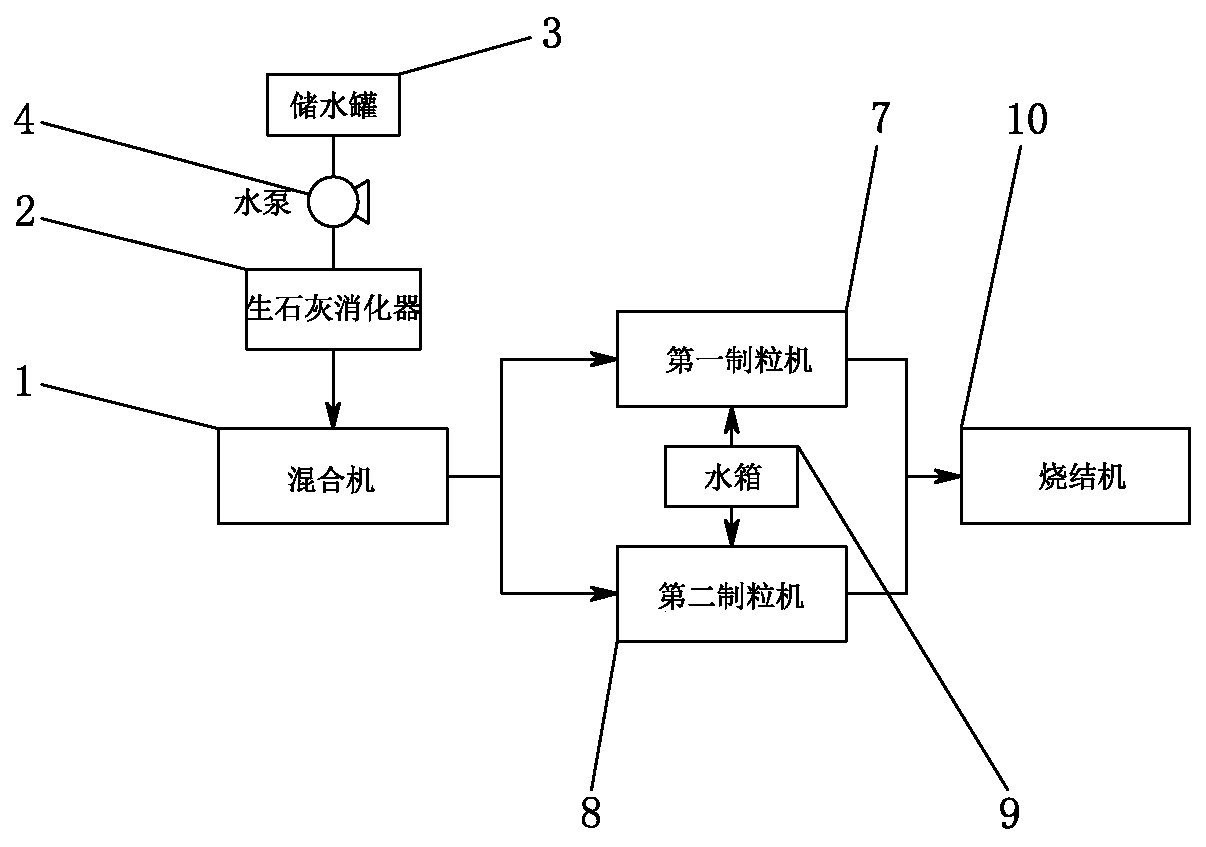

The invention discloses a high-temperature sintering method of a vanadium-titanium ore mixture. The method specifically comprises the following steps that the crushed vanadium-titanium ore mixture isconveyed into a mixer, and quicklime is conveyed into a quicklime digester; high-temperature exhaust gas discharged from a low-temperature section chimney of a ring cooler is introduced into a barrelof the mixer through a fan, the vanadium-titanium ore mixture is heated, the material temperature is improved, and in the heating process, a stirring machine continuously stirs, so that the high-temperature exhaust gas and the vanadium-titanium ore mixture are in full contact; and a steam pipe is connected into a water storage tank. By improving the water adding temperature in the quicklime digester, the mixture is heated by introducing the high-temperature waste gas discharged from the ring cooler into the mixer, normal-temperature water supplemented by a granulator is heated, by means of thethree heating measures, the temperature of the mixture is improved, the over-wetting phenomenon caused by water vapor condensation in a material layer is avoided, the air permeability of the materiallayer is improved, then the sintering productivity is improved, and the fuel consumption is reduced.

Owner:YUNNAN DESHENG STEEL CO LTD

Preserved beancurd containing functional factor and preparation method thereof

The invention discloses preserved beancurd containing a functional factor, which comprises components of soybean and edible (medicinal) fungi. A preparation method for the preserved beancurd containing the functional factor comprises the following steps: soybean, edulcoration, soaking, soybean grinding, filtering separation, soybean milk, soybean milk cooking, soybean milk curdling, blanking, block division, pehtze preparation fermentation, salted pehtze, filling, ripening, and a finished product. During soybean milk curdling, a mixed solution of an aqueous solution of edible (medicinal) fungiultra-fine powder and the soybean milk is added, and the soybean milk curdling is realized by the following steps: removing roots of the edible (functional) fungi and carrying out edulcoration on theedible (medicinal) fungi; carrying out ultrafine grinding on the edible (medicinal) fungi after drying or insolating; adding water to dissolve, wherein the ratio of the edible (medicinal) fungi ultra-fine powder to the water is 1:4; adding the soybean milk at 100 DEG C with the same quantity as the aqueous solution of the edible (medicinal) fungi ultra-fine powder into the mixture to dilute afterthe mixture is stirred fully and evenly; and during filling, the aqueous solution of the edible (medicinal) fungi ultra-fine powder is added. The preserved beancurd is rich in functional factor and multiple nutrients and has the advantages of health care function, tasty mouthfeel and simple processing.

Owner:JIANGSU ANHUI BIO TECH +1

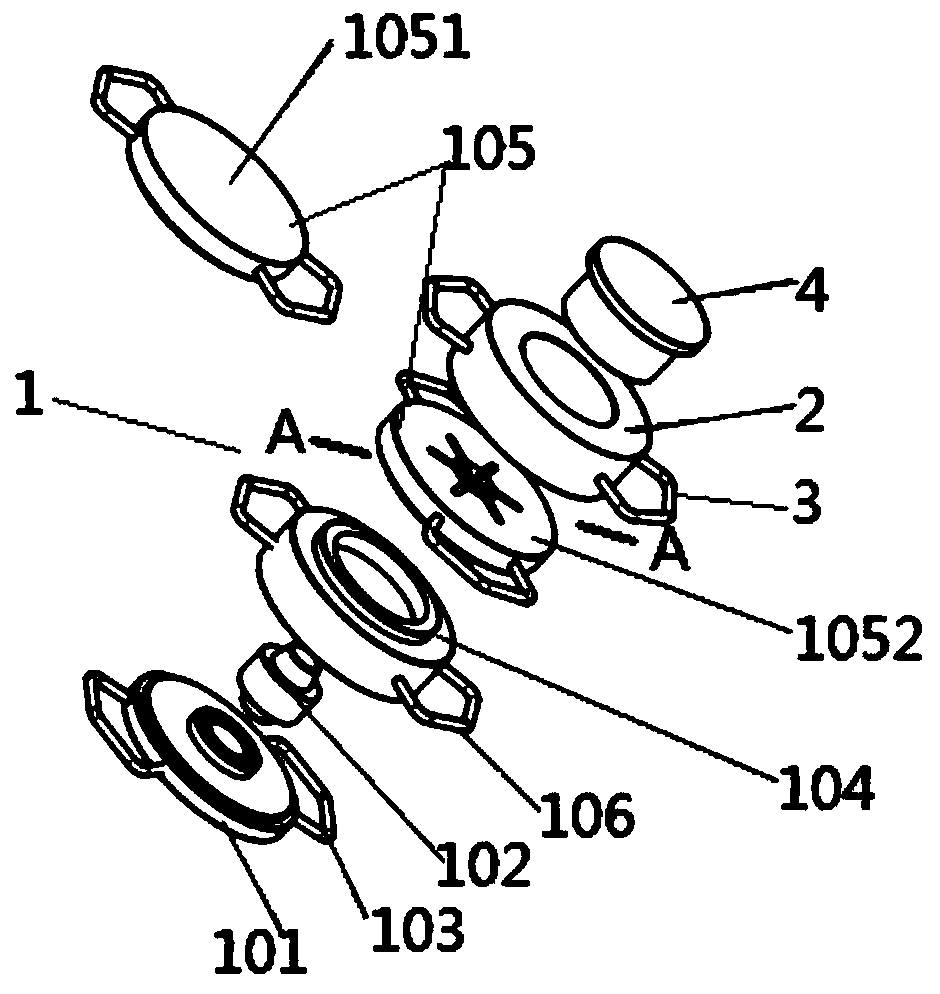

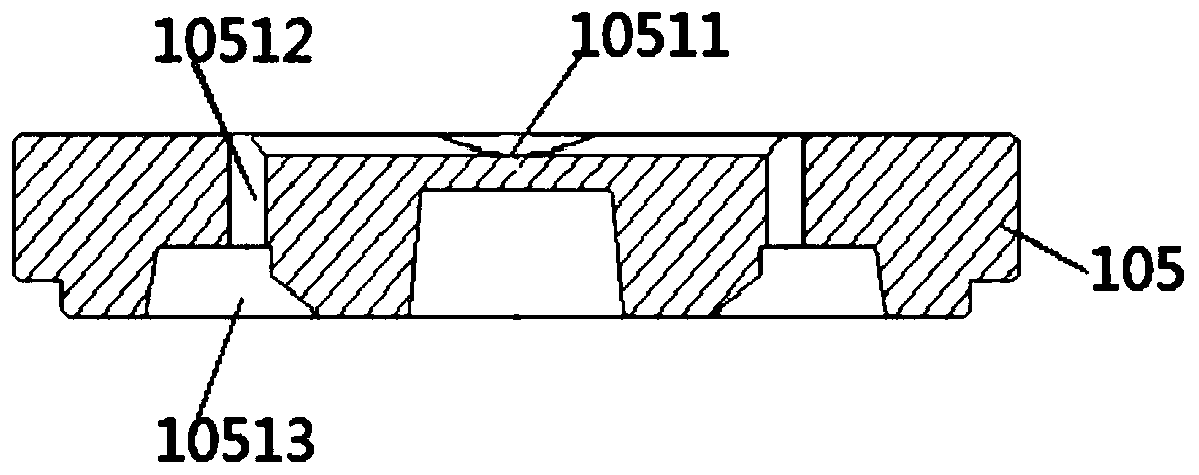

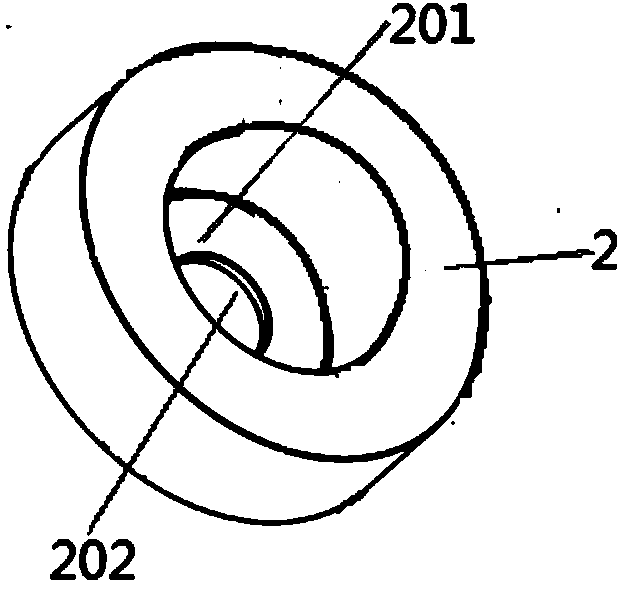

Packer rubber barrel die device and rubber barrel preparing method

The invention discloses a packer rubber barrel die device. A rubber barrel forming die is included. A glue injection barrel is arranged at the upper portion of the rubber barrel forming die and is ofa hollow cylinder structure. The two sides of the glue injection barrel are symmetrically connected with a pair of handles I. A pressing injection head is arranged in the glue injection barrel and canbe freely separated from the glue injection barrel. The packer rubber barrel die device is reasonable in structure design, and fusing and flowing distribution of sizing materials before the sizing materials flow into the die are optimized. Through the design of a flow guiding groove, the material temperature before the sizing materials enter a die cavity can be better increased, it is guaranteedthat the sizing materials injected into the die cavity can be sufficiently fused, and accordingly, radial and axial cracking risks during rubber barrel pressure bearing setting are reduced. It can beguaranteed that the die structure is simple and machining is convenient, and the rubber barrel product quality is improved as well.

Owner:SHANGHAI REAL SEALING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com