Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Prevent sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

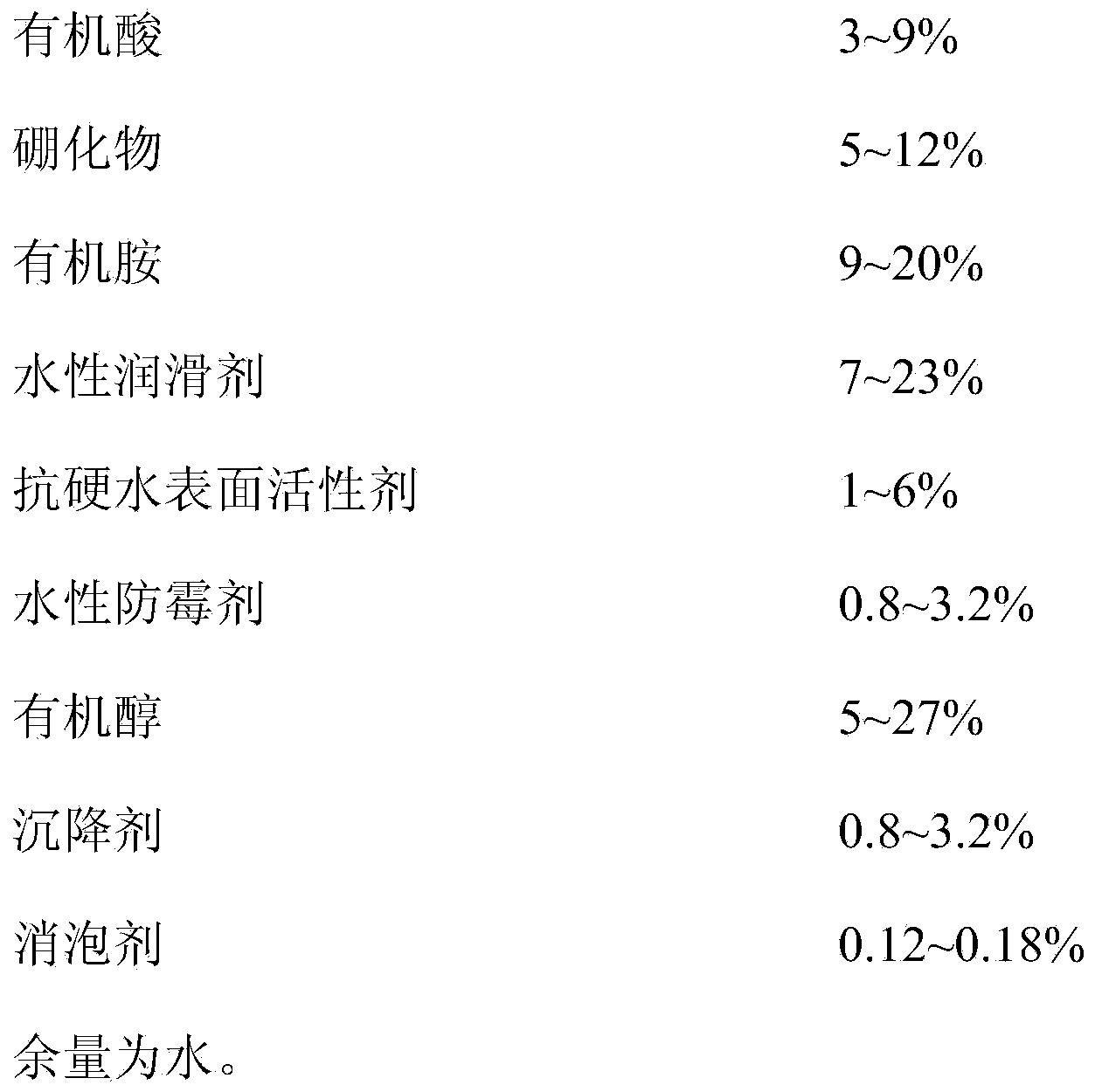

Full-synthetic glass grinding fluid

ActiveCN103525533AImprove general performanceGuaranteed service lifeLubricant compositionWater basedBoride

The invention discloses an environment-friendly glass grinding fluid, which is efficient, and long in service. The full-synthetic glass grinding fluid is prepared from an organic acid, a boride, an organic amine, a water-based lubricant, a hard water-resisting surfactant, a water-based mould inhibitor, an organic alcohol, a settling agent, a defoaming agent and water in a mixing manner. The glass grinding fluid disclosed by the invention has excellent cooling property, anti-rotting ability and lubricating abrasion resistance, and outstanding hard water resistance, can be recycled for a long period of time, can ensure the working accuracy and the service life of a tool, and has excellent cleaning performance; the blocking phenomenon of a grinding wheel can be effectively prevented; the product is good in settleability; processing is facilitated; the product is free of poison, environment-friendly, free of pollution, small in smell, good in working performance, good in compatibility with a paint of equipment, low in pH value, free of bad effects on skin and the like; the phenomenon that the paint of the equipment peels off is not generated. The grinding fluid disclosed by the invention is simple in reparation method, low in cost, excellent in performance, and good in market prospect at present.

Owner:东莞太平洋博高润滑油有限公司

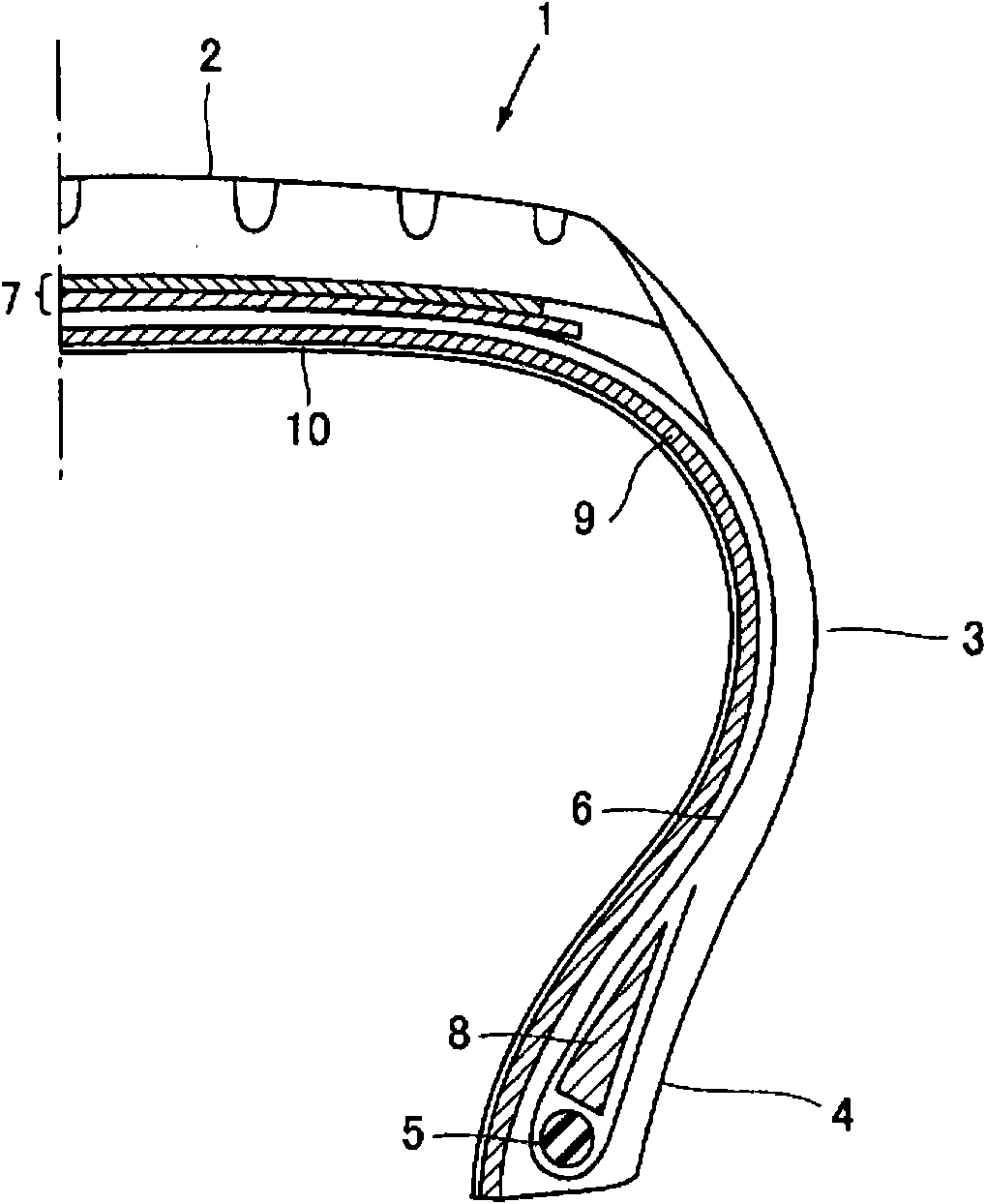

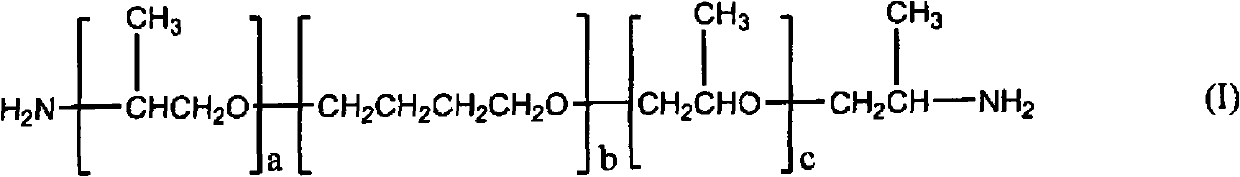

Method for producing polymer sheet for inner liner and method for producing pneumatic tire

InactiveCN102019733ADoes not cause air intakePrevent stickingTyresSpecial tyresPolymer scienceVulcanization

The present invention provides a polymer sheet for an inner liner and a method for producing a pneumatic tire, which do not cause an air-in phenomenon between an inner liner and an insulation rubber or a carcass rubber in the vulcanization step, and also can prevent adhesion between the inner liner and a bladder. The method for producing a polymer sheet for an inner liner includes the steps of preparing an unvulcanized polymer sheet made of a polymer mixture containing 99 to 60% by mass of a styrene-isobutylene-styrene triblock copolymer, and 1 to 40% by mass of a polyamide-based polymer containing polyamide in the molecular chain and having a Shore D hardness of 70 or less, and at least one of the steps of coating one surface of the unvulcanized polymer sheet with a water-soluble paint 2 to 5 times, and coating with a mold-releasing rubber in a thickness of 0.001 mm to 0.1 mm.f.

Owner:SUMITOMO RUBBER IND LTD

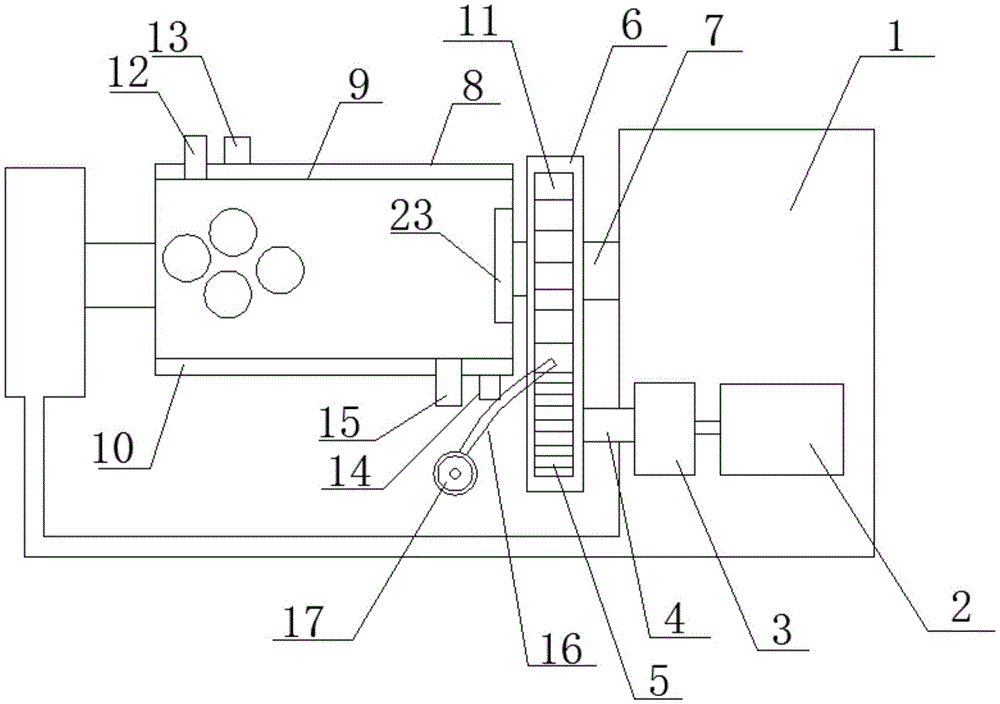

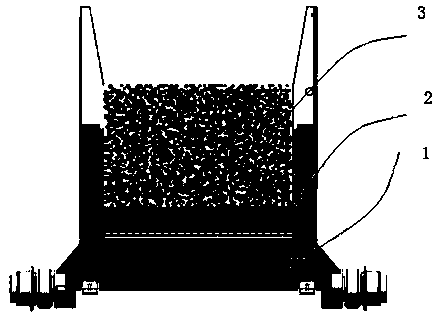

Ball grinding mill

InactiveCN106140403AShorten the timeRun fastGear lubrication/coolingGrain treatmentsDrive shaftEngineering

The invention discloses a ball grinding mill. The ball grinding mill comprises a machine frame and a ball grinding barrel. A motor is installed on the lower portion of the right end of the machine frame. The output end of the motor is connected with a speed reducer. The output end of the speed reducer is connected with a transmission shaft. The transmission shaft is provided with a drive gear. The left end and the right end of the ball grinding barrel are connected to the machine frame through rotating shafts. The rotating shaft at the right end is provided with a gear, and a protection cover is arranged outside the gear and the drive gear. The protection cover is provided with a hose stretching into the protection cover. The other end of the hose is connected with a piston barrel. The ball grinding barrel comprises an inner barrel body and an outer barrel body. A cooling cavity is formed between the inner barrel body and the outer barrel body. The cooling cavity is provided with a cooling liquid inlet and a cooling liquid outlet. A sound absorption material lining layer is arranged on the inner side of the inner barrel body. A lining plate is arranged on the inner side of the sound absorption material lining layer. A lifting groove is formed in the inner wall of the lining plate. The lifting groove and the inner wall of the lining plate are both provided with wear-resisting layers. A static elimination device is further arranged at the right end of the inside of the inner barrel body. The ball grinding mill is simple in structure, convenient to use, capable of achieving sound insulation and abrasion resistance, high in stability and long in service life.

Owner:苏州旋特自动化科技有限公司

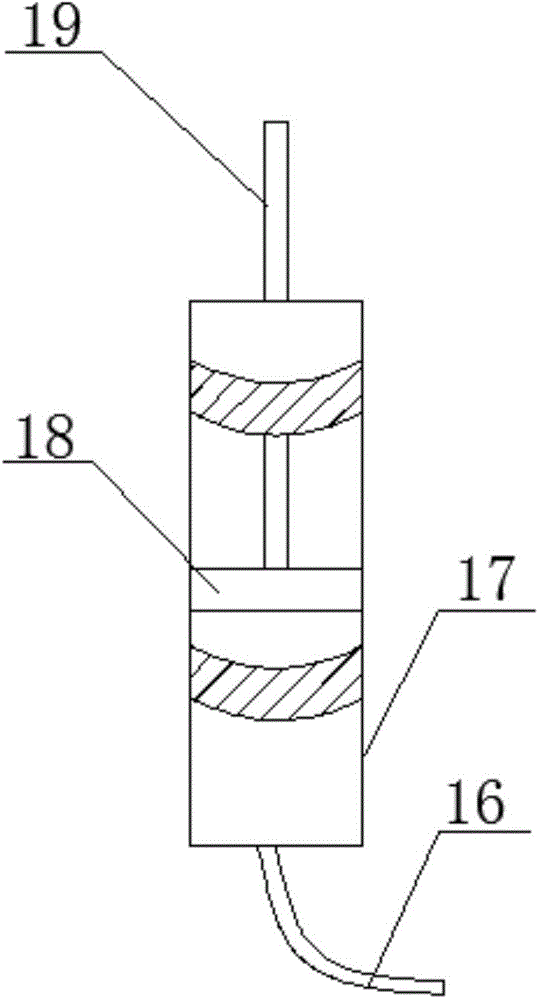

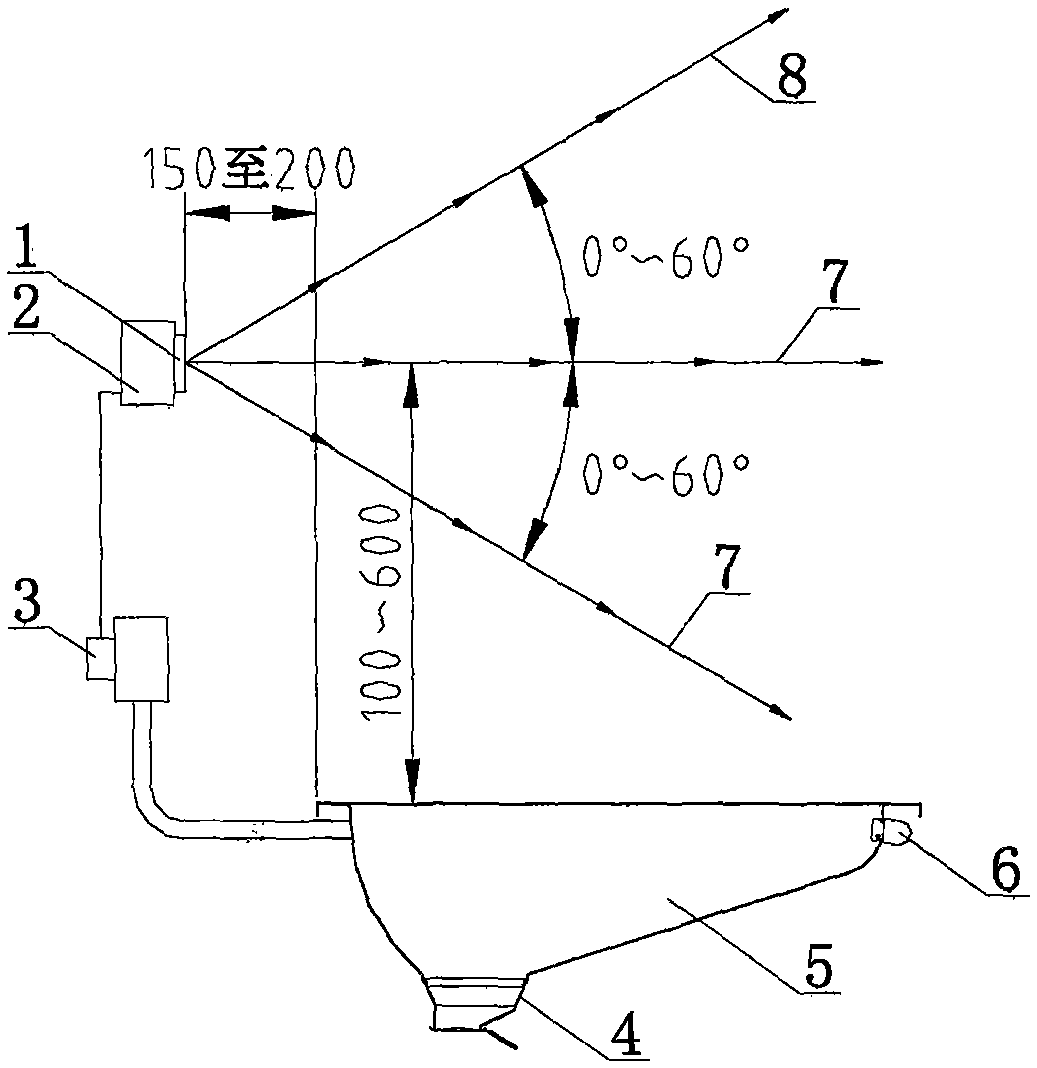

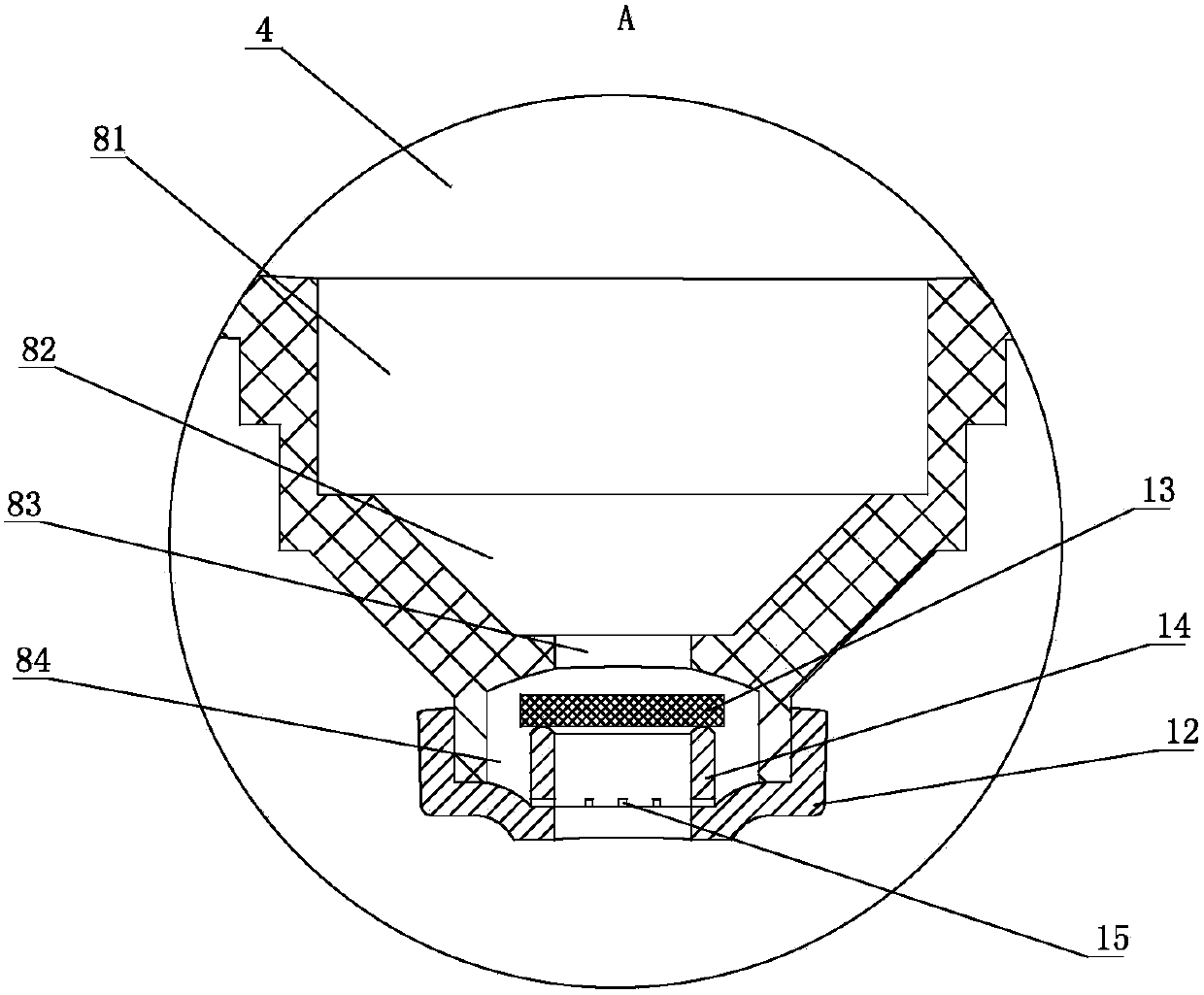

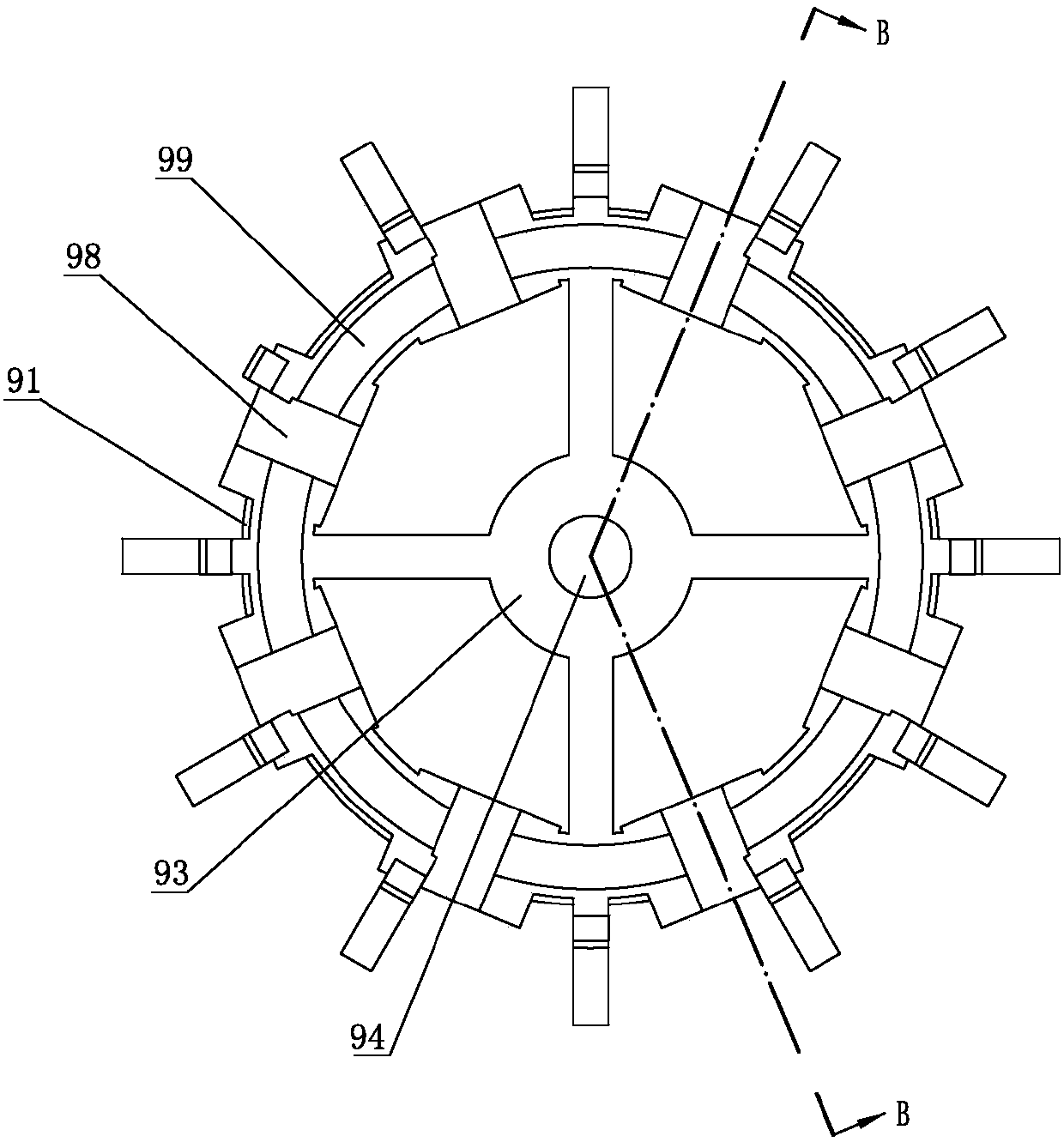

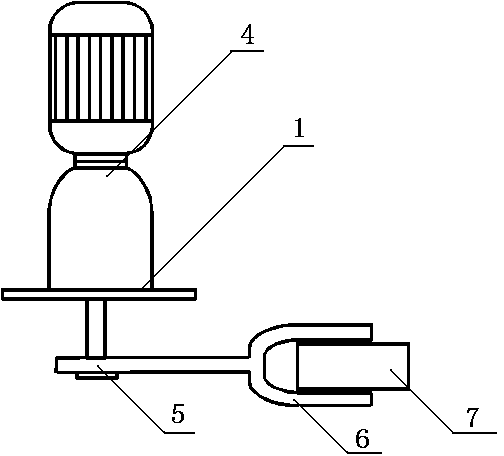

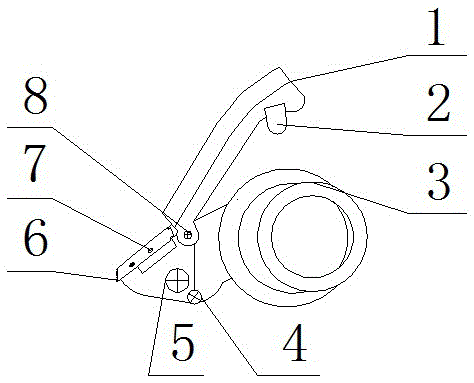

Water-saving toilet fitting capable of automatically recognizing and flushing urine and excrement and toilet cleaning method thereof

The invention provides a water-saving toilet fitting capable of automatically recognizing and flushing urine and excrement and a toilet cleaning method thereof. An infrared human body sensing device (1) detects whether a toilet is used by someone or not and transmits a signal to a control device (2) when a person comes and goes, the control device (2) recognizes whether the person defecates or urinates according to a set program and controls a flushing electromagnetic valve (3) to be on and off to flush the toilet fitting through a special flushing nozzle (6), and a water-seal balance weight turning plate (4) is adopted to block odor. The water-saving toilet fitting can automatically recognize urine and excrement and can save more than 75% of water; a small amount of water is adopted to moisten a basin under certain conditions, so that adhesion of sewage is prevented and the water-waving toilet fitting is convenient to clean.

Owner:SANHE LANJIESHI ENVIRONMENTAL PROTECTION TECH CO LTD

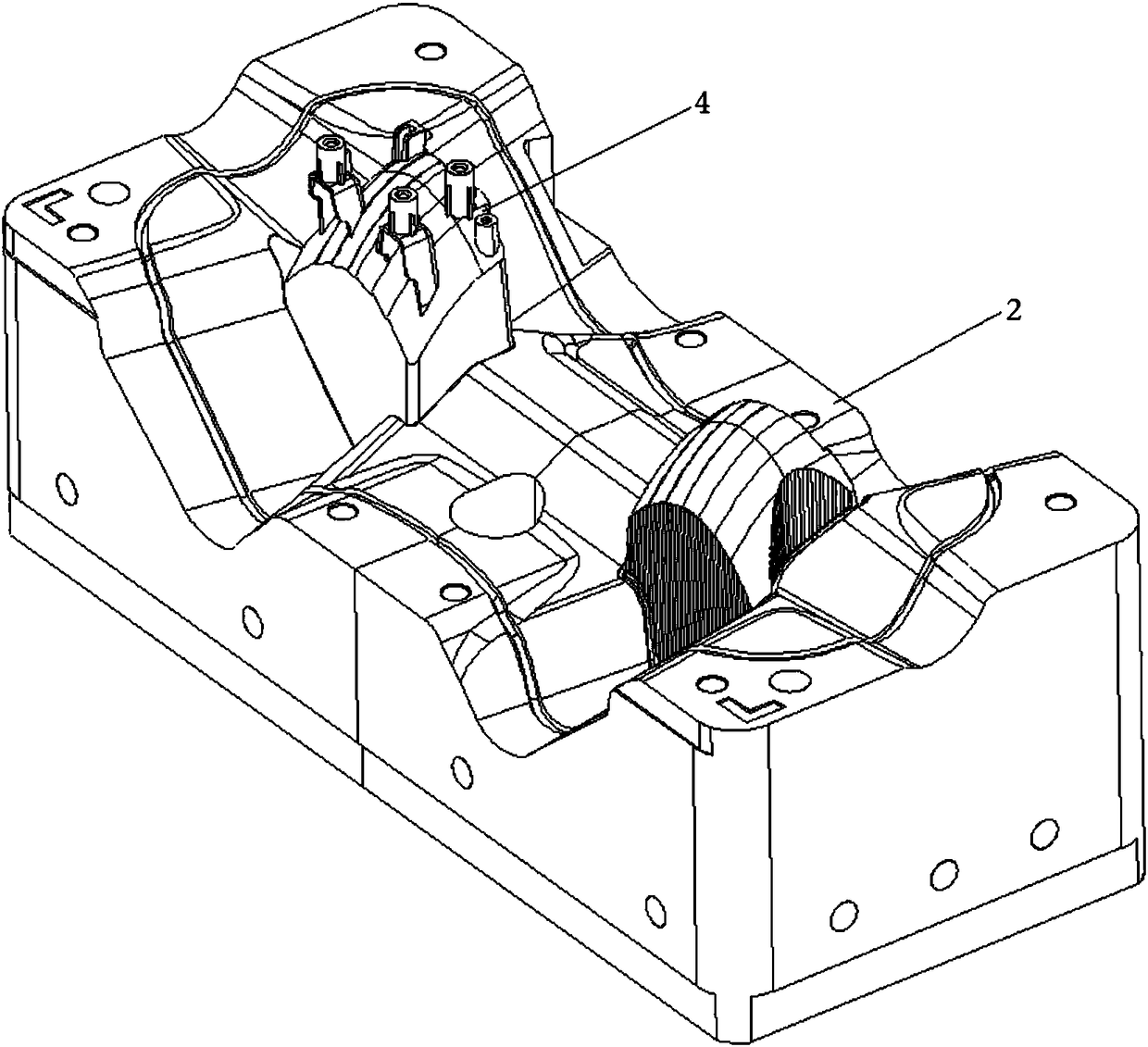

Horizontal type oil-gas separator for diesel engine

PendingCN107829800AControl speedImprove filtering effectMachines/enginesCrankcase ventillationControl valvesDiesel engine

The invention discloses a horizontal type oil-gas separator for a diesel engine. The horizontal type oil-gas separator comprises a shell (1) and a filter element (2). The shell (1) is internally provided with a filter cavity (3) and a buffer cavity (4). The filter cavity (3) is formed in the transverse side of the buffer cavity (4) and communicates with the buffer cavity (4). A gas inlet (5) is formed in the position, below the filter cavity (3), of the shell, wherein the gas inlet (5) allows mixed gas to enter therein. The gas inlet (5) communicates with the filter cavity (3) through a gas inlet channel (6). A gas outlet (7) is formed in the position, above the buffer cavity (4), of the shell (1), and an oil returning opening (8) is formed in the position, below the buffer cavity (4), ofthe shell (1). The filter element (2) is located in the filter cavity (3) and is of an annular structure. An adjustment valve (9) is arranged at the position, above the gas inlet channel (6), inside the filter cavity (3). The outer diameter of the adjustment valve (9) is less than the inner diameter of the filter element (2) but greater than the inner diameter of the gas inlet channel (6). The adjustment valve (9) is eccentrically arranged relative to the gas inlet channel (6). Compared with the prior art, the horizontal type oil-gas separator has the beneficial effects of being high in oil-gas separation efficiency and good in application stability.

Owner:宁海县雄达模塑有限公司

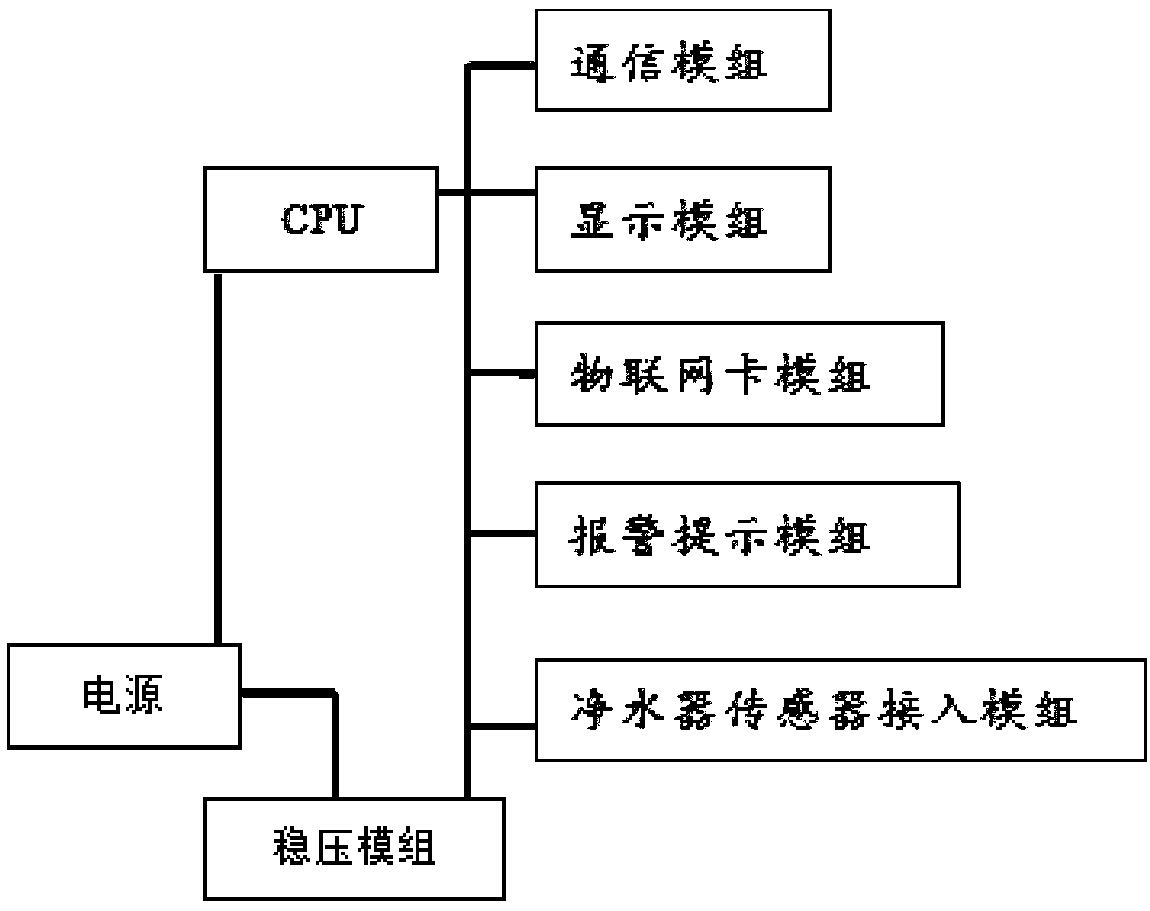

Internet of thing water purifier intelligent control method and computer board thereof

PendingCN108706662AMonitoring statusEnsure healthy waterWater treatment parameter controlPayment architectureWater useNetwork connection

The invention discloses an Internet of thing water purifier intelligent control method and a computer board thereof. The things-of-internet water purifier intelligent control method comprises steps ofbinding a things-of-internet user card, connecting a network, acquiring and recording a device condition, displaying a state, and performing the communication interaction, wherein the user binding and network connection are performed by virtue of a things-of-internet card, a heartbeat packet and a communication packet are regularly transmitted to automatically check a network signal and to reconnect the network, the device state of the purifier is acquired in real time and recorded and displayed, the recording is synchronized with a cloud server, an external control device is communicated with the water purifier device, the external device controls the water purifier device to work and also performs the communication interaction with a cloud server, the communication delay time can be dynamically adjusted according to a network response speed, and the data can be updated in real time. The stability of the network can be ensured, the state of the water purifier device is recorded synchronously in real time, the water purifier device is remotely operated, the data of the server can be updated in real time and can be synchronized, the state of various water purifier device can be more precisely monitored, and the water use healthy can be better ensured.

Owner:河南华码信息科技有限公司

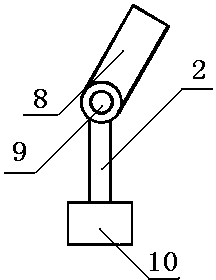

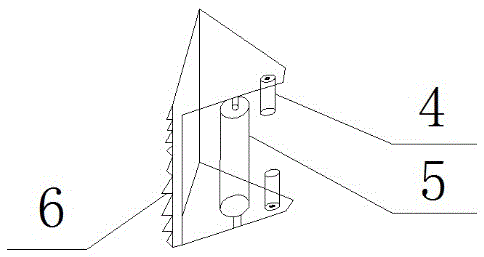

Shaking and hitting device preventing wall pasting inside dust collector

InactiveCN103394491APrevent stickingImprove dust removal effectCleaning processes and apparatusHIT deviceEngineering

The invention discloses a shaking and hitting device preventing wall pasting inside a dust collector, wherein a connecting shaft motor reducing gear rotates slowly to drive a reciprocating poking device to poke a fixed supporting shaking and hitting hammer, and the shaking and hitting hammer shakes and hits the positioning column on a portion where wall pasting is prone to occurring. The shaking and hitting device preventing the wall pasting inside the dust collector is composed of the reciprocating poking device, a shaking and hitting device and a positioning device, the motor reducing gear rotates slowly to drive the reciprocating hammer to poke the shaking and hitting hammer, the shaking and hitting hammer shakes and hits the positioning column on the outer wall of the dust collector under the action of gravity, construction and operation of original equipment are not affected, and a protecting board ensures that industrial dust removing equipment does not deform.

Owner:天门福临科技股份有限公司

Cooking pot and cooking method thereof

ActiveCN103799853APrevent stickingImprove taste qualityMultiple-unit cooking vesselsEngineeringCooking methods

The invention discloses a cooking pot and a cooking method thereof. The cooking pot is designed in order to solve the problem that when food is cooked, the food is stuck on the bottom of a pot. A pair of swinging devices of the cooking pot is additionally arranged on the cooking pot, the cooking method for the swing cooking pot is adopted, and therefore the pot sticking phenomenon caused by cooked food in the cooking pot can be effectively avoided. Thus, the daintiness and the quality of the food in the cooking process are improved and the taste of an eater is improved.

Owner:GEMSIDE ELECTRIC KITCHEN BEIJING TECH

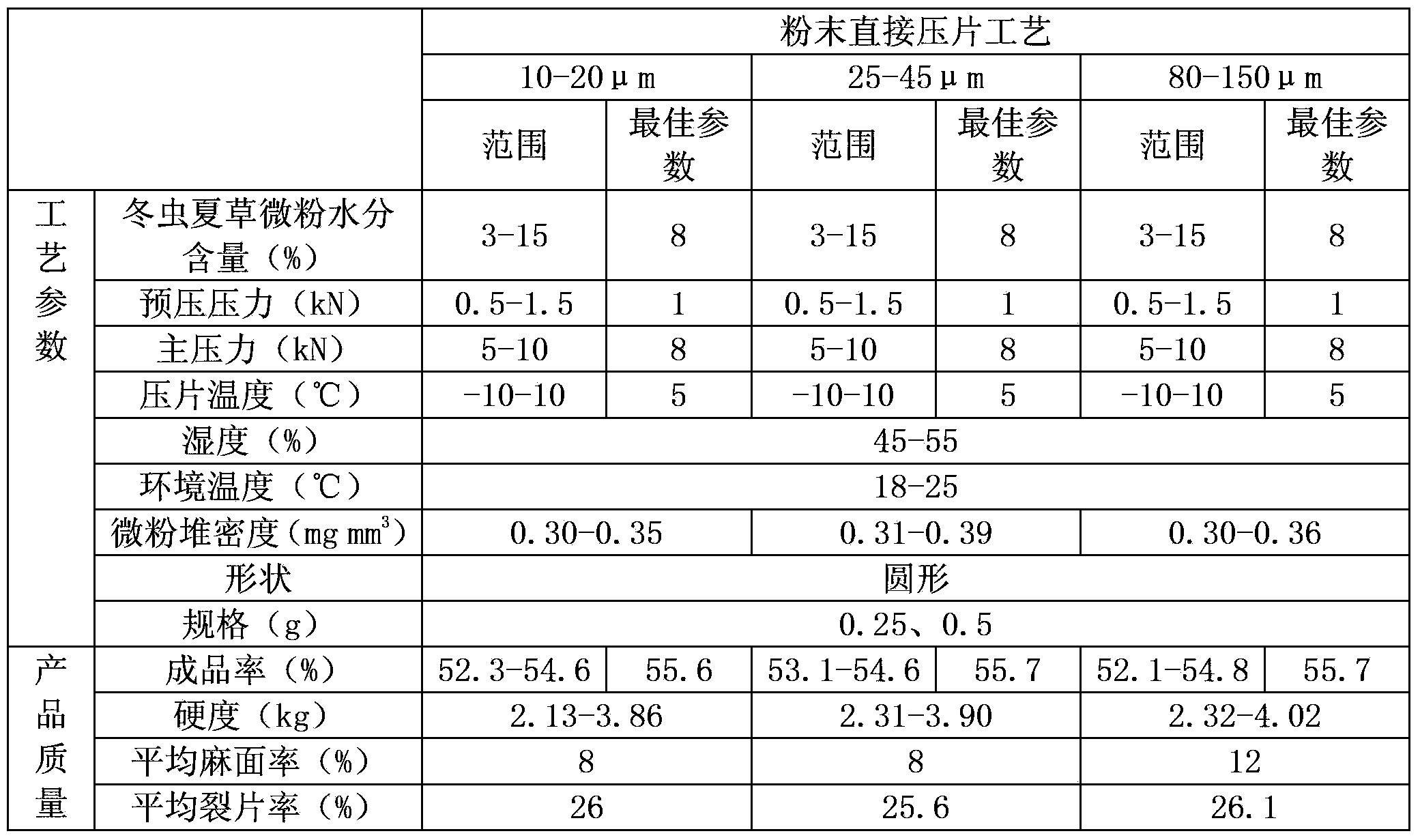

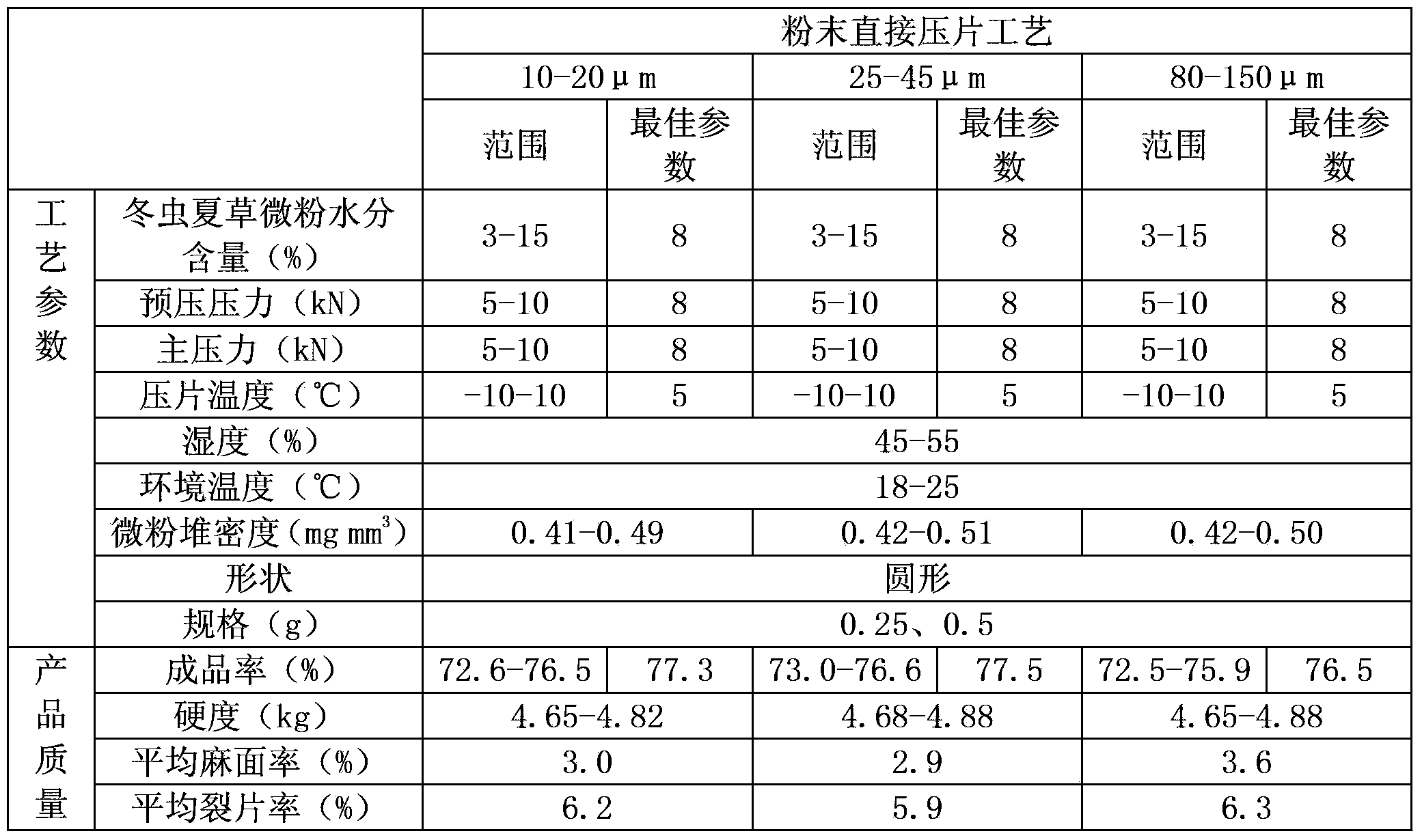

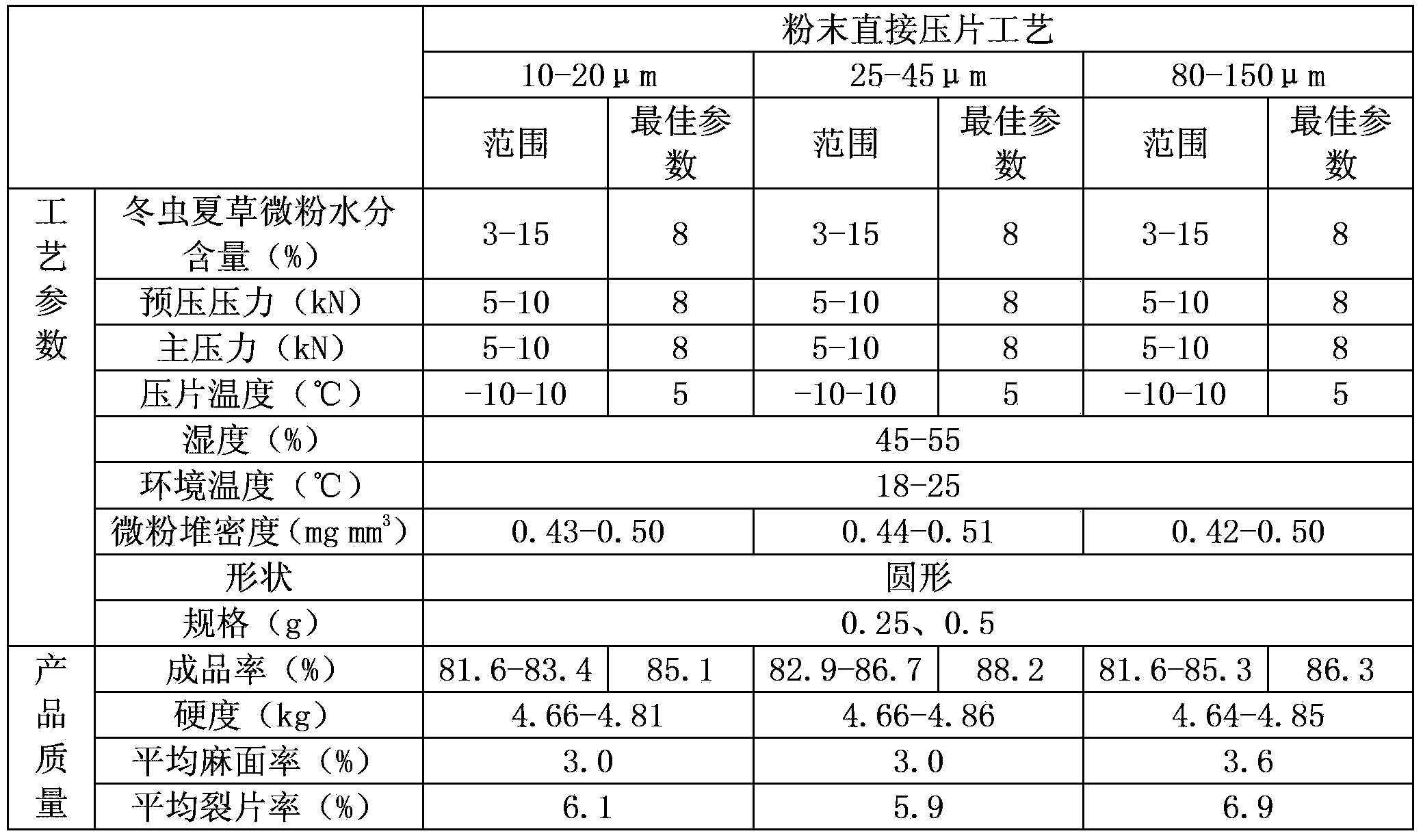

Rhodiola rosea micro powder tablet and preparation method thereof

InactiveCN103381193ALow pitting rateReduce Fragmentation RatePharmaceutical product form changePill deliveryRHODIOLA ROSEA ROOTBreakage rate

The invention discloses a rhodiola rosea micro powder tablet and a preparation method thereof and aims at solving the problem that existing tabletting processes need additional auxiliary materials and the content of effective constituents of prepared tablets is low. The rhodiola rosea micro powder tablet has water content 3-15%, the partical size of the tablet is 1-150mum, the rhodiola rosea micro powder tablet is prepared at the tabletting temperature of subzero 10-10 DEG C, any auxiliary material is not added in the preparation process, and rhodiola rosea micro powder is an unique constituent of the tablet. The purpose of direct tabletting and forming can be achieved by controlling moisture and the temperature or by adopting a circular tabletting process or a dry granulating and tabletting process. The process enables the tablet to be good in appearance and enables the pitted surface rate and the breakage rate to be low, the hardness, the disintegration degree and the breakage degree of the tablet meet the requirement for tablet quality, and the hardness can further ensure the tablet not to fragment in the coating and film covering treatment process of the tablet.

Owner:曹静

Potassium tripolyphosphate preparation method

ActiveCN1799997ASolve the difficulty of mixing and dischargingPrevent stickingPhosphorus compoundsPhosphoric acidChemistry

The invention discloses a making method of potassium tripolyphosphate, which comprises the following steps: proceeding one-step potassium tripolyphosphate synthetic process through high temperature of peroxyphosphoric acid and anhydrous potassium carbonate; producing the needed potassium tripolyphosphate through mixing, neutralizing, drying, grinding, sintering and disintegrating by twin-screw plodder. The invention simplifies the flow path and saves the equipment investment, which improves the conversion rate and quality.

Owner:YUNNAN CHEM RES INST

Machine for sticking ceramic tiles on wall face

The invention provides a machine for sticking ceramic tiles on a wall face and belongs to the field of building devices. The machine consists of a fixing device and a coating device. Four wheels of the machine can rotate in all directions so that the machine can be applied to most occasions, a supporting plate can be retracted to drive a first baffle and a second baffle to move along horizontal sliding grooves, the size of ceramic tiles can be perfectly matched, and gaps of multiple ceramic tiles clamped between the first baffle and the second baffle are small so that the accuracy of the ceramic tiles can be ensured. An adhesive applying machine is fixed to a fixed slide block and can vertically side along a vertical sliding groove, the inner surfaces of the ceramic tiles can be uniformlycoated with an adhesive under the condition that the ceramic tiles are fixed, the ceramic tiles can also be lifted in time, and the ceramic tile laying process is not delayed. A telescopic shaft can telescope to push the ceramic tiles to the surface of a wall, the surface of the telescopic shaft can be vibrated to make the ceramic tiles coated with the adhesive more uniformly, and a fixed shaft can vertically move along a first vertical sliding groove so that multiple ceramic tiles can be laid at a time, and the working efficiency can be improved.

Owner:徐富国

Guard device for port mole

The invention discloses a guard device for a port mole. The guide device comprises a mole main body, wherein a square groove is formed in the side, close to the sea water, of the mole, a plurality ofsliding columns are fixed in the square groove, a lifting plate is connected to the sliding columns in a sliding manner, sliding holes are formed in the lifting plate, the sliding columns penetrate through the sliding holes, the sliding columns are in sliding connection with the lifting plate through the sliding holes, the side, far away from the mole main body, of the lifting plate is movably connected with a first filtering plate, the top of the first filtering plate is movably connected with the side, far away from the mole main body, of the lifting plate, a connector is fixedly arranged between the side, close to the mole main body, of the first filtering plate and the top of the lifting plate, the two ends of the connector are separately fixedly connected with the first filtering plate and the lifting plate, and the two sides of the first filtering plate are both fixedly provided with connecting blocks. The guard device for the port mole can filter off foreign matters and preventthe foreign matters from being brought to the road surface of a port by waves.

Owner:CHINA MARITIME POLICE ACADEMY

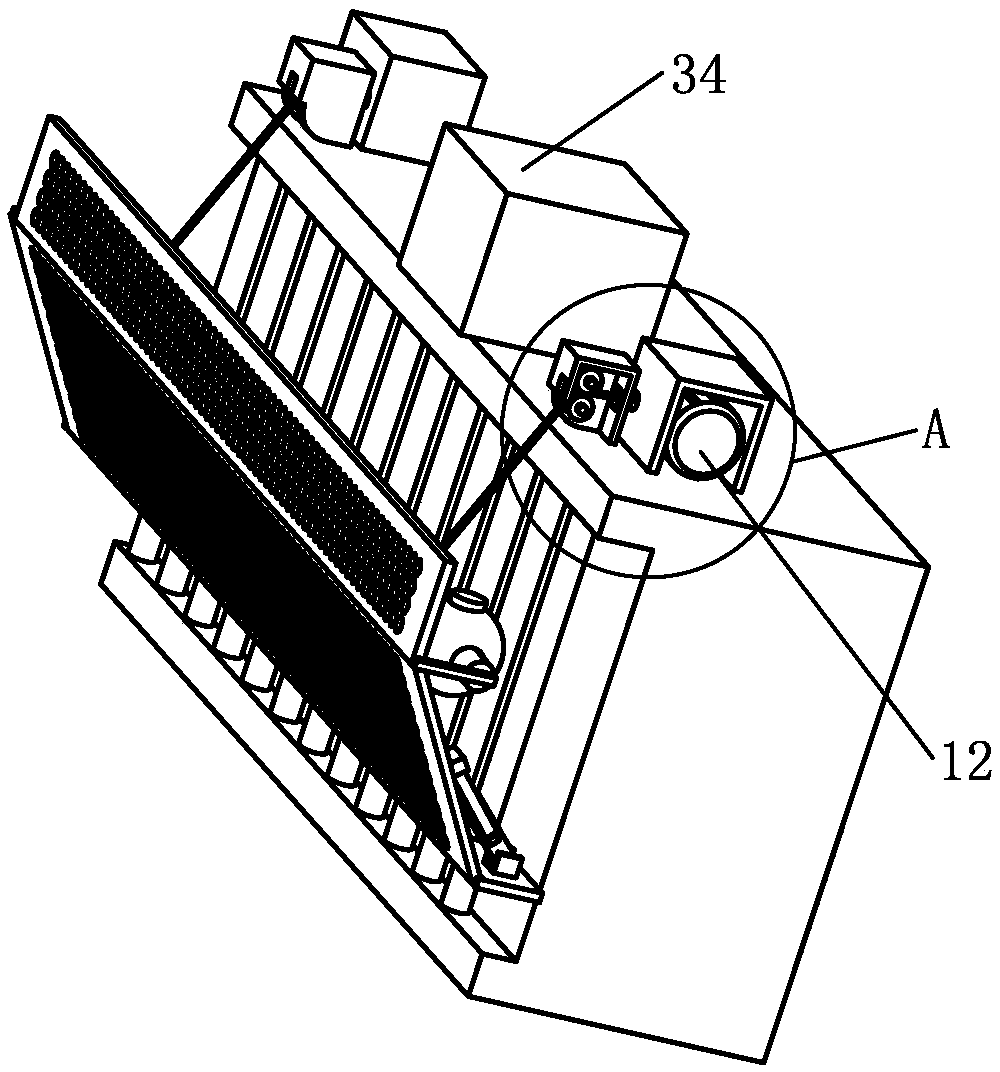

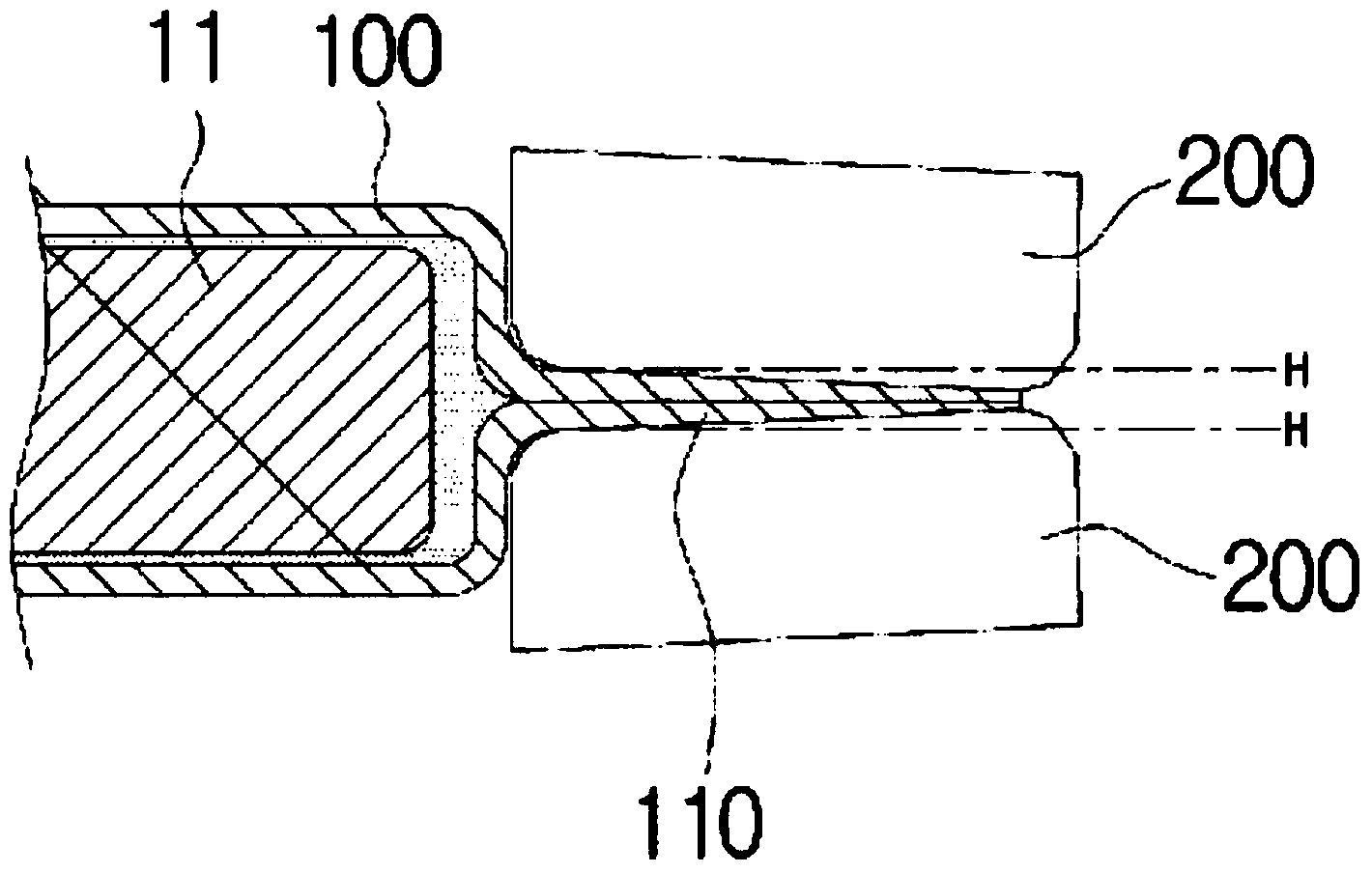

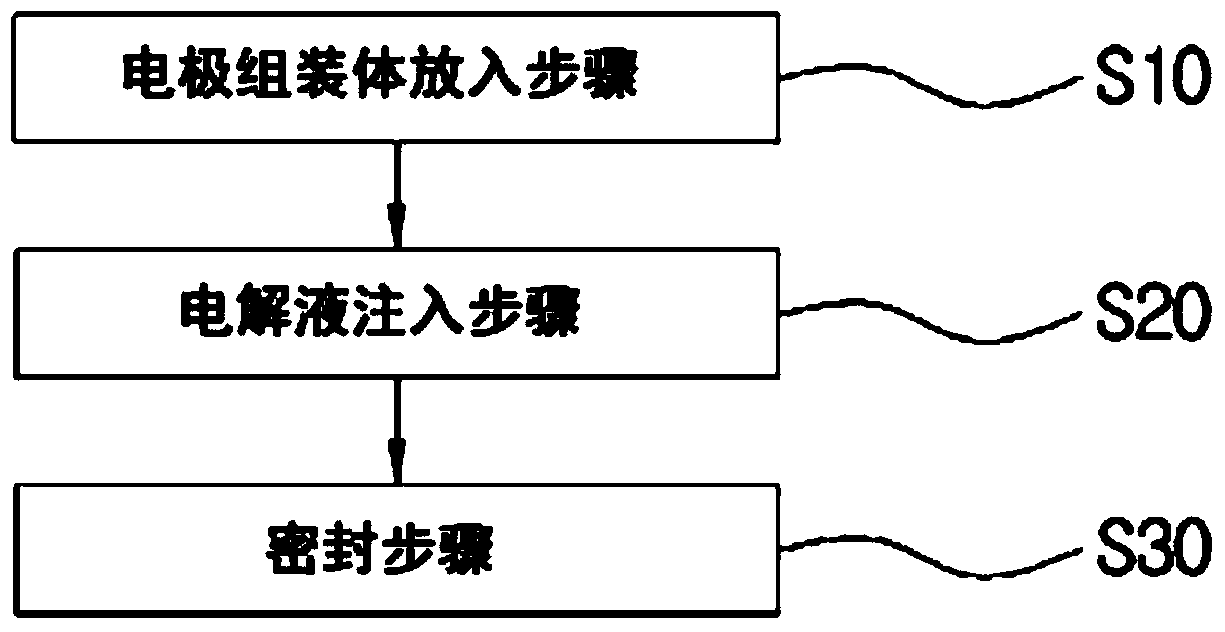

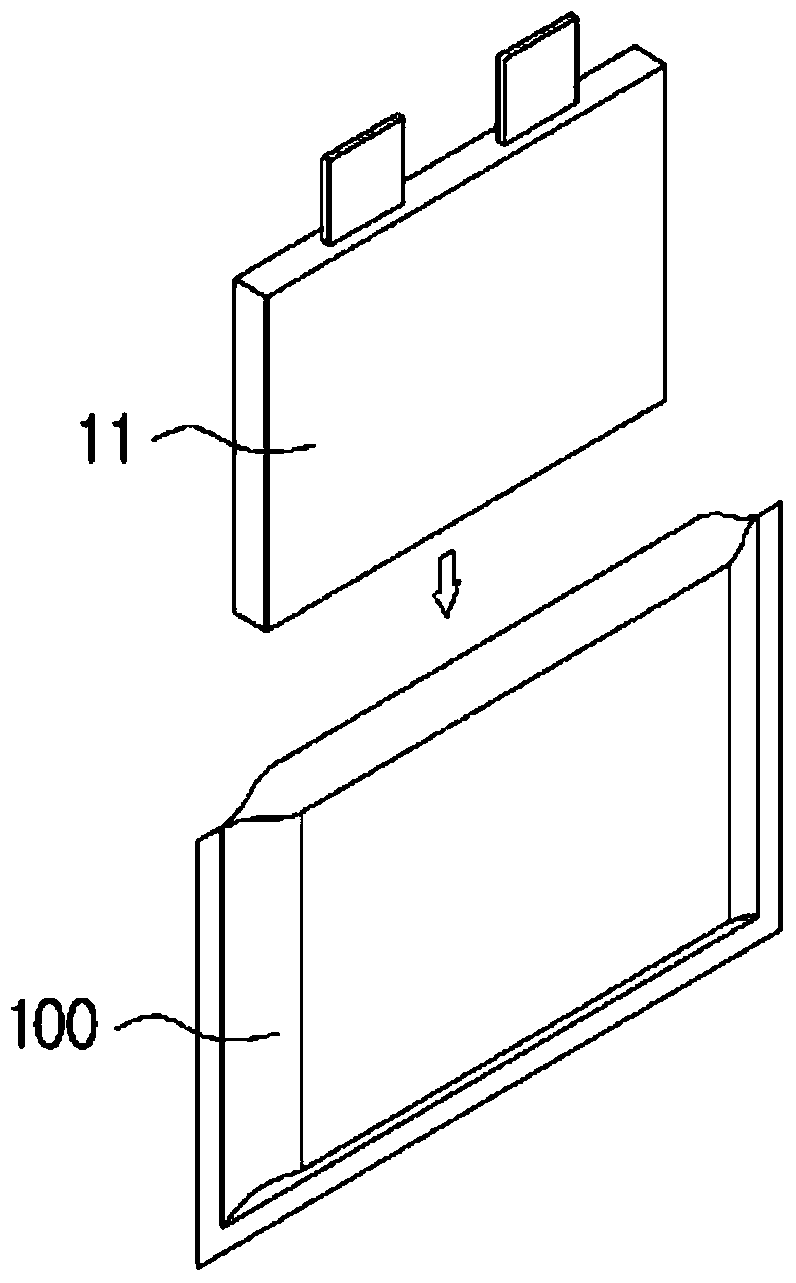

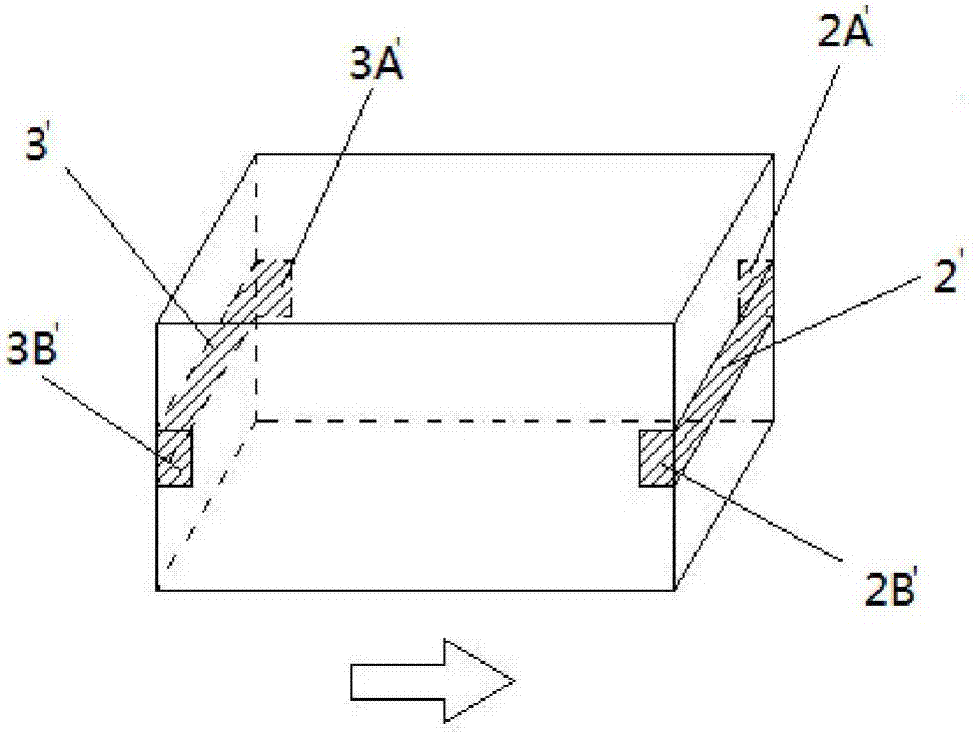

Pouch-type battery, and apparatus and method for sealing pouch-type battery

InactiveCN104067403APrevents the phenomenon of being squeezed into the inside of the bagAvoid interferenceAssembling battery machinesFinal product manufacturePolypropyleneMechanical engineering

Owner:SK INNOVATION CO LTD

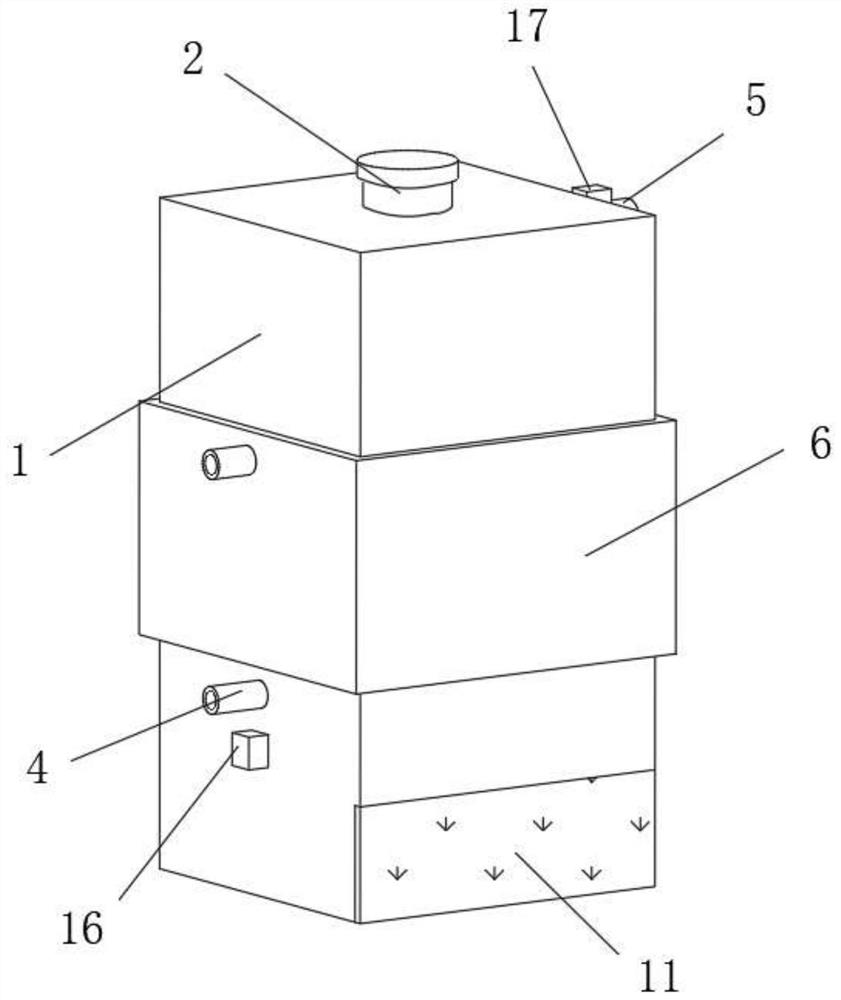

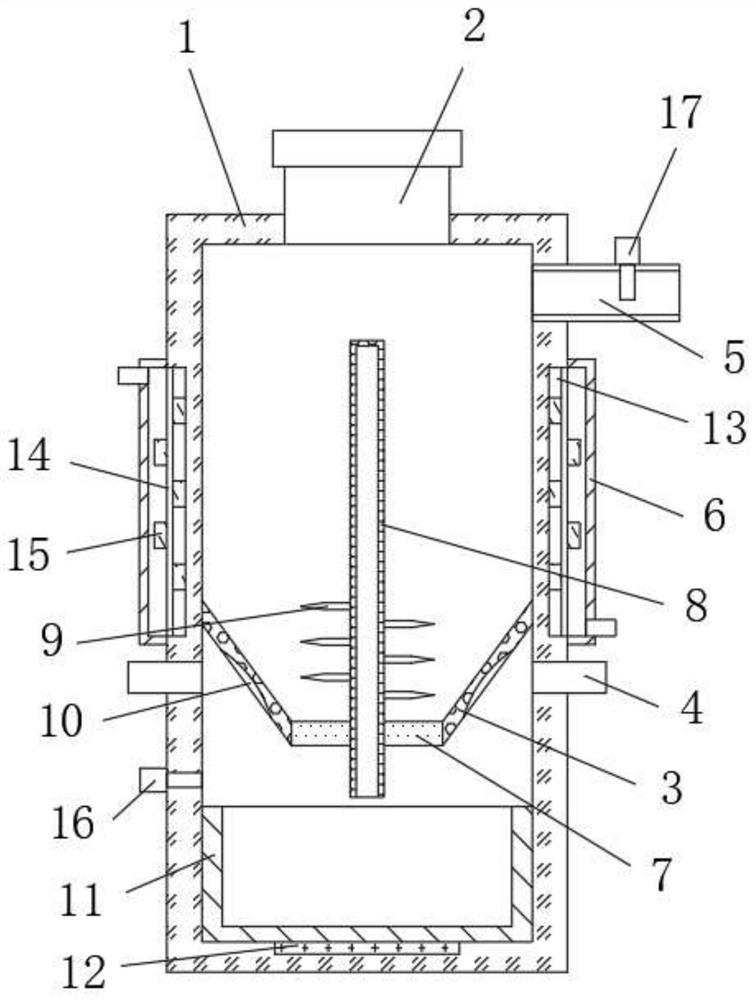

Dry distillation device for oil shale processing

InactiveCN111676041AIncreased air flow and heating effectPrevent stickingDirect heating destructive distillationSpecial form destructive distillationMining engineeringGeotechnical engineering

The invention belongs to the technical field of oil shale processing. The invention particularly relates to a dry distillation device for oil shale processing. The problem that in the prior art, the dry distillation effect on oil shale is poor is solved. The following scheme is proposed: the device comprises a dry distillation kettle, wherein a feeding pipe is arranged at the top of the dry distillation kettle; filter screen plates are arranged at the bottom in the dry distillation kettle; air inlet pipes and an air outlet pipe are respectively arranged at parts, below and above the filter screen plate, of the dry distillation kettle; a water bath shell wraps a part, located at the tops of the filter screen plates, of the outer wall of the dry distillation kettle, the inner wall of the drydistillation kettle is of a square structure, the inclined filter screen plates are fixed to the bottoms of the inner walls of the two sides of the dry distillation kettle, the filter screen plates incline downwards towards the side away from the inner wall of the dry distillation kettle, and a vibrating screen is connected to the bottom end between the two filter screen plates through torsionalsprings. The air inlet pipes are arranged on the two sides of a bearing surface, crushed solid components on the bearing surface are screened out from the middle position through a vibrating screen, and the situation that air circulation is affected due to the fact that meshes of the whole bearing surface are blocked is avoided.

Owner:烟台暄炜智能科技有限公司

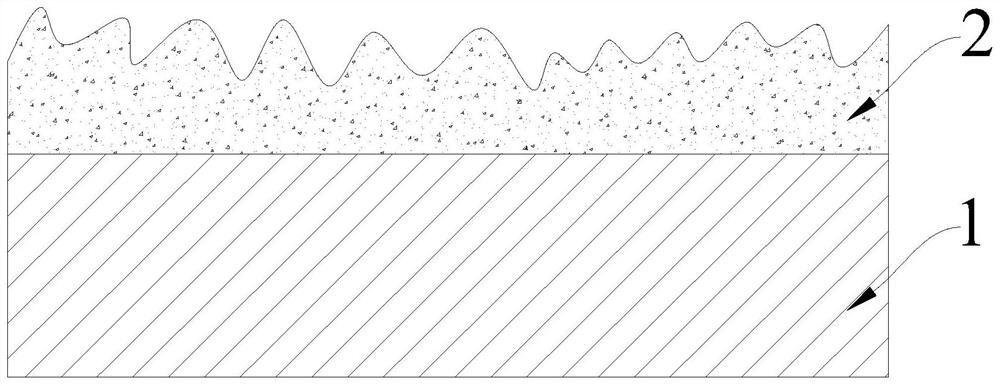

Non-stick utensil

PendingCN112137418AHigh hardnessImprove wear resistanceCooking-vessel materialsCooking processComposite material

The invention provides a non-stick utensil which comprises a utensil base body and a non-stick layer, the inner surface of the utensil base body is covered with the non-stick layer, and the non-sticklayer is of a film-shaped structure formed by a mixture of a titanium-containing material and a non-stick material. According to the non-stick utensil, the non-stick utensil with non-stick performancecan be provided, and the pot sticking phenomenon in the cooking process is prevented.

Owner:WUHAN SUPOR COOKWARE

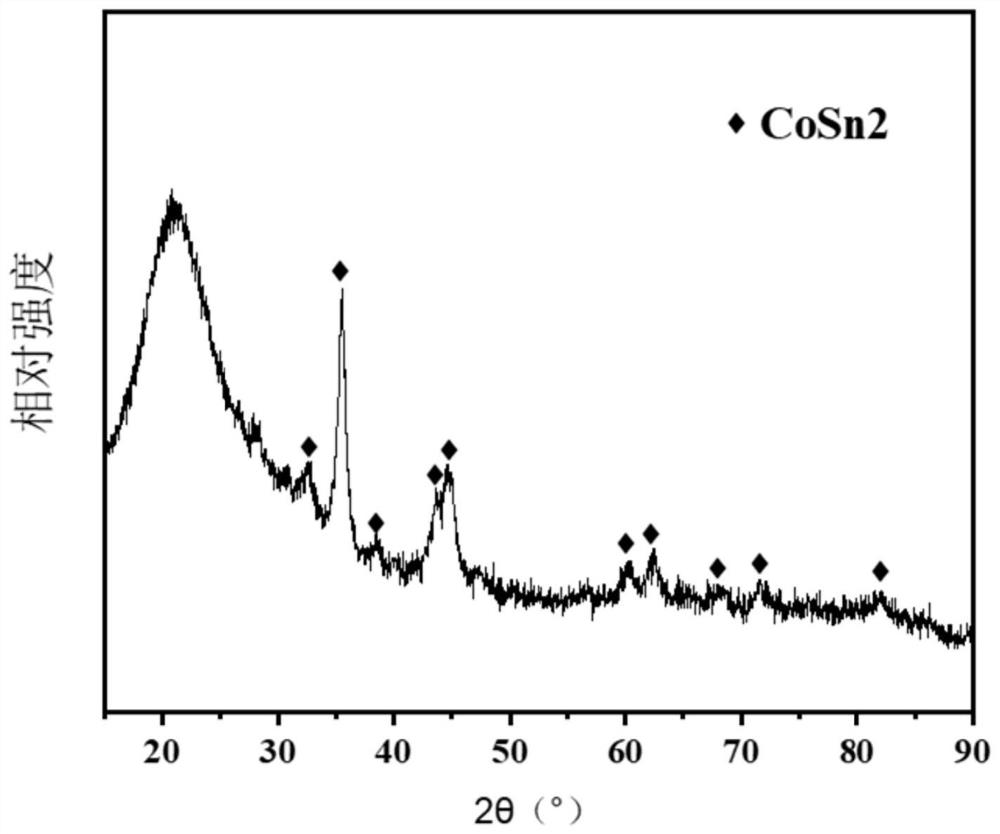

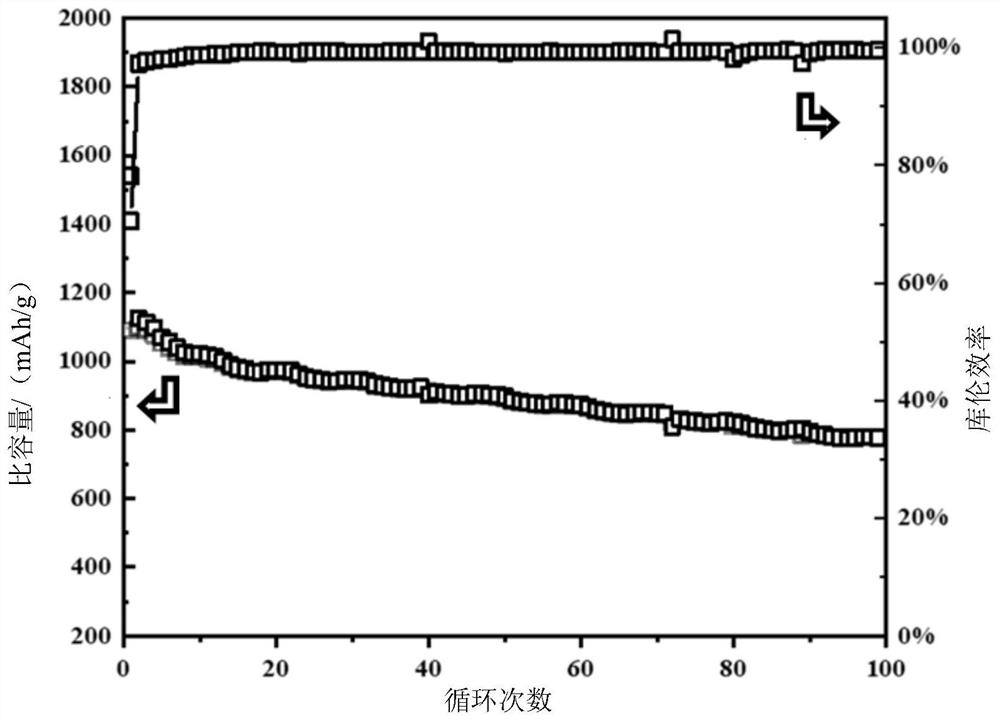

Silicon monoxide-based negative electrode material with high reversible capacity, preparation and application thereof

ActiveCN112635730AIncreased diffusion rateReduce adverse effectsMaterial nanotechnologyCell electrodesSilicon monoxideElectrical battery

The invention belongs to the technical field of lithium ion batteries, and discloses a silicon monoxide-based negative electrode material with high reversible capacity, preparation and application thereof. The silicon monoxide-based negative electrode material is mainly prepared from raw materials in a ball milling manner. When the raw materials are silicon monoxide, tin powder and cobalt powder, the silicon monoxide accounts for 30-70% of the total mass of the raw materials, the Sn powder accounts for 10-50% of the total mass of the raw materials, and the Co powder accounts for 5-25% of the total mass of the raw materials; when the raw materials are silicon monoxide, tin powder, cobalt powder and a carbon material, the silicon monoxide accounts for 40-70% of the total mass of the raw materials, the tin powder accounts for 10%-30% of the total mass of the raw materials, the cobalt powder accounts for 5%-15% of the total mass of the raw materials, and the carbon material accounts for 5-30% of the total mass of the raw materials. The invention also discloses a preparation method of the silicon monoxide-based negative electrode material. The negative electrode material disclosed by the invention has high reversible capacity, relatively good initial coulombic efficiency and excellent cycling stability. The negative electrode material is used for preparing a lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

Optical product grinding fluid

InactiveCN102286307AGuaranteed service lifePrevent stickingLubricant compositionEngineeringGrinding wheel

The invention discloses a grinding fluid for optical products. The invention has excellent cooling performance, ensures machining accuracy and tool life; has good cleaning performance, and effectively prevents grinding wheel sticking and blocking; has no unpleasant gas, and has good workability. Low pH value, no adverse effects on the skin.

Owner:陆兴艳

Adhesive tape cutting device

The invention provides an adhesive tape cutting device. The adhesive tape cutting device comprises an adhesive tape cover board, an adhesive tape fixing ring, an adhesive tape idler wheel, an adhesive tape sawtooth blade and an adhesive tape cover board rotary shaft. An adhesive tape protective rod is arranged above the adhesive tape cover board. The adhesive tape cover board rotary shaft is arranged on the left side of the adhesive tape fixing ring. The adhesive tape idler wheel is arranged below the adhesive tape cover board rotary shaft. An adhesive tape driven wheel is arranged below an adhesive tape driving wheel. The adhesive tape sawtooth blade is arranged on the left side of the adhesive tape cover board rotary shaft and fixed to the head of the adhesive tape cutting device through a nut. Compared with the prior art, the adhesive tape cutting device has the advantages that when the adhesive tape cutting device is used, the protective rod on the adhesive tape cover board prevents adhesive tape from sliding down in the use process, the adhesive tape driven wheel is arranged on the head of the adhesive tape cutting device, when sliding down from the adhesive tape driving wheel, the adhesive tape is bonded to the adhesive tape driven wheel, the situation that adhesive heads are bonded is avoided, the adhesive tape sawtooth blade at the head of the adhesive tape cutting device is arranged to be of a round edge structure, and the adhesive tape cutting device is simple in structure and high in practicability.

Owner:SHENZHEN YIHAOGUI TECH CO LTD

Self-circulation filtering method in solid waste pyrolysis incineration

InactiveCN111054160AAvoid enteringSolve the blockageDispersed particle filtrationIncinerator apparatusOil sludgeSlurry

The invention discloses a self-circulation filtering method in solid waste pyrolysis incineration. The method comprises the following steps: crushing incinerated residues, circularly taking the crushed residues as a filtering layer of an incineration unit, and paving the residues at the bottom of the incineration unit. The filtering method reduces dusts in the incineration process, solves the problem of hardening of the residues in the incineration process, further improves the stability and reliability of the process system, and is suitable for pyrolysis incineration disposal of solid wastessuch as waste incineration fly ash, chemical waste salts, organic silicon slurry residues, oil sludge, domestic sludge, chemical sludge, printing and dyeing sludge, rectification residues, leather sludge, electroplating sludge and chromium residues.

Owner:重庆锦生悦智能装备有限公司

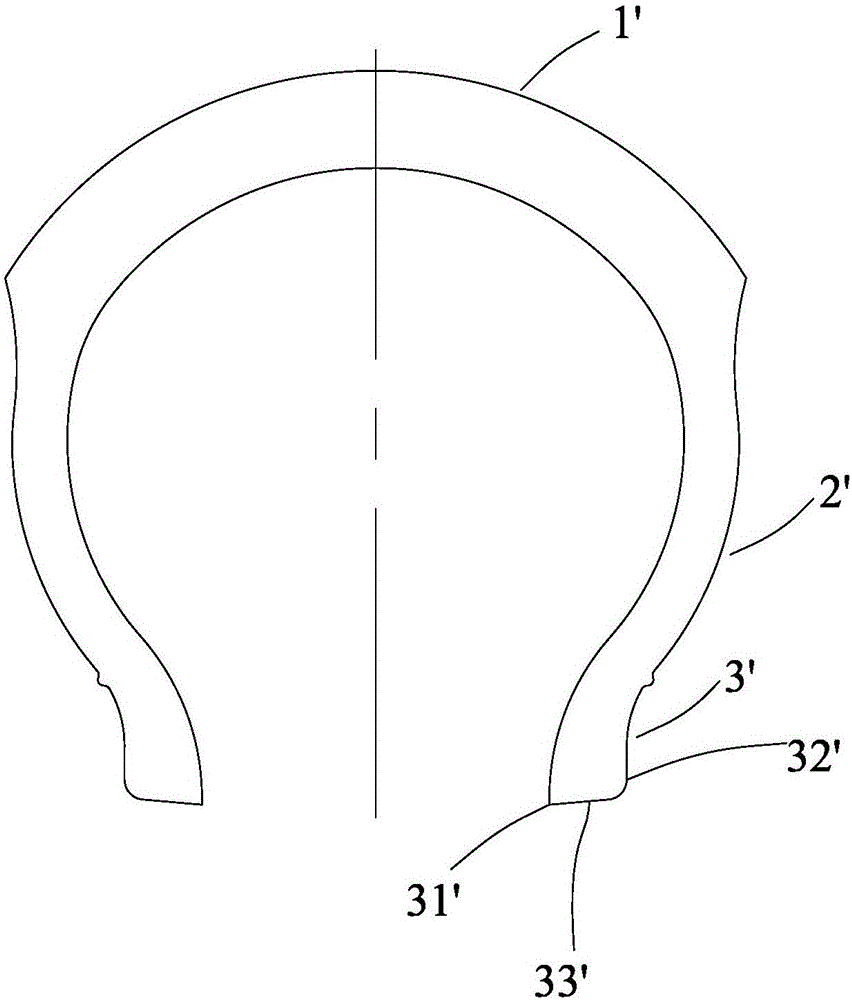

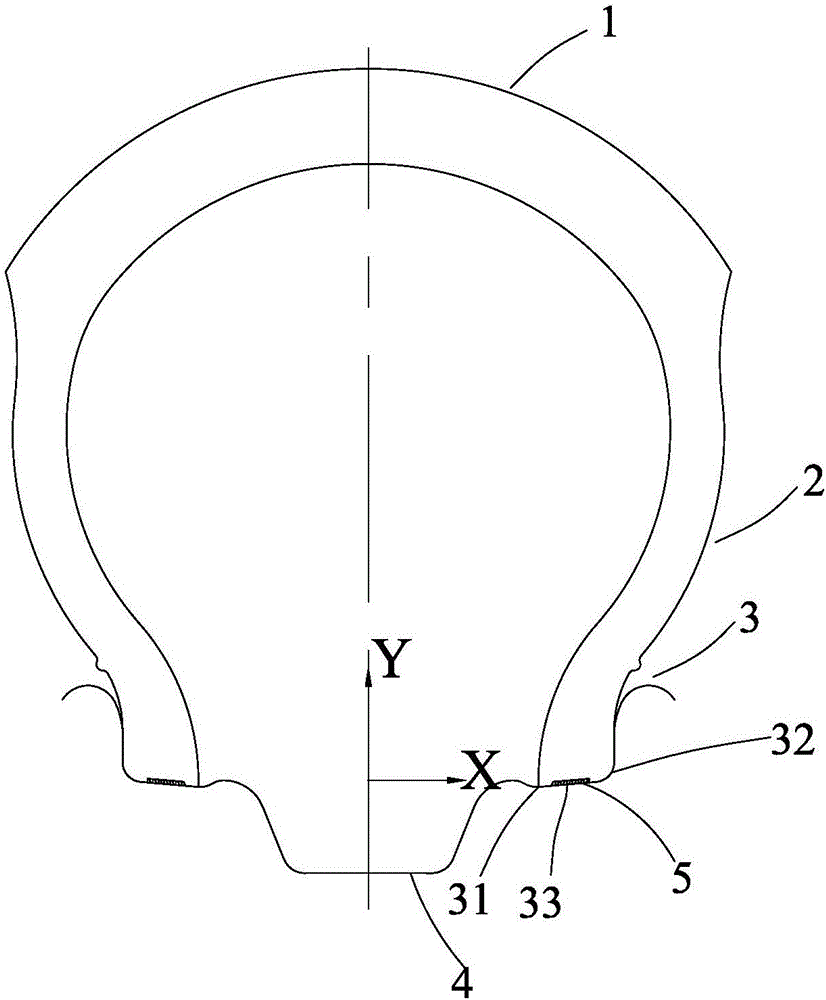

Tire bead structure

The invention discloses a tire bead structure. A tire comprises a tire tread portion, two tire side portions and two tire bead portions; the tire bead outer edge portion, matched with a rim tire ring base, of each tire bead portion comprises a tire bead toe portion, a tire bead heel portion and a tire bead bottom portion; at least two concave-convex portions are distributed on the whole circumference of each tire bead bottom portion at an equal interval; and each concave-convex portion is formed in the manner that a plurality of convex portions and concave portions are arranged at intervals in the axial direction. The tire bead structure can guarantee the rigidity of the tire bead portions and guarantee that the friction force between the rim tire ring bases is large enough, and the holding performance of the tire bead bottom portions is improved; and when the tire and a rim run under high load and high speed, the slippage and bead disengagement phenomena of the tire bead portions and the rim tire ring bases can be avoided.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

Method for separation production of rare earth ferrosilicon alloy with rotary hearth furnace

ActiveCN106834587AReduce smelting intensityIncrease costTransportation and packagingRotary drum furnacesFerrosiliconRare earth

The invention relates to a method for separation production of rare earth ferrosilicon alloy with a rotary hearth furnace. The method includes the steps of 1), raw material treatment; 2), material distribution for the rotary hearth furnace; 3), reduction of melting points for the rotary hearth furnace; 4), secondary briquetting; 5), rear earth ferrosilicon melting and the like. By the arrangement of the specific steps and movement of the steps, overall efficiency in producing the rear earth ferrosilicon alloy by the aid of iron-containing rare earth ores is improved, and production cost is greatly reduced.

Owner:北京安康科创节能环保科技有限公司 +1

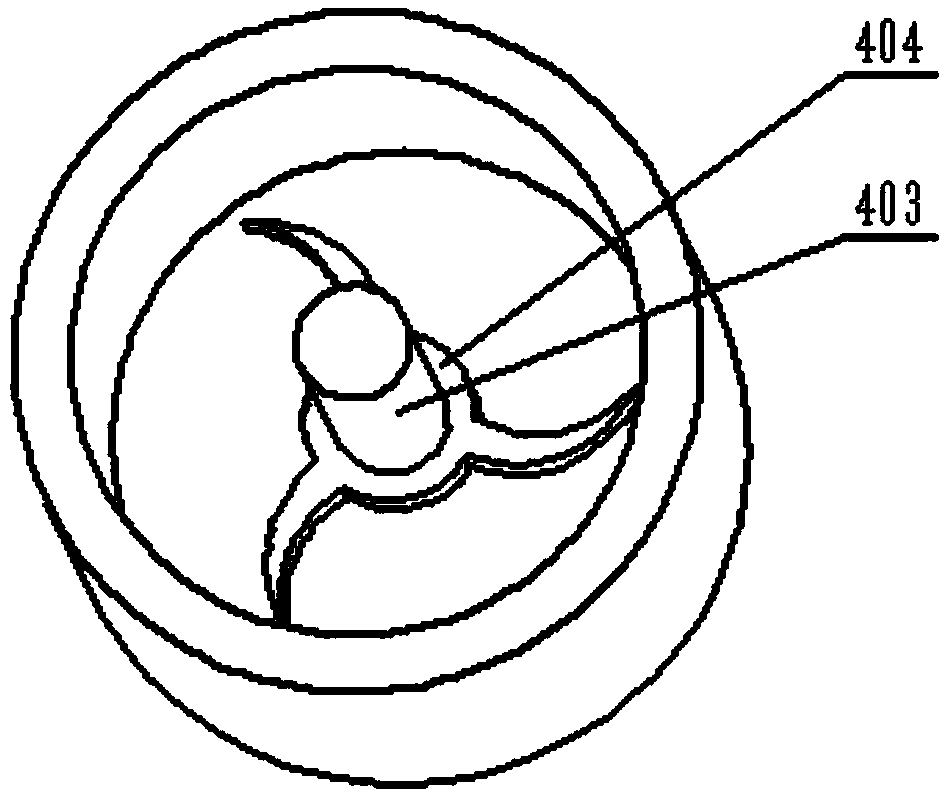

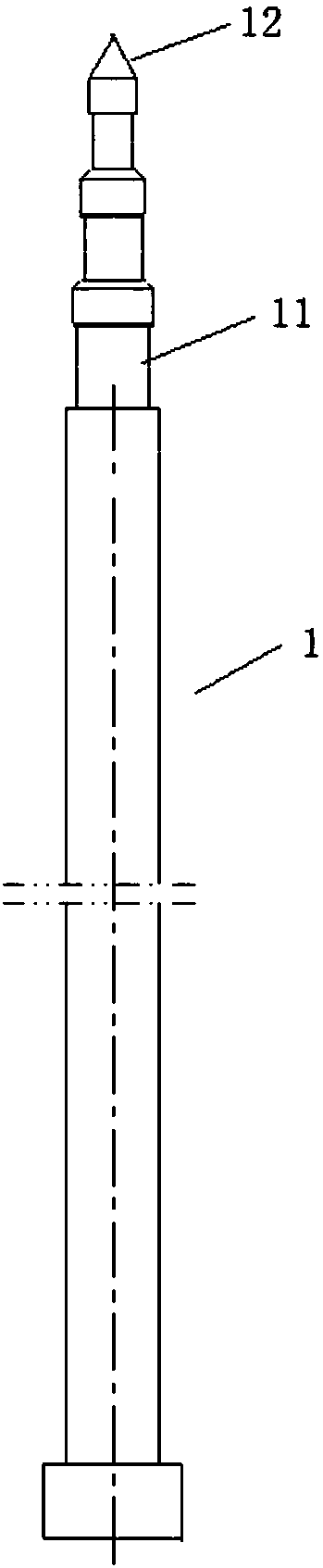

Sprue puller and reflecting mirror mold

The invention discloses a sprue puller and a reflecting mirror mold and belongs to the field of BMC (Bulk Molding Compound) injection molds. The sprue puller is characterized in that a material pulling head at the top end part of the sprue puller is in a pagoda shape with a plurality of layers; each layer consists of stepped columns formed by connecting two cylinders with large upper parts and small lower parts; the top end of the material pulling head is a conical spire. The sprue puller is arranged in the reflecting mirror mold; the bottom end of the sprue puller is movably arranged on the movable mold side; the top end part of the sprue puller penetrates through the movable mold side and extends into the fixed mold side. According to the sprue puller and the reflecting mirror mold disclosed by the invention, a product is pulled at the movable mold side by the material pulling head in the pagoda shape at the top end part of the sprue puller during mold opening, so that sticking of afixed mold is prevented; finally, the product is demolded by ejection of the movable mold.

Owner:HASCO VISION TECHNOLOGY CO LTD

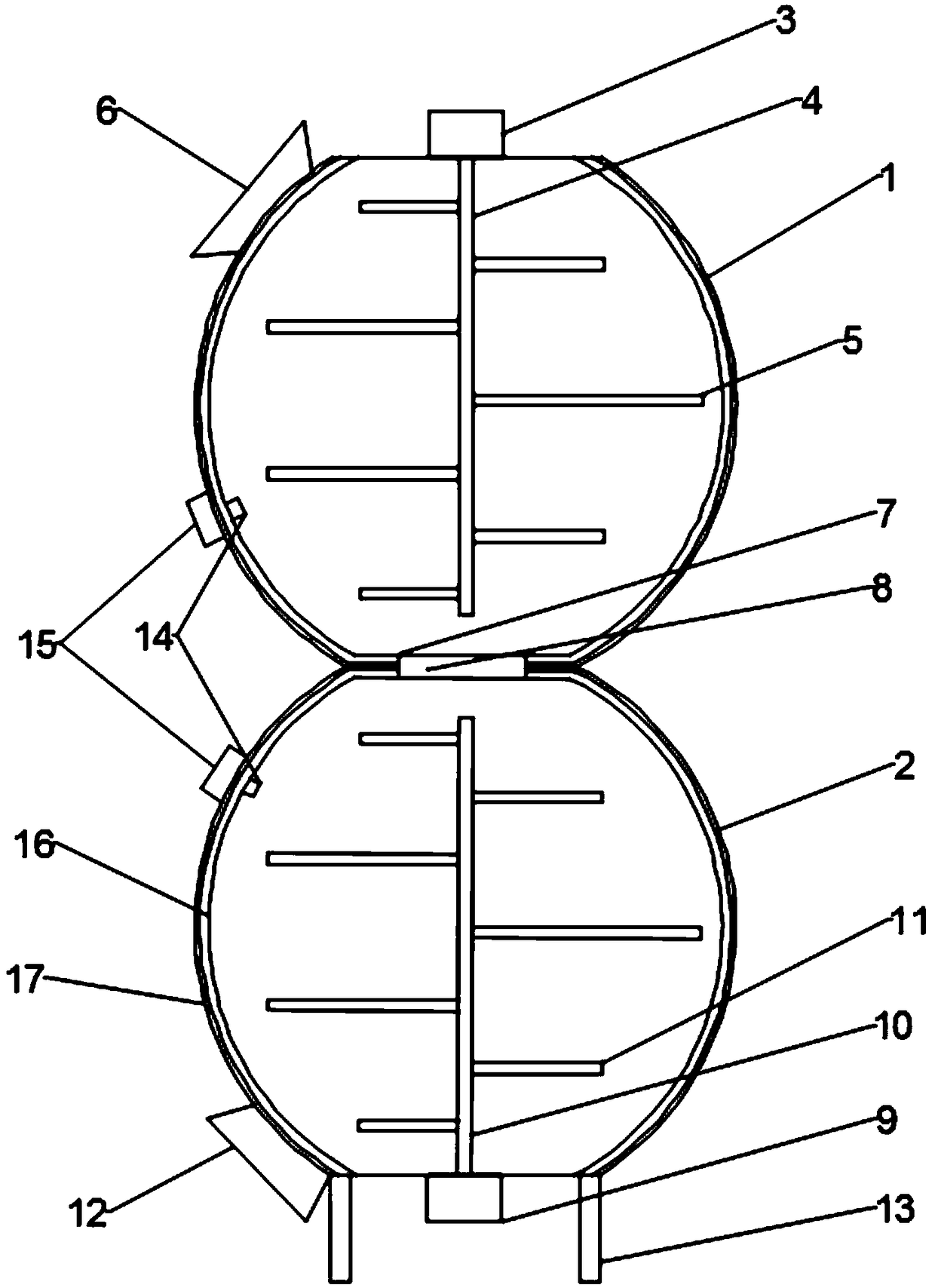

Organic fertilizer fermenting device

InactiveCN109206173APrevent stickingHelp the whereaboutsOrganic fertiliser preparationAgricultural engineeringContinuous production

The invention relates to a fertilizer fermentation device, in particular an organic fertilizer fermentation device. The organic fertilizer fermentation device comprises a fermentation tank I and a fermentation tank II. The top of the fermentation tank I is provided with a motor. A stirring shaft that is connected to the motor stretches into the fermentation tank I. Multiple stirring paddles are uniformly arranged on the section, which is in the fermentation tank I, of the stirring shaft at intervals from top to bottom. The lower end of the stirring shaft is close to the bottom wall of the fermentation tank I. The lateral wall of the fermentation tank I is provided with a feed hopper for filling fermentation raw materials into the fermentation tank I. The middle of the bottom wall of the fermentation tank I is provided with a material outlet, which is provided with a discharge door that can be closed or opened; and the material outlet is communicated with the fermentation tank II. The vertically arranged fermentation tanks that are communicated with each other can satisfy different fermentation conditions of mixed bacterium fermentation to carry out continuous production; and due tothe rhombus structure, the fermented fertilizer can conveniently fall down or will not be stuck on the wall.

Owner:樊争梅

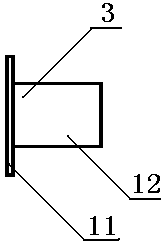

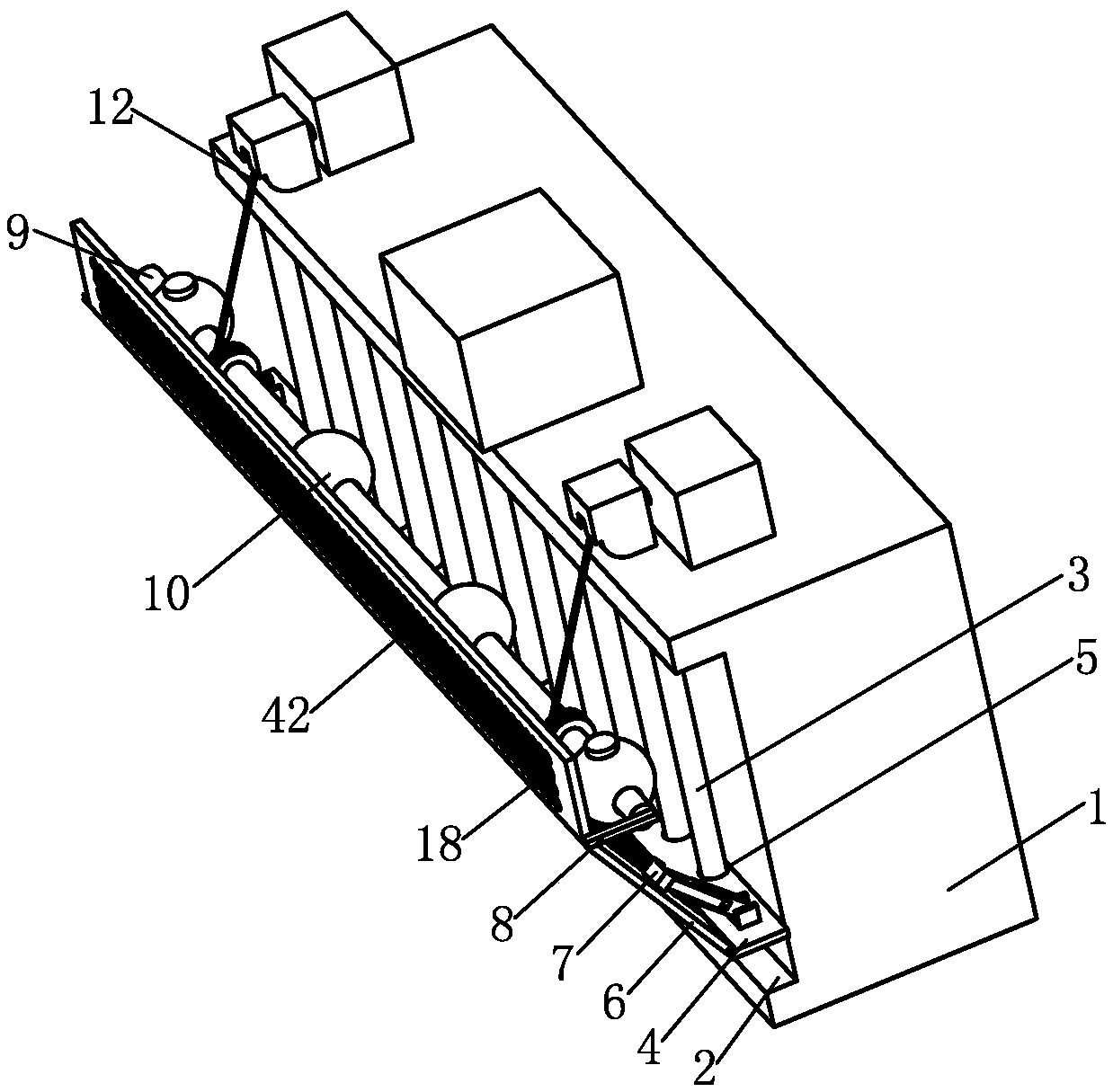

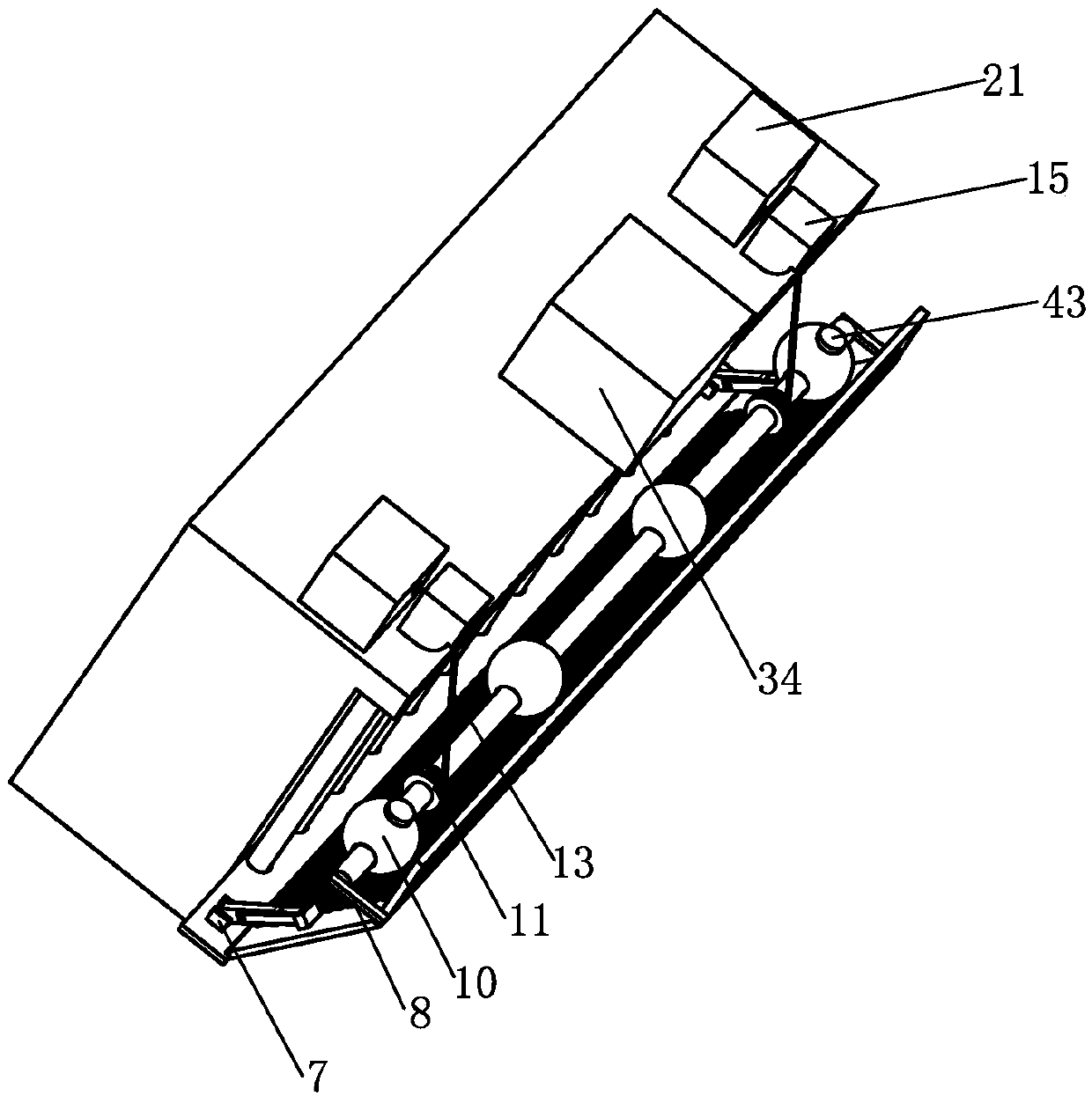

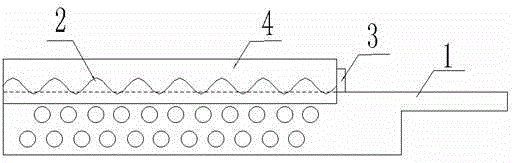

Cutting device for material cut-off

InactiveCN106671147APrevent stickingReduce frictionPharmaceutical product form changeMetal working apparatusProduction lineTemperature control

The invention discloses a cutting device for material cut-off. The cutting device for material cut-off is composed of a tool main body (1) and a heating device, wherein the heating device consists of an electric heating wire (2), a temperature control switch (3) and a housing (4). A plurality of hollow holes are distributed in the tool surface of the tool body (1). The cutting device can effectively prevent occurrence of a tool pasting condition. The tool holes are formed in the tool body, so that friction force during cutting can be effectively reduced. The cutting device is simple and reasonable in structure, ensures production line to be smoother, is low in manufacturing cost, and is suitable for being popularized on a large scale.

Owner:RUGAO FUGANG MACHINERY PARTS CO LTD

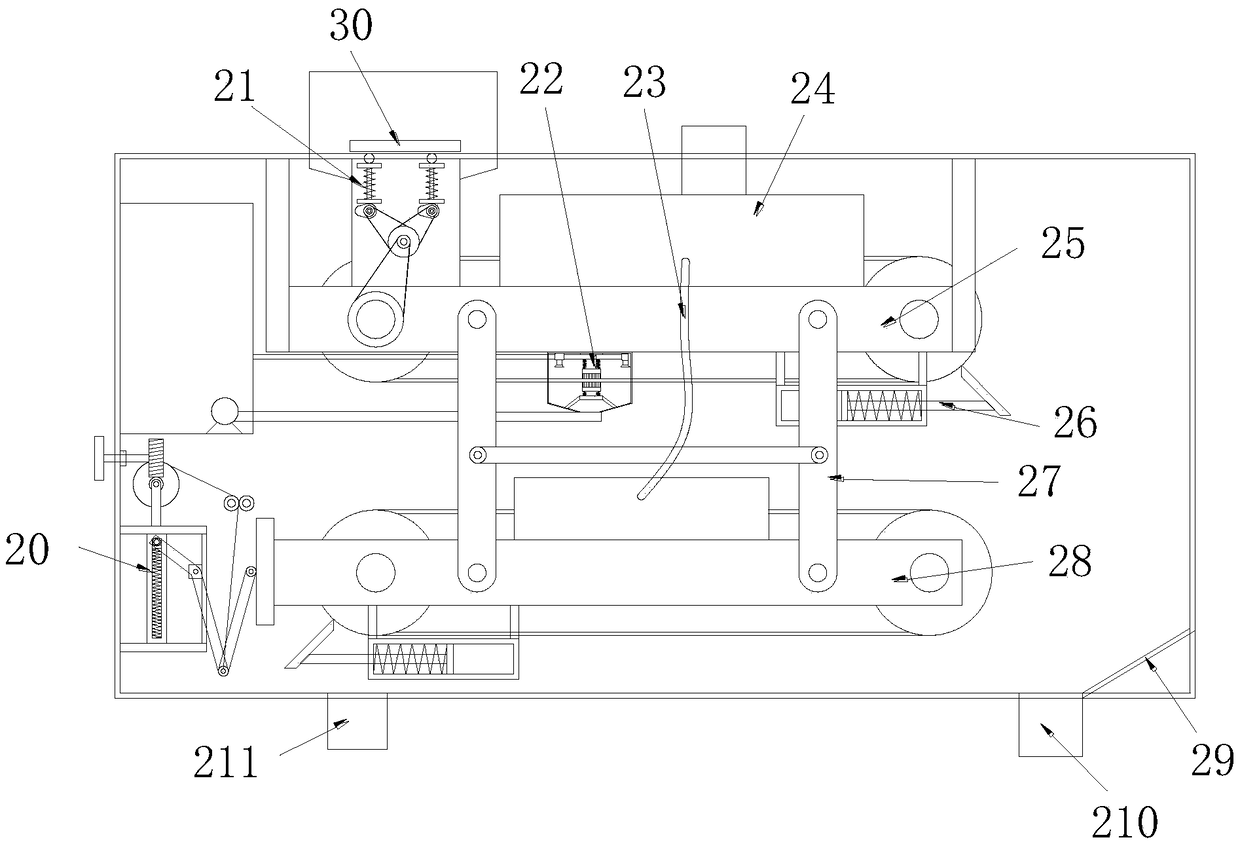

High-humidity efficient pulverizer

PendingCN111420755APrevent stickingIncrease crushing outputGrain treatmentsElectric machineryPulverizer

The invention discloses a high-humidity efficient pulverizer which comprises a shell, a filing plate, a motor, a main shaft, hammer pieces, a support and a column body. A feeding port and a discharging port are formed in the shell, the main shaft is movably installed in the shell, the motor is in transmission connection with the main shaft, the support is fixedly installed on the main shaft, the column body is fixedly installed on the support, the hammer pieces are movably arranged on the column body in a sleeving mode, the hammer pieces are sheet blades, and the filing plate is fixedly installed on the inner side wall of the shell. The high-humidity efficient pulverizer has the advantages that the long-term puzzling problem about crushing of high-humidity materials with the water contentlarger than 45% in the industry is solved, and compared with a traditional wet material crusher, the high-humidity material crusher has the advantage that the power consumption is obviously reduced.

Owner:中科美大(宜昌)环保科技有限公司

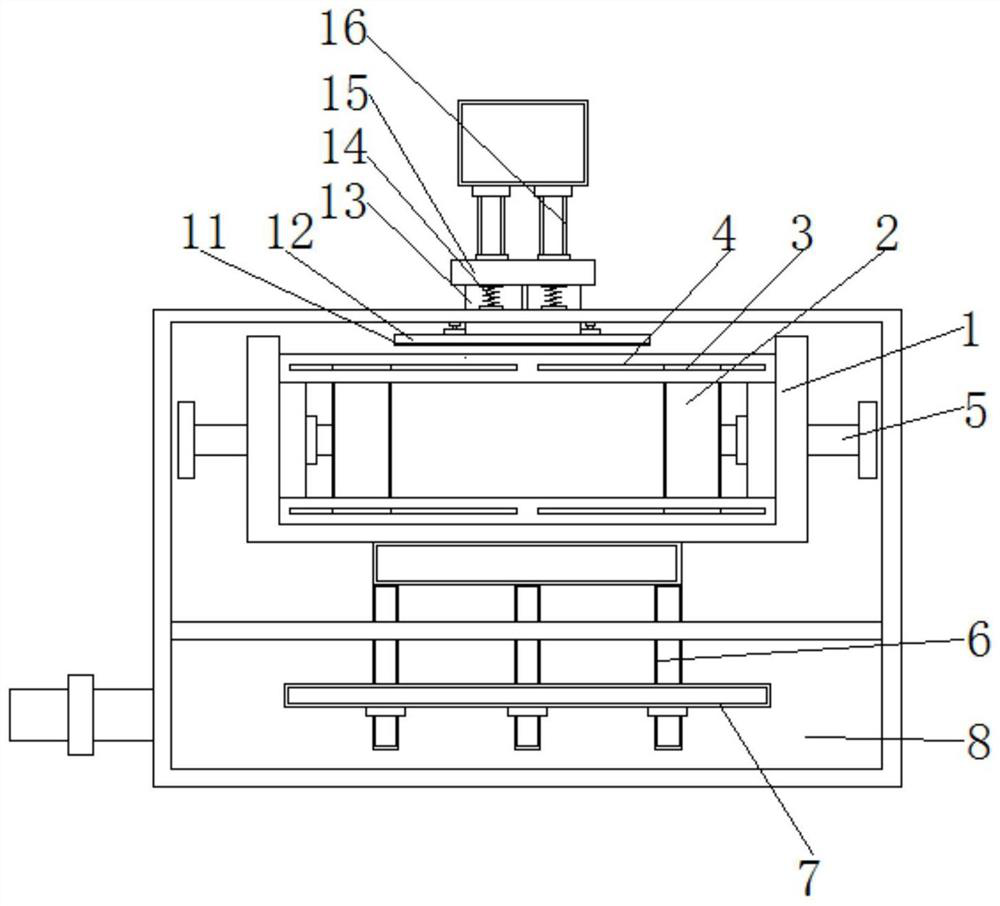

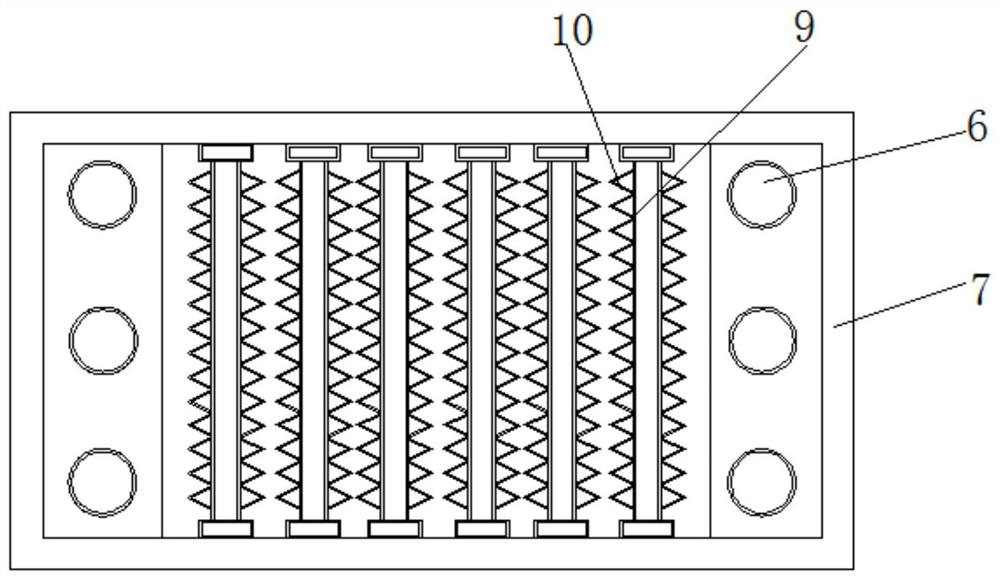

Safety reaction kettle capable of preventing sticking and grinding and fully mixing

InactiveCN112844289AWell mixedWon't stickTransportation and packagingMixer accessoriesBLENDER/MIXERStructural engineering

The invention relates to the technical field of chemical equipment, and discloses a safe reaction kettle capable of preventing sticking and grinding and fully mixing. The safe reaction kettle comprises an upper shell, a lower shell, a feeding pipe, a shaking mechanism, a stirring mechanism, a mixing filter screen and a discharging pipe, wherein the feeding pipe is arranged at the top of the upper shell, and the inner side of the top of the upper shell is fixedly connected with a pull rod; the mixing filter screen is arranged below the pull rod, the shaking mechanism is arranged on the lower side of the mixing filter screen, the edge of an opening of the upper shell is provided with an upper buckling edge, the edge of an opening of the lower shell is provided with a lower buckling edge, the upper buckling edge is provided with a buckling groove, and the lower buckling edge is provided with a buckling block matched with the buckling groove. The outer side of the edge of the lower buckling edge is fixedly connected with at least three stand columns, and the upper buckling edge can rotate in the stand columns. The stirring mechanism is arranged at the center of the bottom of the lower shell, and the discharging pipe is arranged on the right side of the bottom of the lower shell. According to the invention, the problems that in the prior art, in the material mixing process of a reaction kettle, material residues are likely to be generated, mixing is not uniform enough, sticking and grinding are likely to happen, and the safety coefficient is low are solved.

Owner:ZHEJIANG UNIV OF TECH

Forming device for making candies

InactiveCN112293546AIncrease cooling areaIncrease contact areaConfectionerySweetmeatsMechanical engineeringPhysics

The invention discloses a forming device for making candies, which comprises a template box and a damping rod, an adjusting plate is arranged in the template box, adjusting blocks are fixed to the upper side and the lower side of the adjusting plate, adjusting grooves are connected to the outer surfaces of the adjusting blocks, and a dissipation body is connected to the outer surface of a heat dissipation roller. An anti-sticking pad is arranged above the template box, the inner surface of the anti-sticking pad is connected with a mold plate, a feeding box is arranged at the rear end of the template box, a rotating plate is arranged in the feeding box, the tail end of the rotating plate is connected with a rotating rod, the tail end of the rotating rod is provided with an elastic gasket, and the inner surface of the elastic gasket is connected with a damping groove, and the damping rod is located in the damping groove. According to the forming device for making candies, the damping rodis arranged to provide power for the damping groove to move, the damping rod can be well wrapped by the half-surrounded damping groove, and therefore the damping effect on the damping rod is improved.

Owner:湖南新中意食品有限公司

Finished cigarette box adhesive tape sealing pushing sticking device and method

PendingCN107972927AGuaranteed to stick firmlyAvoid warpingWrapper twisting/gatheringMechanical engineeringEngineering

The invention discloses a finished cigarette box adhesive tape sealing pushing sticking device and method. The pushing sticking device comprises a first pushing portion and a second pushing portion which are arranged on the first side of a cigarette box pushing machine and further comprises a third pushing portion and a fourth pushing portion which are arranged on the second side of the cigarettebox pushing machine. The first pushing portion and the second pushing portion are distributed in the axial direction of the cigarette box conveying machine. The third pushing portion and the fourth pushing portion are distributed in the axial direction of the cigarette box conveying machine. The first pushing portion and the second pushing portion are connected through a first support, the third pushing portion and the fourth pushing portion are connected through a second support, and the first pushing portion, the second pushing portion, the third pushing portion and the fourth pushing portion are used for pushing the bent end of adhesive tape used for sticking a cigarette box opening in the direction from the bent area to the tail area of the adhesive tape. The problem that the two endsof the finished cigarette box adhesive tape are warped or not firmly stuck is avoided.

Owner:王荣华

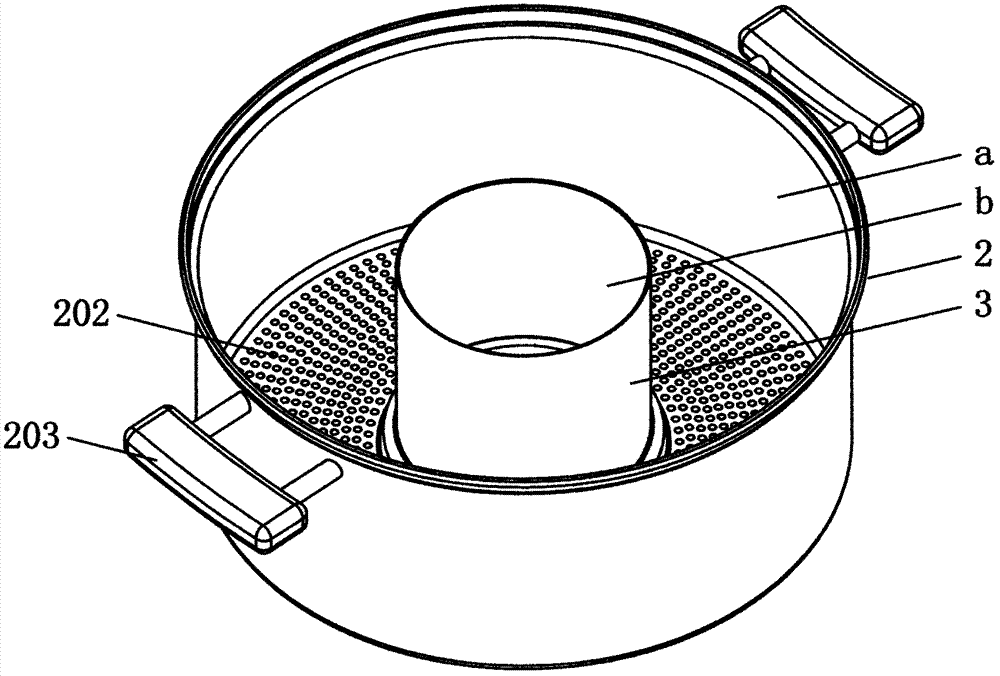

Hot pot without tainting of two odors

InactiveCN107536461AReduce contact areaEasy to assembleMultiple-unit cooking vesselsCooking insertsEngineeringTower

The invention relates to a hot pot without tainting of two odors. The hot pot comprises a pot body and a pot cover. The pot cover is covered on the pot body. An inner cavity of the pot body is detachably provided with an isolation tower. The isolation tower divides the inner cavity of the pot body into an annular cavity and a center cavity which are not communicated with each other. The pot coveropens and closes a top opening of the annular cavity, and covers on the center cavity. Through arranging the isolation tower, the inner cavity of the pot body is divided into the center cavity and theannular cavity which are not communicated, to realize a function of non-tainting of two odors. A user can enjoy two kinds of odors in one pot. The isolation tower is detachably assembled on the pot body through a rib cooperation portion. An annular rid and the rib cooperation portion are cooperated with each other through a conical surface, so as to provide convenience for assembling, and effectively ensure leakproofness. In addition, through arranging a non-stick structure on the bottom of the pot body, contact area of the pot body and food surfaces is reduced, and food is supported, and a phenomenon of sticking on a pot is effectively prevented.

Owner:吴健宏

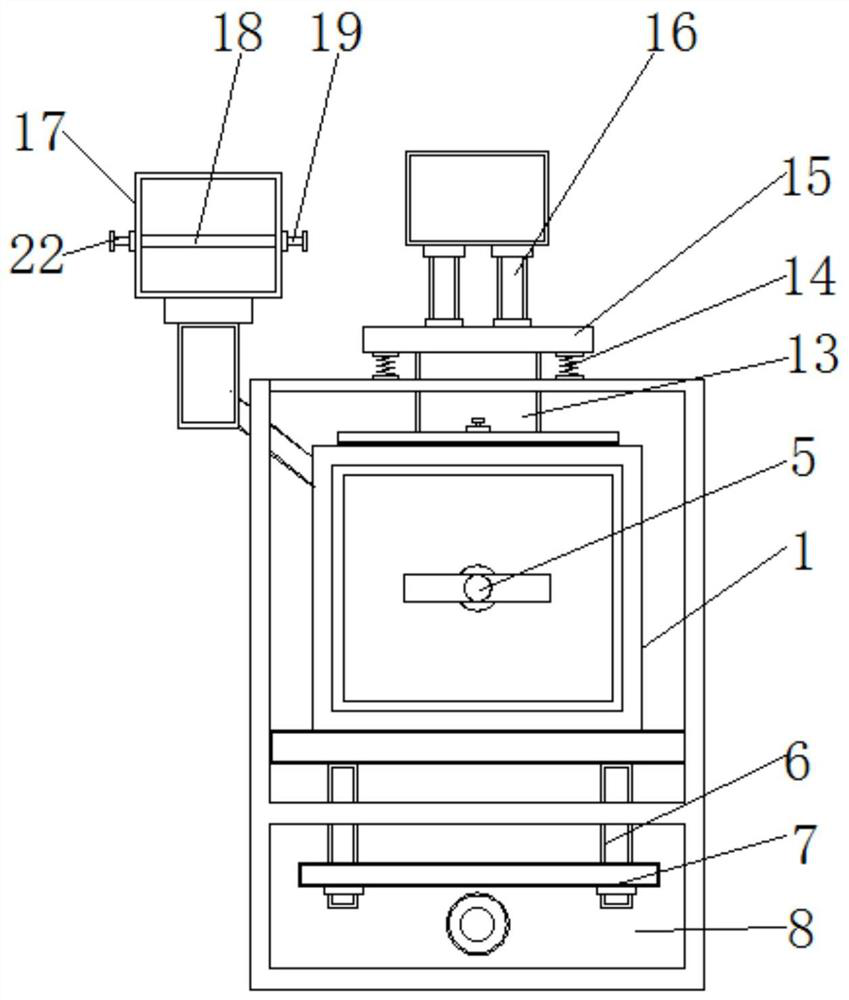

High-viscosity fermentation feed drying device capable of performing real-time monitoring

ActiveCN108917373APrevent stickingImprove work efficiencyCleaningDrying gas arrangementsEngineeringWork productivity

The invention discloses a high-viscosity fermentation feed drying device capable of performing real-time monitoring. The high-viscosity fermentation feed drying device structurally comprises a bottomframe, a box body, a barrel, a hot air blower, a control board, a moisture sensitive sensor, a WiFi module, a fault monitoring component and a touch screen. The high-viscosity fermentation feed dryingdevice can scrap a material, wall sticking is prevented, cleaning is performed automatically, manual cleaning is not needed, the working efficiency is improved, the material is dried, the drying areais large, and the drying efficiency is improved. In addition, the effect of saving energy and intelligent error reporting can be achieved.

Owner:哈尔滨天博饲料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com