Shaking and hitting device preventing wall pasting inside dust collector

A dust collector and shock technology, which is applied in the field of anti-sticking wall treatment of industrial dust removal equipment, can solve the problems of beating and deformation of the dust collector, affecting the dust removal effect, shortening the service life of the equipment, etc., achieving simple and convenient installation, preventing wall sticking and improving dust removal. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

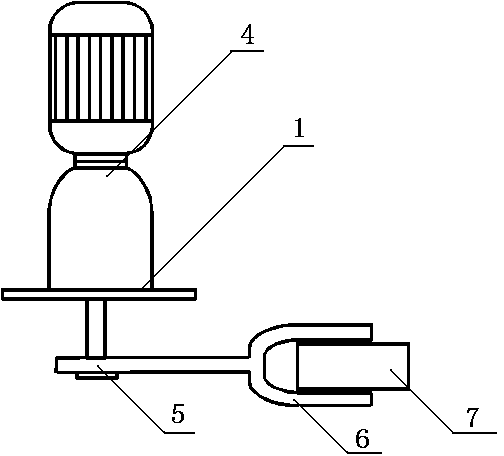

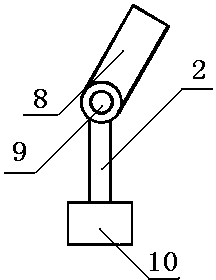

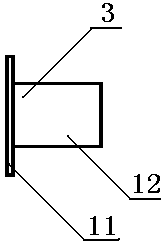

[0014] See figure 1 , figure 2 , image 3 , shown in the figure is a vibrating device for preventing the inner wall of the dust collector. It includes a shaft-connected motor reducer 4, the shaft end is connected horizontally to a bracket 5, and the end of the bracket 5 is connected to two parallel and separated splints 6, and a bearing 7 is fixed inside the splint 6; the vibrator 2 is composed of a toggle contact column 8 and a sleeve 9 , Vibrating hammer 10, the contact column 8 and the vibrating hammer 10 are connected at an angle of 110 degrees, the joint is provided with a sleeve 9, and a connecting rod is worn on the sleeve 9, and the connecting rod is fixed to the outer wall of the dustproof device through a bracket The locator 3 is made up of a protective plate 11 and a positioning column 12, the positioning column 12 is fixed on the protective plate 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com