Sprue puller and reflecting mirror mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

[0020] First, the present invention provides a pull rod

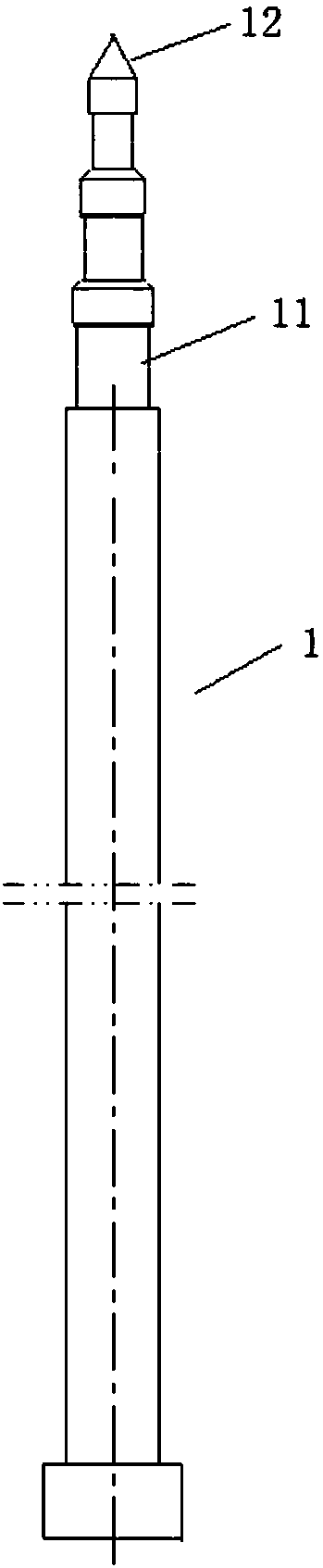

[0021] In Example 1, refer to figure 1 As shown, the pulling head at the top of the pulling rod 1 is in the shape of several layers of pagodas, and each layer is composed of two stepped columns 11 connected by two upper and lower columns. The top is a conical cusp 12.

[0022] Specifically, the longitudinal section of the conical apex 12 is an isosceles triangle, and the apex angle of the isosceles triangle is 60 degrees. The edge of the top surface of each layer of stepped columns 11 is provided with a chamfer, and the chamfer is specifically 45 degrees.

[0023] Furthermore, the said stepped column 11 has three layers in total, the diameters of the same upper cylinders in each layer of stepped columns decrease sequentially from bottom to top, and the diameters of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com