Rhodiola rosea micro powder tablet and preparation method thereof

The technology of Rhodiola rosea and micropowder tablets is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and devices for making medicines into special physical or taking forms, so as to achieve low preparation cost, improve curative effect, and prevent extrusion. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

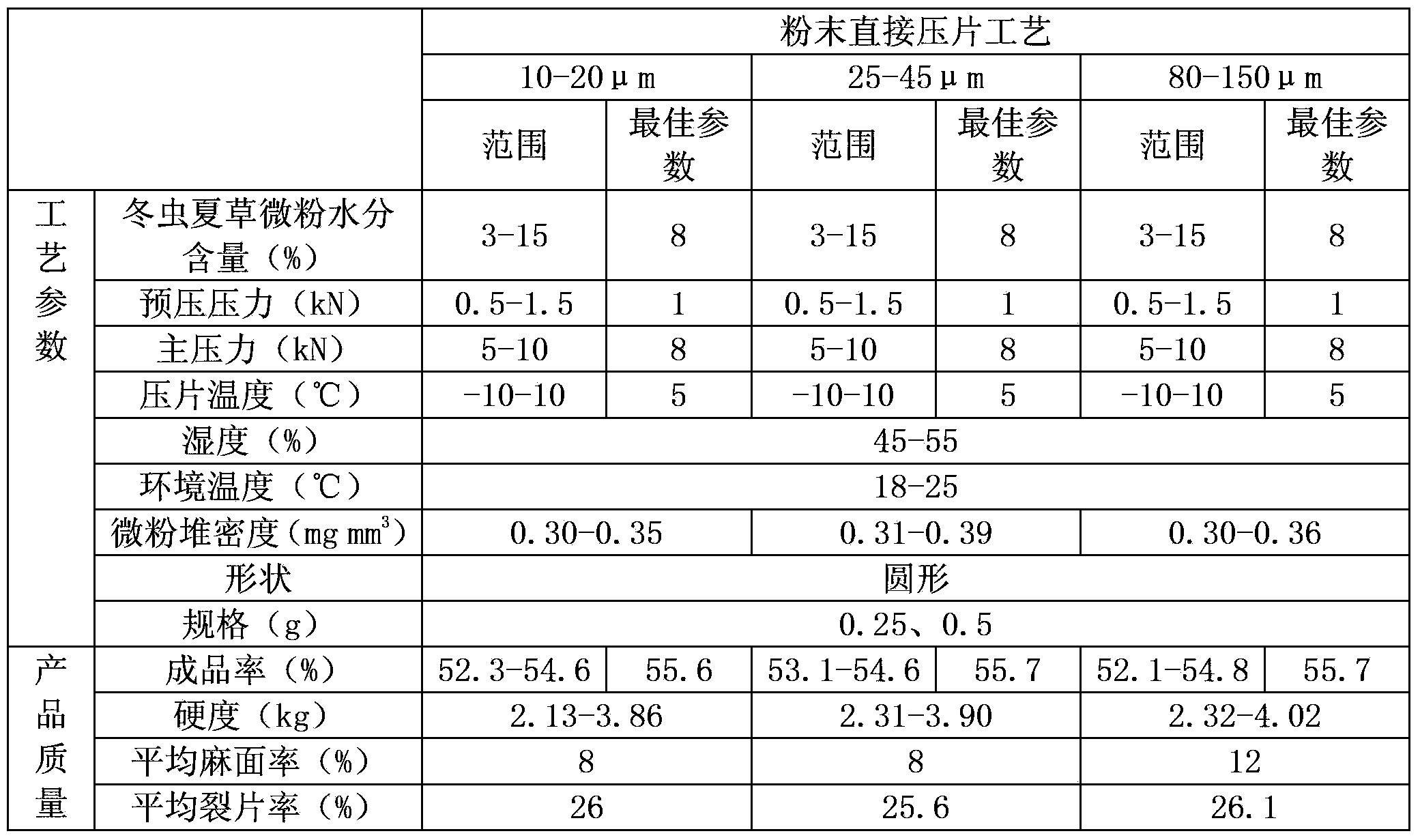

[0072] Embodiment 1 micropowder direct compression tablet process

[0073] 1. Raw materials: Rhodiola micropowder, particle size D90=25-45μm, moisture content about 8%.

[0074] 2. The rotation speed of the tablet press is 15 / h, the pre-compression pressure is 8kN, and the main pressure is 8kN.

[0075] 3. The tableting temperature is set to 5°C.

[0076] 4. The ambient temperature is 22°C and the ambient humidity is 48%.

[0077] Compress tablet according to above-mentioned process, tablet specification 0.25g / tablet, 100 tablets.

Embodiment 2

[0078] Embodiment 2 cycle tabletting process

[0079] 1. Raw material: Rhodiola micropowder, particle size D90=25-45μm, moisture content more than 8%.

[0080] 2. The rotation speed of the tablet press is 15 / h, the pre-compression pressure is 8kN, and the main pressure is 8kN.

[0081] 3. The tableting temperature is set to 5°C.

[0082] 4. The ambient temperature is 22°C and the ambient humidity is 48%.

[0083] When compressing tablets according to the above process, the powder is first pressed into tablets, then crushed through a 60-80 mesh sieve, and then compressed into tablets again. If the requirements are not met, repeat the steps of tablet compression until the quality of the tablet is qualified, and the tablet specification is 0.25g / piece, 100 pieces.

Embodiment 3

[0084] Embodiment 3 cycle tabletting process

[0085] 1. Raw material: Rhodiola micropowder, particle size D90=25-45μm, moisture content more than 8%.

[0086] 2. The rotation speed of the tablet press is 15 / h, the pre-compression pressure is 8kN, and the main pressure is 8kN.

[0087] 3. The tableting temperature is set to 5°C.

[0088] 4. The ambient temperature is 22°C and the ambient humidity is 48%.

[0089] Press the tablet according to the above process, first press the powder into a large plate, then crush it through a 60-80 mesh sieve, and then press it again. The tablet specification is 0.25g / tablet, 100 tablets.

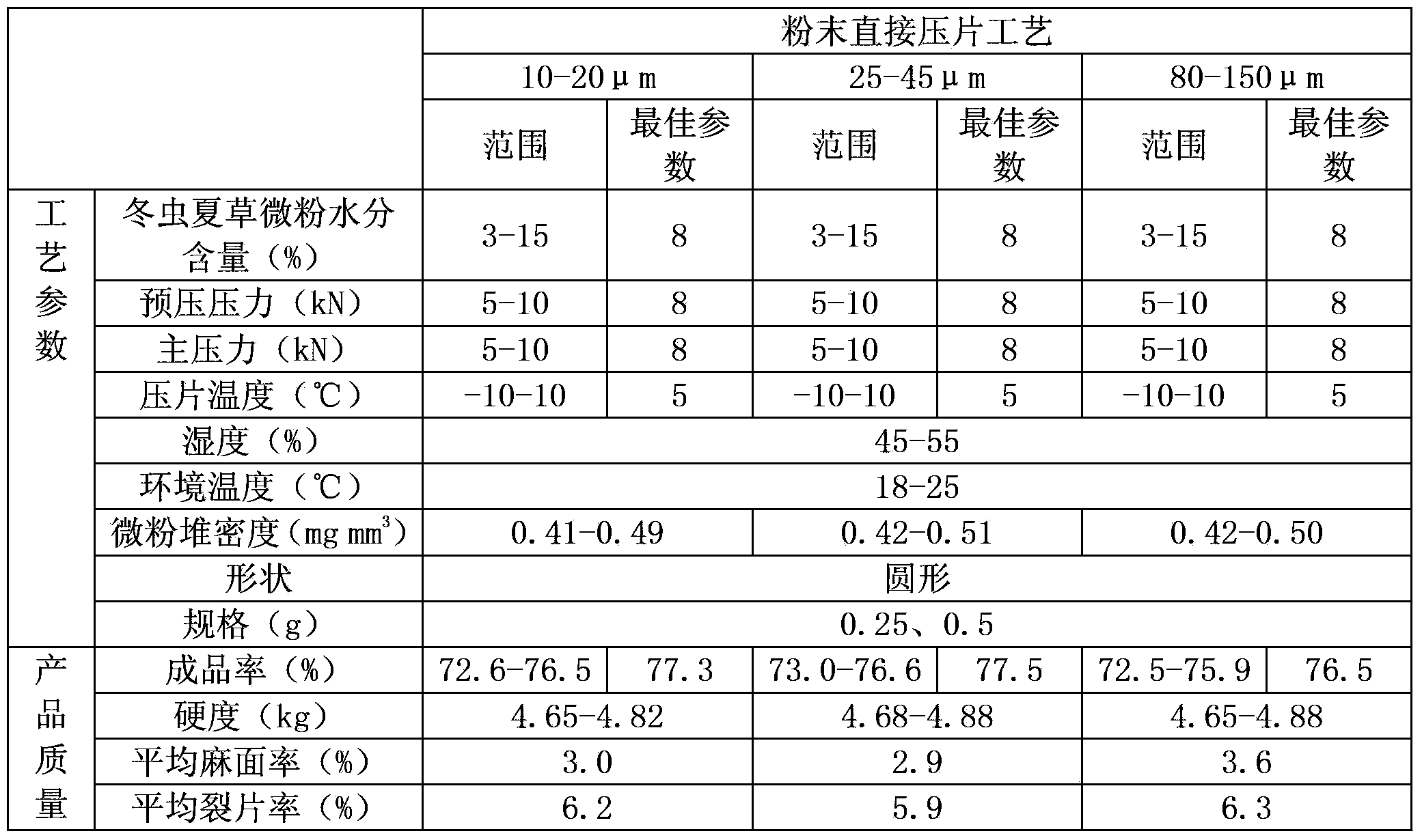

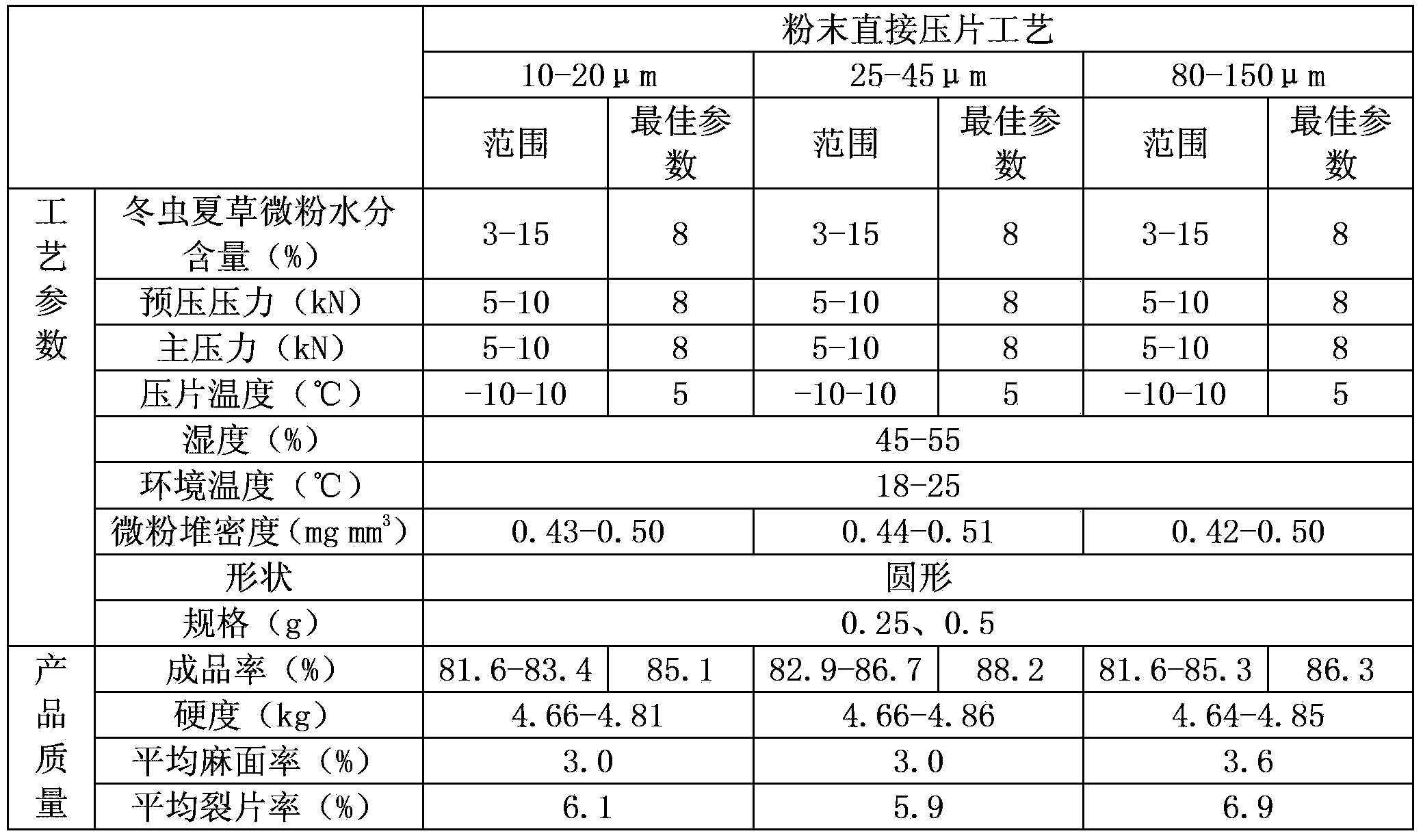

[0090]Rhodiola rosea was pressed into tablets through three kinds of process compression, and the obtained tablets were compared in quality, see Table 6.

[0091] Table 6 Comparison table of three kinds of process results (based on 100 micropowder tablets)

[0092]

[0093] Through the comparison in the above table 6, the above three processes can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com