Organic fertilizer fermenting device

A fermentation device and organic fertilizer technology, which is applied in the field of organic fertilizer fermentation devices, can solve the problems of endless output, different fermentation temperatures, and difficulty in continuous production of fermentation tanks, and achieve the effect of preventing wall sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with specific embodiments.

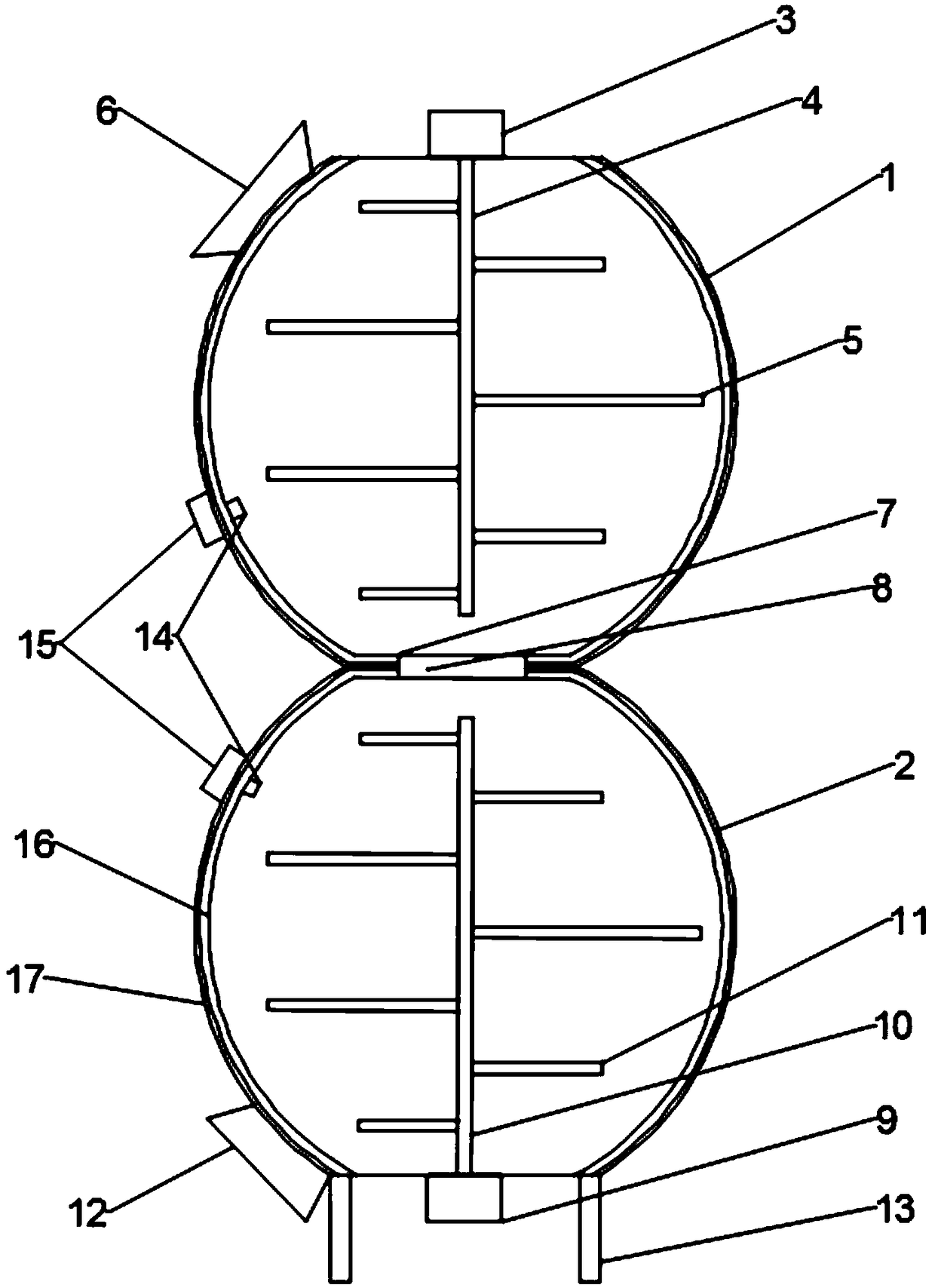

[0015] The structure of a kind of organic fertilizer fermentation device is as figure 1 As shown, it is characterized in that it includes a fermenter I1 and a fermenter II2; the top of the fermenter I1 is provided with a motor 3, and the stirring shaft 4 connected with the motor 3 extends into the fermenter I1, and the stirring shaft 4 The part located in the fermenter I1 is evenly spaced from top to bottom with a number of stirring paddles 5, the lower end of the stirring shaft 4 is close to the bottom wall of the fermenter I1, and the side wall of the fermenter I1 is A feed hopper 6 for filling fermentation raw materials into the fermenter I1 is provided, a discharge port 7 is opened in the middle of the bottom wall of the fermenter I1, and a discharge door that can be opened and closed is provided at the discharge port 7 body 8, the discharge port 7 runs through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com