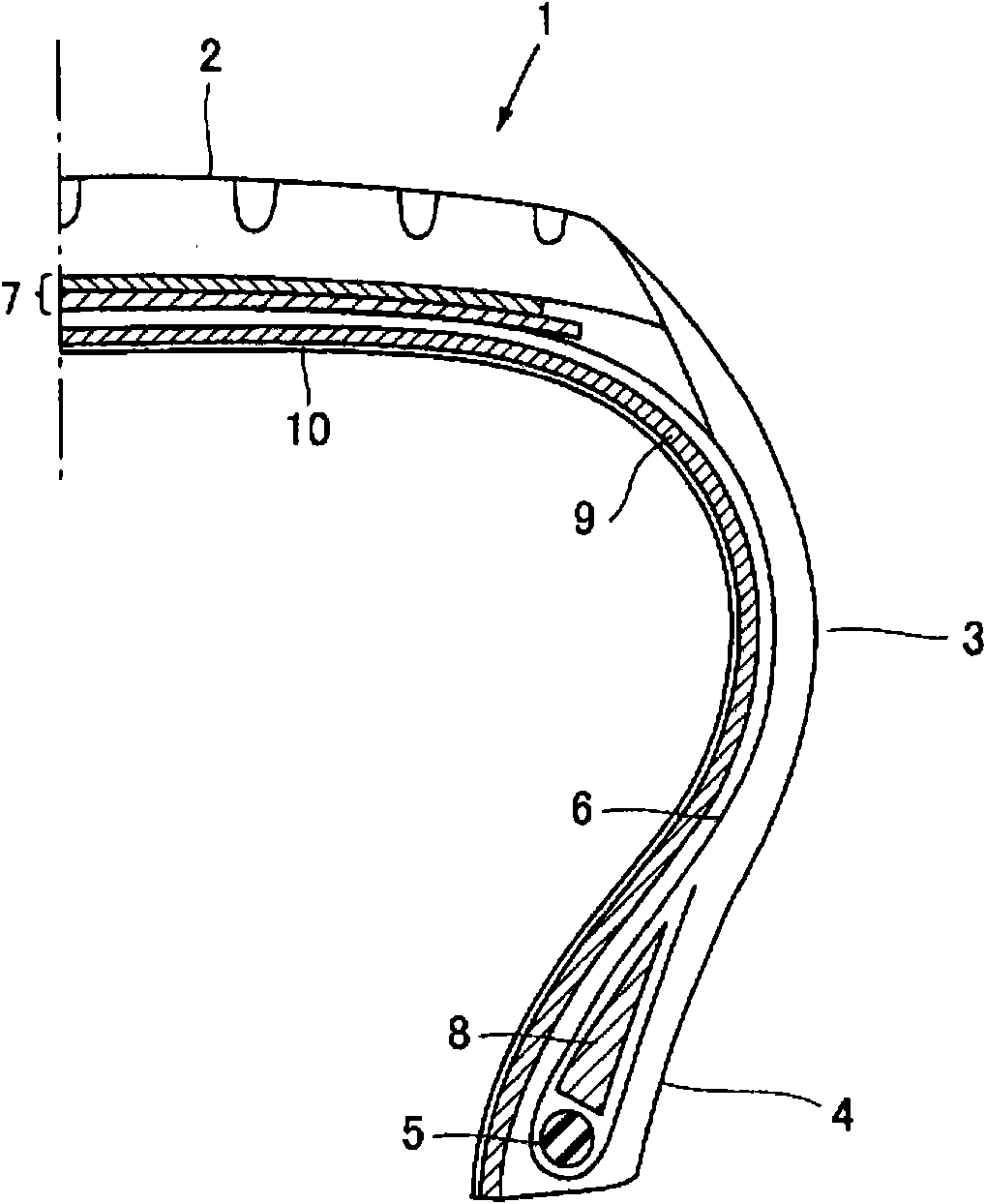

Method for producing polymer sheet for inner liner and method for producing pneumatic tire

A polymer and airtight layer technology, applied in special tires, tire parts, chemical instruments and methods, etc., can solve problems such as complex steps, and achieve the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

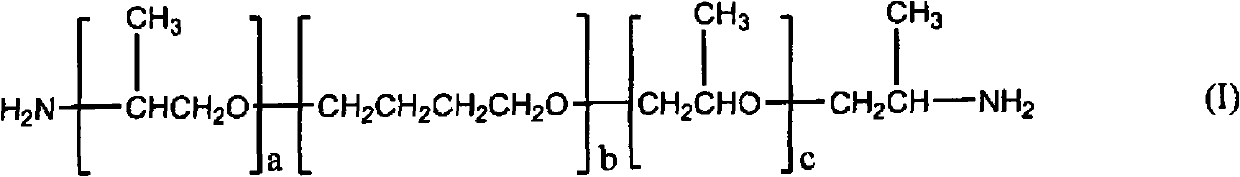

Method used

Image

Examples

Embodiment 1 to 10

[0109]

[0110] According to each formulation shown in Table 1, a twin-screw extruder (screw diameter: φ50mm, L / D: 30, barrel temperature: 220°C) was charged with polymer mixture components and fillers and formed into pellets, and then unvulcanized The polymer sheet was produced by a T-die extruder (screw diameter: φ80 mm, L / D: 50, die width: 500 mm, barrel temperature: 220° C., film thickness: 0.3 mm).

[0111] One surface of the unvulcanized polymer sheet was coated and / or sprayed with a release agent under the conditions shown in Table 1, thereby obtaining a polymer sheet for an inner liner. The mold release agent used was obtained by the following method.

[0112] The water-soluble paint was prepared by thoroughly mixing a mixed liquid containing: 45% by mass mica (D1000, manufactured by Nippon Talc Co., Ltd.) under stirring, passing the liquid through a paint roller and filtering the liquid through an 80 mesh filter ), 15 mass % emulsified silicone oil (Wacker E2891, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com