Method for producing pneumatic tire

一种充气轮胎、硫化轮胎的技术,应用在特殊轮胎、轮胎零部件、胎等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

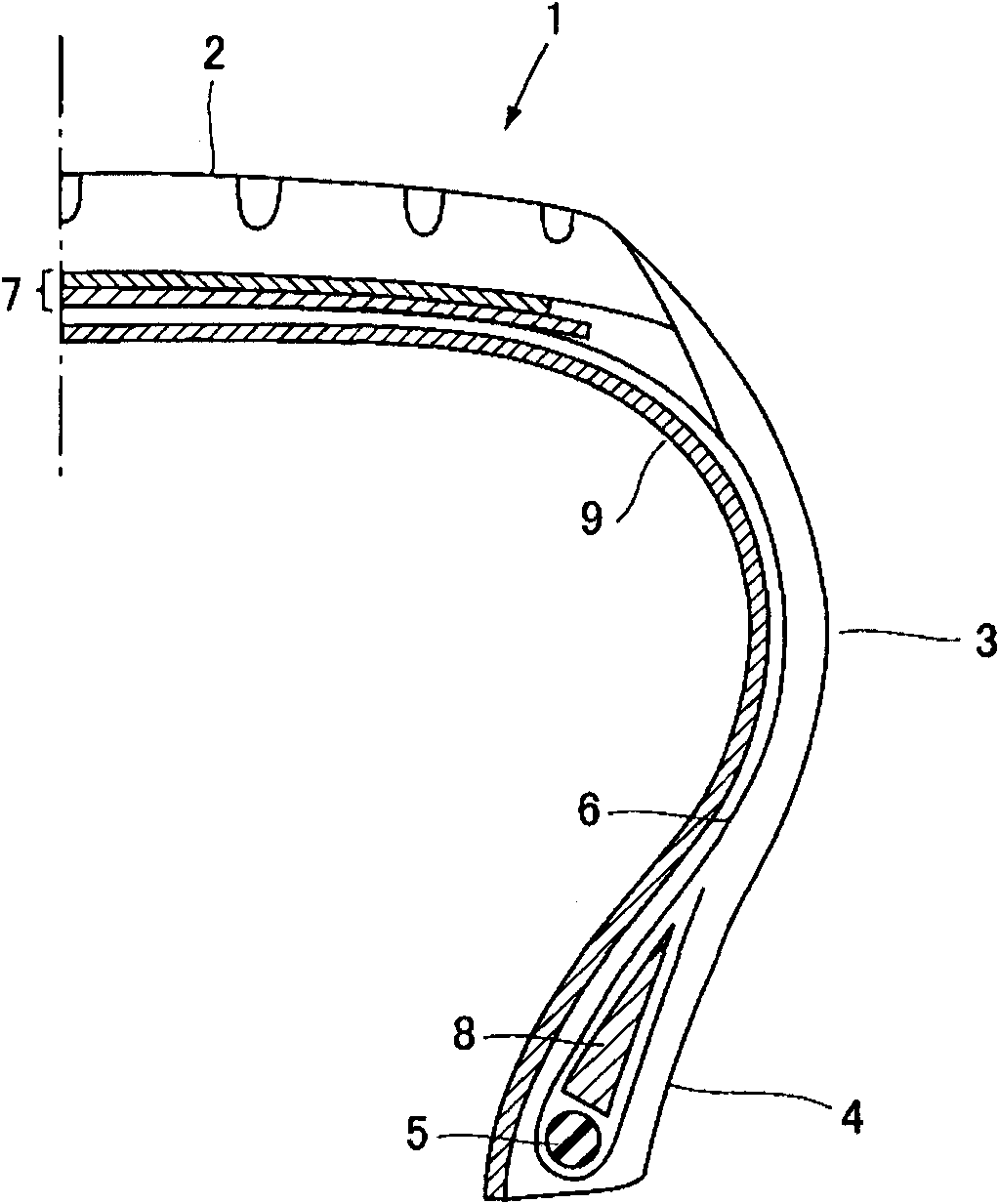

Image

Examples

Embodiment 1 to 6

[0090]

[0091] (manufacture of pneumatic tires)

[0092] According to each formula shown in Table 2, various compounding agents are loaded into a twin-screw extruder (screw diameter: φ50mm, L / D: 30, barrel temperature: 220° C.) and formed into granules, which are then used for implementation The unvulcanized polymer compositions of Examples 1 to 6 and Comparative Examples 1 to 10 were passed through a T-die extruder (screw diameter: φ80mm, L / D: 50, die width: 500mm, barrel temperature: 220°C, film Thickness: 0.3mm) production.

[0093] The resulting unvulcanized polymer composition is applied to the inner liner portion of the tire to manufacture a green tire. The green tire was pressure-molded in a mold at 170° C. for 20 minutes to obtain a vulcanized tire (195 / 65R15). Then, the vulcanized tire was cooled by introducing water for controlling the cooling temperature shown in Table 2 into the bladder. After the lapse of the cooling time shown in Table 2, the vulcanized tir...

Embodiment 7 to 12

[0128]

[0129] (production of vulcanized polymer sheets)

[0130] According to each formula shown in Table 4, various compounding agents are loaded into a twin-screw extruder (screw diameter: φ50mm, length: 1m, barrel temperature: 220°C) to form granules, and then extruded through a T die Machine (spiral diameter: φ80mm, control temperature: 220°C, film thickness: 0.6mm) to produce unvulcanized polymer sheets.

[0131] The resulting unvulcanized polymer sheet was heated at 170° C. for 2 minutes to produce a vulcanized polymer sheet. For vulcanized polymer sheets, an air permeability test was performed.

[0132] (air permeability test)

[0133] According to the American Society for Testing and Materials ASTM D 1434 75M, measure the air permeability of the vulcanized polymer sheet (×10 11 cm 3 cm / cm 2 ·s·cm·Hg). The less air infiltration, the better the airtightness.

[0134] (manufacture of pneumatic tires)

[0135] The resulting unvulcanized polymer sheet is applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com