Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Play the role of sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packer

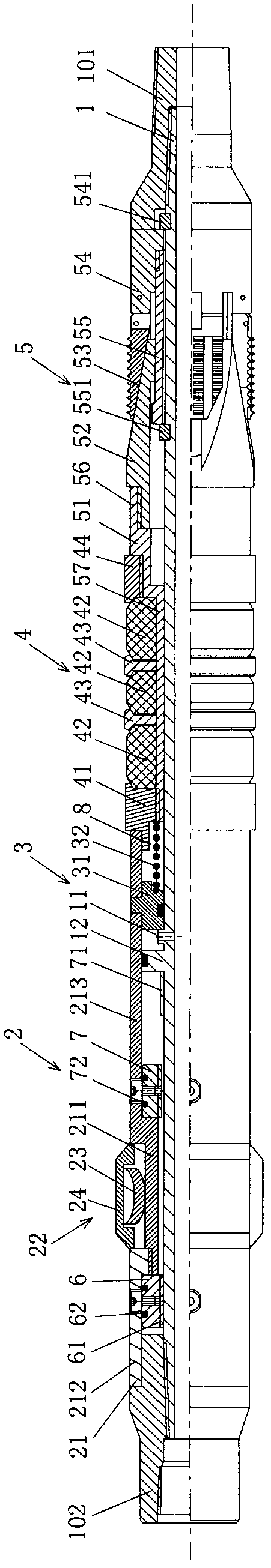

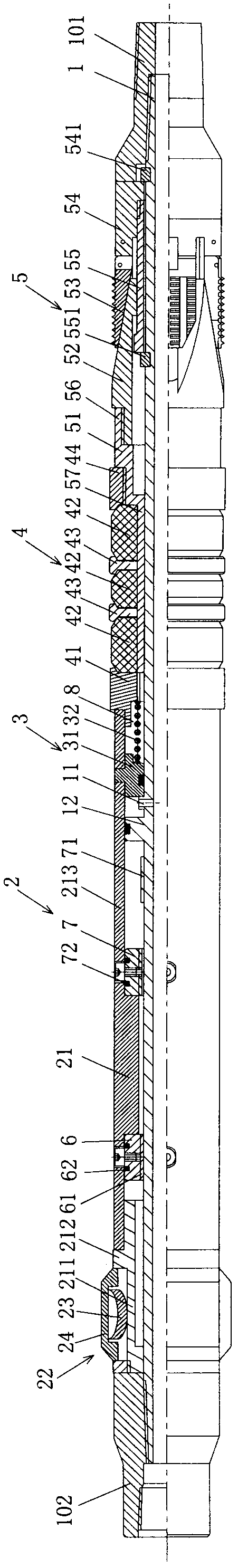

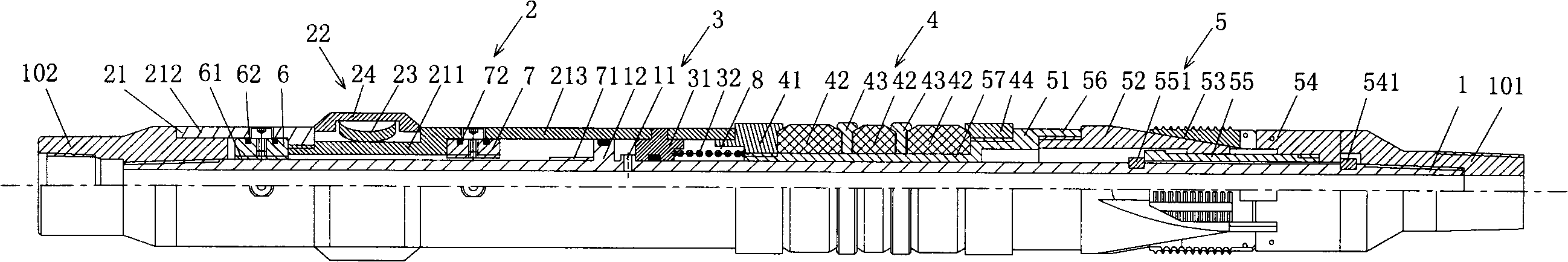

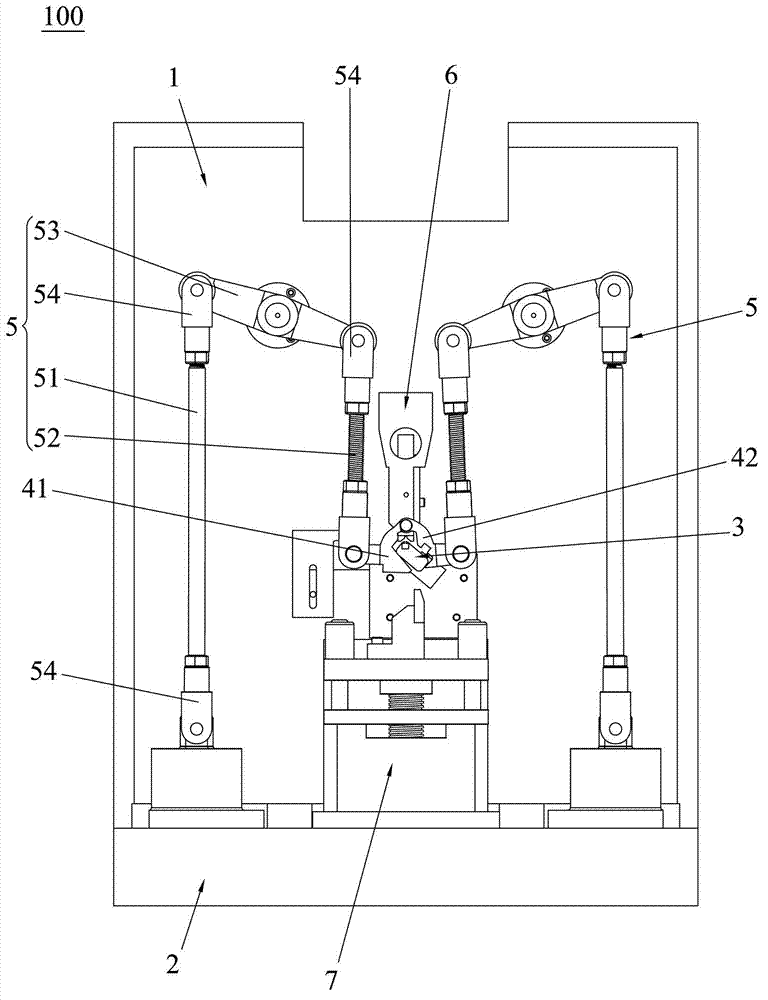

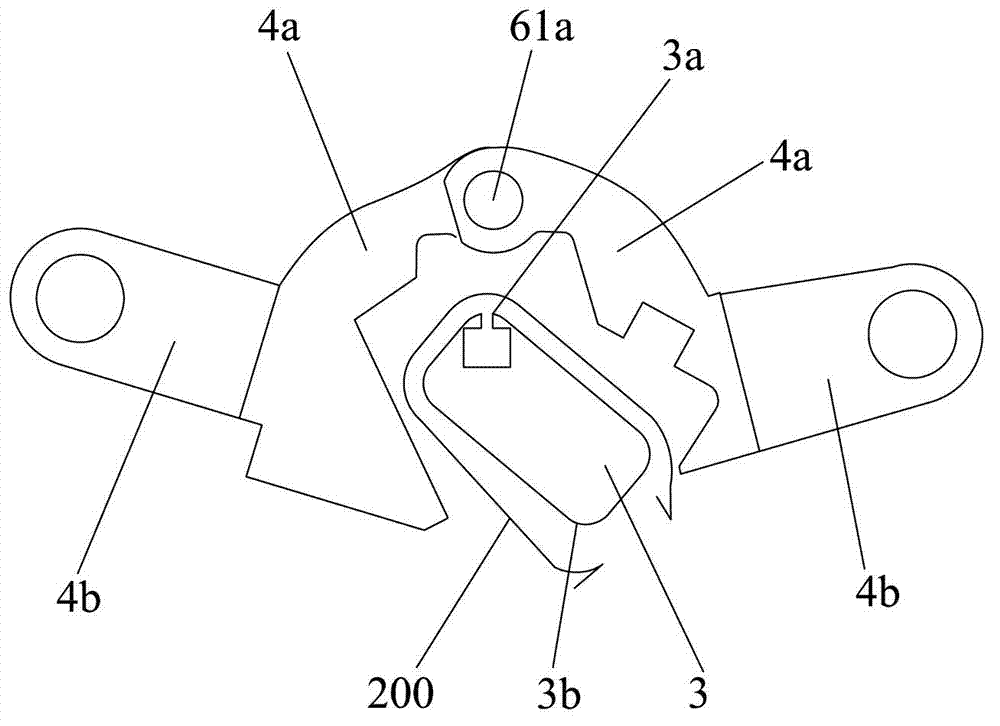

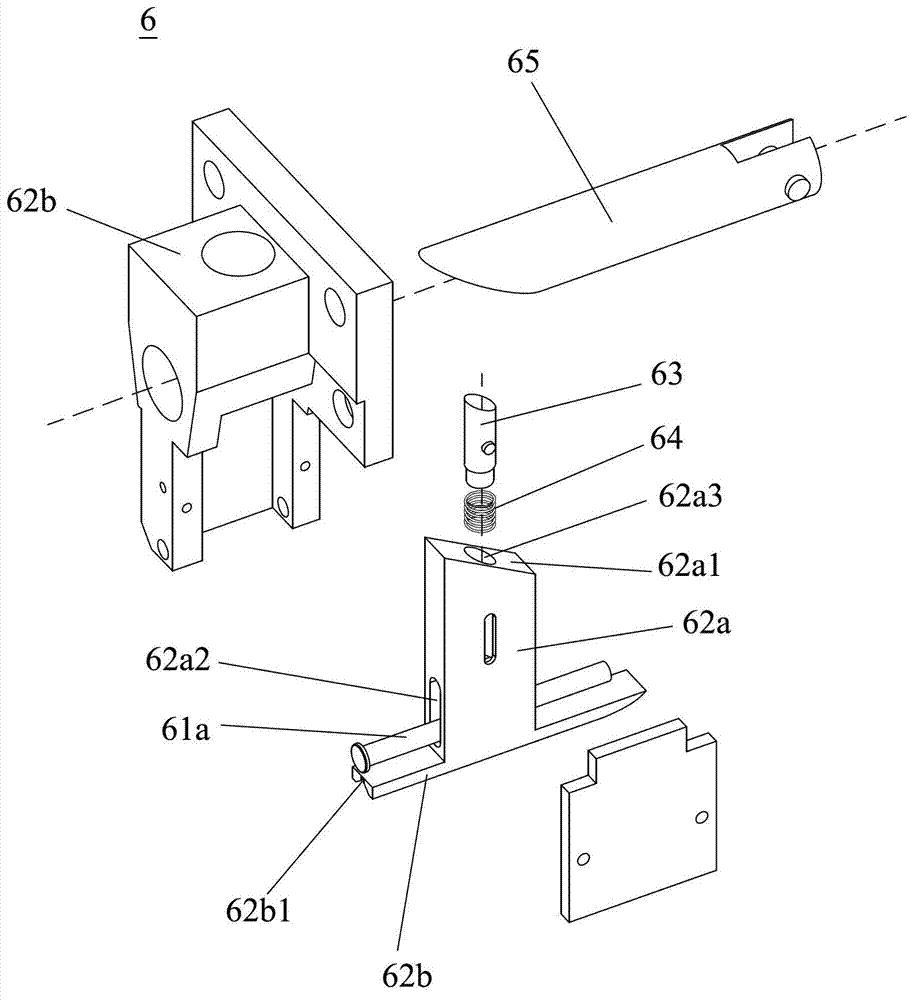

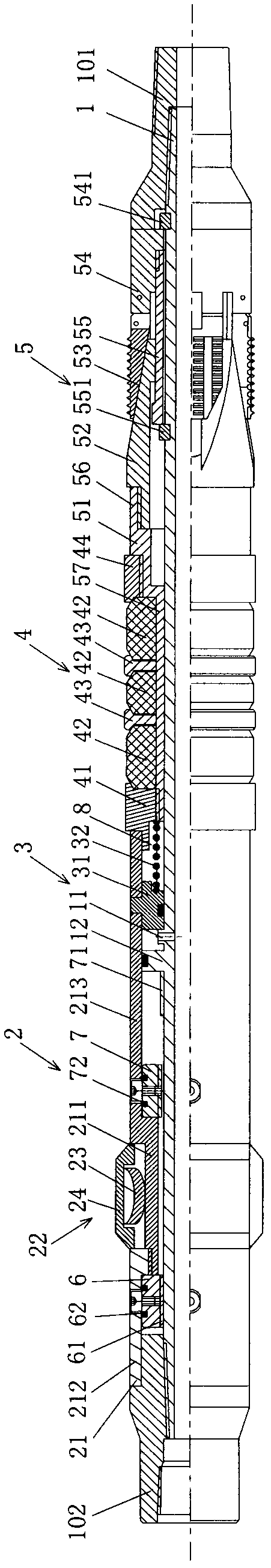

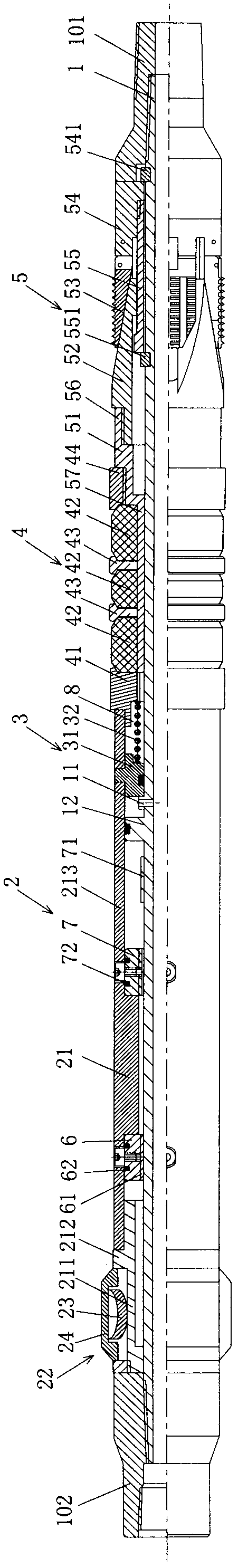

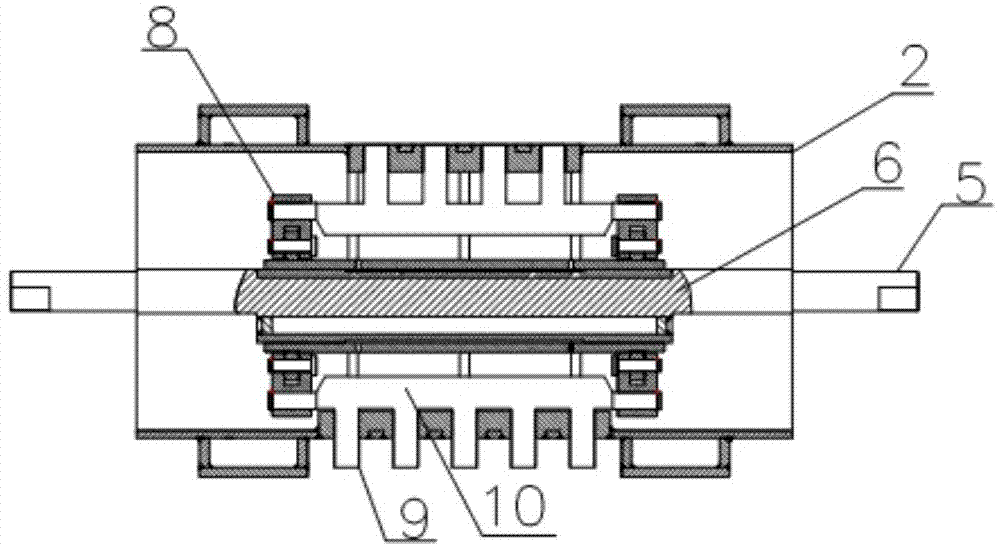

InactiveCN102337860AGood effectReduced risk of settingSealing/packingElastic componentLocking mechanism

The invention provides a packer which comprises a central tube as well as a locking mechanism, an actuating mechanism, a sealing mechanism and an anchor mechanism which are arranged outside the central tube, wherein the actuating mechanism enables the sealing mechanism and the anchor mechanism to act; the locking mechanism comprises a lock sleeve adjacent to the sealing mechanism, a locating component arranged outside the lock sleeve, a right-hand nut and a left-hand nut arranged inside the lock sleeve and spaced at an interval, and a right-hand thread section and a left-hand thread section arranged on the outer wall of the central tube and corresponding to the right-hand nut and the left-hand nut; a through hole is arranged on the wall, corresponding to the lock sleeve, of the central tube and a baffle is arranged outside the wall of the tube; the baffle and the inner wall surface of the lock sleeve are sealed and connected to form a cylinder bottom of a piston cavity; and the actuating mechanism comprises a piston arranged in the piston cavity and connected with the lock sleeve and an unpacking elastic component connected with the piston. The packer has the advantages that the prevention of midway setting and setting failure can be effectively realized, the working reliability is improved, the multi-time setting and unpacking in one string can be realized, the borehole operation procedure is simplified, the working efficiency is improved, and the cost is greatly saved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

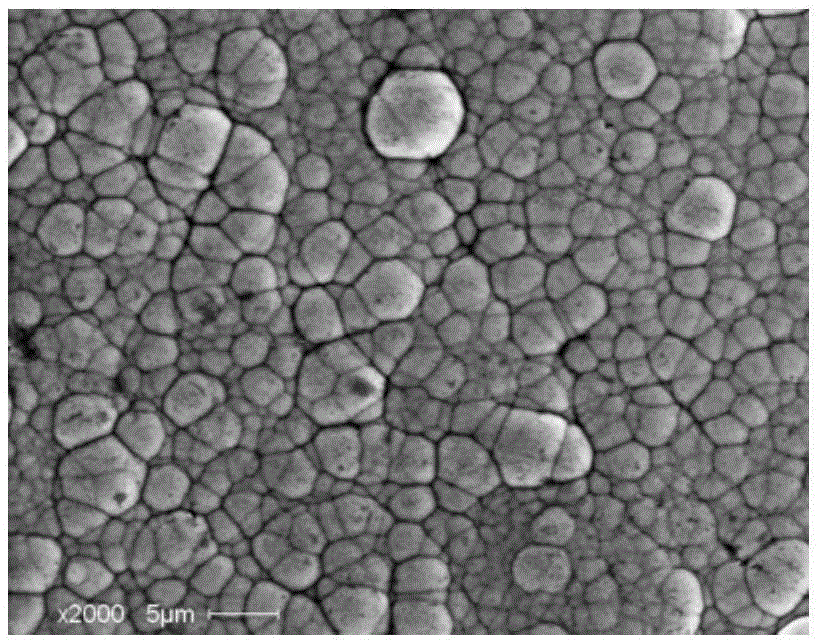

Preparation method of novel titanium-nickel medical implantation material

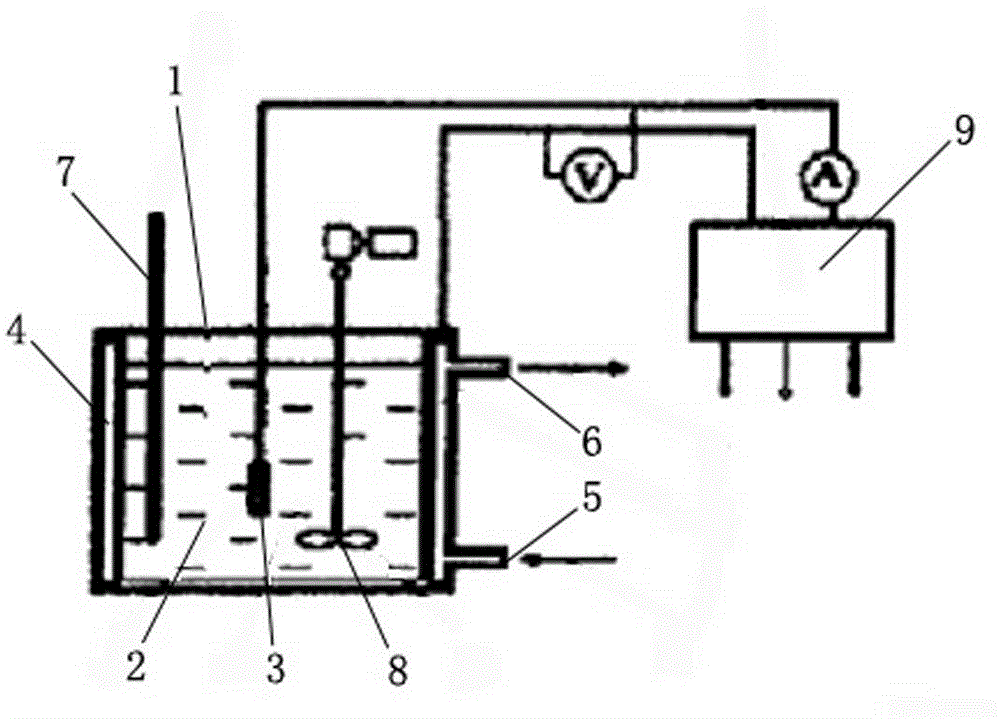

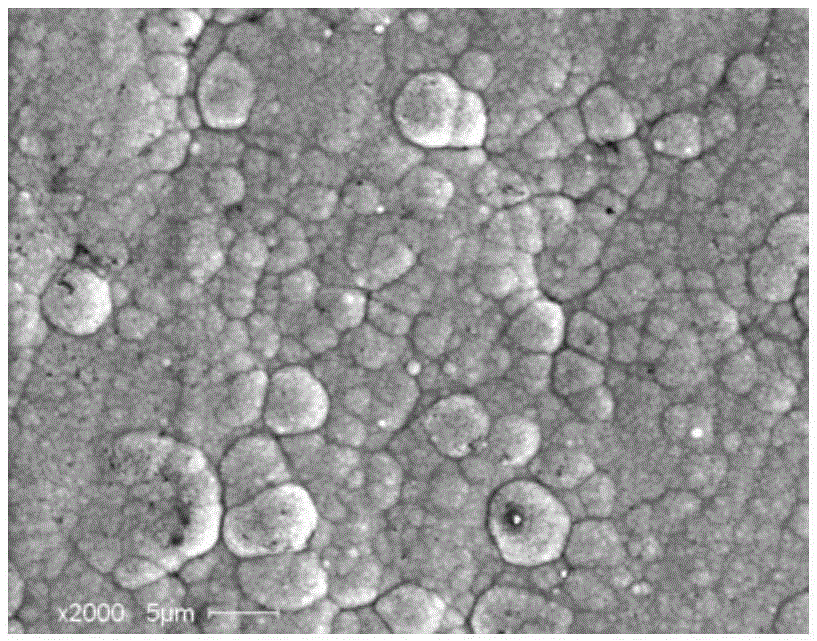

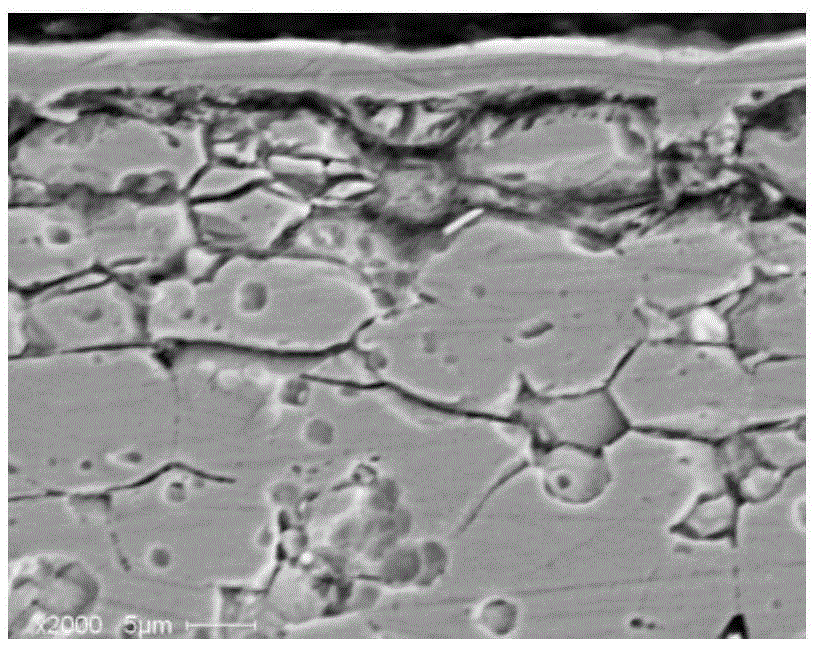

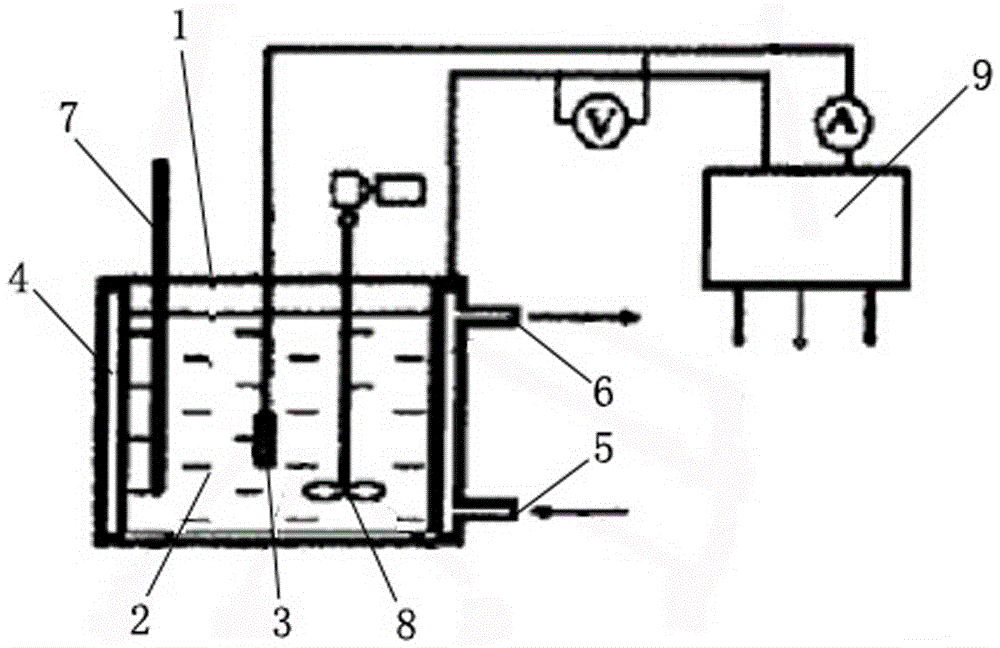

InactiveCN104087935AIsolationSolve the problem of difficult direct micro-arc oxidationSurface reaction electrolytic coatingSolid state diffusion coatingMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method of a novel titanium-nickel medical implantation material, particularly a composite treatment method for preparing a titanium dioxide / aluminum oxide mixture by depositing titanium on a titanium-nickel surface and performing micro-arc oxidation. The method comprises the following steps: firstly, by using a titanium-nickel alloy base as a workpiece, eliminating the oxide film on the workpiece surface by a mechanical-chemical mixed method; secondly, depositing titanium on the workpiece surface by a plasma surface alloying technique; thirdly, carrying out micro-arc oxidation on the workpiece in a micro-arc oxidation device; and finally, carrying out ultrasonic cleaning on the workpiece, and drying to obtain the finished product. The material can effectively isolate the precipitation of the nickel element in the titanium-nickel alloy, and the ceramic film layer of the titanium base surface subjected to micro-arc oxidation has the advantages of fewer surface voids, high hardness, high corrosion resistance, favorable insulativity and high binding force with the base metal. The method has the characteristics of favorable technical repetitiveness, controllable quality and the like, is simple to operate, can be widely used for surface modification treatment of titanium-nickel alloys, and effectively improves the application range and level.

Owner:TAIYUAN UNIV OF TECH

Method for preparing magnesium alloy composite coating with decorativeness and functionality

ActiveCN105887159AImprove the decorative effectWith ceramic propertiesAnodisationVacuum evaporation coatingMicro arc oxidationIon

A method for preparing a magnesium alloy composite coating with decorativeness and functionality comprises the following steps that the surface of a magnesium alloy is polished, and oil removal and degreasing are carried out; micro-arc oxidation is carried out, wherein an electrolyte is subjected to micro-arc oxidation, a current or voltage control method is adopted, the micro-arc oxidation time ranges from 25 min to 60 min, and the thickness of an oxidation film ranges from 5 micrometers to 50 micrometers; ion cleaning is carried out, wherein a component is put in a vacuum coating chamber, the pressure of argon, the pulsed bias voltage and the duty ratio are adjusted, and discharge cleaning is carried out; a metal layer is subjected to pre-coating, wherein a zirconium target or titanium target arc source is adopted, the bias voltage duty ratio and the bias voltage are adjusted, and the metal layer is subjected to coating; and arc ion coating is carried out, wherein the zirconium target or titanium target arc source is adopted, nitrogen or / and acetylene is / are introduced at the vacuum degree being (3-6)*10<-1> Pa, the pulsed bias voltage and the duty ratio are adjusted, the arc current ranges from 60 A to 100 A, and the coating time ranges from 10 min to 60 min. The method for preparing the magnesium alloy coating integrating high decorativeness, high corrosion resistance, high wear resistance and high heat radiation performance belongs to the environment-friendly surface treatment technology.

Owner:GUANGDONG INST OF NEW MATERIALS

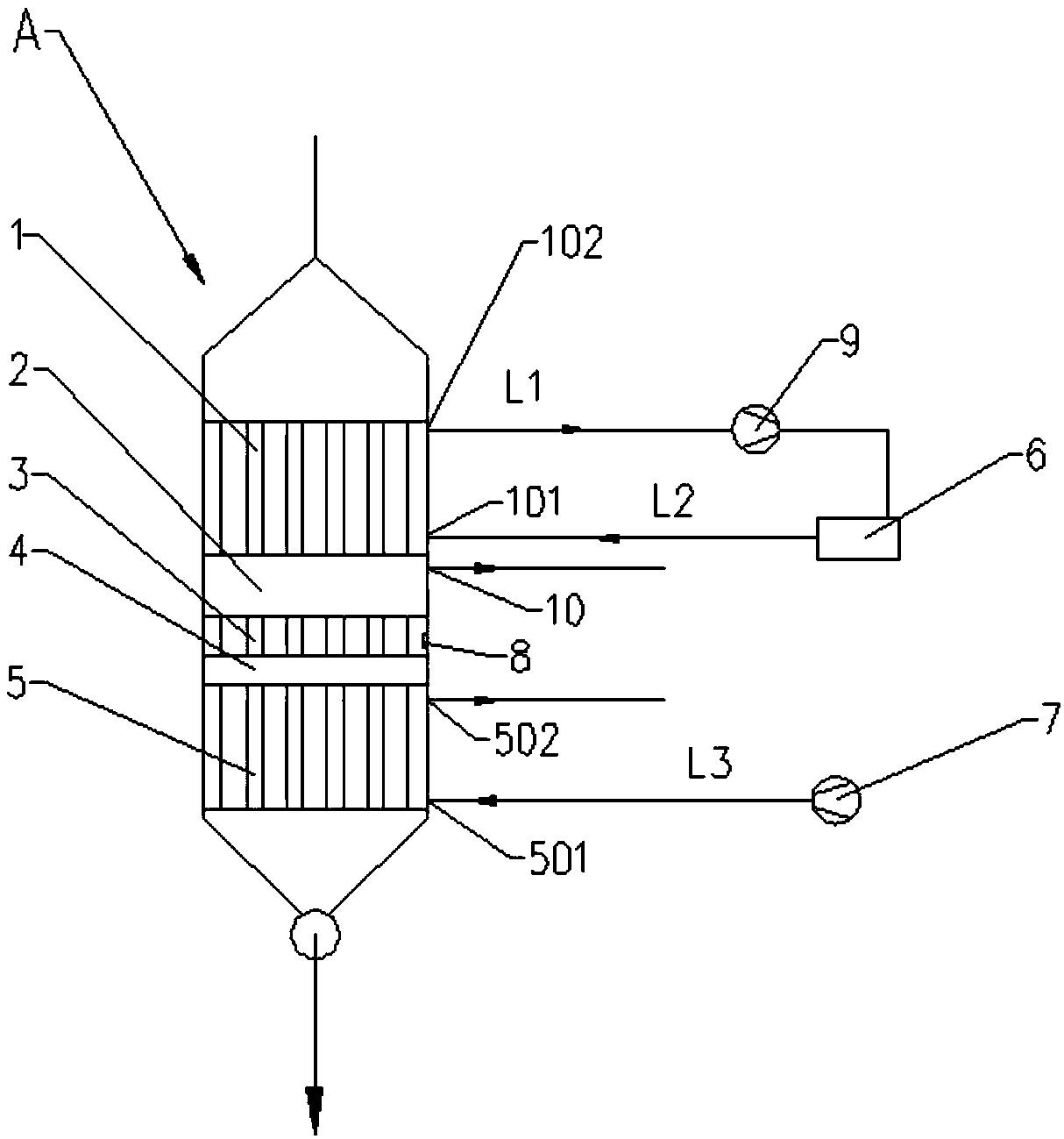

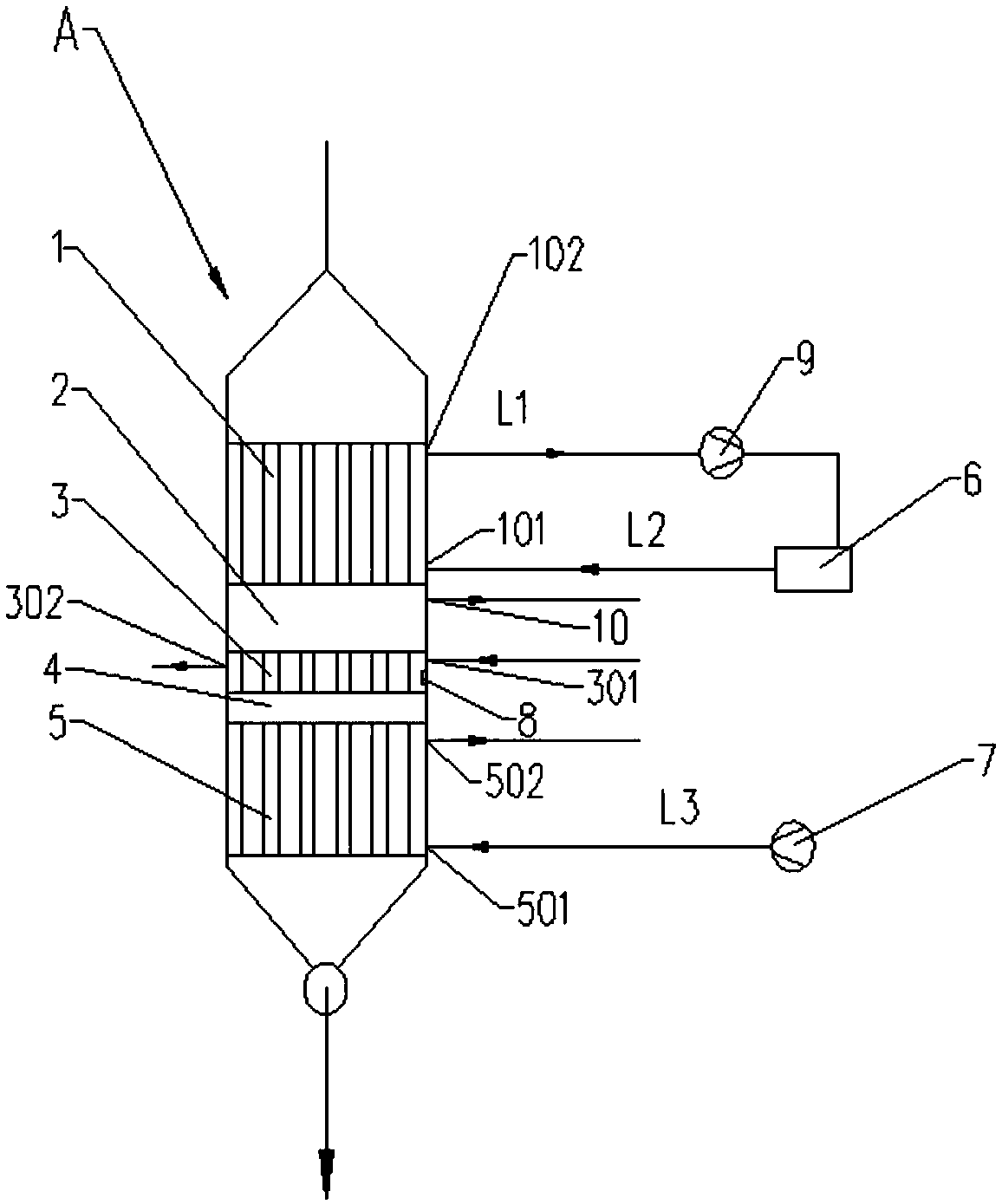

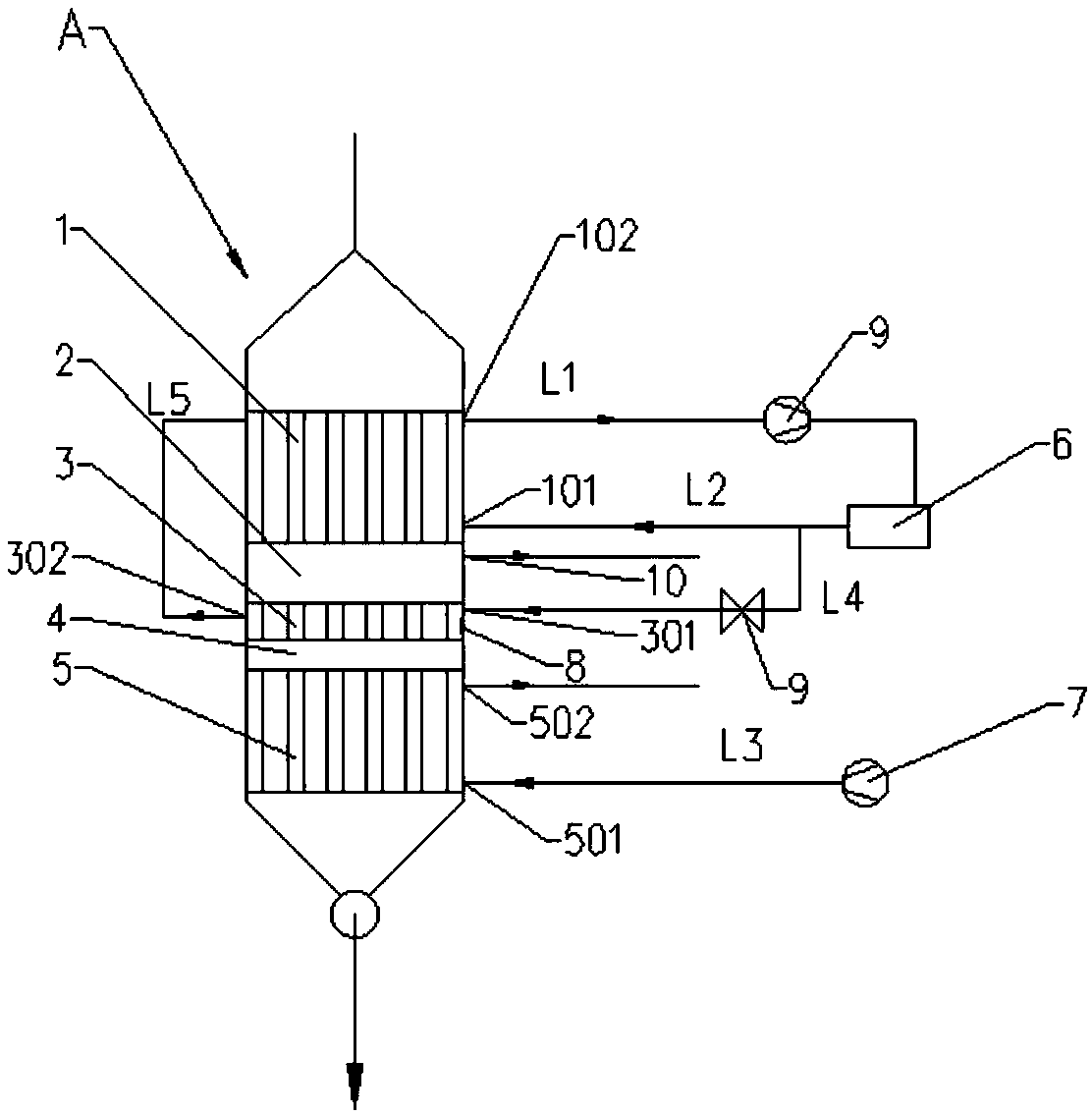

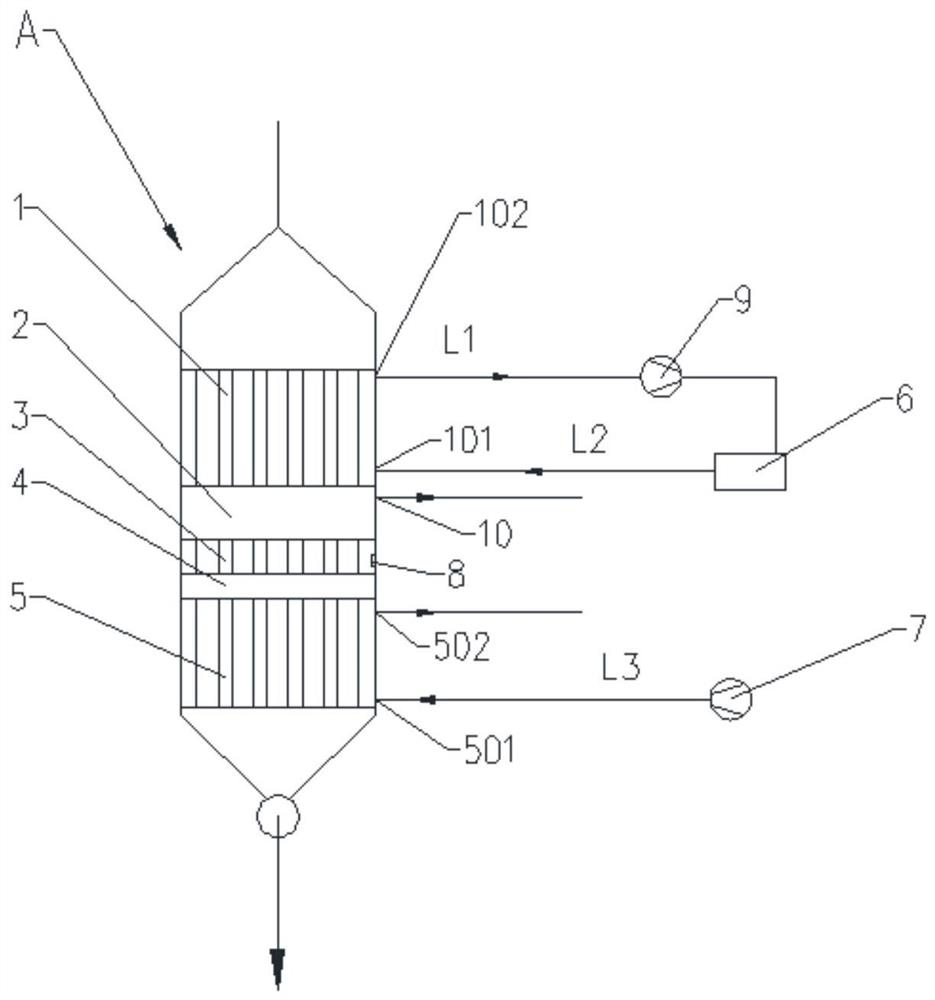

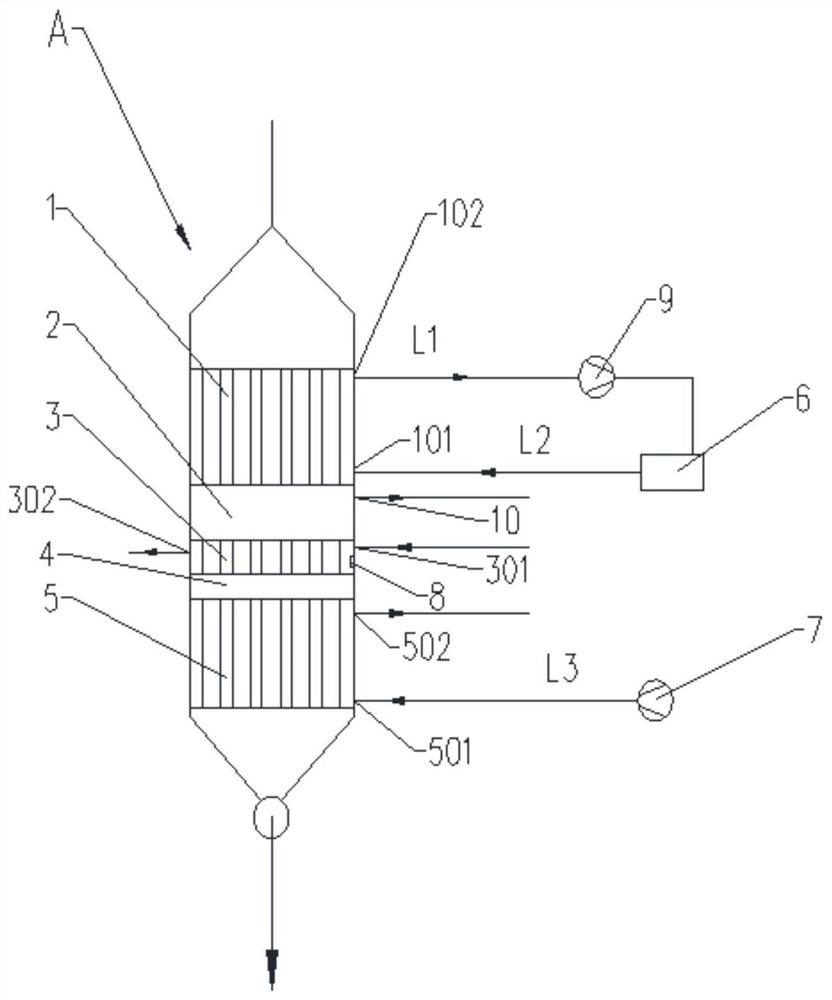

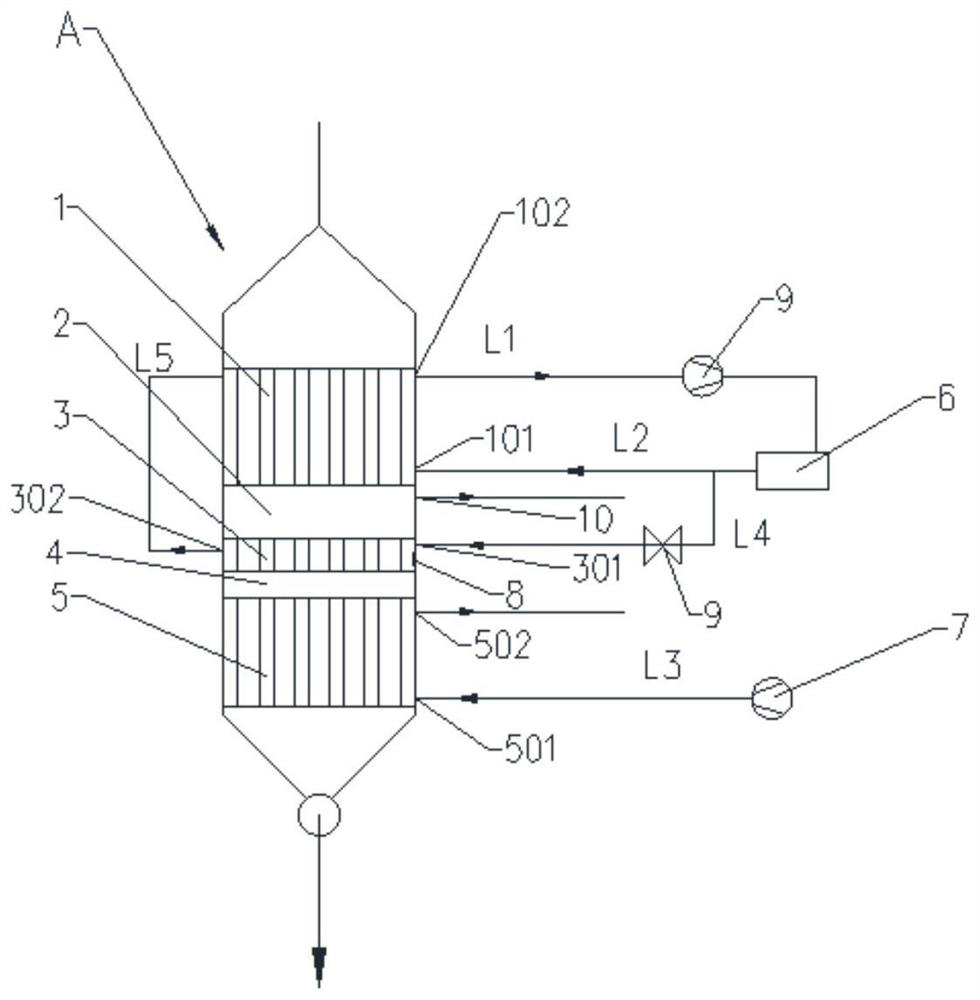

Novel activated carbon desorption tower and activated carbon desorption method

ActiveCN109174070AAvoid blockageAvoid Corrosion ConditionsOther chemical processesDispersed particle separationSpontaneous combustionActivated carbon

The invention provides a novel activated carbon desorption tower. The activated carbon desorption tower comprises a heating section, a first transition section, a transition cooling section, a secondtransition section and a heat exchange cooling section which are arranged from top to bottom. The transition cooling section and the second transition section commonly form a buffer zone to make the first transition section not in direct contact with the heat exchange cooling section, so a sharp drop of the temperature of activated carbon in the desorption tower is avoided, thereby the activated carbon is prevented from scaling on the non-perforated surface of a tube plate in the cooling section, and the desorption tower is prevented from being clogged and corroded. The arrangement of the buffer zone avoids spontaneous combustion of bridging activated carbon directly falling to the bottom of the desorption tower.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Ultrasonic chemical nickel and phosphorus plating method for NdFeB material

InactiveCN105420703AImprove bindingImprove corrosion resistanceLiquid/solution decomposition chemical coatingBinding forceElectroless plating

The invention belongs to the technical field of a chemical plating process and particularly relates to an ultrasonic chemical nickel and phosphorus plating method for an NdFeB material. The method comprises the following steps: mechanical grinding; ultrasonic degreasing; acid pickling and rust removing; flash plating; ultrasonic chemical nickel and phosphorus plating. Compared with a general chemical plating method, the ultrasonic chemical nickel and phosphorus plating method for the NdFeB material, disclosed by the invention, has the advantages that the plating temperature is low, a plated layer is more compact, better corrosion resistance is realized and the plated layer has a better binding force with a base body.

Owner:CHINA IRON & STEEL RES INST GRP +1

Method for preparing magnesium alloy composite coating with self-repair function

ActiveCN105887084ACorrosion resistanceWith ceramic propertiesAnodisationVacuum evaporation coatingPlasma electrolytic oxidationMicro arc oxidation

A method for preparing a magnesium alloy composite coating with a self-repair function comprises the following steps that the surface of a magnesium alloy is polished, and oil removal and degreasing are carried out; an electrolyte is subjected to micro-arc oxidation, a current or voltage control method is adopted, the pulse power frequency and the duty ratio are adjusted, and the micro-arc oxidation time ranges from 15 min to 60 min; the magnesium alloy obtained after micro-arc oxidation is cleaned and dried and is put in a vacuum coating chamber with the pressure being (7-8)*10<-3> Pa and the temperature ranging from 100 DEG C to 200 DEG C, the pressure of argon is adjusted to range from 2 Pa to 3 Pa, the pulsed bias duty ratio ranges from 20% to 30%, the bias voltage ranges from 800 V to 1,000 V, and discharge cleaning is carried out for 2 min to 5 min; a pure aluminum or pure titanium target is adopted, and argon ion bombardment is finished till the pressure ranges from (3-5)*10<-1> Pa, the bias duty ratio ranges from 40% to 50%, and the bias voltage ranges from 500 V to 1,000 V; and the arc current ranges from 60 A to 120 A, and the coating time ranges from 10 min to 60 min. In the method, chromium, fluoride, phosphorus, heavy metal ions and other harmful substances are avoided, and the prepared magnesium alloy coating has corrosion resistance, good heat conductivity and self-repair performance.

Owner:GUANGDONG INST OF NEW MATERIALS

Composite waterproof structure and preparation method thereof

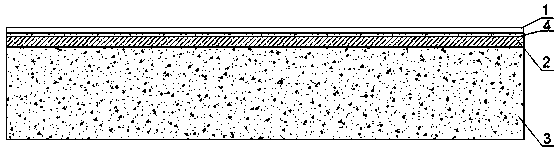

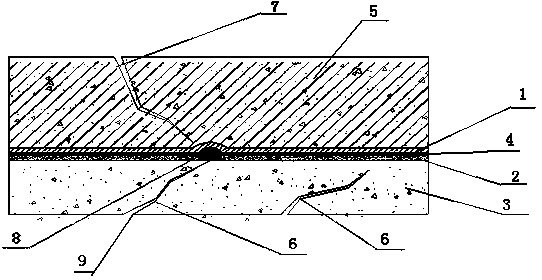

ActiveCN108859344ANo delaminationStrong chemical bondSynthetic resin layered productsLaminationPolymer modifiedSurface layer

The invention discloses a composite waterproof structure and a preparation method thereof, and belongs to the field of building waterproof materials. The composite waterproof structure is prepared from a waterproof coil layer, a reaction type macromolecular elastic coating layer and a waterproof base layer in turn from top to bottom, wherein the waterproof coil layer is prepared from an upper surface layer and a self-sticking material layer in turn from top to bottom; the self-sticking layer is self-sticking polymer modified asphalt. According to the composite waterproof structure and the preparation method thereof disclosed by the invention, separation between the coating and the coil is avoided, and the waterproof effect is perfect.

Owner:四川省威盾新材料有限公司

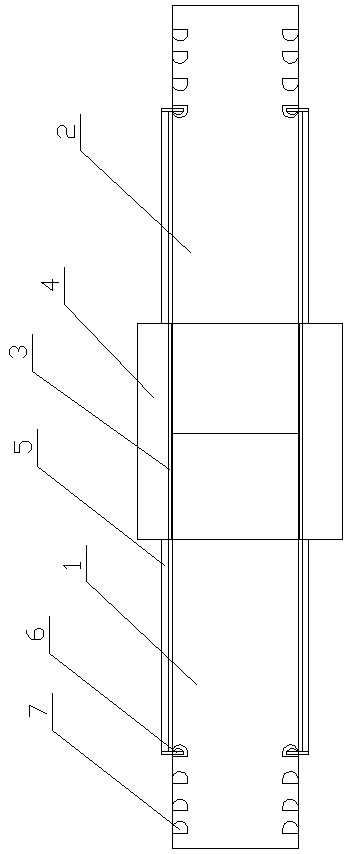

Cylinder shaping mechanism

InactiveCN102814362ASimplified molding stepsFast formingShaping toolsHollow articlesMetal sheetEngineering

The invention discloses a cylinder shaping mechanism, which is applicable to form a cylinder by extruding a metal sheet. The cylinder shaping mechanism comprises a frame, a driving mechanism, a convex die, a pair of concave dies and a pair of pushing mechanisms, wherein the cross section of the convex die is the same as that of the cylinder body, and the convex die is fixed on the frame; the pushing mechanism comprises a first connecting rod, a second connecting rod and a swing arm; one end of the first connecting rod is pivoted with one end of the swing arm, the swing arm is arranged in a horizontal manner and the middle part of the swing arm is pivoted to the frame; the other end of the swing arm is pivoted with one end of the second connecting rod, the concave dies are arranged at both sides of the convex die and provided with pivoting parts and rotating parts; the pivoting parts are pivoted on the frame and the rotating part are pivoted on the other end of the second connecting rod; the pushing mechanism can be driven by the driving mechanism simultaneously, so that the convex die can be coated by two concave dies; and therefore, the cylinder body is formed by extruding the metal sheet. By adopting the cylinder shaping mechanism, the shaping steps can be simplified and the producing efficiency is improved.

Owner:DONGGUAN JINGLI CAN

Packer

InactiveCN102337860BReduced risk of settingImprove reliabilitySealing/packingElastic componentLocking mechanism

The invention provides a packer which comprises a central tube as well as a locking mechanism, an actuating mechanism, a sealing mechanism and an anchor mechanism which are arranged outside the central tube, wherein the actuating mechanism enables the sealing mechanism and the anchor mechanism to act; the locking mechanism comprises a lock sleeve adjacent to the sealing mechanism, a locating component arranged outside the lock sleeve, a right-hand nut and a left-hand nut arranged inside the lock sleeve and spaced at an interval, and a right-hand thread section and a left-hand thread section arranged on the outer wall of the central tube and corresponding to the right-hand nut and the left-hand nut; a through hole is arranged on the wall, corresponding to the lock sleeve, of the central tube and a baffle is arranged outside the wall of the tube; the baffle and the inner wall surface of the lock sleeve are sealed and connected to form a cylinder bottom of a piston cavity; and the actuating mechanism comprises a piston arranged in the piston cavity and connected with the lock sleeve and an unpacking elastic component connected with the piston. The packer has the advantages that the prevention of midway setting and setting failure can be effectively realized, the working reliability is improved, the multi-time setting and unpacking in one string can be realized, the borehole operation procedure is simplified, the working efficiency is improved, and the cost is greatly saved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

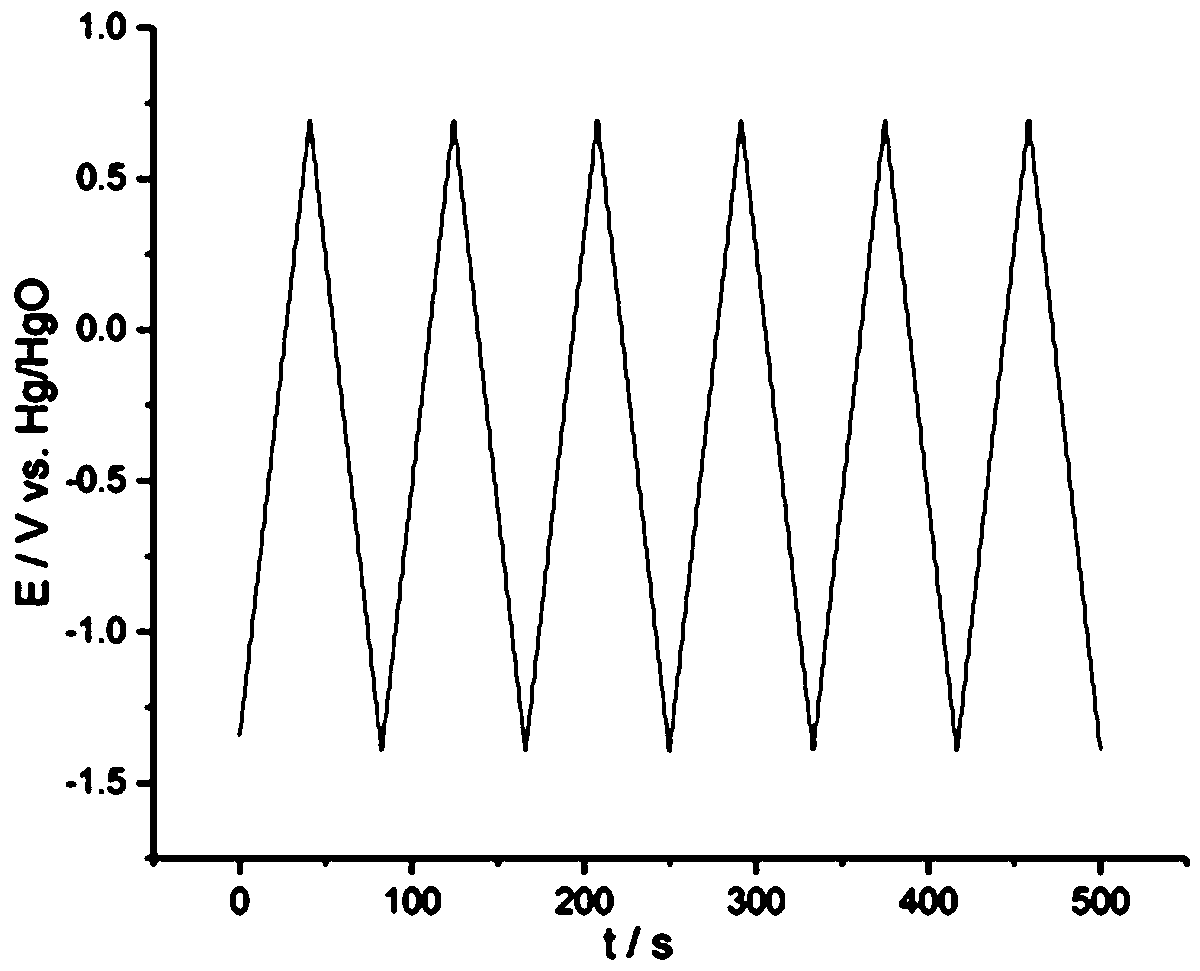

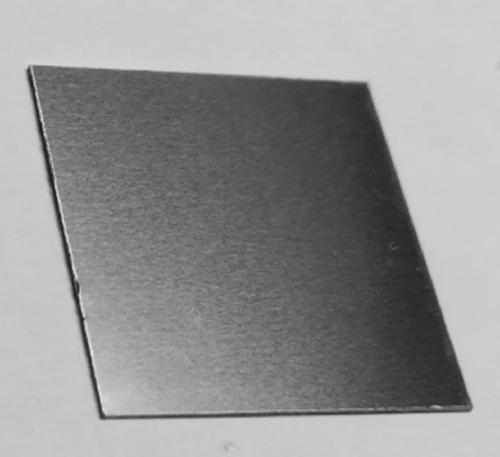

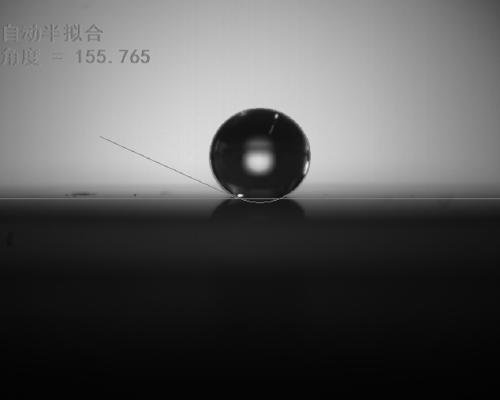

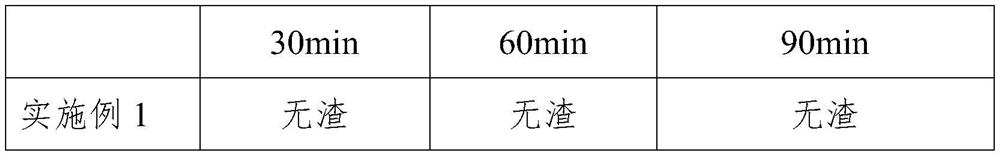

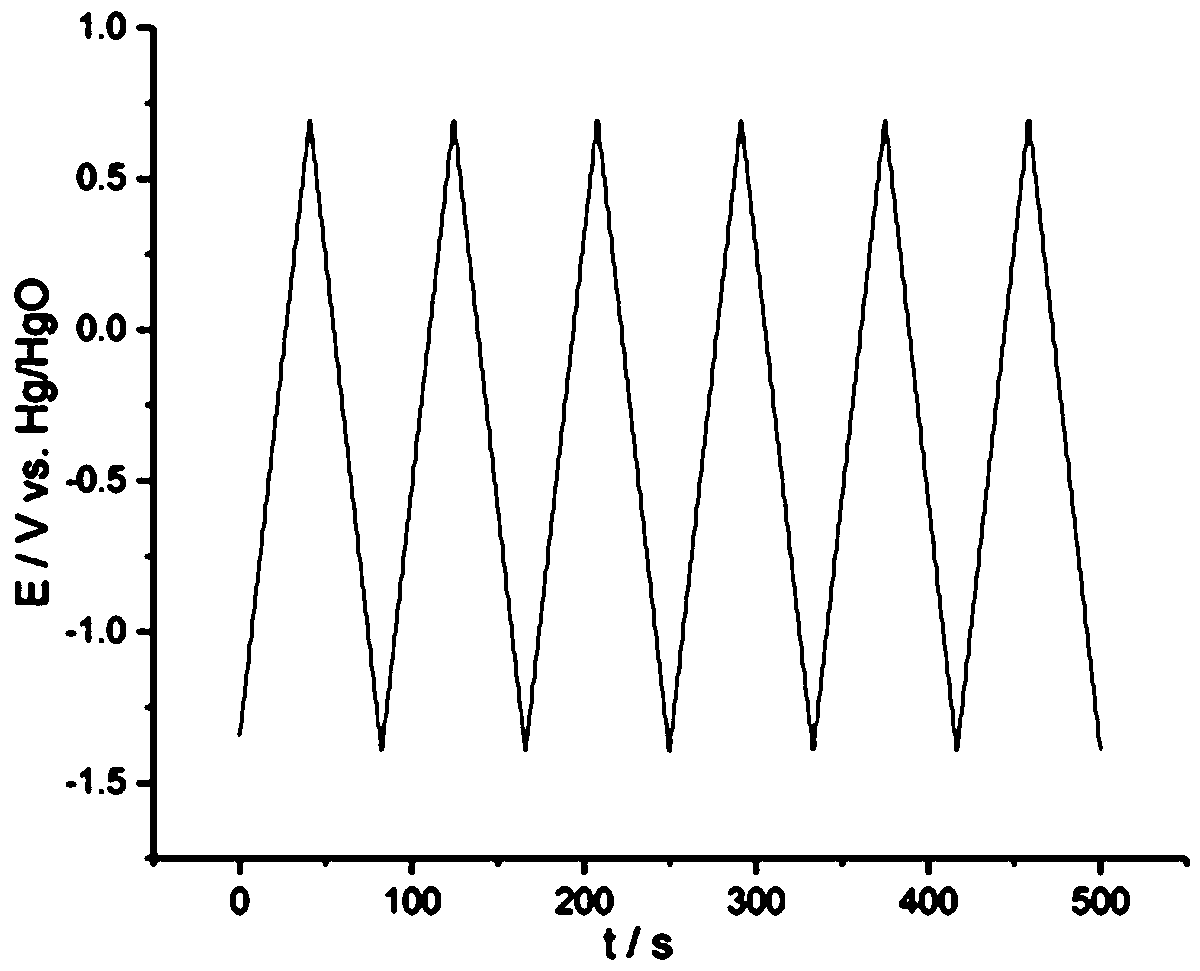

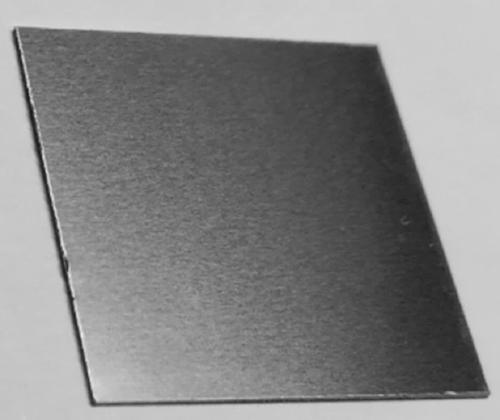

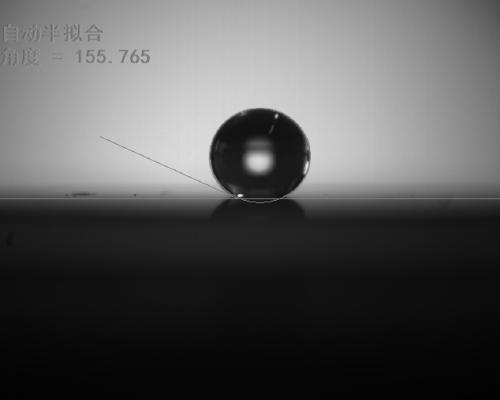

Method of preparing colored superhydrophobic stainless steel on basis of alkaline electrochemical colorant

The invention discloses a method of preparing colored superhydrophobic stainless steel on the basis of an alkaline electrochemical colorant. The method includes following steps: (1), cleaning the surface of stainless steel; (2), putting the stainless steel after being treated in the step (1) into alkaline coloring liquid, taking stainless steel as a working electrode and an inert electrode as a pair electrode to perform triangular wave potential coloring on the stainless steel at 50-60 DEG C, washing and dryinging after coloring is completed to obtain colored stainless steel different in color; (3), coating the surface of the colored stainless steel prepared in the step (2) with a nano silicon dioxide solution, airing, coating a long-chain silane solution, curing the colored stainless steel at 40-120 DEG C for 30-120min to obtain the colored superhydrophobic stainless steel with a transparent superhydrophobic layer. The colored superhydrophobic stainless steel prepared by the method isuniform and bright in color, high in wear resistance and corrosion resistance and lasting in colored antifouling ability.

Owner:HUBEI UNIV

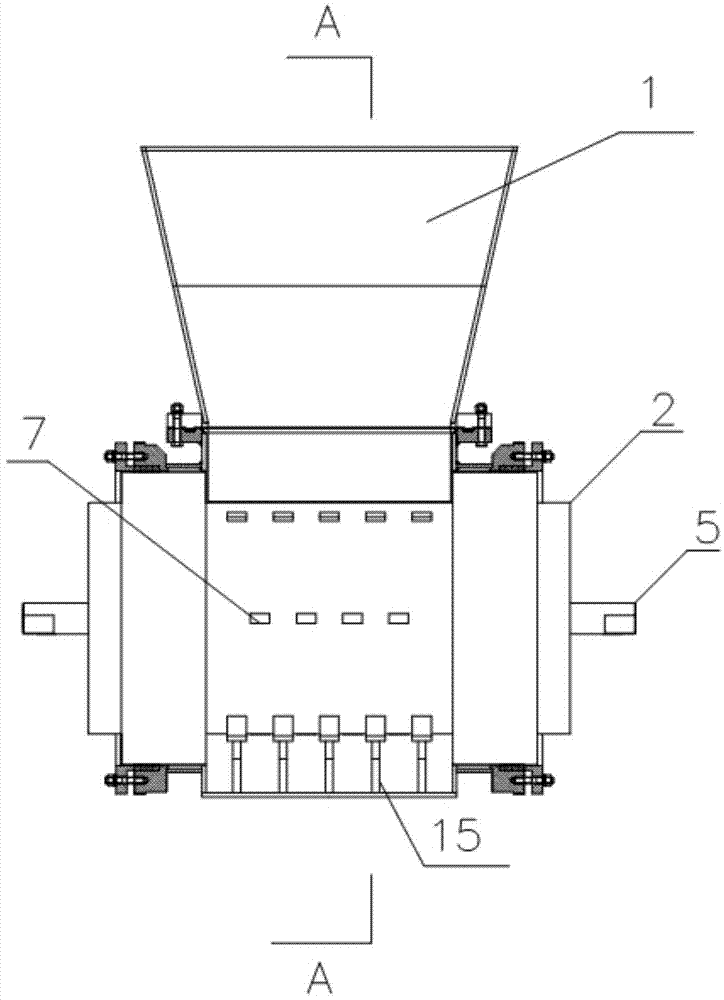

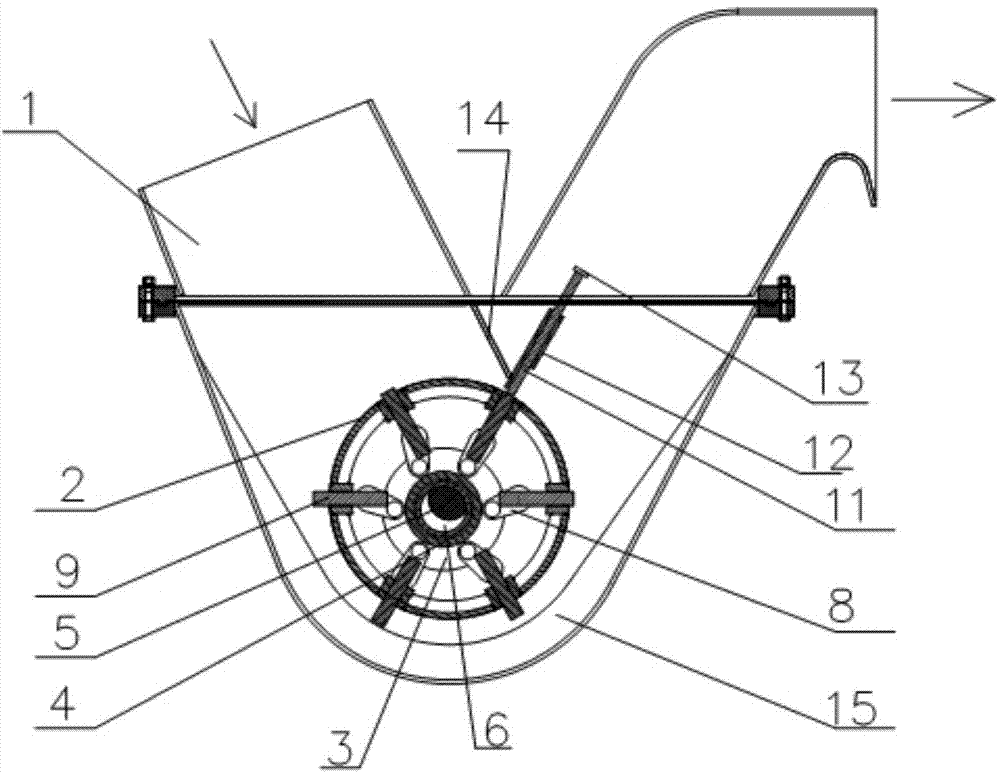

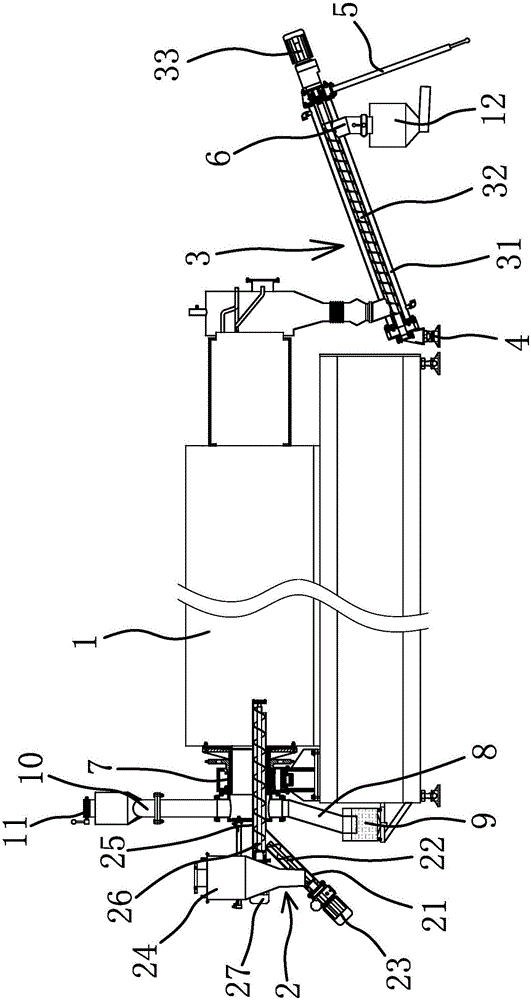

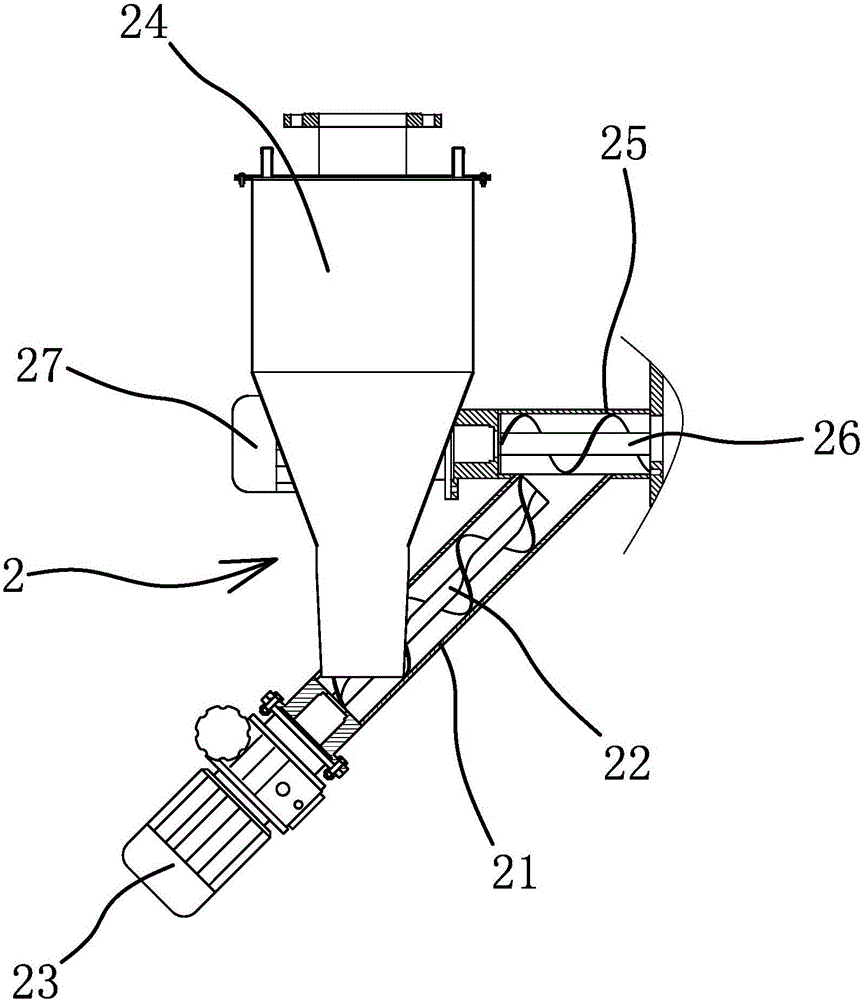

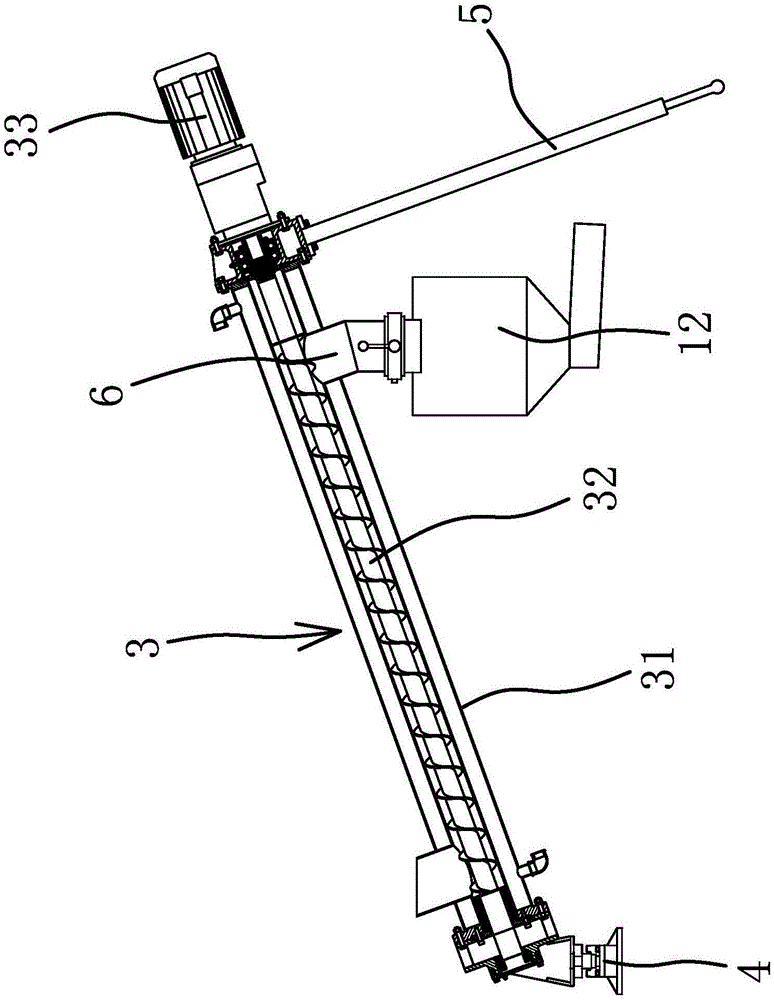

Cracking discharging process and equipment of junked tire

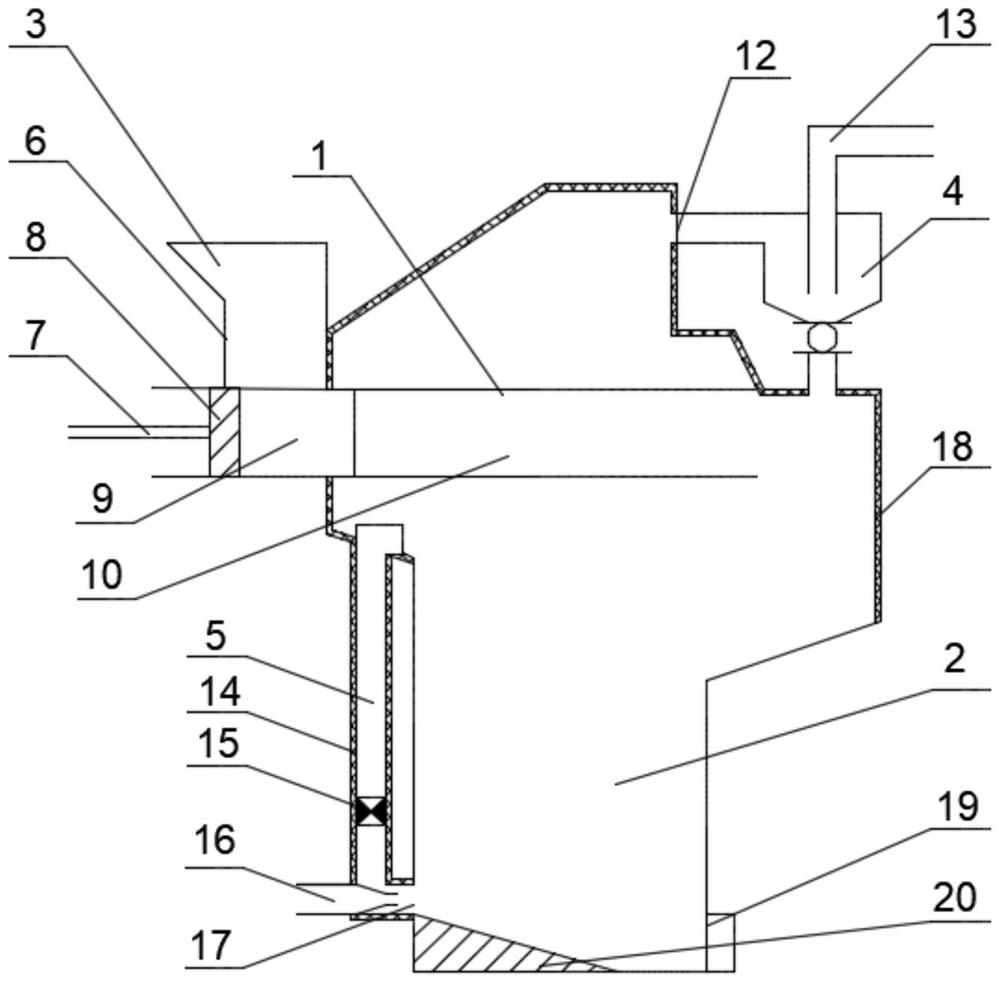

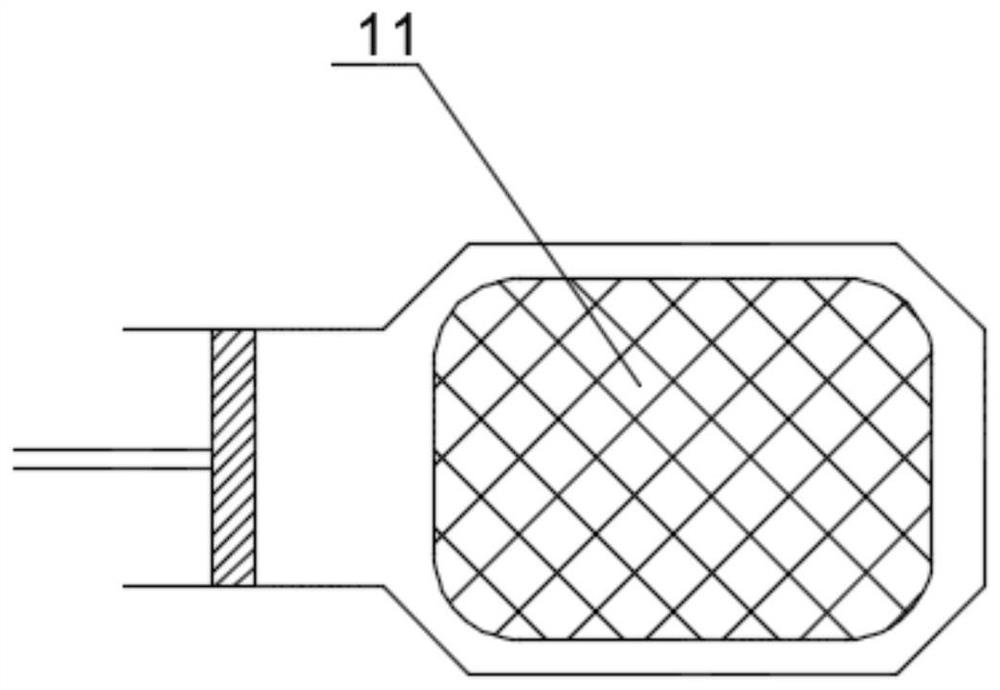

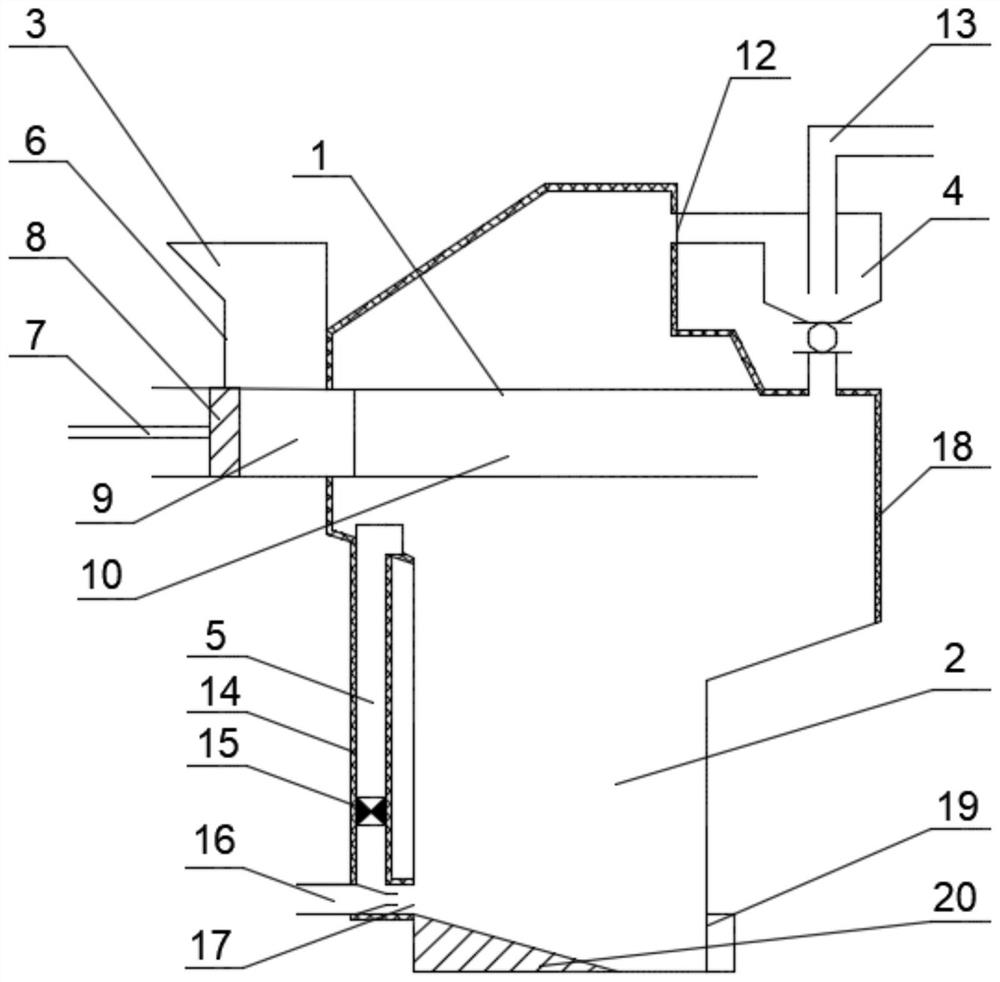

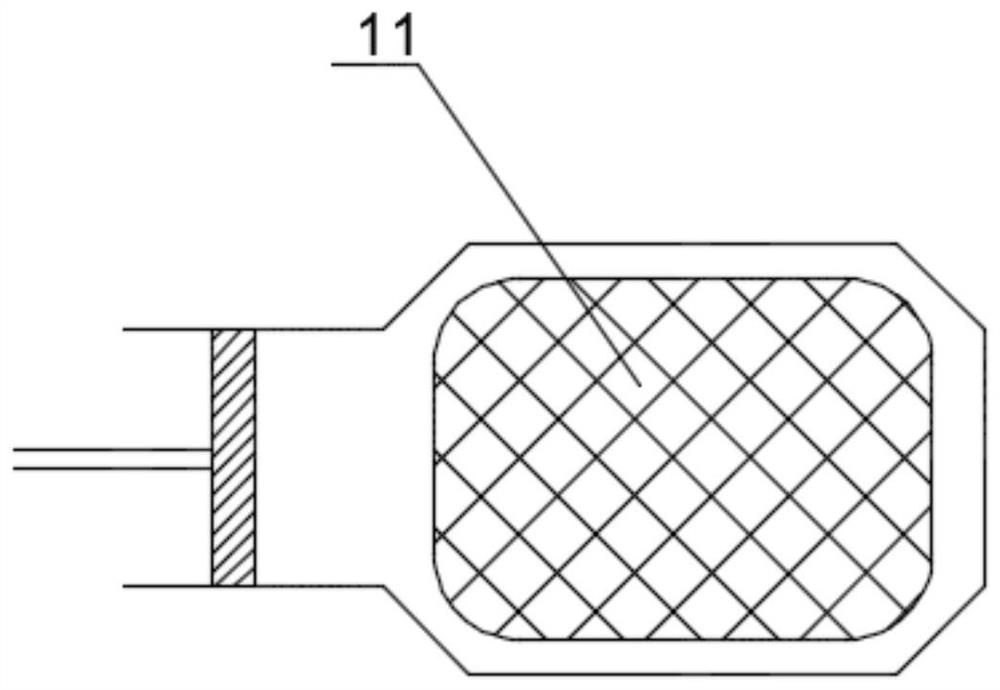

ActiveCN103695020AMaterial realizationPlay the role of sealingPigmenting treatmentLiquid hydrocarbon mixture productionChemical industryMechanical engineering

The invention relates to field of chemical industry, and particularly relates to cracking discharging process and equipment of a junked tire. The process mainly comprises the step as follows: discharging is finished under a sealing state after the overall junked tire is cracked. The equipment comprises a stock bin, wherein a discharge mechanism, a sealing device and a baffle plate are arranged inside the stock bin; the discharge mechanism sequentially comprises a drum, a turntable and an eccentric shaft from outside to inside; a rotating sleeve is arranged between the turntable and the eccentric shaft; the eccentric shaft is composed of a shaft I and a shaft II, which are integrated; the axis of the shaft I is arranged above the axis of the shaft II; the turntable is concentric with the shaft I; the turntable is sleeved at two ends of the shaft II and concentric with the shaft II; an open pore is formed on the drum; connecting rods are arranged on the turntable; an expansion link group movably embedded into the open pore is arranged between two connecting rods of the turntable; the bottom end of the baffle plate is connected with the sealing device; the sealing device and the baffle plate are arranged at the shortest part of the expansion link on an outer barrel. By adopting the interaction of the eccentric structure and the sealing structure, continuous cracking discharging of the overall tire under the sealing state is achieved, and a bran-new path is provided for cracking of the junked tire.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

A preparation method of magnesium alloy composite coating with self-healing function

ActiveCN105887084BCorrosion resistanceWith ceramic propertiesAnodisationVacuum evaporation coatingPlasma electrolytic oxidationMicro arc oxidation

A method for preparing a magnesium alloy composite coating with a self-repair function comprises the following steps that the surface of a magnesium alloy is polished, and oil removal and degreasing are carried out; an electrolyte is subjected to micro-arc oxidation, a current or voltage control method is adopted, the pulse power frequency and the duty ratio are adjusted, and the micro-arc oxidation time ranges from 15 min to 60 min; the magnesium alloy obtained after micro-arc oxidation is cleaned and dried and is put in a vacuum coating chamber with the pressure being (7-8)*10<-3> Pa and the temperature ranging from 100 DEG C to 200 DEG C, the pressure of argon is adjusted to range from 2 Pa to 3 Pa, the pulsed bias duty ratio ranges from 20% to 30%, the bias voltage ranges from 800 V to 1,000 V, and discharge cleaning is carried out for 2 min to 5 min; a pure aluminum or pure titanium target is adopted, and argon ion bombardment is finished till the pressure ranges from (3-5)*10<-1> Pa, the bias duty ratio ranges from 40% to 50%, and the bias voltage ranges from 500 V to 1,000 V; and the arc current ranges from 60 A to 120 A, and the coating time ranges from 10 min to 60 min. In the method, chromium, fluoride, phosphorus, heavy metal ions and other harmful substances are avoided, and the prepared magnesium alloy coating has corrosion resistance, good heat conductivity and self-repair performance.

Owner:GUANGDONG INST OF NEW MATERIALS

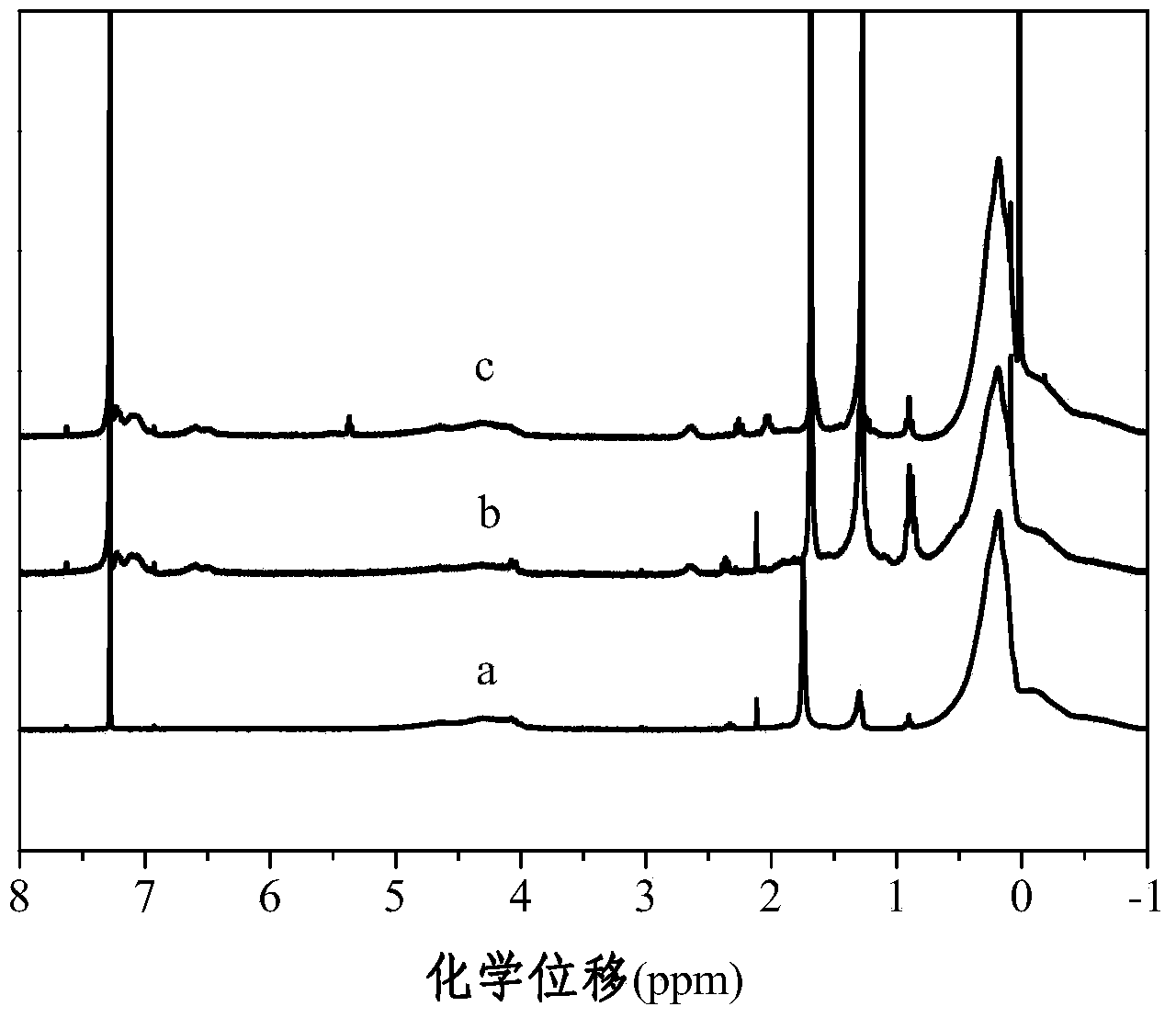

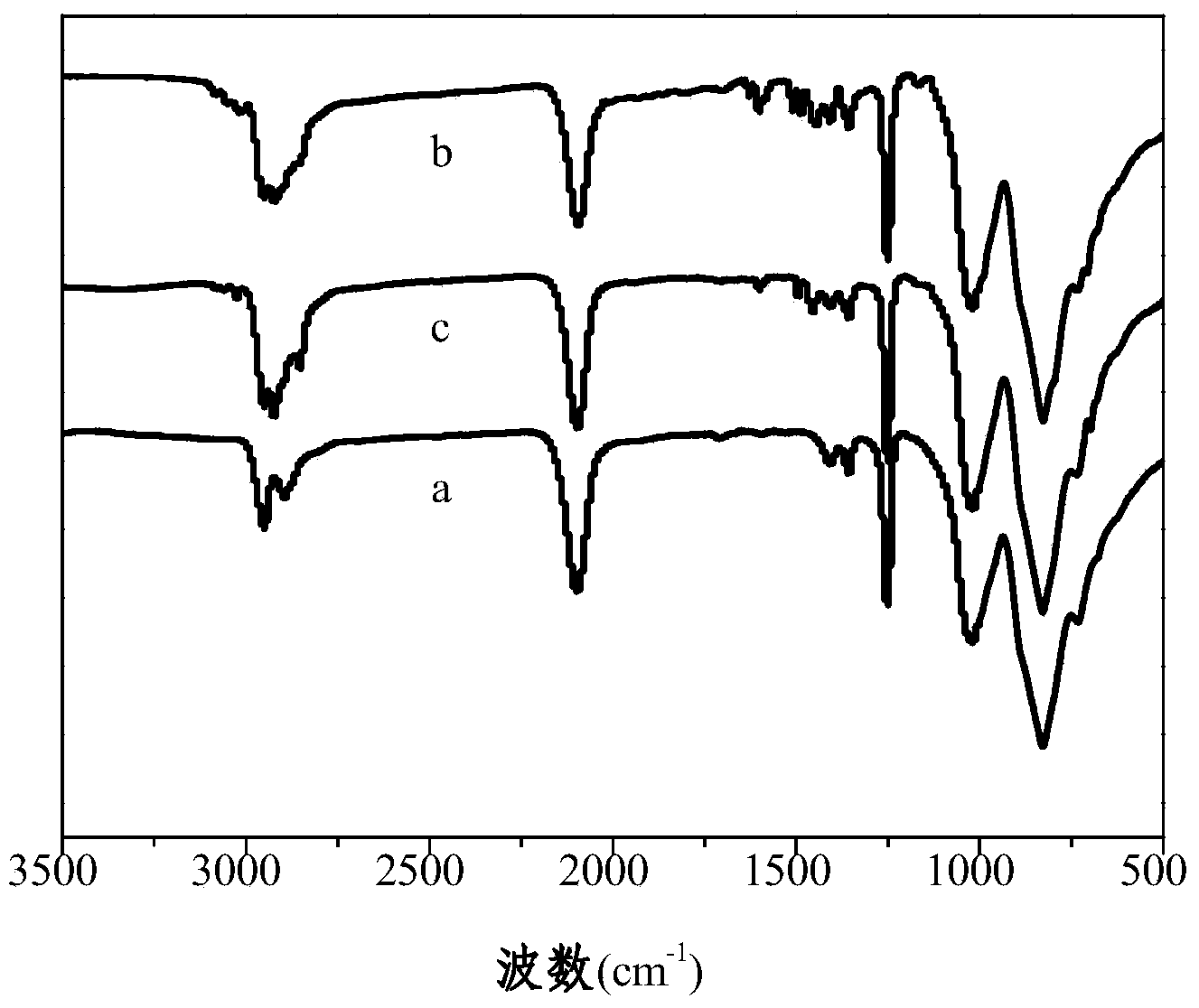

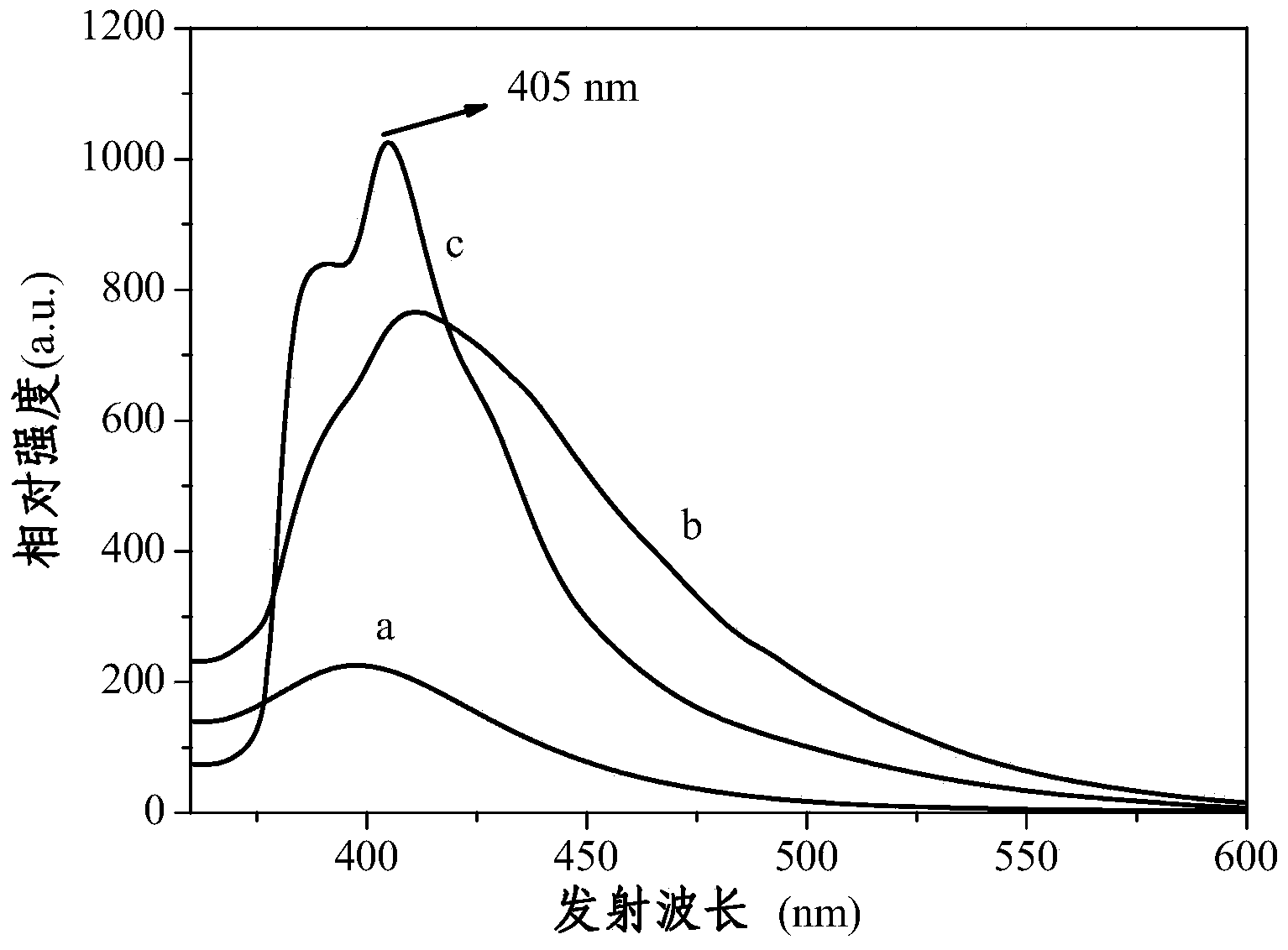

Side-chain aryl conjugated organic light-emitting material and preparation method thereof

InactiveCN104073247APlay the role of sealingImproves antioxidant crosslinkingLuminescent compositionsSide chainUltraviolet lights

The invention discloses a side-chain aryl conjugated organic light-emitting material and a preparation method thereof and relates to an organic light-emitting material. The preparation method comprises the steps of synthesizing polycarbosilane; removing polycarbosilane small molecule; and synthesizing side chain aryl conjugated polycarbosilane. The method specifically comprises the steps of reacting poly(dimethylsiloxane) as a raw material in a high pressure reaction kettle to obtain polycarbosilane, then defoaming polycarbosilane small molecules, and then reacting a small amount of aryl (Pn) organic matters and defoamed polycarbosilane to obtain the solid side-chain aryl conjugated polycarbosilane. The antioxidant crosslinking performance, anti-ultraviolet aging performance and thermal stability are improved. Although the reacted system has a conjugated structure, no rigid planar structure and is lack of an electron donating group, the reaction system still shows relatively strong luminescent performance. After a synthesized product is excited by ultraviolet light of which the wavelength is 350nm, the synthesized product has blue-violet light emission at 410nm, the emission purity is high, no miscellaneous peak is generated and good antioxidant crosslinking performance, anti-ultraviolet aging performance and thermal stability are achieved.

Owner:XIAMEN UNIV

Reaction type elastic polymer coating and preparation method thereof

InactiveCN108822715AAvoid stickinessIncreased polar end groupsPolyurea/polyurethane coatingsToluene diisocyanateDefoaming Agents

The invention discloses a reaction type elastic polymer coating and a preparation method thereof and belongs to the field of building waterproofing materials. The reaction type elastic polymer coatingcomprises a component A and a component B in a weight ratio being 1:1-1:2, wherein the component A comprises raw materials in parts by weight as follows: 30-50 parts of polyether 2000, 30-50 parts ofan asphalt prepolymer, 15-20 parts of a plasticizer, 10-20 parts of a compatilizer, 10-15 parts of toluene diisocyanate, 5-10 parts of hydroxyl-terminated liquid rubber, 2-7 parts of methylene diphenyl diisocyanate and 1-5 parts of a chain extender; the component B comprises raw materials in parts by weight as follows: 50-60 parts of inorganic powder, 25-30 parts of the plasticizer, 10-30 parts of the asphalt prepolymer, 3-8 parts of a curing agent A, 2-3 parts of a catalyst, 0.1-1 part of a defoaming agent, 0.1-1 part of a dispersing agent and 0.1-1 part of a wetting agent. The reaction typeelastic polymer coating has the advantages of being good in durability, good in water resistance, good in fatigue durability, high in adhesive strength and the like.

Owner:杰心(成都)环境科技有限公司

Method for preparing self-lubricating composite membrane layer on surface of titanium alloy drill rod through two-step method

InactiveCN108411348AImprove wear resistanceSimple process conditionsSurface reaction electrolytic coatingPretreated surfacesMicro arc oxidationEmulsion

Owner:SOUTHWEST PETROLEUM UNIV

Micro-arc oxidation electrolyte for preparing high-corrosion-resistance and high-wear-resistance coating on surface of magnesium alloy and preparation method and application of micro-arc oxidation electrolyte

InactiveCN112239880AReduce microcracksIncreasing the thicknessAnodisationMicro arc oxidationActive agent

The invention discloses a micro-arc oxidation electrolyte for preparing a high-corrosion-resistance and high-wear-resistance coating on the surface of a magnesium alloy and a preparation method and application of the micro-arc oxidation electrolyte. The electrolyte is formed by adding 0.5-50 g / L of additive zirconium silicate and 0.5-5 g / L of anionic surfactant sodium dodecyl benzene sulfonate onthe basis of one to three kinds in 1-50 g / L of sodium metaaluminate, 1-50 g / L of sodium silicate, 1-50 g / L of sodium phosphate and 0.5-20 g / L of one kind in sodium hydroxide and potassium hydroxide. ZrO2 and SiO2 decomposed from zirconium silicate in the micro-arc oxidation process provide a heterogeneous nucleation core for forming a ceramic coating, ZrO2 is used as a ceramic toughening phase, and formation of defects such as microcracks in a film layer can be reduced. Undecomposed zirconium silicate particles can also play a role in hole sealing, the thickness, density and hardness of a micro-arc oxidation film and the combination degree of the micro-arc oxidation film and a base body are increased, and therefore the corrosion resistance and wear resistance of the coating are greatly improved. In addition, compared with direct addition of ZrO2 and SiO2, the electrolyte taking zirconium silicate as the additive has the cost advantage of being low in cost.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

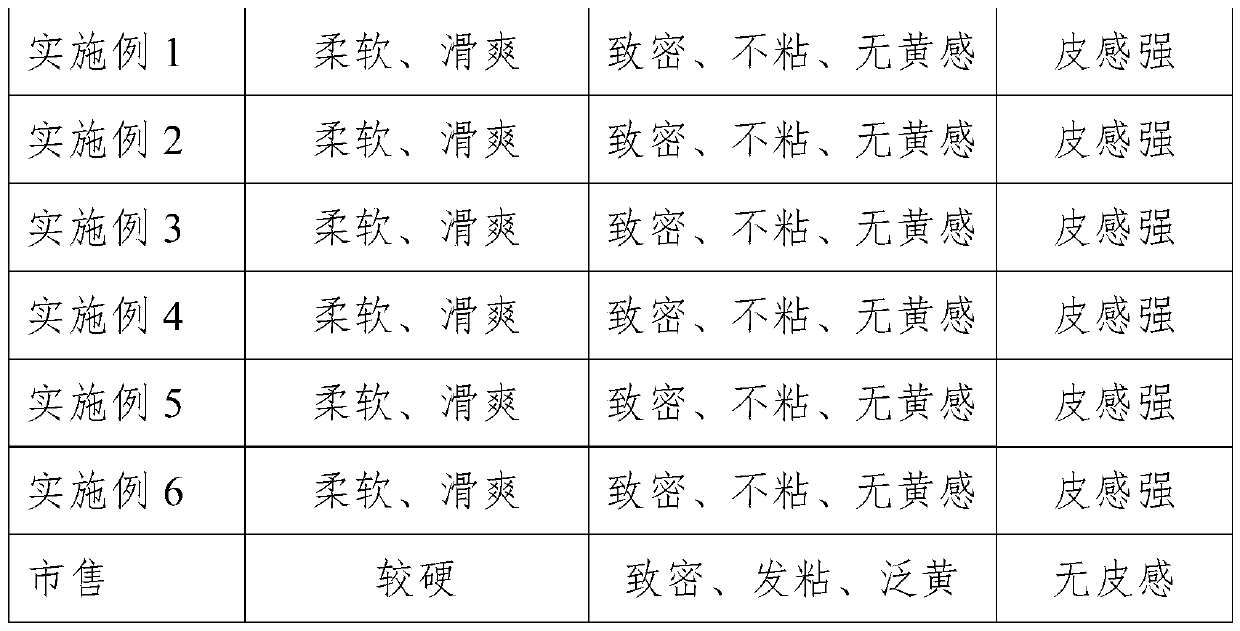

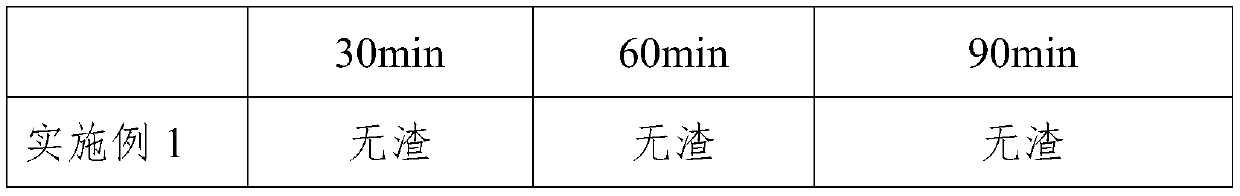

Acrylic finishing emulsion and preparation method thereof

ActiveCN111172759AStrong water resistanceStrong weather resistanceLight resistant fibresLiquid repellent fibresPolymer sciencePolymer chemistry

The invention relates to the technical field of fabric finishing, and discloses an acrylic finishing emulsion. The acrylic finishing emulsion comprises the following raw materials in parts by weight:15 to 35 parts of acrylic emulsion I, 55 to 80 parts of acrylic emulsion II, 3 to 5 parts of mechanical stabilizer, 1.5 to 3.5 parts of wetting dispersant reagent, and 0.1 to 0.2 parts of defoamer. Apreparation method of the acrylic finishing emulsion comprises the following steps of step (1), preparing the acrylic emulsion I; step (2), preparing the acrylic emulsion II; and step (3), preparing the acrylic finishing emulsion. The invention can prepare the finishing emulsion which makes the fabric hand feeling soft and the skin feel strong through the corresponding raw material ratios and thecorresponding preparation process.

Owner:成都德美精英化工有限公司

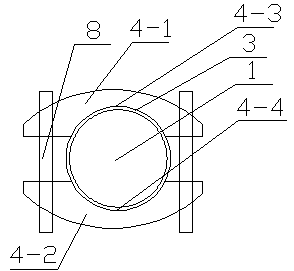

Sealing structure of screw kiln

The invention provides a sealing structure of a screw kiln, belongs to the technical field of machinery, and solves the problem of poor sealing effect of a conventional screw kiln. The screw kiln comprises a furnace tube. The sealing structure comprises a feeder and a discharger, wherein the feeder is arranged at a feed end of the furnace tube; the discharger is arranged at a discharge end of the furnace tube; a feed opening of the feeder is located below a discharge opening of the feeder in the vertical direction; the discharge opening of the feeder is fixedly connected with the feed end of the furnace tube in a sealing way; a feed opening of the discharger is located below a discharge opening of the discharger in the vertical direction; and the feed opening of the discharger is fixedly connected with the discharge end of the furnace tube. The sealing structure has the advantage of improving the effect of the screw kiln.

Owner:宜春天赐高新材料有限公司

Flexible connection device of air conditioner pipes

PendingCN110541988ASimple structureEasy to produceDucting arrangementsLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a flexible connection device of air conditioner pipes. The flexible connection device of the air conditioner pipes comprises a first pipe, a second pipe, a clamping sleeve anda fastening device. A through hole is formed in the clamping sleeve. The first pipe and the second pipe are inserted into the through hole of the clamping sleeve from the two ends of the clamping sleeve. The fastening device is clamped to the clamping sleeve. The two ends of the fastening device are provided with a plurality of elastic bands. One end of each elastic band is fixedly connected withthe fastening device, and the other end of each elastic band is provided with a clasp. Buckling grooves matched with the clasps are formed on the first pipe and the second pipe. The clasps are hookedinto the buckling grooves. The clamping sleeve is made of a flexible material. When the fastening device is clamped, the clamping sleeve clamps and fixes the first pipe and the second pipe, and the clamping sleeve seals the first pipe and the second pipe. The flexible connection device of the air conditioner pipes is reasonable and simple in structure, easy to produce and manufacture and convenient to use. The flexible connection device enables the air conditioner pipes to be flexibly connected, and the flexible connection device has great market application and popularization value.

Owner:江苏雪旺制冷科技有限公司

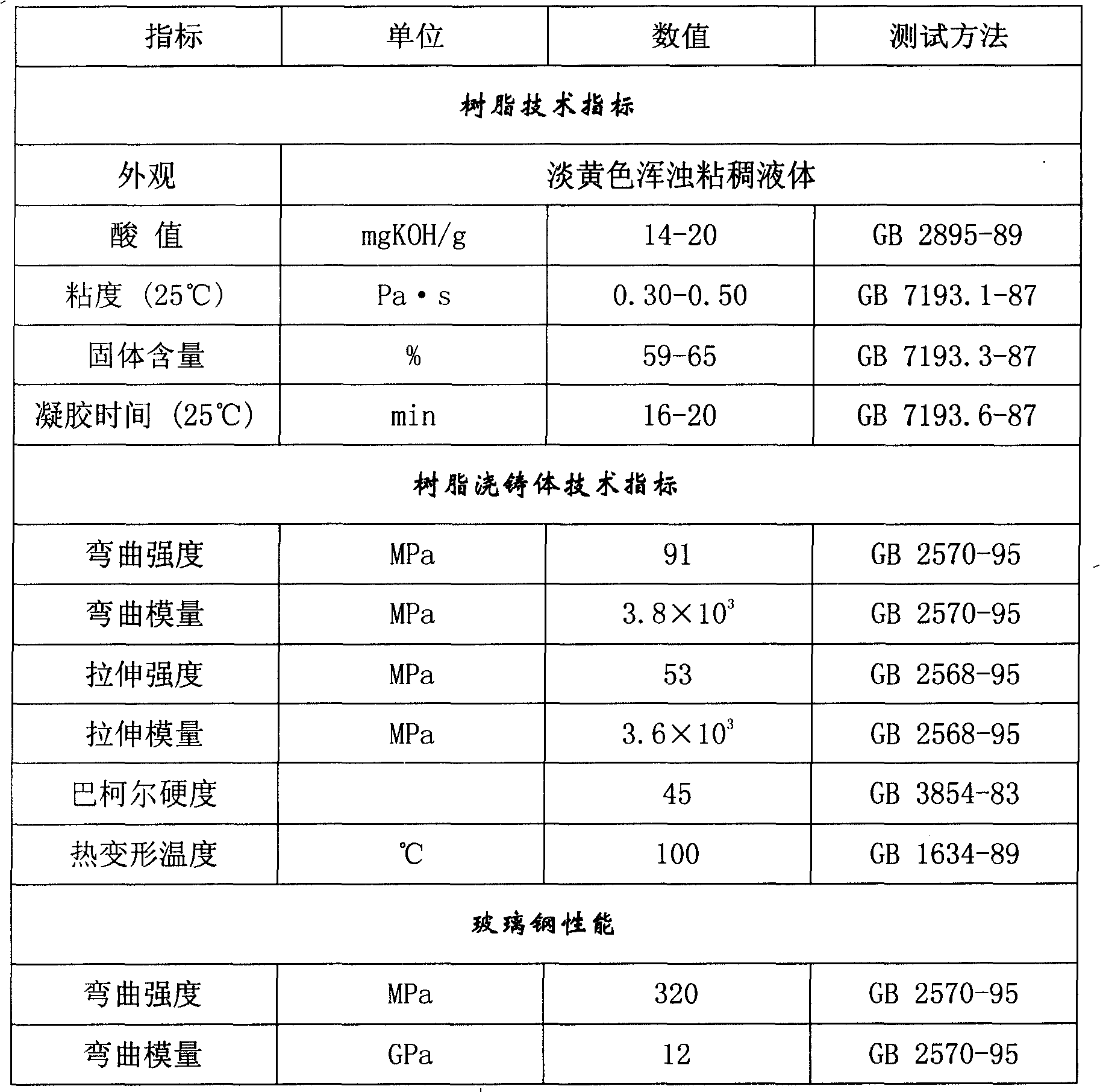

Process for producing terephthalic unsaturated polyester resin by using terephthalic acid rinsing residue

InactiveCN100453577CImprove utilization efficiencyOpen up new sourcesOrganic compound preparationCarboxylic compound preparationP-Aminobenzoic acidFibre-reinforced plastic

This invention is preparation of unsaturated polyester resin. The raw material is the terephthalic acid waste containing terephthalic acid 80%-90% and p-aminobenzoic acid 10%-20%. The procedure is as followings: add diatomic alcohol and catalytic composite into the terephthalic acid waste for polycondensation reaction. Add unsaturated diacid for further polycondensation. Add phenylethene for permutoid reaction. This invention's raw material is wasted washing water. The facility is the general ones for unsaturated polyester resin. The product has lower price, high quality, stability and environment-friendness. It could be used in a large scale of tube of glass fibre reinforced plastic, storage tank and instrument backing strip.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

Combined partial circulation biomass gasification furnace and working method thereof

The invention discloses a combined partial circulation biomass gasification furnace and a working method thereof, belonging to the technical field of biomass energy gasification and utilization. The feeding section of a horizontal furnace body is respectively connected with a feeding system and a drying and gasifying section; the drying and gasifying section is embedded into the inner middle upperpart of a vertical furnace body and is separated from the vertical furnace body through an upper partition plate and a lower partition plate respectively; an outlet of the drying and gasifying section communicates with the middle part of the vertical furnace body; vent holes are formed in the upper partition plate and the lower partition plate; a crude gas outlet is formed in the upper portion ofthe vertical furnace body and connected with a dust removal device; the dust removal device is connected with a combustible gas outlet pipe, and a solid outlet of the dust removal device communicateswith the middle part of the vertical furnace body; an air inlet is formed in one side of the bottom of the vertical furnace body, and an ash outlet is formed in the other side of the bottom of the vertical furnace body; a gasified gas circulating device is arranged outside the vertical furnace body; and an upper end inlet of the gasified gas circulating device communicates with the middle part ofthe vertical furnace body, and a lower end inlet of the vertical furnace body communicates with the air inlet. According to the invention, gasification efficiency can be improved, and meanwhile, a tar content in generated combustible gas is greatly reduced.

Owner:XI AN JIAOTONG UNIV

Method for preparing high-compactness zirconium oxide ceramic knife raw material powder

ActiveCN103332931BImprove density uniformityPlay the role of sealingCeramic knifeZirconium oxychloride

The invention discloses a method for preparing high-compactness zirconium oxide ceramic knife raw material powder. The powder comprises the following components in parts by molar ratio: 1 part of base material, 0.0001 to 0.5 part of dense agent and 0.0002 to 0.08 part of surfactant, wherein the base material is a composition of zirconium oxychloride and yttrium nitrate in the molar ratio of 97 to 3, the dense agent is a composition of calcium metaborate, magnesium chloride and liquid sodium silicate in the molar ratio of 1 to 0.05-1.3 to 0.2-1.9, and the surfactant is a composition of peregal and triethanolamine lauryl sulfate in the molar ratio of 1 to 2-5. The calcium metaborate, the magnesium chloride and the liquid sodium silicate are combined with the zirconium oxychloride and the yttrium nitrate to form a composite oxide, the effect of sealing a hole is achieved, and the density uniformity of a ceramic knife product is improved.

Owner:FUJIAN JOHNSON MINING

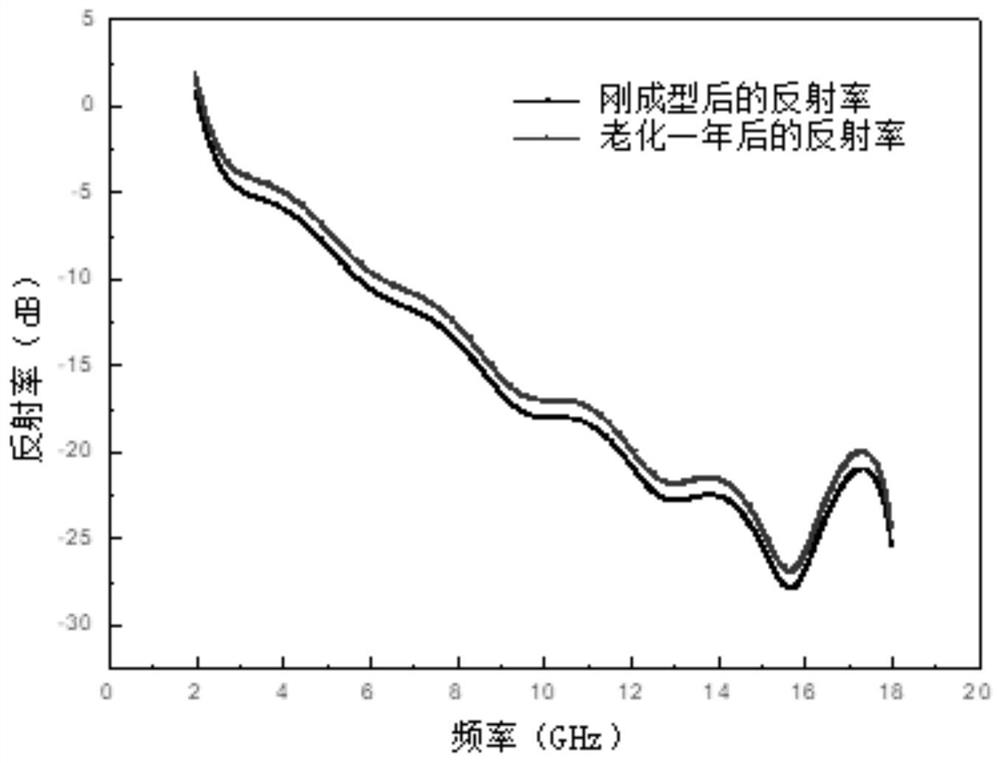

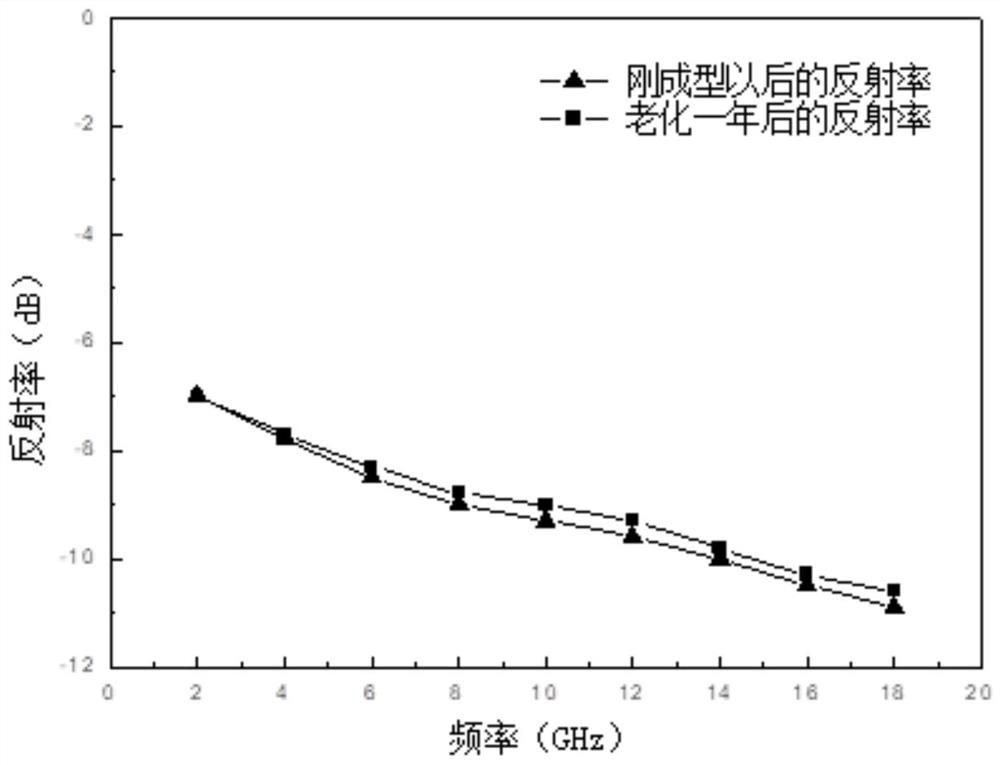

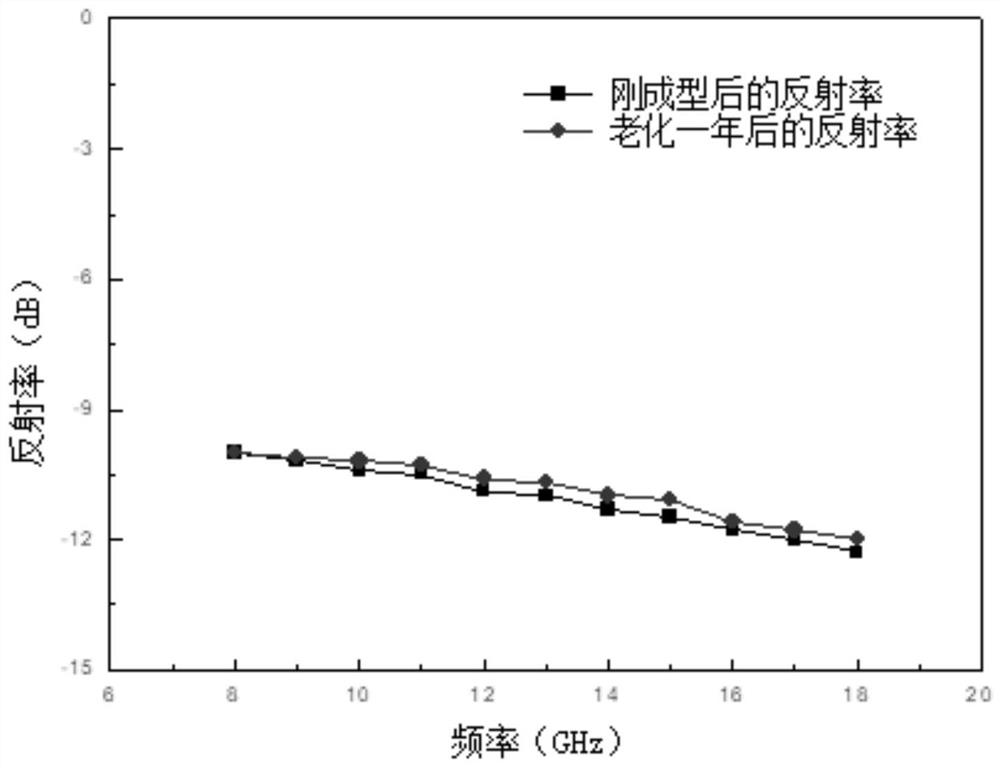

Wave-absorbing foam and preparation method thereof

ActiveCN114853422APlay the role of sealingBarrier contactSolid waste managementCeramicwarePolymer sciencePolymer resin

The invention discloses wave-absorbing foam, and belongs to the technical field of wave-absorbing materials. The wave-absorbing foam is prepared from the following materials in parts by mass: 50 parts of cement powder; 30 to 50 parts of water; 0.5 to 10 parts of a foam stabilizer; 0.5-10 parts of a foaming agent; 5-30 parts of polymer resin; 1-20 parts of a resin curing agent; and 5-100 parts of an electromagnetic wave absorbent. The invention also provides a preparation method of the wave-absorbing foam, which comprises the following steps: S1, weighing the resin curing agent and the water in proportion to obtain a mixture A; s2, weighing 1 / 3-1 / 2 mass fraction of the polymer resin and the electromagnetic wave absorbent to obtain a mixture B; s3, adding the mixture B into the mixture A to obtain a suspension C; s4, adding cement powder, a foam stabilizer, a foaming agent and the remaining parts by mass of polymer resin into the suspension C to obtain wave-absorbing foam slurry; and S5, pouring the wave-absorbing foam slurry into a mold to obtain the wave-absorbing foam block.

Owner:安徽璜峪电磁技术有限公司

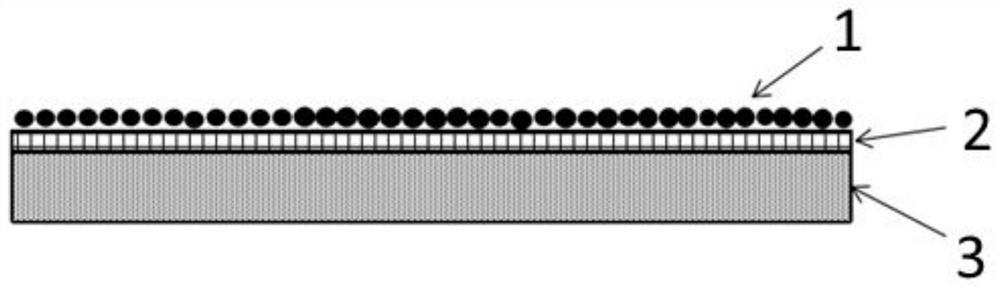

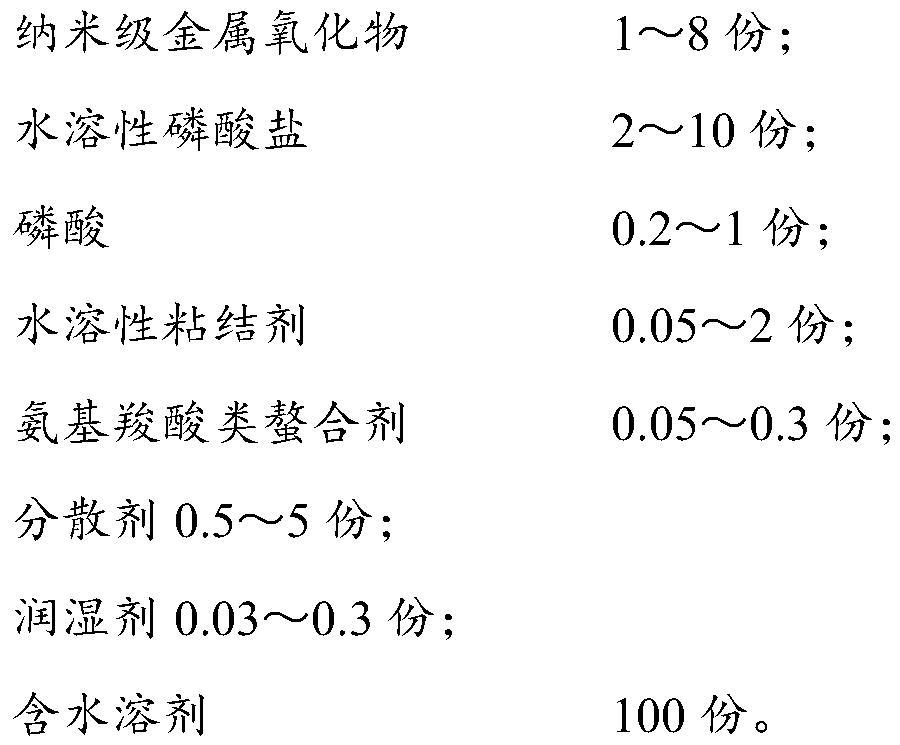

Environment-friendly coating with high corrosion resistance and preparation method thereof

ActiveCN113861729AImprove corrosion resistanceIncrease surface tensionAnti-corrosive paintsCorrosion resistantPhosphate

The invention discloses a high-corrosion-resistance environment-friendly coating and a preparation method thereof, and belongs to the field of coatings. The coating includes: nanoscale metal oxide, water-soluble phosphate, phosphoric acid, a water-soluble binder, an aminocarboxylic acid chelating agent, a dispersing agent, a wetting agent and a water-containing solvent; wherein the nanoscale metal oxide is a transition metal oxide or a rare earth metal oxide; the nanoscale metal oxide is dispersed in a water-containing solvent in the form of particles to form a homogeneous system; the water-containing solvent is a water-containing methanol solvent. On the basis of a phosphate system corrosion-resistant coating, the nano-scale metal oxide is uniformly dispersed in the coating, and the nano-scale metal oxide can be deposited in micropores or cracks of a phosphating film to achieve a hole sealing effect, so that the corrosion-resistant effect of a metal product on moisture and an acid medium is greatly improved.

Owner:新纶新能源材料(常州)有限公司

A combined partial circulation biomass gasifier and its working method

ActiveCN112111301BImprove gasification efficiencyPromote pyrolysisCombustible gas productionCombustible gasDust control

The invention discloses a combined partial circulation biomass gasification furnace and its working method, belonging to the technical field of biomass energy gasification utilization. The feeding section of the horizontal furnace body is respectively connected with the feeding system and the drying-gasification section; the drying-gasification section is embedded in the middle and upper part of the vertical furnace body and separated from the vertical furnace body by the upper partition and the lower partition respectively , the outlet of the drying-gasification section communicates with the middle of the vertical furnace body; the upper partition and the lower partition are provided with ventilation holes; the upper part of the vertical furnace body is provided with a crude gas outlet, which is connected to the dust removal device The combustible gas outlet pipe is connected, and the solid outlet of the dust removal device is connected to the middle of the vertical furnace body; one side of the bottom of the vertical furnace body is provided with an air inlet, and the other side is provided with an ash outlet; the gasification gas circulation device is installed in the vertical Outside the straight furnace body, the upper inlet of the gasification gas circulation device communicates with the middle of the vertical furnace body, and the lower inlet communicates with the air inlet. The gasification efficiency can be improved, and the tar content in the generated combustible gas can be greatly reduced.

Owner:陕西德润厚泽环境科技有限公司

A composite waterproof structure and preparation method

ActiveCN108859344BNo delaminationStrong chemical bondSynthetic resin layered productsLaminationPolymer modifiedStructural engineering

The invention discloses a composite waterproof structure and a preparation method thereof, and belongs to the field of building waterproof materials. The composite waterproof structure is prepared from a waterproof coil layer, a reaction type macromolecular elastic coating layer and a waterproof base layer in turn from top to bottom, wherein the waterproof coil layer is prepared from an upper surface layer and a self-sticking material layer in turn from top to bottom; the self-sticking layer is self-sticking polymer modified asphalt. According to the composite waterproof structure and the preparation method thereof disclosed by the invention, separation between the coating and the coil is avoided, and the waterproof effect is perfect.

Owner:四川省威盾新材料有限公司

A kind of acrylic finishing emulsion and preparation method thereof

ActiveCN111172759BStrong water resistanceStrong weather resistanceLight resistant fibresLiquid repellent fibresPolymer sciencePolymer chemistry

The invention relates to the technical field of fabric finishing, and discloses an acrylic finishing emulsion, comprising the following raw materials in parts by weight: 15-35 parts of acrylic emulsion, 55-80 parts of acrylic emulsion, 3-5 parts of mechanical stabilizer, wetting agent 1.5-3.5 parts of dispersant and 0.1-0.2 part of defoamer. A method for preparing an acrylic finishing emulsion, comprising the following steps: (1) preparing an acrylic emulsion 1; (2) preparing an acrylic emulsion 2; (3) preparing an acrylic finishing emulsion. The invention can prepare the finishing emulsion which can make the fabric feel soft and the skin feel strong through the corresponding raw material ratio and the corresponding preparation process.

Owner:成都德美精英化工有限公司

A method for preparing colored superhydrophobic stainless steel based on alkaline electrochemical coloring

The invention discloses a method of preparing colored superhydrophobic stainless steel on the basis of an alkaline electrochemical colorant. The method includes following steps: (1), cleaning the surface of stainless steel; (2), putting the stainless steel after being treated in the step (1) into alkaline coloring liquid, taking stainless steel as a working electrode and an inert electrode as a pair electrode to perform triangular wave potential coloring on the stainless steel at 50-60 DEG C, washing and dryinging after coloring is completed to obtain colored stainless steel different in color; (3), coating the surface of the colored stainless steel prepared in the step (2) with a nano silicon dioxide solution, airing, coating a long-chain silane solution, curing the colored stainless steel at 40-120 DEG C for 30-120min to obtain the colored superhydrophobic stainless steel with a transparent superhydrophobic layer. The colored superhydrophobic stainless steel prepared by the method isuniform and bright in color, high in wear resistance and corrosion resistance and lasting in colored antifouling ability.

Owner:合肥龙智机电科技有限公司

A kind of preparation method of titanium-nickel medical implant material

InactiveCN104087935BIsolationSolve the problem of difficult direct micro-arc oxidationSurface reaction electrolytic coatingSolid state diffusion coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a preparation method of a novel titanium-nickel medical implantation material, particularly a composite treatment method for preparing a titanium dioxide / aluminum oxide mixture by depositing titanium on a titanium-nickel surface and performing micro-arc oxidation. The method comprises the following steps: firstly, by using a titanium-nickel alloy base as a workpiece, eliminating the oxide film on the workpiece surface by a mechanical-chemical mixed method; secondly, depositing titanium on the workpiece surface by a plasma surface alloying technique; thirdly, carrying out micro-arc oxidation on the workpiece in a micro-arc oxidation device; and finally, carrying out ultrasonic cleaning on the workpiece, and drying to obtain the finished product. The material can effectively isolate the precipitation of the nickel element in the titanium-nickel alloy, and the ceramic film layer of the titanium base surface subjected to micro-arc oxidation has the advantages of fewer surface voids, high hardness, high corrosion resistance, favorable insulativity and high binding force with the base metal. The method has the characteristics of favorable technical repetitiveness, controllable quality and the like, is simple to operate, can be widely used for surface modification treatment of titanium-nickel alloys, and effectively improves the application range and level.

Owner:TAIYUAN UNIV OF TECH

A kind of activated carbon analysis tower and activated carbon analysis method

ActiveCN109174070BAvoid blockageAvoid Corrosion ConditionsOther chemical processesDispersed particle separationActivated carbonSpontaneous combustion

The invention provides a novel activated carbon desorption tower, the activated carbon desorption tower includes a heating section, a first transition section, a transition cooling section, a second transition section and a heat exchange cooling section arranged from top to bottom; the transition cooling section, the second transition section Sections together constitute a "buffer zone", so that the first transition section does not directly contact the heat exchange cooling section, avoiding a sharp drop in the temperature of the activated carbon in the desorption tower, thereby preventing the activated carbon from scaling on the unopened surface of the upper tube sheet in the cooling section, Prevent the clogging and corrosion of the desorption tower. At the same time, due to the setting of the "buffer zone", the situation of spontaneous combustion caused by the "bridge" activated carbon falling directly to the bottom of the desorption tower is avoided.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com