Micro-arc oxidation electrolyte for preparing high-corrosion-resistance and high-wear-resistance coating on surface of magnesium alloy and preparation method and application of micro-arc oxidation electrolyte

A technology of micro-arc oxidation and wear-resistant coating, which is applied in the field of electrolyte, can solve the problems of environmental pollution raw material prices, low corrosion resistance, and low porosity, and achieve low price, enhanced corrosion resistance and wear resistance, and reduced The effect of microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

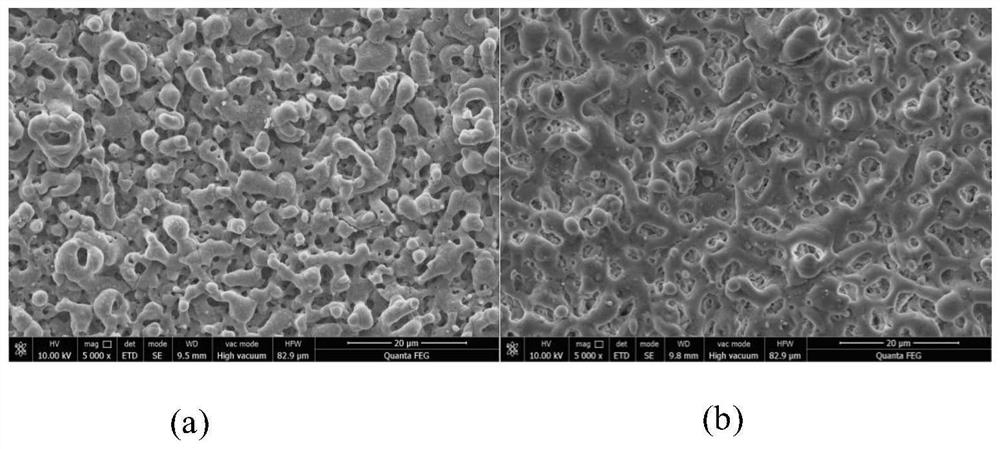

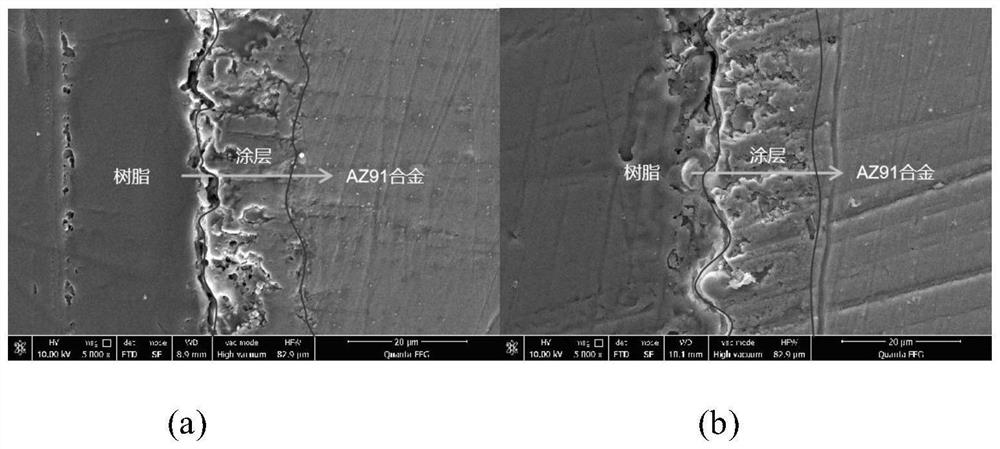

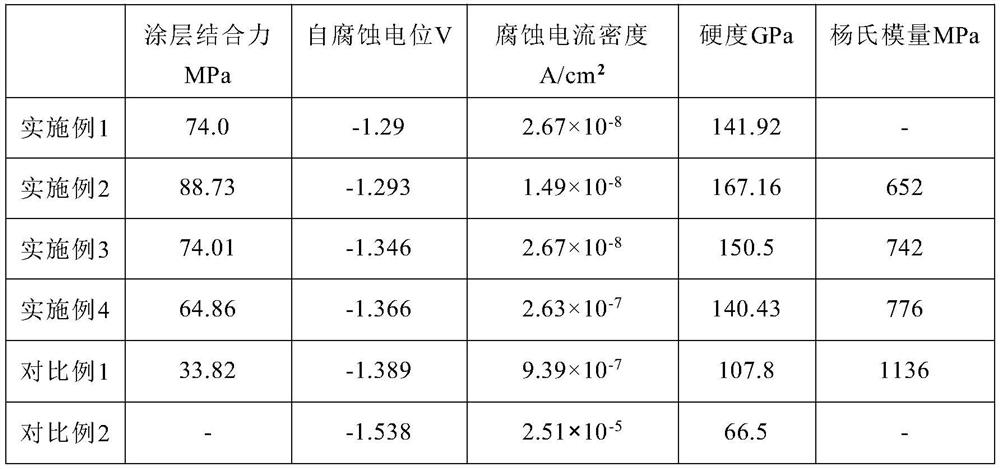

Image

Examples

Embodiment 1

[0018] 1) Pretreatment

[0019] The AZ91 alloy samples were sequentially polished with SiC sandpaper to remove the oxide skin on the surface until the surface of the samples was smooth and showed a bright metallic luster. Then place the sample in acetone and ultrasonically clean it for 10 min to remove oil and fine particles on the surface of the sample. Then rinse with absolute ethanol, and finally dry with cold wind to obtain the sample to be treated by micro-arc oxidation.

[0020] 2) Configure the electrolyte

[0021] Mix 2g / L sodium metaaluminate, 1g / L sodium silicate, 4g / L sodium phosphate, 6g / L sodium hydroxide with water to form an electrolyte, stir with a high-speed stirring device to keep the electrolyte uniform precipitation.

[0022] 3) Setting parameters

[0023] Prepared in constant voltage mode, positive voltage 400V, negative voltage 30V, current frequency 600Hz, positive duty ratio 30%, negative duty ratio 10%, processing time 10min, reaction temperature c...

Embodiment 2

[0029] 1) Pretreatment

[0030] The AZ91 alloy samples were sequentially polished with SiC sandpaper to remove the oxide skin on the surface until the surface of the samples was smooth and showed a bright metallic luster. Then place the sample in acetone and ultrasonically clean it for 10 min to remove oil and fine particles on the surface of the sample. Then rinse with absolute ethanol, and finally dry with cold wind to obtain the sample to be treated by micro-arc oxidation.

[0031] 2) Configure the electrolyte

[0032] Mix 1g / L sodium silicate, 4g / L sodium phosphate, 6g / L sodium hydroxide, 1g / L sodium dodecylbenzenesulfonate and 15g / L zirconium silicate with water to form an electrolyte, Stir with a high stirring device to keep the electrolyte even and free of precipitation.

[0033] 3) Setting parameters

[0034] Prepared in constant voltage mode, positive voltage 400V, negative voltage 30V, current frequency 600Hz, positive duty ratio 30%, negative duty ratio 10%, pro...

Embodiment 3

[0040] 1) Pretreatment

[0041] The AZ91 alloy samples were sequentially polished with SiC sandpaper to remove the oxide skin on the surface until the surface of the samples was smooth and showed a bright metallic luster. Then place the sample in acetone and ultrasonically clean it for 10 min to remove oil and fine particles on the surface of the sample. Then rinse with absolute ethanol, and finally dry with cold wind to obtain the sample to be treated by micro-arc oxidation.

[0042] 2) Configure the electrolyte

[0043] Mix 1g / L sodium silicate, 4g / L sodium phosphate, 6g / L sodium hydroxide, 1g / L sodium dodecylbenzenesulfonate and 25g / L zirconium silicate with water to form an electrolyte, Stir with a high stirring device to keep the electrolyte even and free of precipitation.

[0044] 3) Setting parameters

[0045] Prepared in constant voltage mode, positive voltage 400V, negative voltage 30V, current frequency 600Hz, positive duty ratio 30%, negative duty ratio 10%, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com