Glass reinforced solution and use thereof

A glass strengthening, solution technology, applied in the field of impact resistance solution, can solve the problems of long time, low impact resistance, glass surface cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Component content of glass strengthening solution: Potassium silicate 47.5wt% strengthening accelerator 5wt% water 47.5wt%.

[0036] Wherein the strengthening accelerator is a mixture of potassium hydroxide and potassium phosphate trihydrate, wherein potassium hydroxide is 3.84wt% of the strengthening accelerator, and potassium phosphate trihydrate is 96.16wt% of the strengthening accelerator;

[0037] The method of using the above glass strengthening solution to increase the glass strength: immerse the soda lime float glass initially strengthened by strengthening solution II, strengthening solution III and strengthening solution IV respectively in the above glass strengthening solution at a temperature of 60°C for 60 minutes, then wash and dry , that is.

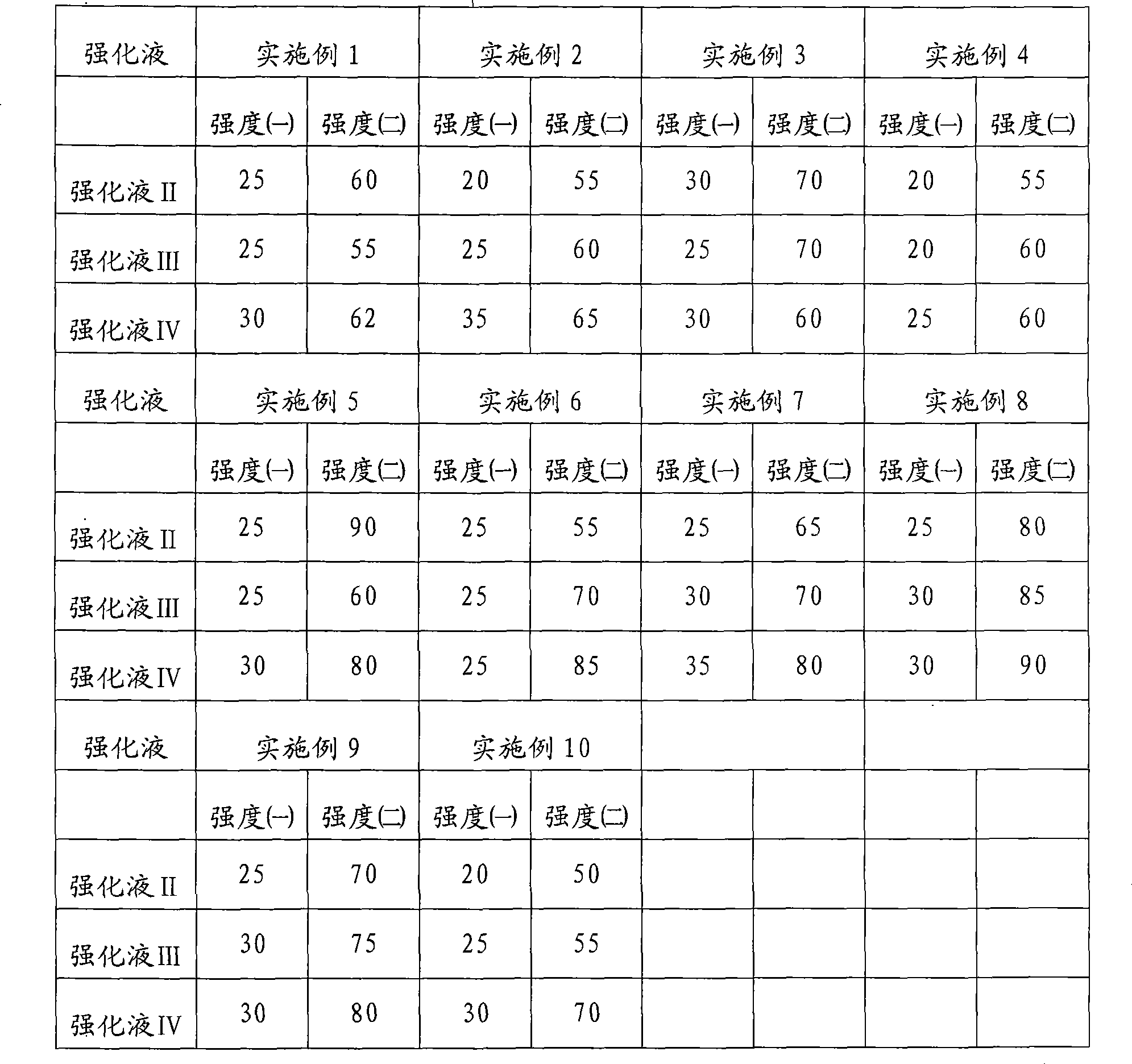

[0038] See Table 1 for the strength of the initially strengthened soda-lime float glass and the strength of the glass after further strengthening using the glass strengthening liquid of the present invention.

Embodiment 2

[0040] Component content of glass strengthening solution: Potassium silicate 10wt% strengthening accelerator 6wt% water 84wt%;

[0041] Wherein strengthening accelerator is potassium hydroxide;

[0042] The method of using the above glass strengthening solution to increase the glass strength: immerse the soda-lime float glass initially strengthened by strengthening solution II, strengthening solution III and strengthening solution IV respectively in the above glass strengthening solution at a temperature of 80°C for 100 minutes, then wash and dry , that is.

[0043] See Table 1 for the strength of the initially strengthened soda-lime float glass and the strength of the glass after further strengthening using the glass strengthening liquid of the present invention.

Embodiment 3

[0045] Component content of glass strengthening solution: Potassium silicate 70wt% strengthening accelerator 2wt% water 28wt%;

[0046] Wherein the strengthening accelerator is potassium phosphate trihydrate;

[0047] The method of using the above glass strengthening solution to increase the glass strength: immerse the soda lime float glass initially strengthened by strengthening solution II, strengthening solution III and strengthening solution IV respectively in the above glass strengthening solution at a temperature of 55°C for 80 minutes, then wash and dry , that is.

[0048] See Table 1 for the strength of the initially strengthened soda-lime float glass and the strength of the glass after further strengthening using the glass strengthening liquid of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com