Preparation method for graphene oxide modified polymer cement-based anti-corrosive paint

A graphene modification and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of difficult to meet the long-term anti-corrosion of coatings, insufficient anti-corrosion performance, reduced service life, etc., to optimize mechanical properties, prevent cracking, improve The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

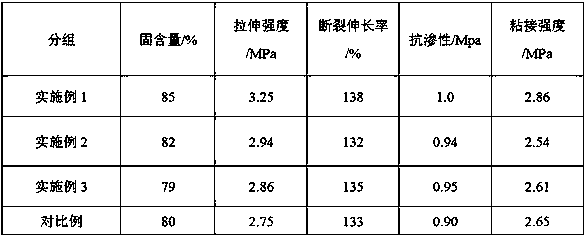

Examples

Embodiment 1

[0030] A preparation method for a graphene oxide modified polymer cement-based anticorrosion coating, comprising the following steps:

[0031] (1) Graphene oxide carboxylation

[0032] Add 15 parts of graphene oxide to 55 parts of 0.5 mol / L sodium hydroxide alkali solution, and ultrasonically disperse for 2 hours. Then add 8 parts of chloroacetic acid and ultrasonically disperse for 1-2h. Finally, the product was separated by suction filtration with a 0.22 μm PTFE filter membrane, and the filter cake was repeatedly centrifuged and washed to neutrality to remove impurities. The obtained product was dried under vacuum at 45 °C for 12 h to obtain a homogeneous carboxylated graphene oxide solution.

[0033] (2) Synthesis of graphene oxide modified polyacrylate emulsion

[0034] Stir 2 parts of anionic emulsifier, 2 parts of nonionic emulsifier, and 35 parts of deionized water evenly, then add 55 parts of acrylic monomer, and stir magnetically for 30 minutes to obtain a pre-emuls...

Embodiment 2

[0049] A preparation method for a graphene oxide modified polymer cement-based anticorrosion coating, comprising the following steps:

[0050] (1) Graphene oxide carboxylation

[0051] Add 20 parts of graphene oxide into 60 parts of 0.5 mol / L sodium hydroxide alkali solution, and ultrasonically disperse for 2 hours. Then add 10 parts of chloroacetic acid and ultrasonically disperse for 1-2h. Finally, the product was separated by suction filtration with a 0.22 μm PTFE filter membrane, and the filter cake was repeatedly centrifuged and washed to neutrality to remove impurities. The obtained product was dried under vacuum at 45 °C for 12 h to obtain a homogeneous carboxylated graphene oxide solution.

[0052] (2) Synthesis of graphene oxide modified polyacrylate emulsion

[0053] Stir 1 part of anionic emulsifier, 1 part of nonionic emulsifier, and 30 parts of deionized water evenly, then add 50 parts of acrylic monomer, and stir magnetically for 30 minutes to obtain a pre-emul...

Embodiment 3

[0068] A preparation method for a graphene oxide modified polymer cement-based anticorrosion coating, comprising the following steps:

[0069] (1) Graphene oxide carboxylation

[0070] Add 10 parts of graphene oxide into 50 parts of 0.5 mol / L sodium hydroxide alkali solution, and ultrasonically disperse for 2 hours. Then add 5 parts of chloroacetic acid and ultrasonically disperse for 1-2h. Finally, the product was separated by suction filtration with a 0.22 μm PTFE filter membrane, and the filter cake was repeatedly centrifuged and washed to neutrality to remove impurities. The obtained product was dried under vacuum at 45 °C for 12 h to obtain a homogeneous carboxylated graphene oxide solution.

[0071] (2) Synthesis of graphene oxide modified polyacrylate emulsion

[0072] Stir 3 parts of anionic emulsifier, 3 parts of nonionic emulsifier, and 35 parts of deionized water evenly, then add 60 parts of acrylic monomer, and stir magnetically for 30 minutes to obtain a pre-emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com