Acrylic finishing emulsion and preparation method thereof

An acrylic emulsion and acrylic technology, applied in fiber treatment, liquid-repelling fibers, light-resistant fibers, etc., can solve the problems of no imitation leather, hard fabric, no leather feeling effect, etc., to achieve improved compatibility, strong The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

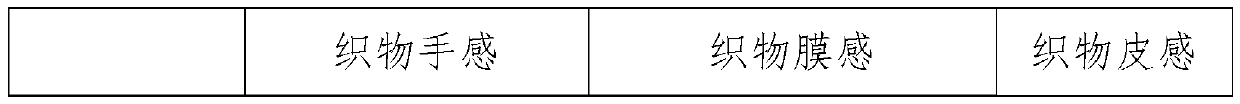

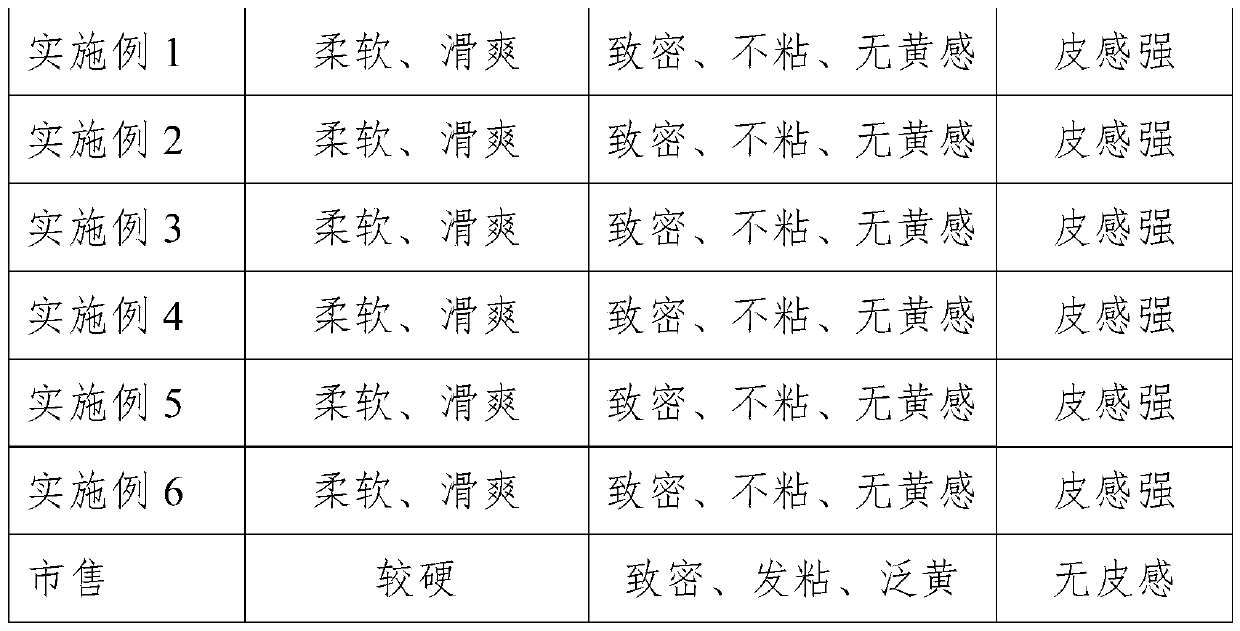

Examples

Embodiment 1

[0032]In this embodiment, an acrylic finishing emulsion includes the following raw materials in parts by weight: 15 parts of acrylic emulsion one, 80 parts of acrylic emulsion two, 3 parts of LF031 surfactant, 3.5 parts of D607 and 0.1 part of T301; the acrylic emulsion One includes the following raw materials in parts by weight: 40 parts of deionized water, 55 parts of methyl methacrylate, 1 part of 18 methacrylate, 3.5 parts of butyl acrylate, ammonium lauryl polyoxyethylene ether sulfate, isomeric alcohol Mix 0.3 parts of polyoxyethylene ether and sodium vinyl sulfonate, 0.8 parts of KPS and 0.2 parts of sodium bisulfite; the acrylic emulsion two includes the following raw materials in parts by weight: 40 parts of deionized water, 55 parts of butyl acrylate, 2 parts of polyether modified silicone oil, 4.5 parts of hydroxyethyl acrylate, 0.5 parts of ammonium lauryl polyoxyethylene ether sulfate, isomeric alcohol polyoxyethylene ether and sodium vinyl sulfonate, 0.4 parts of ...

Embodiment 2

[0038] In this embodiment, an acrylic finishing emulsion includes the following raw materials in parts by weight: 35 parts of acrylic emulsion one, 55 parts of acrylic emulsion two, 5 parts of LF131 surfactant, 1.5 parts of AD01 and 0.2 part of 012; the acrylic acid Emulsion 1 includes the following raw materials in parts by weight: 45 parts of deionized water, 48 parts of ethyl methacrylate, 3 parts of 20 methacrylate, 2 parts of ethyl acrylate, sodium dodecyl diphenyl ether disulfonate, fat Alcohol polyoxyethylene ether and allyloxy hydroxypropane sulfonic acid sodium salt mixed 0.5 part, APS 1 part and sodium metabisulfite 0.1 part; the acrylic emulsion II includes the following raw materials in parts by weight: 50 parts of deionized water, ethyl acrylate 40 parts, 3.5 parts of linear polydimethylsilicone oil, 2 parts of hydroxypropyl acrylate, sodium dodecyl diphenyl ether disulfonate, fatty alcohol polyoxyethylene ether and allyloxy hydroxypropane sulfonic acid sodium salt...

Embodiment 3

[0044] In this embodiment, an acrylic finishing emulsion includes the following raw materials in parts by weight: 25 parts of acrylic emulsion one, 60 parts of acrylic emulsion two, 4 parts of LF132 surfactant, 2 parts of D607 and 0.1 part of L012; Emulsion one includes the following raw materials in parts by weight: 42 parts of deionized water, 50 parts of styrene, 2 parts of 22 methacrylate, 3 parts of lauryl acrylate, sodium lauryl sulfate, fatty alcohol polyoxyethylene ether and vinyl Mix 0.4 parts of sodium sulfonate, 0.9 parts of tert-butyl hydroperoxide, and 0.2 parts of white block; the acrylic emulsion 2 includes the following raw materials in parts by weight: 45 parts of deionized water, 50 parts of lauryl acrylate, and 3 parts of hydroxyl silicone oil , 3 parts of acrylic acid, 0.6 parts of sodium lauryl sulfate, fatty alcohol polyoxyethylene ether and sodium vinyl sulfonate, 0.3 parts of hydroxyethyl methacrylate, 0.3 parts of tert-butyl hydroperoxide and 0.08 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com