High-performance environment-friendly water-based conductive antistatic coating and preparation method thereof

An anti-static coating, high-performance technology, used in conductive coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problem of unstable coating resistance, and achieve the effects of corrosion inhibition, fast conductivity, and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

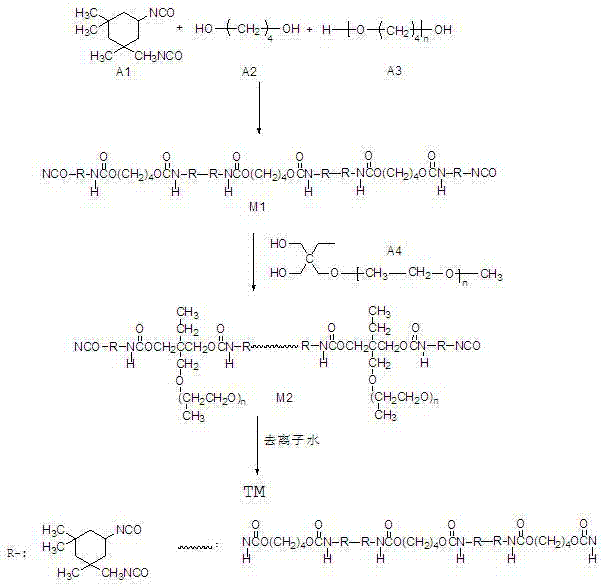

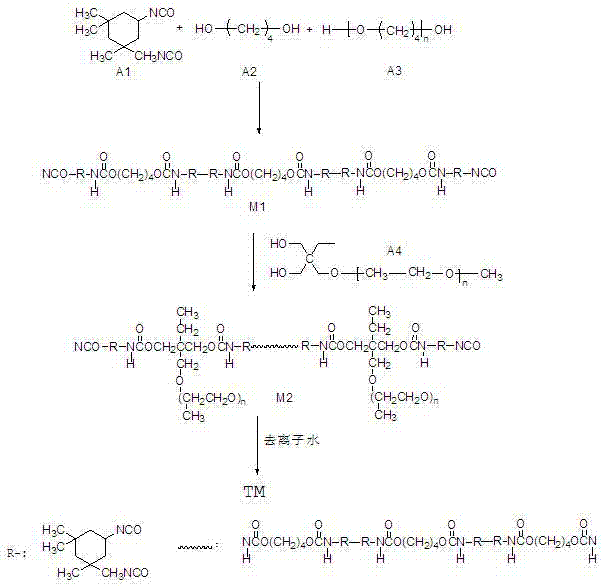

Method used

Image

Examples

Embodiment

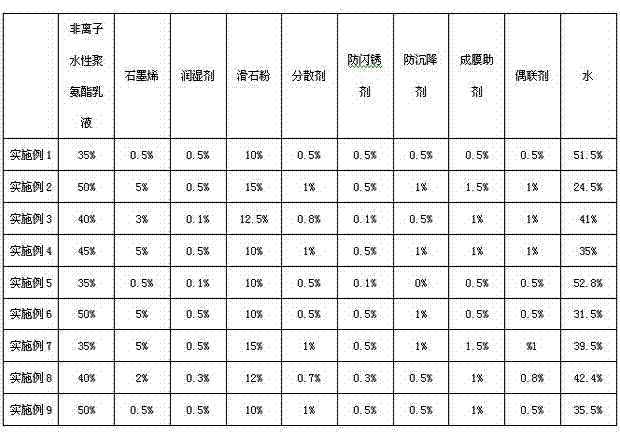

[0045] This embodiment provides a high-performance environmental protection water-based conductive antistatic coating, its raw materials and mass percentage content are as follows: non-ionic water-based polyurethane emulsion: 35-50%, graphene: 0.5%-5%, wetting agent: 0.1-0.5%, talcum powder: 10-15%, dispersant: 0.5-1%, anti-flash rust agent: 0.1-0.5%, anti-settling agent: 0.-1%, film-forming aid: 0.5-1.5% , Coupling agent: 0.5-1%, the rest is water.

[0046] Its preparation method is:

[0047] 1) Mix non-ionic water-based polyurethane emulsion with wetting agent, talcum powder, coupling agent and anti-flash rust agent in a disperser and stir at high speed for 0.5 hours to obtain a uniform system;

[0048] 2) Continue to add anti-sedimentation agent, talc powder and graphene to the above homogeneous system and shear at high speed for 1 hour, then move to a grinder and grind until the average particle size is less than 40 μm;

[0049] 3) Pour the ground slurry into the paint m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com