Process for producing terephthalic unsaturated polyester resin by using terephthalic acid rinsing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

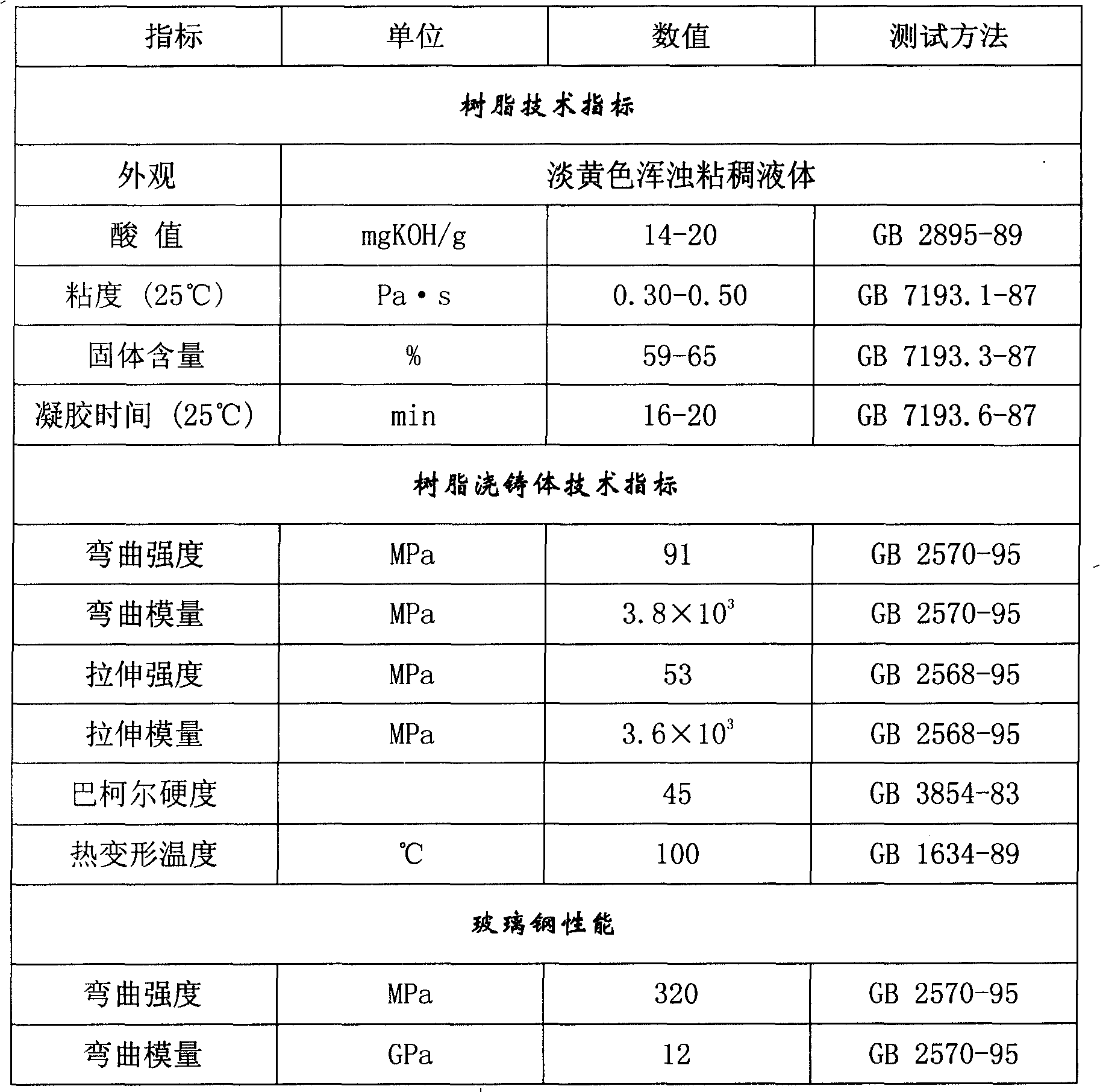

Image

Examples

Embodiment 1

[0028] In a four-necked flask with a thermometer, a stirrer, a nitrogen inlet pipe and a fractionation device, successively drop into 76g propylene glycol, 55g diethylene glycol, and 102g terephthalic acid washing residue (wherein the moisture content is 20%, and the phthalic acid Diformic acid 65g, p-toluic acid 16g), 0.4g composite catalyst (including 0.3g tetrabutyl titanate and 0.1g zinc acetate). When the nitrogen gas is fed, the temperature is gradually raised. When the temperature of the reactant is 130-140°C, water begins to distill out. Continue to raise the temperature, and control the temperature of the fractionation column to be lower than 105°C until the acid value is lower than 10mgKOH / g. Lower the material below 160°C and add 98g of maleic anhydride, gradually increase the temperature and control the temperature of the fractionation column to be lower than 105°C, when the acid value reaches below 60mgKOH / g, start vacuuming to force the water to evaporate until th...

Embodiment 2

[0030] With 37g ethylene glycol, 76g propylene glycol, 119g terephthalic acid washing residue (wherein water content 25%, terephthalic acid 76g, p-toluic acid 13g), 0.4g composite catalyst (comprising 0.3g tetrabutyl zirconate and 0.1g sodium acetate) into the device shown in embodiment 1, in subsequent steps, fumaric acid 116g, hydroquinone 0.05g, styrene 171g, operate by the same operating steps as in embodiment 1.

Embodiment 3

[0032] With 159g diethylene glycol, 156g neopentyl glycol, 200g terephthalic acid washing residue (wherein water content 30%, terephthalic acid 123g, p-toluic acid 17g), 0.6g composite catalyst (comprising 0.45 g tetrabutyl titanate and 0.15g manganese acetate) drop into the device shown in example 1, maleic dianhydride is changed into 196g in subsequent steps, hydroquinone is changed into 0.10g, styrene is changed into 350g, Operate in the same steps as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com