Sealing structure of screw kiln

A technology of sealing structure and spiral kiln, which is applied in the field of machinery, can solve the problems of poor sealing effect and lower product quality, and achieve the effect of improving quality, avoiding air entry, and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

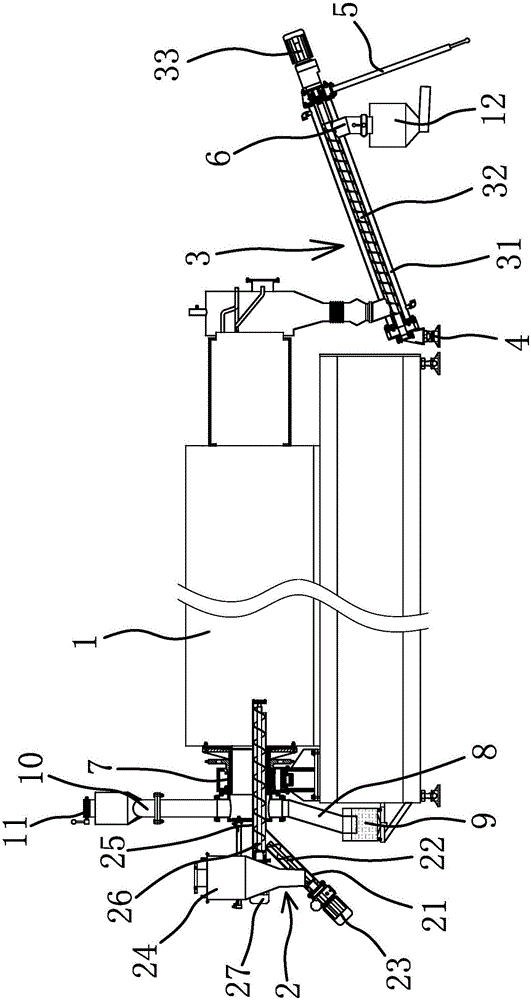

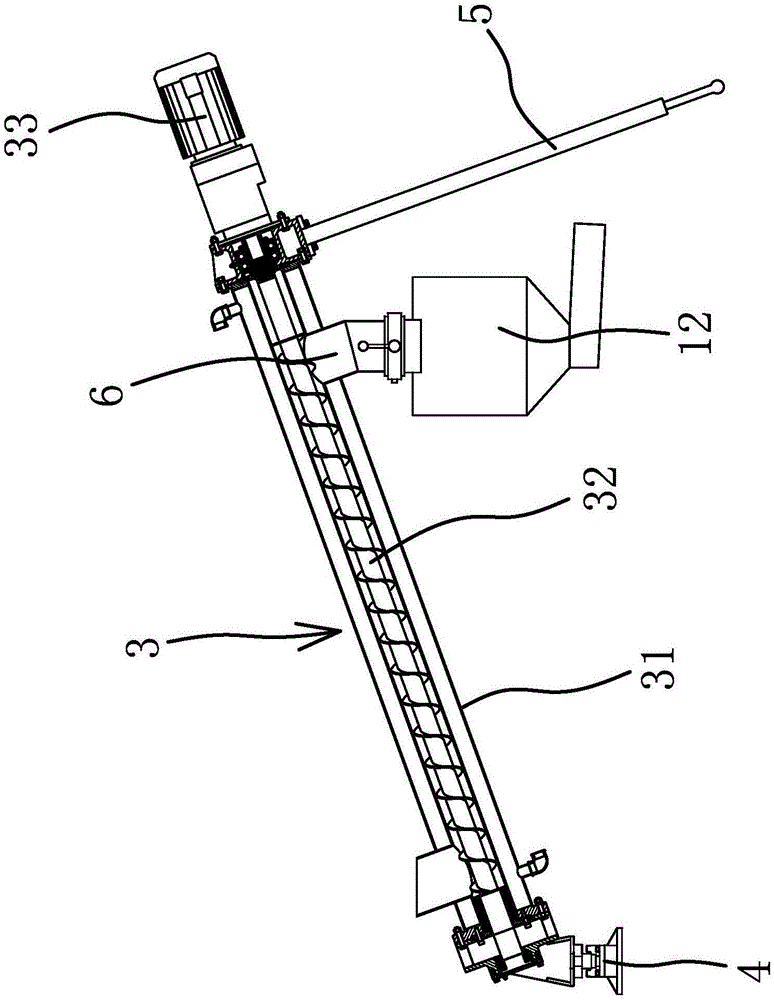

[0027] Such as figure 1 As shown, the spiral kiln includes a furnace tube 1, a feeder 2, a discharger 3 and a connecting cylinder 7. The feeder 2 is arranged at the feed end of the furnace tube 1, and the discharger 3 is arranged at the outlet of the furnace tube 1. At the material end, the feeder 2 and the discharger 3 are used as a sealing structure to seal the furnace tube 1, so that the two ends of the furnace tube 1 form a material seal.

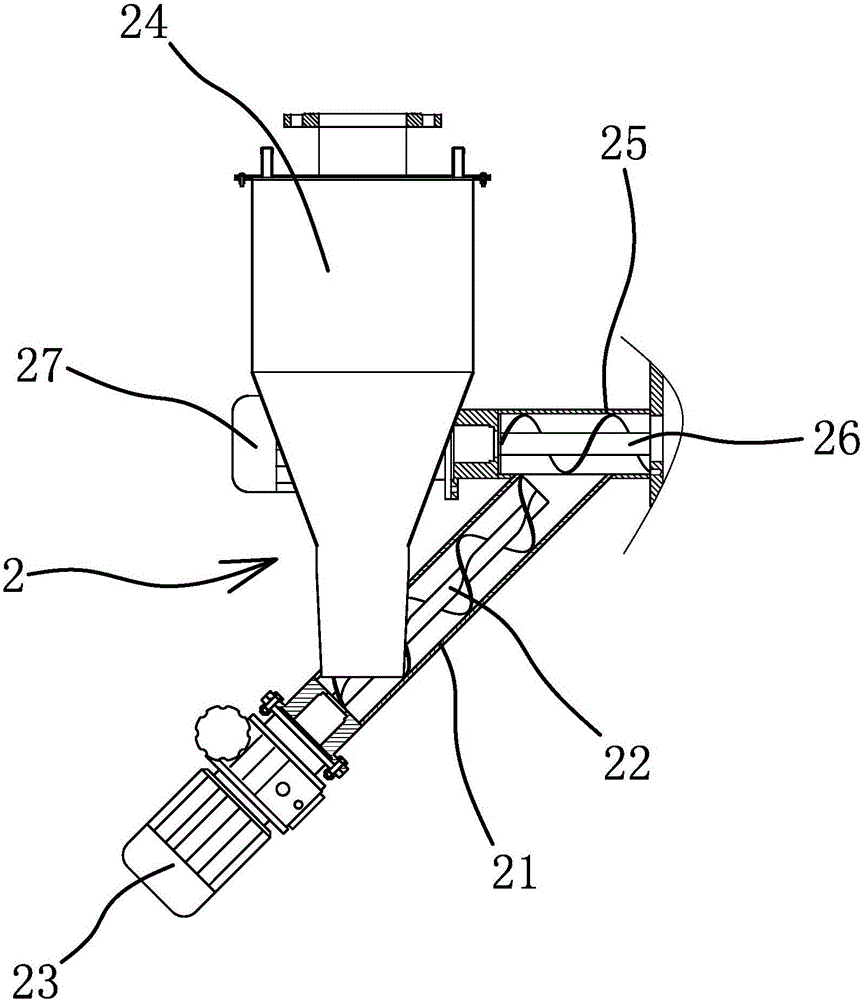

[0028] Such as figure 2 As shown, the feeder 2 includes a first conveying pipe 21 , a first screw rod 22 , a first driver 23 , a feeding bin 24 , a second conveying pipe 25 , a second screw rod 26 and a second driver 27 .

[0029] The first conveying pipe 21 is arranged obliquely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com