Packer

A technology of packer and sealing mechanism, which is used in sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problem of poor reliability of the locking function of the locking mechanism, low downhole operation efficiency, complicated operation, etc. problems, achieve high reliability, simplify downhole operations, and reduce risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

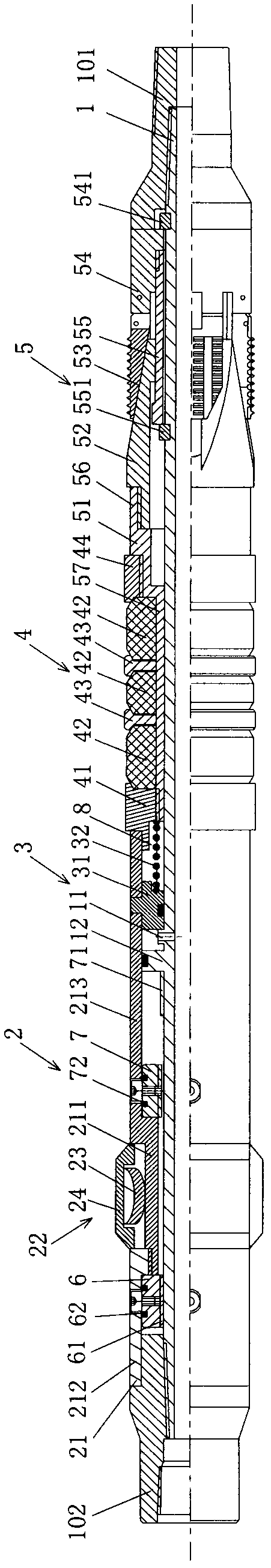

[0022] Such as figure 1 As shown, the present invention provides a packer such as by hydraulic setting, which is mainly used to seal the annulus of oil well casing, including: a center pipe 1 and a locking mechanism 2 arranged outside the center pipe 1, an actuator Mechanism 3, sealing mechanism 4 and anchoring mechanism 5, the actuator 3 makes the sealing mechanism 4 and the anchoring mechanism 5 act, the upper and lower ends of the center pipe 1 are respectively connected with the upper joint 101 and the lower joint 102, and the upper joint 101 is connected by the oil pipe. Drive the central tube 1 to rotate at the same time to complete the setting and unsealing actions; the improvement of the present invention is that the locking mechanism 2 includes a locking sleeve 21 adjacent to the sealing mechanism 4, a positioning assembly 22 located outside the locking sleeve 21, an installation The positive nut 6 and the reverse nut 7 which are separated by a certain distance inside...

Embodiment approach 2

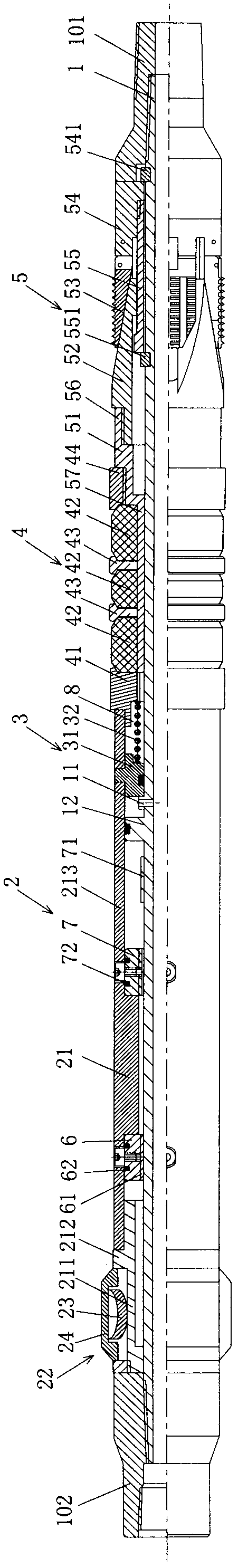

[0038] Such as figure 2 As shown, the principles, effects, specific implementation steps and processes of this implementation mode are consistent with those of the implementation mode 1, only slightly different in component arrangement and structure.

[0039] In this embodiment, the locking sleeve 21 of the locking mechanism 2 also includes an engaged lower locking sleeve 212 and an upper locking sleeve 213, the lower locking sleeve 212 is adjacent to the lower joint 102, the difference is: the upper locking sleeve Bolt holes are opened on 212, the positive nut 6 and the anti-nut 7 are installed on the upper lock sleeve 213, and the reduced diameter section 211 is formed on the lower lock sleeve 212, so that the positioning assembly 22 is moved to the lower joint 102 and connected with the lower joint 102 is adjacent to and located below the positive nut 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com