Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Permanent use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic machining method of difficult-to-cut material, fine-module internal gear and device

InactiveCN102896383AIncrease feed rateImprove processing efficiencyMachining electrodesElectrical-based machining electrodesElectrolytic agentEngineering

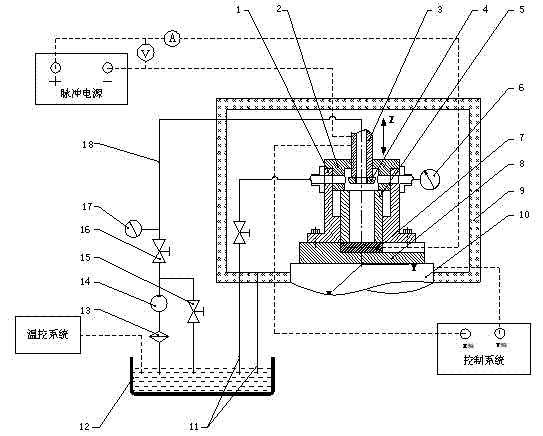

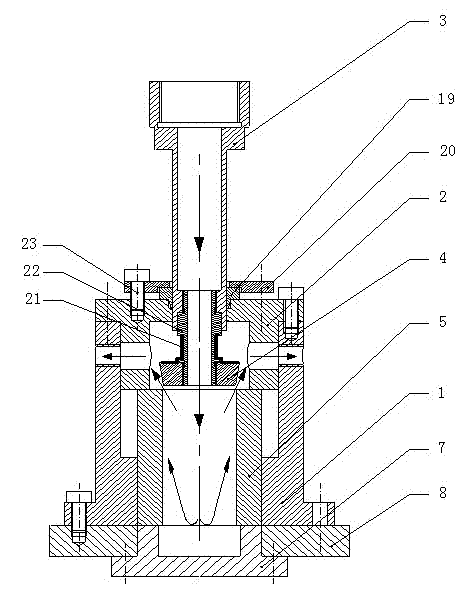

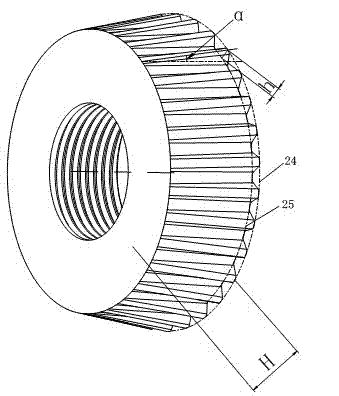

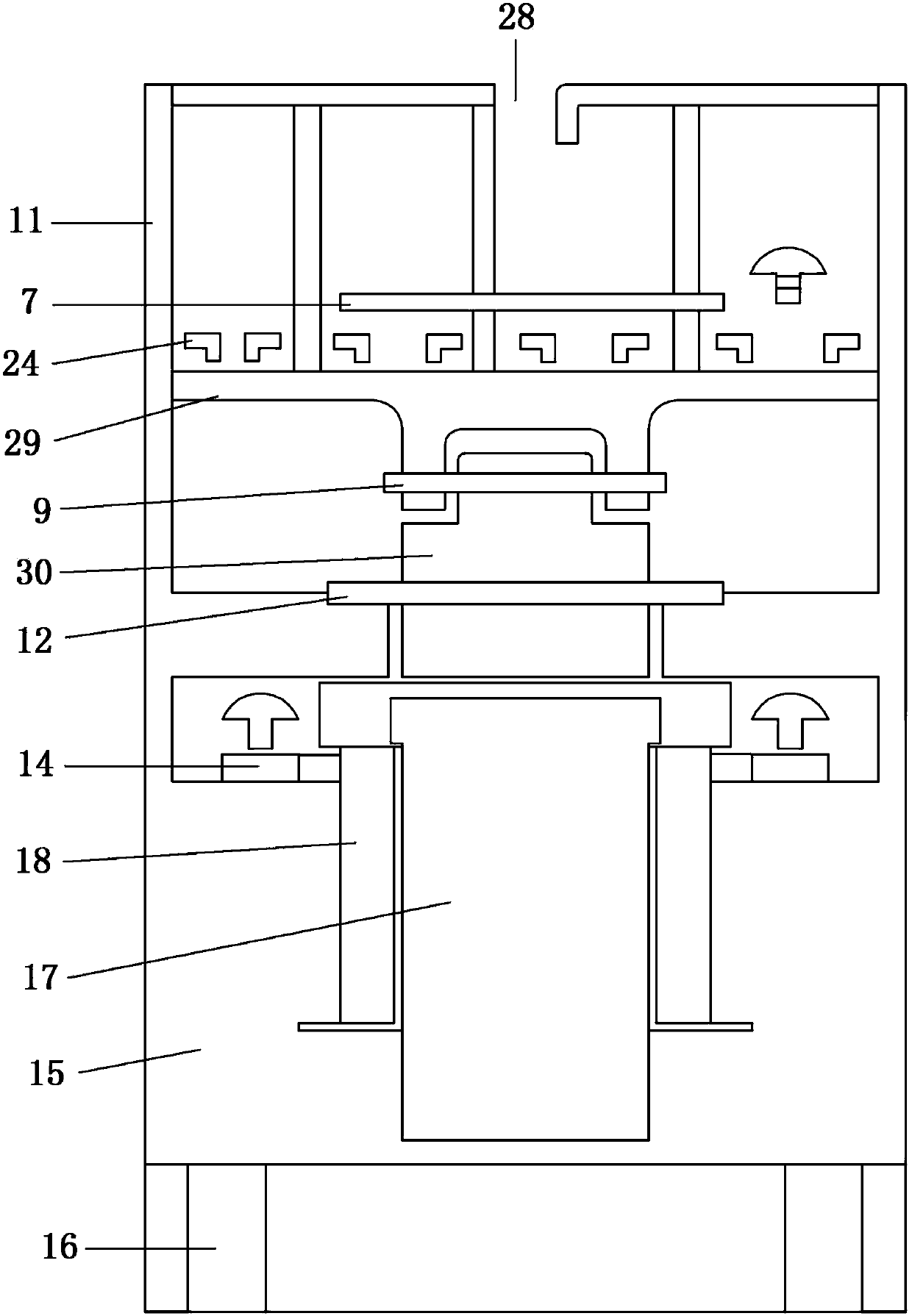

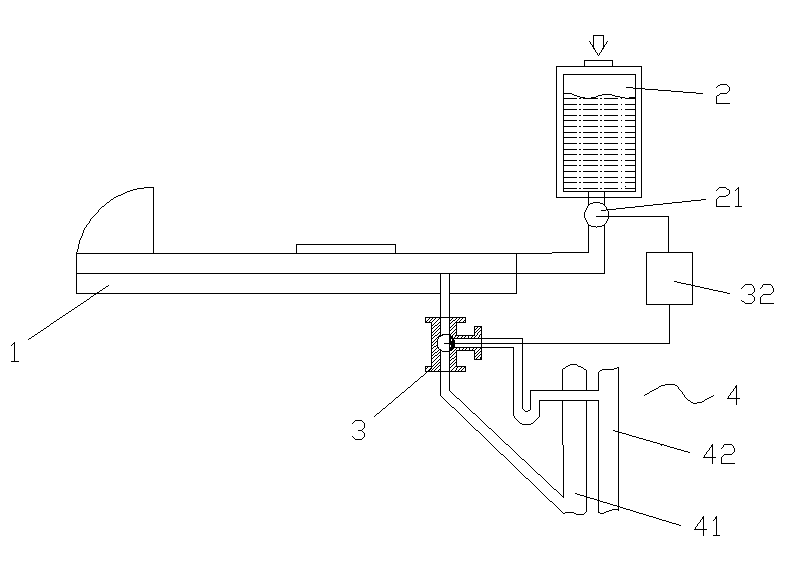

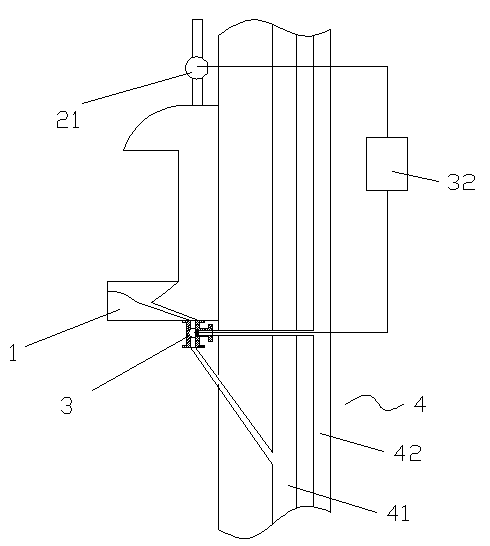

The invention discloses an electrolytic machining method of a difficult-to-cut material, a fine-module internal gear and a device. The method comprises the following steps that a tool cathode with a top-bottom different shape structure is adopted; the surface of the small end of the tool cathode is circular, and a gap between the tool cathode and a work piece pre-hole is served as an initial machining gap which can ensure that a flow field is stable; the large end of the tool cathode is served as a cathode tooth; a part from the small end to the large end of the tool cathode is smoothly transited to a cathode tooth shape from a circular; a forward flow and backpressure electrolyte flowing mode is adopted; and electrolyte flows into a hollow channel of a cathode system, further an organic glass cavity with organic pieces is filled with the electrolyte, and then the electrolyte flows out off the gap between the tool cathode and the work piece. The tool cathode adopts a top-bottom different shape structure, can realize three-dimensional feeding, a pre-hole is arranged in a work piece blank, so that a feeding speed of the tool cathode is improved by 5 to 10 times relative to the feeding speed of an end surface during electrolytic machining, a machining process is stable, and the method is beneficial to improvement of machining efficiency and forming accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

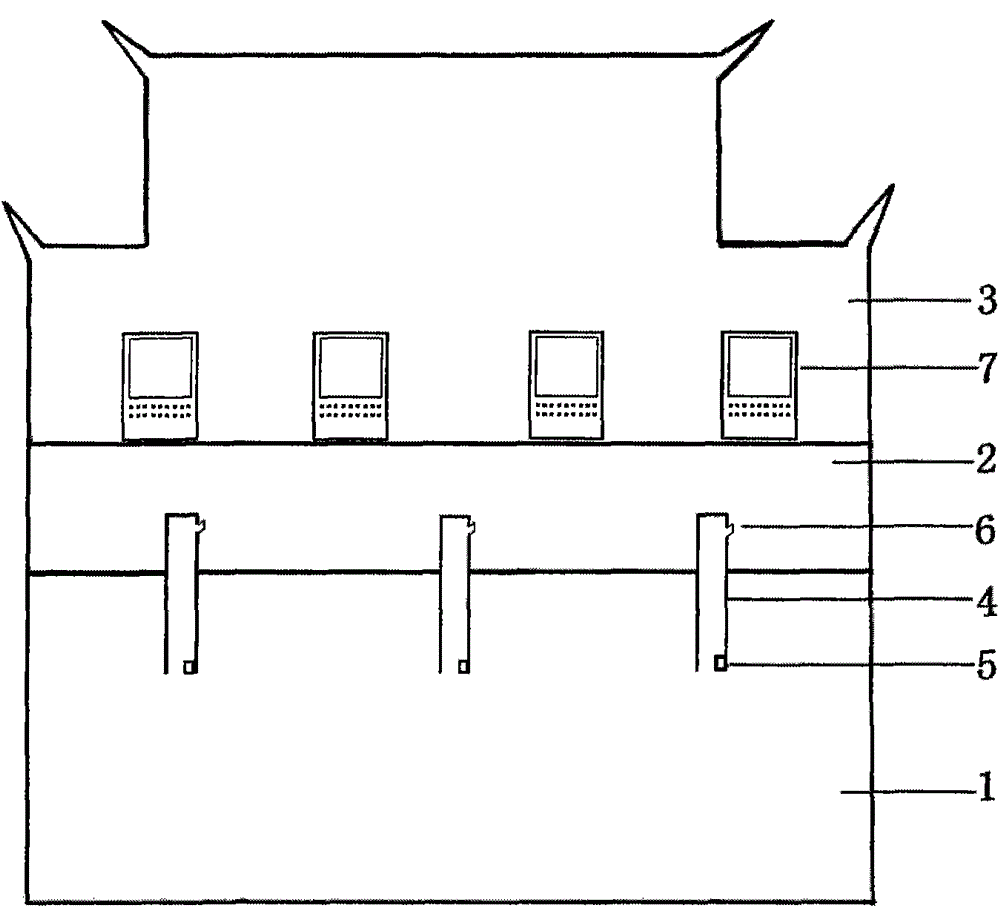

Environment-friendly kitchen waste disposer and waste disposal method

The invention relates to an environment-friendly kitchen waste disposer and a waste disposal method by using the waste disposer. The environment-friendly kitchen waste disposer is embedded underground and comprises a waste accommodating layer, a water system heating layer, a heat complementing layer and a heat insulating layer, wherein a smashing device for smashing wastes and biodegradation complex bacteria and / or biodegradation enzymes for degrading the wastes are arranged in the waste accommodating layer; and smashed and degraded fluid is discharged into a septic tank or a blowdown pipe through a drainage outlet. The waste disposal method comprises the following steps: (1) placing the environment-friendly kitchen waste disposer underground; (2) smashing the kitchen wastes by using the smashing device; and (3) fermenting the biodegradation complex bacteria and / or biodegradation enzymes and the wastes for degradation; and 4, discharging or recycling part of or all of fermented humus to the septic tank. The environment-friendly kitchen waste disposer does not occupy area, does not exhaust odor to the atmosphere, and is free of noises and low in energy consumption and suitable for places, such as canteens, communities, hotels, dining mechanisms and the like where the kitchen wastes are centralized.

Owner:黄震宇

Zirconium-oxide catalyst for producing biodiesel, as well as preparation method and application of zirconium-oxide catalyst

ActiveCN103752297AImprove thermal stabilityImprove conversion ratePhysical/chemical process catalystsFatty acid esterificationBiodieselAlcohol

The invention discloses a zirconium-oxide catalyst for producing biodiesel, as well as a preparation method and an application of the zirconium-oxide catalyst. The zirconium-oxide catalyst comprises the following substances in percent by weight: 80%-95% of ZrO, 2%-18% of Al2O3, 1%-17% of TiO2, 5%-25% of NaHCO3, and 10%-50% of NaCl. The preparation method comprises the following steps: weighing the ZrO2, the Al2O3 and the TiO2, and carrying out ball milling for 24 hours, then adding the NaCl and the NaHCO3, adopting acid silica sol as a binding agent, mixing uniformly, granulating, forming, and drying for 12 hours at the temperature of 120 DEG C; maintaining the temperature for one hour at the temperature of 500 DEG C in a muffle furnace, then rising the temperature to 1460-1600 DEG C rapidly, roasting for 40-200 minutes and cooling. A pipe-type reactor is filled with the zirconium-oxide catalyst, wherein the reaction temperature is 250-300 DEG C, the reaction pressure is 7-14MPa and the alcohol-oil volume ratio is (0.5:1)-(7:1). The zirconium-oxide catalyst is good in heat stability, high in conversion rate, strong in repeated utilization and resistant in acid and water, and can be permanently used by one-time filling; under the resistance of a bed layer, the zirconium-oxide catalyst is stable in structure, not slimed, not easily blocked and very suitable for industrial production; loose pores are formed in the catalyst and in the surface of the catalyst, so that the catalyst has the extremely-high catalytic activity.

Owner:NANCHANG UNIV

Fruit tree insect prevention technology by aid of covers

InactiveCN103283542APrevent it from harmingAvoid harmAnimal repellantsPlant protective coveringsDiseaseFruit set

The invention belongs to the technical field of disease and insect pest prevention and control for fruit trees, and particularly relates to a fruit tree insect prevention technology by the aid of covers. The fruit tree insect prevention technology is characterized in that according to research findings on fruit setting characteristics of different varieties of fruit trees and activity rules of injurious insects on the fruit trees, when single fruit trees or in-line fruit trees or vast fruit trees which have different fruit setting characteristics and the injurious insects with different activity rules are specifically protected by the covers in proper periods, fruits can be isolated from the injurious insects and are effectively prevented from being harmed by the injurious insects, the photosynthesis of the fruit trees is hardly affected by selected cover materials, obvious influence of the selected cover materials on the temperature and the humidity required by each fruit tree is prevented, and a physical protection layer can be provided for each single fruit tree, the in-line fruit trees or the vast fruit trees; simple supports of the covers comprise upright columns (timber piles or steel tubes) and drawn steel wires, and the covers can be shifted as needed, can be operated easily and conveniently and are economical and durable. The fruit tree insect prevention technology has the advantages that dependence on pesticides for pest control and corresponding pesticide and labor cost input can be greatly reduced for fruit growers, the commodity rate of the fruits is increased, and the safety of the fruits is improved.

Owner:SOUTH CHINA AGRI UNIV

Thermal transfer in-mould decoration and preparation method thereof

InactiveCN102673293AComplete reproductionFirmly attachedOrnamental structuresSpecial ornamental structuresWrinkle skinPolymer science

The invention discloses a thermal transfer in-mould decoration and a preparation method thereof. As the thermal transfer in-mould decoration and the method adopt laser to grave metal gravure, and adopt a method for gravure printing and thermal transferring, a high-resolution effect (which is 600 dpi) of PET film sheet printing is realized, continuous patterns and gradient patterns can completely reappear, and the color with high transparence and high transmittance on the PET back surface can be realized. The color saturation is high, and the adhesion of a graphic ink layer and a PET film is firm. The in-mould decoration can bear the high-temperature impact, can extend while the PET film is extended in a 3D thermal forming process, and has high extension. The extended surface is completed, the ink layer cannot be broken and has no wrinkles. The thermal transfer in-mould decoration and the preparation method not only can realize the large-scale continuous production, but also can perfectly overcome the shortcoming that hot-melt resin of the ink coating layer cannot bear the high temperature impact during the molding process. Products obtained by using the method cannot flush ink and glue and has complete patterns. The patterns have the performances of high gloss, anti-friction, anti-scratch and weather resistance, so that the thermal transfer in-mould decoration and the preparation method can be permanently used with fidelity.

Owner:TEC HI PRINTING TECH

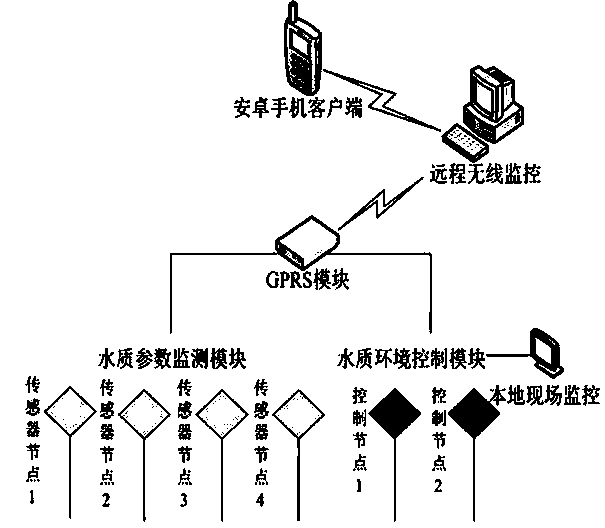

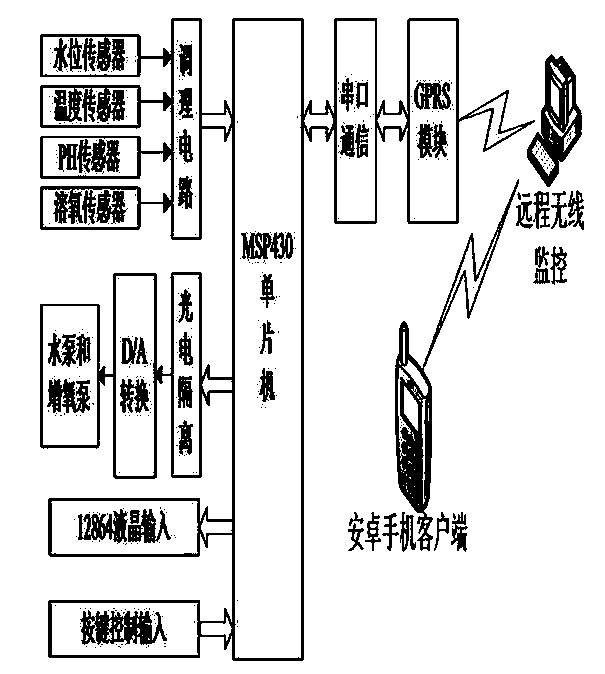

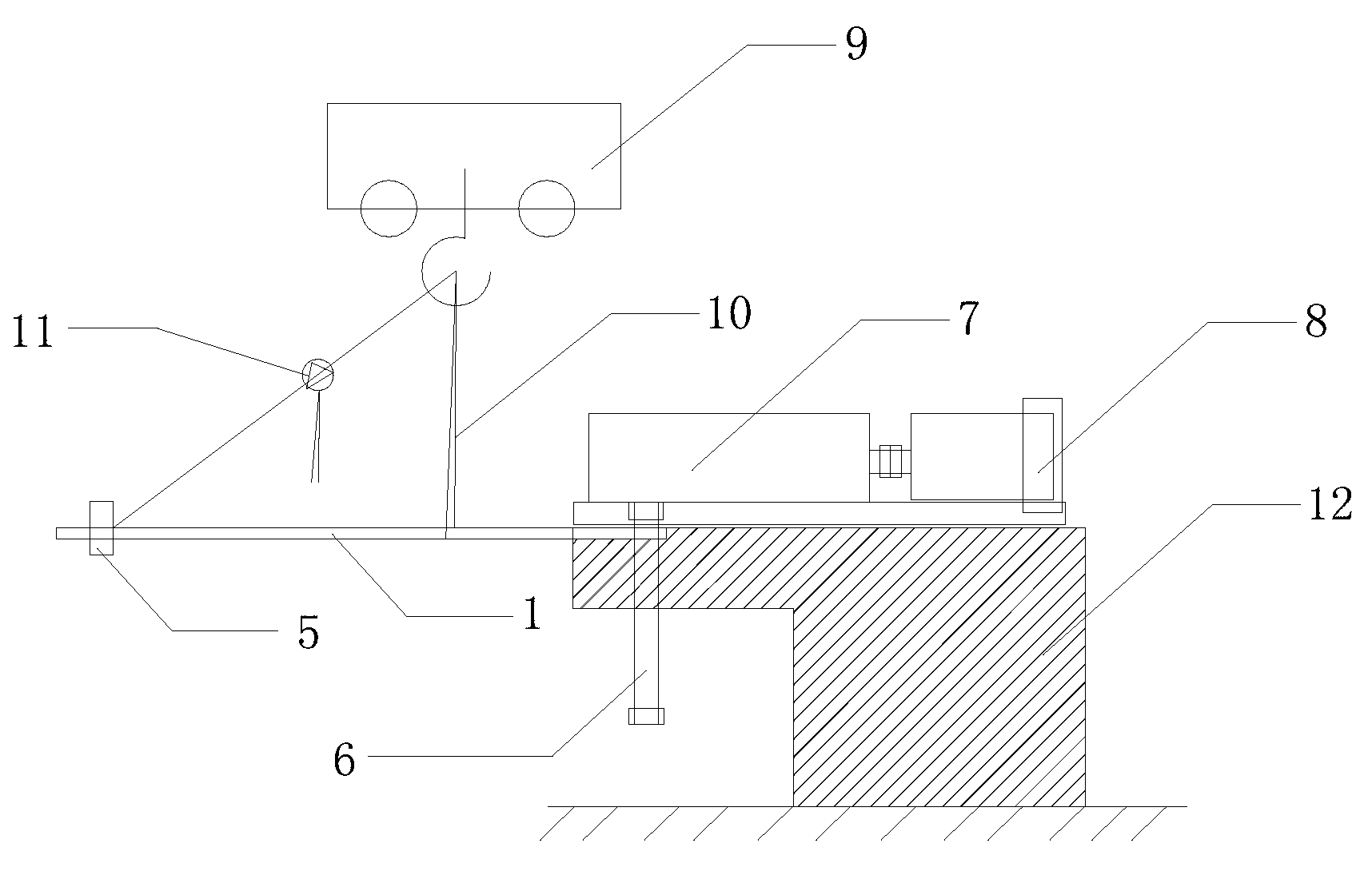

Remote monitoring system based on GPRS transmission and operating method

InactiveCN103645684ALow priceHigh measurement accuracyTotal factory controlProgramme total factory controlMicrocontrollerThe Internet

The invention discloses a remote monitoring system based on GPRS transmission and an operating method, the system including an underlying control module, a transmission module, a local on-site monitor, a remote wireless monitor and an Android mobile phone client. The underlying control module consists of several parameter real-time monitoring modules, and a water quality control module, a water quality parameter monitoring module, a signal conditioning circuit and an MSP430 single-chip microcomputer are disposed in each parameter real-time monitoring module; the transmission module is a GPRS transmission module; the local on-site monitor is an LCD controlled by the MSP430 single-chip microcomputer; the remote wireless monitor is an upper computer equipped with monitoring software programmed by use of a VB language; and the Android mobile phone client is a mobile phone with monitoring software. The system can achieve wireless reception of water quality parameters and wireless transmission of control commands on the mobile phone and the upper computer via Internet and GPRS wireless networks, and negative factors of wired networks, such as high laying cost of lines, complex wiring and the like are avoided.

Owner:JIANGSU UNIV

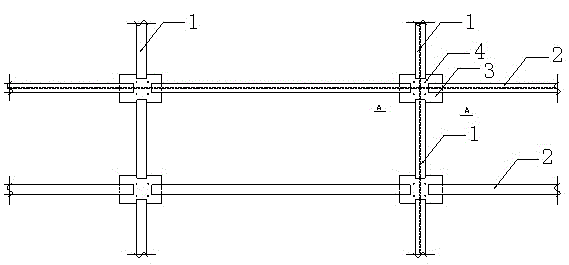

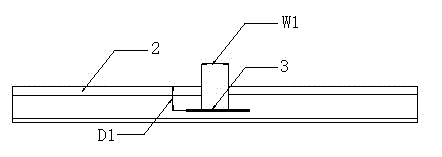

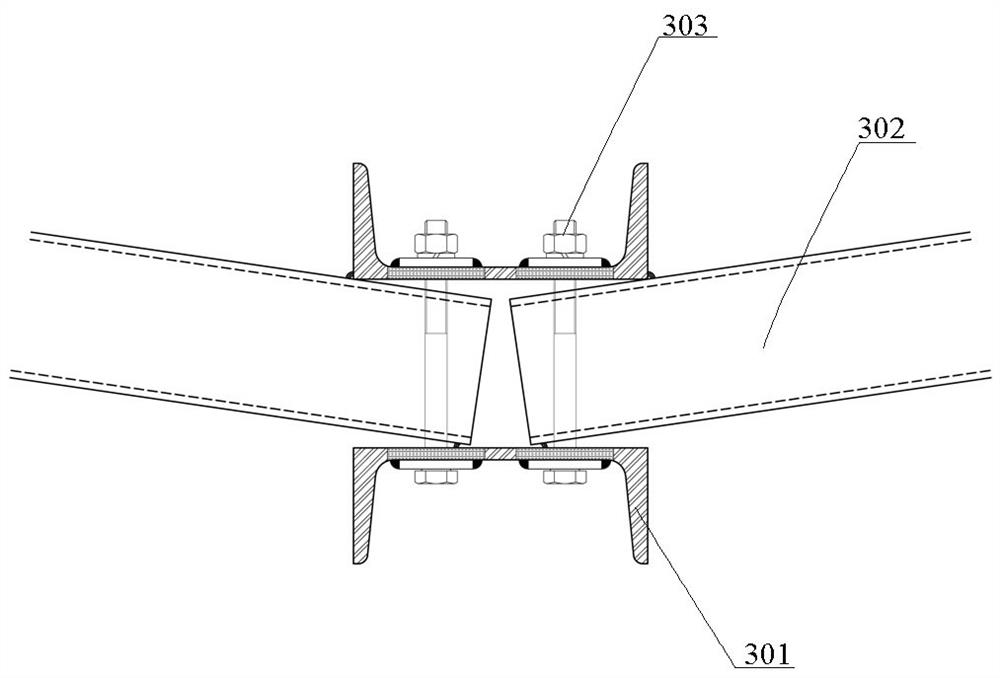

Flatcar track cross arranging method

ActiveCN104631226AAdvantages of cross-setting methodThe structure of the cross setting is simpleRail switchesMovable tracksControl theorySteel plates

A flatcar track cross arranging method comprises crossing two tracks, and is characterized by comprising the following steps of a, slotting the two tracks, and b, arranging liner steel plates. The flatcar track cross arranging method has the advantages of simple flatcar track cross arranging structure, convenience in production and low cost; stable flatcar track cross arranging structure, traffic safety, capability of being used permanently, and no need of maintenance.

Owner:MCC5 GROUP CORP SHANGHAI

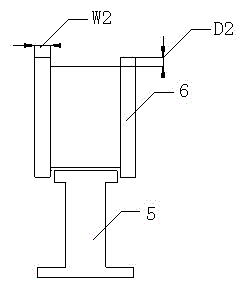

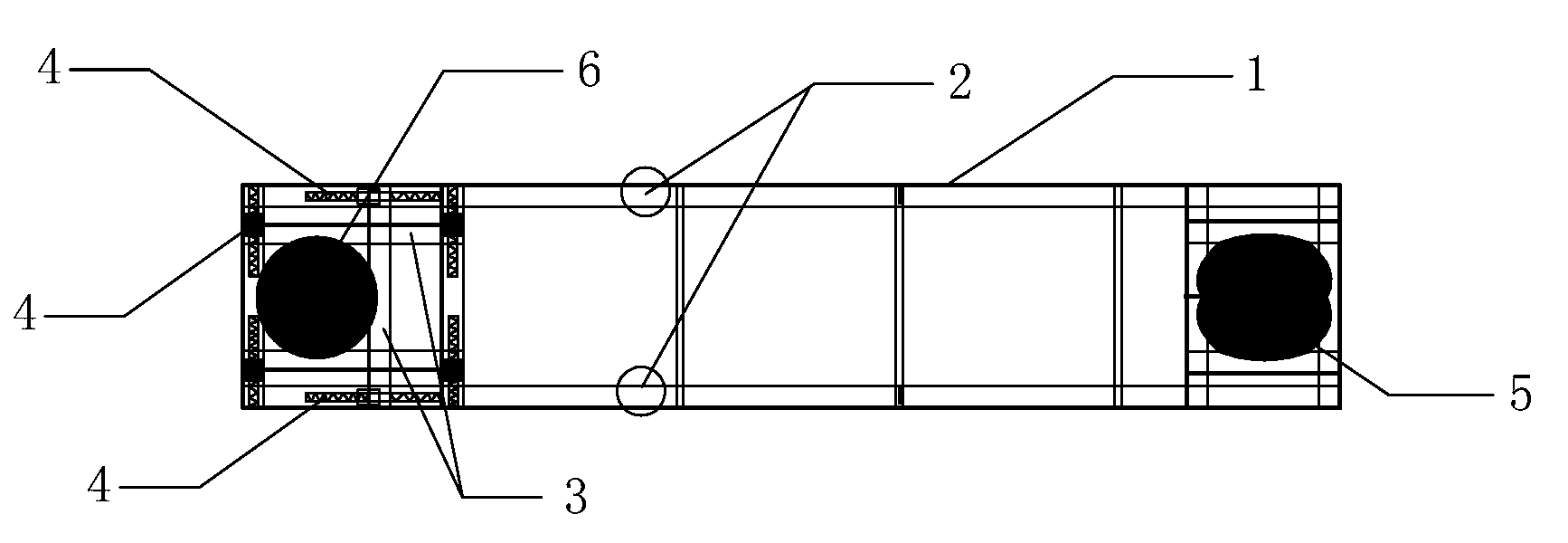

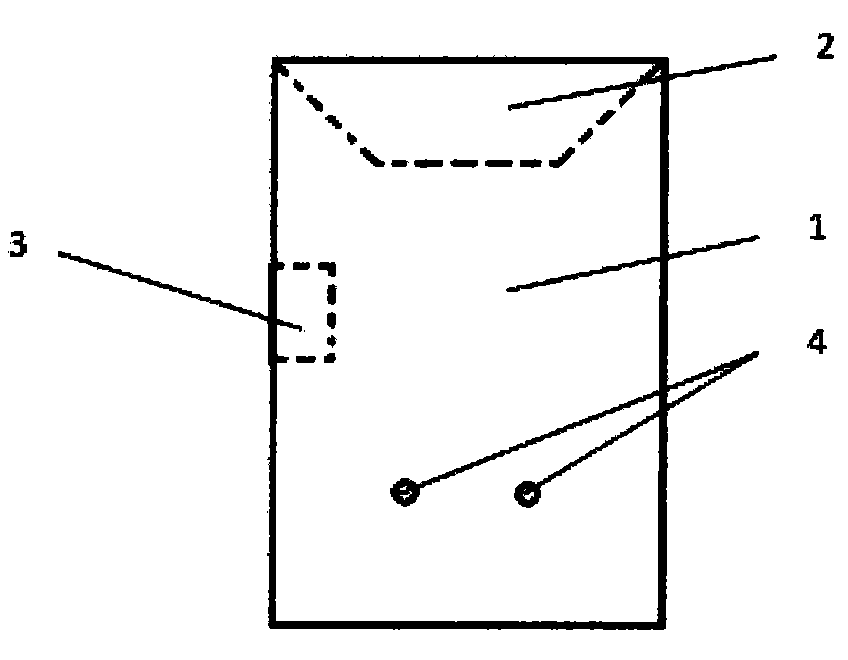

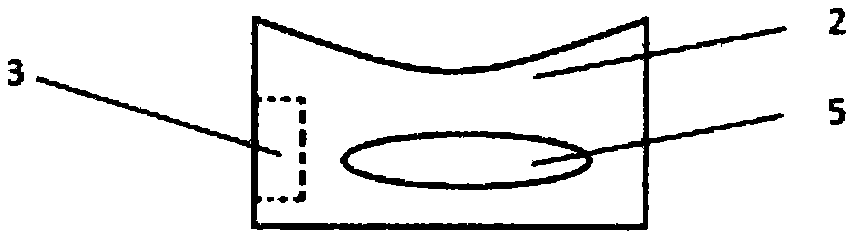

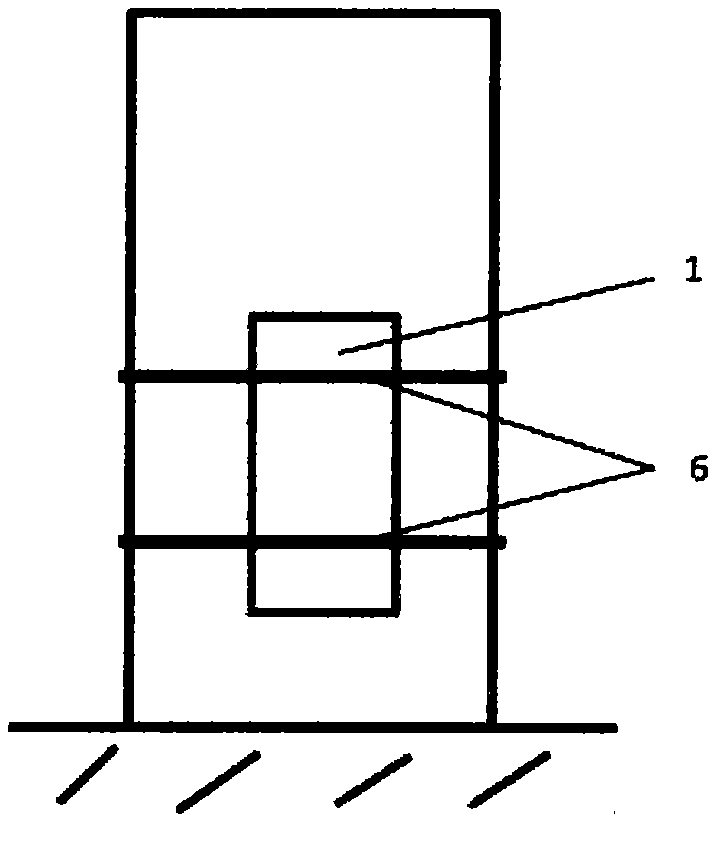

Hanger for mounting universal shaft of vertical mill and application method of hanger

ActiveCN103803397AImprove construction efficiencyEasy maintenanceLoad-engaging elementsEngineeringSteel frame

The invention discloses a hanger for mounting a universal shaft of a vertical mill. The hanger comprises a steel frame (1), a sealed bracket and a balance weight block (5). The hanger is characterized in that the steel frame (1) is a rectangular frame welded by angle iron at the periphery and a large amount of round steel; a pair of lifting lugs (2) are arranged at two sides of the middle of the rectangular frame; the sealed bracket is fixedly arranged at one end of the steel frame (1); the sealed bracket is a square frame formed by angle iron (3) at the periphery and adjusting bolts (4), and can adjust the size of the square frame by adjusting the movable angle iron at two adjacent sides and the adjusting bolts so as to be applicable to clamping universal shafts (6) with different diameters to enable the universal shafts (6) to be mounted; the balance weight block (5) is an iron barrel with the adjustable weight and is arranged at the other end of the steel frame (1). The hanger has the advantages of being simple in structure and convenient to fabricate, the universal shaft can be safely and stably conveyed to the mounting position directly, the construction efficiency is improved, the hanger is fast and convenient to maintain in the future and can be used for a long time, and the engineering construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

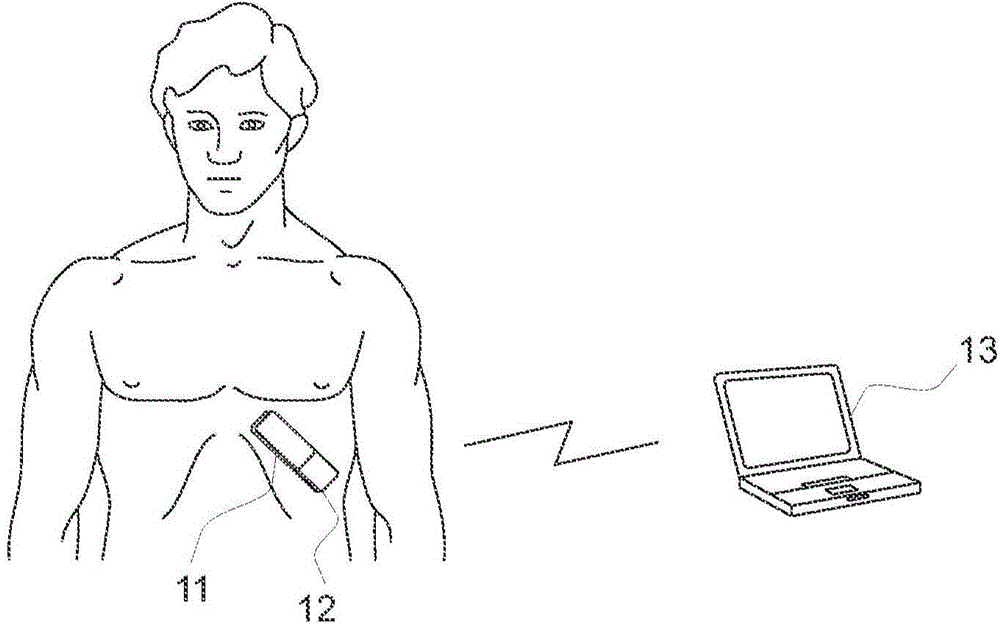

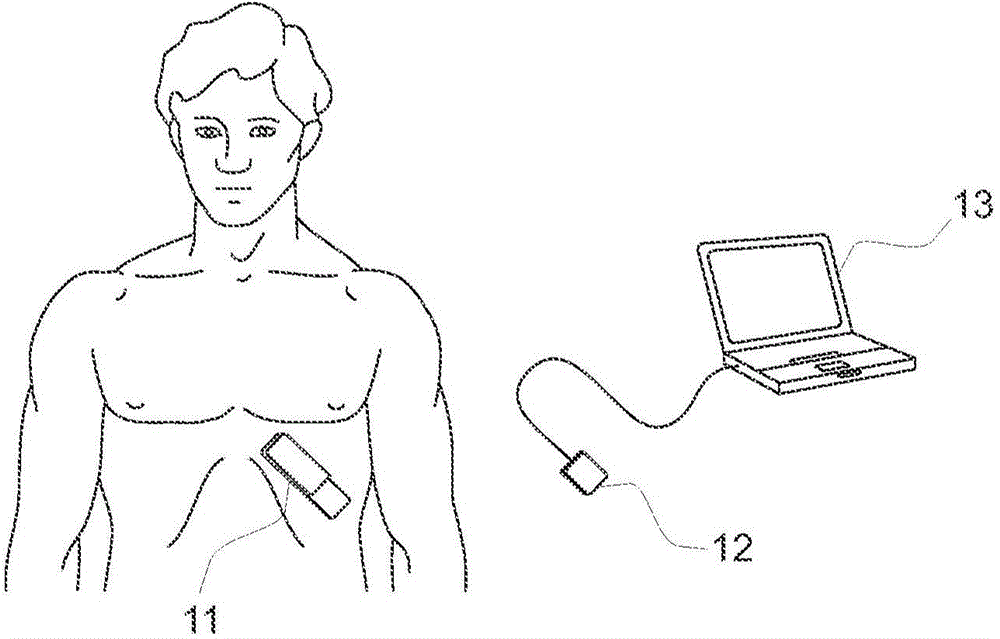

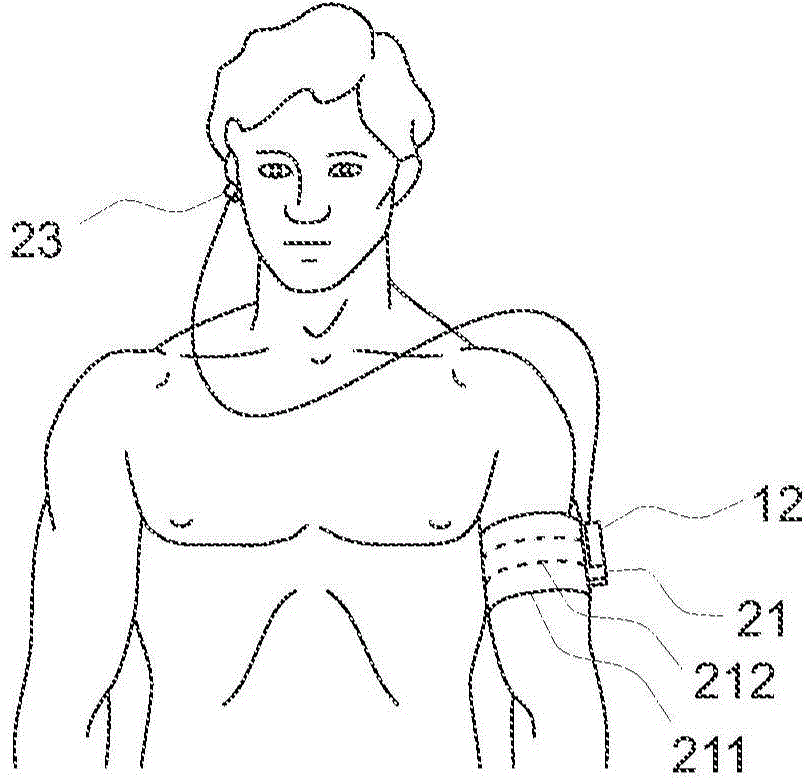

A control module and an arrangement for measuring a biosignal

InactiveCN104797188AMaintain personal safetyPermanent useElectroencephalographyElectrocardiographyRechargeable cellEngineering

The present disclosure discloses an arrangement for measuring a biosignal. The arrangement has a sensor module and a control module. The sensor module has structure for sensing at least one biosignal and a first connector for interfacing with the control module. The control module has a first counterpart connector connected to the first connector of the sensor module, structure for processing biosignal data sensed with the sensor module, a storage memory for storing processed bio signal data, a rechargeable battery for providing operating power for the control module, structure for wirelessly transmitting the processed biosignal data to a computing device, such as a PC, a tablet PC or a smart phone, for post-processing, and a second connector for interfacing with a second electrode.

Owner:BITTIUM BIOSIGNALS OY

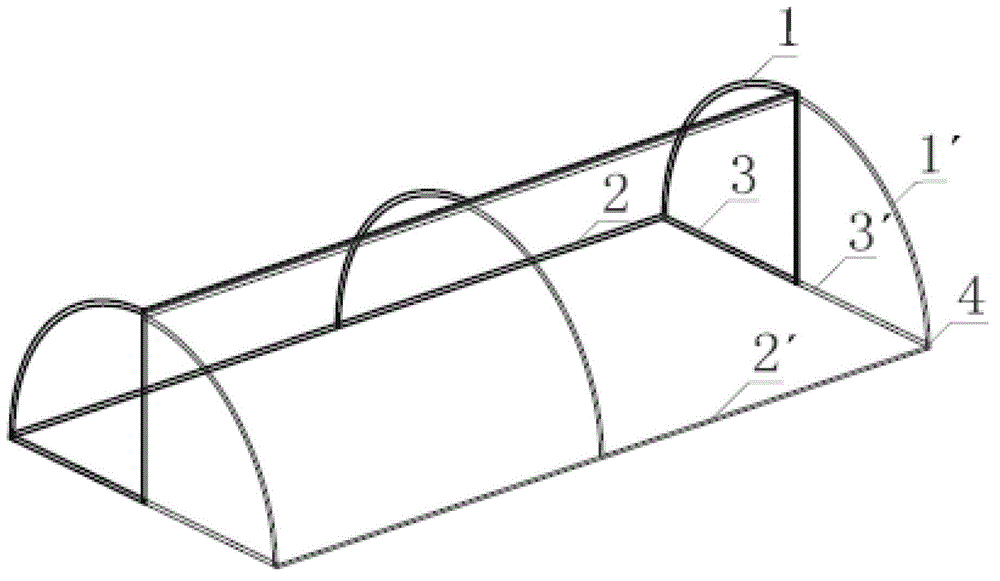

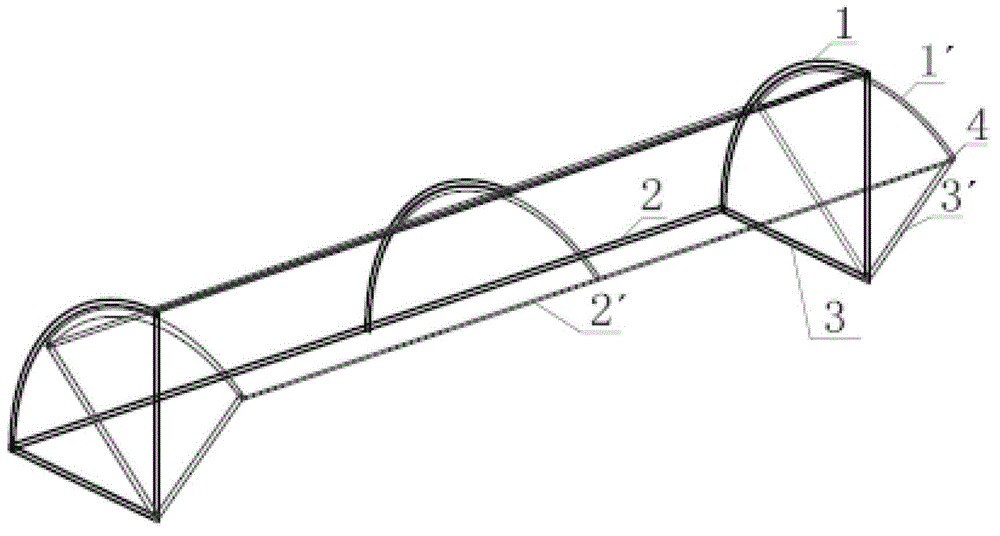

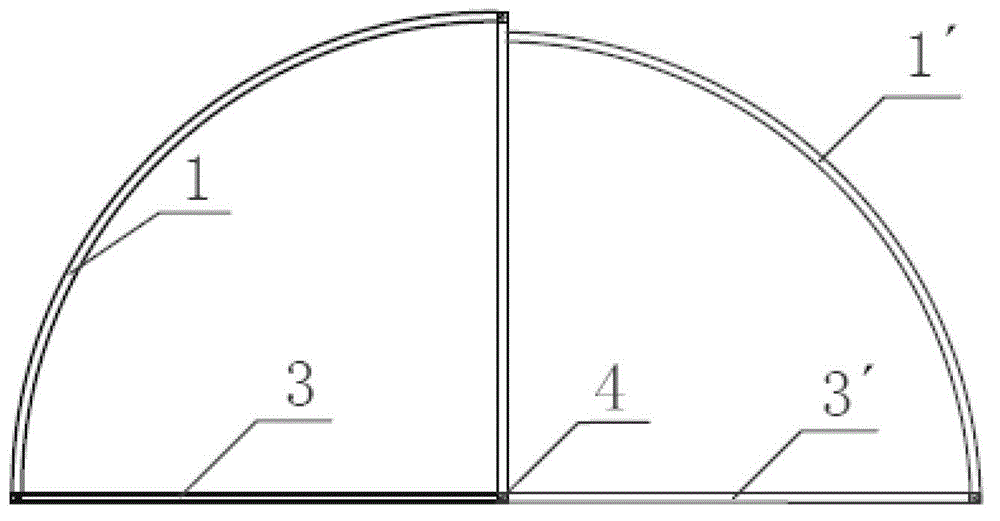

Small arched shed

InactiveCN102715037AReasonable structural designEasy to assembleClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses a small arched shed and belongs to the technical field of agricultural facilities. The technical scheme is that two ends of an arc-shaped framework (1) which is 1 / 4 of a circle are fixedly connected with two short pipes (3) which are connected in a mutually perpendicular mode so that a fixed side wall of the small arched shed is formed, two or more than two straight pipes (2) are vertically fixed between two fixed side walls so that a fixed half arched shed is formed, the other half arched shed is of a movable structure, and the other half arched shed and the fixed half arched shed are symmetrical in structures. Two half arched sheds are connected at the position of a circle center of the arc-shaped framework, a connecting line between connecting points of the two side walls serves as a rotating axis of the movable half arched shed, and accordingly the movable half arched shed is freely opened and closed. Covering films are arranged on the fixed half arched shed and the movable half arched shed. The small arched shed has the advantages of being reasonable in structure, capable of being reused, low in running cost, convenient to transport, assemble and move, green and environment-friendly, facilitating operation in the arched shed by workers, and being capable of being applied to fields and being also capable of being applied to sunlight greenhouses in early spring, later autumn or winter and the like.

Owner:BEIJING CAU FUTONG GARDENING

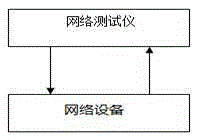

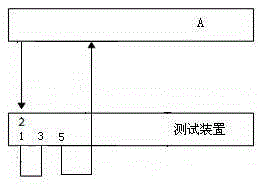

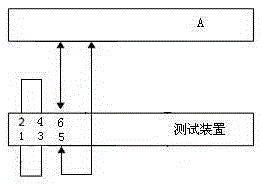

Device for testing throughput capacity of network equipment based on switchboard and test method

ActiveCN105323122AData exchange function qualifiedEasy to implementData switching networksVirtual LANSignal source

The invention relates to the field of transmission of network information, and in particular relates to a device for testing the throughput capacity of network equipment based on a switchboard and a test method. According to the device and the method for testing the throughput capacity of the network equipment based on the switchboard, ports of the switchboard are added into two different virtual local area networks, and the two ports positioned in the same local area network are connected with each other through a network wire, and fed with appointed unicast frames to form signal sources; the network equipment to be tested is connected with the two ports, positioned in the different virtual local area networks, of the switchboard respectively, to detect whether the switch function of the network equipment to be tested is normal or not by testing whether the total data transmitting and receiving amounts of the two ports of the switchboard are equal or not. The device and the method are easy to implement and low in cost; meanwhile, the switchboard serving as a test device can be used permanently after being configured, and is practical and convenient; and furthermore, when the switchboard further has multiple ports in addition to the ports serving as the signal sources, a plurality of sets of network equipment to be tested can be tested simultaneously.

Owner:BEIJING BROADWIT TECH

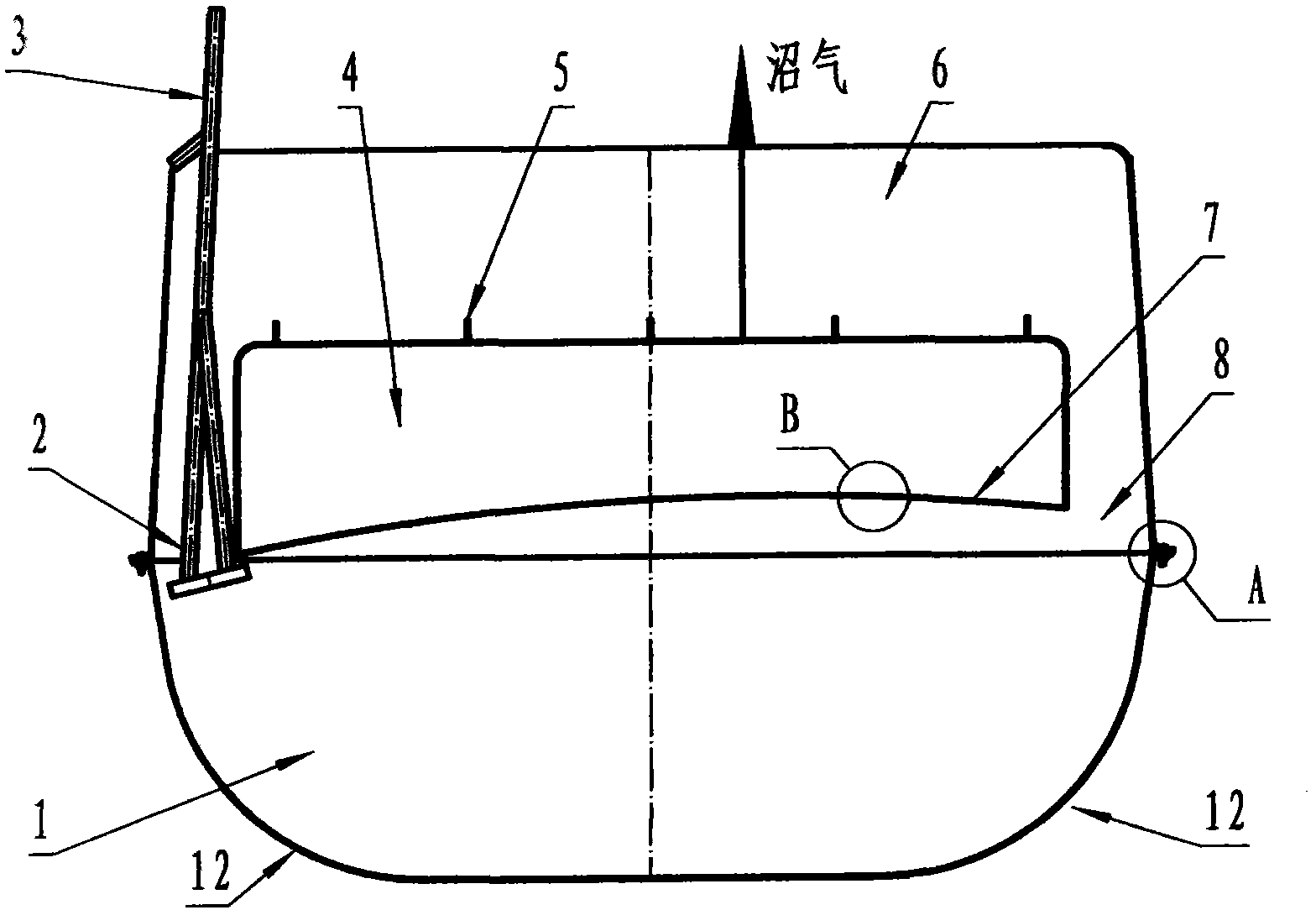

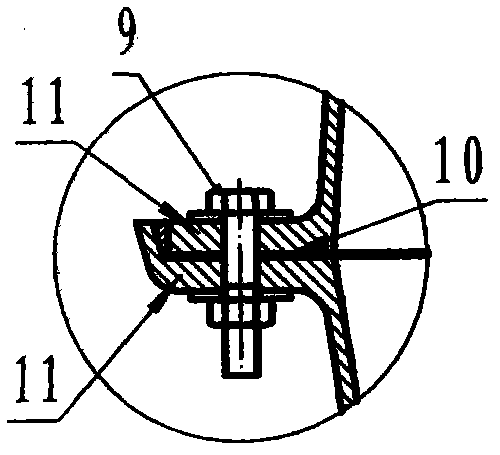

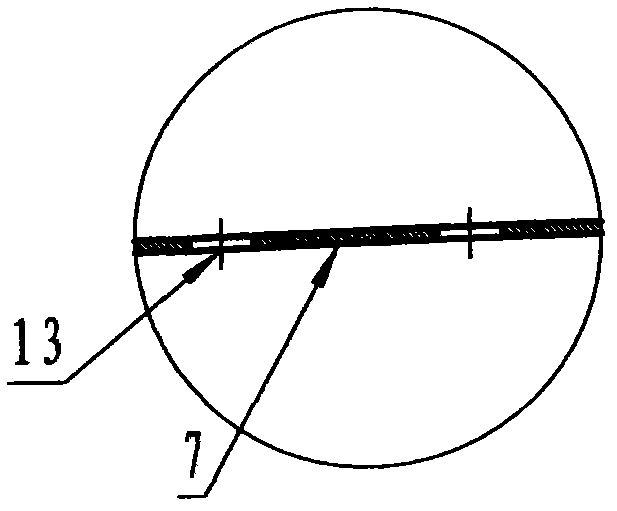

Double hydraulic straw methane pool for self-circulation medium temperature two-step fermentation and forced discharging method

InactiveCN102061255AIncrease temperatureLow costGas production bioreactorsWaste based fuelGlass fiberHigh concentration

The invention relates to a double hydraulic straw methane pool for self-circulation medium temperature two-step fermentation and a forced discharging method. The double hydraulic straw methane pool is characterized in that glass fiber reinforced plastics, plastics or steel plates are used for making a cuboid double hydraulic methane pool; a water pressure room doubles as an acidification pool, an acidification fluid automatically circulates, and sun insolation is carried out to realize double hydraulic self-circulation medium temperature fermentation without crusting; and forced feeding of a feeding push plate is carried out, thereby forced discharging is realized, the problem of straw biogas residue discharging is solved and independent gas production or mixed gas production of high-concentration straws and excrement is realized. The invention has the beneficial effects that the number of suitable users of the methane pool can be increased from 28 percent to 100 percent, which is beneficial to scale enlargement of the methane pool with energy saving, emission reduction and permanent persistence in scale enlargement and is beneficial to self-sufficiency of national rural domestic energy; the gas production efficiency is enhanced, and the volume of the pool body is reduced, thereby the cost of the methane pool is lowered and the methane pool can be supplied in free to nationwide farmers in the country. In addition, the double hydraulic straw methane pool is convenient to transport, can be installed per se and can be movably used.

Owner:季忠铁

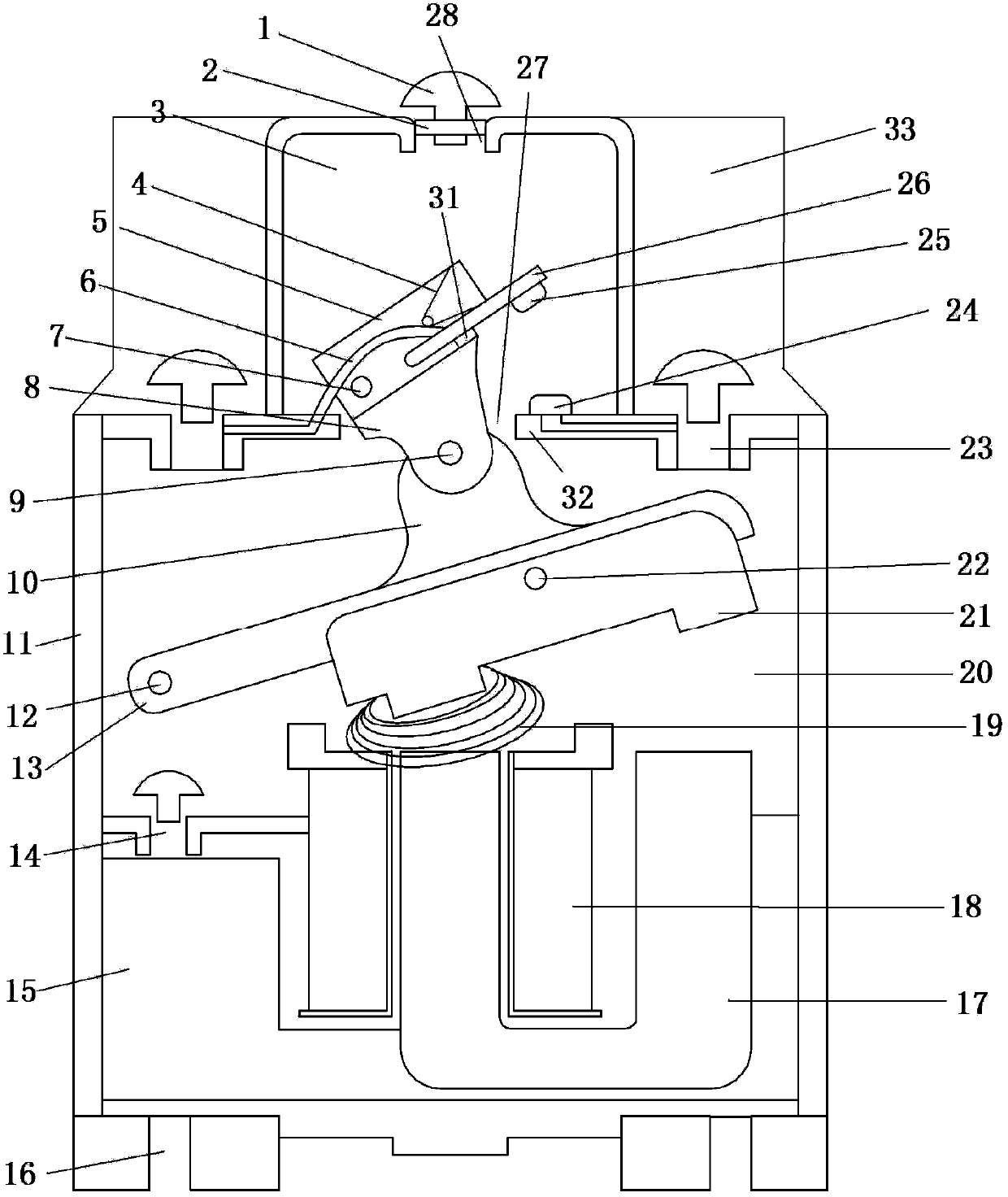

Contactor

ActiveCN103996568ANot easy to damageExtended service lifeElectromagnetic relay detailsContactorEngineering

The invention discloses a contactor which is long in service life, safe and reliable. The contactor comprises an insulating housing, a lower fixed iron core, an upper movable iron core, a lower lever mechanism and an upper lever mechanism, wherein the lower fixed iron core is mounted at the bottom of an inner cavity of the insulating housing; a coil is arranged on the lower fixed iron core; the upper movable iron core is mounted on the lower lever mechanism; a return iron core spring is arranged at one end, provided with the coil, of the lower fixed iron core; the lower fixed iron core is connected with the upper movable iron core by the return iron core spring; the upper lever mechanism is connected with the lower lever mechanism; an upper contact is arranged on the upper lever mechanism; a lower contact corresponding to the upper contact is arranged on the inner cavity of the insulating housing; a plurality of contact lead connectors connected with the upper contact and the lower contact are arranged outside the insulating housing; and an oil filler hole is formed at the top end of the insulating housing. The contactor has the benefits that insulating oil is filled from the oil filler hole, so that no spark is generated during contact actuation, the contactor is not oxidized or damaged easily, and can be used permanently, and the service life of the contactor is prolonged greatly.

Owner:南平市建阳区波特安电子科技有限公司

Menu display method for home network system

InactiveCN1755593AConvenient control and monitoring of productsEasy to controlInput/output processes for data processingComputer scienceMoving window

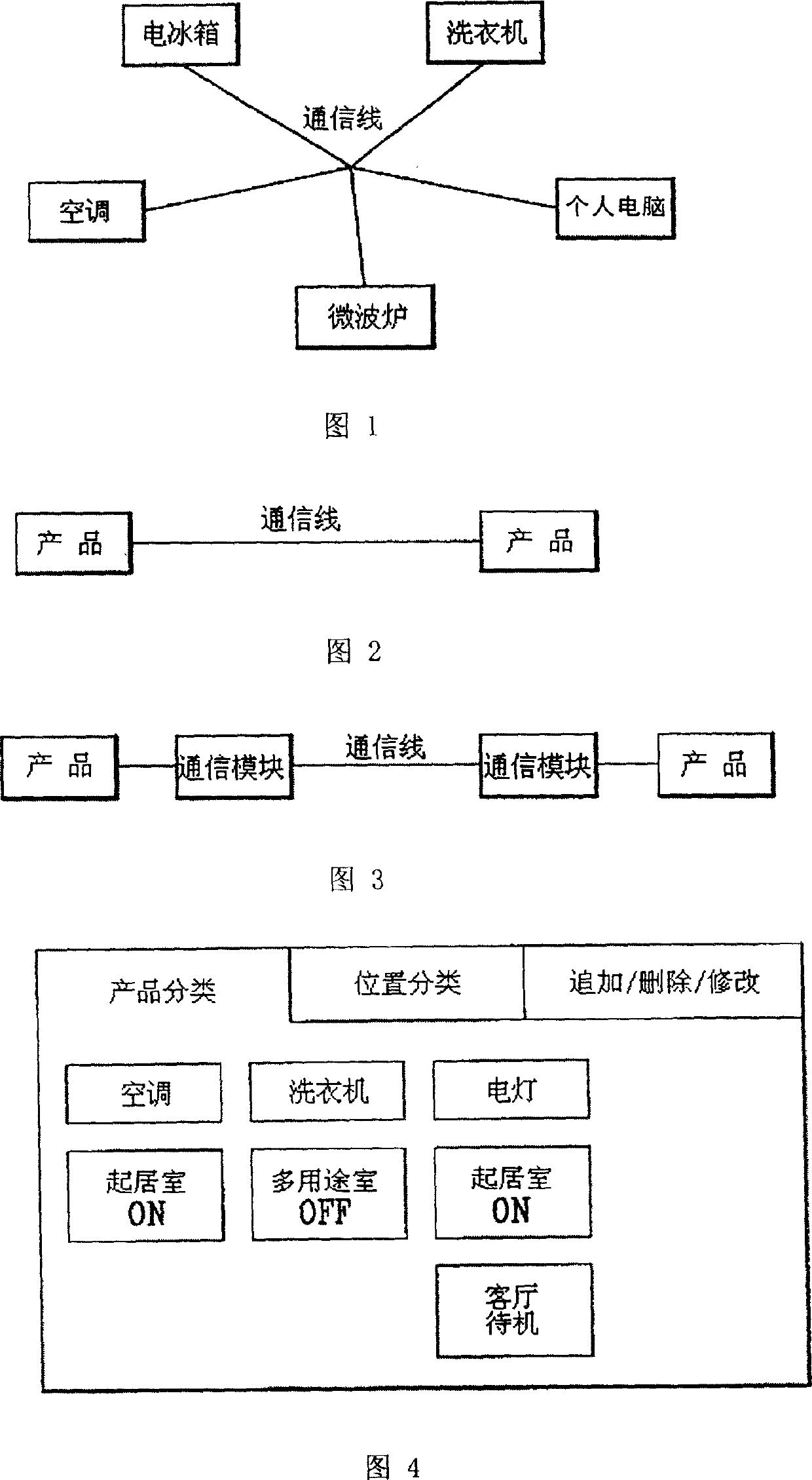

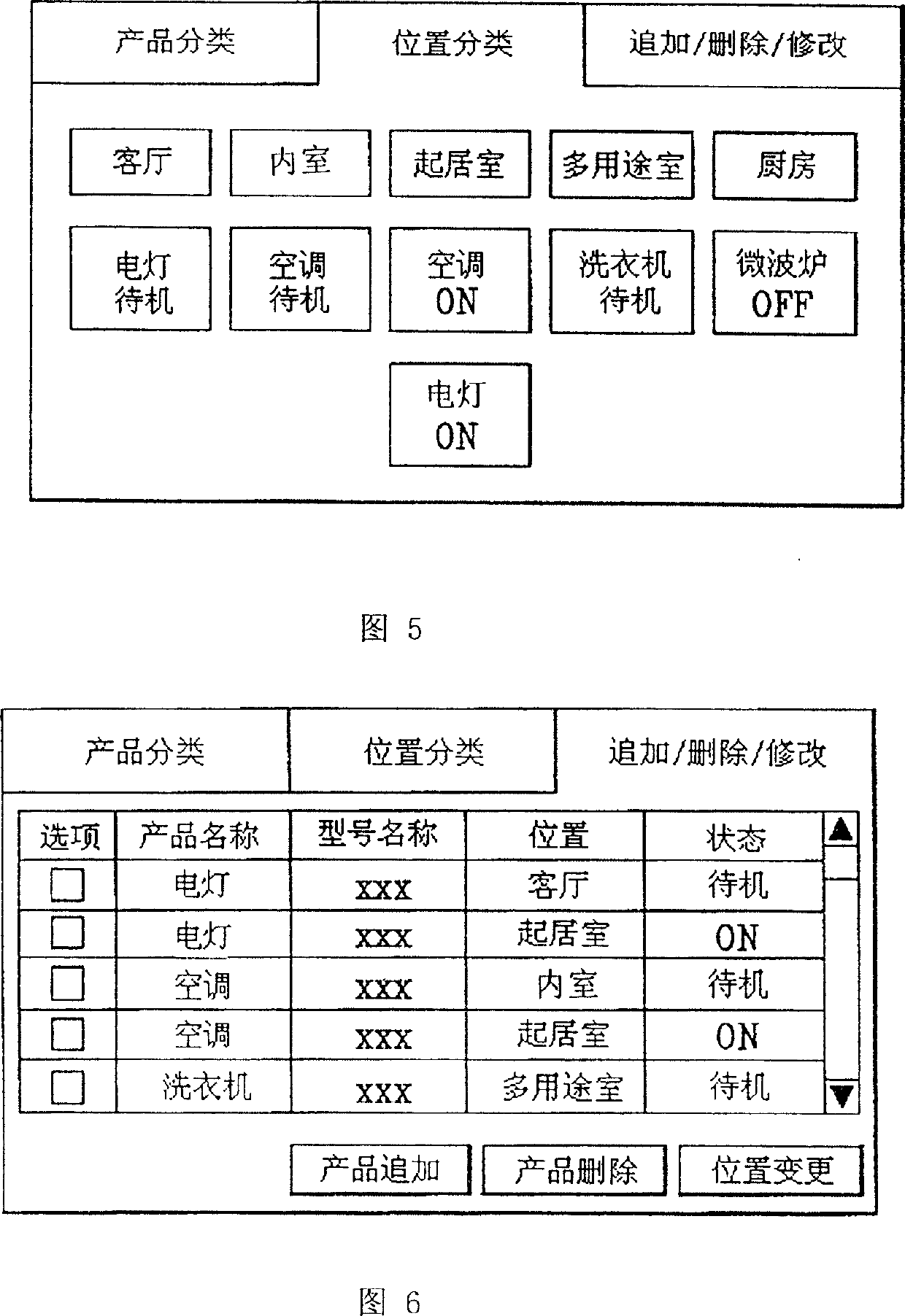

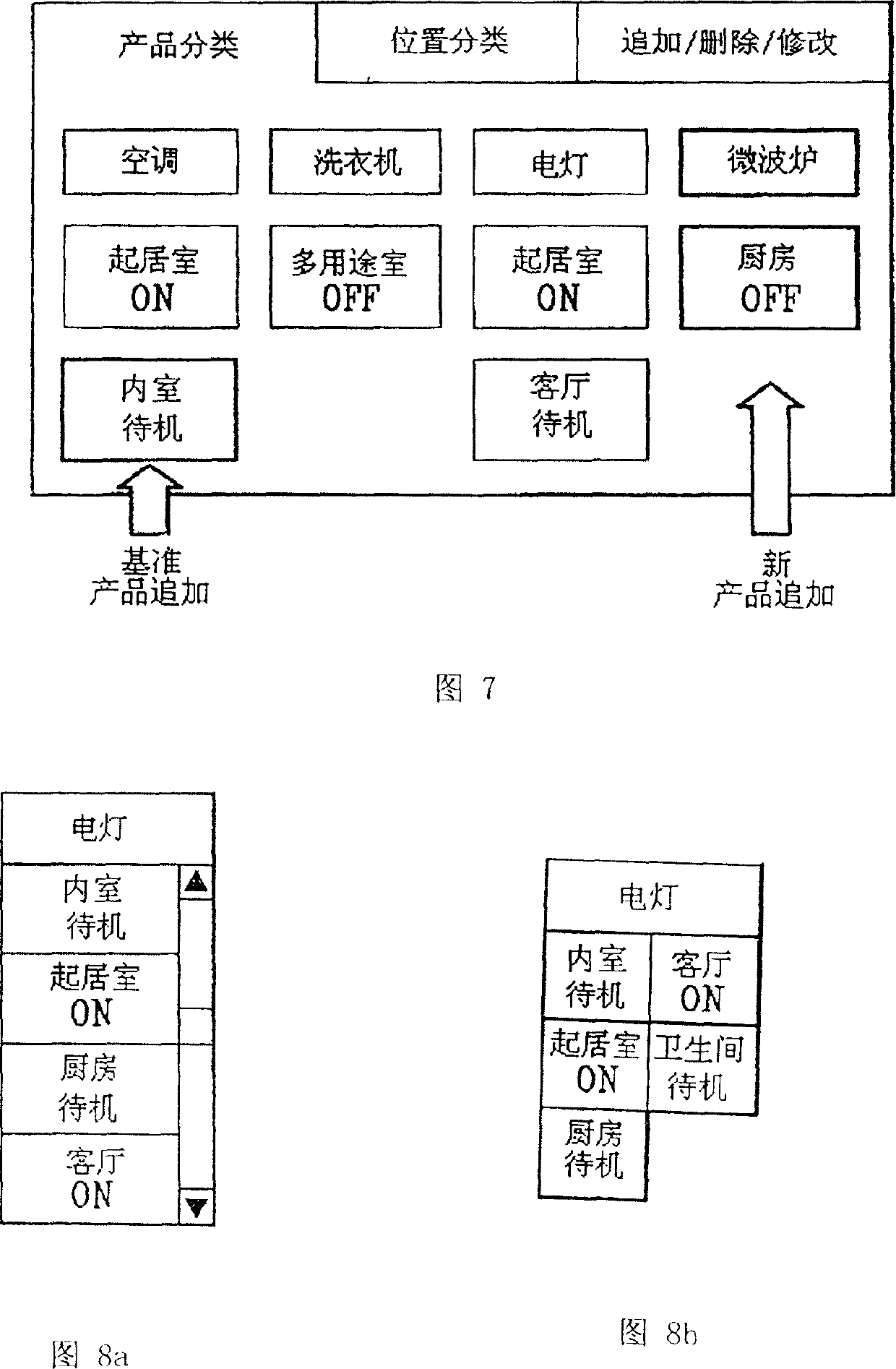

The invention discloses a menu picture display method of a home network system in the field of home network system. The menu picture comprises: a produce sorting submenu which displays the location of each product and the product condition of the corresponding location by the product name, a location sorting submenu which displays the product name and the product condition of the corresponding location by the product location, a submenu which displays the choice, product name, the corresponding type, the install location and the condition by form type, displays the menu moving window of the searching product o the design area of the form and displays the order of product adding, product deleting and location altering and so on.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

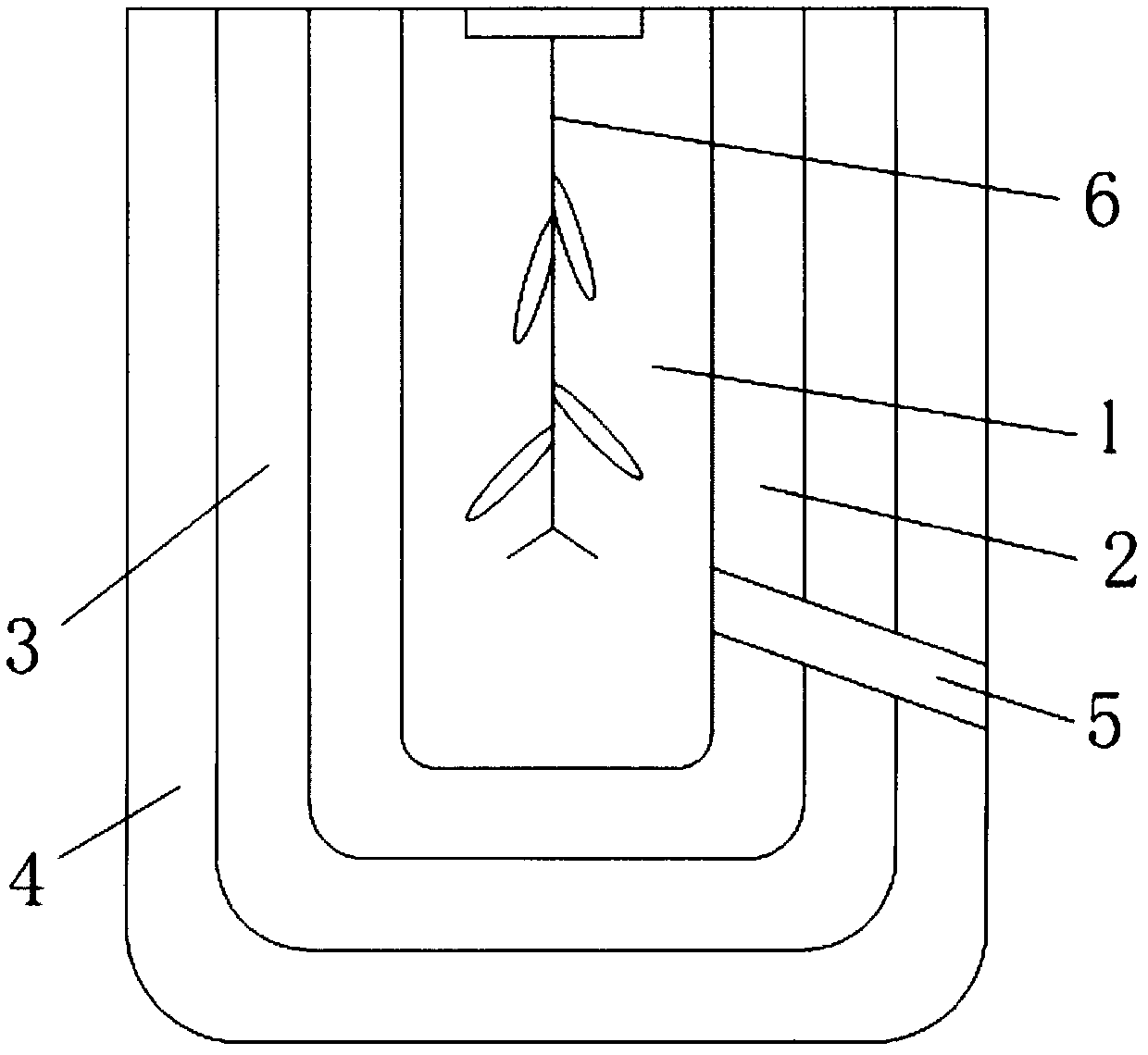

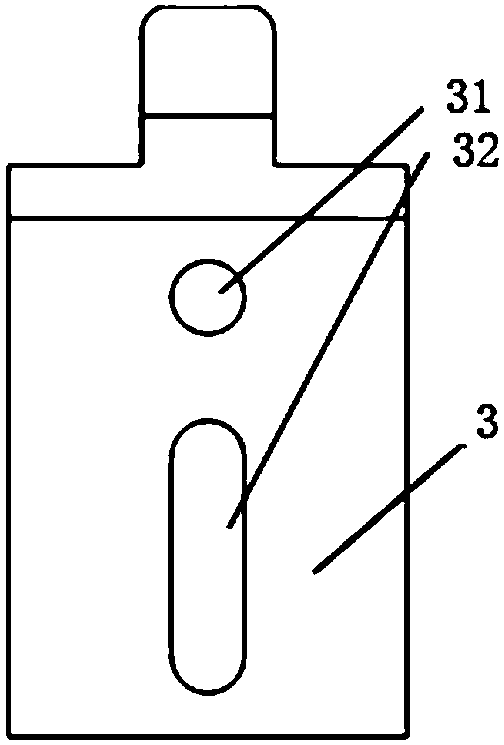

Hylobitelus xiaoi Zhang adult trapping and killing device and application method thereof

The invention discloses a hylobitelus xiaoi Zhang adult trapping and killing device and an application method thereof. The trapping and killing device comprises a barrel 1, a cone 2 and a tying belt 6; the cone 2 is reversely fastened to the barrel 1; both insides and outsides of the barrel 1 and the cone 2 are blackened; a slide layer is formed on the upper surface of the cone 2; a trapping core chamber 3 is arranged in the middle of the inner wall of the barrel 1; 2-4 small holes 4 are drilled in the middle lower part of the wall of the barrel 1. The application method comprises the following steps: an attractant or an insect acrasin is prepared into a trapping core of an appropriate size and the trapping core is put into the trapping core chamber 3; the cone 2 is reversely fastened to the barrel 1; the barrel 1 is fixed to the root of a pine tree within a hylobitelus xiaoi Zhang infringement region by use of the tying belt 6; and an appropriate amount of water is put into the barrel 1. The hylobitelus xiaoi Zhang adult trapping and killing device is simple in structure, low in cost, usable permanently after being mounted once in the forest, safe to use, free from pollution on the environment and good in trapping and killing effect. The trapping and killing device also can be used for predicting the hylobitelus xiaoi Zhang and capturing living adults.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

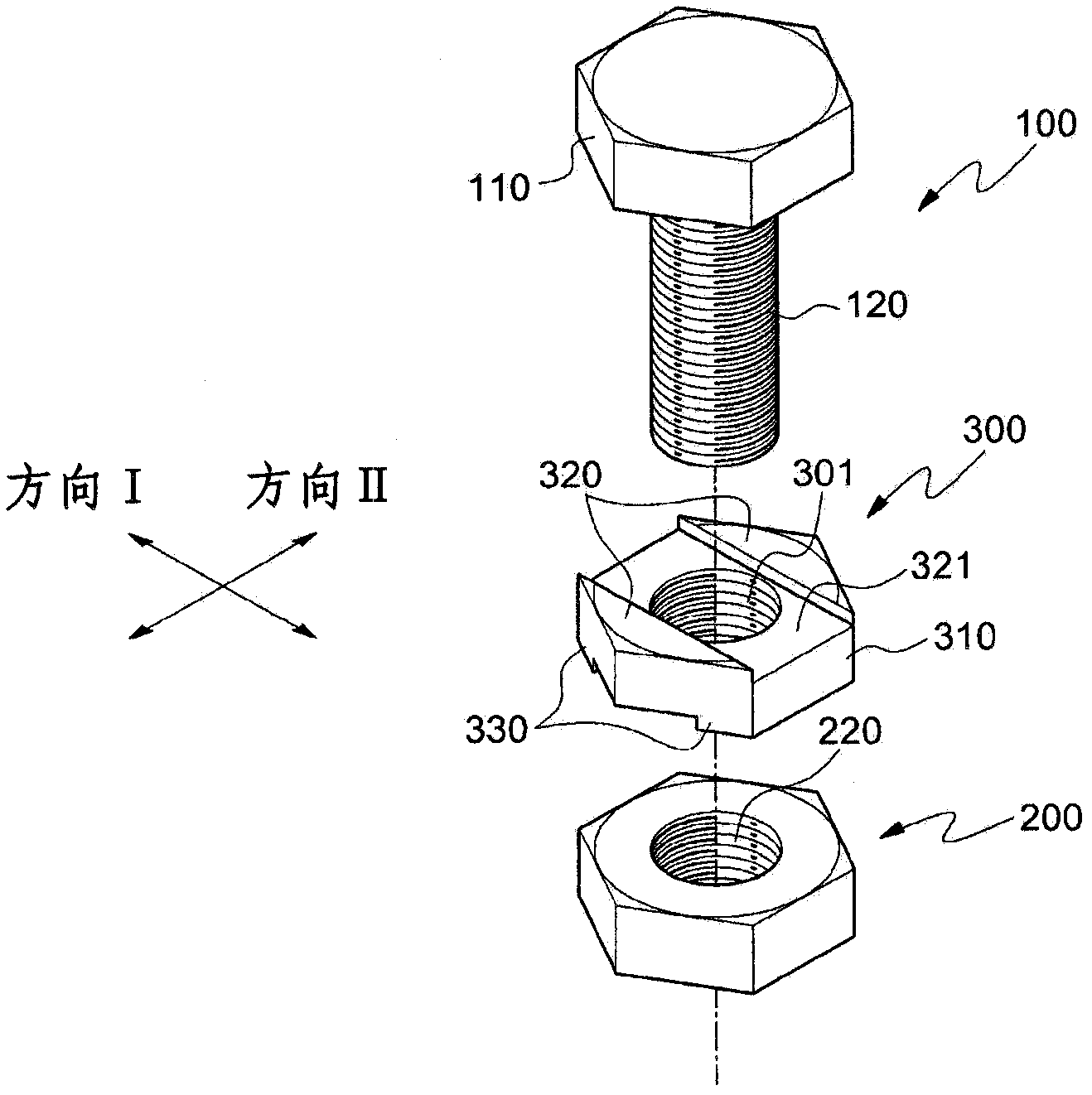

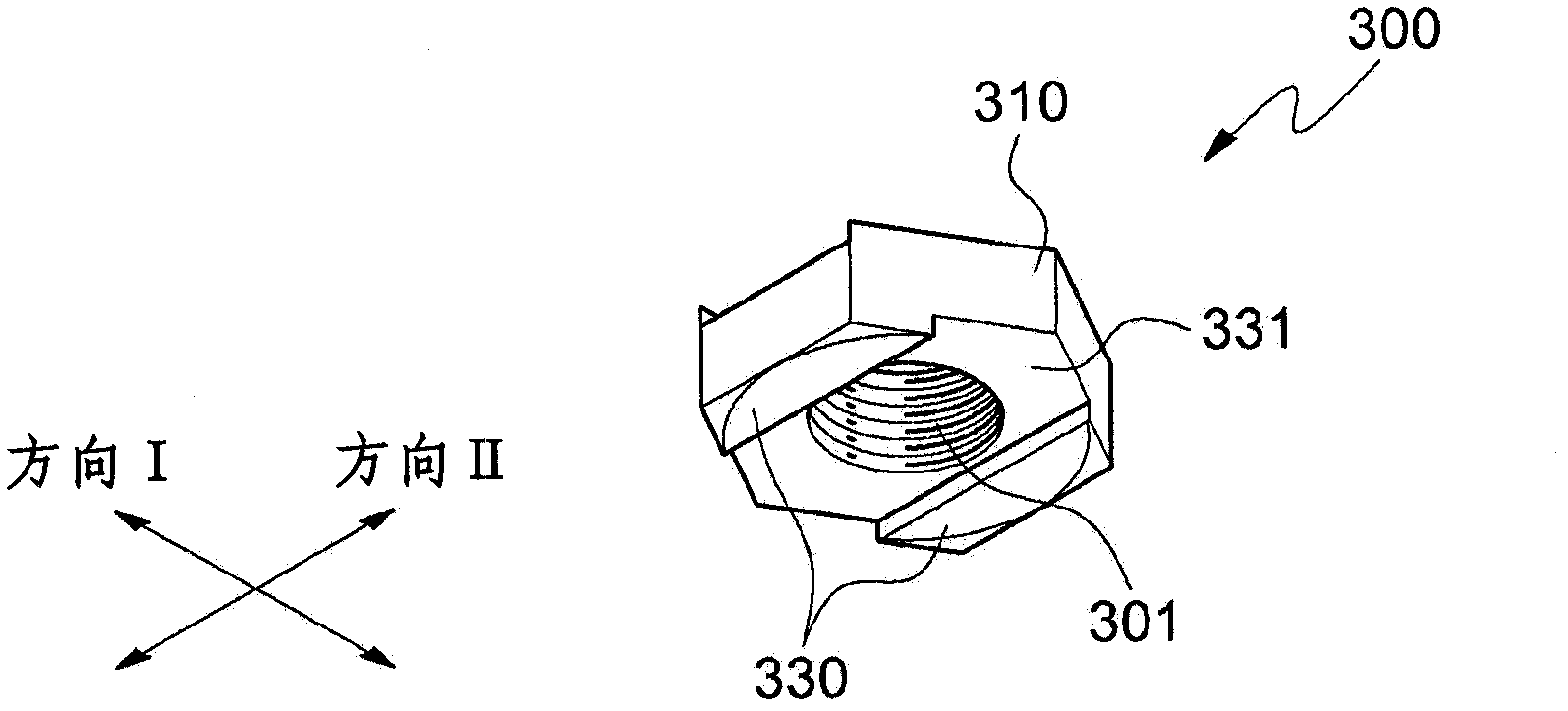

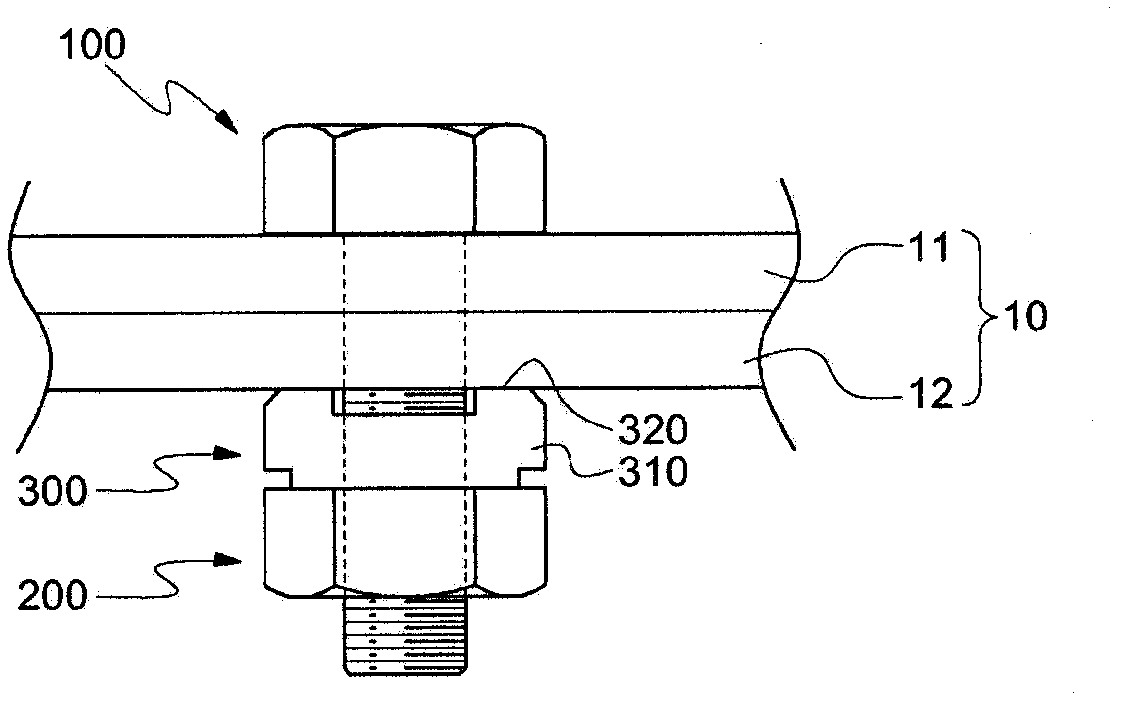

Lock nut and a fastening unit comprising the same

ActiveCN102985707AImprove anti-loosening performancePromote decompositionNutsBoltsMechanical engineering

Owner:李容国

Method of making excised aleuriospore permanent slide exemplar

InactiveCN101063644APermanent usePermanent slide usePreparing sample for investigationEducational modelsIonChemistry

This invention discloses one ion powder bubble permanent specimen process method, which comprises the following steps: a, adding the absorptive alcohol into centrifuge tube and picking up the bubbles into the tubes; b, putting into centrifuge machine; c, absorbing the alcohol in the tube and adding some; d, using absorptive tube for alcohol in tube and adding dimethylbenzene; e, adding the mixture of dimethylbenzene and resin glue into the tube; f, using glass bar to dip one drop of bubble floating on the load slice then covering to process permanent glass specimen.

Owner:HENAN AGRICULTURAL UNIVERSITY

Method for quickly purifying wheat thermo-photo sensitive genic male sterile line

PendingCN107996396AShorten the timeImprove purification effectPlant genotype modificationBiotechnologyGenotype

The invention discloses a method for quickly purifying wheat thermo-photo sensitive genic male sterile line, comprising the following steps: late sowing in winter, screening a typical K78S sterilize characteristic strain in the breeding field of the wheat sterile line K78S, performing bagging treatment on the typical K78S sterilize characteristic strain; harvesting the seeds of the bagged strain next summer, obtaining the double haploid lines of the wheat thermo-photo sensitive genic male sterile line by using a technology of inducing the wheat haploid by hybridization of wheat and corn; sowing in next winter by two stages, identifying by microscopic examination by stages, screening a line with similar fertility with K78S and with completely homozygous gene; performing expanding propagation in next summer to obtain a breeder's seed with stable fertility and homozygous gene of K78S. Compared with the traditional purifying method, the time can be shortened to half at least, the double haploid lines of the wheat sterile line with homozygous gene can be obtained within two years. According to the invention, purifying can be performed from genotype, the purifying effect is stable, the method can be used permanently and continuous purifying is not needed after the purifying, identifying and isolation and propagation are performed onece.

Owner:FOOD CROPS RES INST YUNNAN ACAD OF AGRI SCI

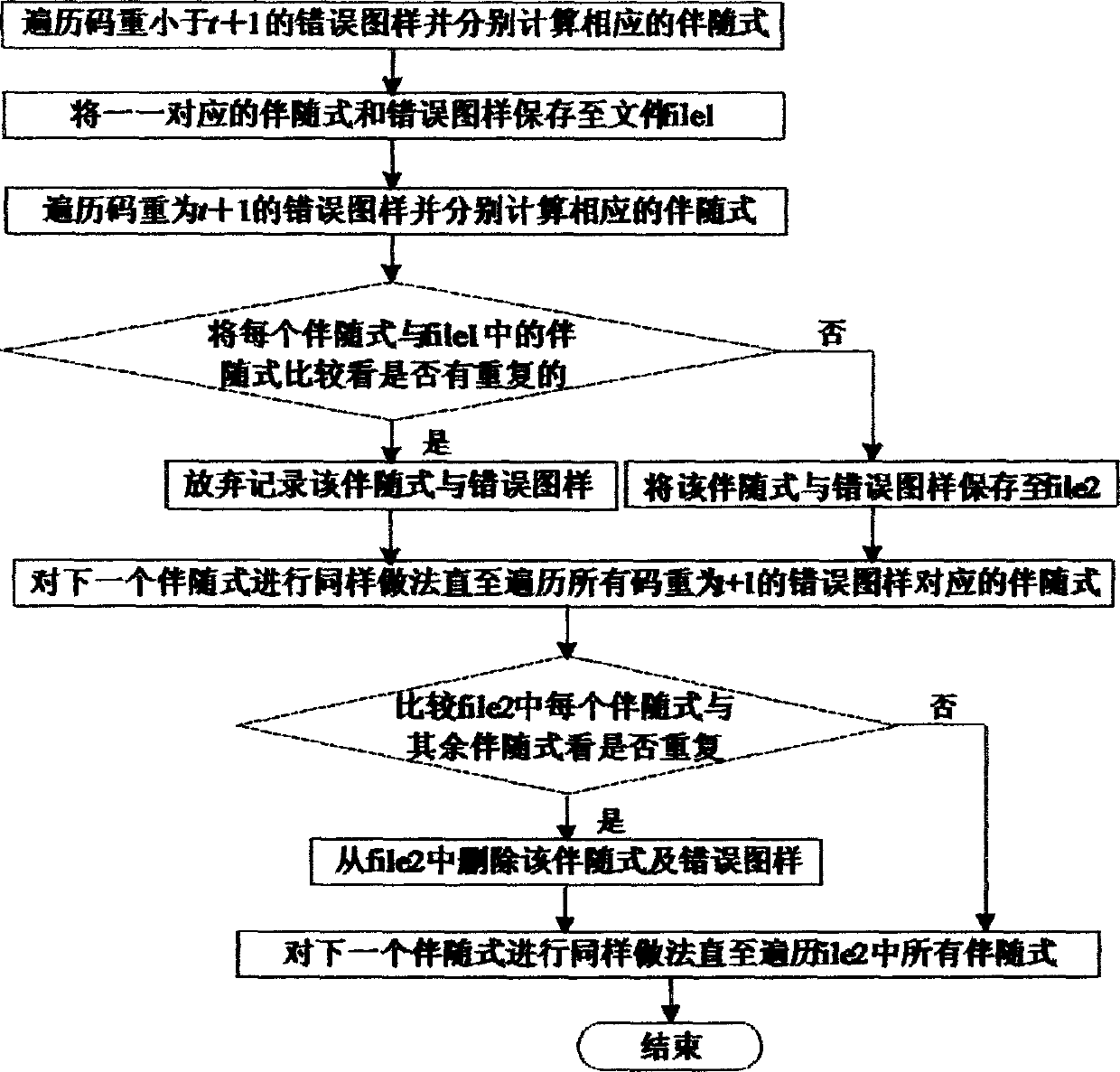

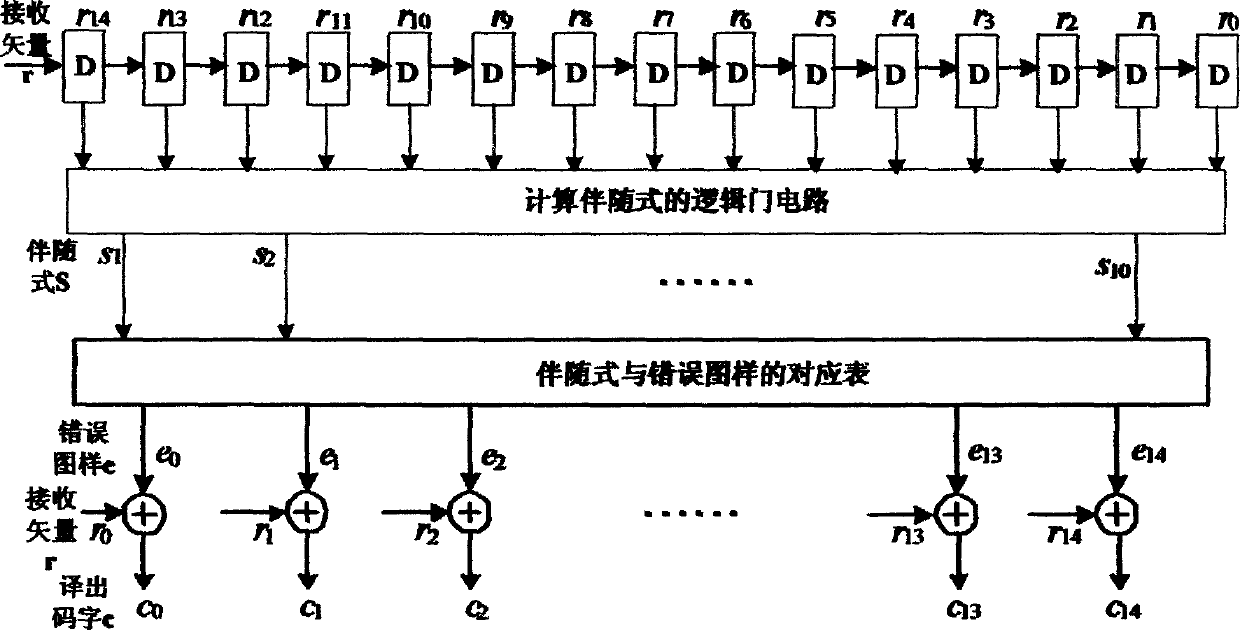

Method for extending circulation code error correcting ability

InactiveCN1588835ADecoding speed is fastSave resourcesError preventionComputer hardwareError correcting

A method for extending EC ability of a cycle code includes following steps: a, traversing error patterns with the code weight less than 1+1 and computing out the adjoint formula corresponding to one error pattern, b, storing the patterns and adjoint formulas in filel, c, traversing error patterns with 1+1 code weight and computing out adjoint formulas corresponding to the error patterns, d, comparing computed adjoint formulas with those stored in filel, e, operating the same way on error patterns with 1+1 code weight till traversing all error patterns with 1+1 code weight, f, comparing each adjoint formula in file 2 with the rest in file2, g, processing the next in the same way till traversing all formulas finally to array and store the error patterns from small to big in terms of the adjoint formulas.

Owner:SOUTHEAST UNIV

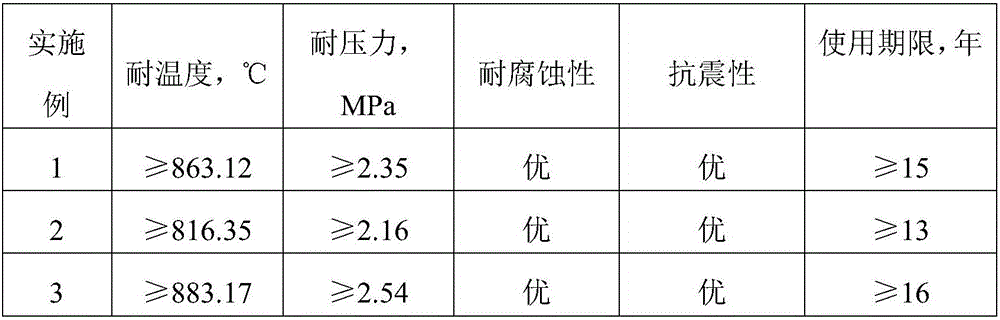

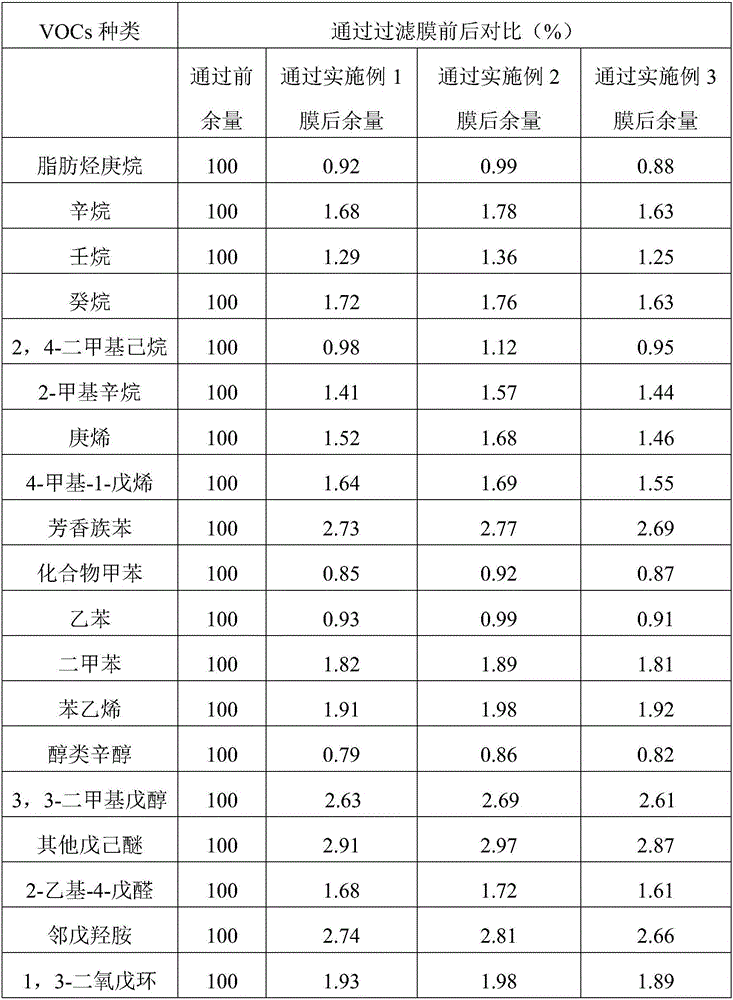

Filtering membrane for treating volatile organic compounds

InactiveCN106310979ARapid Active Absorption AdsorptionPermanent useSemi-permeable membranesGas treatmentFiberHigh absorption

The invention discloses a filtering membrane for treating volatile organic compounds. The filtering membrane comprises the following raw materials by weight part: 40-80 parts of feldspar, 30-50 parts of quartz, 10-20 parts of sodium silicate, 16-24 parts of activated carbon, 10-15 parts of zeolite, 8-12 parts of kieselguhr, 6-10 parts of carbon fiber, 2-3 parts of glass fiber, 0.4-0.6 part of catalyst, 0.5-0.8 part of cross-linking agent, 0.3-0.5 part of tackifier, 0.8-1.5 parts of plasticizer, 0.9-1.6 parts of flexibilizer and 0.4-0.6 part of stabilizer. The filtering membrane for treating volatile organic compounds provided by the invention is rich in active carbon, kieselguhr and zeolite, can directly absorb toxic gas including VOCs and has the characteristics of permanent use, high temperature and high pressure resistance, corrosion resistance, high absorption efficiency, excellent anti-seismic property and low preparation cost.

Owner:毛敬英

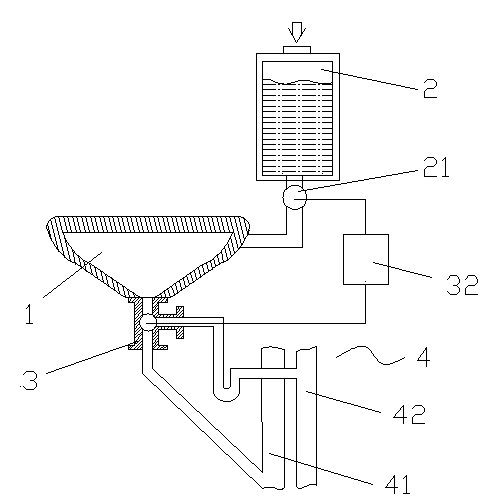

Environment-friendly system for excrement-water/urine-water separation and collection

The invention relates to the technical field of excrement-water separation, in particular to an environment-friendly toilet apparatus for excrement-water / urine-water separation and collection. The environment-friendly toilet apparatus comprises a water tank and a body. A three-way valve is connected to the bottom of the body and is connected with two connecting pipes which are independent; one connecting pipe is a blow-down pipe communicated with an excrement collection tank; the other connecting pipe is a drain pipe communicated with the blow-down pipe. The environment-friendly toilet apparatus has the advantages that excrement and water are separated for convenience of collection, active components are never diluted by the water, and organic fertilizer can be greatly collected for free; the organic fertilizer can be transported for farmland irrigation and restoration of the natural circulation of materials; methane gas, deep-processed fertilizer and proteins can be produced; fouling odor can be isolated effectively, a trap is omitted, flushing water is little, and water resources are saved; excrement and flushing water are separated and are discharged to urban sewers, low pollution is caused to rivers and lakes, underground water and soil are protected, cleaning work of septic tanks is reduced, and urban sanitation cost is reduced; the environment-friendly toilet apparatus is good in operation stability, simple in structure, low in cost and easy to maintain.

Owner:洪果平

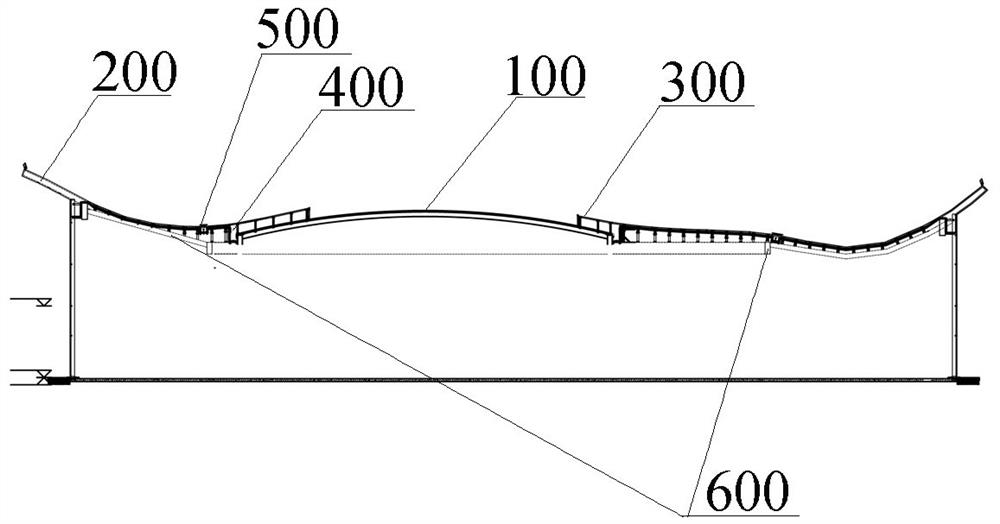

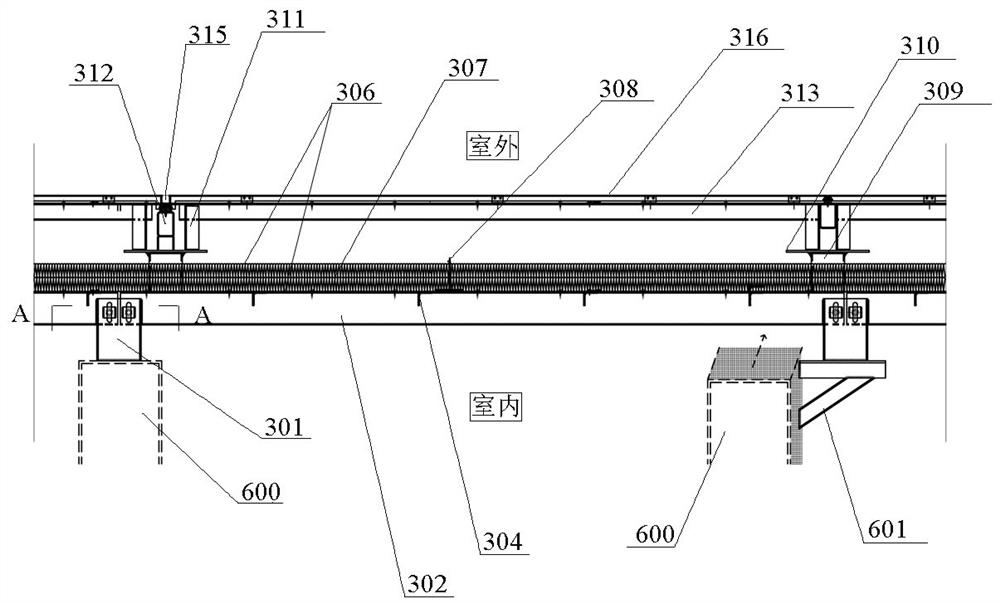

Lotus-leaf-shaped roof

PendingCN113982198AGood drainageEasy to shape the roofRoof covering using slabs/sheetsRoof drainageEnvironmental geologyMetal roof

The invention relates to a lotus-leaf-shaped roof comprising a daylighting roof located in the center and a metal roof body laid in a cornice mode from the outer edge of the daylighting roof to the upper portion, and annular gutters are arranged at the joint of the metal roof body and the daylighting roof and the low-lying position of the metal roof body around the roof body. The metal roof comprises steel adapters, primary and secondary purline structures, heat preservation structures laid on the primary and secondary purline structures, keel adapters, transverse and longitudinal keels and roof panels, all of which are sequentially connected with the main steel structure from bottom to top. According to the scheme, the technical problem of the connecting structure of the daylighting roof and the metal roof is solved, and the lotus-leaf-shaped roof has the advantages of good drainage effect and convenience in roof modeling; meanwhile, manufacturing cost is low, popularization is convenient, limiting is reasonable, wind pressure resistance is high, and thermal expansion and cold contraction are free; the whole roof panel is stable in performance, can be used permanently, can be widely applied to metal roof decoration of various large buildings, and meets the requirements of drainage and lighting.

Owner:中建二局装饰工程有限公司 +1

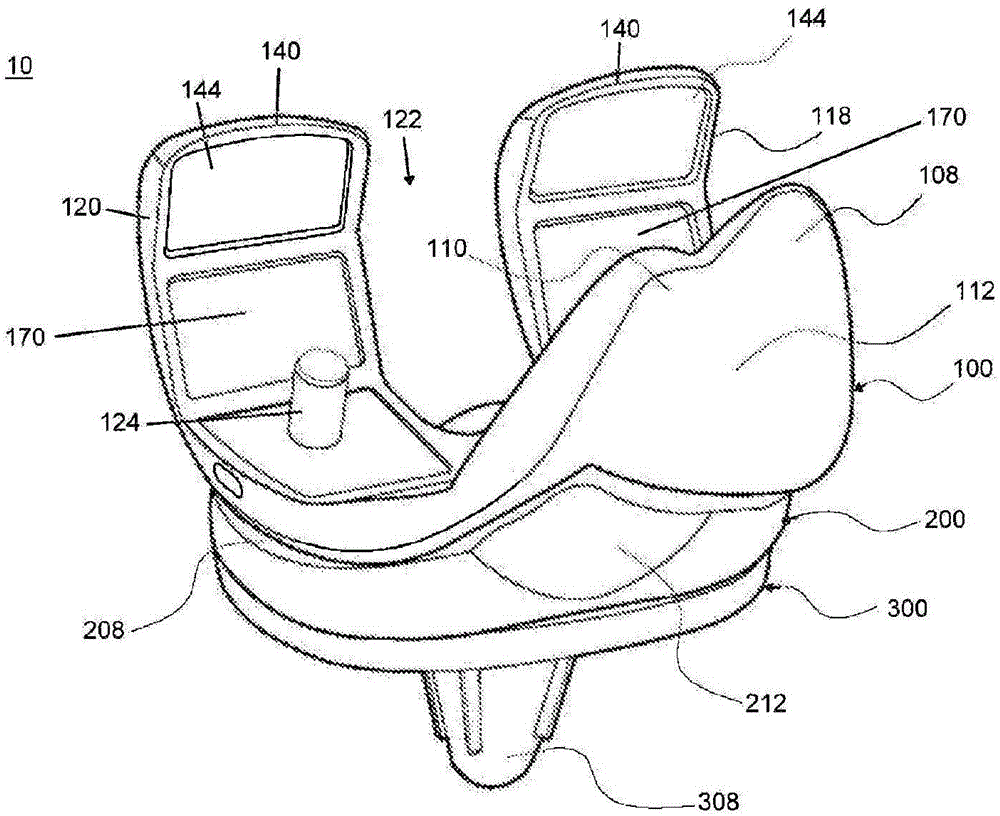

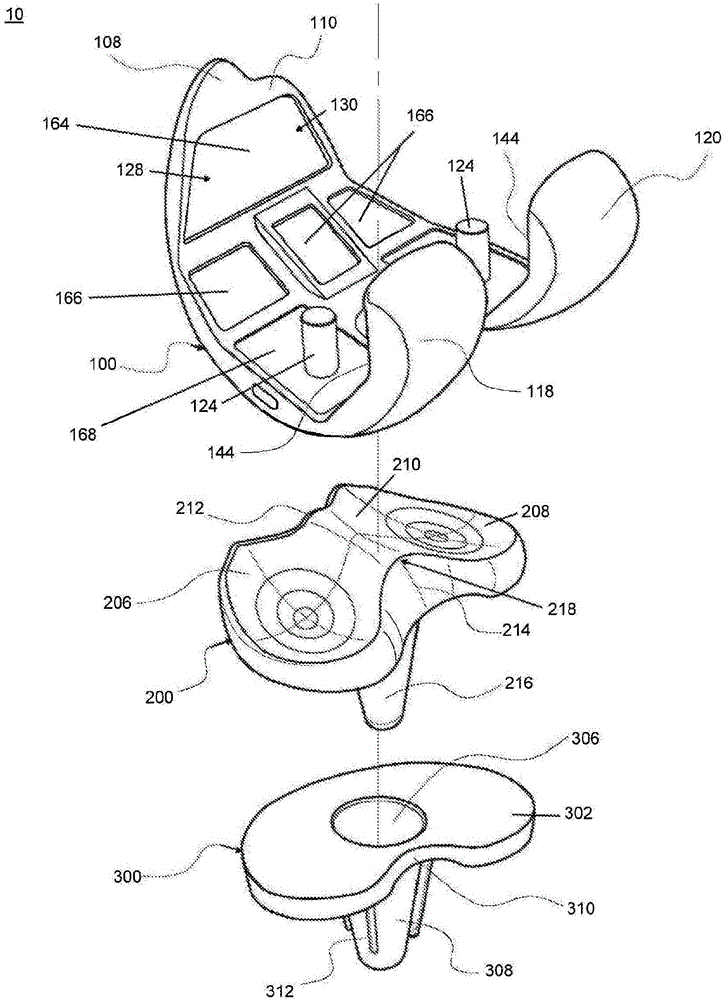

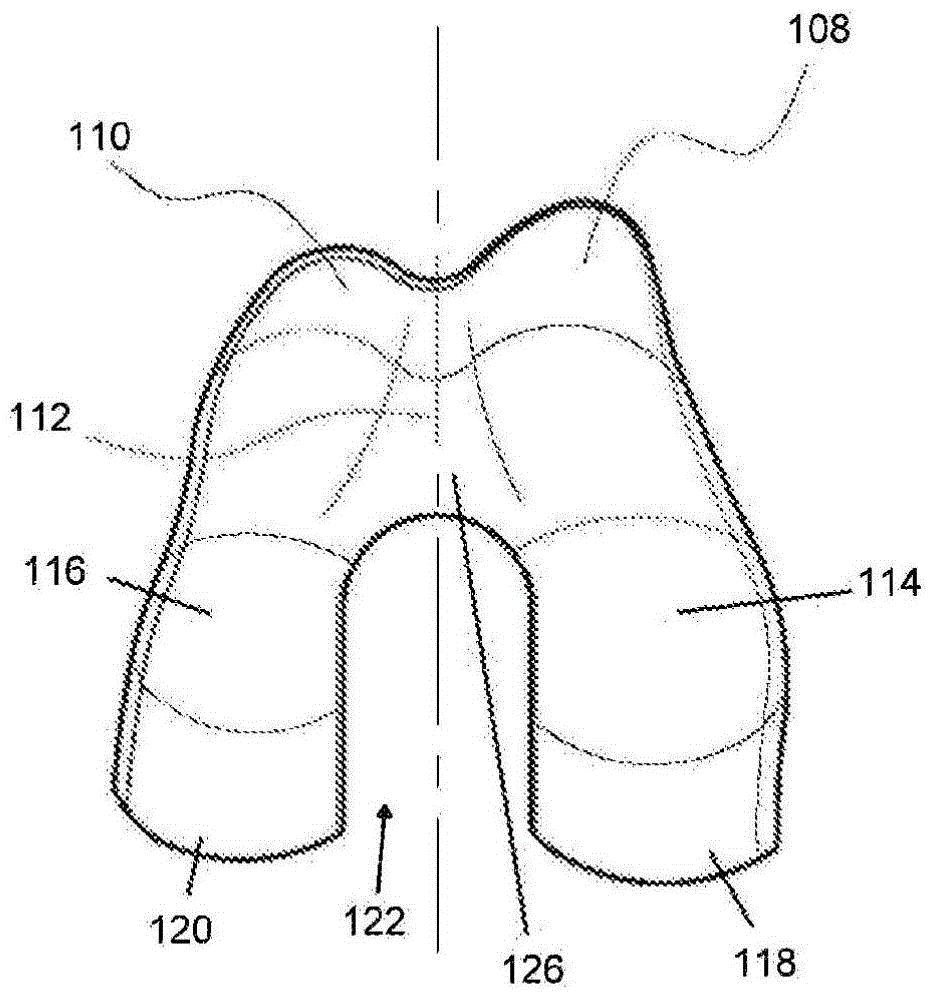

Femoral component for a femoral knee implant system

A femoral knee replacement prosthesis is disclosed including a femoral component, a tibial bearing component, and a tibial platform component. The femoral component includes an anterior condyle with a proximal lateral aspect adjacent a proximal medial aspect and separated by a patella groove, a distal lateral aspect adjacent a distal condyle medial aspect, and a lateral posterior condyle parallel with a medial posterior condyle. The distal condyle lateral and medial aspects are inferior the proximal lateral and medial aspects and the lateral and medial posterior condyles extend posteriorly from the distal condyle lateral and medial aspects. The tibial bearing component includes a proximal side for mating with the femoral component and a distal side. The tibial platform component includes a proximal side with an opening for receiving the tibial bearing component and a distal side including a post adapted to be fixed in a tibia.

Owner:康亨昱

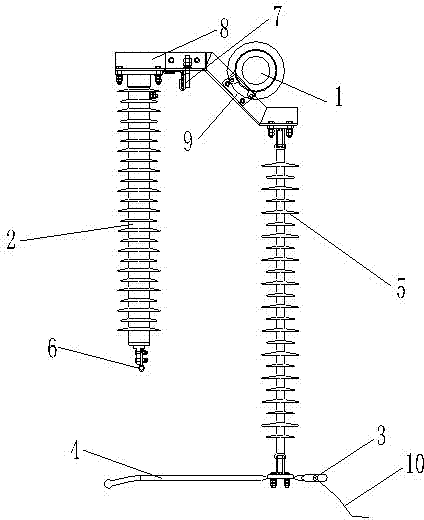

Pure air gap arrester

ActiveCN103701038APermanent useFixed discharge distance is accurateSpark gap detailsOvervoltage arrestors using spark gapsHigh resistanceFiber

The invention discloses a pure air gap arrester. The pure air gap arrester comprises a discharge counter, a discharge counter frame, a suspension beam below the discharge counter frame, an arrester main body, an upper gap rod, a fixing universal hook, a lower gap rod, an insulator, and a connection wire mounting hole, wherein the arrester main body and the insulator are arranged in parallel; both the upper gap rod and the lower gap rod are made of, by weight, carbon fiber 40%, high-carbon graphite 40%, copper powder 5%, white steel powder 5% and conductive resin 30% by pressing, wherein the carbon fiber is in a bar-like, round, octagonal, elliptical or ovale shape. The pure air gap arrester provided by the invention has the advantages of long service life, high stability, high strength, low specific gravity, light weight, and high resistance to heat, corrosion and radiation.

Owner:吉林市能兴电力设备有限公司

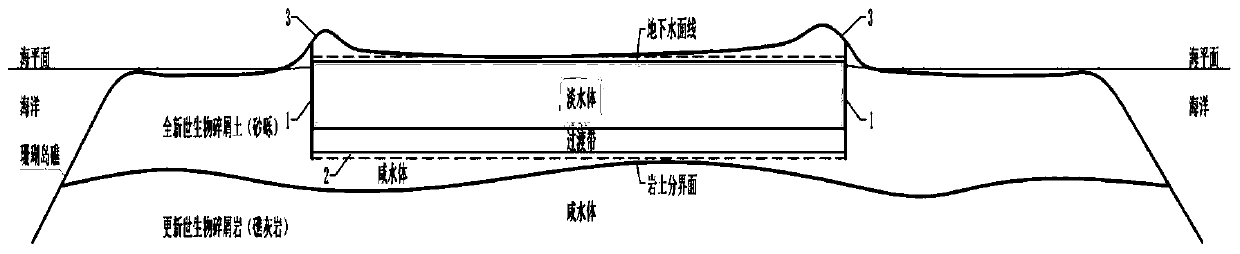

Coral island underground fresh water reservoir and construction method thereof

PendingCN111236140AIncreased freshwater storage capacityExcellent developabilityDamsHydraulic engineering apparatusNatural stateSalt water

The invention discloses a coral island underground fresh water reservoir and a construction method thereof. The coral island underground fresh water reservoir comprises an annular vertical anti-seepage body and an underground storable reservoir basin defined by the annular vertical anti-seepage body, the annular vertical anti-seepage body is an underground cutoff wall or an anti-seepage curtain, is arranged along the outer edge of a coral island reef and is used for changing the seepage boundary of underground water, the purpose of expelling salt water and storing fresh water is achieved, thebasic function of storing the fresh water in the reservoir is achieved, and the underground reservoir basin is an underground loose coral gravel soil body defined by the annular vertical anti-seepagebody. According to the coral island underground fresh water reservoir and the construction method, the occurrence form of the underground fresh water of the coral island reef is changed, so that the small coral island reef which is not easy to form an underground fresh water lens body in a natural state can also form an underground fresh water resource; the underground fresh water is intercepted,the total amount of the underground fresh water resource is increased, the problems that under the natural state, the available fresh water amount of the coral island reef is small, and the fresh water lens body is unstable and fragile are effectively solved, and social and economic benefits are remarkable; and surface vegetation conservation is facilitated, and ecological benefits are remarkable.

Owner:浙江省水利水电勘测设计院有限责任公司

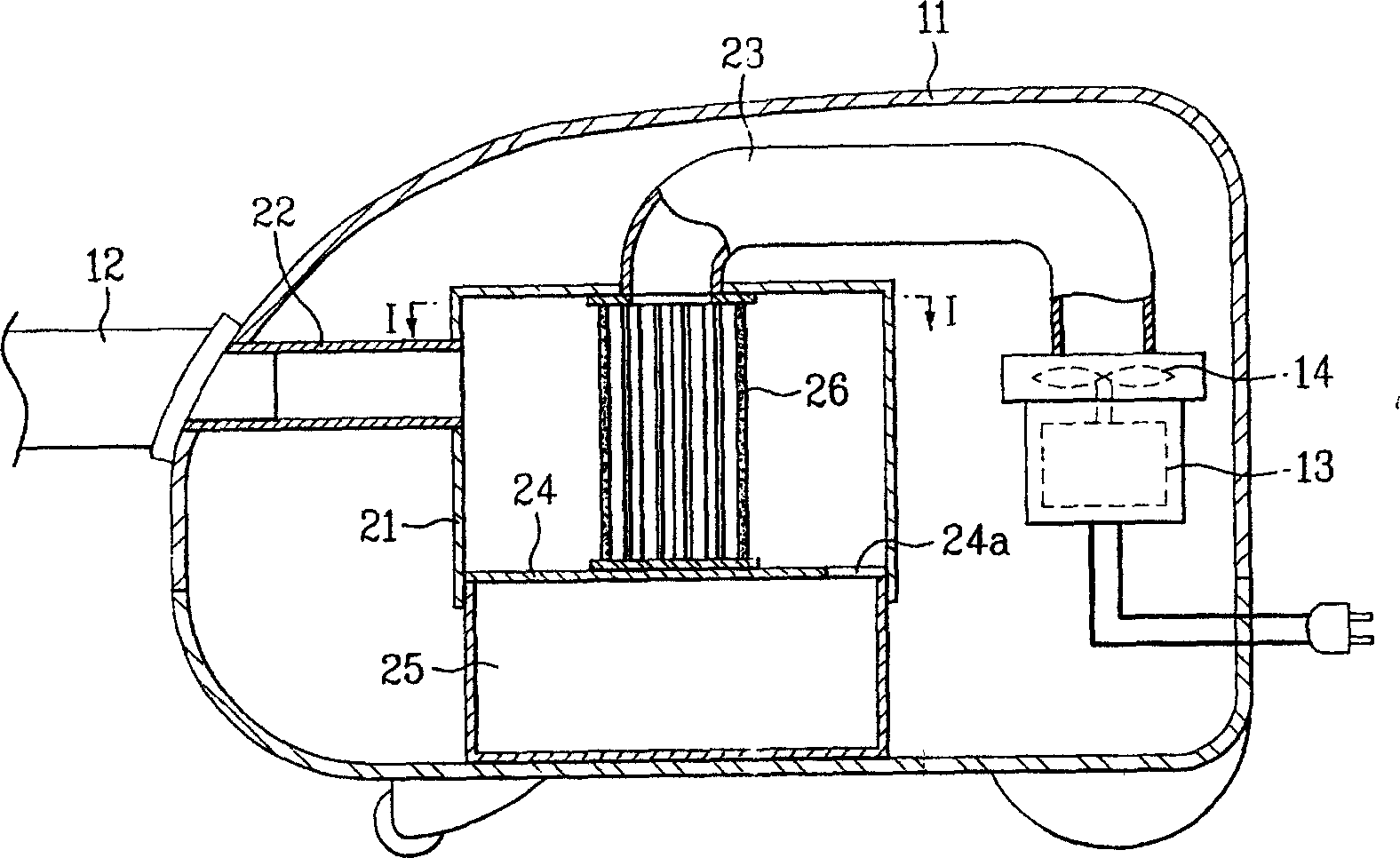

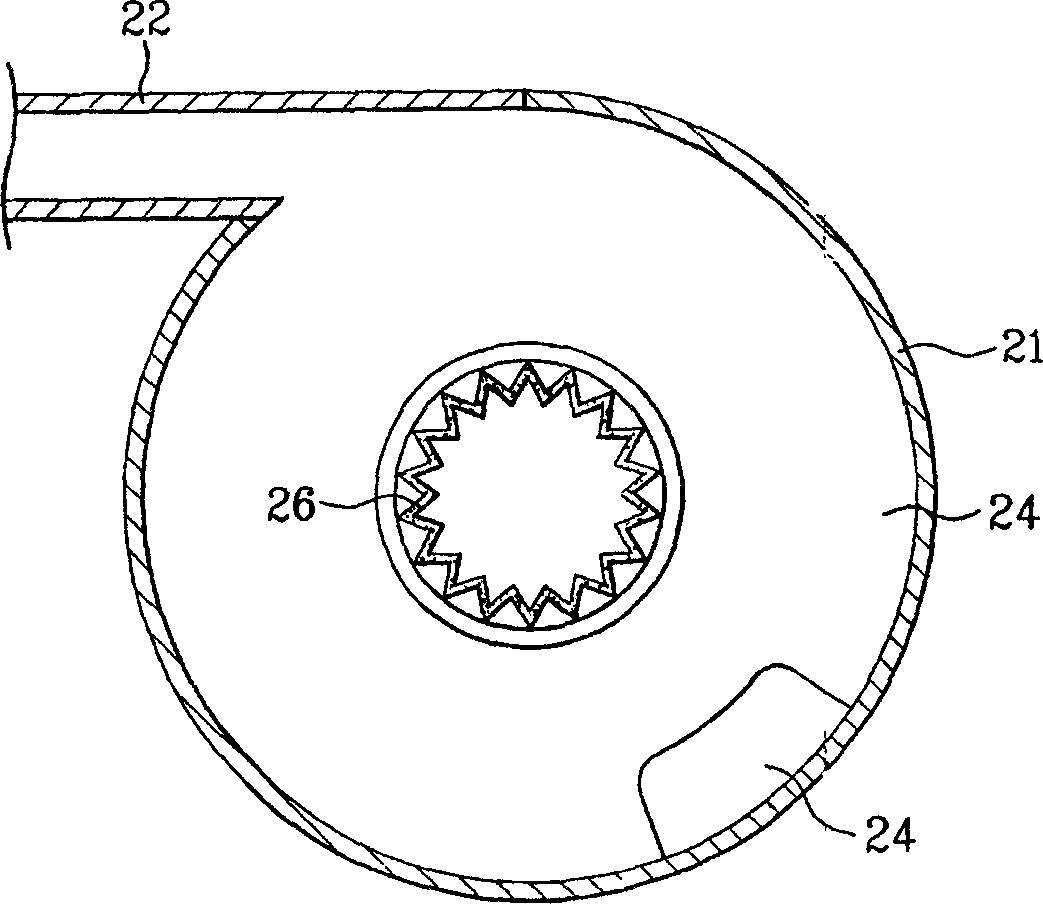

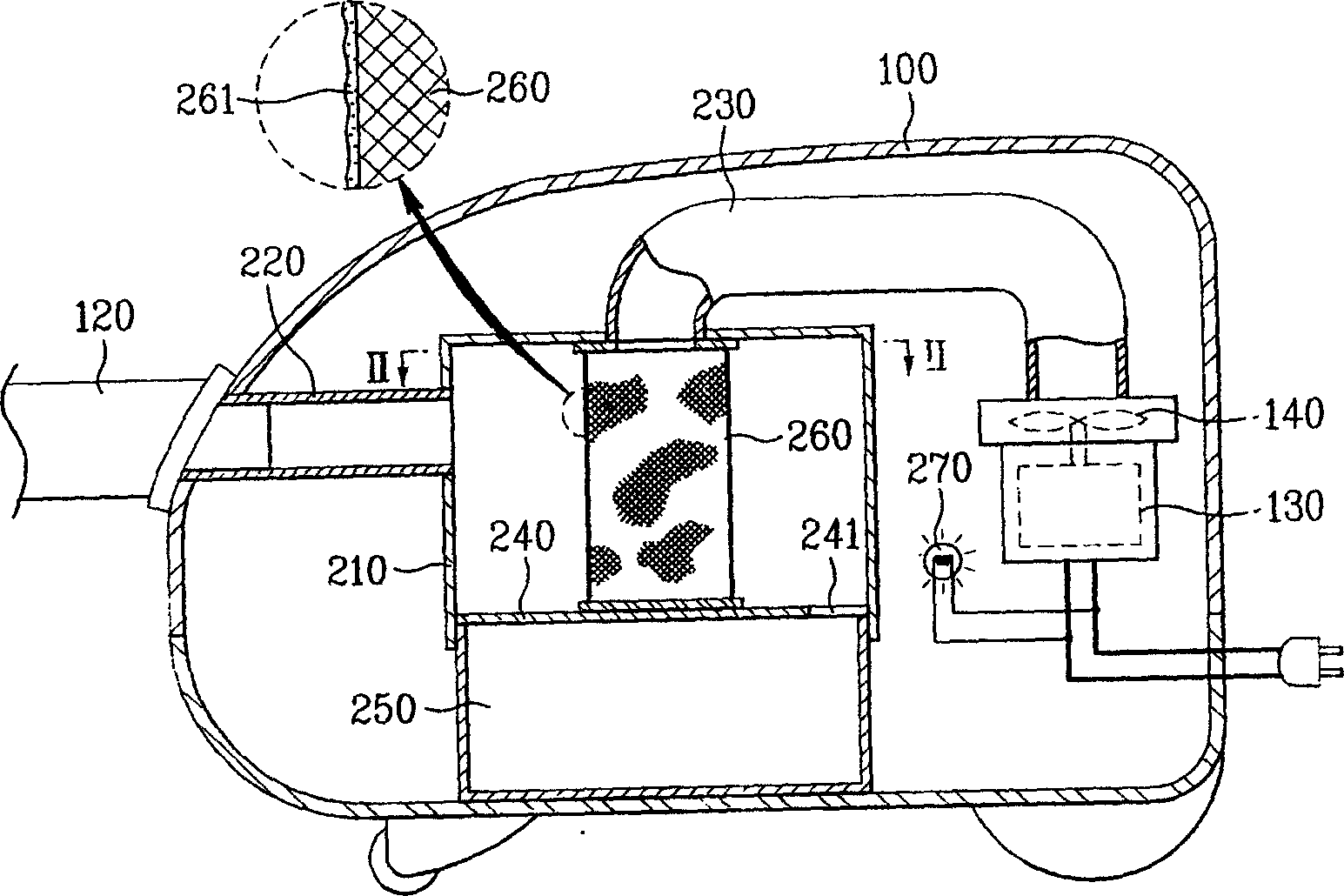

Cyclone type dust collecting unit

A cyclone dust collector able to prevent the pollution of microbes to filter is composed of a main body with motor and fan, a cyclone casing, an air inlet pipe, an air outlet pipe, a filter whose surface is coated by photocatalyst, and light source.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

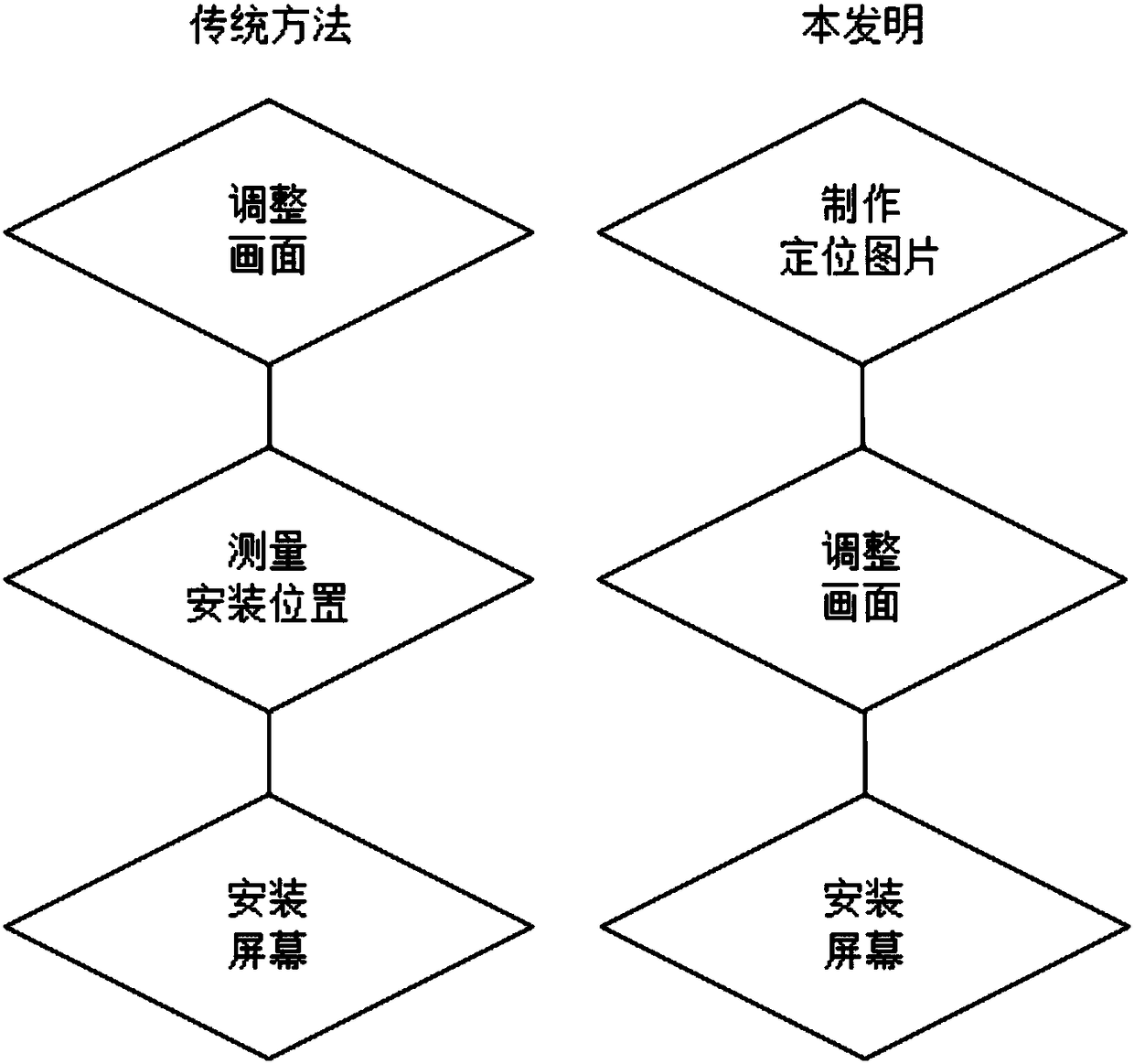

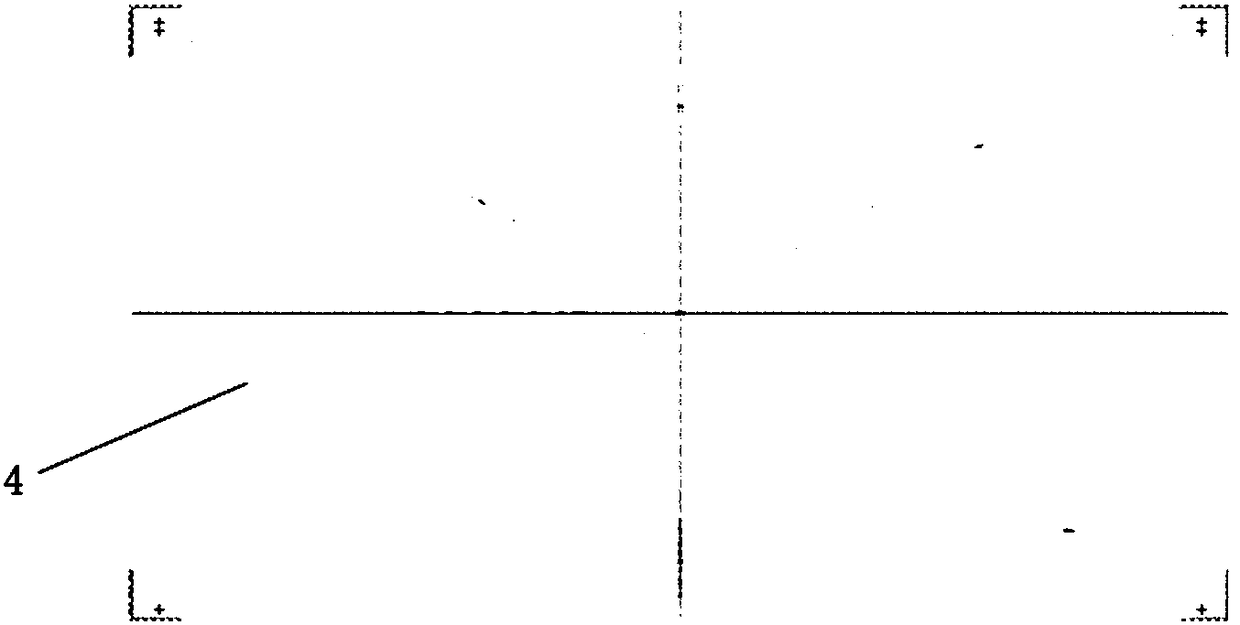

Optimized ultra short throw laser projection television hard screen installation method

InactiveCN108156432AAvoid Mass DimensioningReduce mistakesPicture reproducers using projection devicesDimension measurementComputer engineering

The invention discloses an optimized ultra short throw laser projection television hard screen installation method. The method comprises the following steps that 1, a pendant installation drawing matched with a hard screen is made to be a picture file of an equipment support format in advance; 2, the picture file is put in internal storage of projection equipment; 3, when the hard screen is installed, a picture is called from the projection equipment and projected; 4, the picture is projected to meet the size of the hard screen through mobile projection equipment; 5, the installation positionin the picture is the final installation position of the hard screen; 6, the hard screen is installed according to the positions; 7, after the hard screen is installed, the picture exits. According tothe technical scheme, by means of the optimized ultra short throw laser projection television hard screen installation method, a large amount of dimension measurement in a traditional installation method is avoided, time and labor are saved, errors are reduced, the precision is guaranteed, pictures for installation positioning can be used permanently and used once and for all.

Owner:CHINA HUALU GRP

Land-saving cemetery

InactiveCN103556865ASave land areaSatisfy the feeling of remembrance and commemorationBurial vaultsMonumentsLand areaInjection port

The invention relates to a building, in particular to a cemetery. The land-saving cemetery comprises a cemetery body, wherein the cemetery body is divided into an underground part and an overground part; the underground part comprises an underground palace and a bone ash chamber; the bone ash chamber is located on the basement level 1; the underground palace is located under the bone ash chamber and connected with the land; bone ash pipes are arranged in the bone ash chamber; injection ports are formed in the upper ends of the bone ash pipes; the lower parts of the bone ash pipes are connected with the underground palace; the overground part is a yearning area and used for holding a memorial ceremony and yearning. The land-saving cemetery provided by the invention can be used permanently after the cemetery body is built, saves land, is environment-friendly and can satisfy people's demands for recalling and commemorating the departed.

Owner:陈海霞

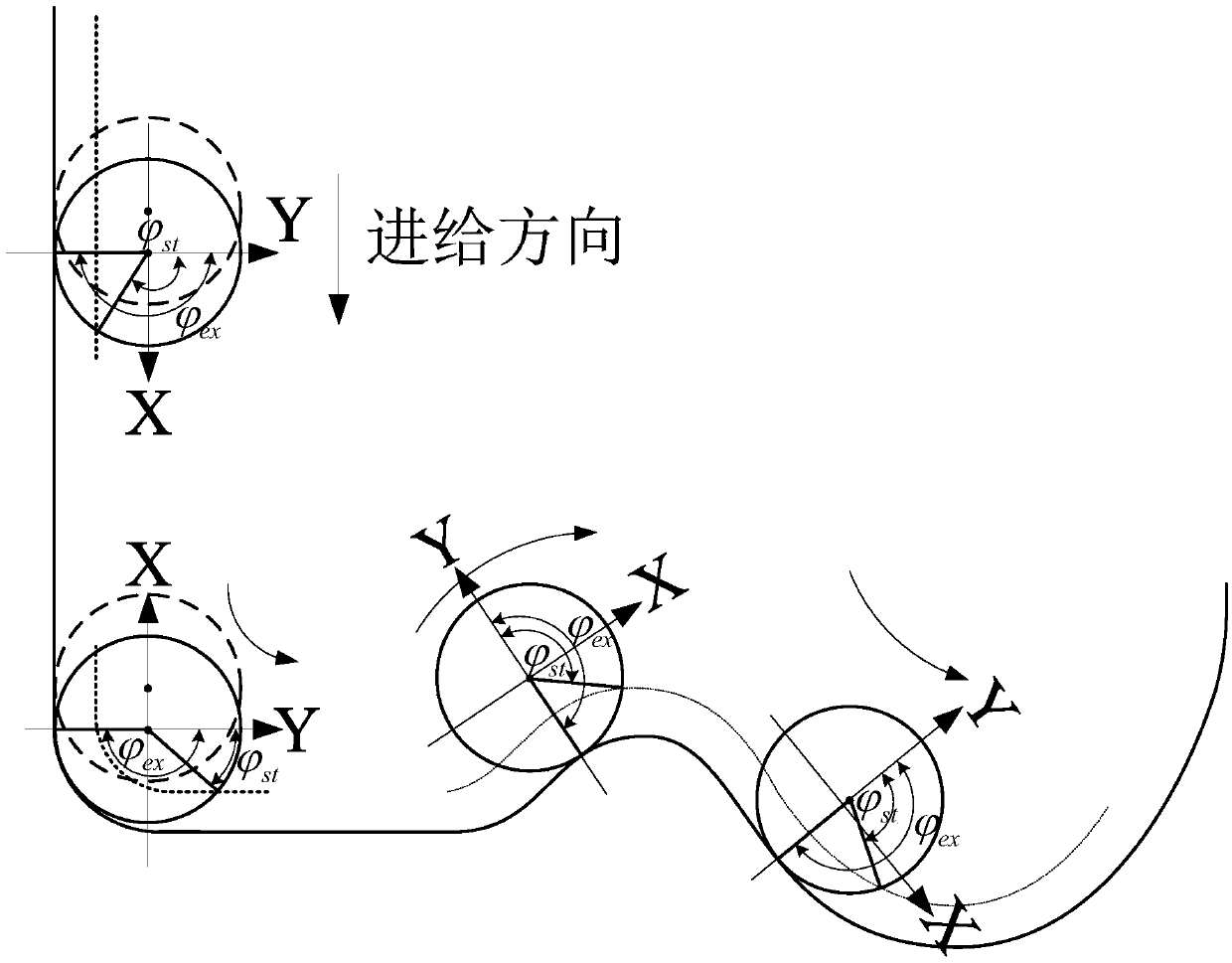

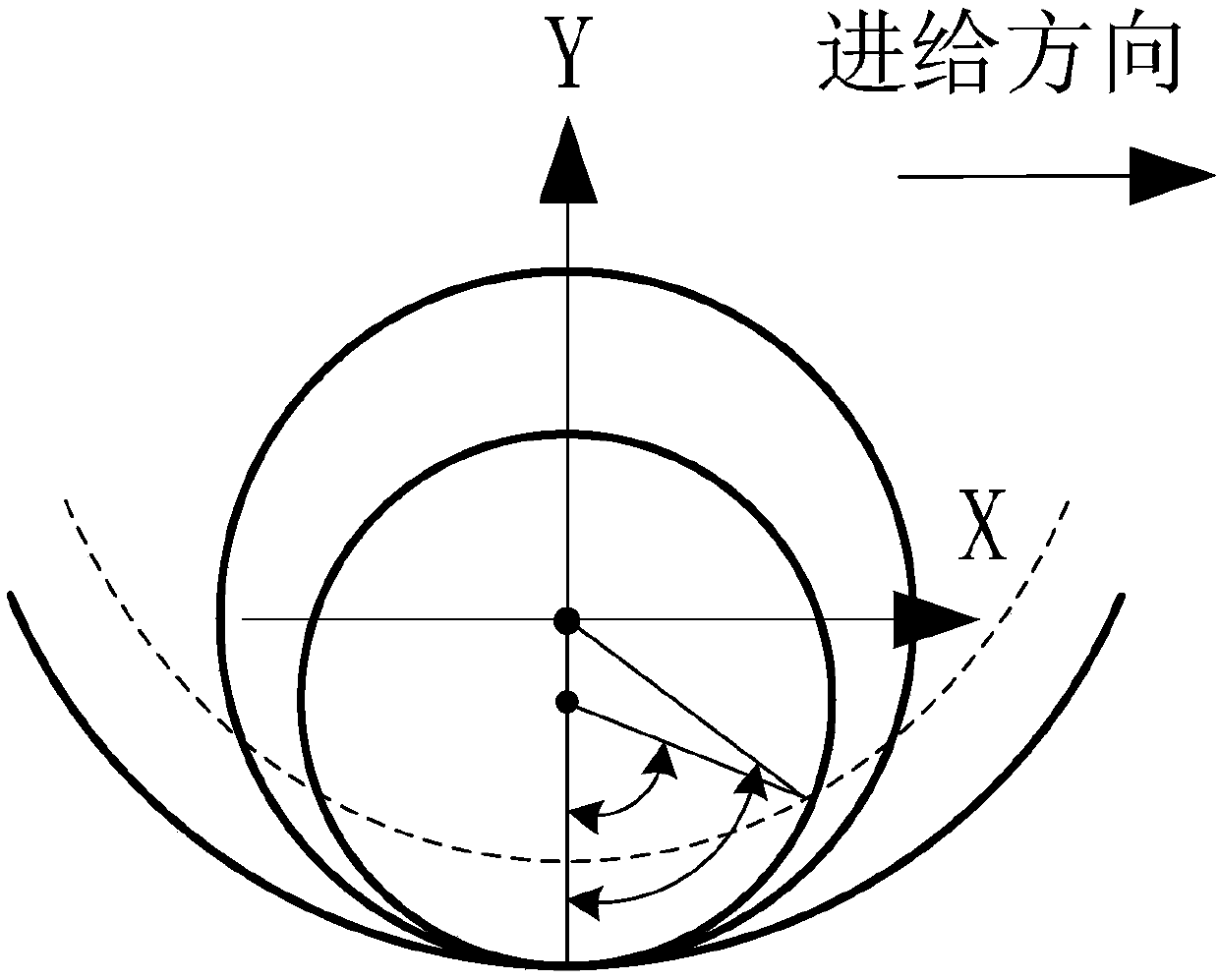

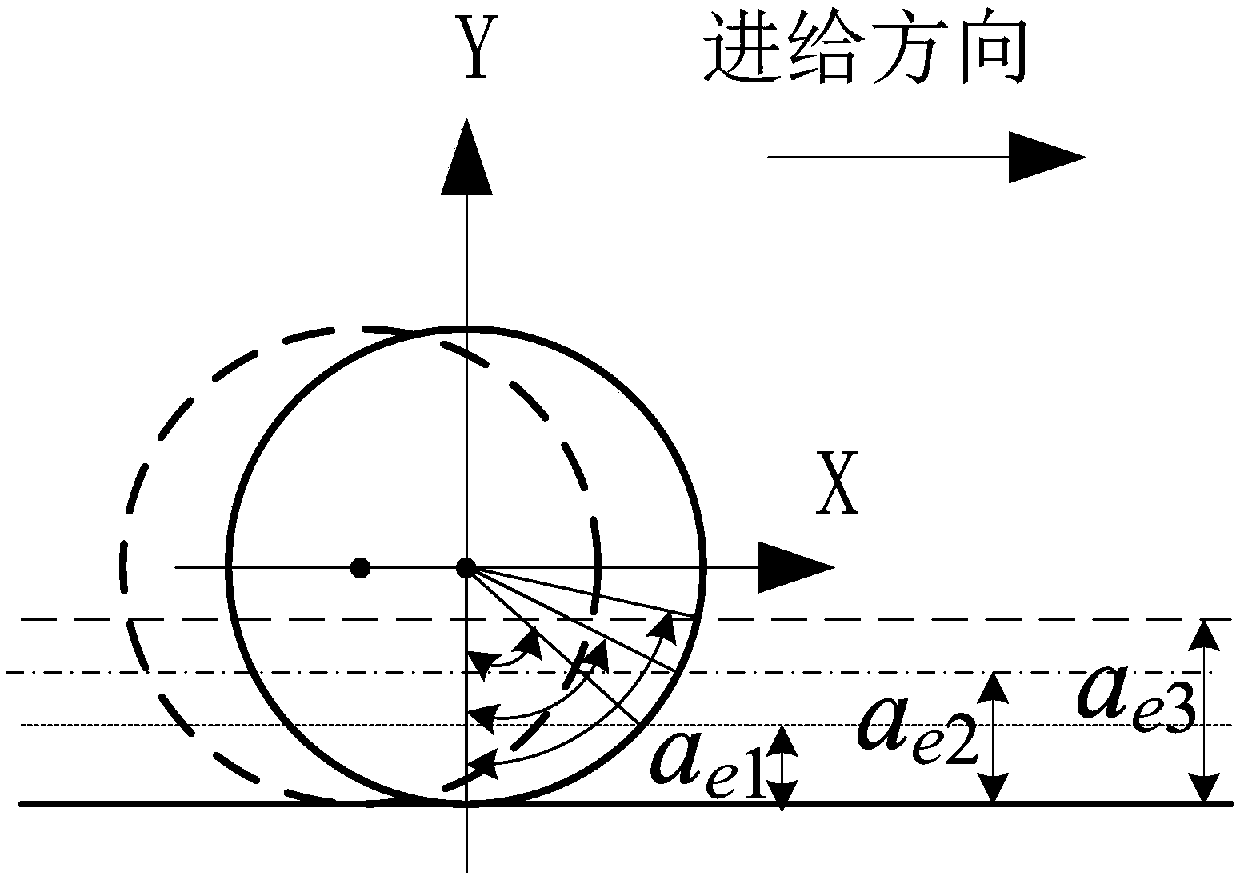

Method for prediction of flutter in numerical-control milling of mold cavities

InactiveCN108746795AFlutter predictions are accurateGuarantee processing qualityMilling equipment detailsNumerical controlMilling cutter

The invention relates to a method for prediction of flutter in numerical-control milling of mold cavities, aiming to solve problems that conventional methods for predicting stability in milling utilizing single tool path are low in applicability, which causes low accuracy of flutter prediction, accelerates failure of tools and affects processing quality of mold cavities. The method for predictionof flutter in numerical-control milling of mold cavities includes the step 1, building the relative transfer function of a tool-workpiece system; the step 2, introducing the relative transfer function of the tool-workpiece system to a three-dimensional milling stability model to obtain a critical axial cutting depth at the milling flutter frequency of a milling cutter; the step 3, judging whetherthe mold cavities flutter in numerical-control milling according to the critical axial cutting depth obtained in the step 2. The method is applied to the field of numerical-control milling of the mold cavities.

Owner:HARBIN UNIV OF SCI & TECH

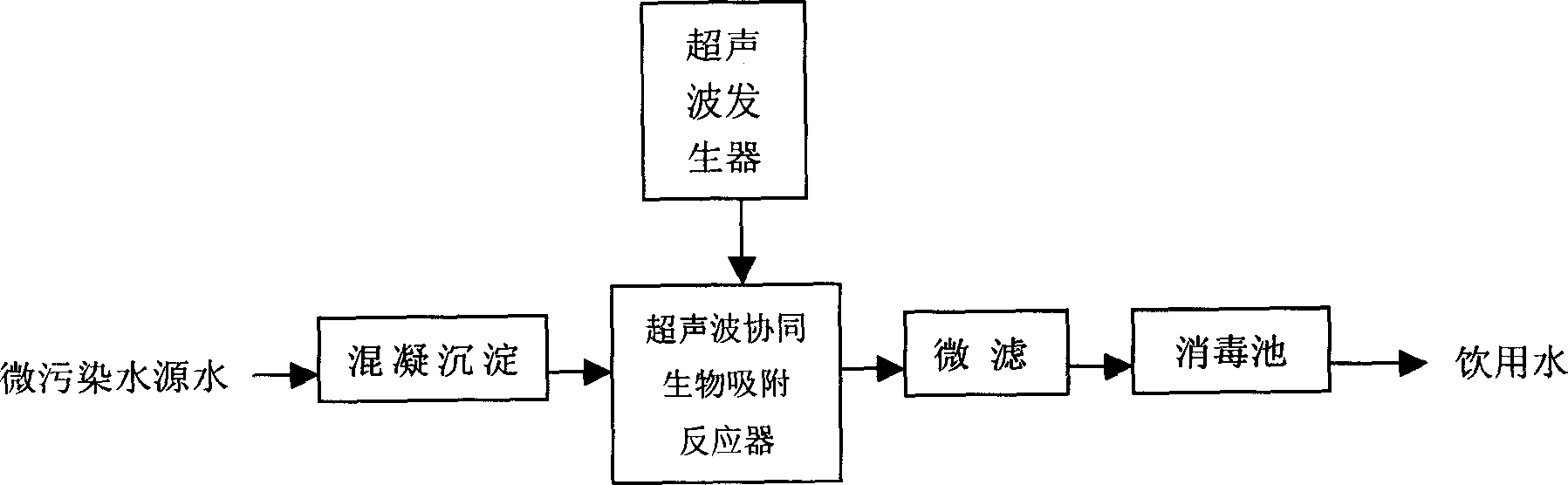

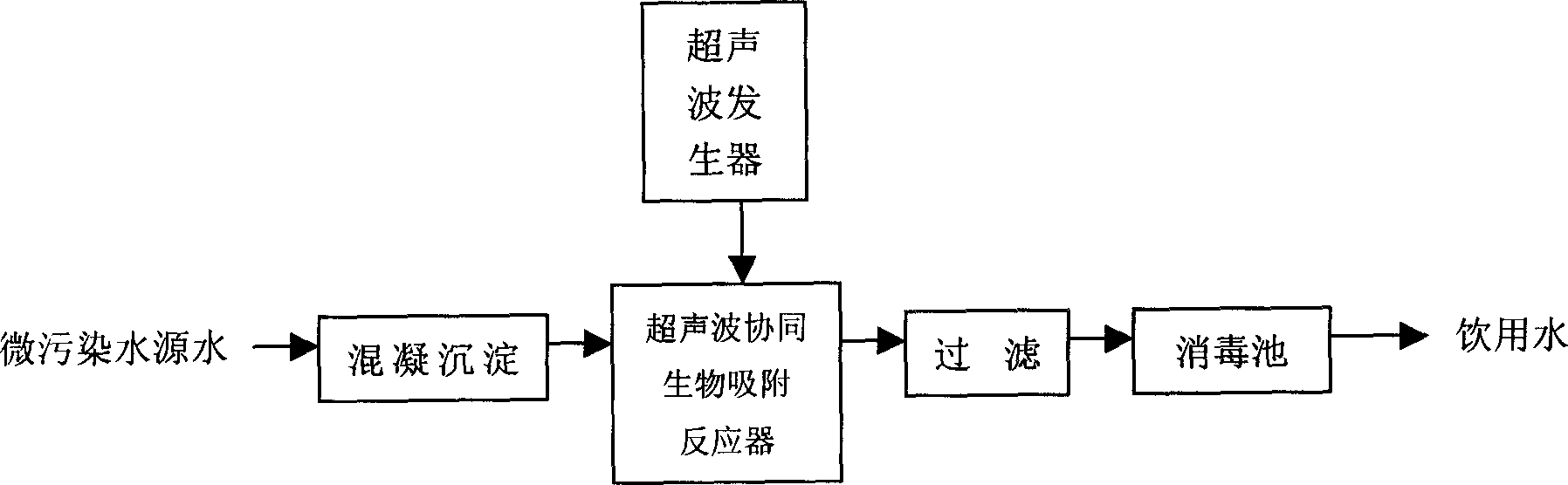

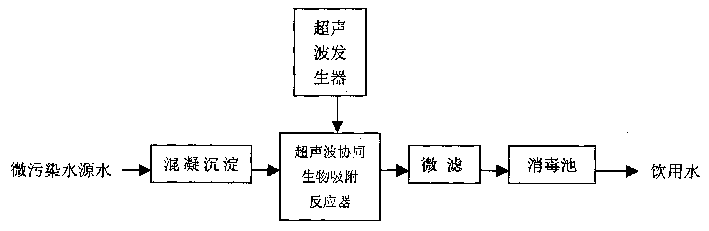

Ultrosonic wave concerted biological adsorption water treating method

InactiveCN1491909AGood removal effectEfficient and stable removal effectMultistage water/sewage treatmentWater sourceWater quality

The present invention relates to synergic ultrasonic wave and biological adsorption method of treating water. In the reactor, granular or powdered active carbon with microbe attached is filled and is made in fluidized state owing to water flow and aeration to eliminate biodegradable and hard-to-biodegrade organic matter effectively. The active carbon is microbe regenerated constantly. Ultrasonic wave is made to radiate the microbe attached to the active carbon to raise mass transfer capacity of microbe cell wall, increase the activity of enzyme and strengthen the capacity of microbe in degrading hard-to-biodegrade organic matter. Even if in water temperature lower than 15 deg.c, the said method can reach potassium permanganate index eliminating rate as high as 40 % to polluted water source. The method is used in water treating system with high water quality requirement.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com