Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Not prone to warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

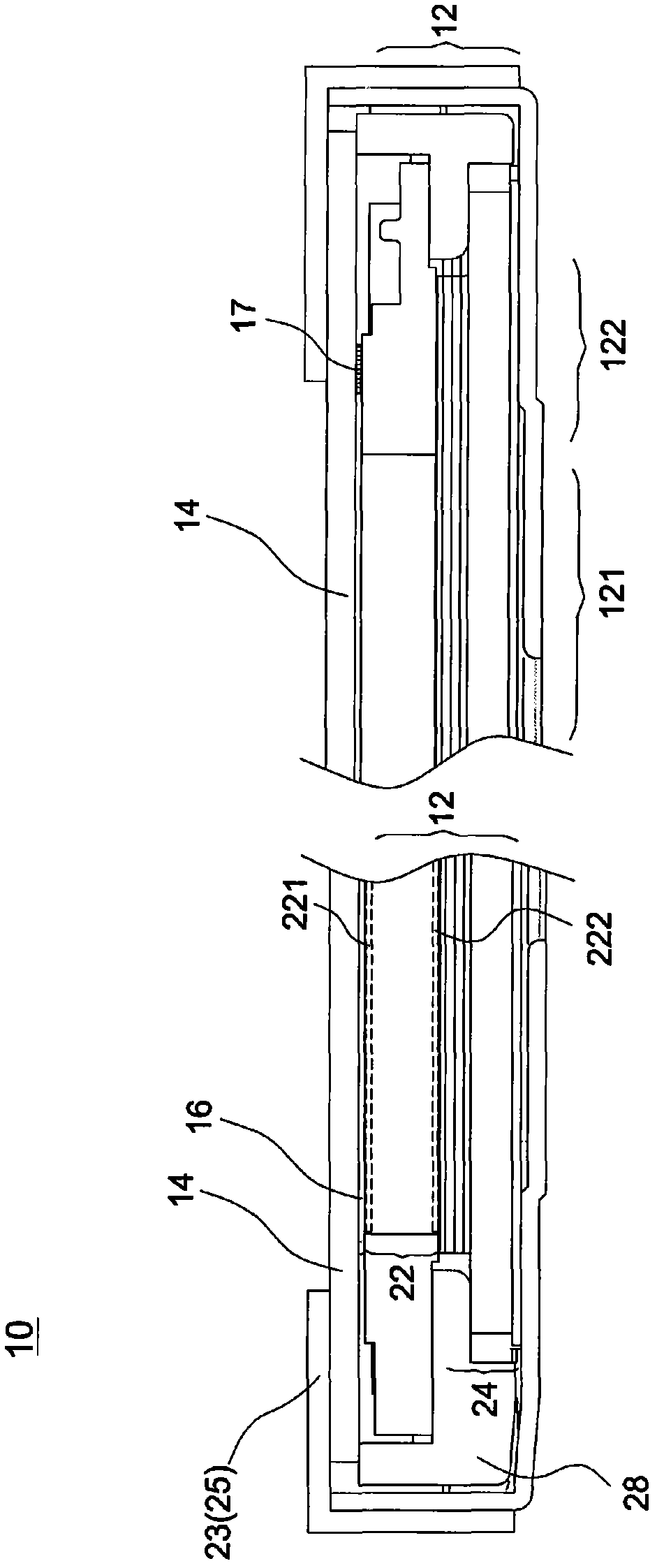

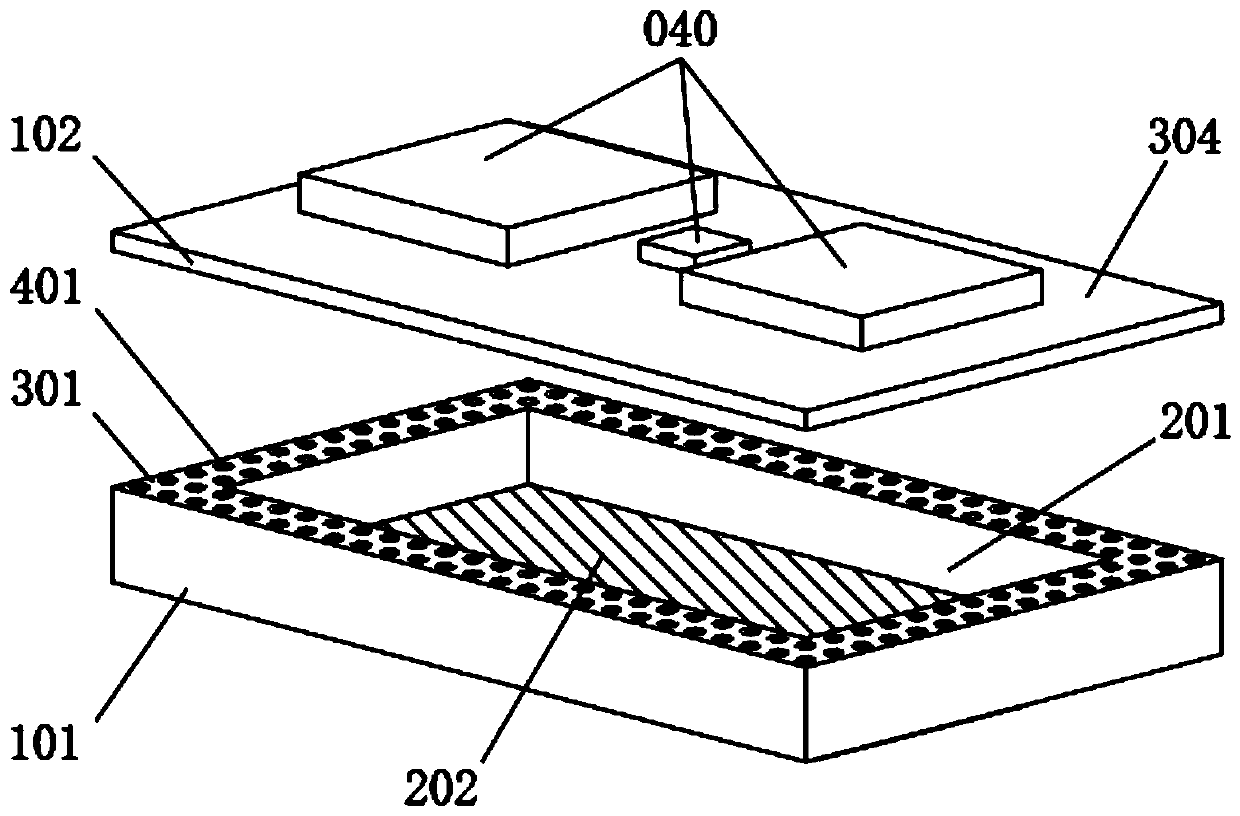

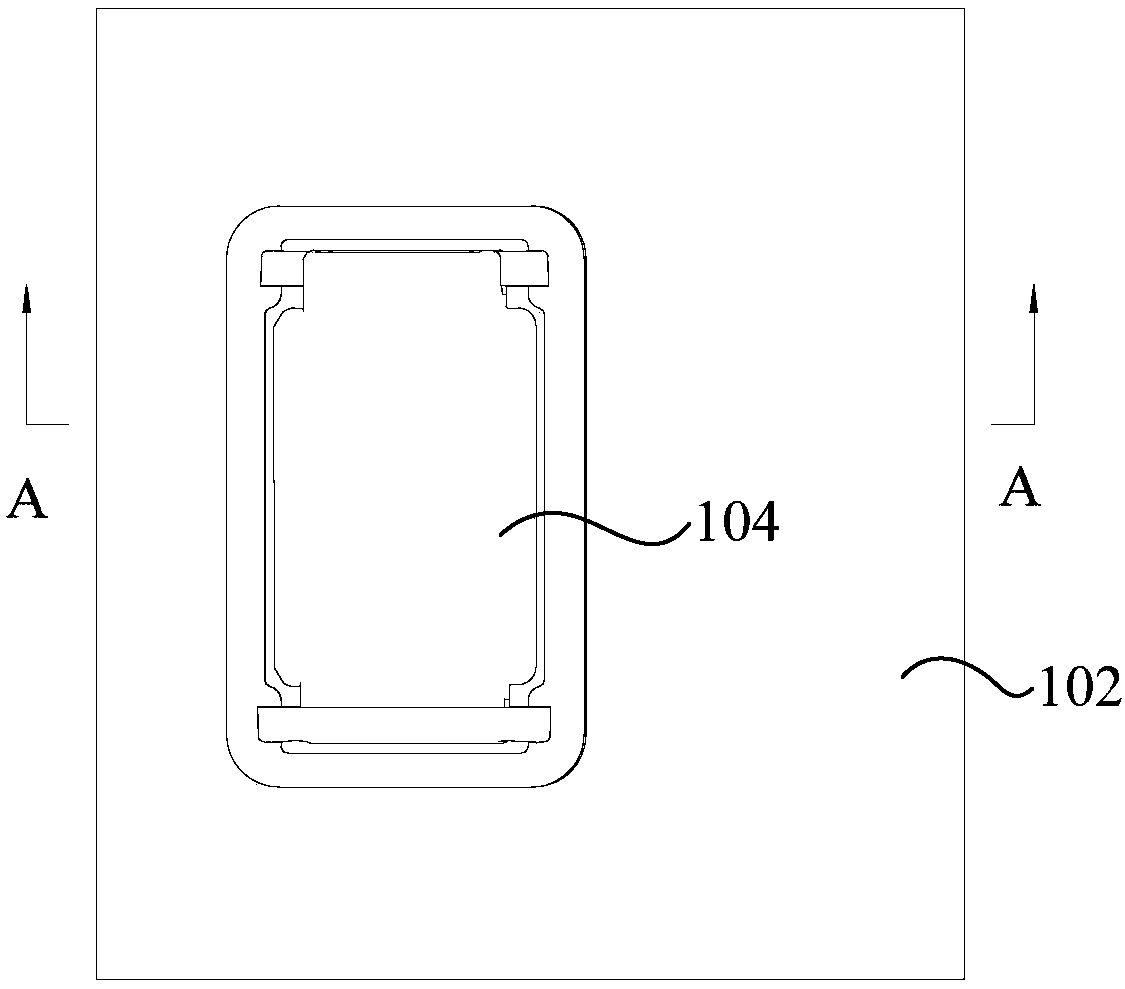

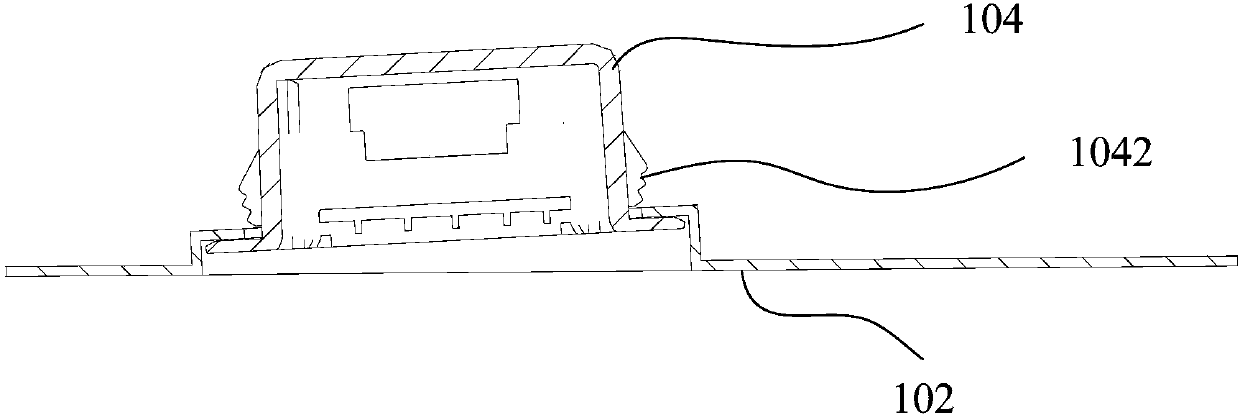

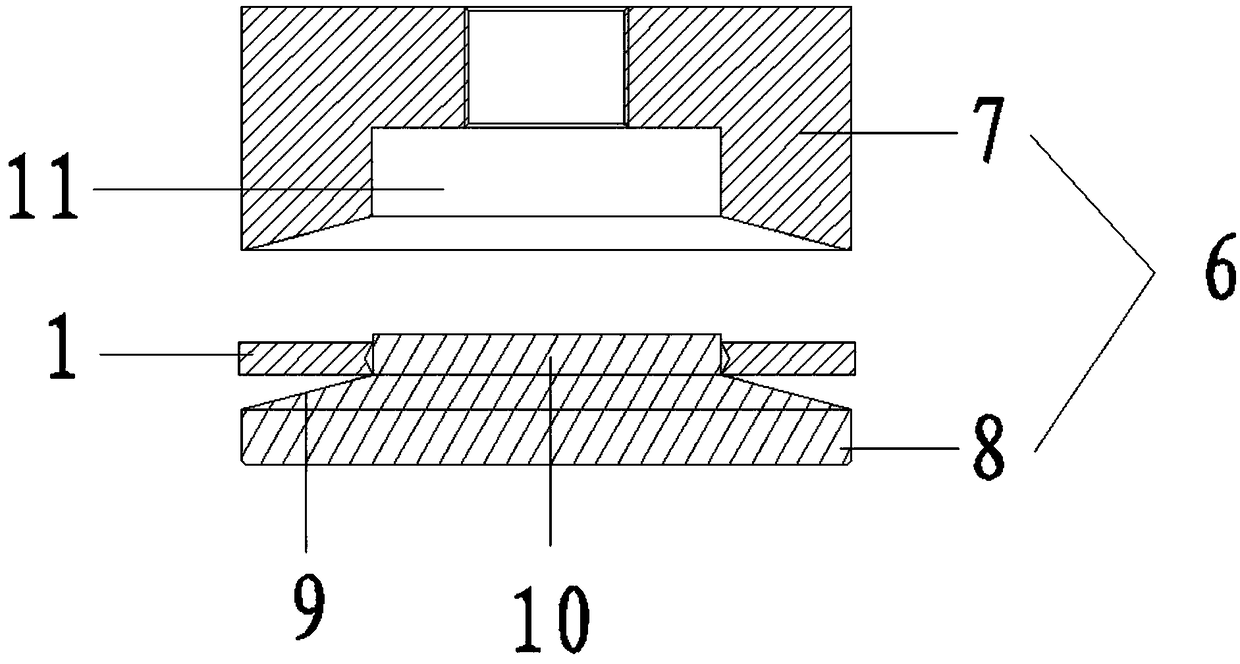

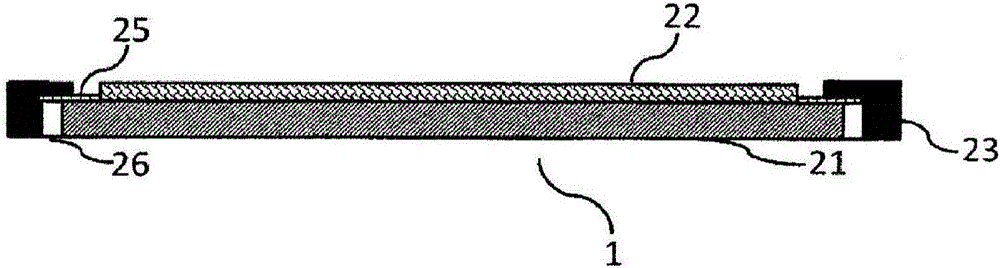

Touch display device

InactiveCN102566808ANot prone to warpingSimplify the assembly processStatic indicating devicesInput/output processes for data processingLiquid-crystal displayTouch Senses

The invention discloses a touch display device which comprises a liquid crystal display module and a touch sensing element, wherein the touch sensing element is attached to one surface of the liquid crystal display module.

Owner:YOUNG LIGHTING TECHNOLOGY INC

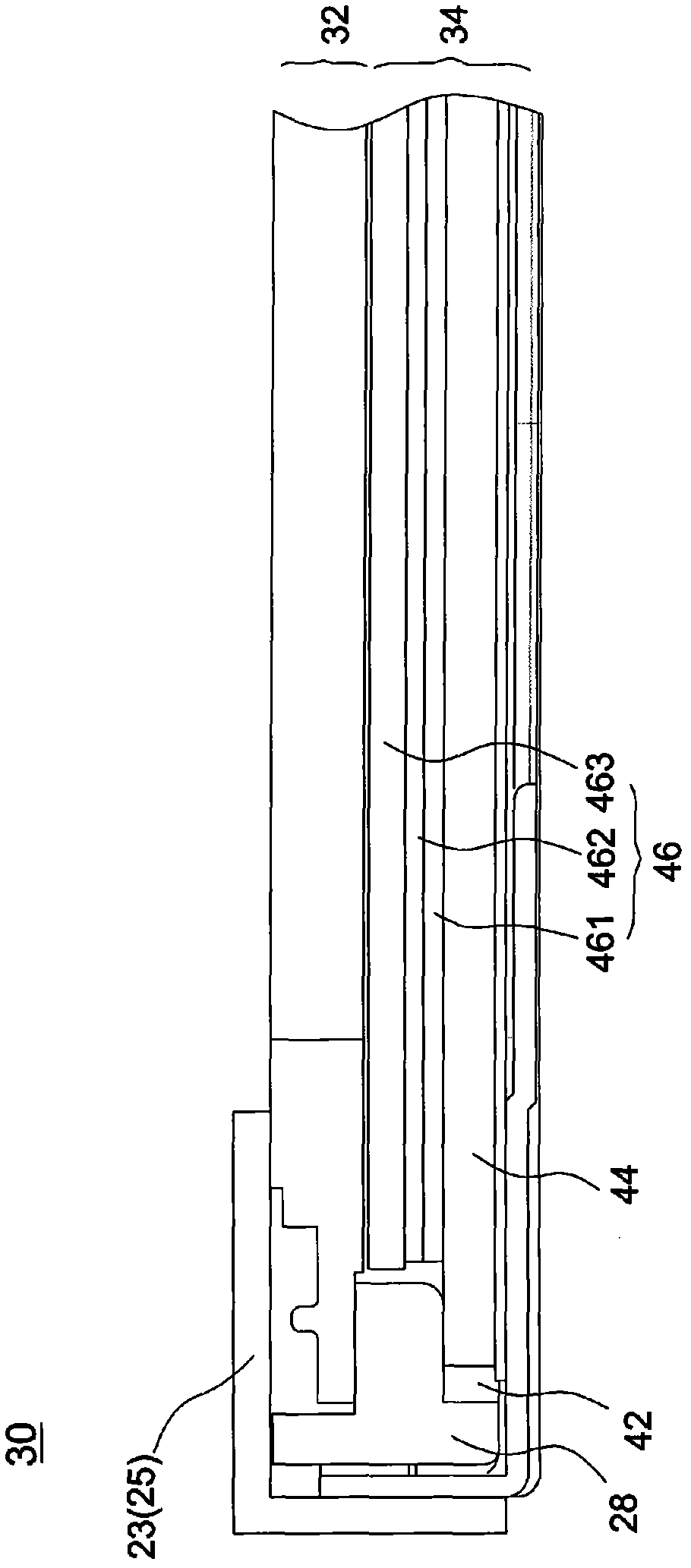

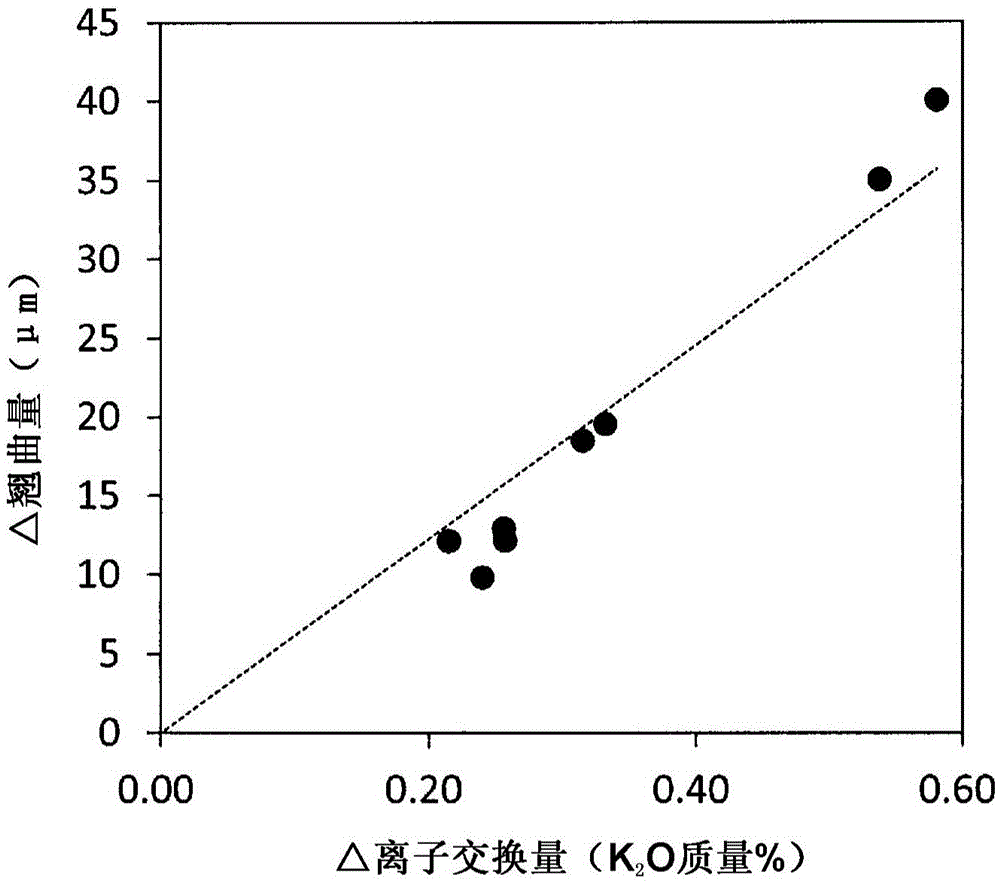

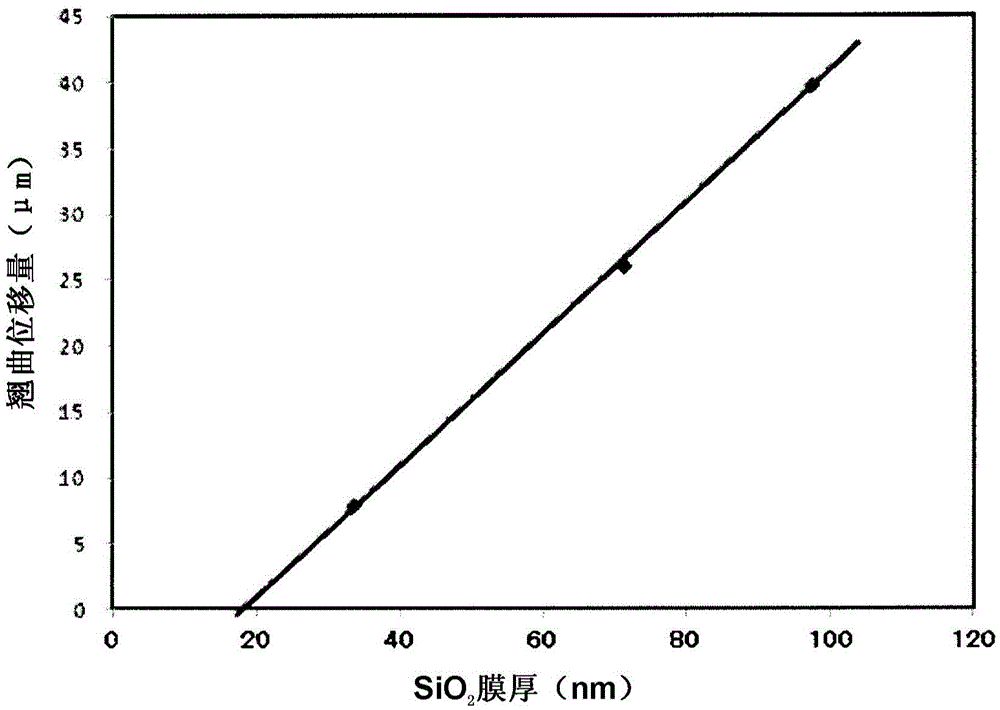

Method for reducing warpage of glass substrate by chemical strengthening treatment, and chemically strengthened glass and method for producing same

InactiveCN105473525AReduce the difference in ion exchange capacityNot prone to warpingCoatingsPotassium nitrateSilicon

The present invention relates to a method which comprises forming a film having at least one layer on at least a top surface of a glass substrate that is produced by a float method and has a bottom surface and the top surface to thereby reduce the warpage of the glass substrate which can be caused by a subsequent chemical strengthening treatment, wherein the bottom surface is in contact with a molten metal during molding and the top surface is opposed to the bottom surface. In the method, the glass substrate can have a compressive stress layer depth of 20 mum or less when the glass substrate is subjected to a chemical strengthening treatment with potassium nitrate melt at 420 DEG C for 150 minutes, and the film contains at least one of oxides and composite oxides each comprising silicon and has a film thickness of 17 nm or more.

Owner:ASAHI GLASS CO LTD

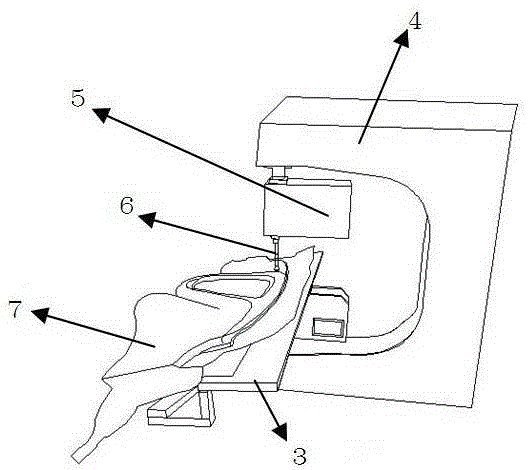

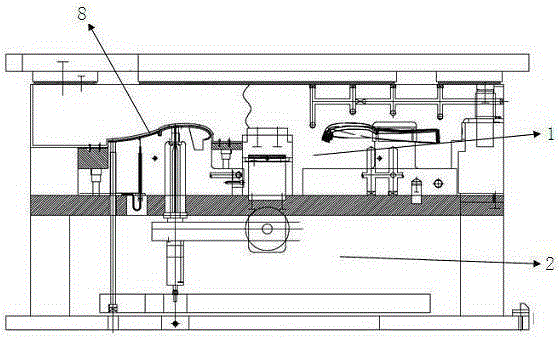

Injection molding method for soft surface and stitch lines of automotive door interior trimming panel

ActiveCN105196474AReduce processEasy to operateDomestic articlesCoatingsEngineeringInjection molding machine

The invention discloses an injection molding method for a soft surface and stitch lines of an automotive door interior trimming panel. The method comprises the following three steps: 1 surface premolding; 2 finishing adding of real stitch lines to complicated shapes of curved surfaces and the like through 3D stitching on the surface; and 3 carrying out injection molding through a low-pressure injection molding mold to finish the injected automotive interior with the surface with target grains and the stitch lines. Products produced by the injection molding method are uniform in size, can be seamlessly lapped with matched parts, and are high in size stability, relatively small in internal stress, and not easy to deform; the stitch lines can be added to the curved surfaces and complicated surfaces; and the model of the automotive door interior trimming panel is beautified.

Owner:QUANXING TOOLING EQUIP NANJING

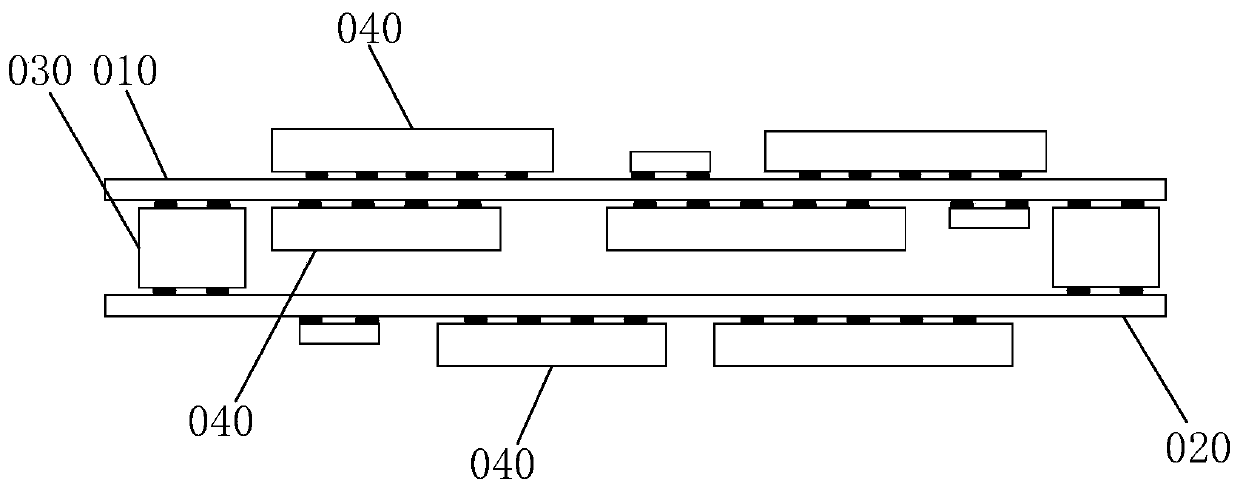

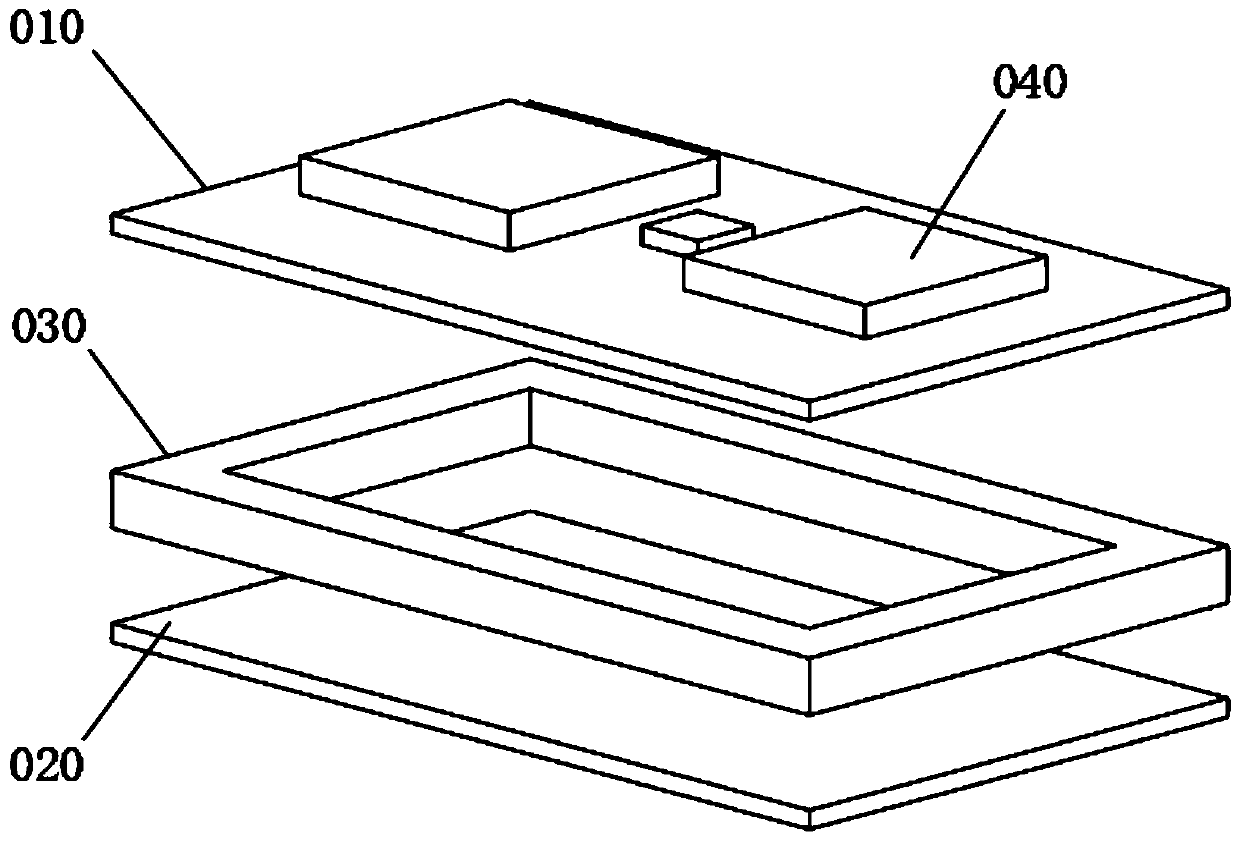

Printed circuit board, manufacturing method thereof and electronic equipment

InactiveCN110149762AAvoid warpingAvoid the consequences of electrical connection failuresPrinted circuit assemblingPrinted circuits structural associationsSurface mountingEngineering

The embodiment of the invention provides a printed circuit board, a manufacturing method thereof and electronic equipment. The printed circuit board comprises a first printed circuit board. The firstprinted circuit board comprises a first surface and a second surface, and the first surface and the second surface are opposite in direction. The first printed circuit board is provided with a first groove, and an opening of the first groove faces the first surface. The first surface is provided with a first bonding pad. An electronic element is mounted on the second surface. The printed circuit board also comprises a second printed circuit board which comprises a third surface and a fourth surface, and the third surface and the fourth surface are opposite in direction. The third surface is provided with a second bonding pad, and the second bonding pad corresponds to the first bonding pad in position. The third surface and the fourth surface are respectively provided with electronic elements. The first printed circuit board and the second printed circuit board are welded through the first bonding pad and the second bonding pad to form a stacked structure. The printed circuit board provided by the invention is not likely to warp, has stronger stress deformation resistance, and can prolong the service life of electronic equipment.

Owner:HUAWEI TECH CO LTD

Polyurethane board and preparation method thereof

The invention discloses a polyurethane board and a preparation method thereof. The manufacturing method comprises the following steps of uniformly mixing a component A, a component B and compound filler to prepare a foaming material, injecting the foaming material into a die for compression molding, and finally demoulding to form a polyurethane board product, wherein the component A comprises a polyether polyol auxiliary a and a polyester polyol auxiliary b; the component B is isocyanate; the filler is prepared from an inorganic powder material, a plant powder material and a fiber material. According to the manufacturing method, the polyurethane board product is manufactured by uniformly mixing the compound polyester polyol, the isocyanate and the compound filler, injecting the mixture into the die and carrying out heat-preservation pressing. The obtained product is high in mechanical performance strength, low in linear shrinkage rate during storage and use, is not easy to warp after long-term storage and high in production and secondary processing precision, does not easily absorb water and can be applied to the field having high requirement on size precision.

Owner:昆山市柳鑫电子有限公司

Military electrical connector insulator and preparation method thereof

ActiveCN109897347AImprove product qualitySmall volume shrinkagePlastic/resin/waxes insulatorsFiberAlkali free

The invention relates to the technical field of electrical connectors, and concretely relates to a military electrical connector insulator and a preparation method thereof. A material for the insulator for a motor mounting seat comprises, by weight, 90-110 parts of PBT, 10-20 parts of phenolic resin, 10-15 parts of polytetrafluoroethylene, 6-12 parts of hollow glass beads, 15-20 parts of alkali-free glass fibers, 9-14 parts of a composite toughening agent, 15-20 parts of a composite flame retardant, 2-6 parts of a compatibilizer, 1-2 parts of a lubricant, 2-4 parts of a silane coupling agent,2-3 parts of an antioxidant and 5-10 parts of an inorganic filler. The military electrical connector insulator prepared in the invention has the advantages of excellent mechanical properties, good wear resistance, good heat resistance, good flame retardation property, excellent use safety and reliability, high dimensional accuracy and long service life. The preparation method of the military electrical connector insulator has the advantages of simplicity, high efficiency, easiness in control of the operation process, facilitation of industrial production, and stable product quality.

Owner:东莞市时运佳实业投资有限公司

Anti-aging wood-plastic composite material board and preparation method thereof

The invention relates to an anti-aging wood-plastic composite material board and a preparation method of the board. The preparation method comprises the steps of: firstly, evenly stirring plastic particles, diisopropylbenzene peroxide, nano-titanium dioxide, antioxidant, antioxidant synergist, light stabilizer, basic magnesium sulfate whisker, stearic acid and oxidized polyethylene; carrying out melt blending and pelleting by adopting an extruder to obtain modified plastic particles; and then stirring the modified plastic particles, wood powder and pigment, and carrying out melt blending and extruding forming by adopting the extruder to obtain the anti-aging wood-plastic composite material board. The anti-aging wood-plastic composite material board is convenient to produce and manufacture, low in cost, less in plastic consumption and wood consumption, environment-friendly and high in modulus and rigidity, does not easily cause buckling deformation, and is free from cracking and damage by worms, resistant in ultraviolet light and thermal oxidizing aging, free from color fading and decomposition and long in service life. The anti-aging wood-plastic composite material board can be used as an open-air table and chair, a stool, a picnic table, a flower box, a guardrail, a sign and the like to be widely applied to occasions such as a park, a court, municipal administration, a dock and the like.

Owner:G&S HUZHOU ENTERPRISES

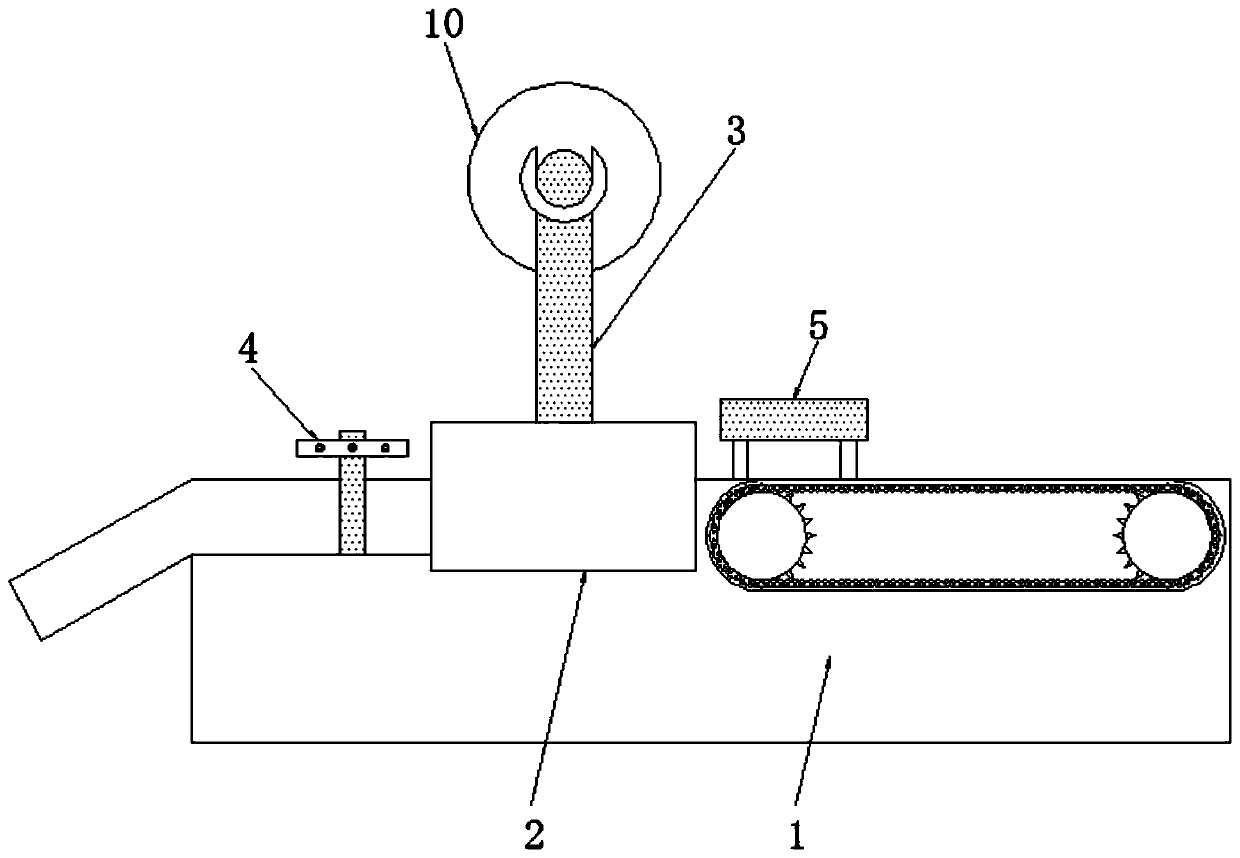

Leveling device for manufacturing printed circuit board

ActiveCN107708309AEasy to flattenImprove flattening effectPrinted circuit manufacturePrinted circuit boardConveyor belt

The invention discloses a leveling device for manufacturing a printed circuit board. The leveling device comprises a base. Four first support rods are symmetrically arranged on the base. The two firstsupport rods with corresponding positions are connected together with a fixing plate thereon. A fixing plate is fixedly connected between the two fixing plates. Two driving rollers are commonly connected rotatably between two fixing plates. Two driving rollers are commonly provided with a conveyor belt thereon. A PCB in process is arranged on the conveyor belt. Each of the fixing plate is fixedlyconnected with a first mounting plate and a second mounting plate on the upper surface. Each first mounting plate is rotatably connected with a first connecting rod and a rotating rod thereon. Each second mounting plate is rotatably connected with a second connecting rod thereon. The leveling device in the invention has the advantages of ingenious structure, convenient use, stable overall device,multiple flattening modes, good flattening effect, few occurrence of warping phenomenon, reduction of many hidden troubles in subsequent steps and unnecessary scrapping, reduction of production cost,and high promotion value.

Owner:乐凯特科技铜陵有限公司

Moulded wire and preparation method thereof

InactiveCN104231524AEasy to prepareLow costMonocomponent synthetic polymer artificial filamentSmooth surfaceSilane coupling

The invention provides a high-precision moulded wire for printing a high quality three-dimensional object. The moulded wire is prepared from the following components in parts by weight: 1-3 parts of a saline coupling agent, 5-40 parts of glass beads and 57-94 parts of resin. The moulded wire has good circular degree and relatively small diameter standard deviation in the length direction. The three-dimensional object printed by the moulded wire has a good smooth surface, a stable size and good strength. In addition, the invention further provides a preparation method of the moulded wire.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD OF ZHUHAI

Antistatic plastic-wood composite board and preparation method thereof

The invention relates to an antistatic plastic-wood composite board and a preparation method of the antistatic plastic-wood composite board. The preparation method comprises the steps of mixing wood flour, plastic particles, maleic anhydride grafted plastic particles, glyceryl monocaprate, dodecyl diethanolamine and industrial white oil at high speed, cooling and crushing to obtain plastic-wood composite grains; and then mixing the plastic-wood composite grains, copper powder, stearic amide, talcum and zinc stearate at high speed, and carrying out fusion blending and extrusion forming by adopting an extruder. The antistatic plastic-wood composite board is convenient to produce and manufacture, low in cost, low in consumption of plastic and wood, environment-friendly, high in modulus and rigidity, creep-resistant, and excellent in antistatic effect, can be repeatedly regenerated and does not generate warping deformation. The plastic-wood composite board can be used as outdoor desks and chairs, wooden stools, picnic tables, flower tanks, guardrails, indicators and other products to be widely applied parks, courts, municipal administration and other occasions like the traditional plastic-wood boards, and can also be used in chemical industry, petroleum and other special environments.

Owner:江苏森诺塑胶科技有限公司

Production method of skin-moistening moisture-keeping paper special for mothers and infants

PendingCN108642966AGentle to the touchIncrease humidityNon-fibrous pulp additionSpecial paperFiberStart stop

The invention discloses a production method of skin-moistening moisture-keeping paper special for mothers and infants. The skin-moistening moisture-keeping paper comprises the following component: a bleached soft wood and broadleaf wood pulp plate. The skin-moistening moisture-keeping paper is prepared through the following steps: S1, taking the bleached soft wood and broadleaf wood pulp plate asslurry, and respectively dispersing the slurry into long-fiber slurry and short-fiber slurry by a hydraulic pulper; S2, beating the long-fiber slurry to a beating degree of 19-22 degrees SR through adisc mill, defibering the short-fiber slurry through a high-frequency defibering machine, mixing the defibered short-fiber slurry with the long-fiber slurry according to a proportion of 60:40, and beating the obtained mixture to a beating degree of 26-30 degrees SR through a leveling mill; S3, adding a softening agent of 0.8-1.2 kg / T; S4, enabling the prepared slurry to form original paper; S5, carrying out spraying by a spraying device; S6, linking the start-stop of the spraying device with a rewinder program, and reeling up a coiled paper roll by a rewinder; and S7, carrying out packaging. According to the invention, plant extracts are used as raw materials, skins are not damaged easily, the preparation is simple, and the product quality is improved.

Owner:ZHEJIANG JINGXING PAPER

Embedded box fixing structure and refrigerating equipment

ActiveCN107702420AIt is not easy to warp the cornersNot prone to warpingDomestic cooling apparatusLighting and heating apparatusEmbedded systemRefrigerated temperature

Owner:HEFEI HUALING CO LTD +2

Modified ABS (Acrylonitrile Butadiene Styrene) bamboo consumable for 3D printing

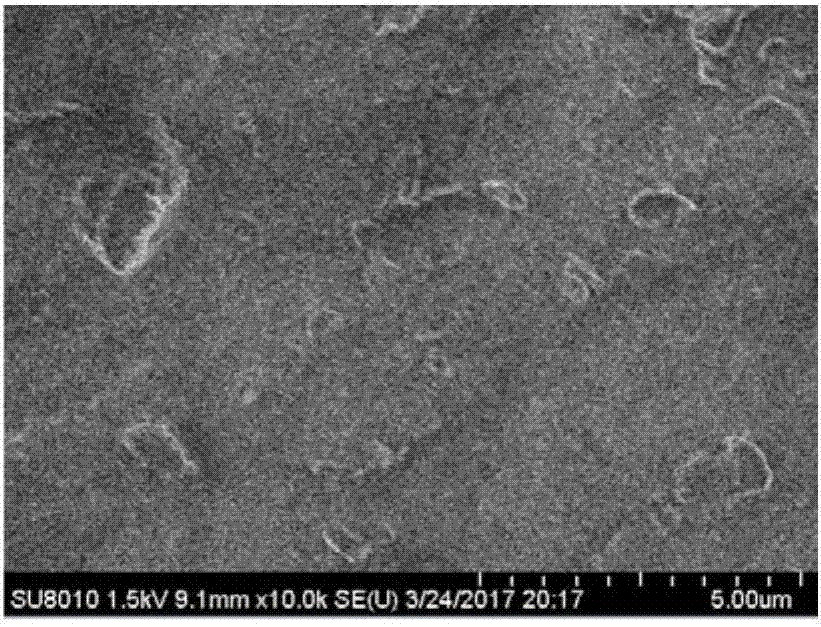

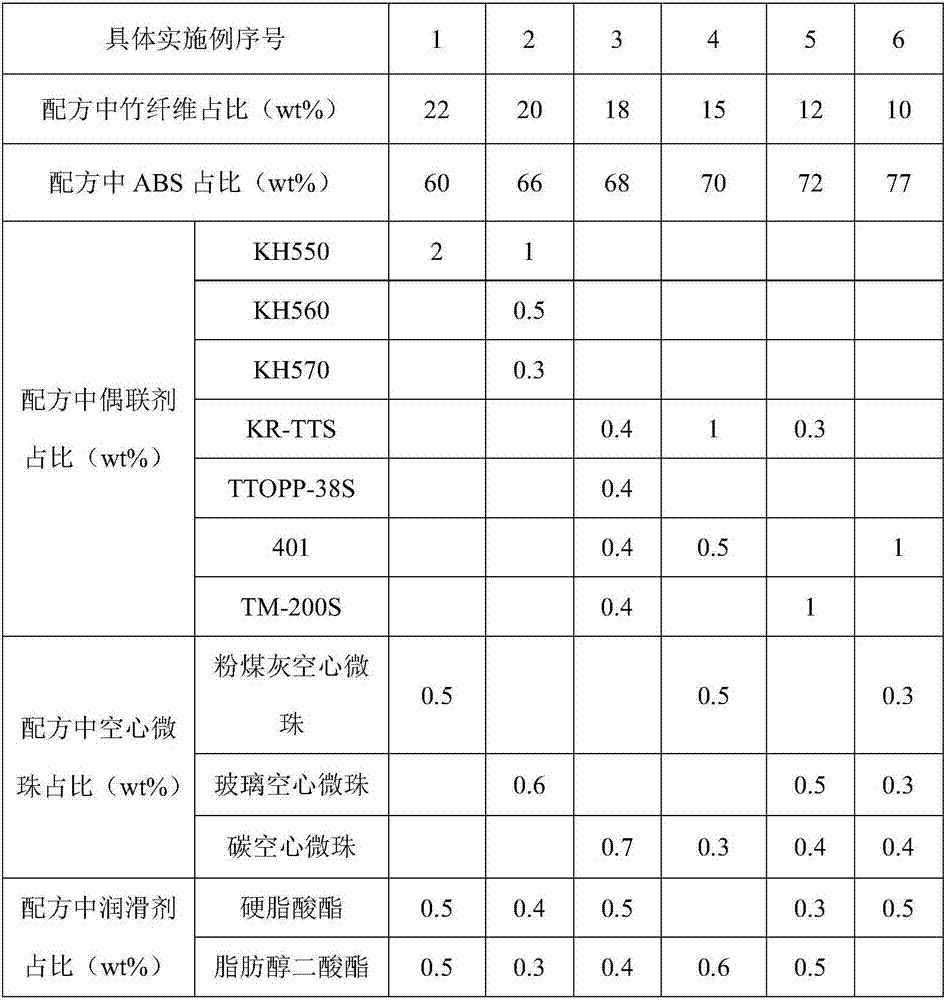

InactiveCN107022166AImprove performanceNot easy to warpAdditive manufacturing apparatusPlasticizerAcrylonitrile butadiene styrene

The invention discloses a modified ABS bamboo consumable for 3D printing. The consumable is prepared from the following raw materials in percentage by weight: 10 to 22 percent of bamboo fiber, 60 to 77 percent of ABS plastic, 1 to 2 percent of coupling agent, 0.5 to 1 percent of hollow microsphere, 0.5 to 1 percent of lubricant, 1 to 2 percent of antioxidant, 2 to 2.5 percent of toughening agent, 5 to 9.3 percent of plasticizer, and 1 to 2 percent of compatilizer. The raw materials are co-blended and granulated through a dual-screw extruder, and particles are prepared into wires which are 1.75+ / -0.05mm in diameters through a 3D printing consumable extruder. The prepared 3D printing consumable is applied to a 3D printing fused deposition technology, an obtained model has the fragrance and hand feel of natural bamboo and can be enhanced by 5 to 20 percent in strength, edge warping is prevented during printing, and a 3D printed workpiece has higher quality.

Owner:QUZHOU UNIV

Mildew-proof plastic-wood composite sheet and preparation method thereof

The invention relates to a mildew-proof plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly mixing 8-hydroxyquinoline copper with running water evenly, atomizing and spraying the solution on the surface of the wood powder to obtain modified wood flour; and then mixing the wood flour with the methylene diphenyl diisocyanate at high speed, thereby obtaining the wood flour subjected to surface treatment; mixing with other components together after drying the wood flour subjected to surface treatment, squeezing out the mixture, cooling and crushing the mixture to obtain plastic-wood composite sheet granules; and finally melting and blending the plastic-wood composite sheet granules by adopting an extruder, squeezing out and molding to obtain the mildew-proof plastic-wood composite sheet. The mildew-proof plastic-wood composite sheet has the advantages of convenience in manufacturing, low cost, environmental friendliness, high modulus, high stiffness, creep resistance, and no buckling deformation; and mildew-proof treatment is not needed, and mildewing does not occur in the use process. The mildew-proof plastic-wood composite sheet can be widely applied to occasions such as parks, playgrounds, municipal administration and the like, and even can be used in damp environments such as dockyard piers, water trestles, beach guardrails.

Owner:江苏森诺塑胶科技有限公司

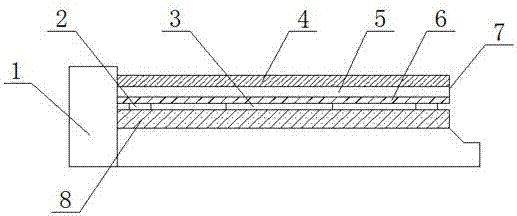

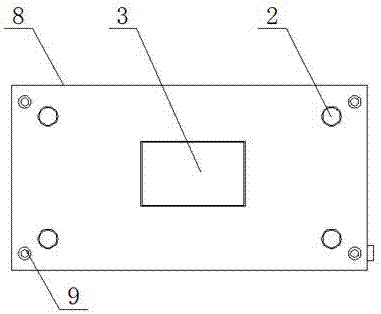

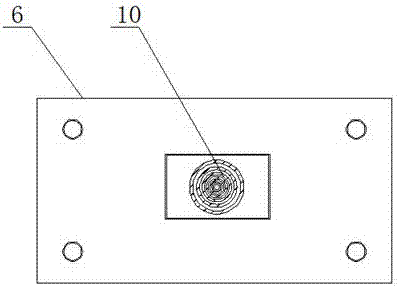

Novel heating bottom plate of 3D (three-dimensional) printing machine

InactiveCN107097425AGuaranteed continuitySolve the plugging problemManufacturing heating elementsRadio reception3d printer

The invention discloses a novel heating bottom plate of a 3D (three-dimensional) printing machine. The novel heating bottom plate comprises a base. An aluminum oxide ceramic substrate is fixedly arranged on the upper side of the base, electromagnets are arranged at four corners of the aluminum oxide ceramic substrate, a radio transmission plate is embedded and mounted in the center of the aluminum oxide ceramic substrate, a heating bottom plate is arranged above the aluminum oxide ceramic substrate and comprises a high-temperature glass layer, a ceramic heating plate and a support plate from top to bottom, and a radio receiving ring which corresponds to the radio transmission plate is arranged in the center of the support plate. The novel heating bottom plate has the advantages that the heating bottom plate can be conveniently integrally taken down to be replaced by a new heating bottom plate on the base after 3D printing forming is carried out, accordingly, the continuity of 3D printing working procedures can be kept, and the printing efficiency can be improved; the problems in the aspect of circuit plugging due to frequent disassembling can be solved by the aid of radio connection modes, a body of the heating bottom plate is made of ceramic materials, accordingly, heat can be uniformly conducted, and edge warping can be prevented.

Owner:芜湖智享三维打印服务有限公司

Plastic floor and manufacturing method thereof

The invention relates to a plastic floor and a manufacturing method thereof. The plastic floor comprises locking plates, wherein an upper latch and a lower latch which are mutually adapted are respectively arranged at two opposite sides of each locking plate, and the upper latch on one locking plate can be overlapped with the lower latch on the other locking plate; the plastic floor comprises a surface layer and a locking layer, wherein the locking layer is connected with the lower surface of the surface layer, and the locking layer comprises at least two locking plates which are overlapped together. The single locking plate of the invention can be set into a size suitable for processing and manufacturing, two or more than two locking plates are overlapped together to form the locking layer which is then connected with the surface layer to form the plastic floor, the plastic floor can be in a larger size suitable for laying, the plastic floor is not easily warped, the plastic floors in multiple sizes can be manufactured by only adopting a set of mould for manufacturing the locking plate and are quite convenient in processing, manufacture and laying.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

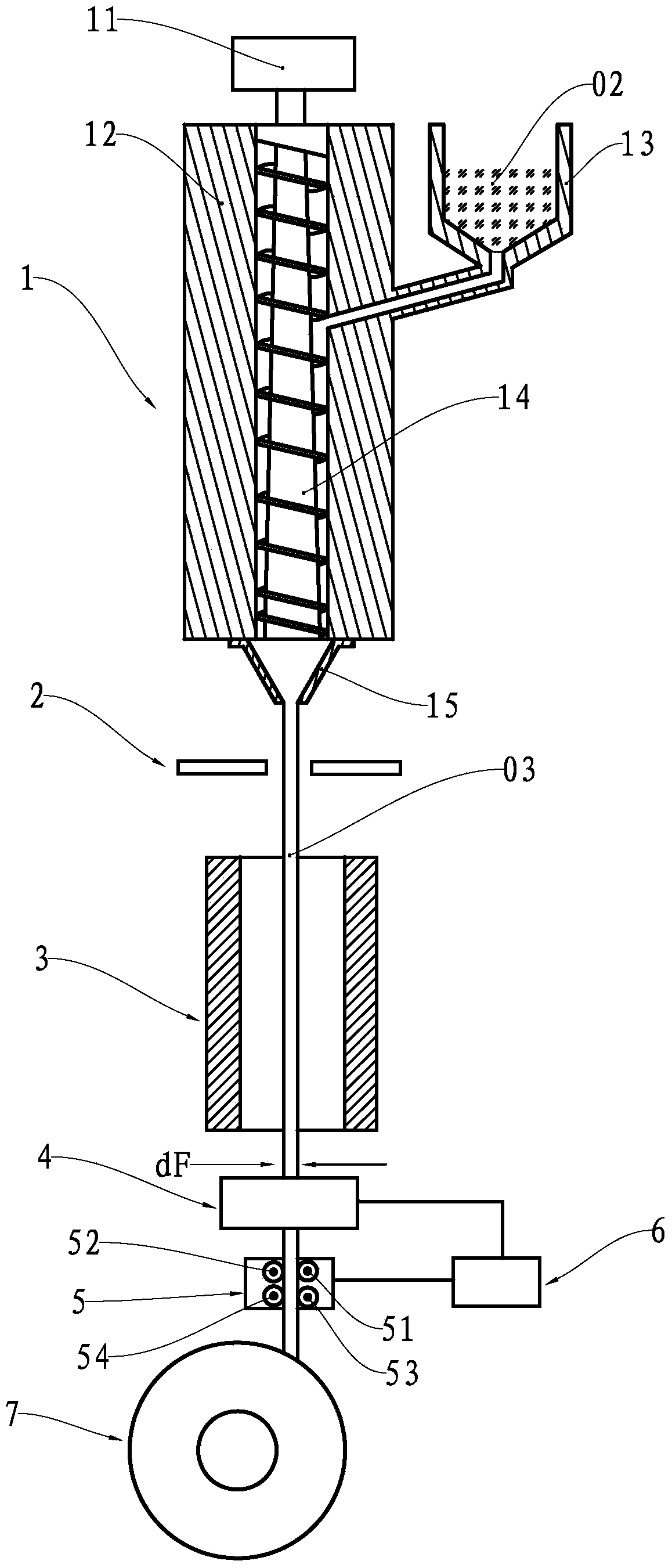

Device capable of utilizing gravity changes to conduct emergency braking and achieving cutting and film coating integration

ActiveCN110587673ALess likely to wrinkleNot prone to warpingSpecial paperLaminationStopped workEngineering

The invention relates to the technical field of automation, and discloses a device capable of utilizing gravity changes to conduct emergency braking and achieving cutting and film coating integration.The device comprises a base. A film coating region is fixedly connected with the top of the base. By means of supporting columns, a rotating shaft and a film roll, springs are movably connected withthe lower portions of the supporting columns, the gravity changes of the film roll are utilized, and therefore the rotating shaft can be subjected to emergency braking and can stop working, the phenomenon that a machine do more idle work in the unwatched process is avoided, and the extra consumption of energy is reduced. By means of a rotating wheel, a connecting strip, a vertical rod and a sliding plate, when the rotating wheel rotates, the left-and-right movement of the sliding plate and the up-and-down movement of a cutting tool can be driven; finished products can be conveyed through the movement of the sliding plate, the finished products are moved to the inclined plane and uniformly collected, and workers do not need to watch the device on the side; and due to the up-and-down movement of the cutting tool, the finished products which are produced after the film coating operation is accomplished can be directly cut, the phenomenon that two machines need to be independently operatedto conduct two procedures is avoided, and the working efficiency of a film coating machine is further improved.

Owner:绍兴市高砚智生物科技有限公司

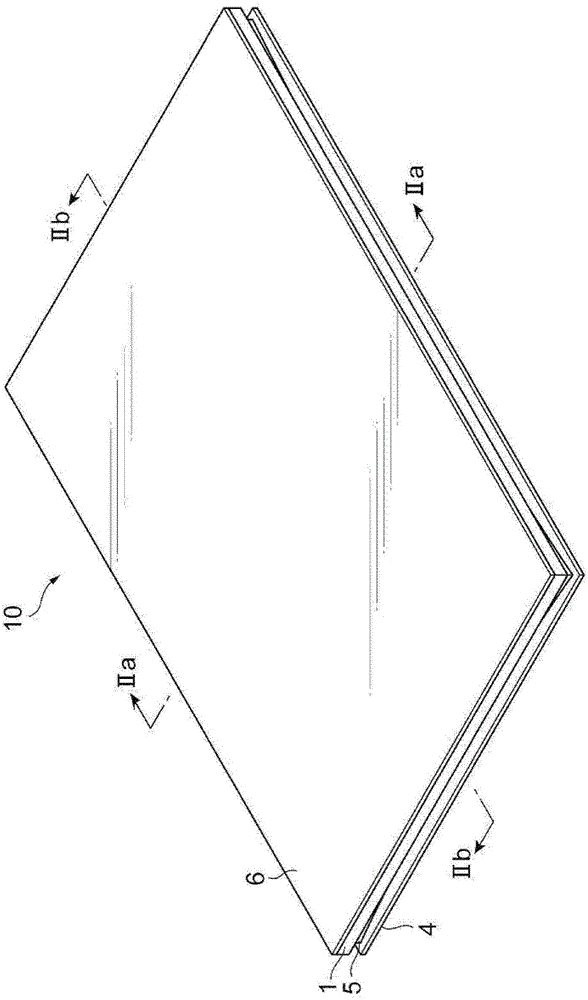

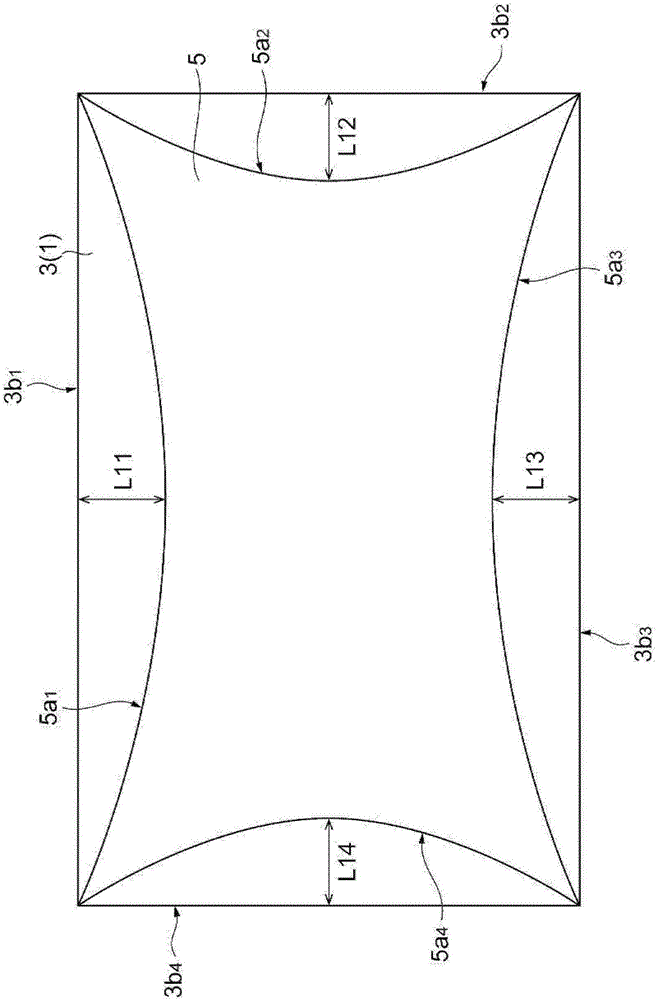

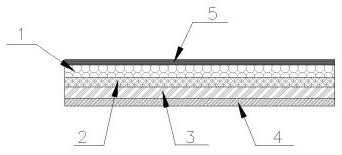

Pressure-sensitive adhesive layer-carrying polarizing plate and image display device

ActiveCN106802442AAvoid lack of glueNot prone to warpingPolarising elementsLaminationDisplay deviceEngineering

A pressure-sensitive adhesive layer-carrying polarizing plate includes a polarizing plate 1, and an adhesive layer 5 laminated on at least one surface of the polarizing plate 1. The polarizing plate 1 is a plan view quadrangle, the ends of the adhesive layer 5 extends along the prolonging direction of a side 3b and has a recessed portion 5a located inside the quadrangle with respect to at least one side 3b on the adhesive layer 5 side of the polarizing plate 1, and the distance between the recessed portion 5a and the side 3b is made larger from the end side of the side 3b toward the center side.

Owner:SUMITOMO CHEM CO LTD

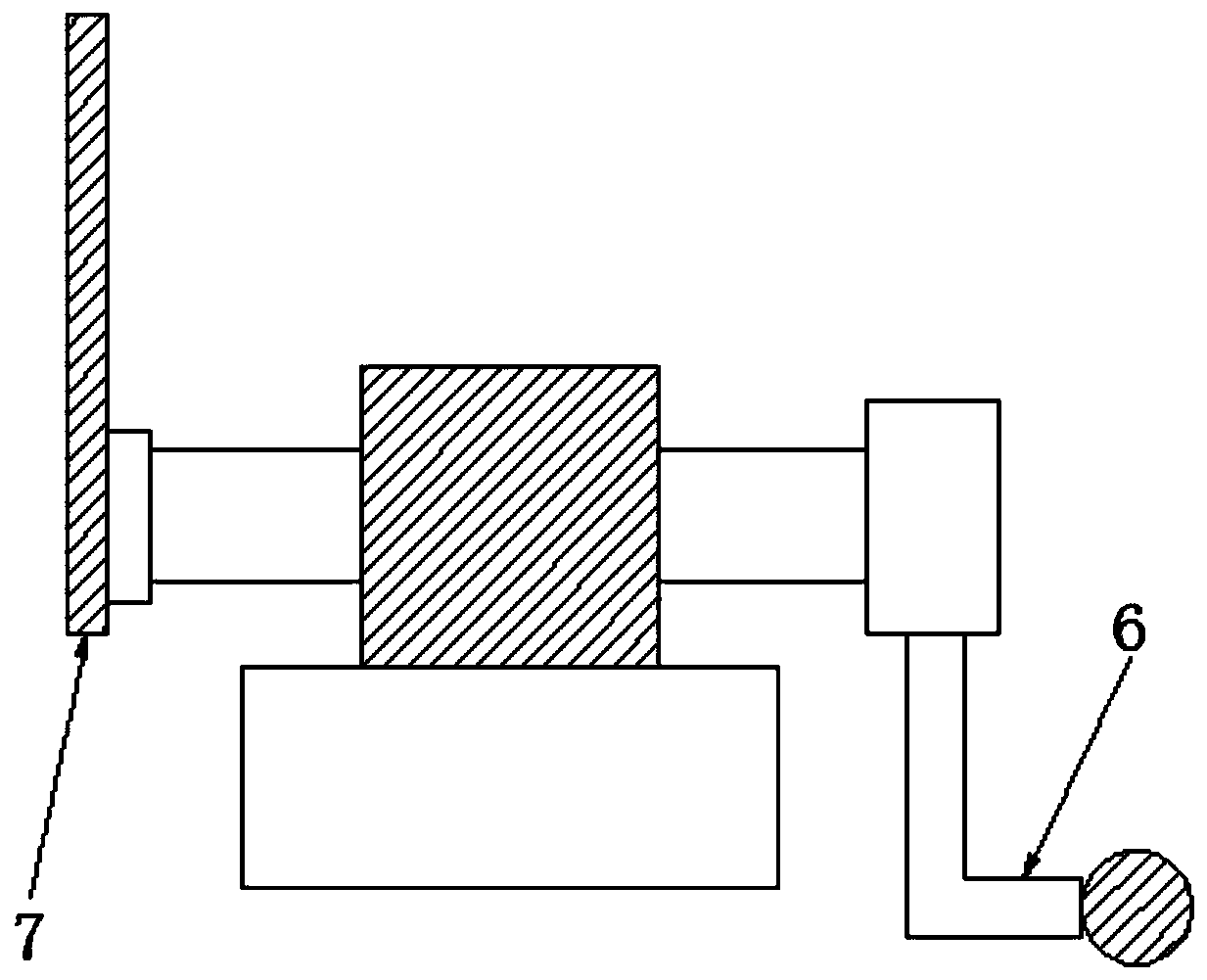

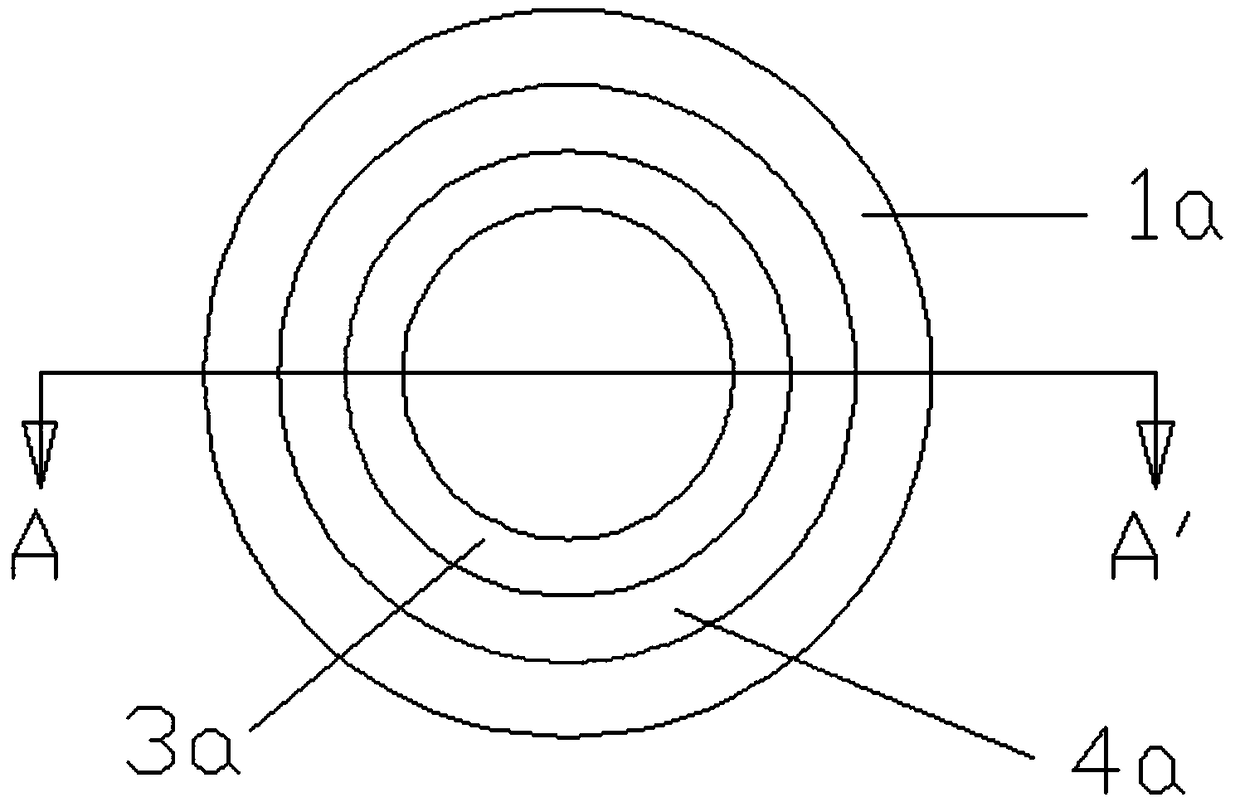

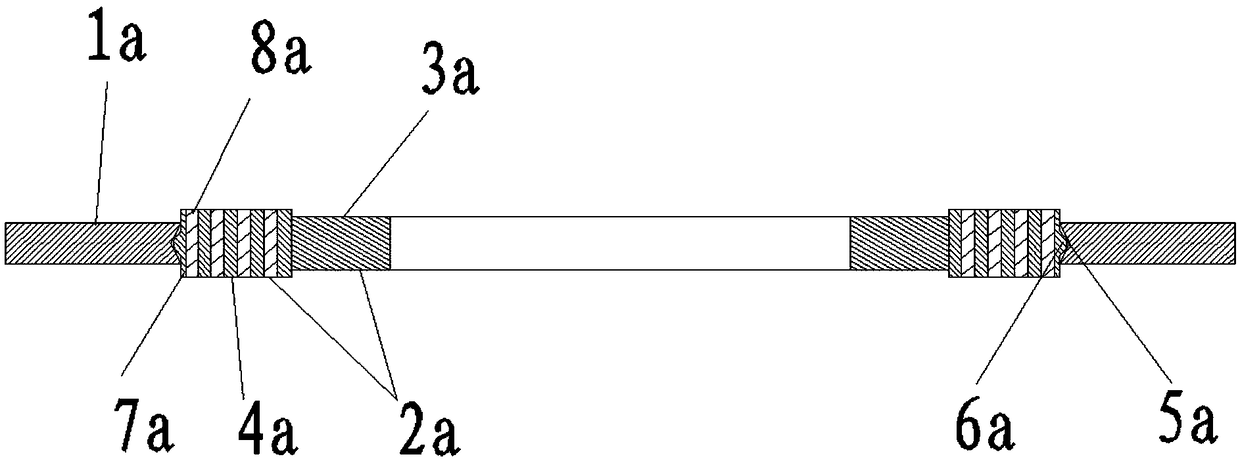

Manufacturing equipment and mold of metal spiral-wound gasket

ActiveCN109093023AEasy to pressEasy to installShaping toolsMetal working apparatusSpiral woundAutomation

The invention discloses manufacturing equipment of a metal spiral-wound gasket. The manufacturing equipment is characterized by comprising an outer ring deformation device and an inner and outer ringautomatic lantern ring leveling device. The outer ring deformation device comprises an outer ring deformation mold used for achieving first deformation of an outer ring, enabling the outer ring to jack up from bottom to top, and expanding the inner diameter of the top of the outer ring. The inner and outer ring automatic lantern ring leveling device comprises a first platform body, a first multistation index plate, a lantern ring mold and an outer ring leveling mold arranged at the first platform body. The lantern ring mold is used for completely compressing an inner ring into the outer ring.The outer ring leveling mold is used for achieving second deformation of the outer ring and leveling the upper and lower surfaces of the outer ring. According to the manufacturing equipment of the metal spiral-wound gasket, during the installation process of the inner ring and the outer ring, annular protrusions at the outer surface of a winding ring of the inner ring are not liable to upwarp or be crushed, flatness and finish degree of the product surface are high, and the automation degree is high. The invention further provides a manufacturing mold of the metal spiral-wound gasket.

Owner:慈溪红叶密封制品有限公司

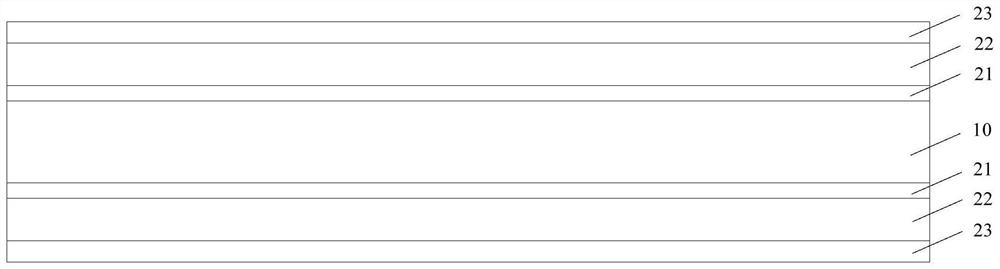

PCB (Printed Circuit Board) base plate with hardening layer and preparation method and application of PCB base plate

PendingCN114536932AStable structureAvoid deformationSynthetic resin layered productsLaminationEpoxyAdhesive cement

The invention provides a PCB base plate provided with a hardening layer. The PCB base plate comprises a base plate and hardening combination layers oppositely arranged on the two sides of the base plate. The hardening combination layer comprises a bonding layer arranged on the surface of the base plate, an aluminum foil arranged on the surface of the bonding layer and a hardening layer arranged on the surface of the aluminum foil; wherein the bonding layer is made of an adhesive or a lubricating coating; the hardening layer is prepared from the following components in parts by weight: 60-85 parts of epoxy resin, 0.03-2 parts of a defoaming agent, 0.03-1 part of a flatting agent, 2-5 parts of a dispersing agent, 7-10 parts of modified polyamine and 10-15 parts of superfine powder calcium carbonate or aluminum oxide. The PCB base plate is stable in structure and not prone to deformation and warping, when the PCB base plate is applied to drilling of a PCB, burrs can be avoided, the drilling quality of the PCB is improved, in addition, when a drill bit drills to the surface of the PCB base plate, heat can be effectively absorbed, and abrasion of the drill bit can be reduced.

Owner:SHENZHEN HONGYUHUI TECH CO LTD

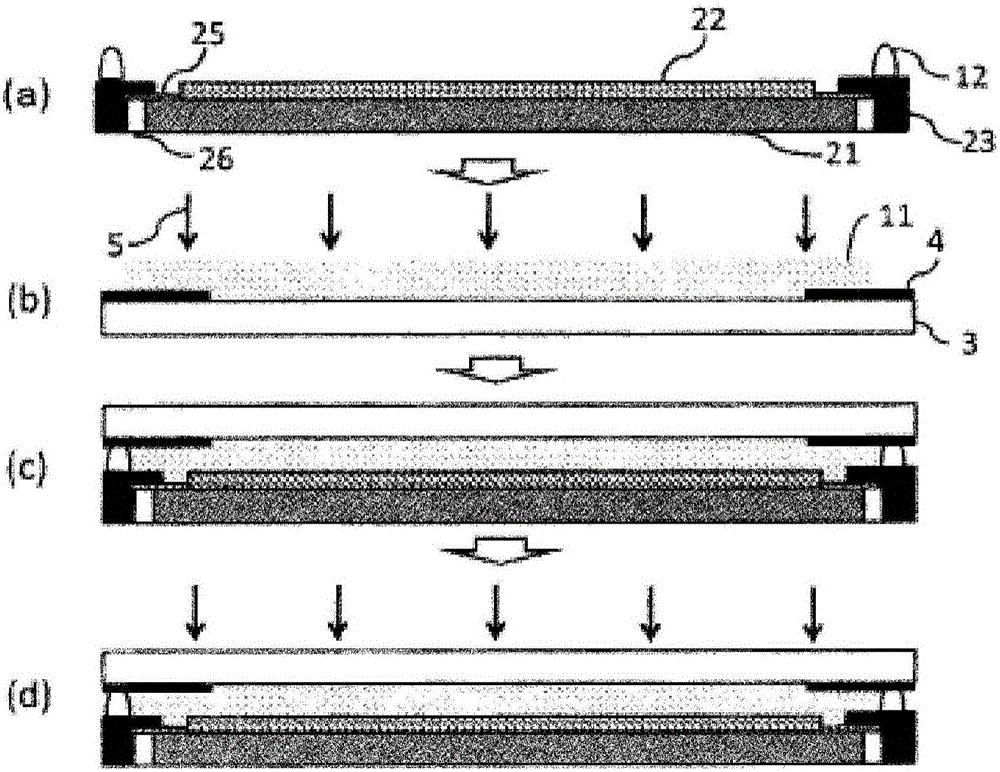

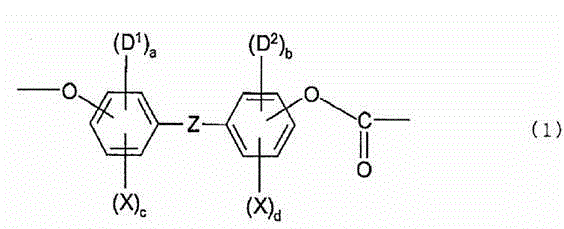

Method for producing optical member and curable resin composition used therein

InactiveCN106575052AImprove productivityNot prone to warpingNon-linear opticsIdentification meansProduction rateLiquid-crystal display

Provided is a method for producing an image display device that is an optical member having excellent productivity and being not susceptible to warping of a substrate, wherein: a second curable resin composition, which exhibits fluidity in an uncured state, is applied to a liquid crystal display unit and / or a protective plate; cured product layers obtained by curing the composition are laminated in the form of lines or dots between the liquid crystal display unit and the protective plate, thereby forming a partition wall between a region that is filled with a first curable resin composition and a region that is not filled with the first curable resin composition; and the partition wall is at least partially provided with a communication part between the two regions. Also provided is a curable resin composition which is used in the method for producing an image display device.

Owner:NIPPON KAYAKU CO LTD

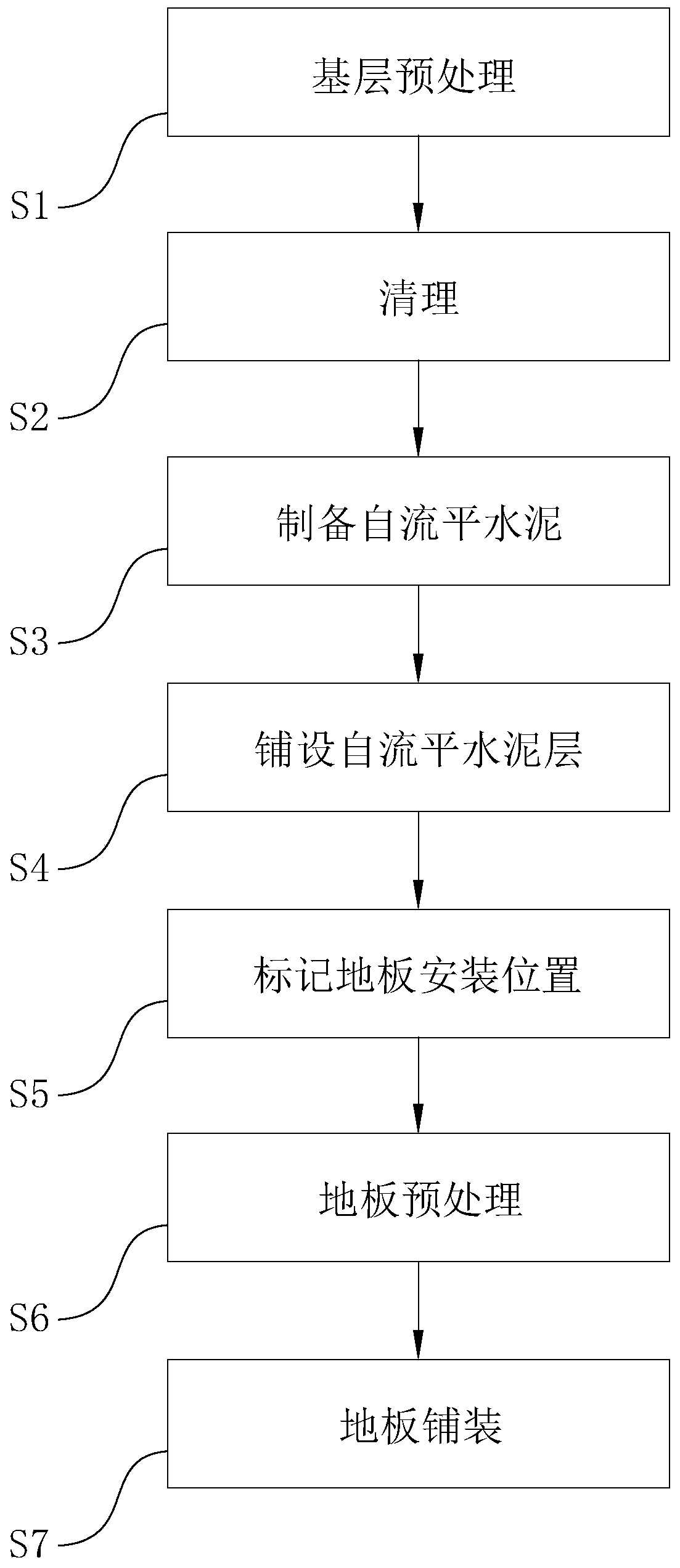

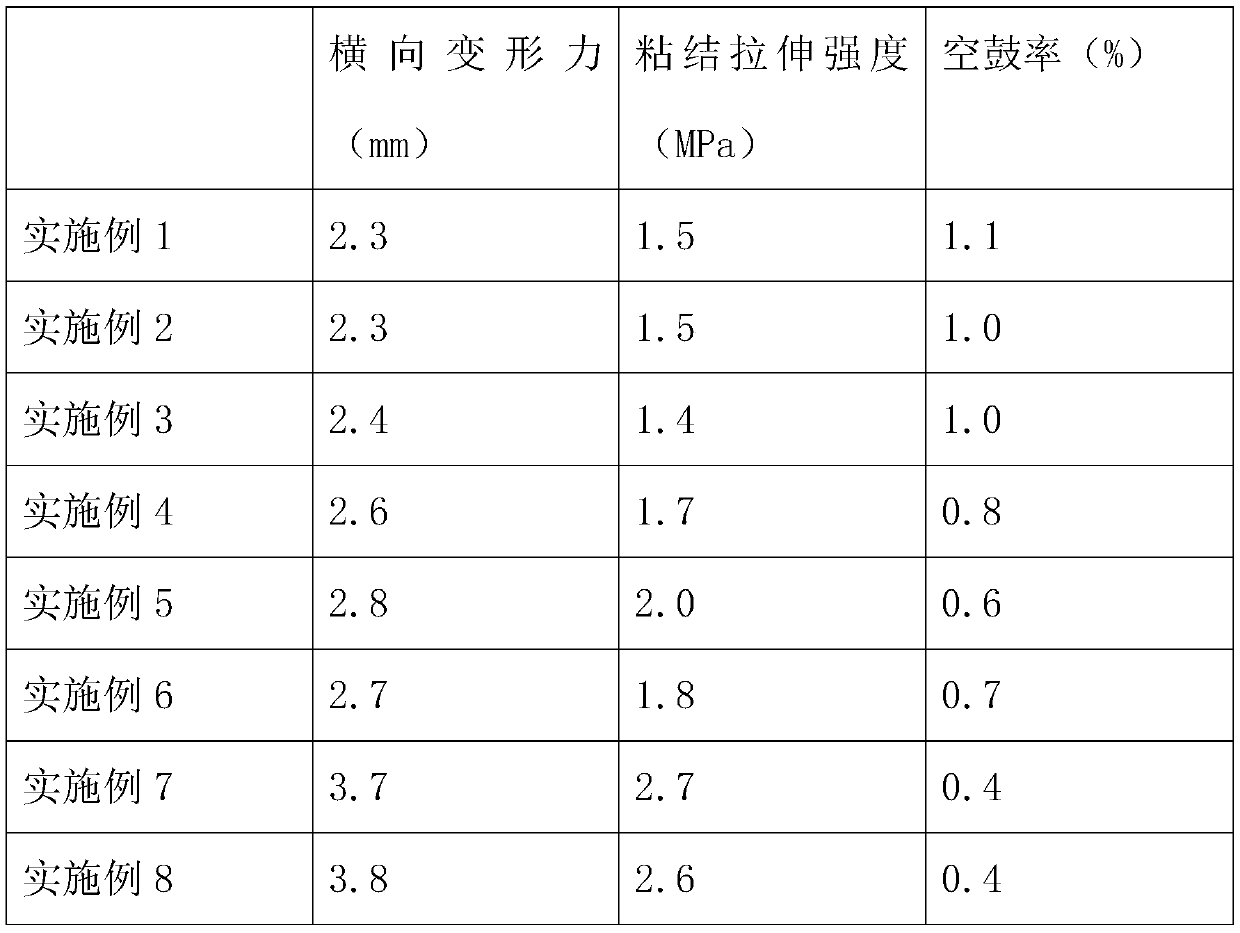

Floor paving method

The invention relates to the field of building decoration, and provides a floor paving method aiming at the problem that a floor is prone to bulging and warping. According to the technical scheme, thefloor paving method comprises the following steps of S1, preprocessing a base layer; S 2, cleaning; S3, preparing self-leveling cement; S4, laying a self-leveling cement layer; S5, marking a floor installation position; S6, preprocessing a floor; and S7, paving the floor, wherein the self-leveling cement comprises the following components of, by mass, 30-35 parts of silicate cement, 5-6 parts ofwater, 0.1-0.2 parts of a water reducing agent, 65-70 parts of sand, 35-40 parts of fly ash, 0.1-0.3 parts of a retarder, 1-3 parts of epoxy resin, 0.1-0.2 parts of 2-anilino pyridine, and 0.01-0.02 parts of periflanthene. The epoxy resin, the 2-anilino pyridine and the periflanthene are compounded for use, so that the flexibility of the self-leveling cement is improved, the bonding strength of the self-leveling cement is improved at the same time, and a floor is less prone to bulging and warping.

Owner:广东优鼎装饰设计工程有限公司

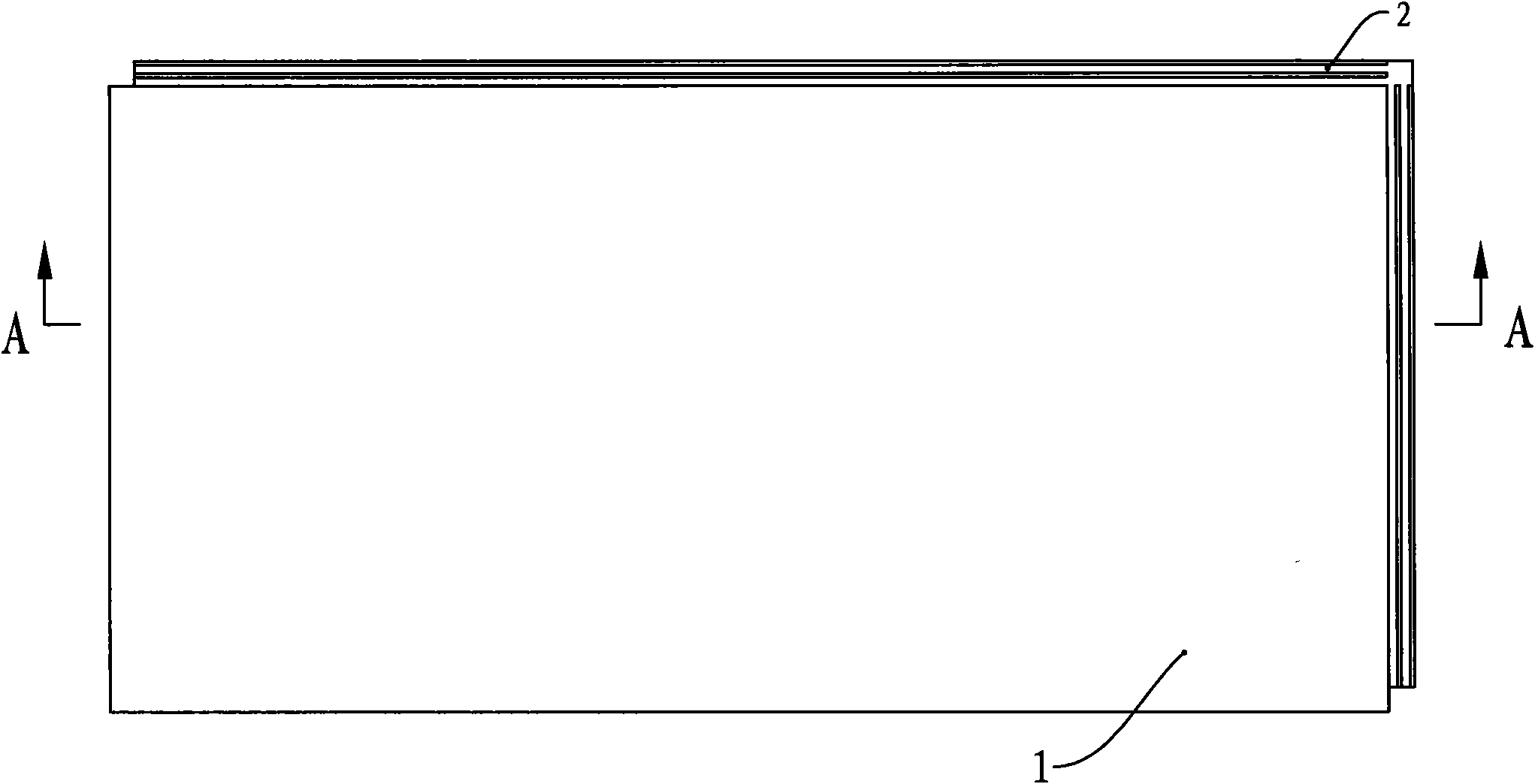

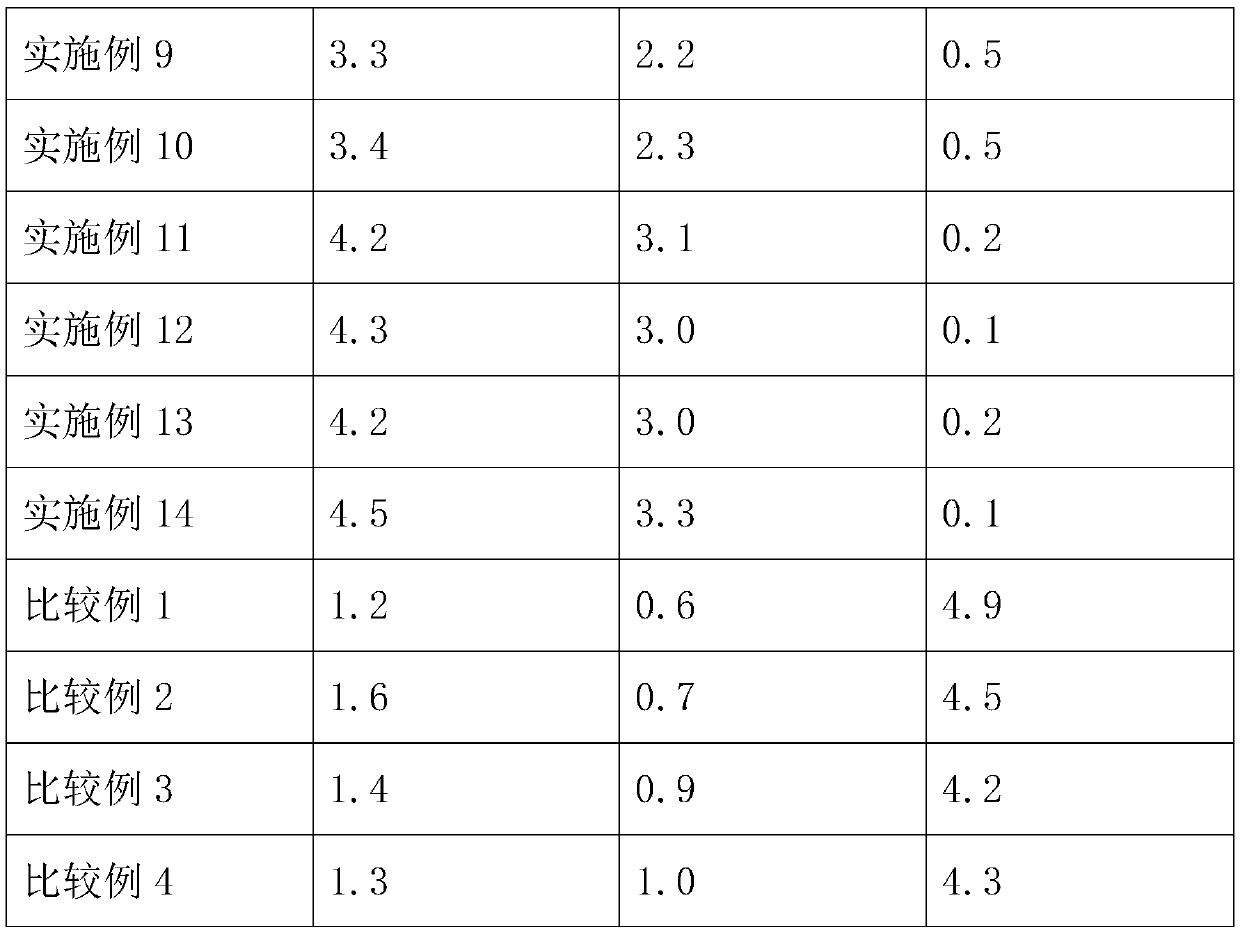

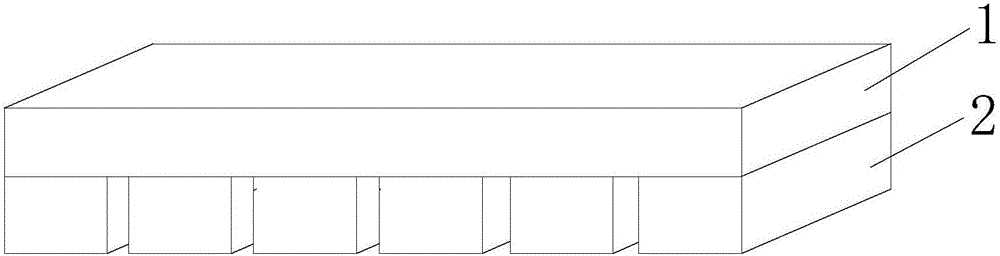

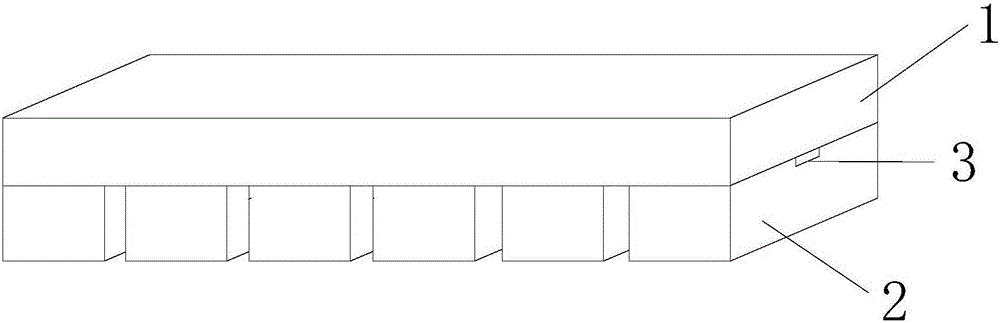

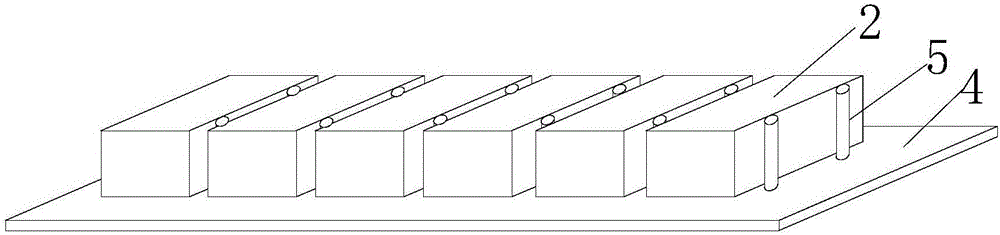

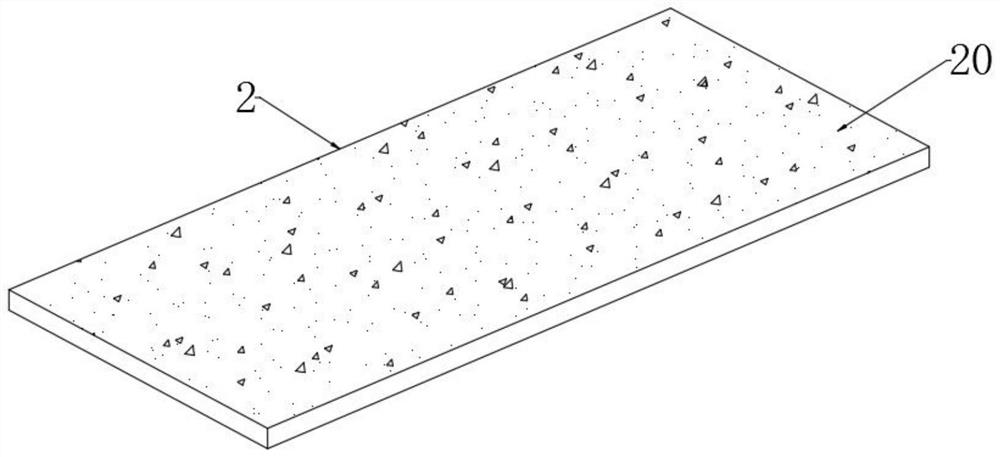

Double-layer solid wood composite floor and manufacturing method thereof

InactiveCN106049821AHigh strengthImprove stabilityWood veneer joiningFlooringSolid woodPulp and paper industry

The invention discloses a double-layer solid wood composite floor and a manufacturing method thereof. The double-layer solid wood composite floor comprises a solid wood face layer (1) with wood grains extending in the length direction of the solid wood face layer; a plurality of small long-strip-shaped battens (2) which are arranged side by side are glued under the solid wood face layer (1); and wood grains of the small long-strip-shaped battens (2) extend in the length direction of the small long-strip-shaped battens (2). The wood grain direction of the small long-strip-shaped battens (2) is perpendicular to the wood grain direction of the solid wood face layer (1), and the length of the small long-strip-shaped battens (2) is equal to the width of the solid wood face layer (1). Gaps are reserved between the adjacent small long-strip-shaped battens (2). According to the double-layer solid wood composite floor and the manufacturing method thereof, the use amount of high-quality solid wood can be reduced effectively, wood resources are saved, and simultaneously high structural strength and whole stability are achieved.

Owner:ZHEJIANG FUMA FLOOR HEATING SCI&TECH CO LTD

Optical film comprising halogenated polycarbonate

ActiveCN102753607ALess coloringImprove heat resistanceCoatingsOptical elementsOligomerPolymer science

Provided is an optical film, which is made of a halogenated polycarbonate, has high heat resistance and high dimensional stability to heat, and is flame retardant. The optical film is obtained by producing a halogenated polycarbonate by a solution-casting method. The halogenated polycarbonate has a glass transition temperature of 230 C or higher, a weight average molecular weight of more than 50,000, and an oligomer content of 0.6% by weight or less.

Owner:TEIJIN KASEK KK

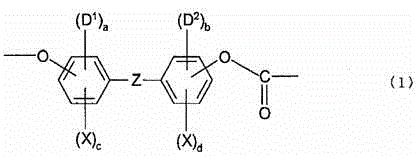

Friction machine for fabrication of liquid crystal cell, liquid crystal cell and its fabrication method, and liquid crystal display device

The invention discloses a friction machine for alignment fabrication of a liquid crystal cell, which comprises at least three friction rollers arranged from forward to backward, and friction cloth moving under drive of the friction rollers. The bottom of the first friction roller is higher than that of the second friction roller, a guide dip angle formed by the friction cloth arranged between the bottom of the first friction roller and the bottom of the second friction roller and a to-be-rubbed surface is an acute angle, and the bottoms of the second friction roller and the other friction roller other than the first one are leveled with one another. The invention also discloses a liquid crystal cell fabrication method using the friction machine for friction alignment, a liquid crystal cell fabricated by the method, and a liquid crystal display device using the liquid crystal cell. The invention overcomes the problems of peeling and warpage when an alignment layer on a substrate is subjected to friction alignment.

Owner:HISENSE VISUAL TECH CO LTD

Three-dimensional pattern layer manufacturing method for vamp

ActiveCN109203743AHigh tensile strengthImprove crispnessShoemaking devicesOther printing apparatusWater basedMixing ratio

The invention relates to a three-dimensional pattern layer manufacturing method for a vamp. The method is characterized in that a three-dimensional pattern layer is lightweight and subjected to buffering protection while high three-dimensional vision effect is realized. The method comprises the following steps: manufacturing at least one silk-screen board based on a designed pattern; performing silk-screening on the vamp through one of the silk-screen boards, and drying to obtain a water-based resin combining layer; performing silk-screening before an outer layer of the water-based resin combining layer is completely dried, and drying to form a water-based foamed ink layer, wherein the water-based foamed ink layer contains an ultraviolet attenuator; irradiating the surface of the water-based foamed ink layer for 15-20s through UV to obtain a modified foamed ink layer of which the melt strength is gradually reduced from outside to inside; physically processing the surface of the modified foamed ink layer to form a plurality of pre-mixing concave areas, drying; performing silk-screening on the outer surface of the modified foamed ink layer through any one of the silk-screen boards, and drying to obtain a foamed color paste layer, wherein the foamed color paste layer is divided from inside to outside through three layers which are formed by coating with different mixing ratio; andthen pressing through a die, and foaming.

Owner:FUJIAN MEIMINGDA SHOES DEVING

Casting-grade PVC decorative film and preparation method thereof

The invention discloses a casting-grade PVC (polyvinyl chloride) decorative film and a preparation method thereof, the PVC decorative film is sequentially provided with release paper and a pressure-sensitive adhesive layer, and a functional layer is arranged on the pressure-sensitive adhesive layer. The functional layer is a PVC (polyvinyl chloride) film layer, a protective layer is arranged above the functional layer, and an air guide pattern is arranged on the release paper. The processing technology is simple, the processing technologies of a color layer, a reverse color layer and the like are omitted, the film is prepared by adopting a coating technology, and tests show that the film is relatively thin, has relatively high toughness and tensile strength, is easy to operate during film pasting, and is not easy to cause an edge warping phenomenon.

Owner:南通百纳数码新材料有限公司

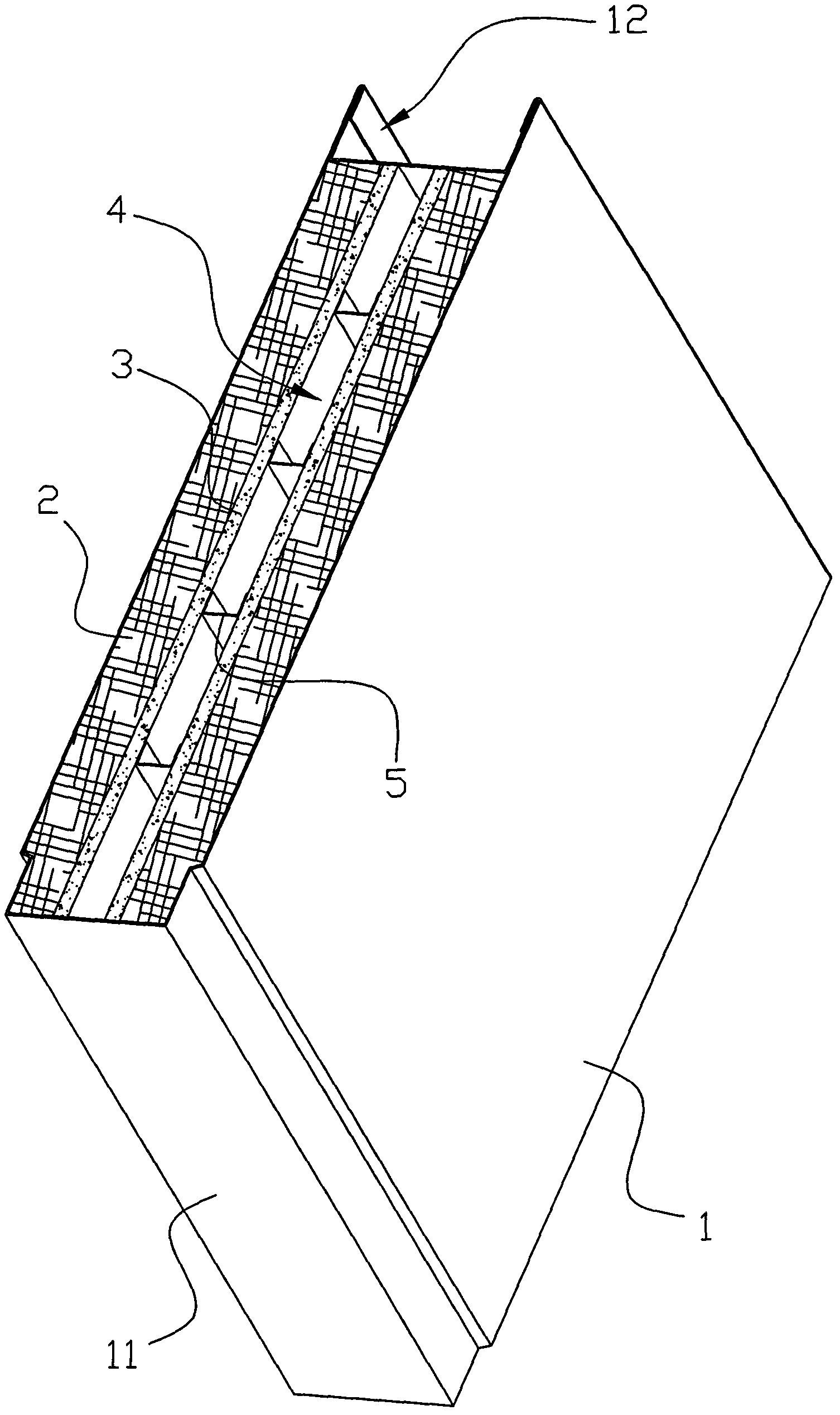

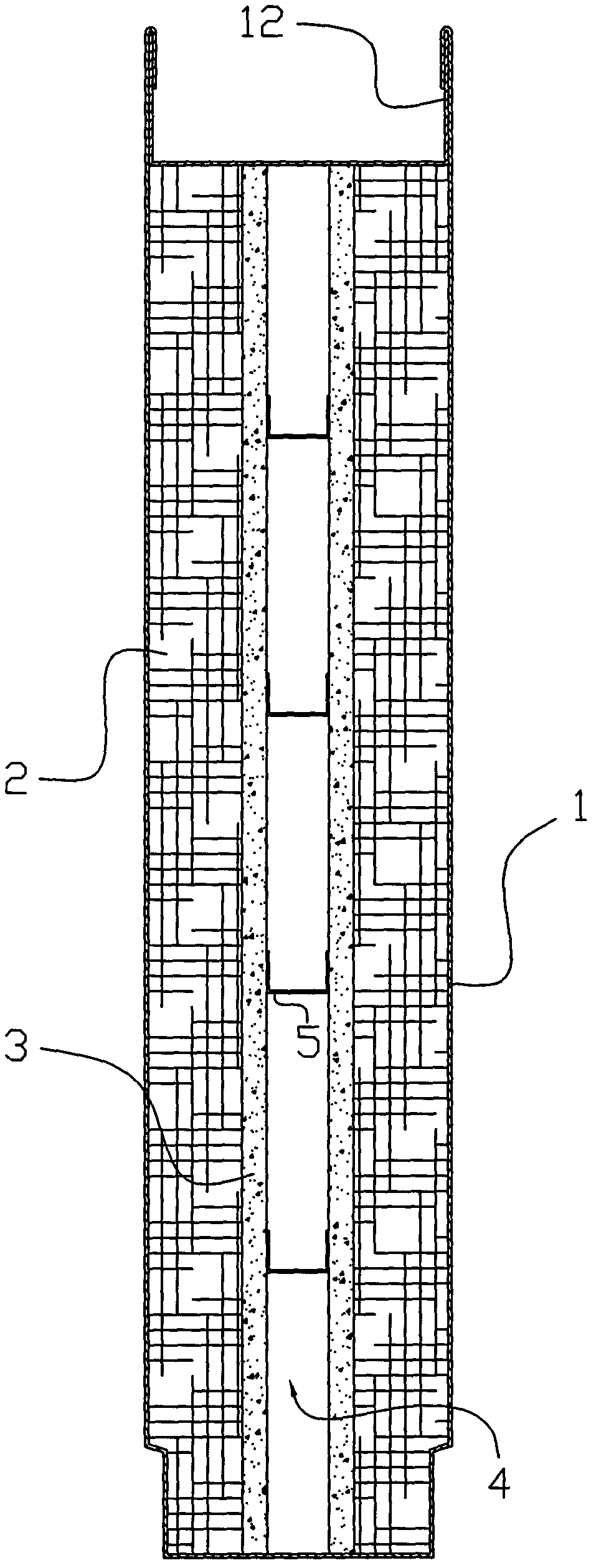

Decorative board with heat-insulating and sound-insulating performance

A decorative board with heat-insulating and sound-insulating performance comprises a board body which comprises an outer wrapping layer (1), rock wool board layers (2), carbonate silicon board layers (3) and a cavity layer (4). The carbonate silicon board layers (3) are arranged in the middle of the board body in a left-right interval manner, a spacing portion between the carbonate silicone board layers (3) on the left and on the right forms the cavity layer (4), the rock wool board layers (2) are arranged on the outer surfaces of the carbonate silicone board layers (3) on the left and on the right respectively , and the rock wool board layers (2) positioned on two sides of the cavity layer (4) are wrapped in the outer wrapping layer (1). The decorative board with the heat-insulating sound-insulating performance has the advantages that rock wool boards and carbonate silicon boards are adopted, so that the decorative board is light in weight, moistureproof, good in fireproof performance, convenient to construct, good in processing performance, capable of being sawed and nailed, less prone to warping and cracking, mothproof and free of heat generation, has good heat-insulating and sound-insulating performance and can meet using requirements of buildings and related decorative places. Especially due to good fireproof performance, under the circumstance of accidents, the decorative board can effectively prevent flame from spreading, so that good safety effect is realized.

Owner:舟山市金海舟船舶设备有限公司

High-weather-resistance matte black shading conductive cloth adhesive tape for small-area plane lap joint

InactiveCN113621317AImprove shading efficiencyNot prone to warpingFilm/foil adhesive primer layersInksFiberAdhesive belt

The invention discloses a high-weather-resistance matte black shading conductive cloth adhesive tape for small-area plane lap joint, and belongs to the technical field of EMI electromagnetic shielding and the field of conductive cloth application. In the using process of the adhesive tape, when light rays penetrate through conductive fiber cloth and irradiate into a storage bag, silver chloride powder and the light rays generate photolysis reaction to become black, the light rays are shielded, meanwhile, the silver chloride powder is subjected to photolysis to generate chlorine and silver, heat generated in the place where the silver chloride powder is directly irradiated by light is dispersed, the temperature is reduced, the balloon is heated to expand due to heat generated in the storage bag, and the multiple magnet blocks repel each other and swing left and right in the storage bag; and the silver chloride powder at the bottom moves through shaking and can make more sufficient contact with light, the light shading efficiency is improved, meanwhile, the expansion bag body is heated to expand downwards to extrude the binder, the binder flows to the bonding face under the action of pressure, and the conductive fiber cloth is not prone to edge warping after being used for a long time.

Owner:江苏伊诺尔新材料科技有限公司

Mildew-proof plastic-wood composite sheet and preparation method thereof

Owner:江苏森诺塑胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com