Pressure-sensitive adhesive layer-carrying polarizing plate and image display device

A technology of adhesive layer and polarizing plate, which is applied in the direction of lamination device, polarizing element, lamination, etc., can solve the problems of reduced adhesive force of polarizing plate, poor liquid crystal display, etc., to prevent glue shortage, not easy to warp, tight high synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

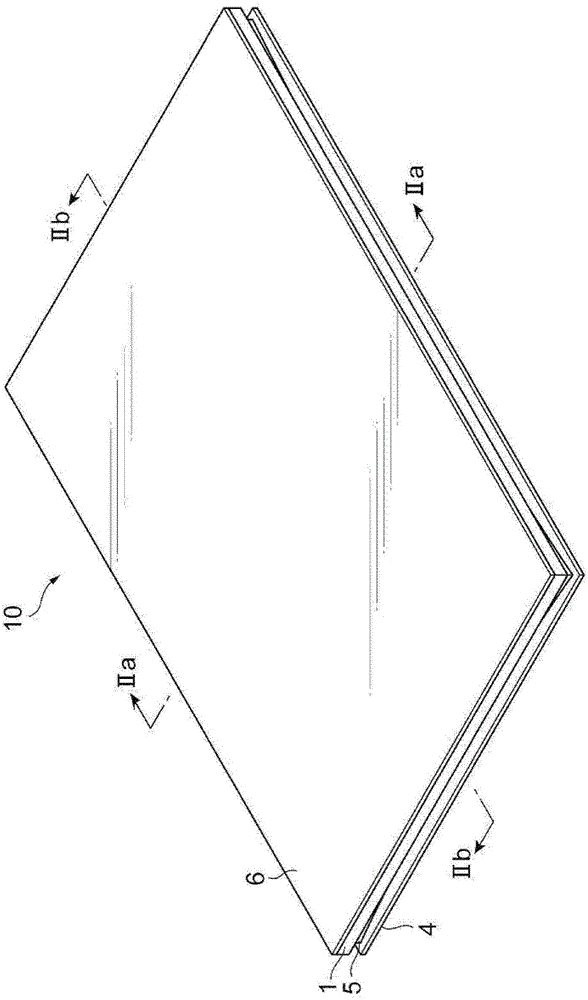

[0085] Separately prepare long polarizers, protective films, and temporary protective films, and use them as figure 1 and figure 2 In the method of lamination sequence, they are bonded by a pair of bonding rollers while conveying them separately. This was cut into a rectangular shape with a long side of 150 mm and a short side of 95 mm. Here, it is cut so that the direction in which the long sides of the rectangle extend coincides with the direction of the polarization axis of the polarizing plate.

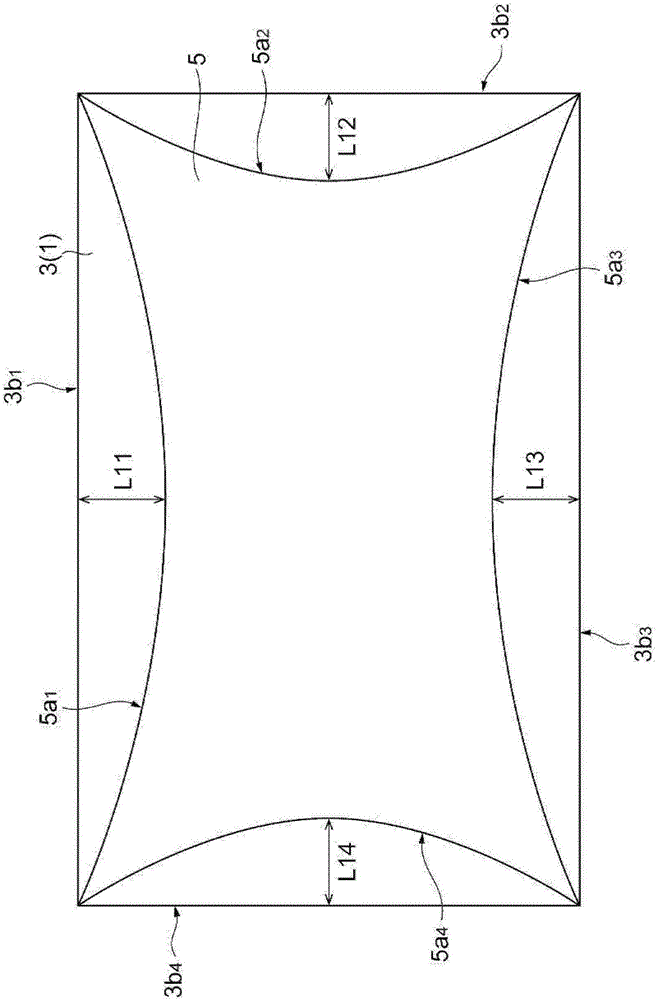

[0086] On the other hand, a laminate in which a separator is laminated on both sides of an adhesive layer is prepared, and the laminate is as follows: image 3 Cut it out so that it becomes a shape with curved sides as shown in . Furthermore, one separator was peeled off, and the pressure-sensitive adhesive layer was bonded to the surface of the above-mentioned polarizing plate cut into a rectangular shape on the side on which the temporary protective film was not provided. T...

Embodiment 1-2、 Embodiment 1-3、 Embodiment 1-4、 Embodiment 1-5

[0094] A polarizing plate with an adhesive layer was produced in the same manner as in Example 1-1 except that the bending width of the adhesive layer was changed to 50 μm, 100 μm, 500 μm, and 1000 μm, and each measurement was performed.

Embodiment 1-6

[0096] Except having bent only one long side among the sides of the adhesive layer in Examples 1-3, the polarizing plate with an adhesive layer was manufactured similarly, and each measurement was performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com