Sealing structure and sealing method of plastic sealing new energy high-voltage direct-current relay

A high-voltage DC, sealed structure technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of uneven dispensing, increase the fluidity of epoxy glue, easy to lack glue, etc., to avoid lack of glue, improve Homogeneous, fluidity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

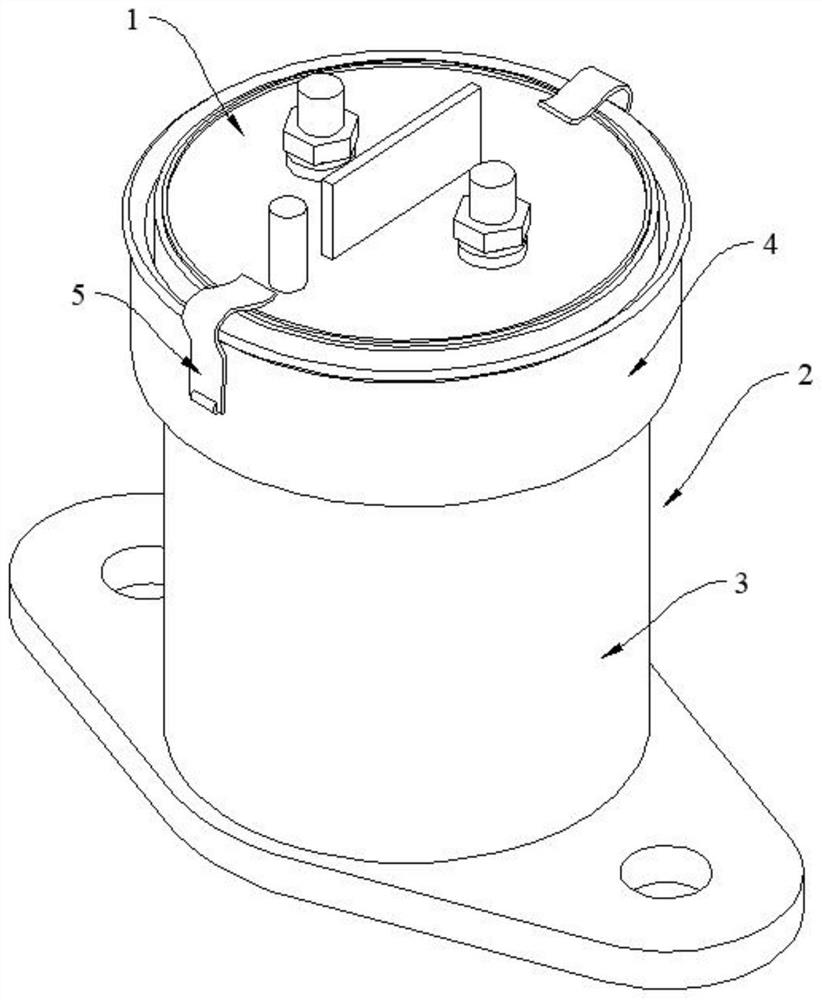

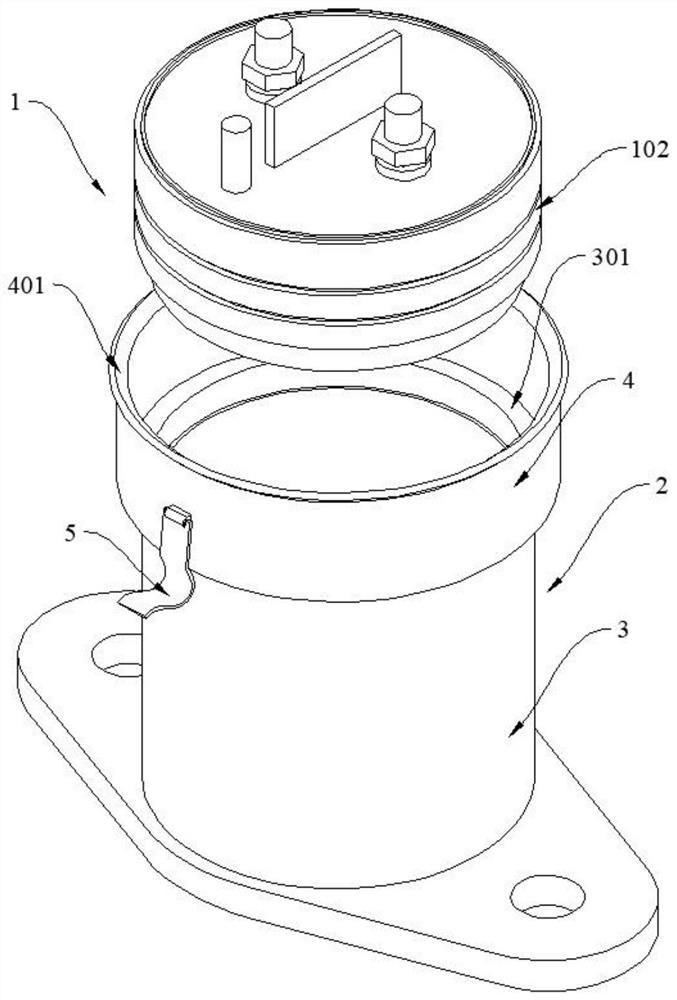

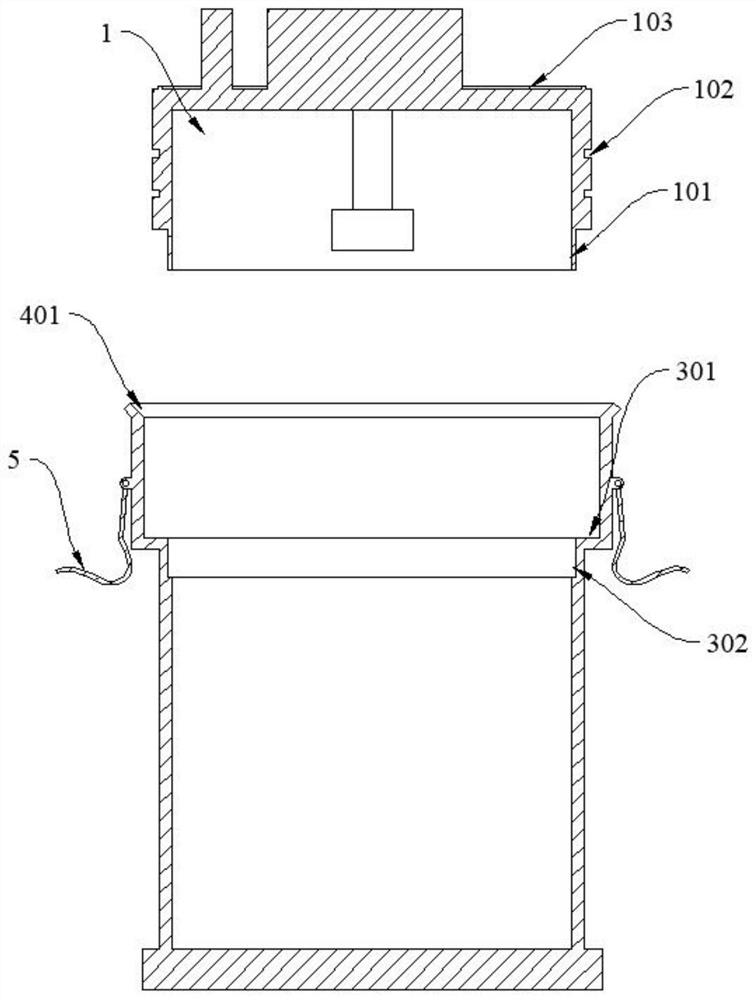

[0035] see Figure 1-Figure 2 As shown, the present invention is a sealing structure of a plastic-sealed new energy high-voltage DC relay, including an upper case 1 and a lower case 2, the upper case 1 is a circular groove with the opening facing downward, and the circumference of the upper case 1 There are two annular grooves 102 on the side. On the one hand, the annular grooves 102 can enhance the connection strength between the upper and lower shells, and on the other hand, increase the filling amount of epoxy glue to improve the sealing performance of the upper and lower shells.

[0036] see Figure 1-Figure 5 The shown lower casing 2 includes a first casing 3 and a second casing 4, the diameter of the second casing 4 is greater than the diameter of the first casing 3, and the lower end surface of the second casing 4 is connected to the bottom surface of the first casing 3. The upper end surface is fixedly connected, and a first step 301 is formed at the joint between the...

Embodiment 2

[0045] see Figure 2-Figure 4 As shown, the lower end surface of the upper housing 1 is fixedly connected with the limiting ring 101, and the upper end surface of the first housing 3 is provided with a limiting groove 302, and the limiting ring 101 is slidably matched with the limiting groove 302 to ensure the uniformity of the glue injection gap. , At the same time, it forms a second barrier to prevent the epoxy glue from losing to the inside of the shell, so as to avoid the loss of epoxy glue into the shell cavity, resulting in local lack of glue. The inner wall of the limiting ring 101 and the inner wall of the upper housing 1 are on the same curved surface. After the limiting ring 101 is matched with the limiting groove 302, the inner wall of the limiting ring 101 and the inner wall of the first housing 3 are also on the same curved surface, ensuring The installation gap of the device inside the housing, while avoiding collisions with the components during the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com