Plastic floor and manufacturing method thereof

A technology of a plastic floor and a manufacturing method, which is applied in the direction of building structure, floor, building, etc., can solve the problems of the floor being easily warped, inconvenient to transport, increase the difficulty and trouble, and achieve the convenience of processing, manufacturing and laying. warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

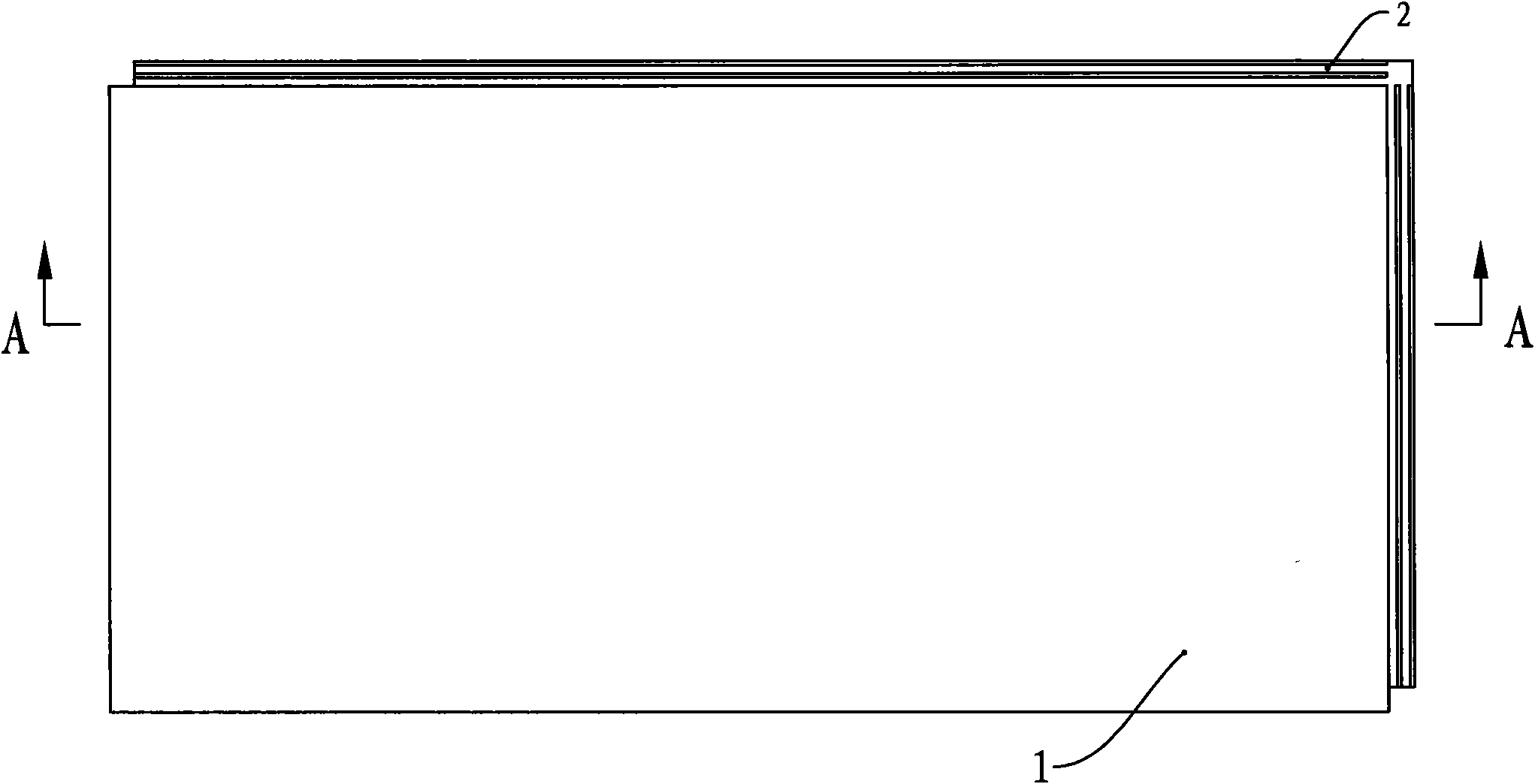

[0014] see figure 1 and figure 2 , The plastic floor includes a surface layer 1, a locking layer 2 and a bottom layer 3, the surface layer 1 and the bottom layer 3 are respectively pasted on the upper surface and the lower surface of the locking layer 2, and the locking layer 2 is sandwiched between the surface layer 1 and the bottom layer 3. The surface layer 1, the locking layer 2 and the bottom layer 3 are all square plastic plates. The surface layer 1 is preferably a PVC plastic board, and the patterns and colors are based on natural wood and stone, and are formed by engraving and printing. As a result, the vinyl flooring presents a very realistic laying effect of natural materials. The surface of the surface layer 1 is also provided with a transparent wear-resistant layer, which is more wear-resistant and less prone to wear than other flooring materials. The bottom layer 3 can be a plastic plate, and the bottom surface of the plastic plate is coated with a layer of im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com