Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Not prone to fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cover glaze and preparation method thereof

The invention discloses a cover glaze which is characterized in that: the constituents of the cover glaze are as follows by weight percentage: 90-96 percent of matte fusion cake, 4-6 percent of gas knife soil, 0.08-0.2 percent of sodium carboxymethylcellulose, 0.03-0.36 percent of industrial sodium tripolyphosphate, and 0.20-0.26 percent of ceramic dispergator, and water accounting for 20-26 percent of total proportion of the raw materials. The preparation process flows of the cover glaze are as follows: raw material incoming inspection--batching--ball milling--detection--deironing and sieving--decaying--warehousing and being sieved by 250 meshes of deironing oscillating screen. The ball milling time is 7-10 hours, and ball-milling glazeslip specific gravity is 1.4-1.9g / cm<3>, and the fineness is 0.6-1.0mm; the flowing speed of the ball-milling glazeslip is controlled above 55s. The cover glaze has the advantages of transparent and smooth performance, bright color and luster and wide market prospect.

Owner:李建平

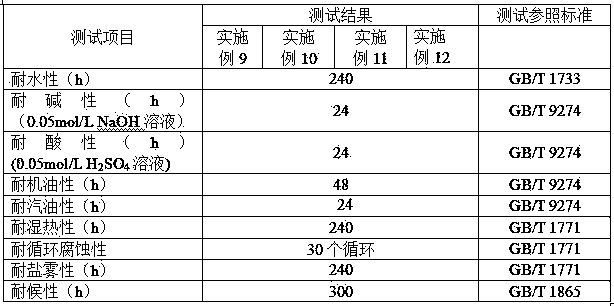

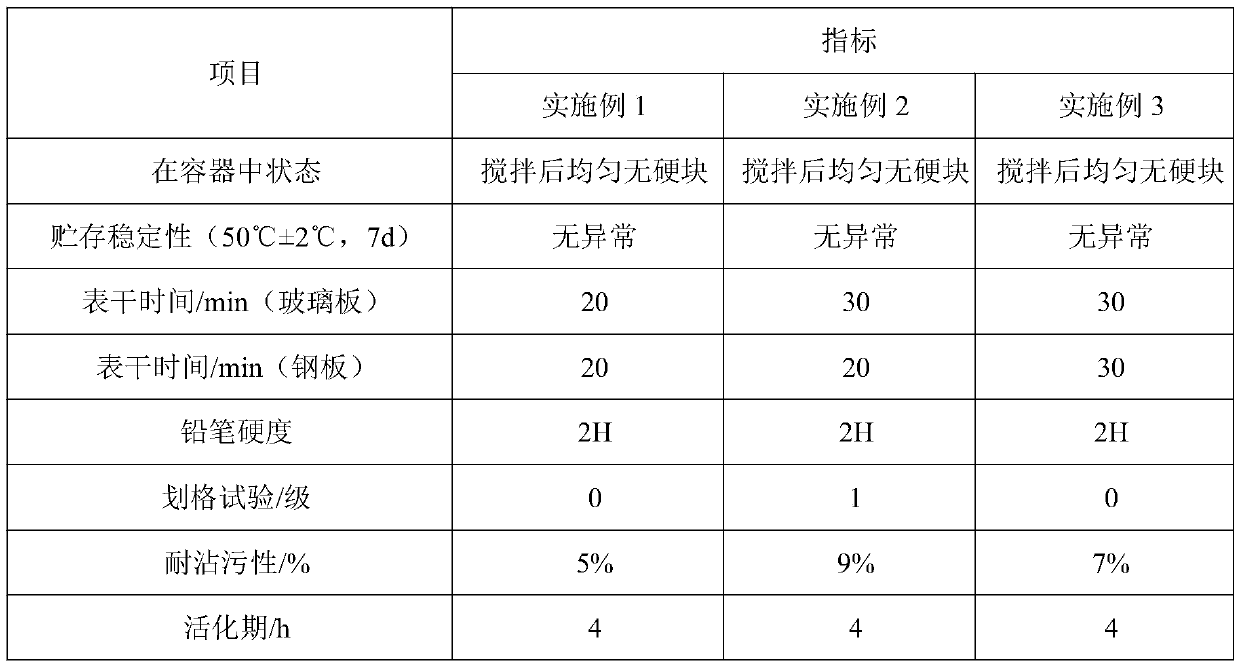

Resin composition for water-based high-performance color gloss coating and preparation method of resin composition

The invention discloses a resin composition for a water-based high-performance color gloss coating and a preparation method of the resin composition. The resin composition is prepared from 30%-60% of water-based castor oil-modified alkyd resin and 40%-70% of water-based acrylic resin, wherein the water-based castor oil-modified alkyd resin is mainly prepared from castor oil, trimethylolpropane, phthalic anhydride, trimellitic anhydride, butoxyethanol, n-butyl alcohol and xylene; and the water-based acrylic resin is prepared from a solvent, methyl methacrylate, butyl acrylate, styrene, hydroxyethyl methylacrylate, crylic acid, benzoyl peroxide, tert-butyl peroxybenzoate, ammonium hydroxide and water. The pigment disclosed by the invention is easily dispersed to below 10 microns, and is stable in storage; the prepared coating performance is excellent; and the glossiness of a film is not reduced during adding water and diluting.

Owner:肇庆千江高新材料科技股份公司

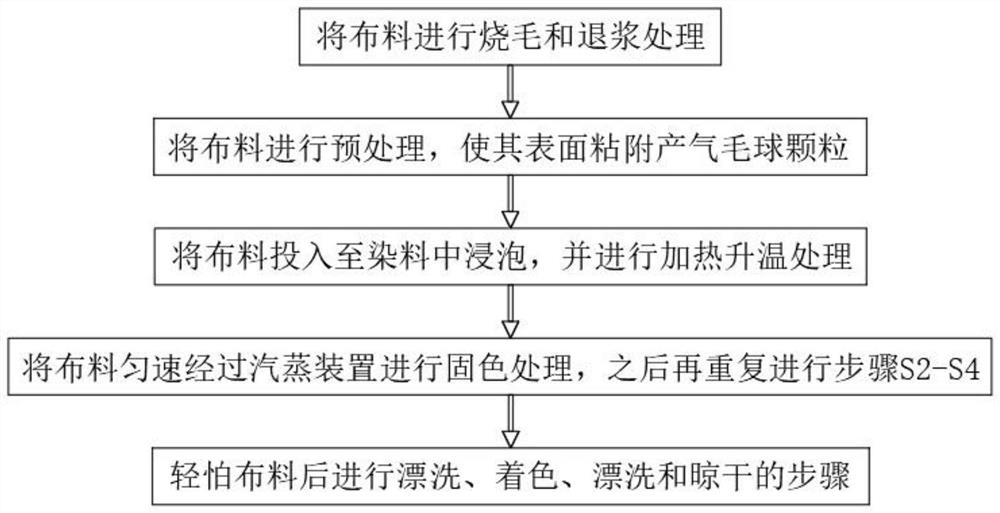

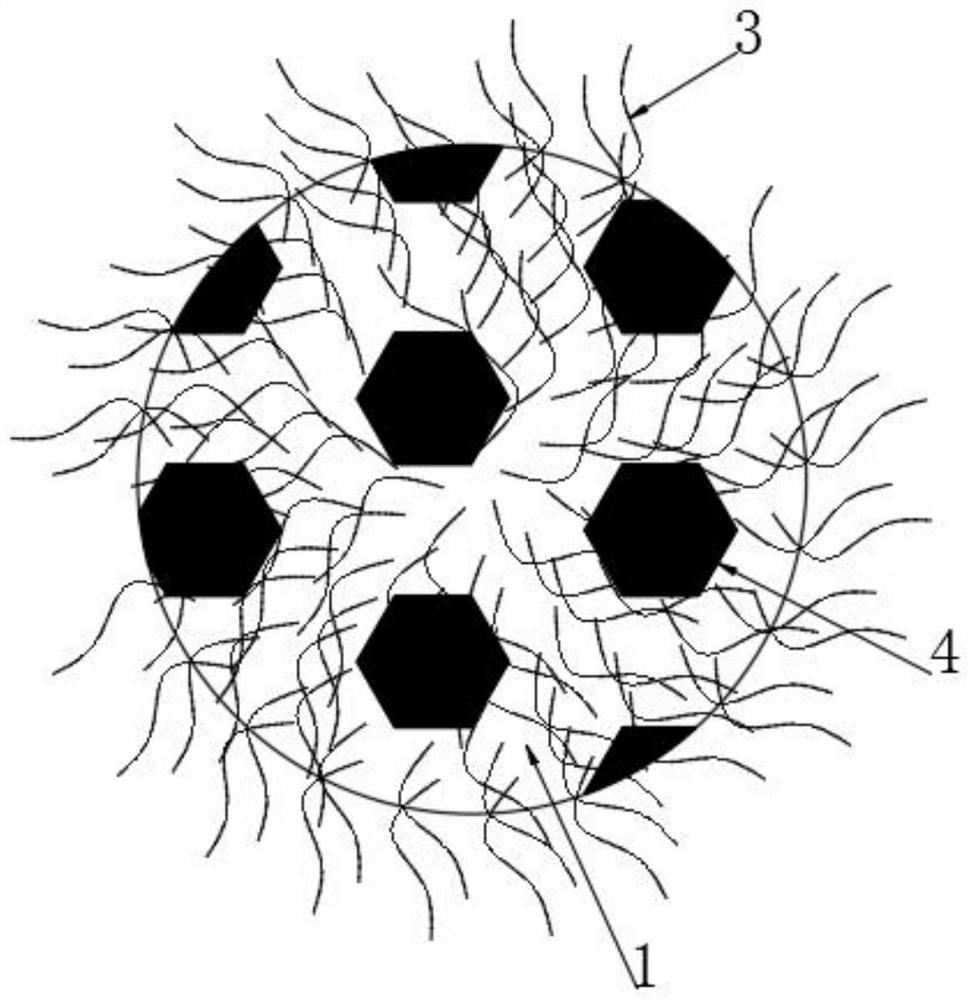

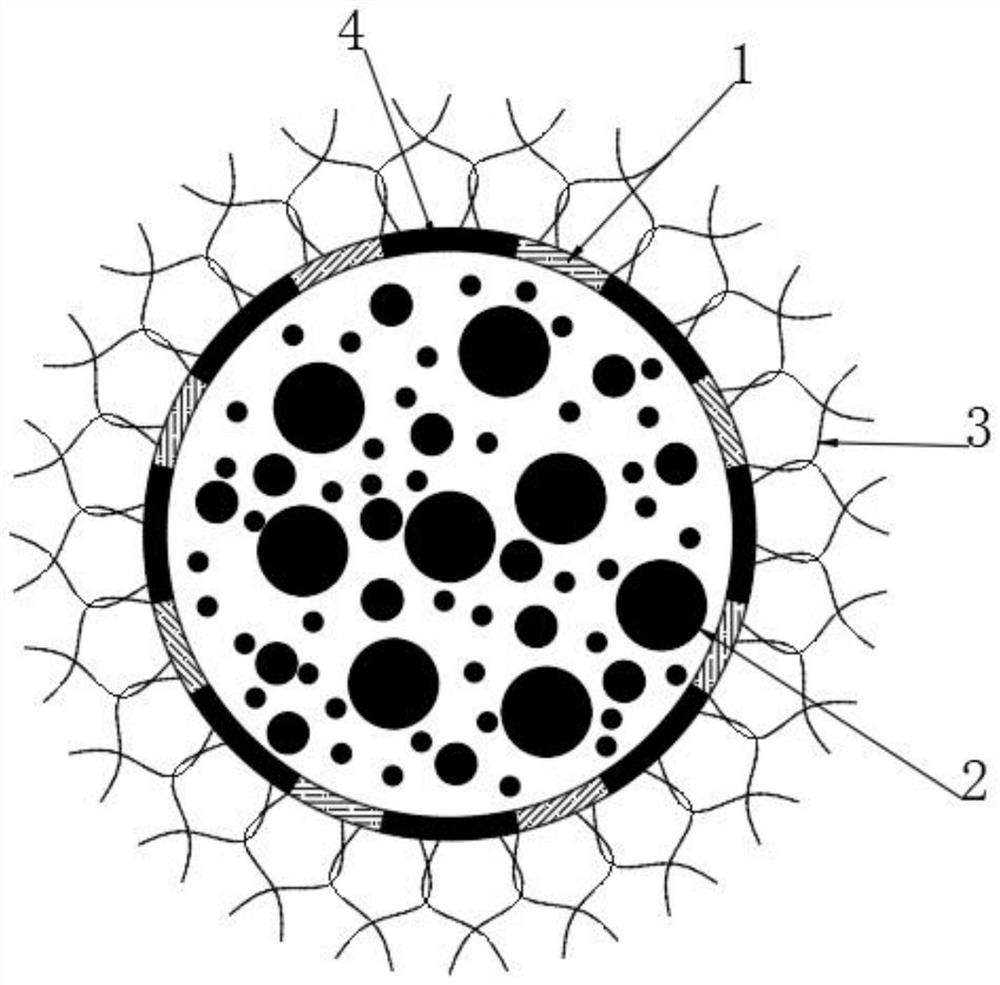

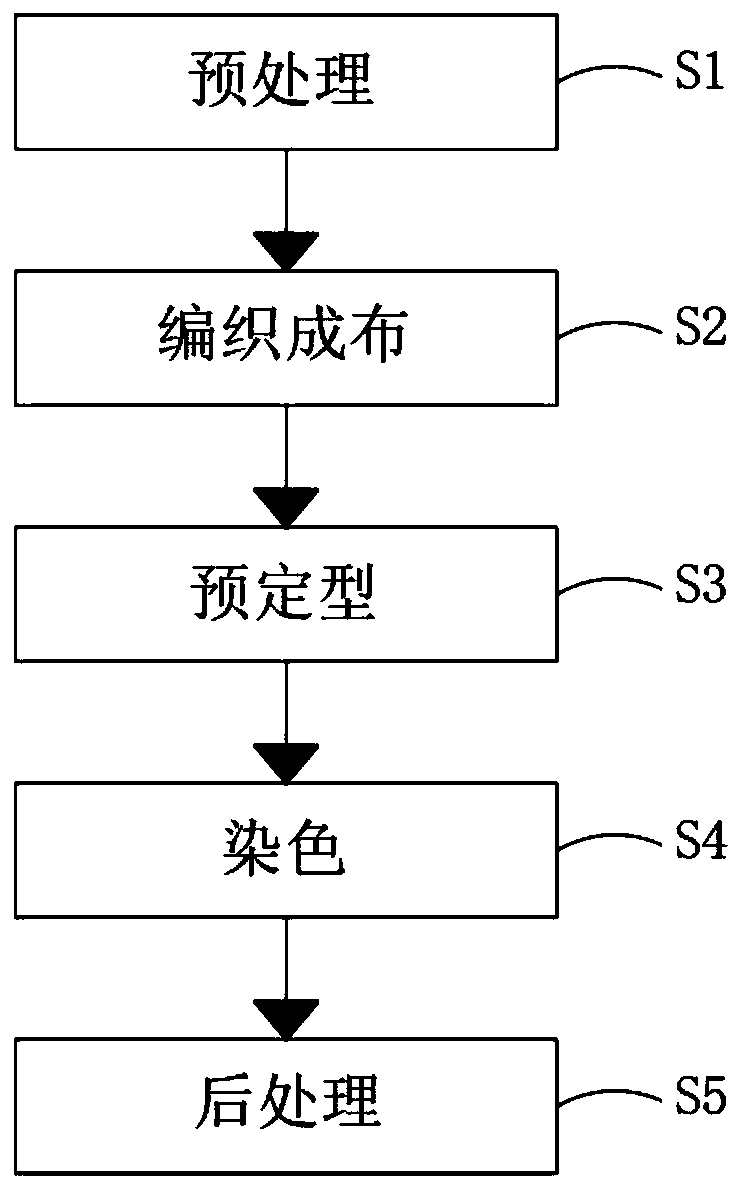

High-fluidity cloth printing and dyeing process

InactiveCN112522972AIncrease humidityEliminate static electricityDyeing processPolymer sciencePolymer chemistry

The invention discloses a high-fluidity cloth printing and dyeing process, and belongs to the field of dyeing. The high-fluidity cloth printing and dyeing process comprises the following steps: adhering aerogenesis fluff ball particles to cloth, and dissolving pre-plugging blocks on the aerogenesis fluff ball particles in water when the cloth is immersed into dye, at the moment, the dye enters a fluff ball shell along pores and makes contact with the aerogenesis particles, and the aerogenesis particles make contact with water in the dye to generate a large amount of carbon dioxide gas, the carbon dioxide gas overflows from the pores, in other words, during dyeing, a large amount of gas overflows from the surface of the cloth, so that the liquidity of the dye around the cloth is effectivelydriven, and thus the speed that the dye molecules enter the cloth is increased; compared with the prior art, the dyeing efficiency is remarkably improved, through arrangement of self-softening fluff,the aerogenesis fluff ball particles can be conveniently adhered to the cloth before dyeing, and after dyeing, due to heating, the self-softening fluff is gradually softened, the aerogenesis fluff ball particles can be conveniently and automatically desorbed from the surface of the cloth, and the manual desorption operation is reduced.

Owner:张光元

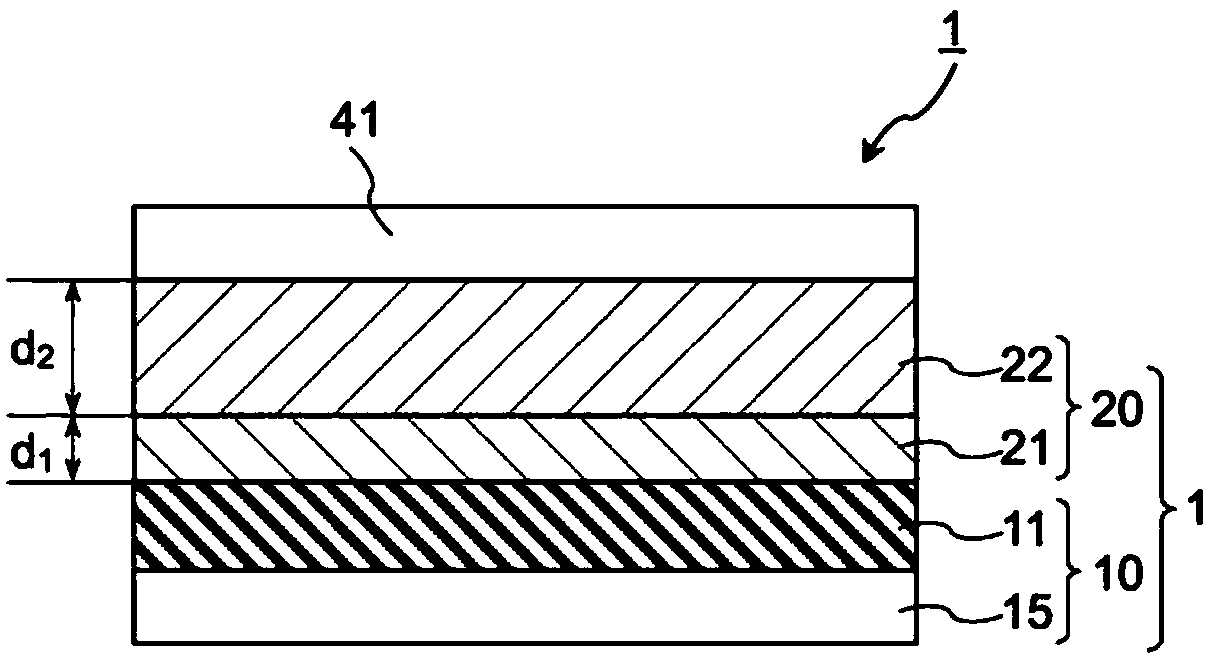

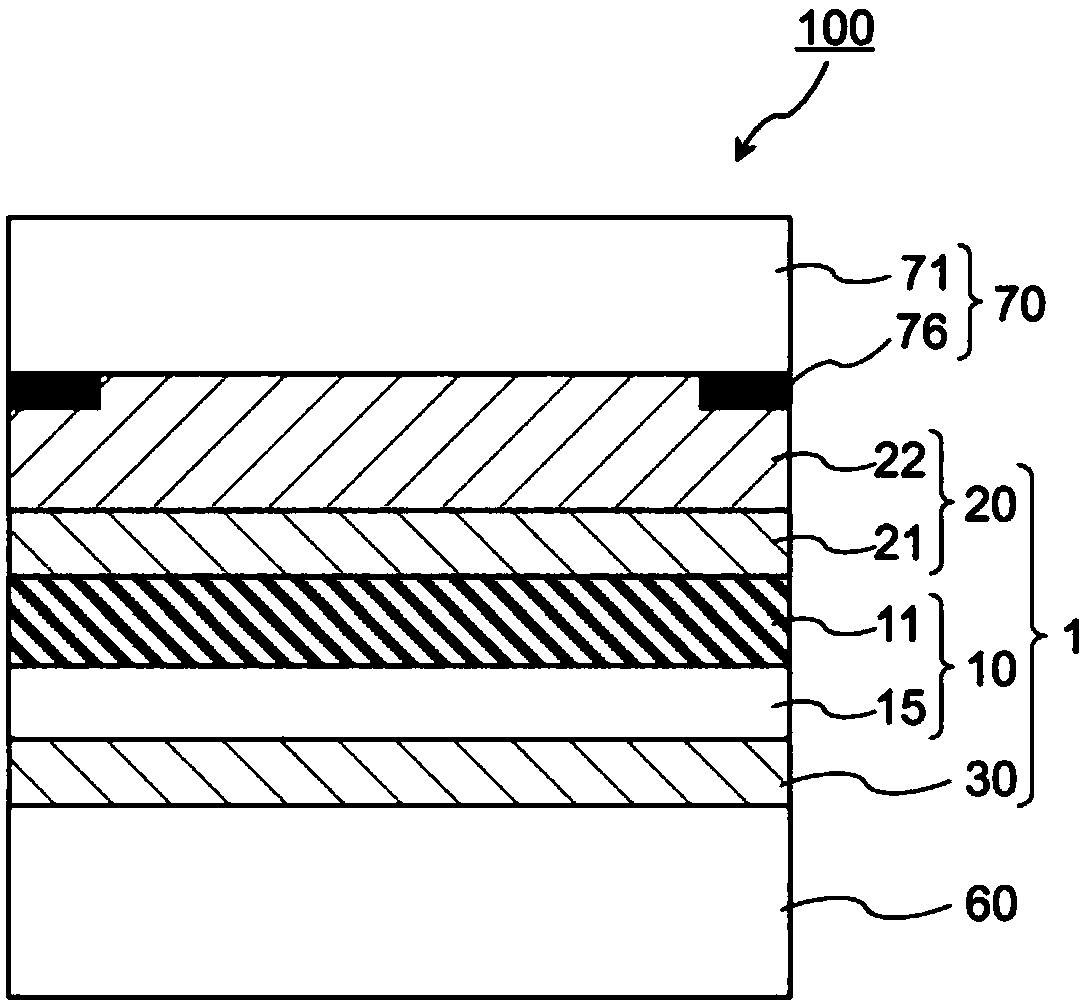

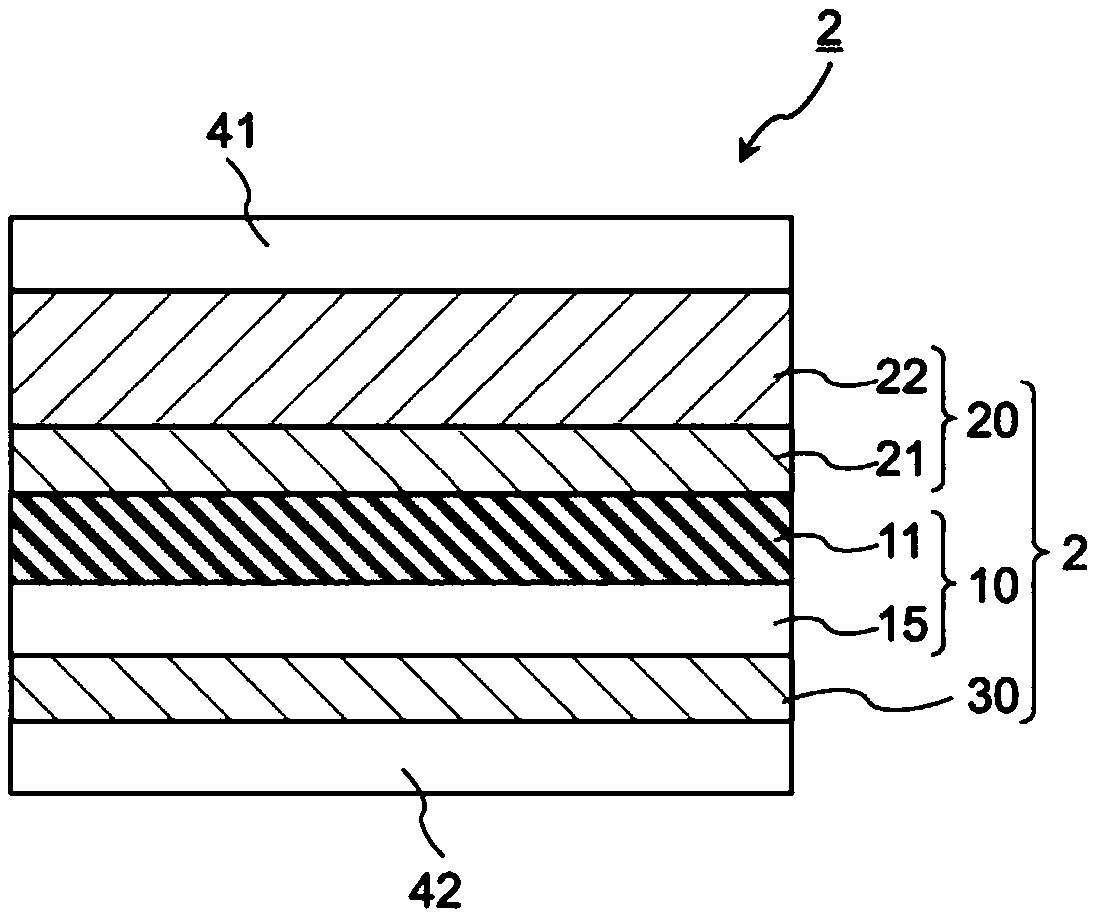

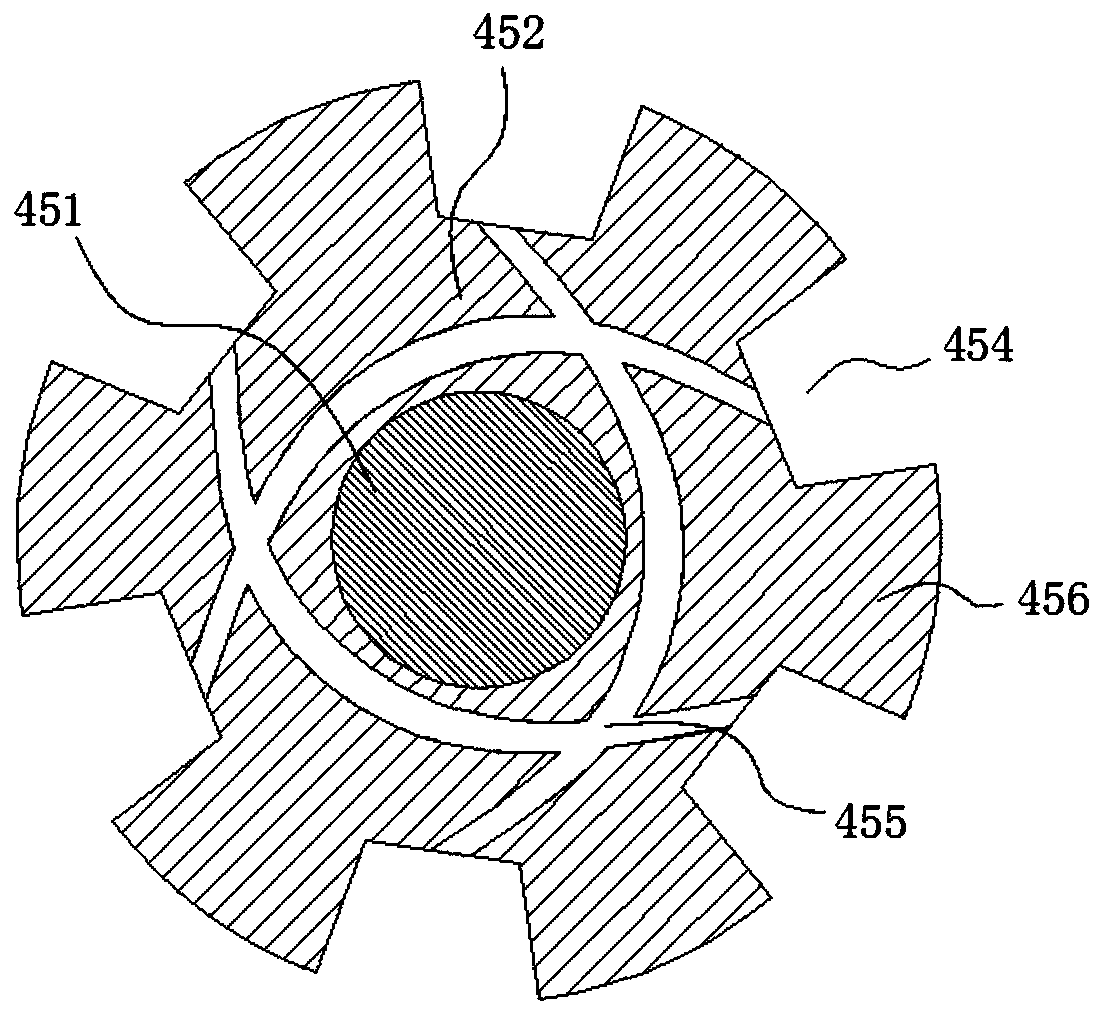

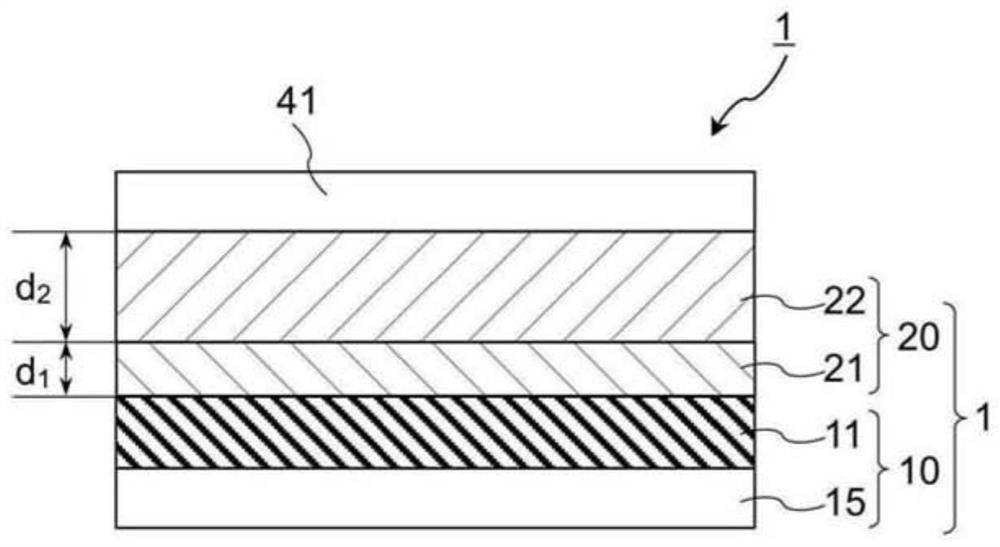

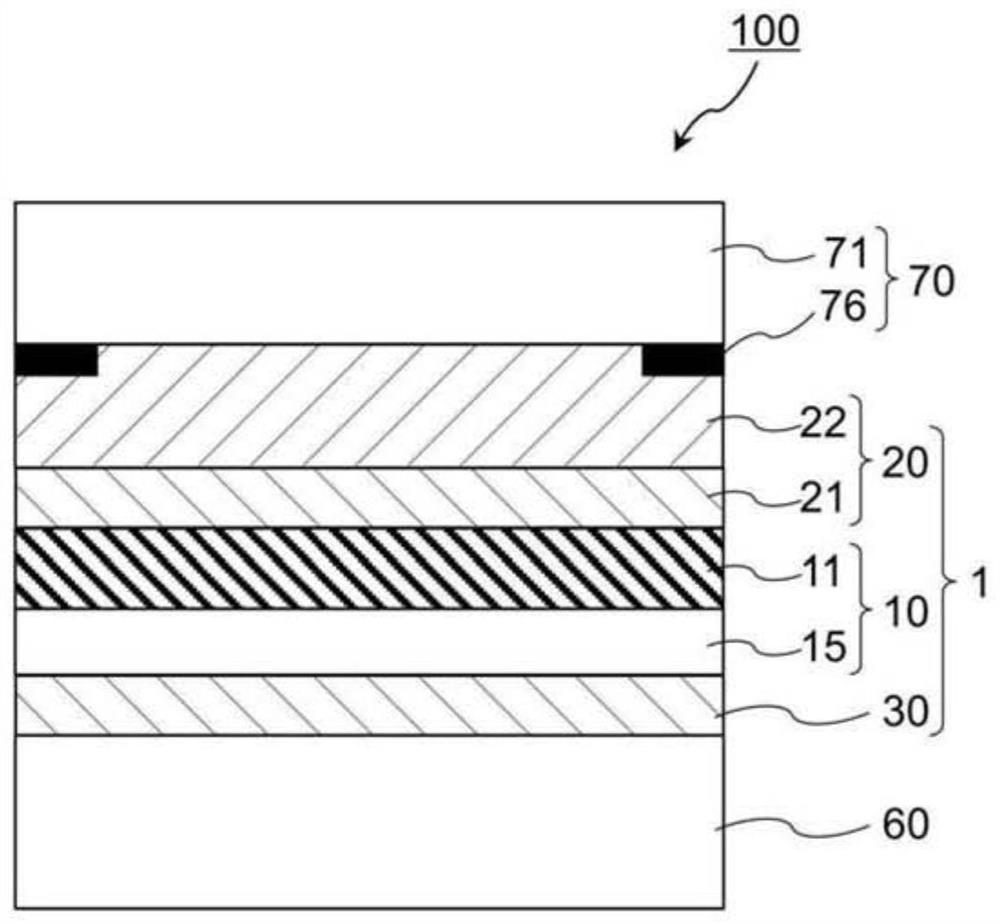

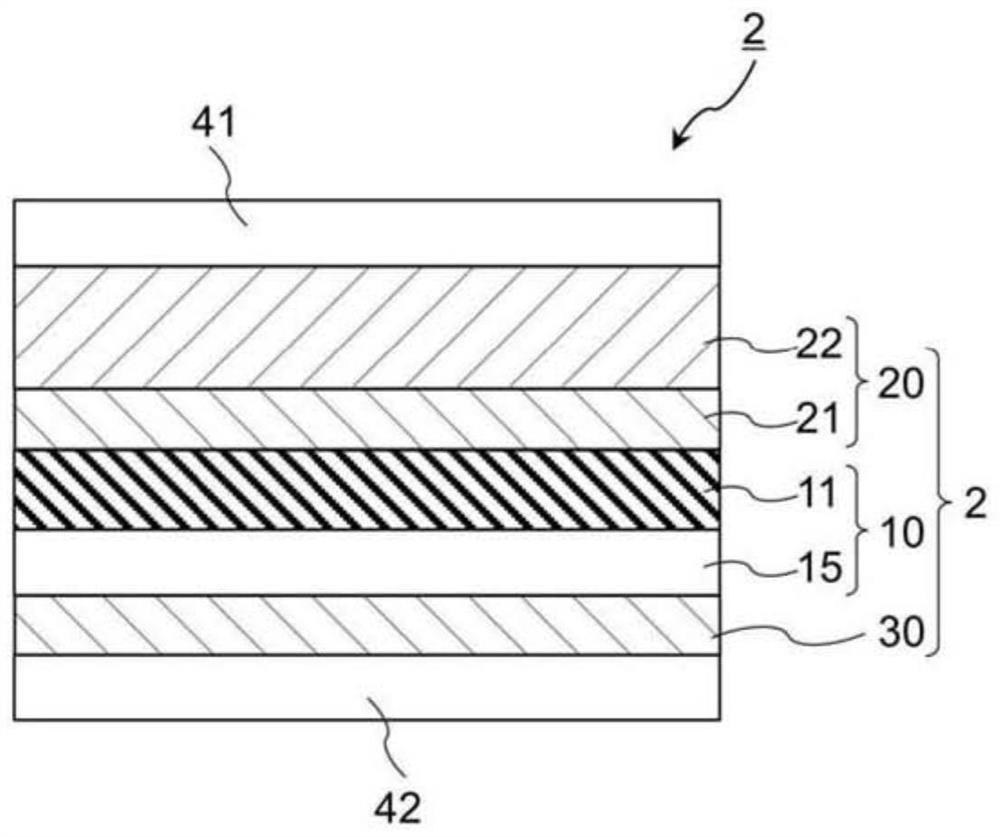

Polarizing plate with adhesive and image display device

ActiveCN108169833ANot prone to fadingInhibit transferNon-macromolecular adhesive additivesFilm/foil adhesivesPolyvinyl alcoholAdhesive

The invention relates to a polarizing plate with an adhesive and an image display device. The polarizing plate (1) with the adhesive comprises a polarizer (11) comprising an iodine-containing polyvinyl alcohol film, a transparent protective film (15) attached to the first main surface of the polarizer and a front side adhesive sheet (20) which is arranged in a manner of being in contact with a second main surface of the polarizer. The front-side adhesive sheet is a laminated adhesive sheet obtained by laminating at least two layers of adhesive layers, and is provided with a first adhesive layer (21) which is arranged in a manner of being in contact with the polarizer and a second adhesive layer (22) disposed so as to be spaced apart from the polarizer. Preferably, the energy storage elastic modulus G '80 at 80 DEG c of the front side adhesive sheet is 1 * 105 pa or less, and the humidity of the first adhesive layer is preferably 150 g / m2 .24 hours or less.

Owner:NITTO DENKO CORP

Paint wiping and coating method for furniture

InactiveCN107952644AImprove stabilityNot easy to deform and swellPretreated surfacesCoatingsWaxLacquer

The invention discloses a paint wiping and coating method for furniture. The paint wiping and coating method for the furniture is characterized by comprising the following steps of A, wiping first-time color water on a furniture wood surface; B, coating an explosion-proof agent on the furniture; C, grinding the furniture to be smooth; D, wiping the second-time color water on the furniture; E, coating first-time thin glue on the furniture; F, uniformly coating raw lacquer on the furniture; G, grinding the furniture; H, wiping the third-time color water on the furniture; I, coating the second-time thin glue on the furniture; J, grinding the furniture to be smooth; K, coating the first-time raw lacquer on the furniture and uniformly wiping the paint; and L, coating the second-time raw lacqueron the furniture and uniformly wiping the paint to obtain a finished product. According to the paint wiping and coating method for the furniture, the paint film formed by the paint wiping and coatingmethod for the furniture is high in stability, better than a wax film and not easy to fade; moreover, the oiliness of the paint film is higher and more full than the wax, and a natural coating slurrycan be formed more quickly and better than the wax in the use process of the furniture, the pores are opened, the permeable raw lacquer is completely absorbed, so that the furniture is high in stability and not easy to deform and expand; and when the wood surface of the furniture is touched by hand, the protoplast of the wood can be sufficiently sensed, and the color of the painted surface of thefurniture is better.

Owner:戴爱国

Blue dye with color fixing effect

InactiveCN111057391AOvercome the shortcomings of not easy to fix colorTo achieve the effect of enhancing colorNatural dyesDyeing processPhotochemistryBaphicacanthus cusia

The invention belongs to the field of dye preparation, and particularly relates to a blue dye with a color fixing effect, wherein the blue dye is prepared from the following raw materials in parts byweight: 20 to 30 parts of baphicacanthus cusia bremek, 20 to 40 parts of polygonum tinctorium, 6 to 9 parts of sodium citrate, 5 to 9 parts of simethicone, 5 to 10 parts of a color enhancing liquid, 1part of a color fixing agent and 1 part of a dispersing agent. The blue dye is derived from plants, has the characteristics of safety, no toxicity, economy and environmental protection, and overcomesthe defect that a plant dye is not prone to color fixing through combined use with the color enhancing liquid; the color enhancing, an adhesive and an auxiliary agent are mixed to prepare the color enhancing liquid; when the color enhancing liquid is added into a dye and is used for dyeing, a color enhancing agent is attached to clothes and is tightly combined with the dye, so that the effects ofcoloring and brightening the clothes are achieved, the clothes are not easy to fade and darken after being washed for multiple times, and the clothes can still keep bright and do not fade or darken after being washed with water for multiple times.

Owner:黎平县侗品源旅游商品服务有限责任公司

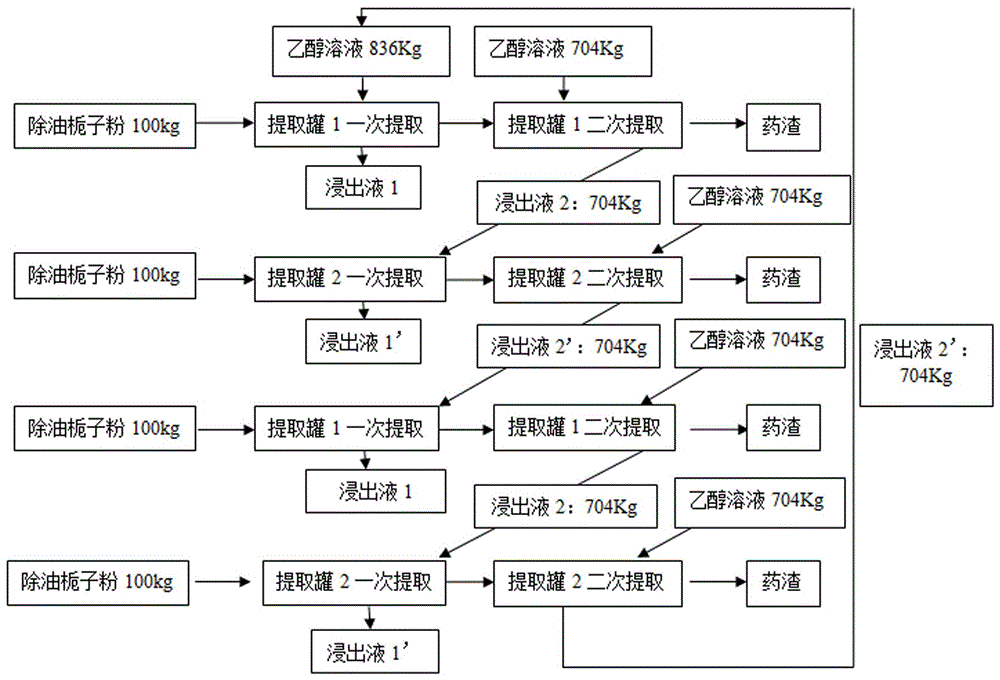

Method for two-pot two stage countercurrent dynamic extraction of gardenia yellow pigment

InactiveCN105670335AReduce dosageReduce energy consumptionSugar derivativesOrganic compound preparationPregnant leach solutionChlorogenic acid

The invention discloses a method for two-pot two stage countercurrent dynamic extraction of a gardenia yellow pigment. The method comprises the following steps: 1, crushing decorticated cape jasmine fruits to obtain 80 mesh powder, and deoiling to obtain cape jasmine oil and deoiled cape jasmine powder; 2, adding an ethanol solution used as an extract solution to the deoiled cape jasmine powder, and carrying out ethanol refluxing two-pot two stage countercurrent dynamic extraction to respectively obtain a leachate 1, a leachate 1' and low-liquid medicine residues; 3, carrying out low temperature concentration on the above leachates to recover most of ethanol, and adding the obtained solution used as a sample solution to pretreated macro-porous adsorption resin to carry out column purification in order to obtain the purified gardenia yellow pigment, geniposide and chlorogenic acid; and 4, adding the low-liquid medicine residues to a proper amount of water, carrying out vacuum distillation condensation to recover water-containing ethanol, and stopping the vacuum distillation condensation until the concentration of ethanol in the medicine residues is lower than 5%. The method has the advantages of stable extraction process, no dead corners of materials in extraction pots, difficult fading and greening of the gardenia yellow, and high extraction efficiency.

Owner:江门市林业科学研究所

Anti-fading fabric softening agent

The invention discloses an anti-fading fabric softening agent which comprises, by weight, 2-8 parts of sodium stearate, 5-10 parts of octamethyl cyclotetrasiloxane, 3-9 parts of aminoethyl aminopropyl methyl dimethoxysilane, 2-10 parts of alkaline catalysts, 3-9 parts of sodium hydrogen sulfite, 12-18 parts of acrylic amide, 3-15 parts of aqueous acrylic resin and 50-85 parts of water. By the mode, the anti-fading fabric softening agent is not easy to yellow, vivid colors of a fabric can be ensured, fading does not easily occur, and the fabric has good softness and is glossy and bright.

Owner:无锡市华誉日用品厂

Art paint coating unlike to fade

The invention relates to an art paint coating unlike to fade. The art paint coating unlike to fade is prepared from the following components in parts by mass: 12-15 parts of silicon micro powder, 5-10parts of water, 2-5 parts of a film forming auxiliary agent, 1-3 parts of a bactericide, 13-20 parts of epoxy modified acrylic resin, 2-8 parts of a flatting agent, 3-6 parts of titanium dioxide, 5-15 parts of a wetting agent, 3-10 parts of a thickener, 18-30 parts of a dispersant and 2-4 parts of a sterilizer. The art paint coating is durable in using effect, and the service life of the art paint coating can be prolonged obviously. As the components of the art paint coating are stable in property and the property of the whole coating is stable too, a fading phenomenon is hard to happen, andthe art paint coating is more durable in color in use.

Owner:徐州隆邦家具有限公司

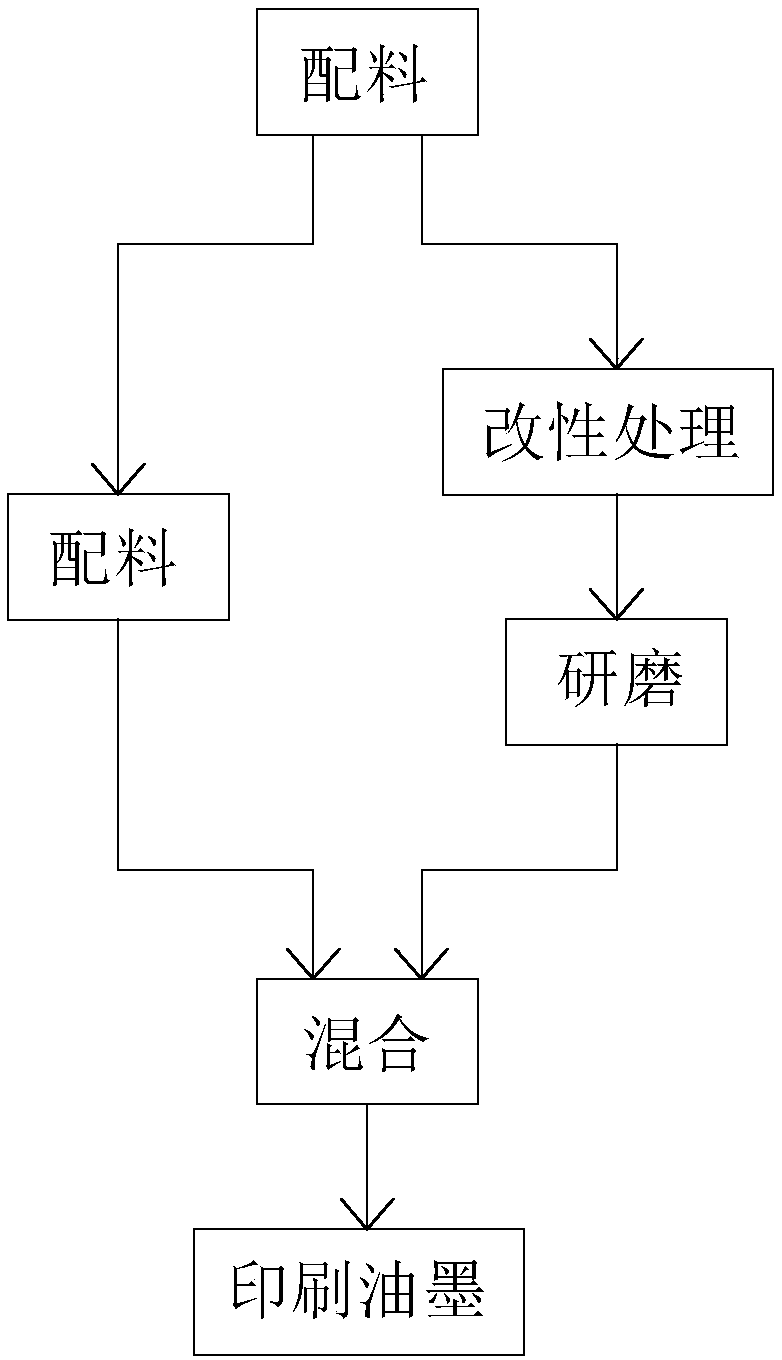

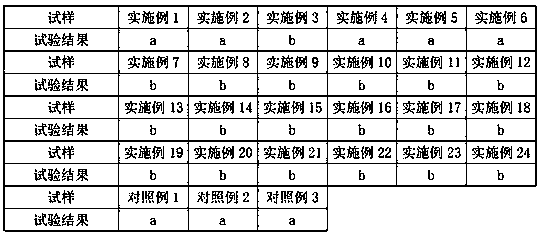

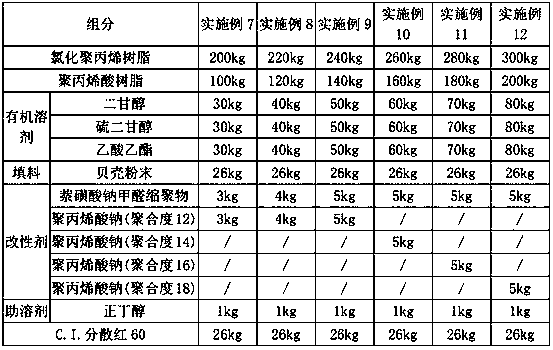

High adhesion printing ink and preparation method thereof

The invention discloses high adhesion printing ink. The high adhesion printing ink is characterized by being prepared from the following raw materials in parts by weight: 20 to 30 parts of chlorinatedpolypropylene resin, 10 to 20 parts of polyacrylic resin, 9 to 24 parts of organic solvent, 1 to 5 parts of inorganic filler, 0.2 to 1.0 part of modifier, 0.1 to 0.5 part of cosolvent and 1 to 5 parts of disperse dye, wherein the solvent is prepared by mixing diethylene glycol, thiodiglycol and ethyl acetate in a mass ratio of 1 to 1 to 1, and the inorganic filler is less than or equal to 10 mu min particle size. The printing ink does not need to be doped with graphene, and is low in cost and high in adhesion fastness. The invention correspondingly discloses a preparation method of the highadhesion printing ink. The printing ink prepared with the method has the advantages of high adhesion, and flatness and smoothness after film formation.

Owner:浙江新中商务印刷有限公司

Process for preparing printed matter with gravure fission effect

ActiveCN110588195AImprove adhesionNot easy to appear edgeInksOther printing apparatusDetonationHigh volume manufacturing

The invention relates to the technical field of printing, and in particular to a process for preparing printed matter with a gravure fission effect. The process for preparing the printed matter with the gravure fission effect comprises the following steps that step A, UV fission ink is printed on a carrier material through a gravure plate; and step B, the carrier material printed with the UV fission ink is sequentially subjected to UV detonation treatment and UV drying and curing treatment to obtain the printed matter with the gravure fission effect. The process for preparing the printed matter with the gravure fission effect is simple to operate, easy to control and high in production efficiency, the printed matter is enabled to have the obvious gravure fission effect, and the cured ink has relatively good adhesion on the carrier material, the phenomena of edge rising, warping and the like are not prone to occurring, relatively good weather resistance and aging resistance are achieved, the phenomenon of yellowing or fading is not prone to occurring, the quality is stable, and the process for preparing printed matter with the gravure fission effect can be used for mass production

Owner:东莞智源彩印有限公司

High-temperature-resistant textile dye

The invention provides a high-temperature-resistant textile dye. The high-temperature-resistant textile dye is prepared from raw materials in parts by weight as follows: 20-40 parts of polyamide resin, 6-10 parts of polyvinyl alcohol, 4-7 parts of ethyl cellulose, 5-6 parts of methylsilicone oil, 5-8 parts of alkyl polyglucoside, 1-2 parts of tannic acid, 1-1.5 parts of aminopropyltriethoxysilane, 0.5-0.8 parts of polypyrrolidone, 3-8 parts of urea, 5-10 parts of turmeric, 2-5 parts of sodium fatty acid, 3-8 parts of sodium alginate, 1-3 parts of nano-titania, 5-8 parts of an antioxidant and 100-120 parts of deionized water. The high-temperature-resistant textile dye has excellent high-temperature-resistant capacity, can meet the dyeing requirements of high-temperature and acid-base environments and other environments, is good in dyeing uniformity, cannot affect the handfeel of textiles and cannot produce fading easily.

Owner:NANTONG RICHISLAND BEDDING DEV CO LTD

Deodorant for paint and preparation method thereof

The invention belongs to the technical field of paints, and specifically discloses a deodorant for a paint and a preparation method thereof. The deodorant comprises components such as triethanolamine,naphthenic acid lithium, linoleic acid, tetrabutyl titanate and carbonic acid ammonium zirconium salt; the deodorant is used for deodorizing the paint and the effect is obvious; odors such as formaldehyde of the paint can be obviously reduced and removed in a short period; in addition, a paint coating can be rapidly dried; and problems such as ageing and color fading can be greatly solved.

Owner:折伟

Staining method for blended yarn weaved fabric

InactiveCN108457104APrevent precipitationEnsure consistencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWoven fabricStain method

The invention provides a staining method for a blended yarn weaved fabric. The staining method solves the technical problems that staining steps in an existing production technology are too simple, the uniformity of fabric color cannot be guaranteed and the staining effect is low. The staining method for the blended yarn waved fabric comprises the following steps: a, weaving the four raw materialssuch as linen fiber, active carbon fiber, viscose filament yarn fiber and polyester fiber into a blended yarn weaved fabric; b, putting 6 to 12 parts of a natural plant pigment, 1 to 3 parts of calcium sulfate, 1 to 3 parts of magnesium sulfate, 0.4 to 0.8 part of aluminum oxide powder, 2 to 5 parts of alcohol and 40 to 50 parts of water together into a stirring machine to prepare a staining solution; c, putting the staining solution in the step b into a staining cylinder of a staining device, and staining the blended yarn weaved fabric in the step a through the staining step; d, putting thestained blended yarn weaved fabric into a baking oven for drying; e, soaking the dried blended yarn waved fabric into clean water for bleaching; and f, taking out the bleached blended yarn waved fabric, and naturally airing the blended yarn waved fabric. The staining method has the advantage of good staining effect.

Owner:海宁市美元达经编有限公司

Waterborne wood paint with high weather resistance and production method of waterborne wood paint

InactiveCN108587352AAvoid damageImprove performanceAntifouling/underwater paintsPaints with biocidesPROPYLENE GLYCOL BUTYL ETHERWeather resistance

The invention discloses a waterborne wood paint with high weather resistance and a production method of the waterborne wood paint. The waterborne wood paint with high weather resistance comprises thefollowing raw materials in parts by weight: 30-40 parts of waterborne acrylic resin, 15-25 parts of waterborne polyurethane resin, 0.3-0.7 part of defoaming agent, 0.2-1 part of substrate wetting agent, 2-5 parts of dipropylene glycol monobutyl ether, 2-4 parts of dipropylene glycol methyl ether, 1-3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.5-1 part of kathon mildewcide, 0.3-0.6part of wetting agent, 1-2 parts of water repellent, 1-3 parts of waterproof agent, 1-3 parts of dry film mildewcide, 0.1-0.5 part of polysiloxane, 0.2-0.5 part of flatting agent, 0.3-0.8 part of hindered amine light stabilizer, 0.5-1 part of ultraviolet light absorber, 0.2-0.5 part of polyurethane tackifier, 0.3-0.8 part of acrylic tackifier and 10-20 parts of deionized water.

Owner:东莞市家美环保涂料有限公司

Roman cloth and manufacturing method thereof

InactiveCN111411442AImproved heat and light resistanceReduce stiffnessWeft knittingHeating/cooling textile fabricsPolyesterYarn

The invention provides Roman cloth and a manufacturing method thereof, and relates to the technical field of fabric production. The Roman cloth is formed by interweaving cotton yarns, polyesters, spandexes, flame-retardant yarns, tc blended yarns and natural bamboo fibers; and the weight percentages of the cotton yarns, polyesters, spandexes, flame-retardant yarns, tc blended yarns and natural bamboo fibers are: 25% to 35% of cotton yarns, 30% to 40% of polyesters, 10% to 20% of spandexes, 10% to 15% of flame-retardant yarns, 8% to 15% of tc blended yarns, and 5% to 10% of natural bamboo fibers. According to the invention, the Roman cloth manufactured has good moisture absorption and relatively high strength, and is not prone to being deformed under the action of external force, and the heat resistance and light resistance of the Roman cloth are both obviously improved; meanwhile the yarns are pretreated before weaving so that the stiffness of materials is reduced, thereby greatly improving the quality of the Roman cloth.

Owner:无锡红博供应链管理有限公司

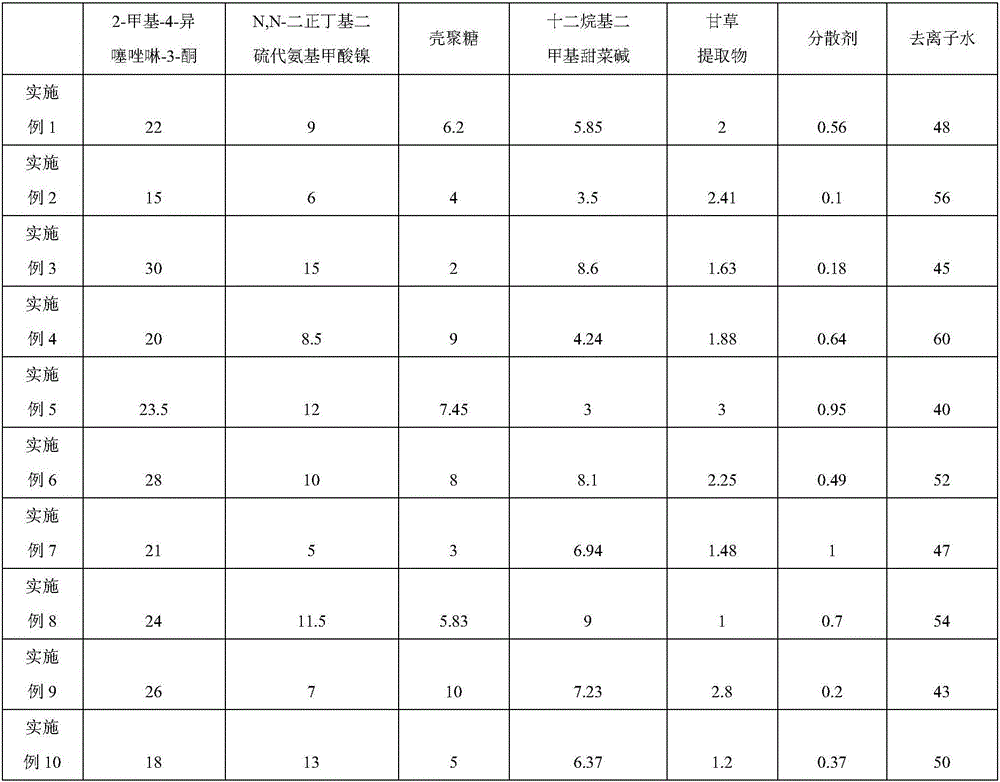

Antibacterial finishing agent for apparel fabrics and finishing process thereof

InactiveCN106049038AImprove antibacterial propertiesProtection from degradationFibre treatmentBetaineKetone

The invention provides an antibacterial finishing agent for apparel fabrics and a finishing process thereof. The antibacterial finishing agent for the apparel fabrics is prepared from, by weight, 2-methyl-4-isothiazolin-3-ketone, N,N-normal-nickel dibutyl dithiocarbamate, chitosan, dodecyl dimethyl betaine, licorice extract, a dispersing agent and deionized water. The antibacterial finishing agent for the apparel fabrics is non-toxic and has a good antibacterial effect and an antistatic function, the apparel fabrics are finished by utilizing the antibacterial finishing agent, and the wrinkle resistance capability of the fabrics can be improved. In addition, the finishing process of the antibacterial finishing agent is simple in operation, and the cost is low.

Owner:太仓红桥服饰有限公司

Composite rock slice slurry and preparation method thereof

ActiveCN109852229AImprove mechanical propertiesAvoid adsorptionPolyurea/polyurethane coatingsWater dispersibleSlurry

The invention discloses a composite rock slice slurry. The composite rock slice slurry comprises a component A and a component B, and the component A comprises, by weight, 2-15 parts of a pigment slurry, 5-25 parts of a zeolite liquid and 30-90 parts of an aqueous hydroxypropene dispersion; the pigment paste comprises a pigment, a coupling agent and a directional agent; the zeolite liquid comprises a zeolite powder, a hydrophobic agent and a wetting agent; the component B comprises 70-90 parts by weight of a water-dispersible isocyanate curing agent; and a weight ratio of the component A to the component B is (5-7):1. The pigment slurry, the zeolite liquid, the aqueous hydroxypropylene dispersion and the water-dispersible isocyanate curing agent synergistically act according to a certain ratio to form the composite rock slice slurry, and composite rock slices prepared from the composite rock slice slurry have the characteristics of excellent wear resistance, excellent water resistance,excellent color retention, short curing time, no after-tack and good storage stability.

Owner:HUBEI QILI NEW MATERIAL CO LTD

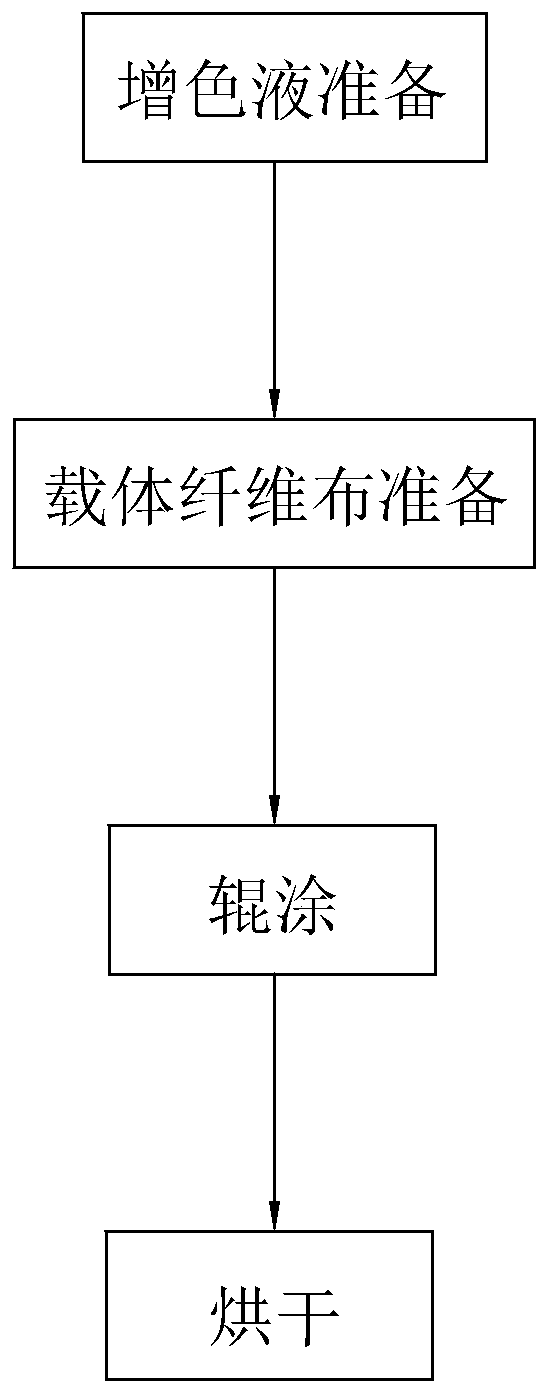

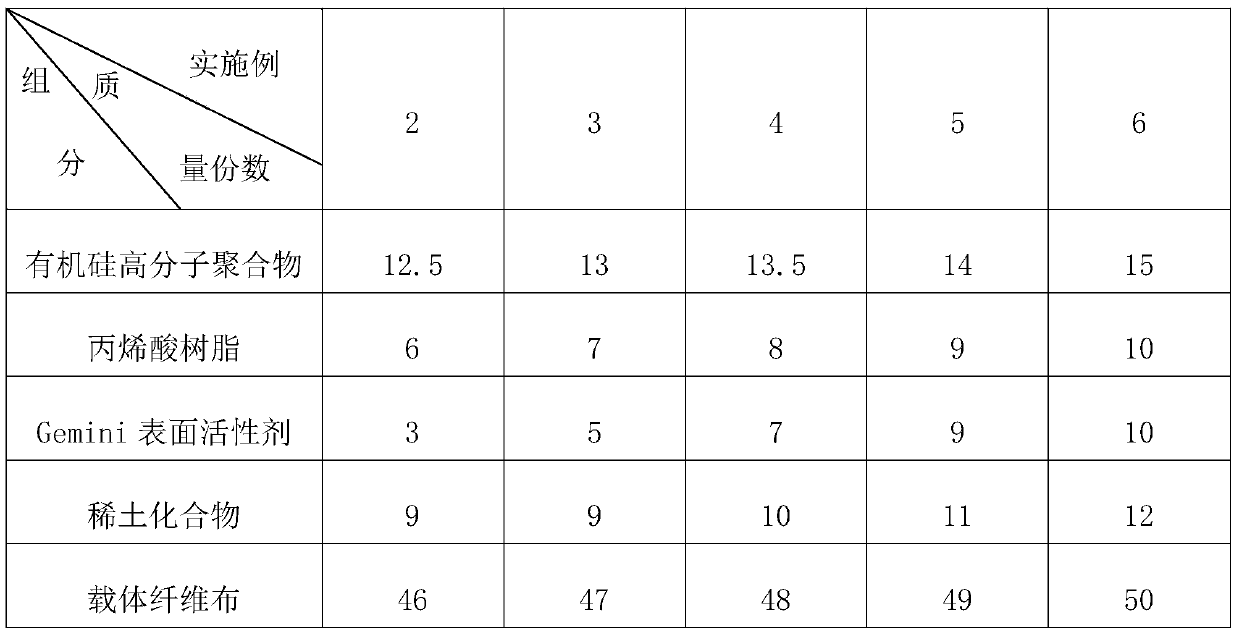

Preparation method of solid color enhancement sheet

The invention discloses a preparation method of a solid color enhancement sheet, and relates to the technical field of fabric color enhancement. The technical scheme mainly includes that the preparation method of the solid color enhancement sheet includes the steps: first, color enhancement liquid preparation: dissolving toners and adhesives in deionized water, adjusting pH (potential of hydrogen)to be 3.5-9, adding auxiliaries and uniformly stirring and mixing the materials to obtain color enhancement liquid; second, carrier fiber cloth preparation: performing fiber opening, carding, wet forming and spunlace processes on fibrous raw materials to obtain carrier fiber cloth; third, roller coating: applying the color enhancement liquid to one surface or two surfaces of the carrier fiber cloth in a roller coating manner; fourth, drying: drying the carrier fiber cloth under the condition of the temperature of 80-120 DEG C to obtain the solid color enhancement sheet. The prepared solid color enhancement sheet has the advantage of capability of preventing clothes from color fading and darkening.

Owner:上海希丝无纺布制品有限公司

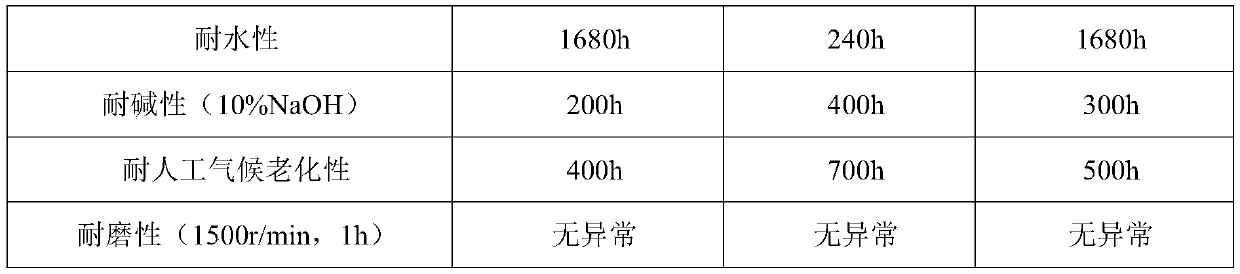

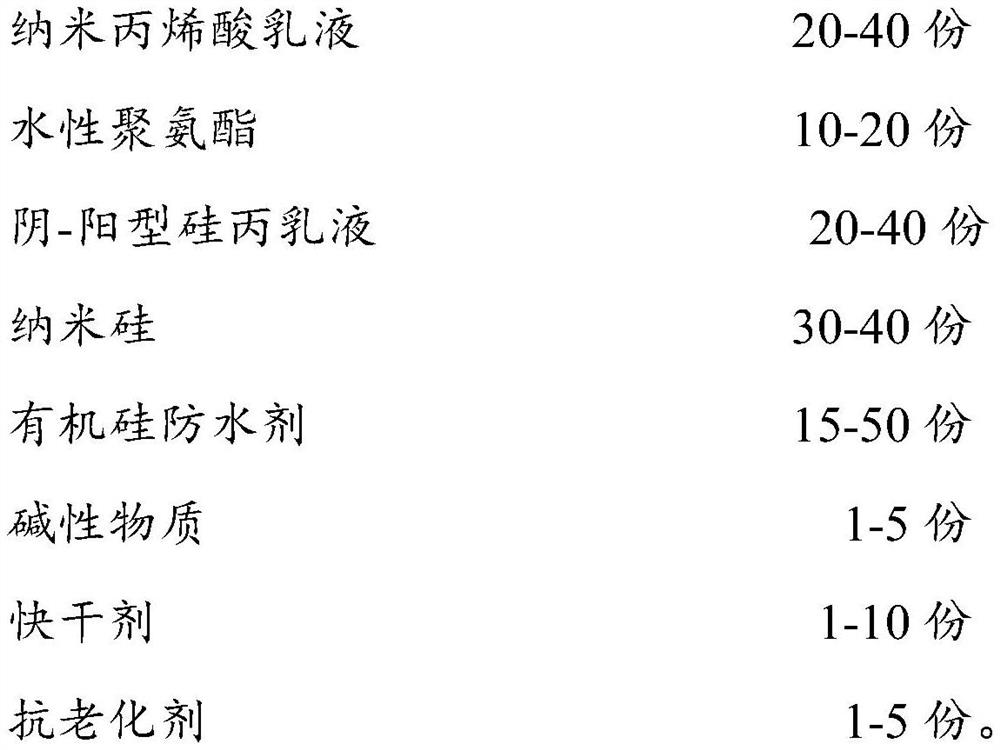

Color fixing agent for artificial colored sand, preparation method of color fixing agent and artificial colored sand

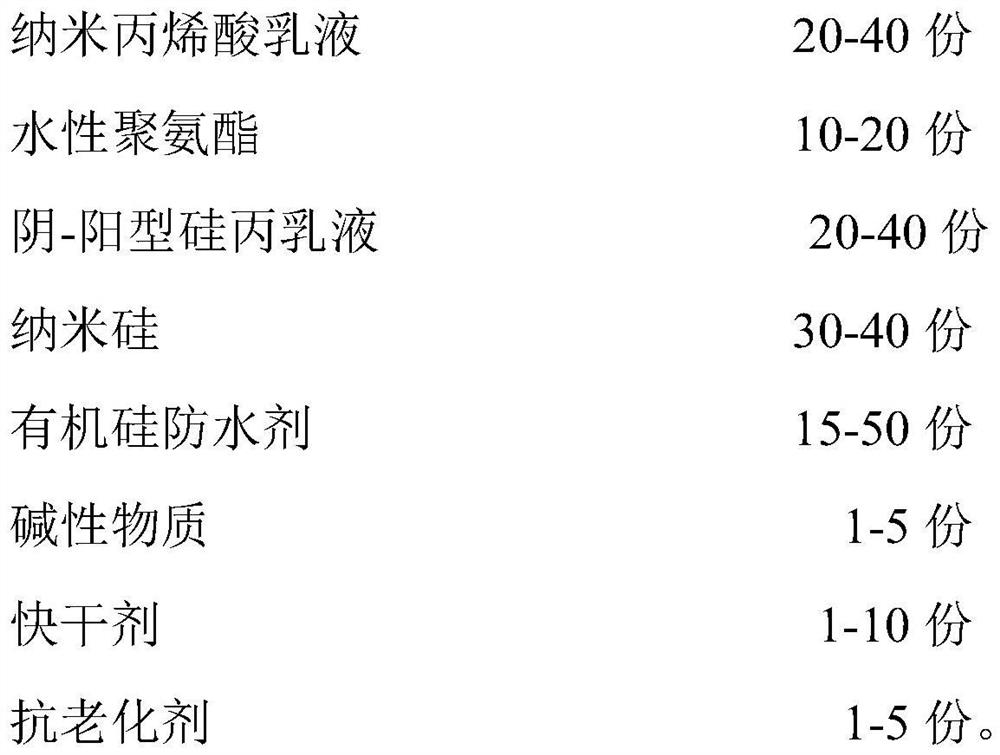

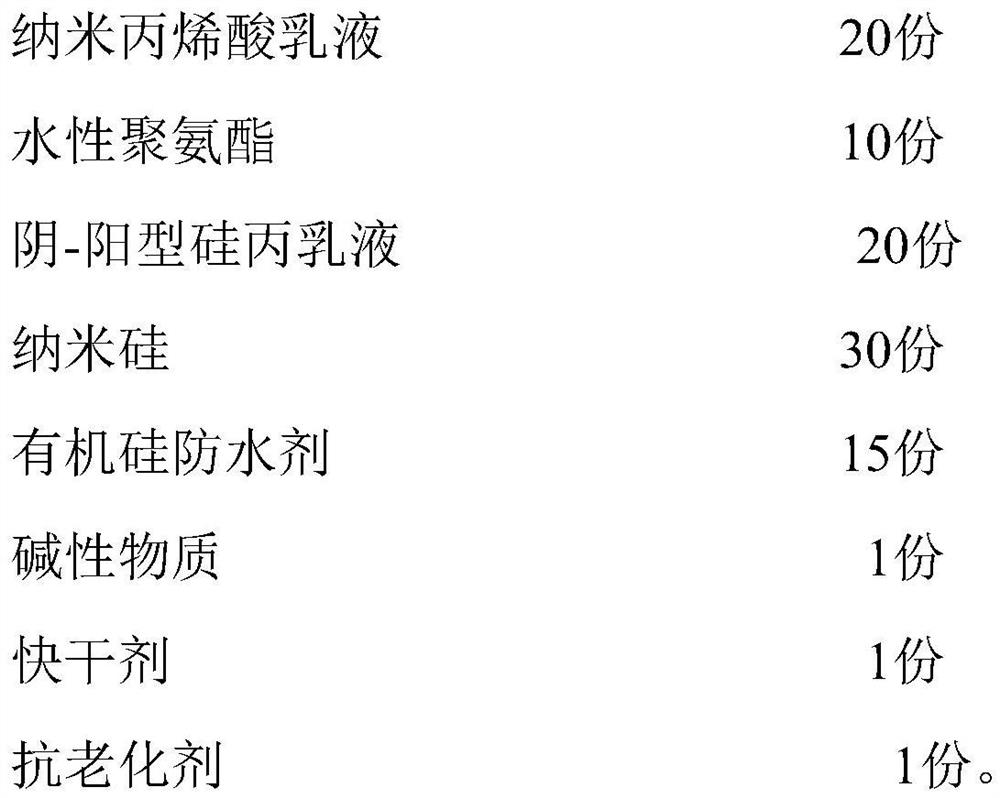

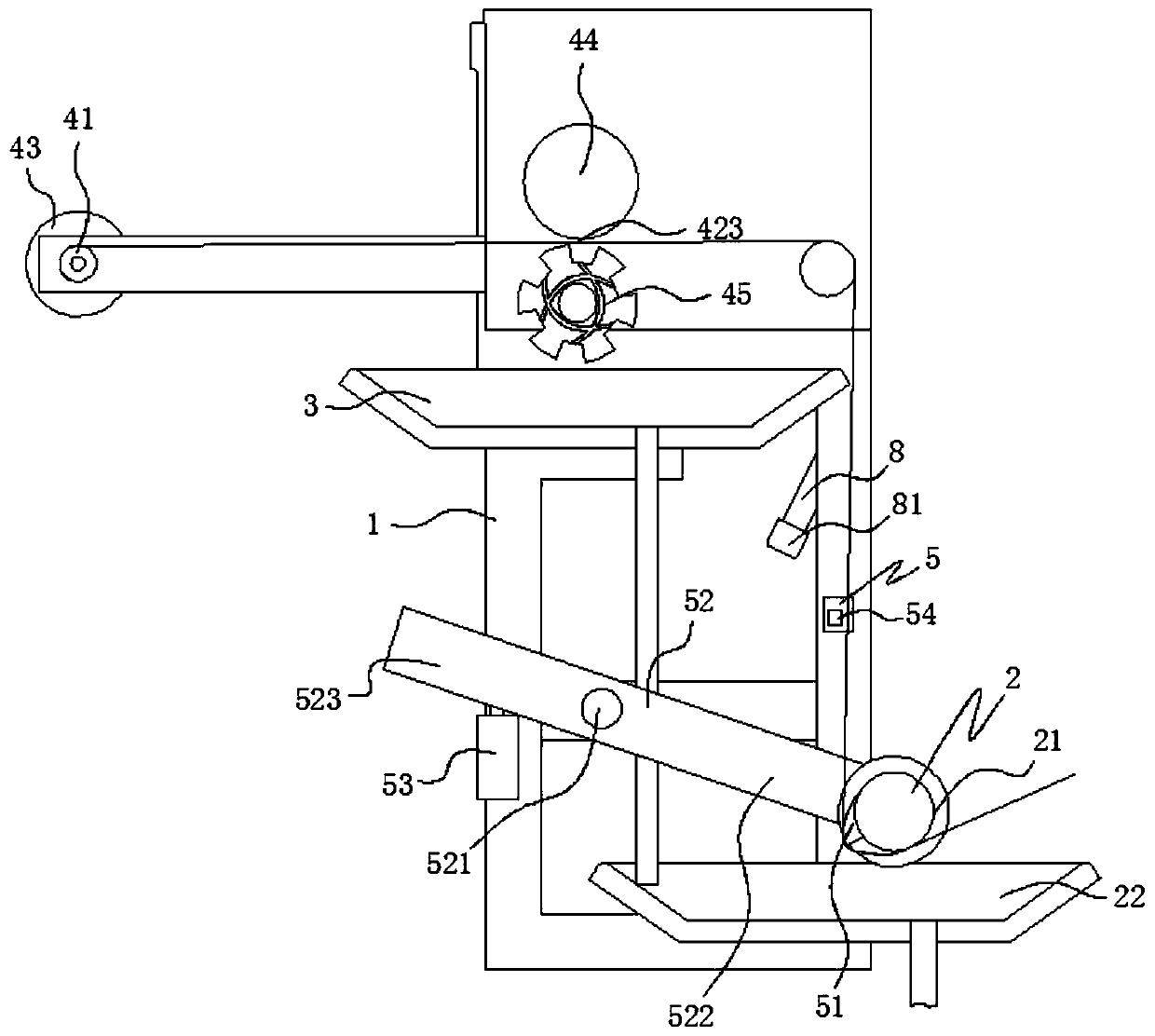

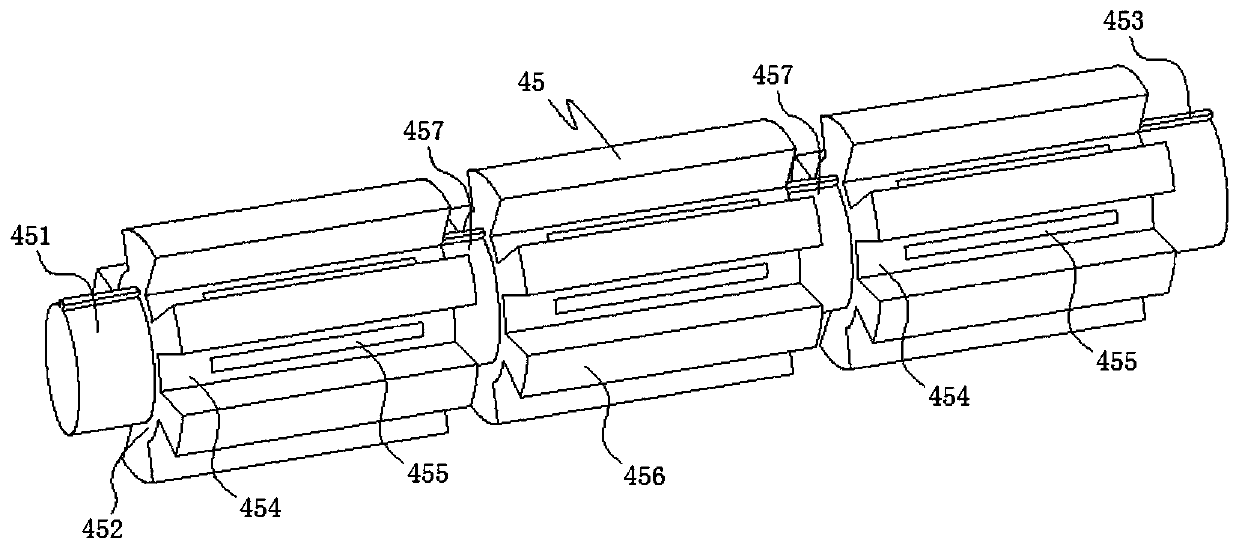

PendingCN114806301ADry fastGood adhesionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsColor effectNano silicon

The invention belongs to the technical field of color fixing agents, and particularly relates to a color fixing agent for artificial colored sand, a preparation method of the color fixing agent and the artificial colored sand. The color fixing agent is prepared from 20 to 40 parts of nano acrylic emulsion, 10 to 20 parts of waterborne polyurethane, 20 to 40 parts of anionic-cationic silicone acrylic emulsion, 30 to 40 parts of nano silicon, 15 to 50 parts of organic silicon waterproof agent, 1 to 5 parts of alkaline substance, 1 to 10 parts of quick drying agent and 1 to 5 parts of anti-aging agent. The preparation method of the color fixing agent comprises the following steps: mixing the nano acrylic emulsion, the waterborne polyurethane, the anionic-cationic silicone acrylic emulsion, the nano silicon, the organosilicon waterproofing agent and the anti-aging agent, then adding the alkaline substance, uniformly stirring, and finally adding the quick-drying agent to prepare the color fixing agent for the artificial colored sand. When being applied to a coating for artificial colored sand, the pigment can effectively improve the coloring effect of a dye coating on the surface of the colored sand, so that the colored sand coating is not easy to fade.

Owner:广东标达新材料有限公司

Ecological granite made of high-grade concrete and manufacturing method of ecological granite

PendingCN113735502AEasy to prepare in advanceReduce consumptionEnvironmental resource managementStone particle

The invention relates to the field of building material structures, in particular to ecological granite made of high-grade concrete and a manufacturing method of the ecological granite. The ecological granite is prepared from the following components in parts by weight: 60 to 70 parts of stone processing tailings, 25 to 35 parts of high-grade cement, 0.5 to 1.2 parts of pigment, 10 to 15 parts of refractory aggregate, 0.5 to 0.8 part of water reducing agent, 0.3 to 0.5 part of penetrating agent and a proper amount of water. The high-grade cement is adopted in the components, so that the structural strength of the whole ecological granite can be guaranteed, and after the sesame white granite tailings are made into sand and polished, exposed stone particles can be consistent with real stone, so that the texture of the finally manufactured product is the same as that of natural stone, and meanwhile, the ecological and environment-friendly concept is better met. Therefore, the manufactured ecological granite has high strength, meanwhile, the texture of the granite can be close to that of natural stone, the price of the granite is far lower than that of real stone, and the granite can become a novel material with good quality and low price.

Owner:漳州砼艺建材有限公司

Antiflaming plastic

InactiveCN103665656ASolve the problem of insufficient flame retardant performanceImprove notched impact strengthFlexural strengthPolyvinyl chloride

The invention relates to an antiflaming plastic which comprises the following components: 70 parts of epoxystearic acid essien ester, 3 parts of zinc borate, 7 parts of antimonous oxide, 50 parts of polyvinyl chloride resin, 30 parts of polypropylene, 20 parts of glass fibers, 12 parts of a flame retardant, 20 parts of diethyl phthalate, 20-30 parts of polytetrafluoroethylene, 12 parts of polyacrylamide, 10 parts of ethylene glycol and 12 parts of silicon dioxide. The plastic also comprises 5 parts of butylated hydroxytoluene. Compared with the prior art, the plastic disclosed by the invention has the performance which is the same as that of the conventional plastic, also solves the problem of low flame retardancy of the conventional plastic due to the flame retardant, is high in notch impact strength, bending strength and hardness and is difficult to crack, deform and fade even under alternate action of high temperature and severe cold; furthermore, the plastic disclosed by the invention is environment-friendly and produces less toxic gas and exhaust smoke during pyrolysis; the market competitiveness of the antiflaming plastic is greatly improved when being compared with the same type of products.

Owner:QINGDAO KECHUANG PLASTIC MACHINERY

Treating and processing method of fraxinus mandshurica wood in furniture production

InactiveCN111805660AImprove dye uptakeImprove dyeing effectWood treatment detailsPressure impregnationPulp and paper industryFraxinus mandschurica

The invention relates to a treating and processing method of fraxinus mandshurica wood in furniture production. The method comprises the following steps that fraxinus mandshurica wood is placed in a prepared softening agent to be soaked for 16-20 min, and then a prepared penetrating agent is used for conducting dipping treatment on the fraxinus mandshurica wood. Adsorption of the interior of the fraxinus mandshurica wood to dye can be improved, and the problems that the dye stays on the surface to color the fraxinus mandshurica wood , the dyeing rate is low, dyeing is uneven and fading occurseasily are solved. The treating and processing flow is simple, environmentally friendly and low in cost, the treated fraxinus mandshurica wood has an excellent dyeing effect, the colors of various rare wood can be imitated, the dyeing rate is high, use of dye is reduced, the dyeing temperature is low, the dyeing time is shortened, and the method has important significance in reducing environmentalpollution. Moreover, dyeing is firm, the durability is good, dye seepage and fading are not likely to happen, and the sense of reality of the wood grain color is achieved.

Owner:ANHUI CHANGFA IND

An energy-saving and efficient printing and dyeing process

InactiveCN108004808BReduce moisture contentEasy to solveFibre treatmentLiquid/gas/vapor removal by squeezing rollersProcess engineeringMaterials science

Owner:佛山市三水盛丰颜纺织科技有限公司

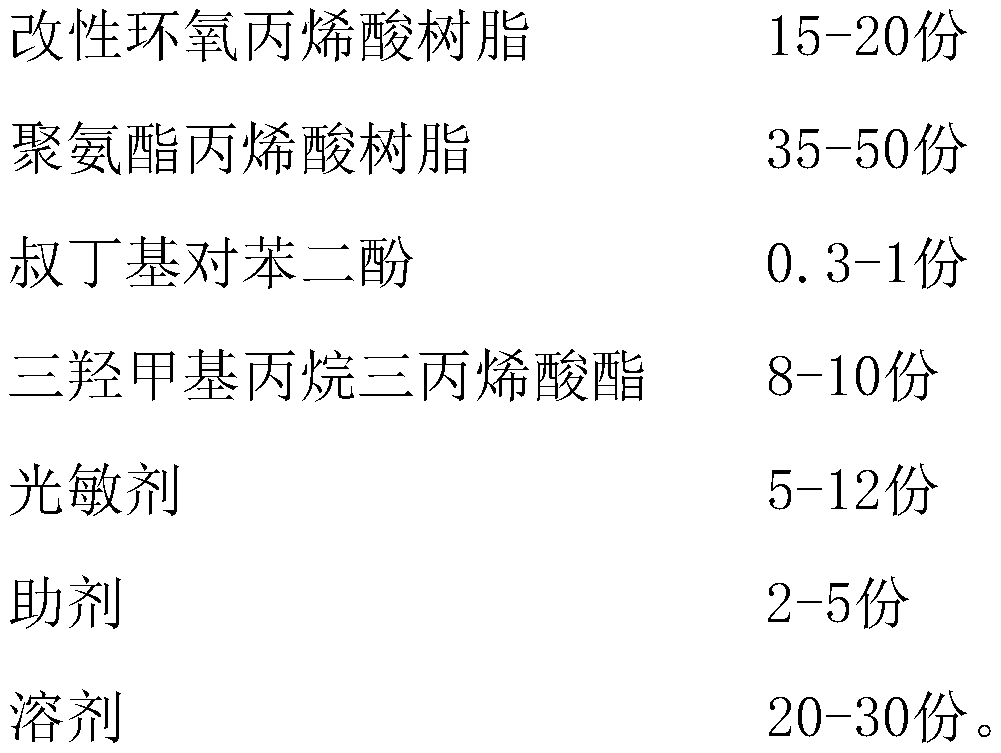

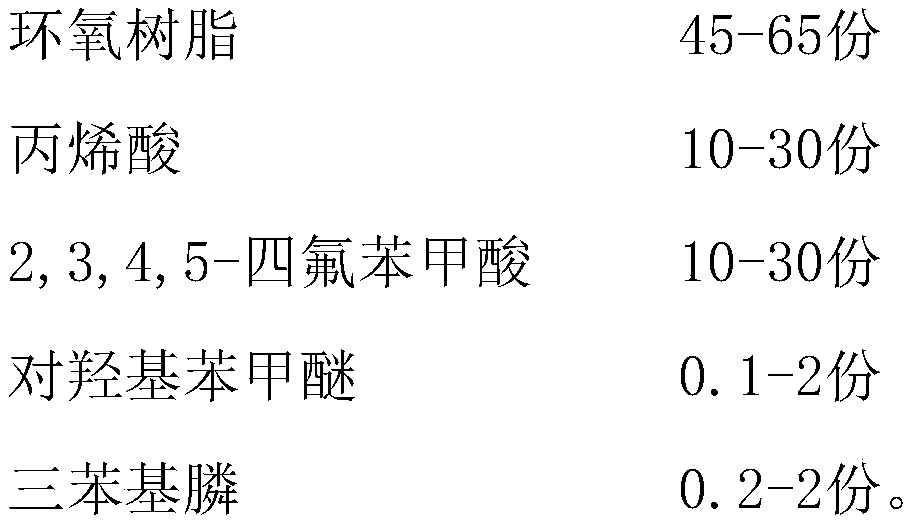

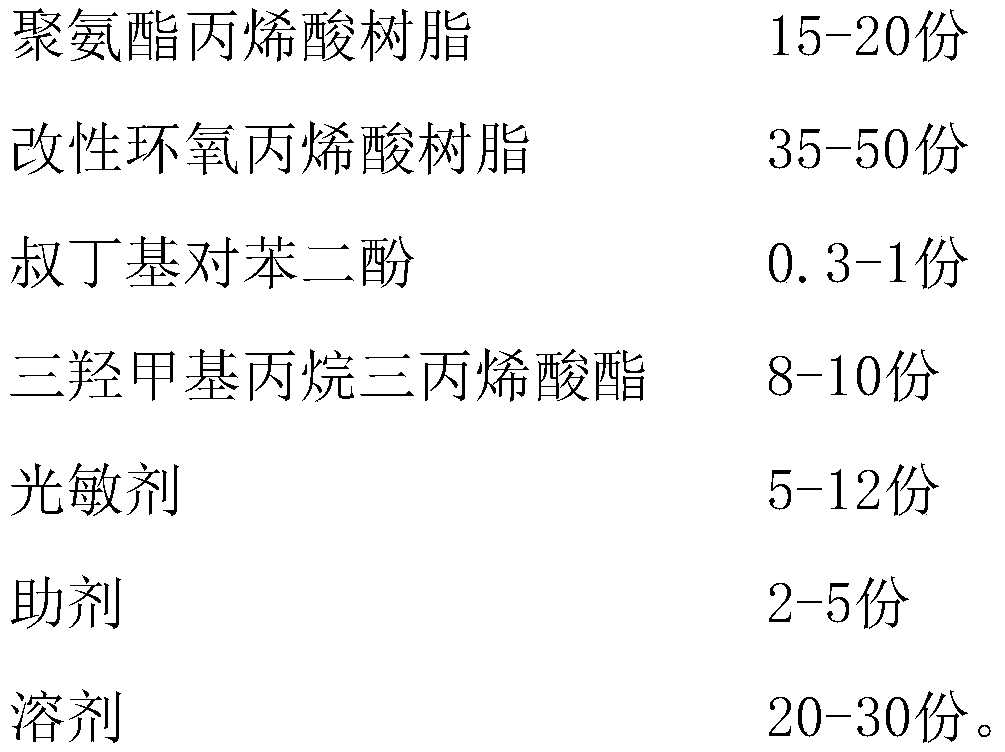

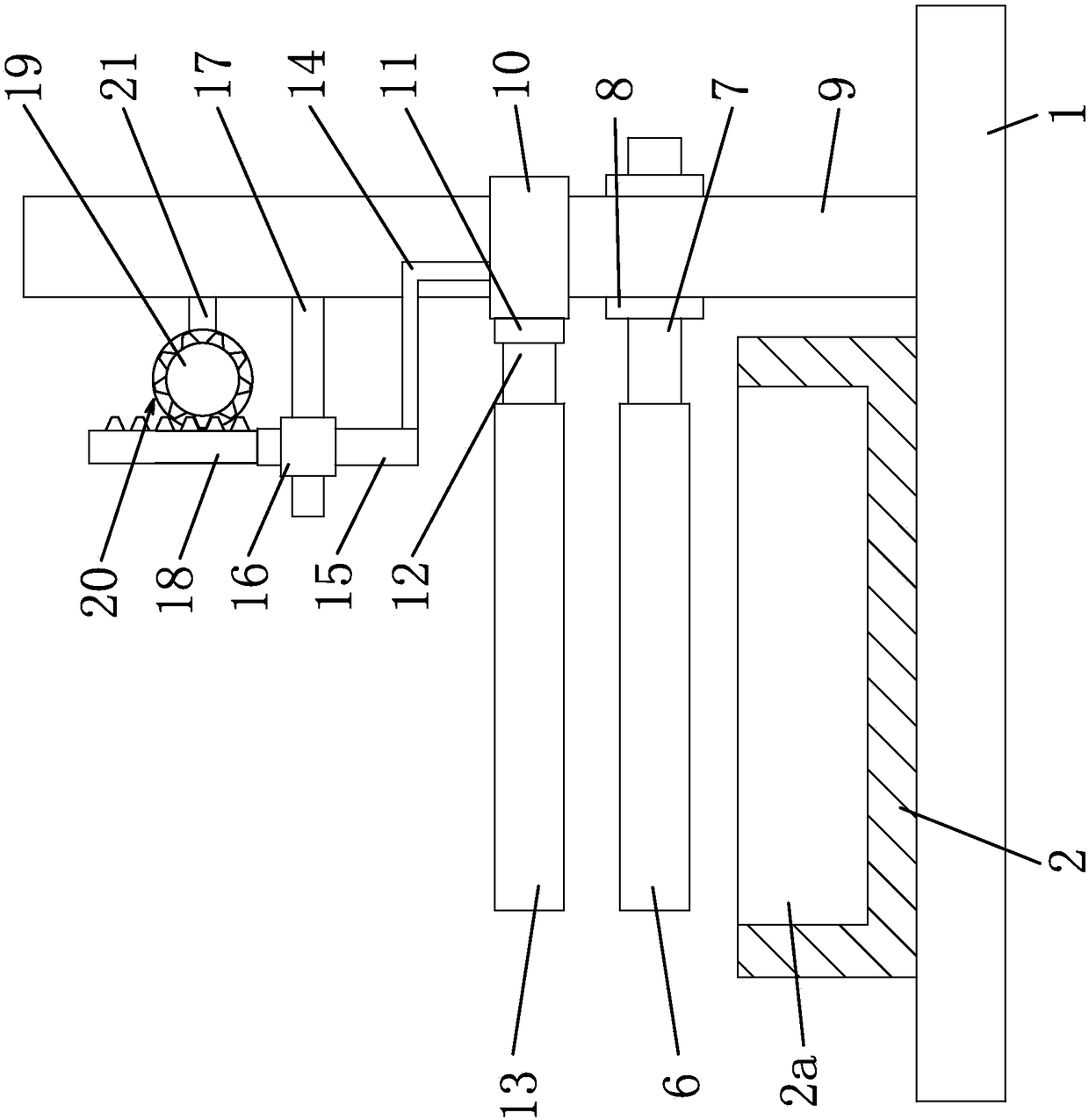

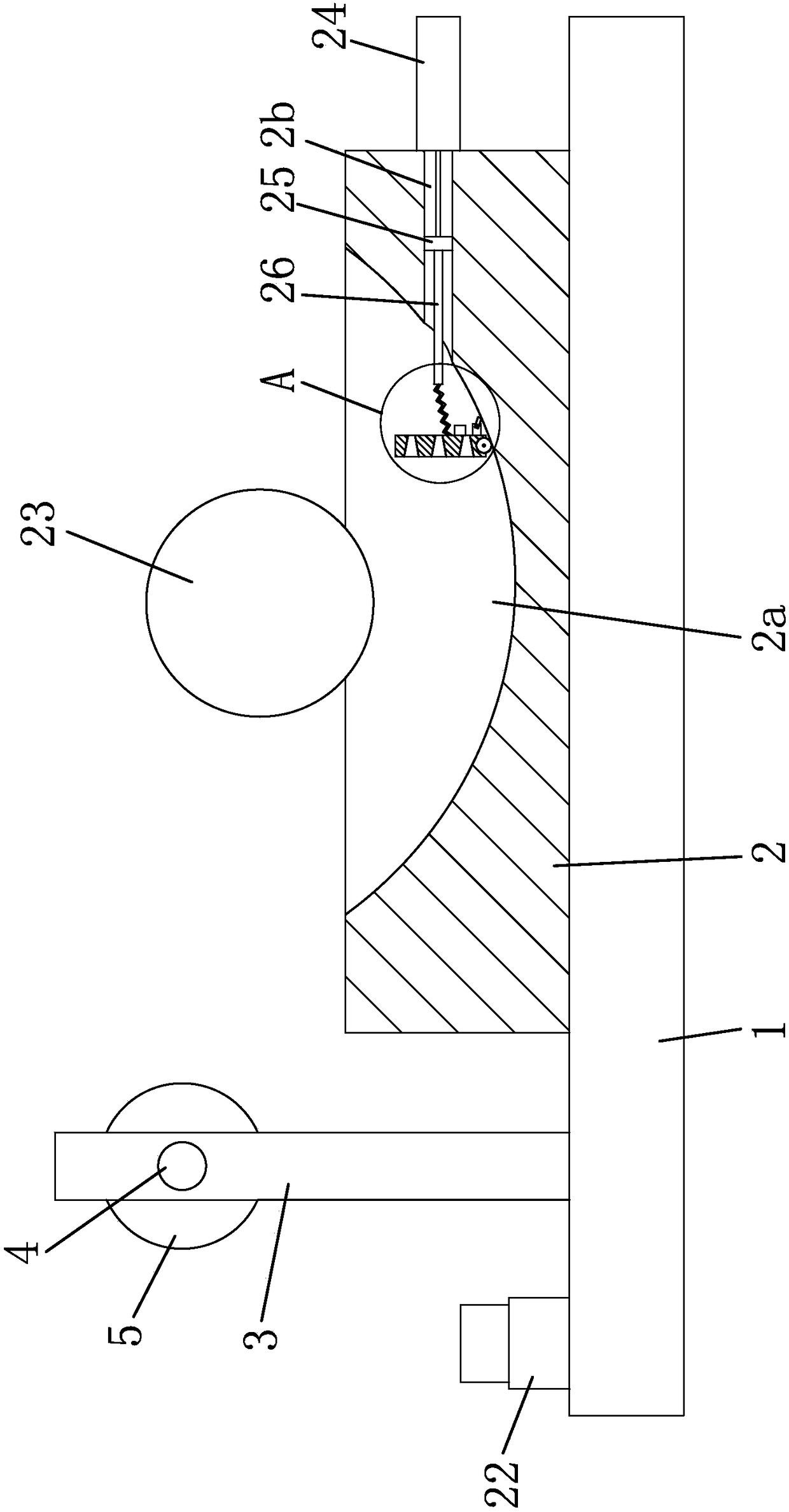

Environment-friendly and energy-saving printing process

InactiveCN110920287AAchieve energy saving effectNot prone to fadingDuplicating/marking methodsChemical industryBenzeneOrganic solvent

The invention discloses an environment-friendly and energy-saving printing process. The environment-friendly and energy-saving printing process comprises the steps that environment-friendly printing ink is used in the printing process firstly, acrylic resin, polypropylene glycol, a latex binder, 2,6-di-tert-butyl-p-cresol, pigments and simethicone are adopted as raw materials of the environment-friendly printing ink, and environmental pollution caused by benzene-containing compounds and organic solvents in traditional printing ink in the printing process is avoided. In the printing process matched with the environment-friendly printing ink, a method of combining infrared film forming and microwave curing is creatively adopted, so that the binding force of the environment-friendly printingink and a printing base material is remarkably improved, the problems of fading and deinking of the printing ink are not prone to occur, the service life of printed matter is prolonged, and the overall energy-saving effect of the printing process is achieved.

Owner:苏州市深广印刷有限公司

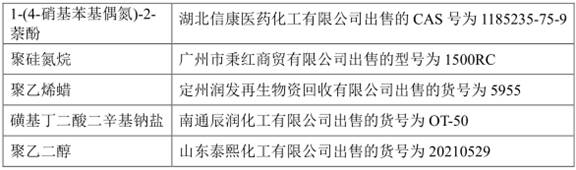

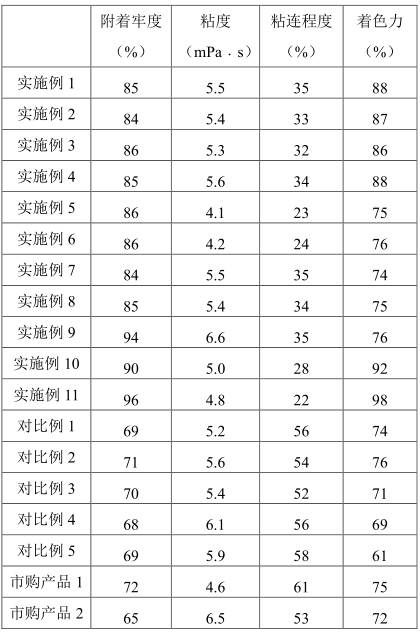

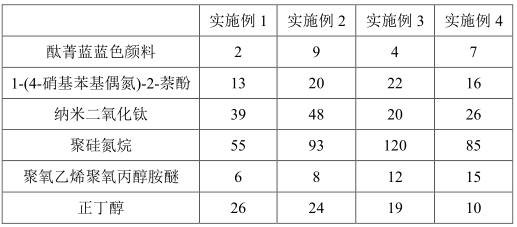

Label not adhered to PVC (polyvinyl chloride)

PendingCN114479554AImprove adhesion fastnessImproved anti-blocking propertiesFilm/foil adhesivesInksAdhesive glueDefoaming Agents

The invention relates to the field of labels, and particularly discloses a label not adhered to PVC (polyvinyl chloride), which comprises a bottom paper layer, a glue layer, a label paper layer and an ink layer which are sequentially arranged from bottom to top, the ink layer is prepared from the following raw materials in parts by weight: 2-9 parts of color pigment; 13 to 22 parts of 1-(4-nitrophenyl azo)-2-naphthol; 20 to 48 parts of nano titanium dioxide; 55 to 120 parts of polysilazane; 6 to 15 parts of a defoaming agent; and 10-26 parts of a diluent. The PVC sun shield has the effect that printing ink on the label is not prone to being adhered to the PVC sun shield.

Owner:苏州工业园区莱博特瑞新材料科技有限公司

Resin composition for water-based high-performance colored bright paint and preparation method thereof

The invention discloses a resin composition for a water-based high-performance color gloss coating and a preparation method of the resin composition. The resin composition is prepared from 30%-60% of water-based castor oil-modified alkyd resin and 40%-70% of water-based acrylic resin, wherein the water-based castor oil-modified alkyd resin is mainly prepared from castor oil, trimethylolpropane, phthalic anhydride, trimellitic anhydride, butoxyethanol, n-butyl alcohol and xylene; and the water-based acrylic resin is prepared from a solvent, methyl methacrylate, butyl acrylate, styrene, hydroxyethyl methylacrylate, crylic acid, benzoyl peroxide, tert-butyl peroxybenzoate, ammonium hydroxide and water. The pigment disclosed by the invention is easily dispersed to below 10 microns, and is stable in storage; the prepared coating performance is excellent; and the glossiness of a film is not reduced during adding water and diluting.

Owner:肇庆千江高新材料科技股份公司

Polarizing plate and image display device with adhesive

ActiveCN108169833BNot prone to fadingInhibit transferNon-macromolecular adhesive additivesFilm/foil adhesivesPolyvinyl alcoholAdhesive

The present invention relates to a polarizing plate with an adhesive and an image display device. A polarizing plate (1) with an adhesive has: a polarizer (11) comprising an iodine-containing polyvinyl alcohol film, a transparent protective film (15) bonded to the first main surface of the polarizer, and a The front-side adhesive sheet (20) provided in such a manner as to contact the second main surface. The front-side pressure-sensitive adhesive sheet is a laminated pressure-sensitive adhesive sheet obtained by laminating at least two pressure-sensitive adhesive layers, and has a first pressure-sensitive adhesive layer (21) disposed so as to be in contact with the polarizer and a spaced apart from the polarizer. A second adhesive layer (22) is deployed. Storage elastic modulus G' at 80°C of the preferred front side adhesive sheet 80 1×10 5 Below Pa, the moisture permeability of the first adhesive layer is preferably 150g / m 2 · Less than 24 hours.

Owner:NITTO DENKO CORP

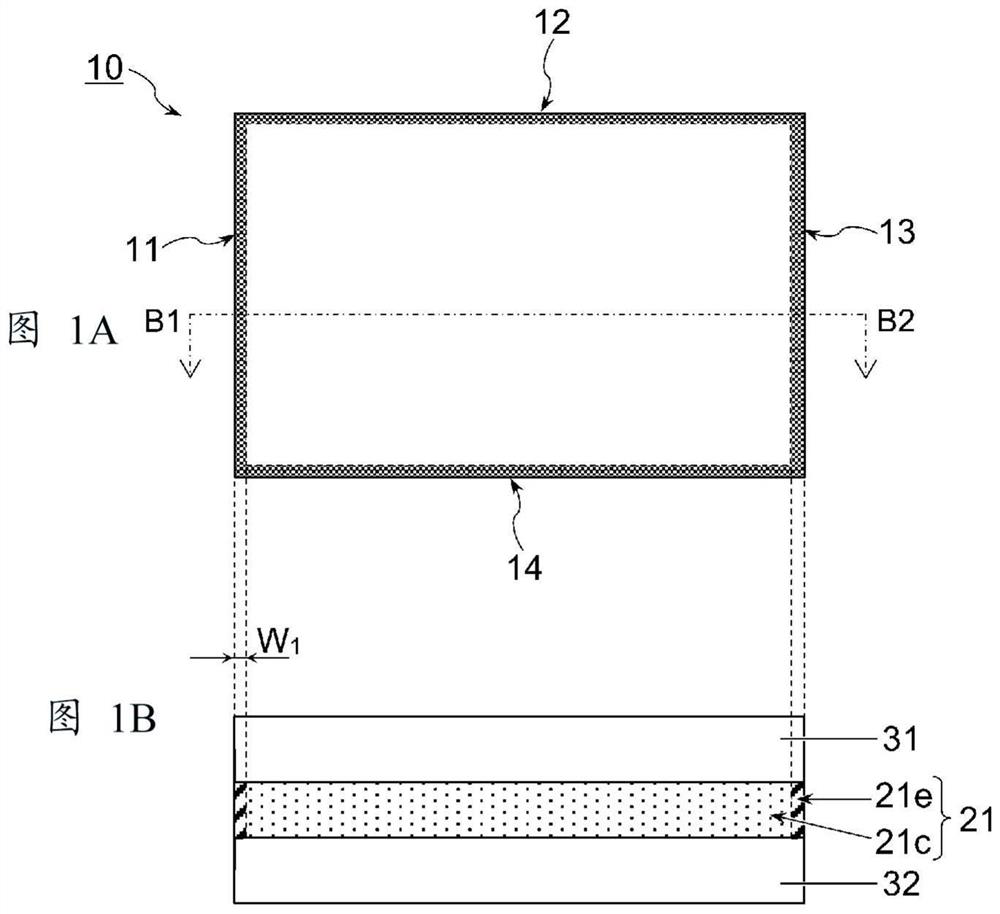

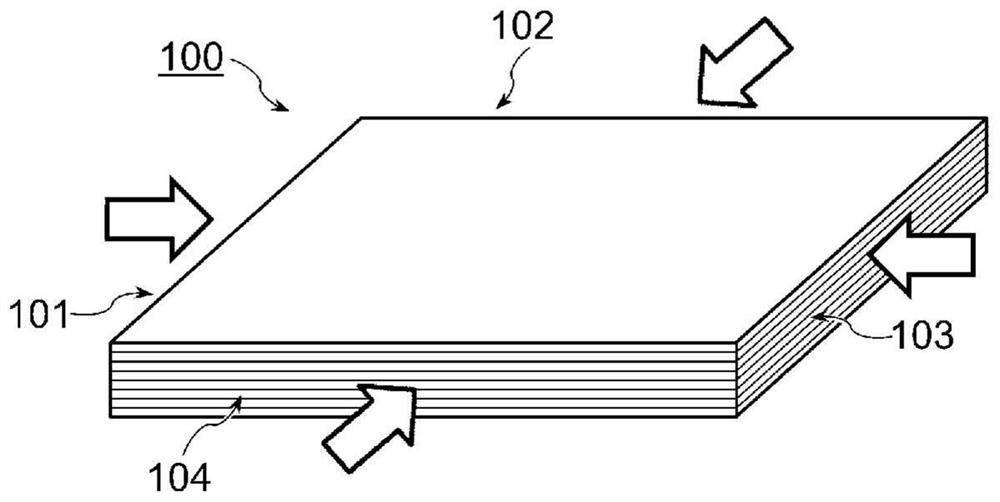

Polarization plate and manufacturing method therefor

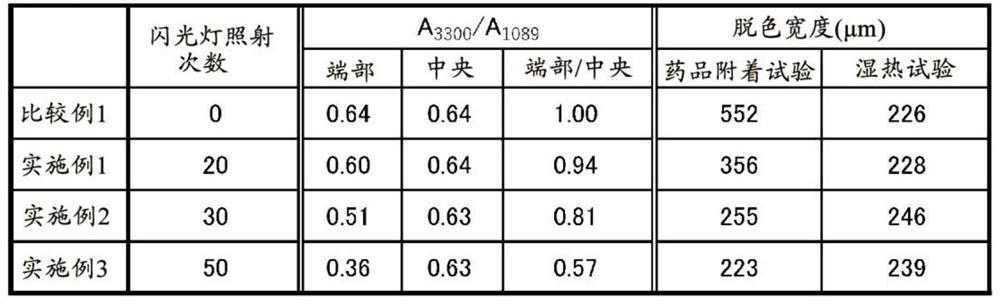

ActiveCN111788502ANot easy to fadeGood durabilityLayered productsPolarising elementsPolarizerOptical absorbance

A sheet polarization plate (10) is provided with a transparent film (31, 32) on at least one surface of a polyvinyl alcohol-based polarizer (21). The polarizer is preferably denatured by irradiating an end surface of the polarization plate obtained by being cut into a sheet, with a light beam having a wavelength in which the light beam can be absorbed by the polarizer. A ratio A3300 / A1089 of an absorbance A3300 of a peak around 3300 cm-1 to an absorbance A1089 of a peak around 1089 cm-1 in an infrared absorption spectrum at an end part in a surface of the polarizer having been subjected to thedenaturation is preferably less than A3300 / A1089 in the infrared absorption spectrum at the center part in the surface.

Owner:NITTO DENKO CORP

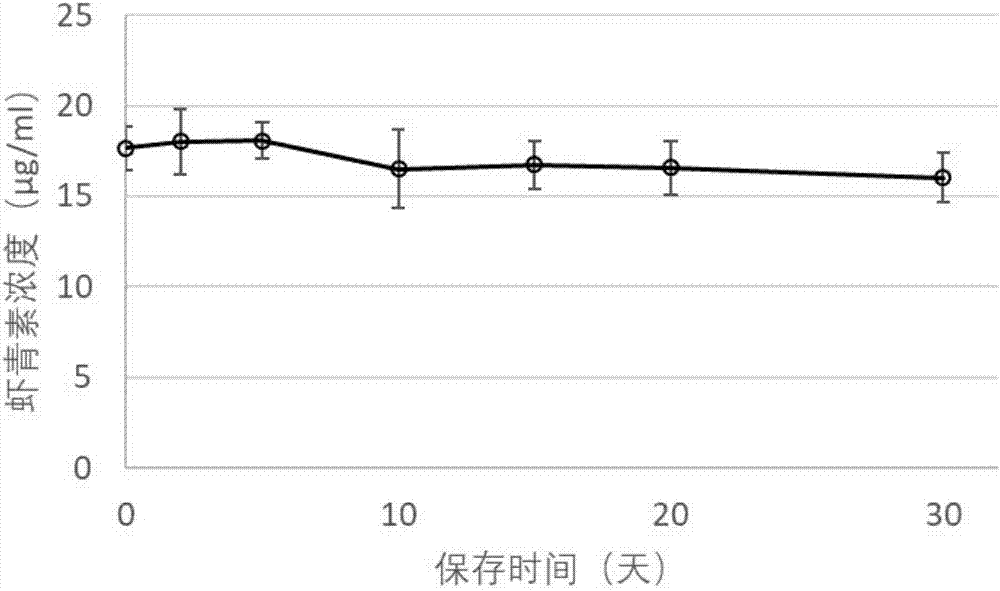

Preparation technology of haematococcus pluvialis extract solid drink

InactiveCN107981144AImprove stabilityNot prone to fadingFood dryingFood ingredient functionsHaematococcus pluvialis extractDesiccant

The invention discloses a preparation technology of a haematococcus pluvialis extract solid drink. The technology comprises the steps as follows: preparation: a water phase and an oil phase are prepared; emulsification: the water phase and the oil phase are mixed in an emulsifier and nitrogen is introduced to exhaust air; homogenization: the emulsified feed liquid is introduced into a high-pressure homogenizer and nitrogen is introduced to exhaust air; spray drying: the homogenized feed liquid is placed in a storage tank and is ready for spray drying: the feed liquid enters a drying tower before nitrogen is introduced into a spray drying agent air inlet for spray drying, a high-pressure pump is switched on for feeding when the exhaust temperature reaches 110-120 DEG C, the air inlet temperature is 150-160 DEG C, and the exhaust temperature is kept in a range of 80-85 DEG C; and cooling, screening, metering and packaging are performed, solid powder obtained after spray drying is sent toa vibrated fluidized bed for cooling, vibrating screening via a vibrating screen, powder receiving, metering and packaging are performed, and the packaged product is checked to be qualified and put in storage. The haematococcus pluvialis extract solid drink prepared by the preparation technology is good in stability and not prone to fading, oil separation and protein agglomeration.

Owner:CHENGDU PURUI BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com