High-fluidity cloth printing and dyeing process

A printing and dyeing process, high fluidity technology, applied in the field of dyeing, can solve the problems of slow diffusion, affecting cloth production, low overall efficiency of printing and dyeing, and achieve the effect of improving dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

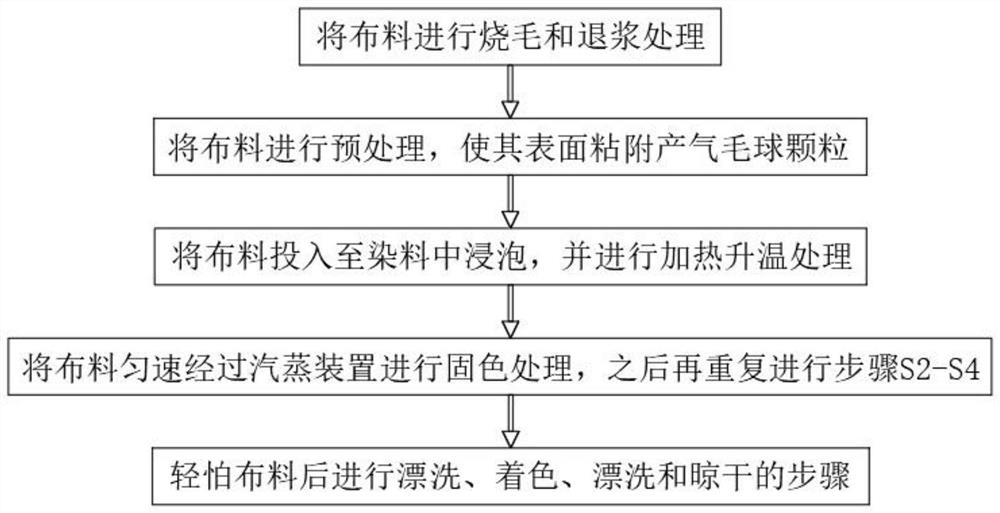

[0049] see figure 1 , a high fluidity cloth printing and dyeing process, comprising the following steps:

[0050] S1. First, singeing and desizing the fabric;

[0051] S2, then the cloth is pretreated to make the air-producing hairball particles adhere to its surface;

[0052] The specific steps of preprocessing are:

[0053] S21, first laying a mesh pad above the dyeing pool, and evenly spreading air-producing hair ball particles on the mesh pad;

[0054] S22. Lay the cloth evenly on the mesh pad, and cover the air-producing hair ball particles, and use the rubber rod to slightly roll the cloth to make the air-producing hair ball particles adhere to the cloth. By slightly rolling the cloth, the air-producing hair ball particles can be assisted It adheres to the surface of the fabric, and at the same time, the strength is light and it is not easy to damage the fabric;

[0055] S23, flanging the cloth and repeating S22 to obtain the cloth with air-producing hair ball partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com