High adhesion printing ink and preparation method thereof

A technology of printing ink and high adhesion, applied in the field of printing ink, can solve the problems of increasing ink production cost and expensive graphene, and achieve the effect of increasing adhesion fastness, low cost and strong covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

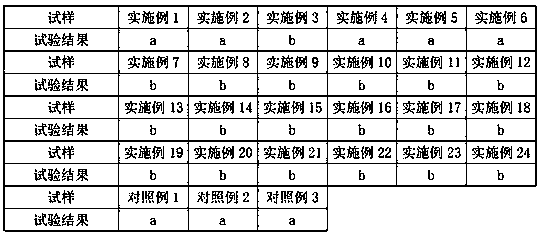

[0049] A printing ink with high adhesion, the content of each component is shown in the table below,

[0050] Table 1.

[0051]

[0052] Among them, shell powder and coral powder are obtained by crushing natural shells and corals, with a particle size of ≤10 μm; commercially available sodium polyacrylate is sodium polyacrylate with a degree of polymerization of 12 and a sodium polyacrylate content of ≥90%; n-butanol is commercially available n-butanol with a purity of ≥99%; in actual production, disperse dyes can be selected from low-temperature, medium-temperature or high-temperature disperse dyes of different colors according to needs, and the disperse dye used in this example is C.I. Disperse Red 60.

[0053] Preparation

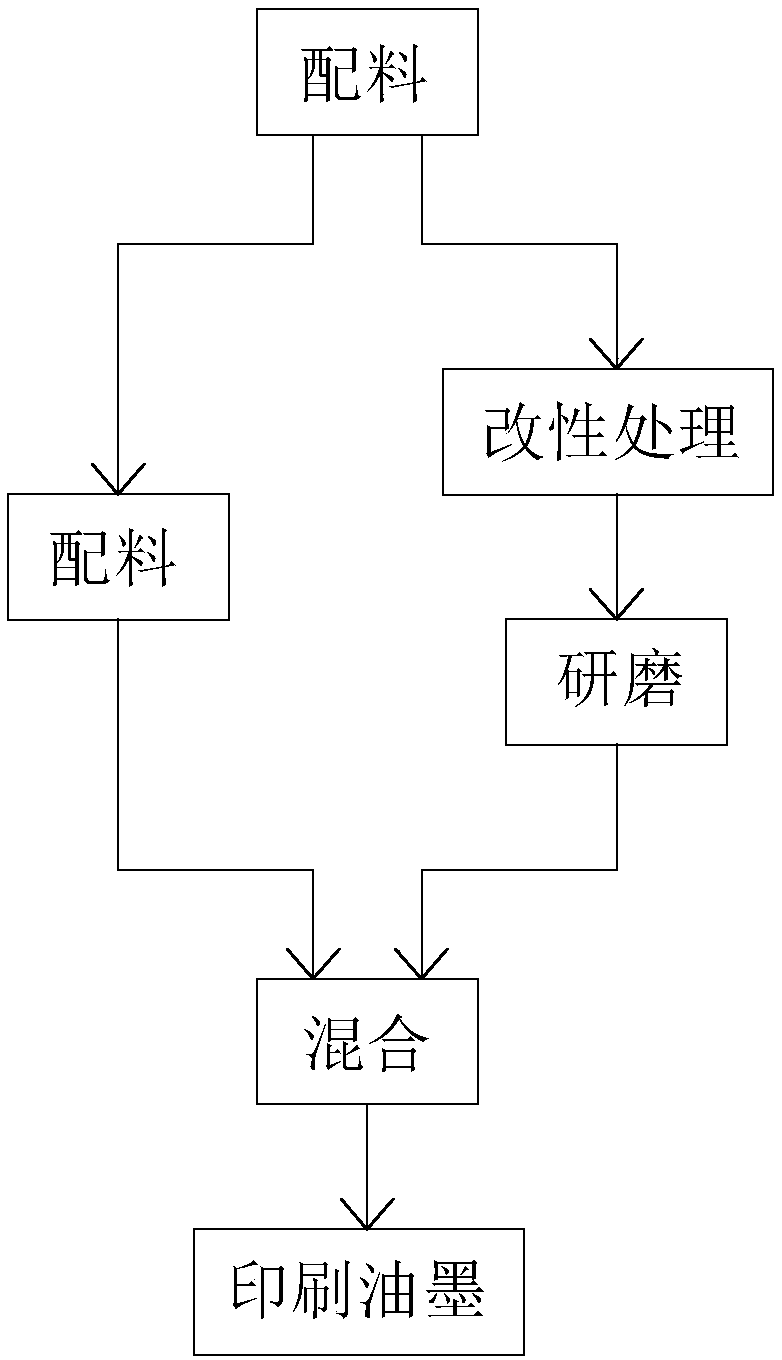

[0054] The technical process of the preparation method of the high adhesion printing ink of embodiment 1-6 is as figure 1 As shown, specifically include the following steps,

[0055] Weighing: Weigh chlorinated polypropylene resin, polyacrylic acid ...

Embodiment 7-12

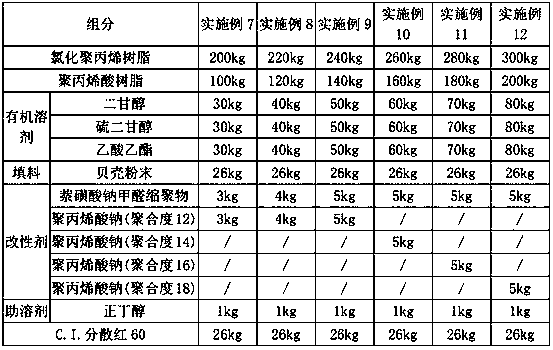

[0061] A printing ink with high adhesion, the content of each component is shown in the table below,

[0062] Table 2.

[0063]

[0064] Examples 7-9 are based on Example 3, and differ from Example 3 only in that the amount of sodium polyacrylate (polymerization degree 12) is different, which are 3kg, 4kg, and 5kg in sequence.

Embodiment 10

[0065] Embodiment 10-12 is based on embodiment 9, and the difference with embodiment 9 is only: select commercially available polyacrylate sodium polyacrylate content ≥ 90% that the degree of polymerization is 14 in embodiment 10; Commercially available sodium polyacrylate with a degree of polymerization of 16 and a content of sodium polyacrylate ≥ 90% was selected; in Example 12, a commercially available sodium polyacrylate with a degree of polymerization of 18 and a content of sodium polyacrylate ≥ 90% was selected.

[0066] Preparation

[0067] The technical process of the preparation method of the high adhesion printing ink of embodiment 7-12 is as figure 1 As shown, specifically include the following steps,

[0068] Weighing: Weigh chlorinated polypropylene resin, polyacrylic acid resin, diethylene glycol, thiodiglycol, ethyl acetate, shell powder, naphthalenesulfonic acid formaldehyde condensation polymer, sodium polyacrylate, n-butanol and C.I. Disperse Red 60;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com