Preparation technology of haematococcus pluvialis extract solid drink

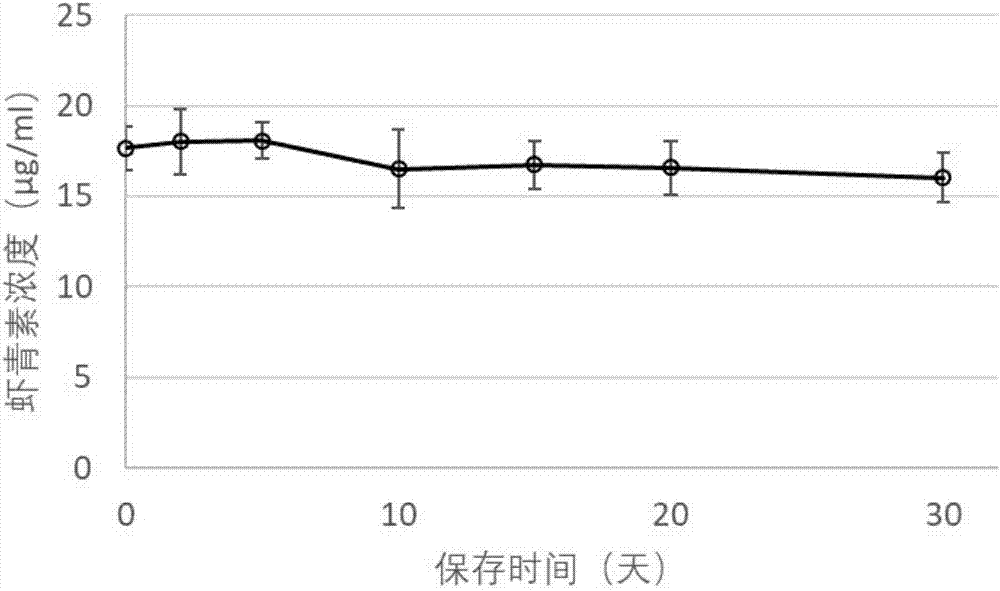

A technology of Haematococcus pluvialis and solid beverages, which is applied in food science, functions of food ingredients, food drying, etc. It can solve the problems of immaturity, protein aggregation, and easy fading, so as to achieve not easy fading and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation technology of Haematococcus pluvialis extract solid beverage comprises the following steps:

[0025] 1. Ingredients, including water phase preparation and oil phase preparation;

[0026] Water phase preparation: heat 100-500 kg of purified water to 75-80°C, add 1-20 kg of sodium dihydrogen phosphate and 0.5-10 kg of sodium ascorbate in turn, stir and adjust the pH of the solution to 6.0-8.0 with appropriate amount of sodium phosphate; Then add 10-100 kg of sodium caseinate, stir at high speed to fully dissolve and hydrate it; then mix with 10-300 kg of starch syrup heated to about 75°C, and stir evenly; finally add 75-80°C purified water to the total 800 liters of volume is used for making aqueous phase standby;

[0027] Preparation of oil phase: Add 5-100 kg of Haematococcus pluvialis extract into a jacketed heating carburetor, feed nitrogen into the carburetor and heat to 75-80°C, then add mono-diglycerides 0-20 kg, 0-20 kg of sorbitan monostearate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com