Color fixing agent for artificial colored sand, preparation method of color fixing agent and artificial colored sand

A color-fixing agent and colored sand technology, which is applied in chemical instruments and methods, multi-color effect coatings, dyed organic silicon compound treatment, etc., can solve the problem of unsatisfactory coating coloring power, hindering the promotion of colored sand, and easy aging and fading of coatings and other problems, to achieve the effect of good coloring effect, wide application range and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

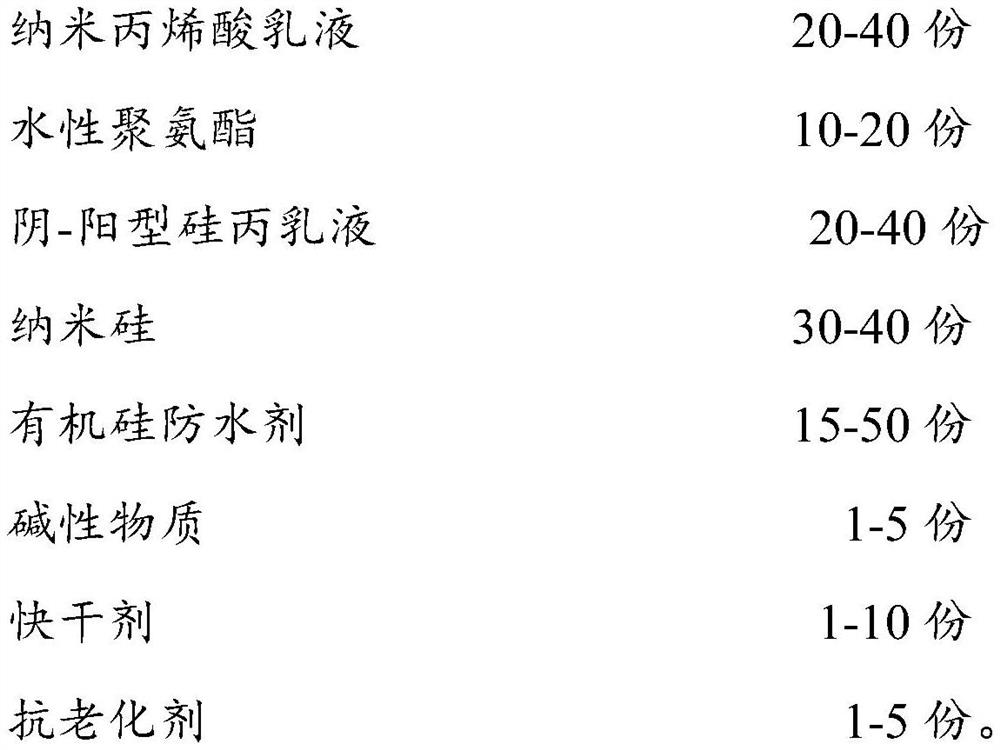

[0035] A color-fixing agent for artificial colored sand, comprising the following raw materials in parts by weight:

[0036]

[0037] Specifically, the preparation method of the yin-yang type silicone-acrylic emulsion is as follows:

[0038] S1, take octamethylcyclotetrasiloxane, vinyltriethoxysilane, dodecylbenzenesulfonic acid, nonylphenol polyoxyethylene ether (10) sulfosuccinic acid monoester disodium salt, hexadecyl Alkyl trimethyl ammonium chloride and distilled water are mixed according to the weight ratio of 15:25:10:12:23:40, the mixed emulsion is heated and condensed and refluxed under stirring conditions, and the mixed emulsion is heated and heated to 80 ℃ for reaction 1.5h, then dropwise added sodium hydroxide solution with a mass fraction of 10% to adjust the pH value of the mixed emulsion to 7.0 to obtain a silicone-acrylic seed emulsion;

[0039] S2, heating the silicone-acrylic seed emulsion to 85°C, and continuously and uniformly adding a mixture of 5 part...

Embodiment 2

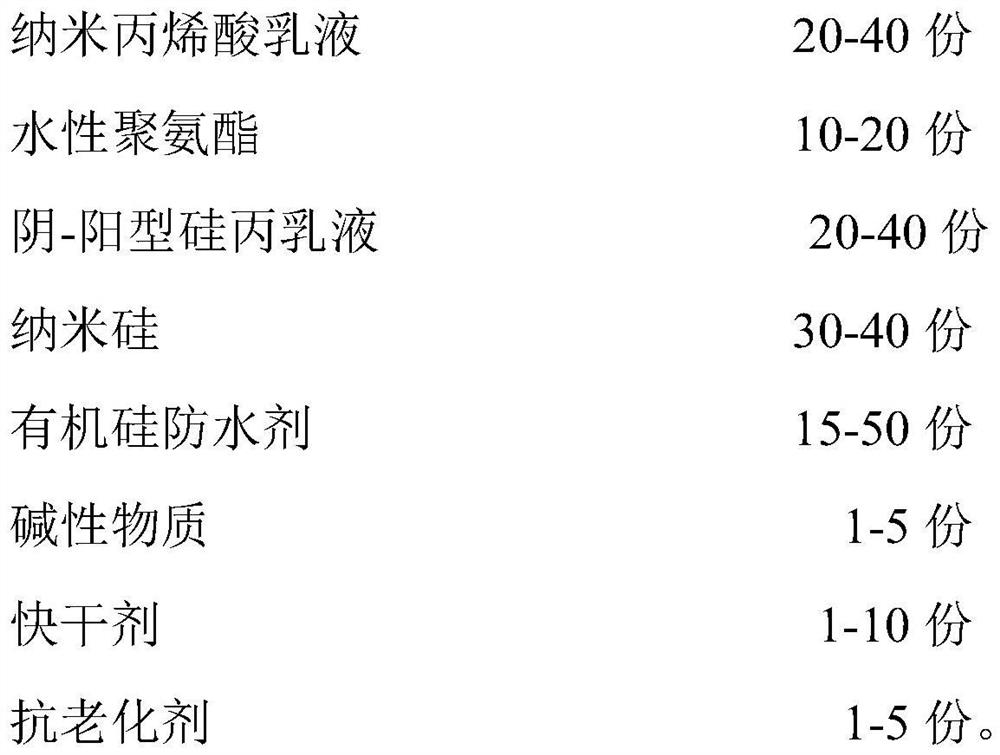

[0051] A color-fixing agent for artificial colored sand, comprising the following raw materials in parts by weight:

[0052]

[0053]

[0054] Specifically, the preparation method of the yin-yang type silicone-acrylic emulsion is as follows:

[0055] S1, take octamethylcyclotetrasiloxane, vinyltriethoxysilane, dodecylbenzenesulfonic acid, nonylphenol polyoxyethylene ether (10) sulfosuccinic acid monoester disodium salt, hexadecyl Alkyl trimethyl ammonium chloride and distilled water are mixed according to the weight ratio of 15:25:10:12:23:40, the mixed emulsion is heated and condensed and refluxed under stirring conditions, and the mixed emulsion is heated and heated to 80 ℃ for reaction 1.5h, then add 10% sodium hydroxide solution dropwise to adjust the pH value of the mixed emulsion to 7.0 to prepare a silicone-acrylic seed emulsion;

[0056] S2, heating the silicone-acrylic seed emulsion to 85°C, and continuously and uniformly adding a mixture of 5 parts by weight o...

Embodiment 3

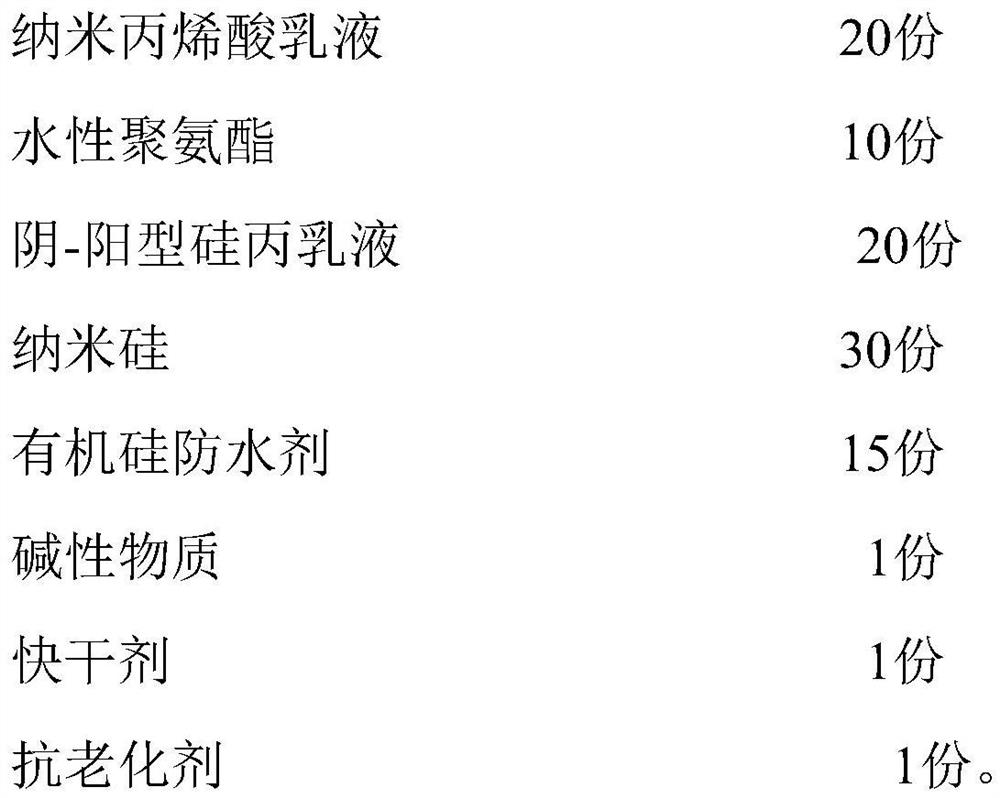

[0066] A color-fixing agent for artificial colored sand, comprising the following raw materials in parts by weight:

[0067]

[0068] Specifically, the preparation method of the yin-yang type silicone-acrylic emulsion is as follows:

[0069] S1, take octamethylcyclotetrasiloxane, vinyltriethoxysilane, dodecylbenzenesulfonic acid, nonylphenol polyoxyethylene ether (10) sulfosuccinic acid monoester disodium salt, hexadecyl Alkyl trimethyl ammonium chloride and distilled water are mixed according to the weight ratio of 15:25:10:12:23:40, the mixed emulsion is heated and condensed and refluxed under stirring conditions, and the mixed emulsion is heated and heated to 80 ℃ for reaction 1.5h, then add 10% sodium hydroxide solution dropwise to adjust the pH value of the mixed emulsion to 7.0 to prepare a silicone-acrylic seed emulsion;

[0070] S2, heating the silicone-acrylic seed emulsion to 85°C, and continuously and uniformly adding a mixture of 5 parts by weight of methyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com