Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Not easy to paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

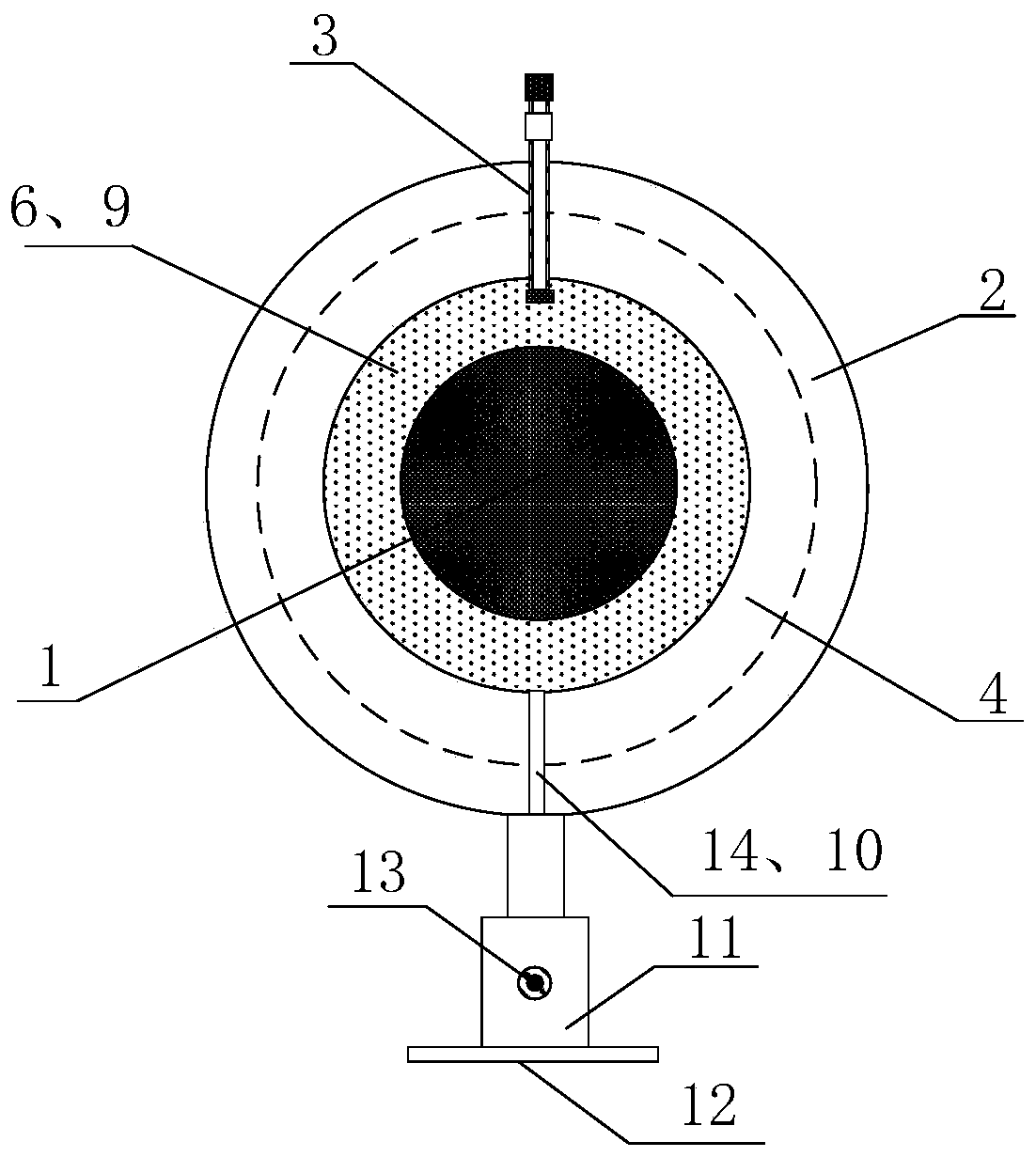

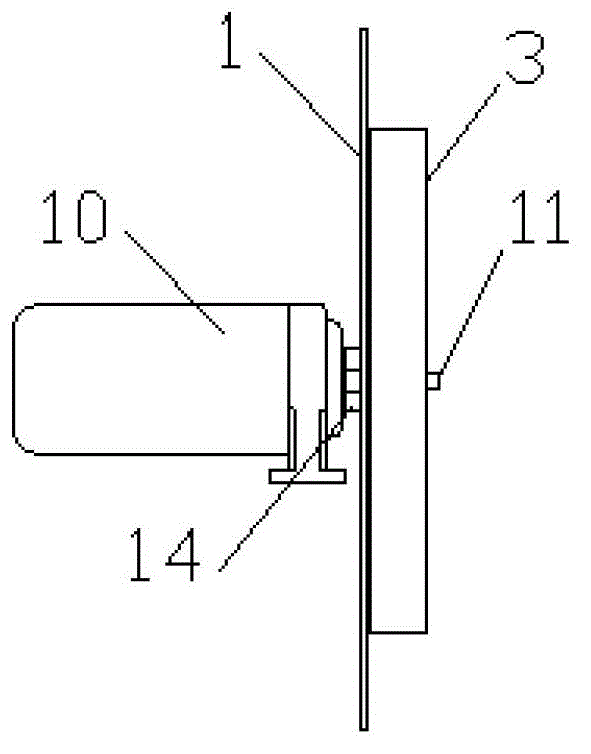

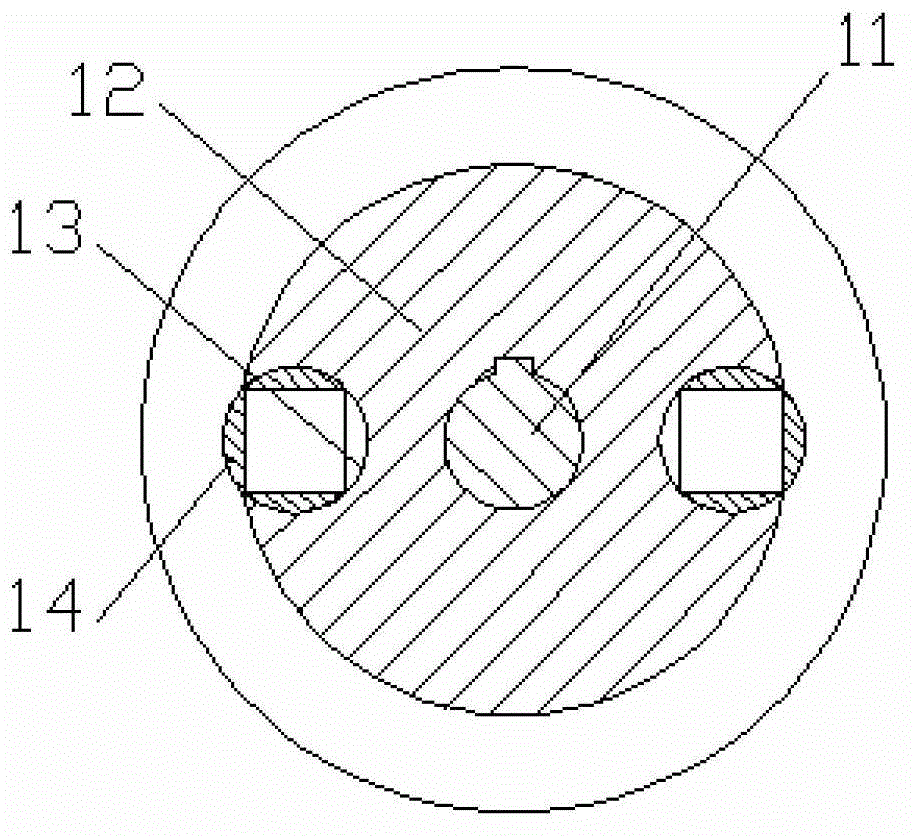

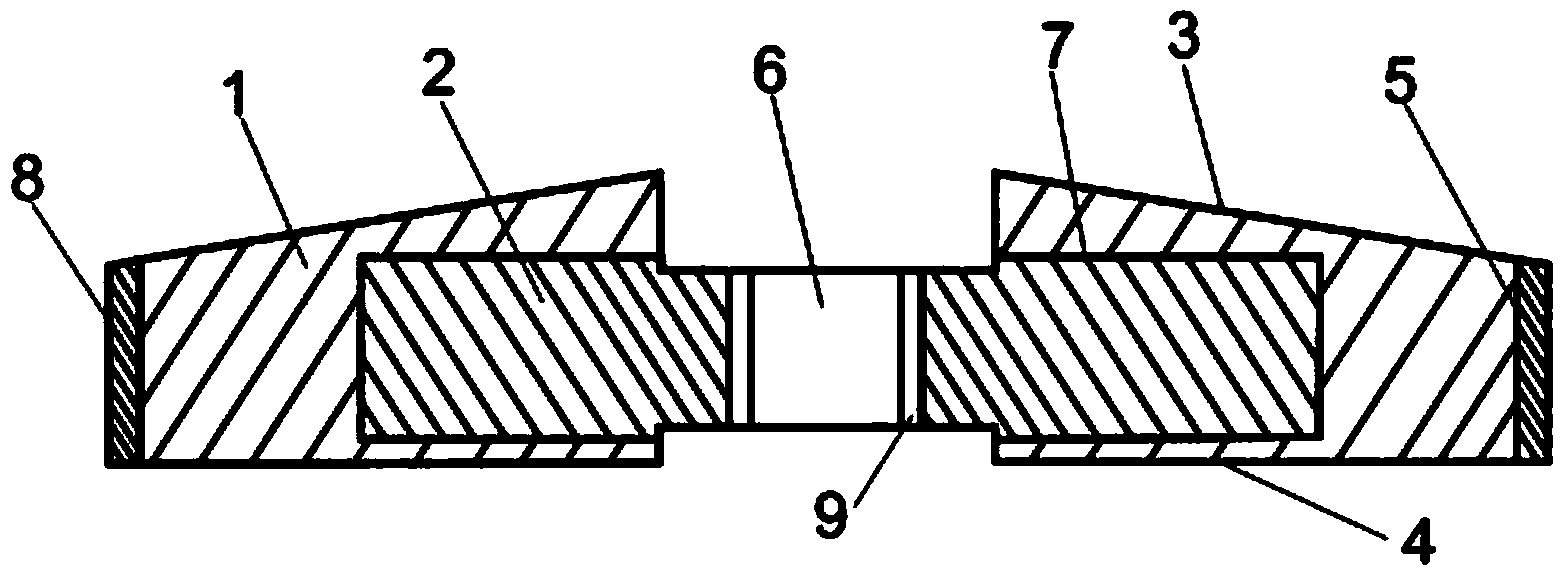

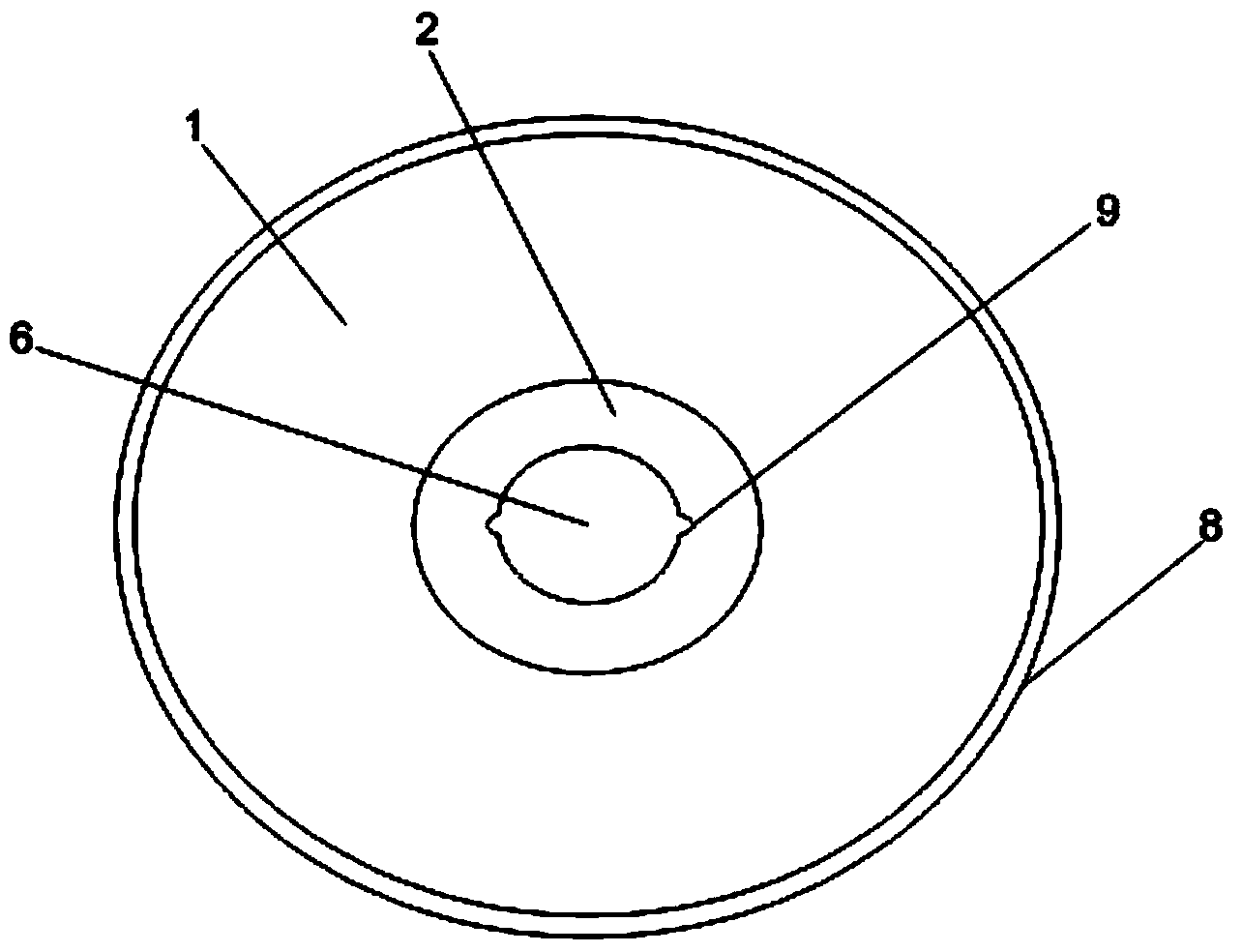

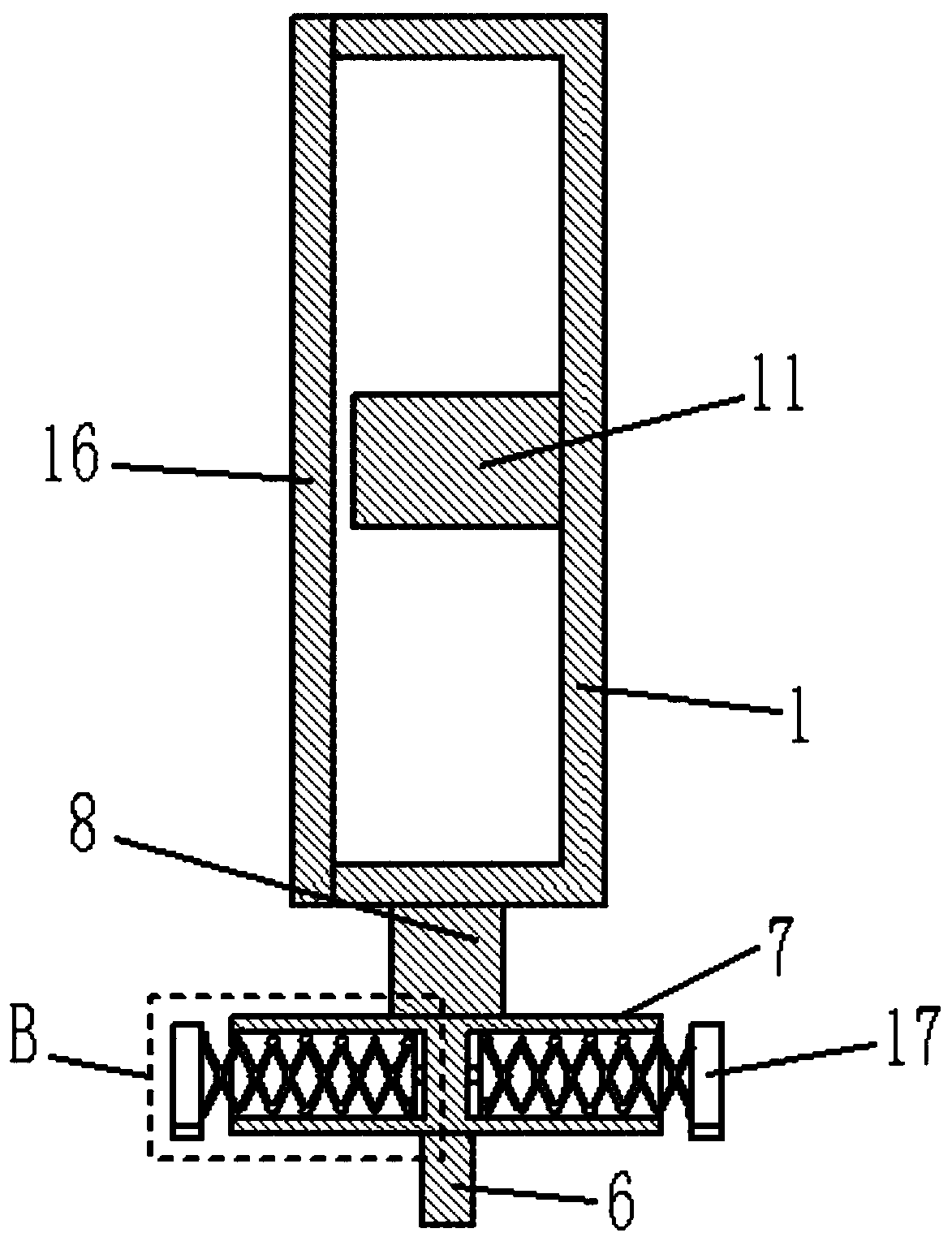

Test piece dynamic lateral strain measurement device and method based on SHPB test system

ActiveCN110926936AThe experimental data is intuitiveAccurate lateral strain measurement dataMaterial strength using single impulsive forceData acquisitionClassical mechanics

The invention discloses a test piece dynamic lateral strain measuring device and method based on an SHPB test system, and belongs to the field of dynamic mechanical property testing of brittle materials such as coal rock by adopting the SHPB test system. The device comprises a fixing system, an oil pressure system and a data acquisition system; the fixing system is used for fixing the whole deviceon an SHPB test bed and adjusting the height of the device; the oil pressure system is used for applying required confining pressure to the test piece and converting a volume change signal of the test piece into an oil pressure change signal; the data acquisition system is used for capturing signals of oil pressure changes and obtaining a time-history change curve of lateral strain. The confiningpressure is applied to the test piece by utilizing the oil pressure system, comprehensive confining pressure loading of the test piece is simulated, and the comprehensive confining pressure loading and axial acting force caused by the split Hopkinson pressure bar device act together, so that simulation of a complex stress state of the test piece is realized; the relation between oil pressure andlateral strain is obtained through signals of oil pressure changes caused by the lateral strain so as to calculate the lateral strain.

Owner:SHANDONG UNIV OF SCI & TECH

Plastic granulator

The invention relates to the field of plastic processing, in particular to a plastic granulator and aims to solve the problem of plastic particle adhesion and improve plastic particle size uniformity.The plastic granulator comprises a first mounting plate, a first collecting frame, supporting seats, an air drying frame, a first bearing seat, a first pulley, a first flat belt, a fourth rotating shaft, a third mounting plate and the like. A second mounting plate is fixedly connected to a lateral portion of the first mounting plate, and the air drying frame is fixedly connected to a lateral portion, away from the second mounting plate, of the first mounting plate. The first bearing seat is embedded to a lateral portion of the air drying frame. The plastic granulator has advantages that the plastic particles accumulated after granulation are less prone to adhesion, and the manufactured plastic particles can be screened and classified to guarantee plastic particle uniformity.

Owner:惠州市启达环美科技有限公司

Cigarette tipping paper coated printing white printing ink and production process thereof

The invention relates to a printing ink and a production process thereof, in particular to a cigarette tipping paper coated printing white printing ink and the production process thereof. The printing ink comprises the materials of titanium pigment, talcpowder, superfine calcium carbonate, polyvinyl butyral, rosin resin, isopropyl alcohol, dioctyl ester and ethanol. The production process of the printing ink comprises the following steps of: (1) weighting the titanium pigment, the talcpowder, the superfine calcium carbonate, the polyvinyl butyral, the rosin resin, the isopropyl alcohol, the dioctyl ester and the ethanol according to a weight ratio; (2) stirring the materials in the step (1) into non-dried powder; (3) putting the materials in the step (2) into a sand mill to perform sand grinding; and (4) filtering the material in the step (3) by using a 20-30-mesh sieve to obtain a finished product. The printing ink has the advantages of low cost, difficult plate pasting during coated printing and little odor.

Owner:河南省联发纸业有限公司

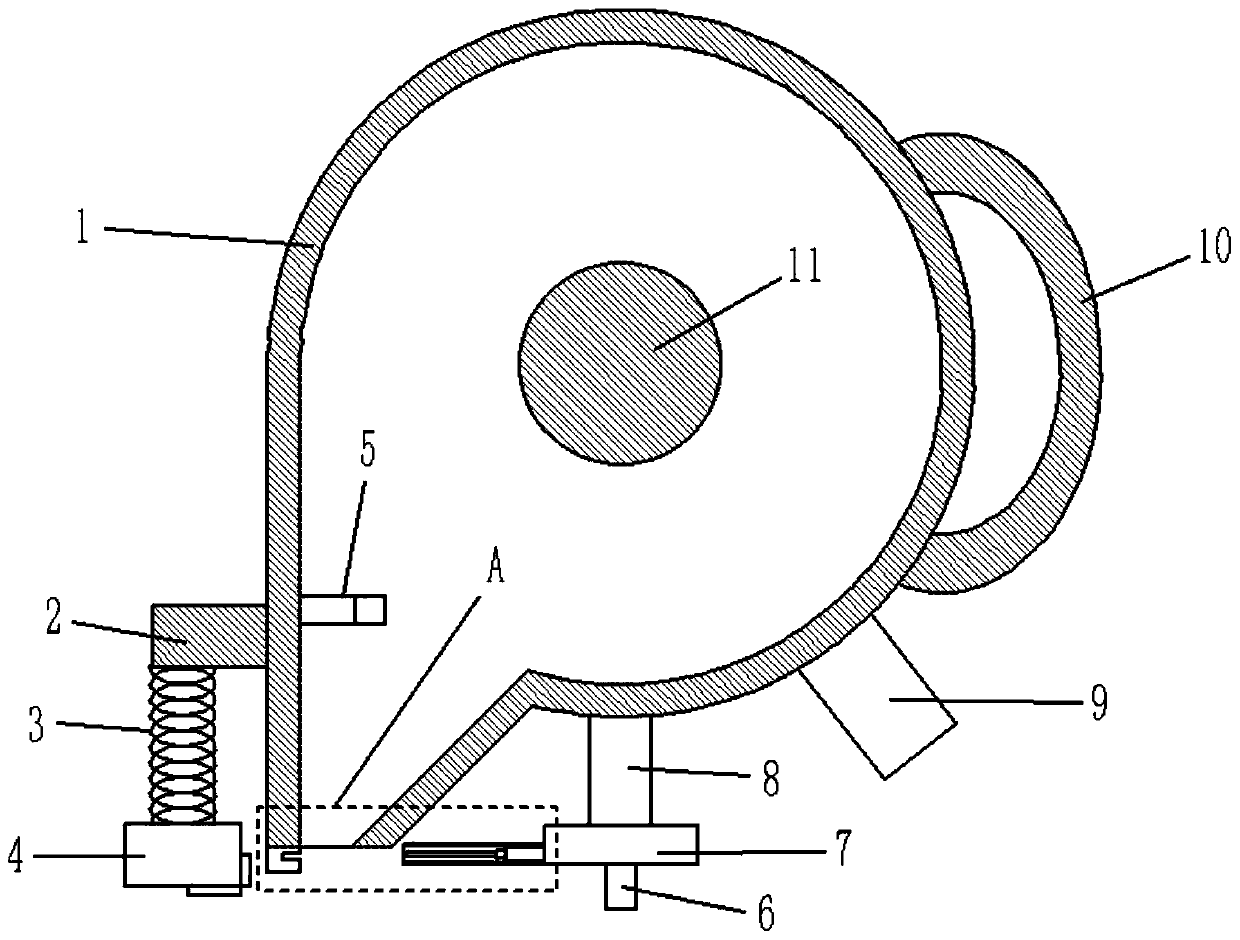

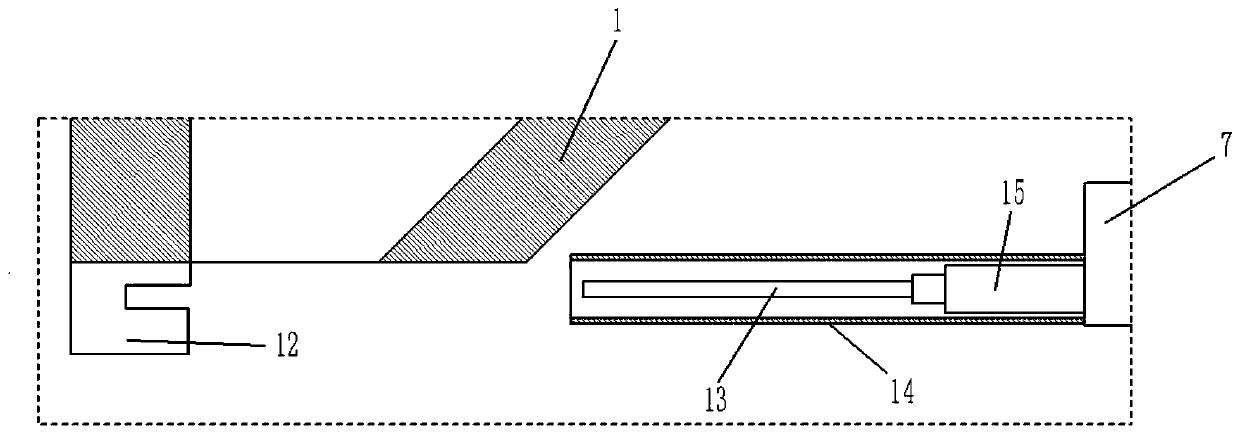

Partition board supplying device for automatic sheet packing machine

The invention discloses a partition board supplying device for an automatic sheet packing machine, which comprises a rotating disc, wherein a mandrel penetrates through the central part of the rotating disc vertically; the mandrel is connected with a speed reducer behind the rotating disc; the outer circumference of the mandrel is in sleeve joint with a partition board mounting jacket in front of the rotating disc; a partition board coil is installed on the partition board mounting jacket; and a partition board quick separation mechanism that separates partition boards from the rotating partition board coil is also arranged on the partition board supplying device. The partition board quick separation mechanism is arranged on the partition board supplying device, and the partition boards that are stuck together can be forcibly separated under the power generated by the rotation of the partition board coil because a separation pin is positioned between the two partition boards all the time and then can be output through a separation guiding wheel when the partition board coil rotates under the driving action of the partition board mounting jacket, so that the partition boards on the partition board coil can be prevented from being stuck together and being not easy to be separated, and the continuous supplying of the partition boards for the sheet packing machine can be ensured.

Owner:惠州市一电电池技术有限公司

Raw soy bean milk production process

InactiveCN1500403AIncrease productivityEasy for mass productionFood preparationWater contentProtein formation

The technological process of produce raw soybean milk includes the steps of dry material sorting, soaking, water sorting, milling, filtering to separate, filling milk, etc. The present invention has high production efficiency and is suitable for mass production. Compared with cooked soybean milk producing process, the present invention has the advantages of easy to control milk concentration, easy filtering, water content of coarse protein after filtering lower than 2.5 %, low power consumption, no denaturing of protein, etc.

Owner:焦春霞

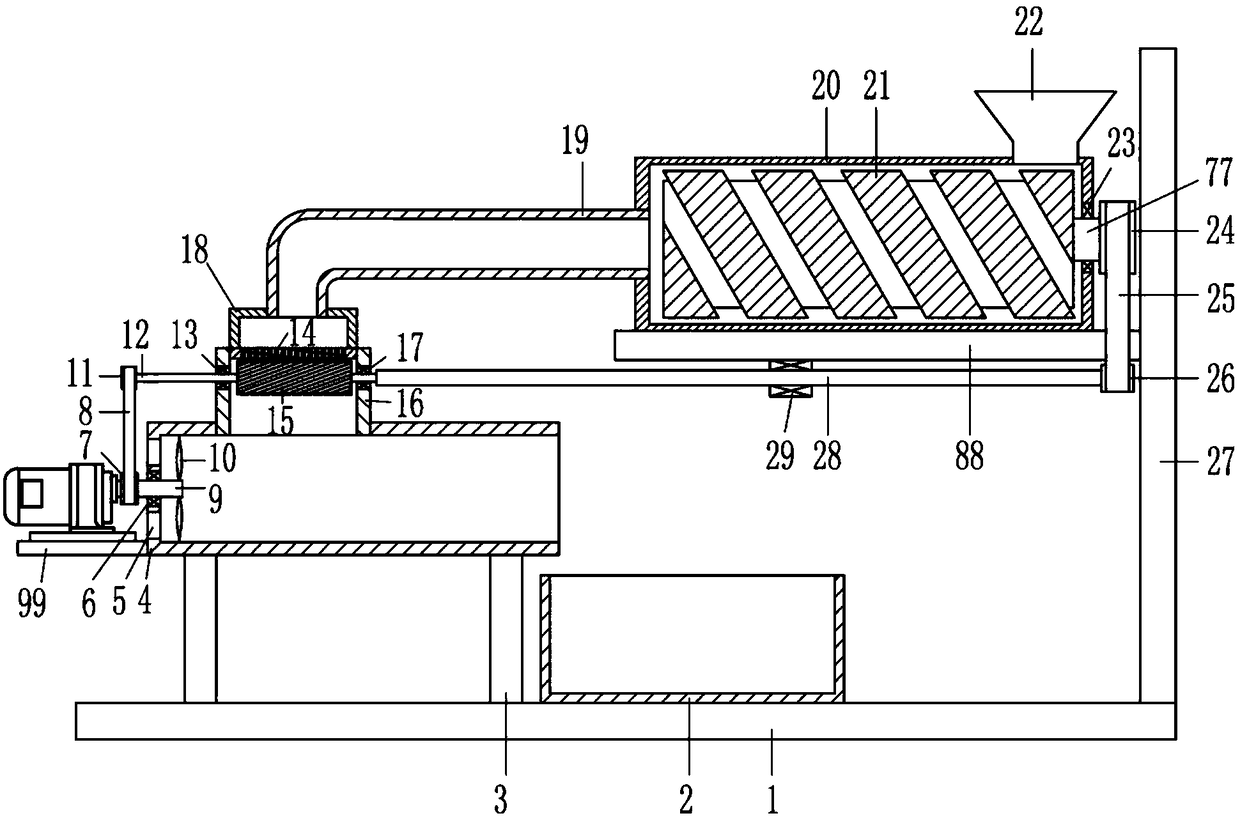

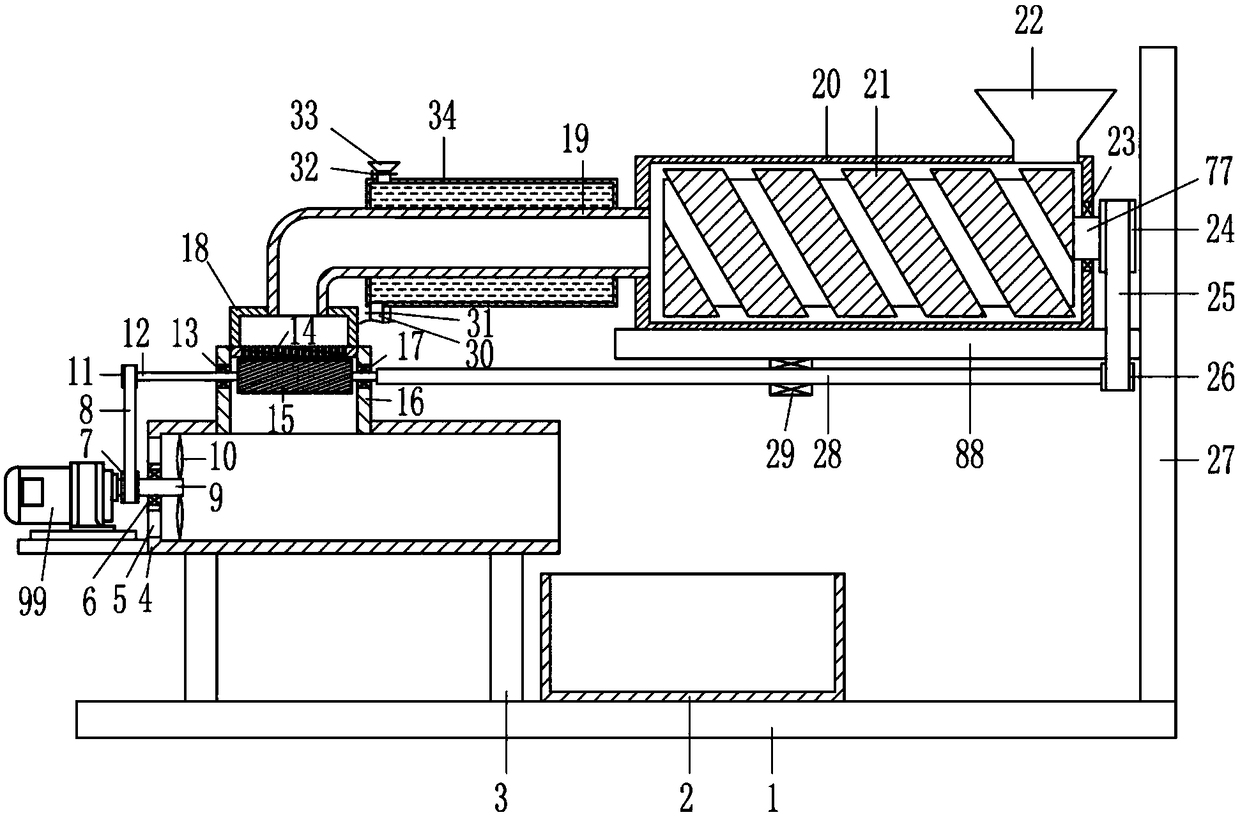

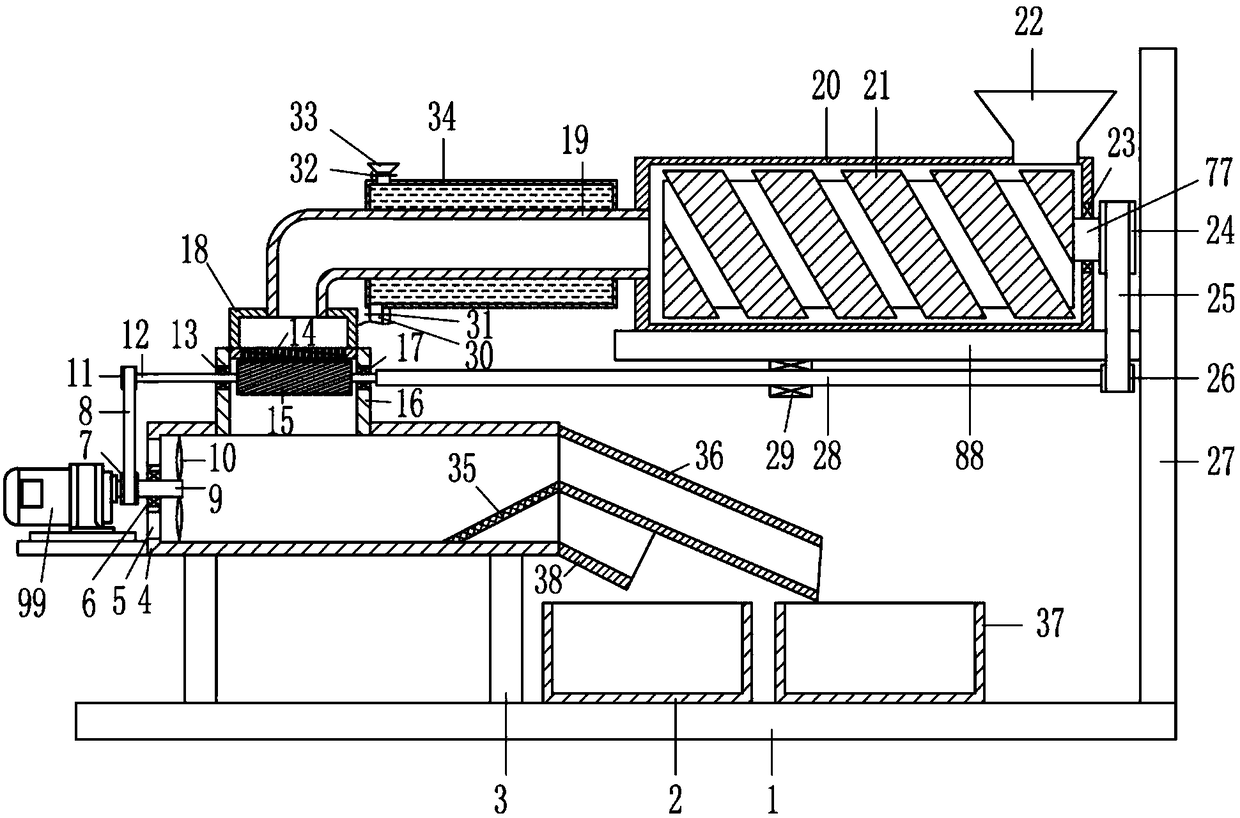

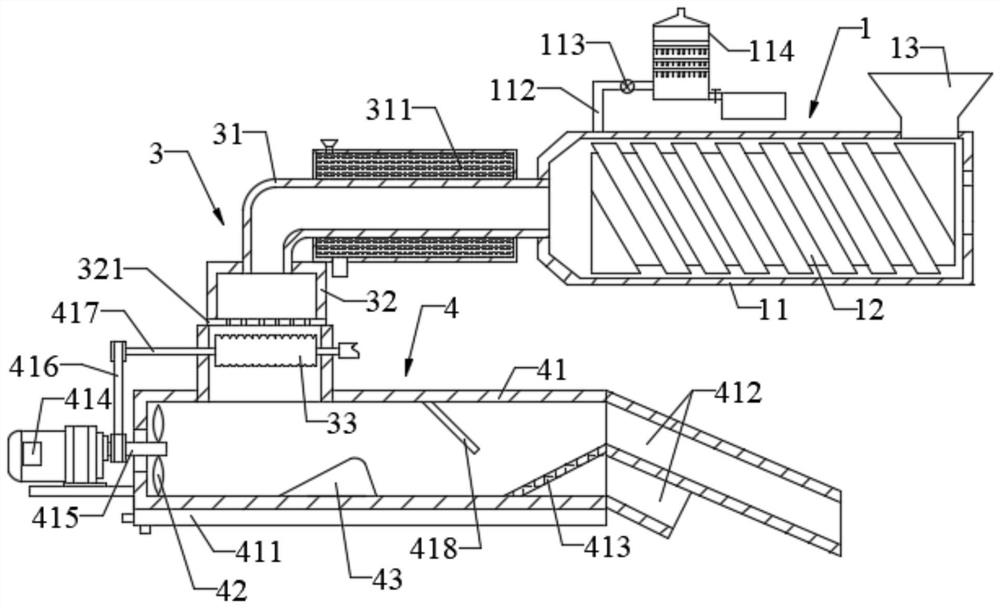

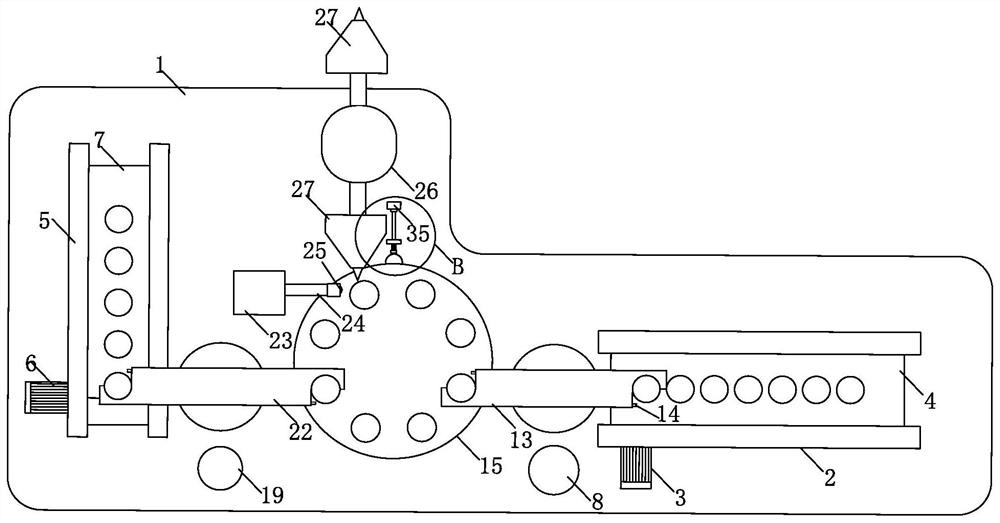

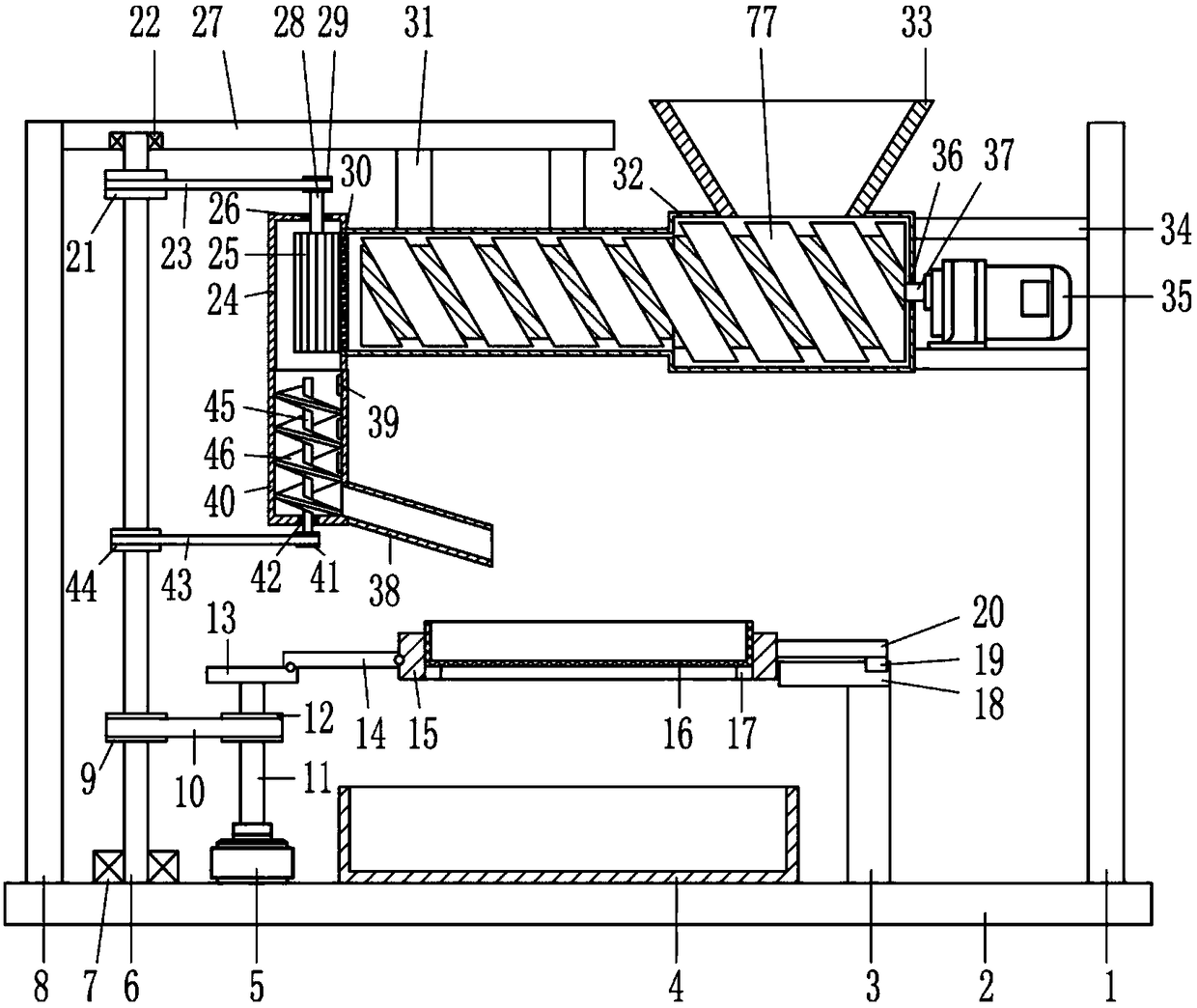

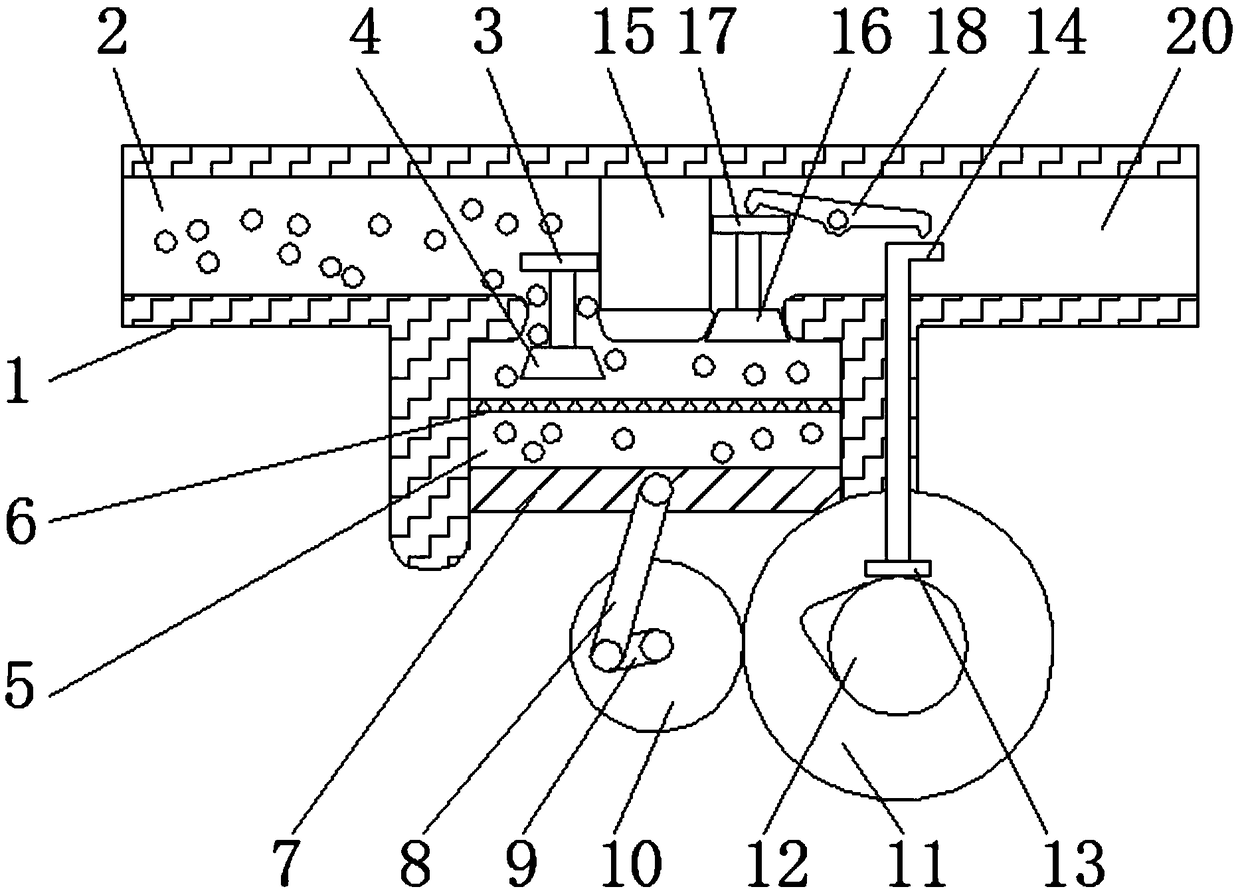

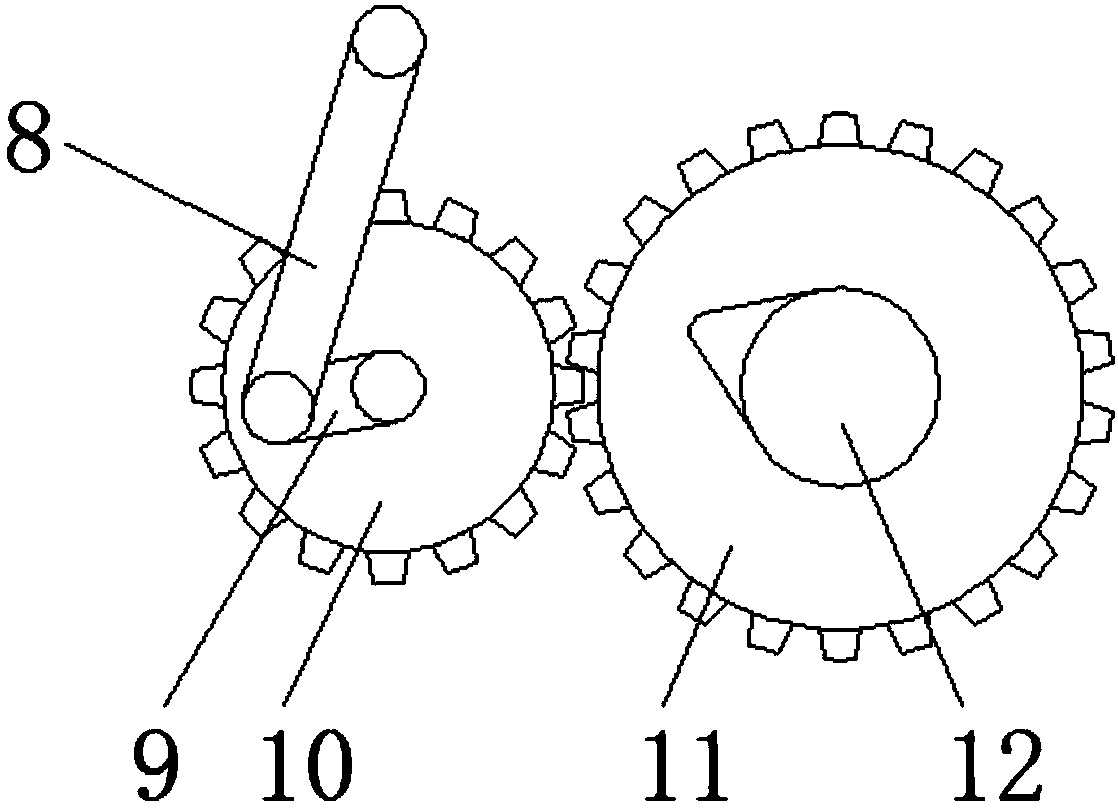

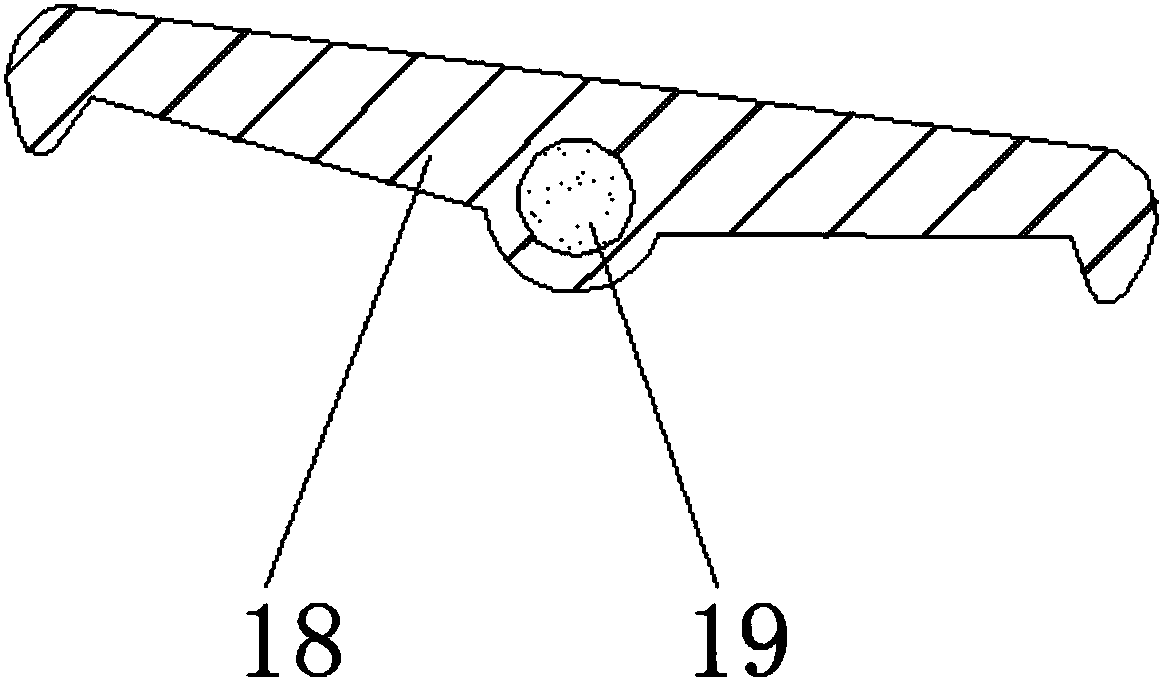

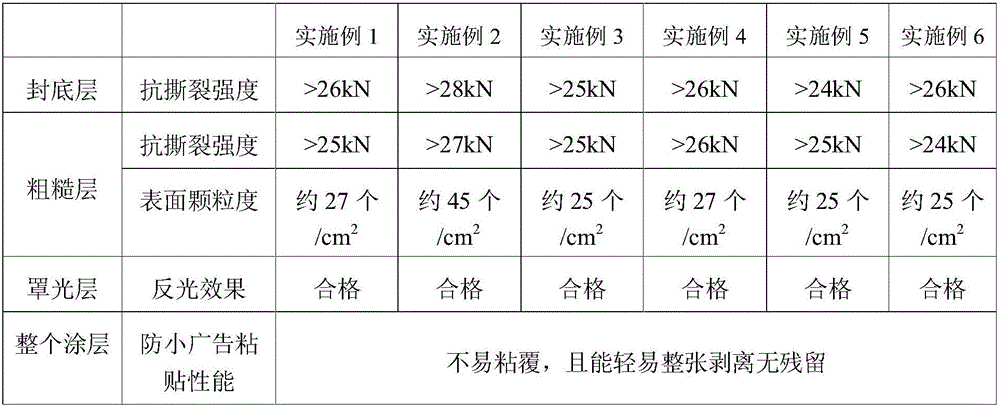

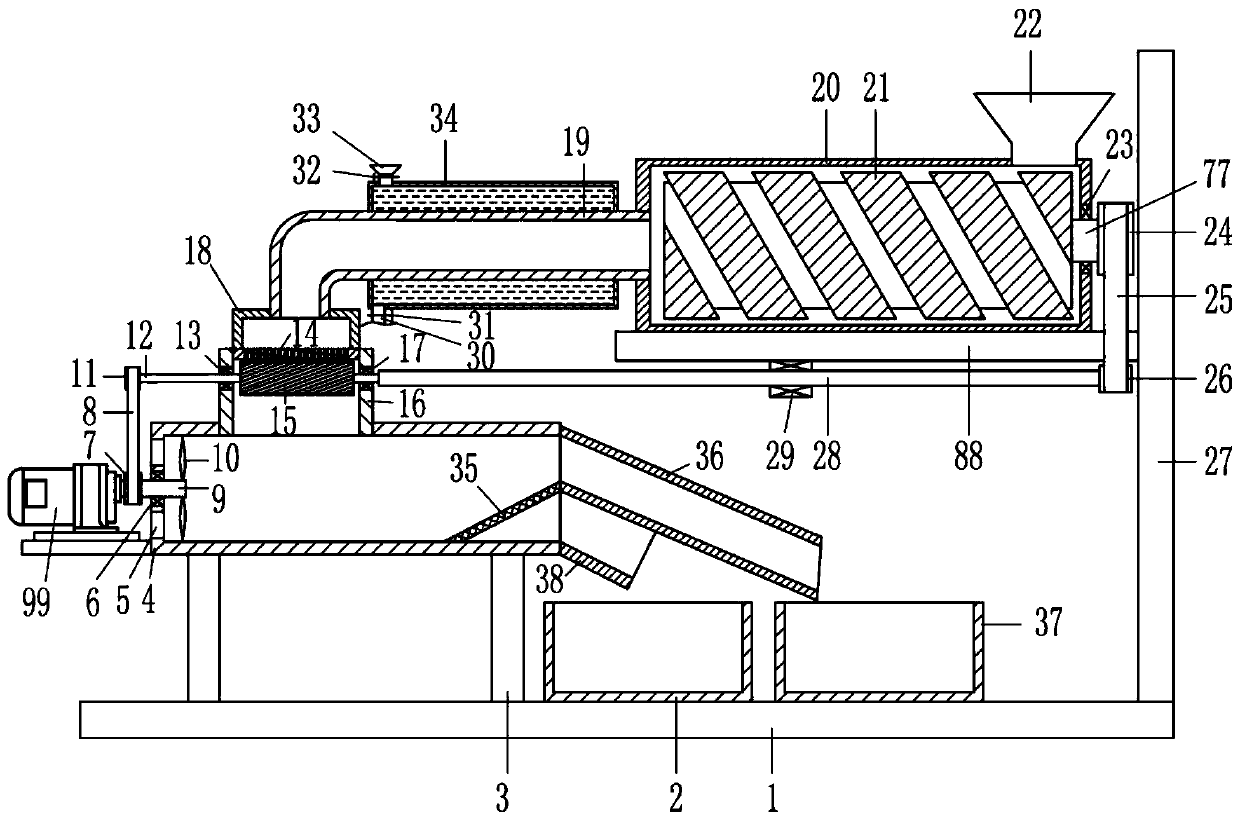

Efficient environment-friendly plastic granulation device

InactiveCN111645221AEasy to pastePaste will notDispersed particle separationDirt cleaningProcess engineeringEnvironmental engineering

The invention relates to the field of plastic processing, in particular to an efficient environment-friendly plastic granulation device. The plastic granulation device comprises a feeding extrusion device, a hot cutting device, a cold cutting device and a cooling discharging device. According to the high-efficiency environment-friendly plastic granulation device, accumulated plastic particles after granulation are not easy to stick together, and the produced plastic particles can be screened and classified to ensure the effect of uniformity of the plastic particles; the cut plastic particles are air-dried by means of wind transportation to ensure that the plastic particles are mutually separated directly and cannot stick together; dual processes of cold cutting and hot cutting are integrated, switching or simultaneous production can be performed according to demands, waste gas is washed by three layers of spray pipes, an adsorption layer can adsorb toxic and harmful gases in the gas, the gas is effectively purified, and pollution is reduced. A waste liquid tank can collect waste liquid generated in the washing process, so that secondary pollution is prevented, and the environment is further protected.

Owner:福建亚通新材料科技股份有限公司

Method for producing cooked rice noodles

InactiveCN103478604AGuaranteed tasteGuaranteed qualityFood shapingFood preparationFood processingExtrusion

The invention relates to a food processing technology, in particular to a method for producing cooked rice noodles. The method comprises the following steps: pumping water by a water pump with a lift range of 50 meters to wash rice for 5-8 minutes, steaming the rice for 25-30 minutes in a steamer with the temperature of 120 DEG C for the first time, separating rice soup for 1.5-2.5 minutes in cold water with the temperature of 10-25 DEG C, steaming the rice in the steamer with the temperature of 120 DEG C for the second time, cooling, mixing, and carrying out extrusion forming to prepare the cooked rice noodles. Edible alkali is added into the cold water in the process of separating the rice soup for adjusting the mouth feel and the color; meanwhile, the rice soaking time is shortened and the quality of the cooked rice noodles is guaranteed through the control on the rice washing time; the cooked rice noodles are chewier through the process of separating the rice soup; the produced rice noodles are mellow and full in color and luster, and comfortable in mouth feel, have low probability of breaking, and are free from pasting.

Owner:兴义市兰琼食品加工厂

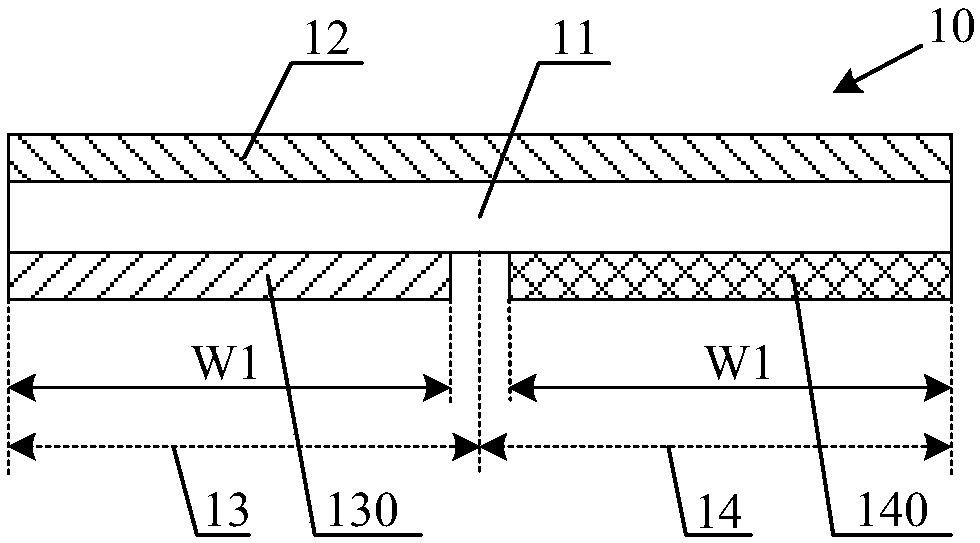

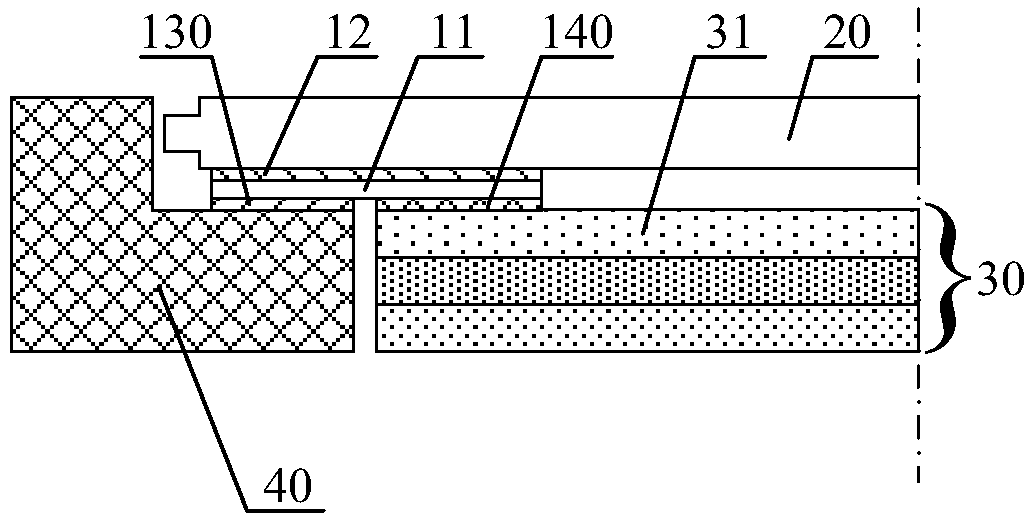

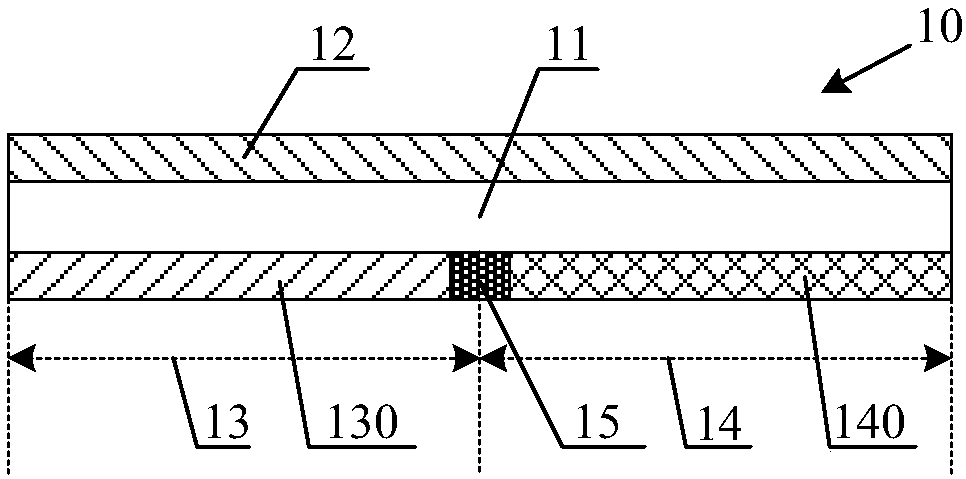

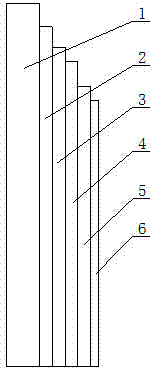

Shading tape and display device

The invention discloses a shading tape and a display device. The shading tape comprises a tape body, a first adhesive layer arranged on the first surface of the tape body as well as a second adhesivelayer and a third adhesive layer which are arranged on the second surface of the tape body; the second adhesive layer and the third adhesive layer are arranged on a first area and a second area correspondingly; and the third adhesive layer has wriggling property and non-transfer property. The display device comprises the shading tape; the surface of an adhesive frame adheres to the second adhesivelayer; the surface of a backlight module adheres to the third adhesive layer; and the surface of a display panel adheres to the first adhesive layer. Due to the wriggling property and the stability of the third adhesive layer, the third adhesive layer does not influence thermal expansion and cold contraction of the film layer of a backlight module membrane layer, the membrane layer is effectivelyprevented from generating wrinkle in a reliability test, and the yield of products is increased. Due to the non-transfer property of the third adhesive layer, the third adhesive layer is not liable to transfer to the membrane layer, the membrane layer is prevented from being stained and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

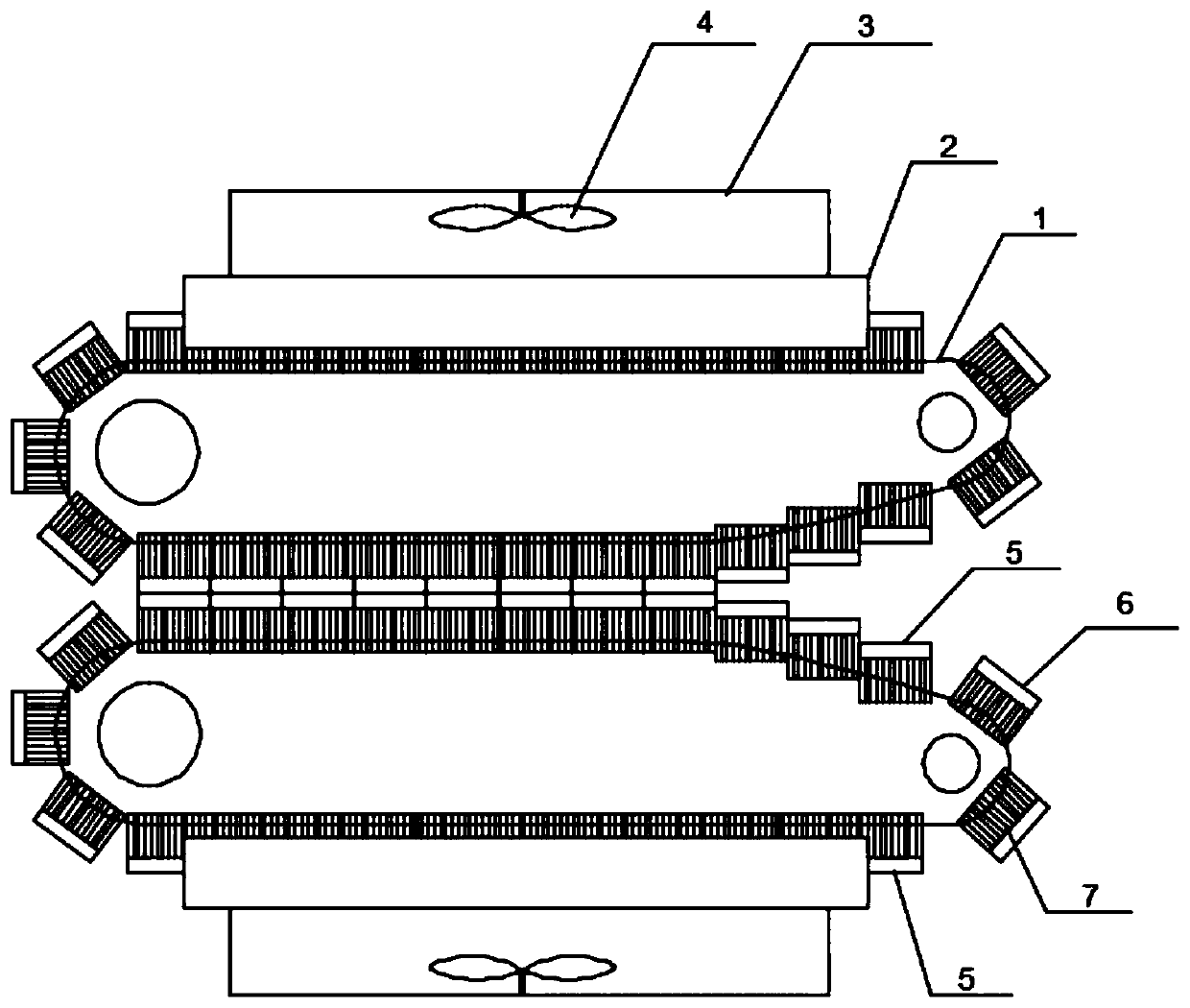

Corrugated pipe molding machine and corrugated pipe production technology based on same

The invention discloses a corrugated pipe molding machine and a corrugated pipe production technology based on same. The corrugated pipe molding machine comprises two circular sealed sliding groove, molds which are moved on the sliding grooves cooperatively form a corrugated pipe molding passage, cooling boxes are arranged on the two sides, away from the corrugated pipe molding passage, of the sliding grooves, the two sides of each mold are connected with heat dissipating pieces, first gaps are formed in the sides, close to the molds, of the cooling boxes in the moving directions of the molds,second gaps are formed in the two ends of the cooling boxes, and the first gaps are communicated with the second gaps to allow the heat dissipating pieces to move towards the first gaps after entering the cooling boxes from the second gaps formed in one ends of the cooling boxes when the molds are moved and penetrate out from the second gaps formed in the other ends; the tops of the cooling boxesare provided with spraying pipes which are connected with an external water source, and nozzles which are uniformly distributed are arranged on the spraying pipes. According to the machine, the problem that water easily flows into the sliding grooves to cause equipment failures when the molds are directly cooled by water, the temperature of the molds which are cooled twice is lower, and the cooling molding efficiency is high.

Owner:GUIYANG XINGSU PIPE IND CO LTD

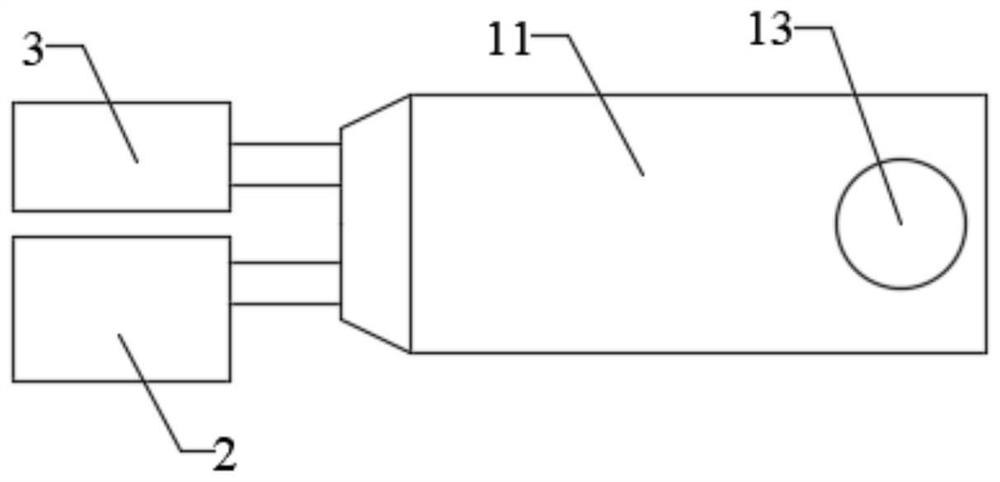

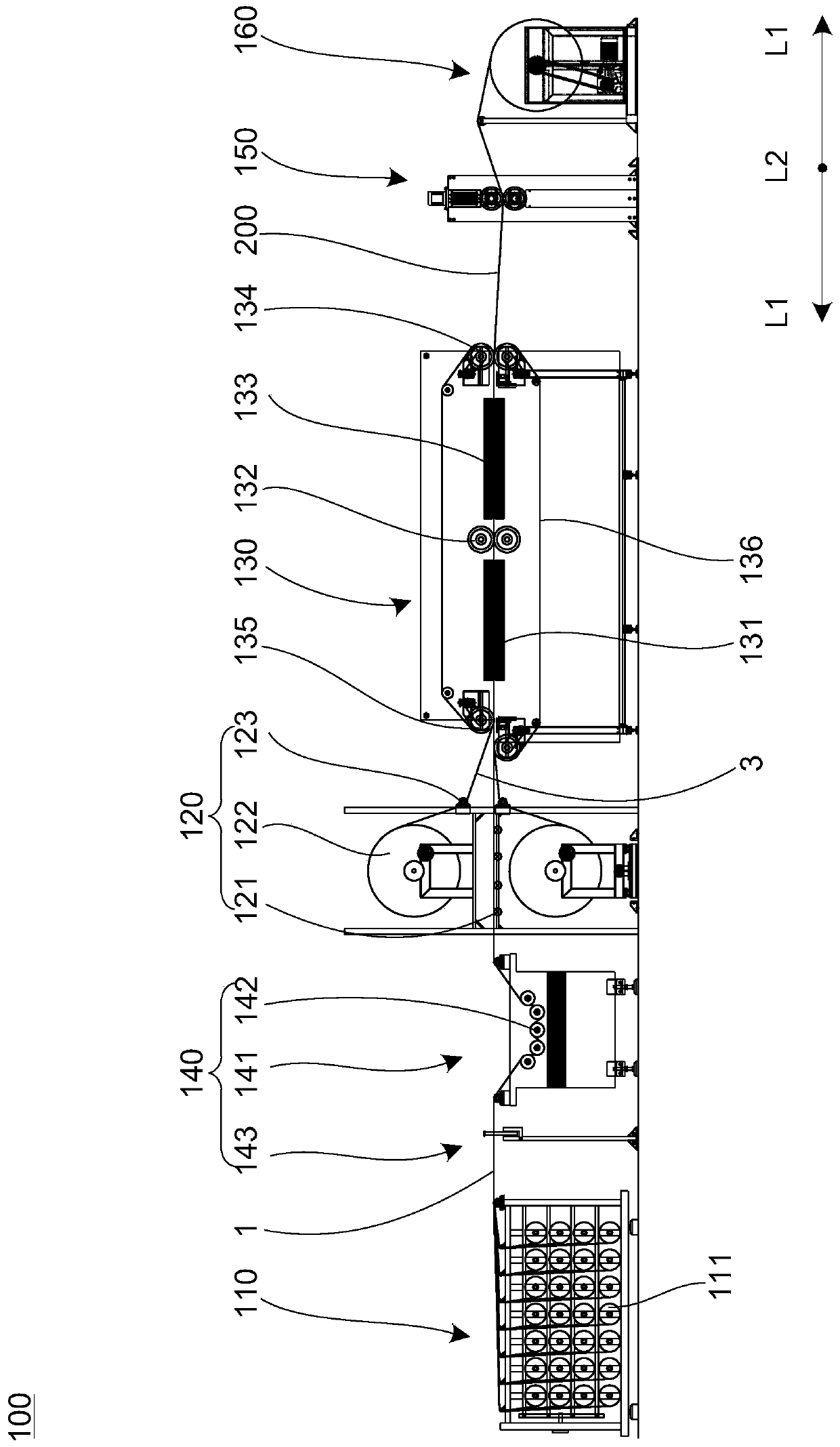

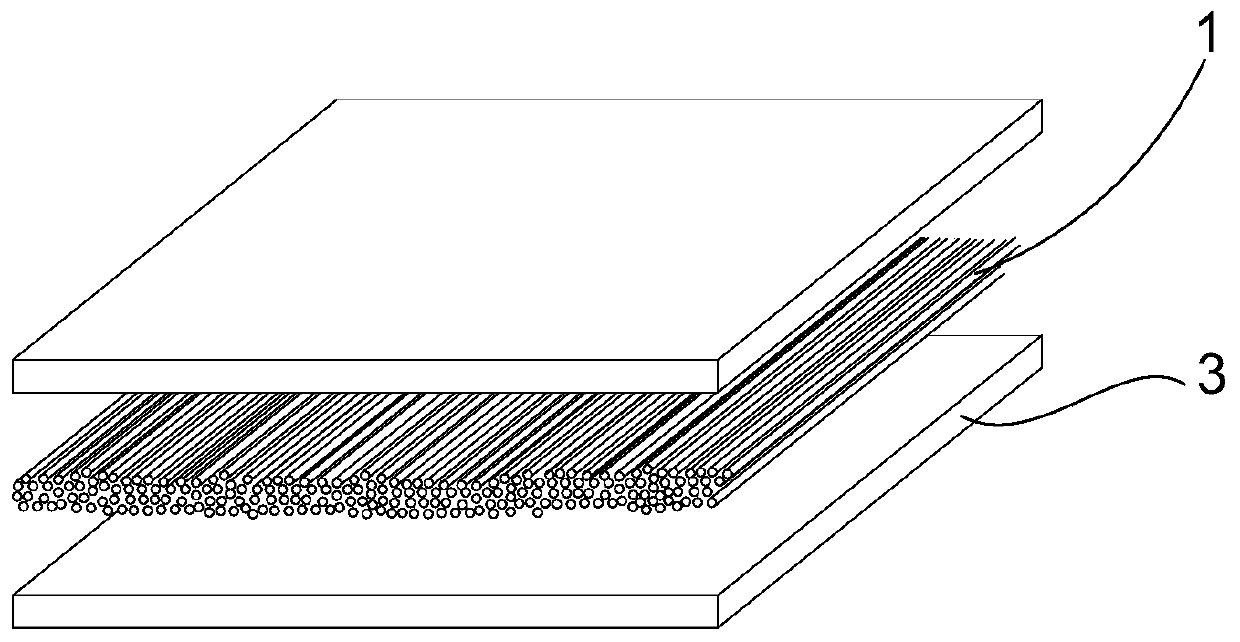

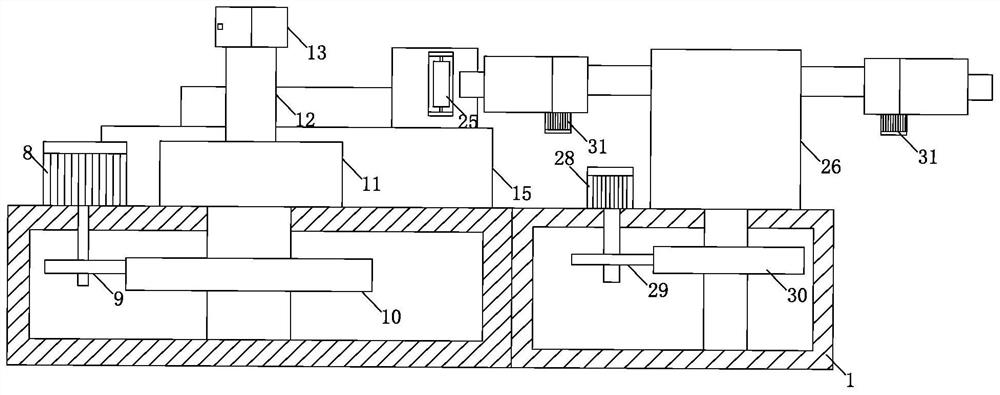

Production equipment and production process of fiber-reinforced thermoplastic resin composite strips

The invention discloses production equipment and production process of fiber-reinforced thermoplastic resin composite strips. The production equipment comprises a fiber supply unit, a pretreatment unit, a film coating unit and a pressing unit. The fiber supply unit is used for storing fibers. The pretreatment unit is located in the downstream position of the fiber supply unit and is configured toreceive the fibers from the fiber supply unit. The pretreatment unit comprises an oscillation device. The oscillation device comprises at least one oscillation roller. The oscillation rollers can perform transverse oscillation so that the fibers can be dispersed into monofilaments. The film coating unit is located in the downstream position of the pretreatment unit. The film coating unit is used for covering the upper portion and the lower portion of each fiber with thermoplastic films. The pressing unit is located in the downstream position of the film coating unit. The pressing unit is usedfor pressing the thermoplastic films and the fibers into the fiber-reinforced thermoplastic resin composite strips. According to the production equipment, the composite strips are prepared by using the thin film and fiber hot pressing mode, and the production equipment has the beneficial effects that the fiber dispersibility is good, and the defects such as dry yarn, cracking and paste are not prone to occurring.

Owner:青岛中集创赢复合材料科技有限公司

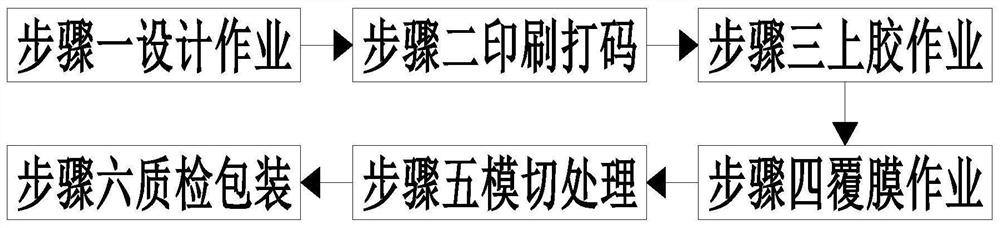

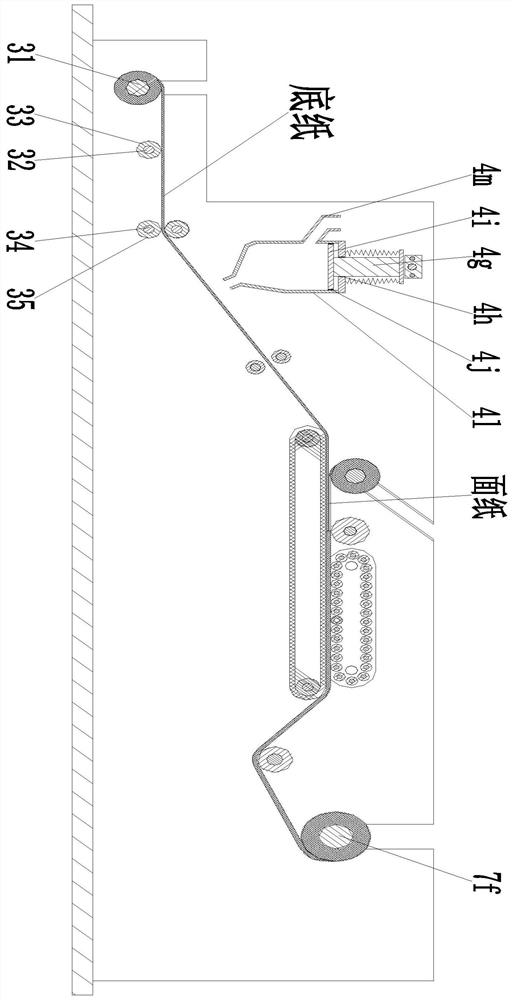

Preparation method of anti-counterfeiting self-adhesive label

ActiveCN112037644AImprove roll qualityAvoid product qualityStampsIdentification meansAdhesiveMaterials science

The invention relates to a preparation method of an anti-counterfeiting self-adhesive label, which mainly comprises the following steps: design operation, printing and coding, gluing operation, laminating operation, die cutting treatment, quality inspection and packaging and the like, and used label gluing and laminating equipment comprises a bottom plate, a support plate, a roll feeding device, aglue spraying device, a smoothing device, a laminating device and a rolling device, according to the invention, the following problems existing in the existing self-adhesive label coating operation can be solved: a, in the traditional self-adhesive label coating operation, a self-adhesive stickercannot be smoothened, and the thickness of the self-adhesive sticker cannot be adjusted, so that the thicknesses of the self-adhesive labels are inconsistent, and the production quality of the self-adhesive label is reduced; and b, when the conventional self-adhesive label coating equipment is used for coating self-adhesive stickers, the adhesive sticker labels are easy to roll together and are not easy to unfold because the self-adhesive stickers are thin, so that the self-adhesive sticker labelsare not easy to adhere, and the production quality of the self-adhesive labels can be improved by tilting or rolling up the corners or edges of the labels.

Owner:ZHEJIANG XIANGYU PAPER PLASTIC PRODS

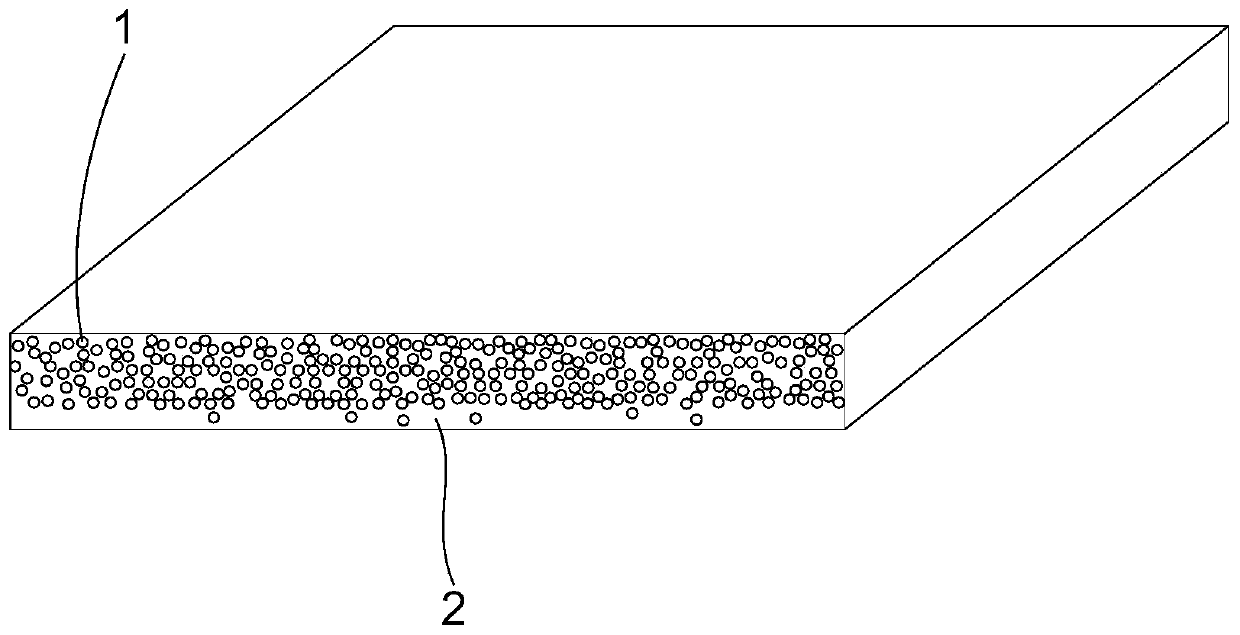

Multifunctional grinding tool

InactiveCN104070447AEfficient use ofSmooth rotationLapping toolsGrinding/polishing hand toolsEngineeringSurface grinding

The invention relates to a multifunctional grinding tool. The multifunctional grinding tool comprises a base body; a grinding layer wraps the four sides of the base body; the grinding layer is that the upper surface is an inclined tapered surface grinding layer, the lower surface is a horizontal surface grinding layer, and the side surface is a cylindrical side surface grinding layer; a rotating shaft hole is formed in the center of the base body. The grinding tool is multifunctional, safe, convenient, and long in service life.

Owner:周开雄

Easy-cleaning wallpaper

InactiveCN107338683AEasy to cleanWon't get wetSpecial paperStarch adhesivesEmulsionPolyvinyl alcohol

The present invention discloses easy-cleaning wallpaper, which comprises a base material layer, an adhesion layer and a water-repellent material layer, wherein the water-repellent material layer is a water-repellent cloth and is prepared from a water-repellent material. According to the present invention, water is heated to a temperature of more than 80 DEG C, 3 times the volume of the hot water is added to starch and rapid stirring is performed until no agglomeration is generated, a polyvinyl alcohol emulsion is added, and uniform mixing is performed to obtain an adhesive so as to be used as the adhesion layer; the water-repellent material layer is adhered on the base material layer, is the surface, can be wiped, cannot be wetted by water, and is easy to clean; and the water-repellent material is not easily adhered to the base material layer due to the hydrophobicity of the water-repellent material, the adhesion layer is prepared by mixing starch and polyvinyl alcohol, the adhesion is performed at the high temperature, and rapid cooling is performed after the adhesion, such that the water-repellent material layer can be adhered to the base material layer.

Owner:广西顺帆投资有限公司

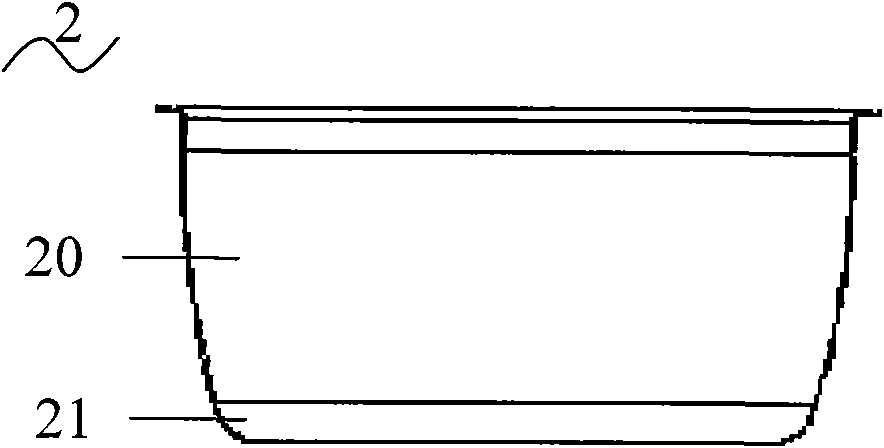

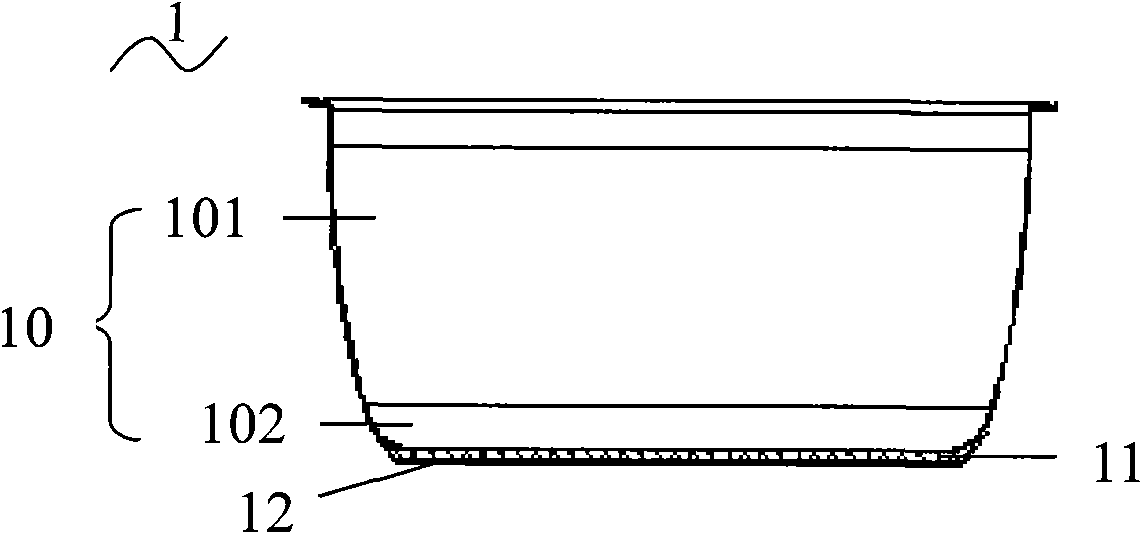

Frying pan and method for preparing frying pan

The invention provides a frying pan and a method for preparing the frying pan. The frying pan comprises a pan body, a first heating layer integrally formed with the pan body, and a second heating layer coated on the first heating layer, wherein a third heating layer is formed between the first heating layer and the second heating layer, and is coated in the second heating layer. A 'steel, aluminum and steel' structure is formed by adding the third heating layer and the second heating layer which is used for coating the first heating layer and the third heating layer, so that the bottom of the frying pan is heated uniformly, and foods are prevented from adhering the pan bottom in a cooking process.

Owner:浙江银海不锈钢制品有限公司

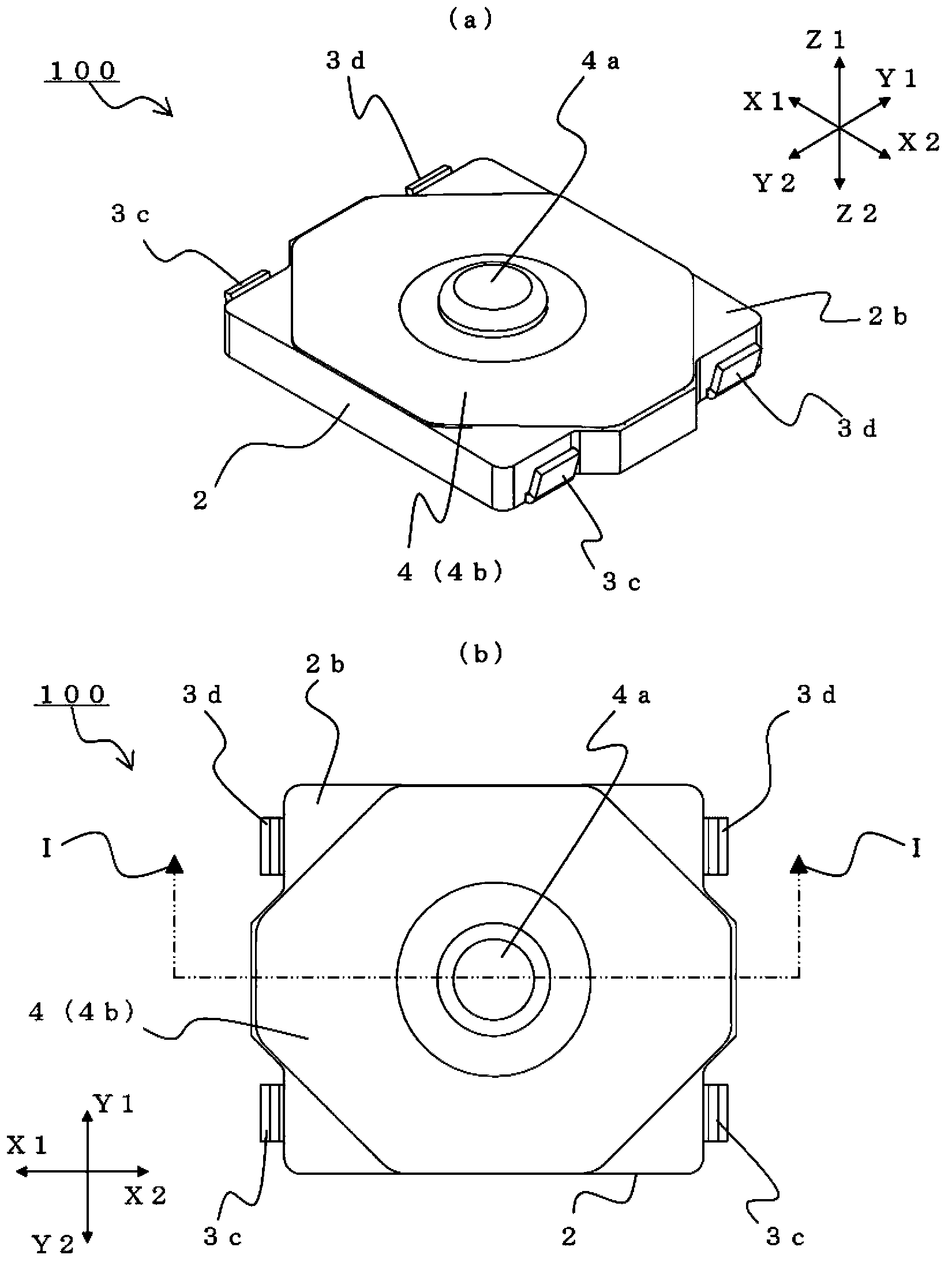

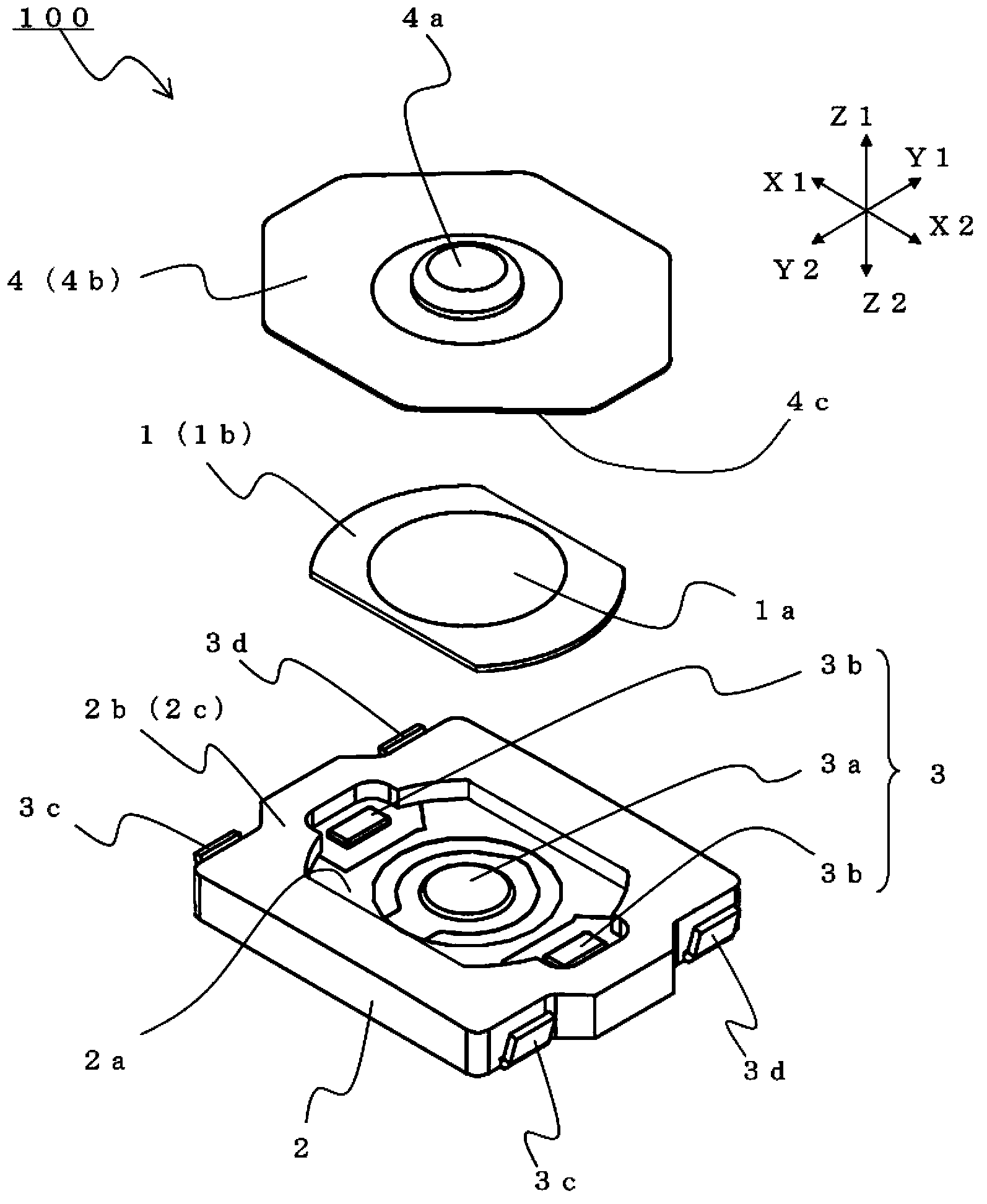

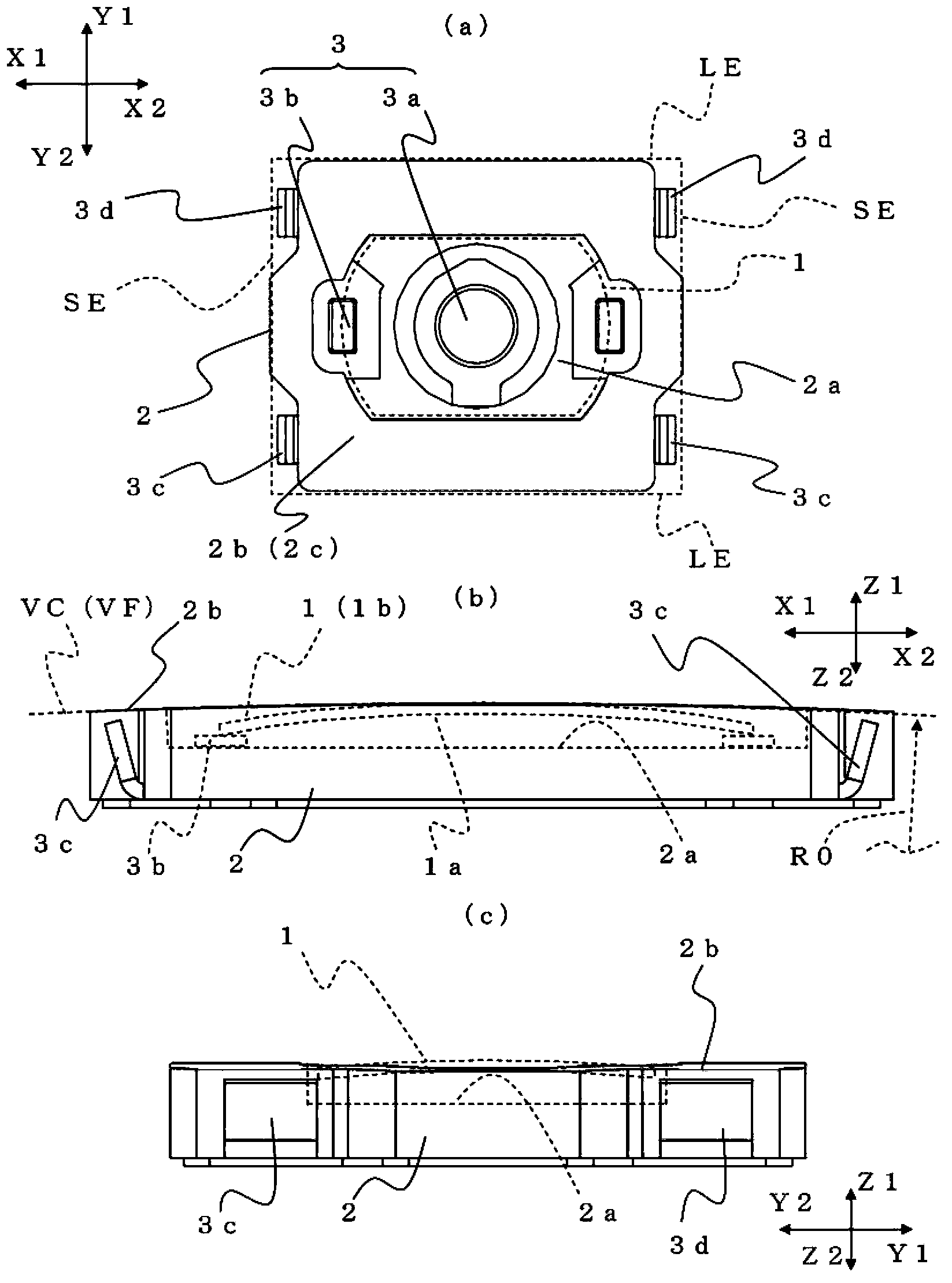

A button switch

ActiveCN103531387ANot easy to reachPrevent operability from deterioratingElectric switchesKey pressingEngineering

Provided is a button switch capable of reliably operating even when pressed in an inclined manner. The button switch comprises a movable contact component, a housing, and a sheet. The movable contact component comprises a bulge portion in a dome shape. The housing comprises an accommodating portion for accommodating the movable contact component and a fixed contact component capable of contacting the movable contact component. The sheet is pasted on a side of the top surface of the housing and comprises a pressing member pressed from an outer side. The structure of the button switch is configured in a manner that in a top view observing the housing of the button switch from top, the appearance shape of the housing is approximately a rectangle; that in the extending direction of at least one group of groups formed by every two oppositely-arranged sides of four sides forming the appearance shape of the housing, at least a part of the top surface of the housing forms a state that the height of the two end portions of the housing from the bottom surface to the top surface of the housing is lower than that of the central part of the housing.

Owner:ALPS ALPINE CO LTD

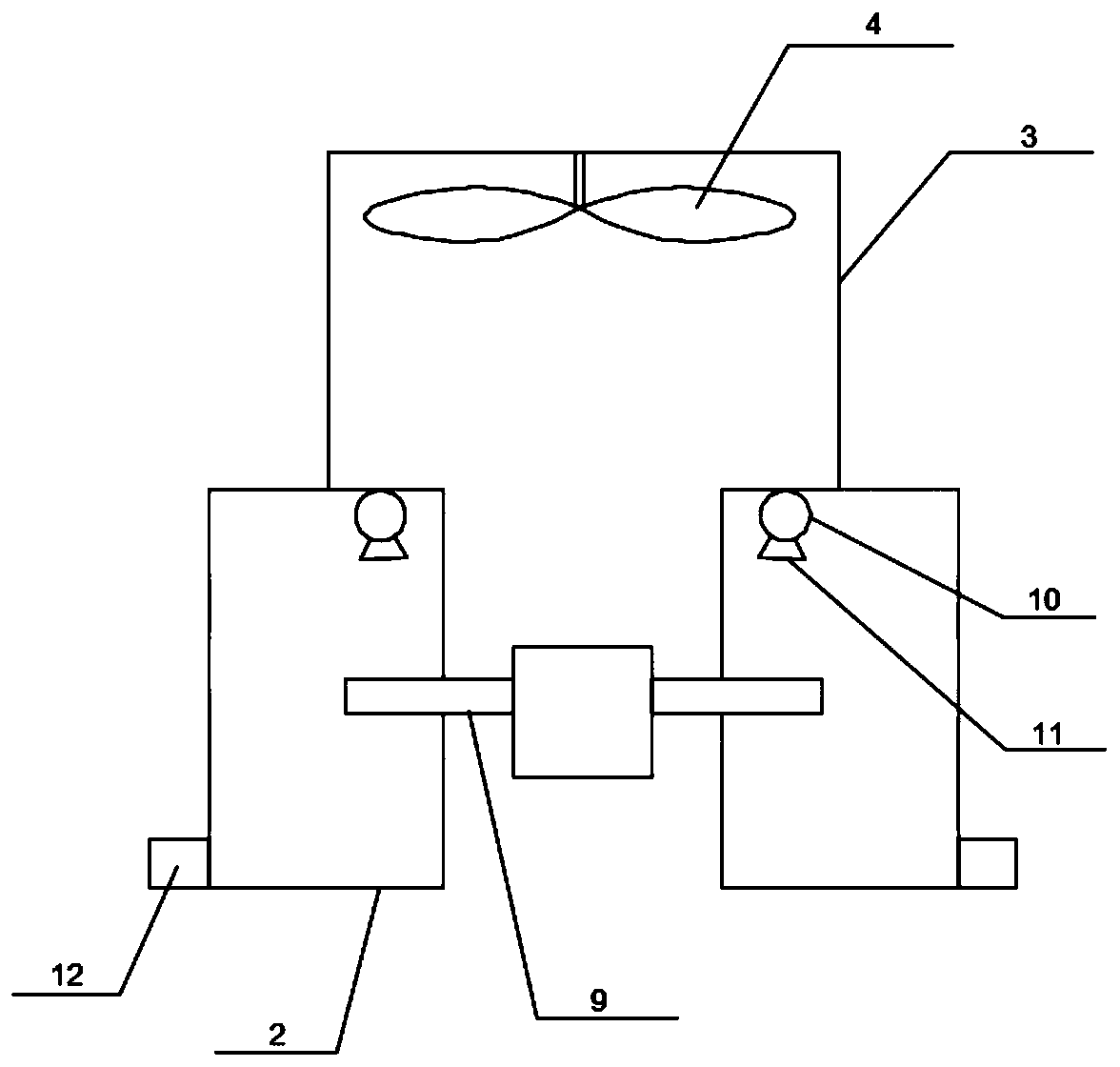

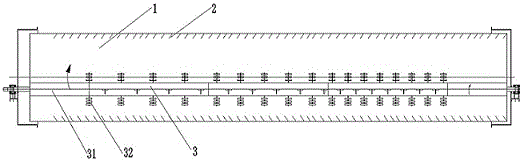

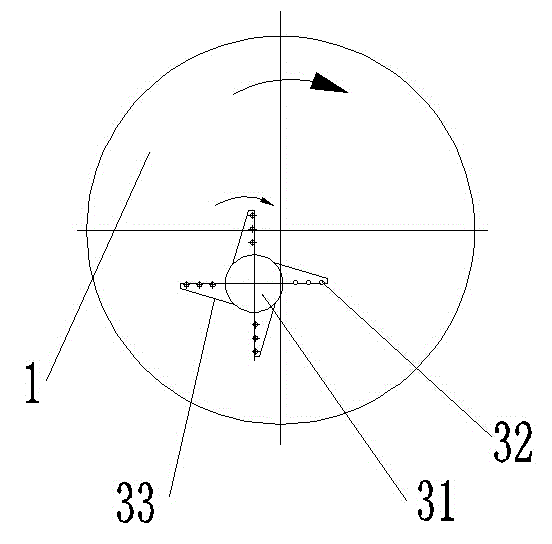

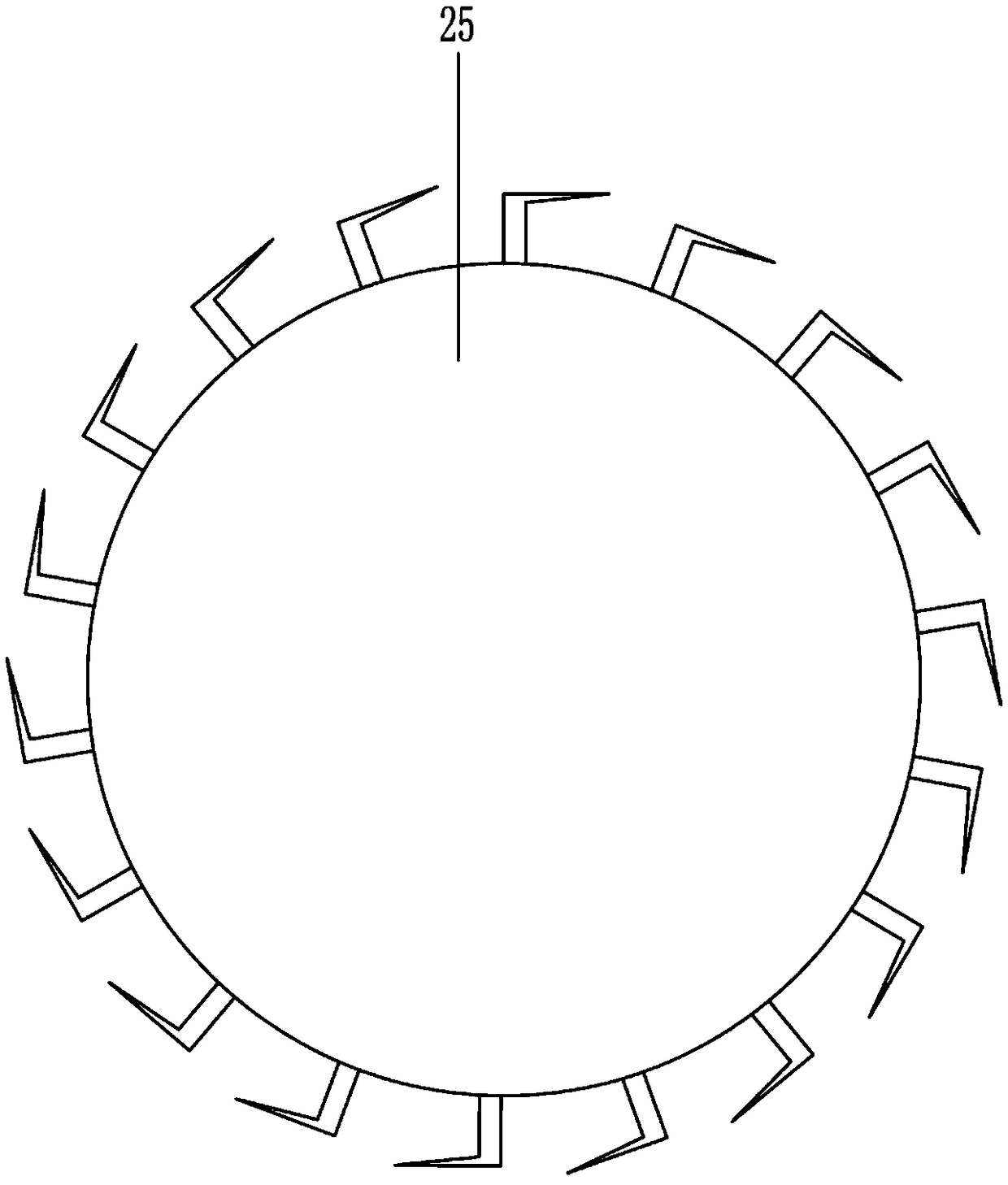

Dryer suitable for guniting corn flakes

InactiveCN104964538AAvoid stickingNot easy to pasteDrying solid materialsDrying machines with non-progressive movementsMechanical engineeringCornflakes

The invention relates to a dryer suitable for guniting corn flakes. The dryer comprises a cylindrical body, a scattering device, and an arc shoveling plate. The cylindrical body is a single layer cylindrical body. The scattering device comprises a rotating shaft installed in the cylindrical body in a cooperation manner, and scattering components installed on the rotating shaft. The rotating shaft is arranged below the longitudinal axis of the cylindrical body in a staggered manner. The axis of the rotating shaft is parallel to the axis of the cylindrical body. The scattering components are arranged on the rotating shaft at a certain interval in a cooperation manner. The scattering component comprises fins and horizontal fins cooperatively arranged on the fins. The arc shoveling plate is a first metal plate cooperatively arranged on the inner wall of the cylindrical body. The dryer makes materials rapidly dry under the action of hot wind, and prevents the materials from sticking on the cylinder wall, so as to improve drying efficiency of the dryer and reduce production cost.

Owner:ZHENGZHOU DINGLI NEW ENERGY TECH

Box sealing pretreatment device for international trade

PendingCN110902039APaste firmlyAvoid damageWrapper twisting/gatheringArticle deliveryTool bitAdhesive belt

The invention discloses a box sealing pretreatment device for international trade. The device comprises a shell, wherein an adhesive tape limiting block is fixed in the shell, an outlet is formed at alower left portion of the shell, a pressing block is arranged on an outer side of the outlet, the pressing block is connected with a lower surface of the connecting block through a spring, a side surface of the connecting block is fixed on the shell, a connecting rod is fixed below the shell, a supporting plate is fixed to the bottom of the connecting rod, a handle and an air blower are sequentially fixed to a right face of the shell from top to bottom, a switch is arranged on the handle, a guide pipe is fixed to the side, facing the outlet, of the supporting plate, one end of a pusher is fixed to a surface of the supporting plate, and a tool bit used for cutting adhesive tape is fixed to the other end of the pusher. The device is advantaged in that when a package is packaged, the switchis turned on firstly, so the air blower works, after a to-be-packaged place is blown clean, the adhesive tape is used for packaging, and the position where the adhesive tape is pasted is pressed tightly through the pressing block, so the adhesive tape is pasted more firmly, and the box is prevented from being damaged in the transportation process.

Owner:JIAOZUO UNIV

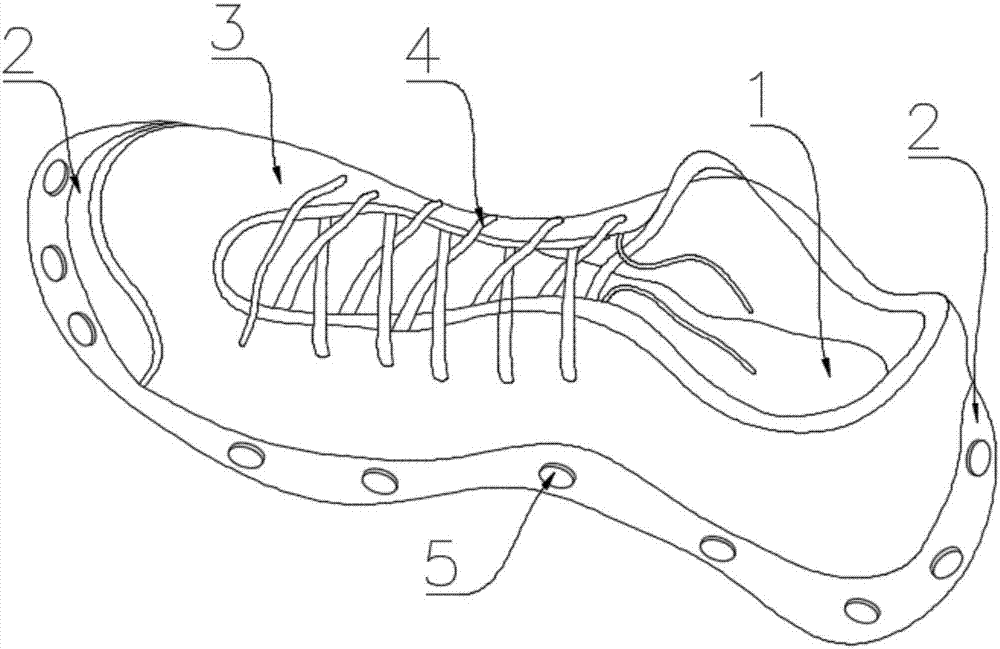

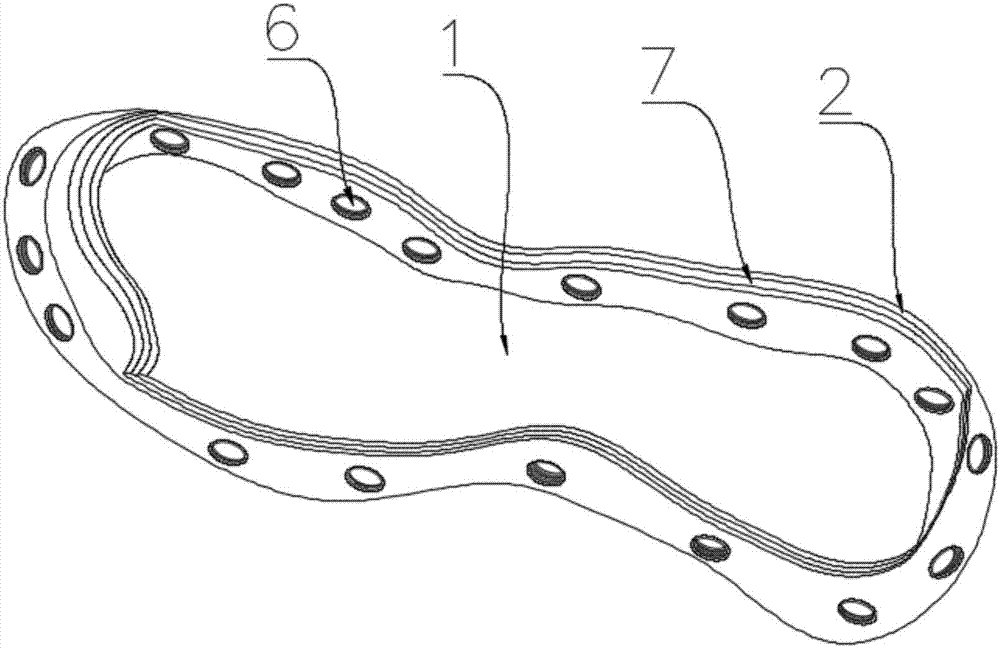

Hydrophobic child's shoes

The invention relates to the field of shoes, in particular to a pair of hydrophobic child's shoes. Each hydrophobic child's shoe comprises a shoe sole, a shoe upper and a shoelace arranged on the shoeupper, wherein a shoe wall is arranged on the periphery of the shoe sole, a side groove is formed in the shoe wall, the shoe upper is detachably fixed and arranged in the side groove and sequentiallycomprises a super-hydrophobic coating, a blending layer, a kapok fiber layer and a Shengma fiber layer from outside to inside, a layer of super-hydrophobic material is arranged on the outer surface of the shoe wall, and the blending layer is formed by weaving Paiste fiber, banana fiber, long polyester fiber, modal fiber, chitin fiber and spandex. The hydrophobic effect and the self-cleaning effect of the pair of hydrophobic child's shoes are better, and the pair of hydrophobic child's shoes are light and durable and have a better practical value.

Owner:FUJIAN QIBU CHILDREN PRODS

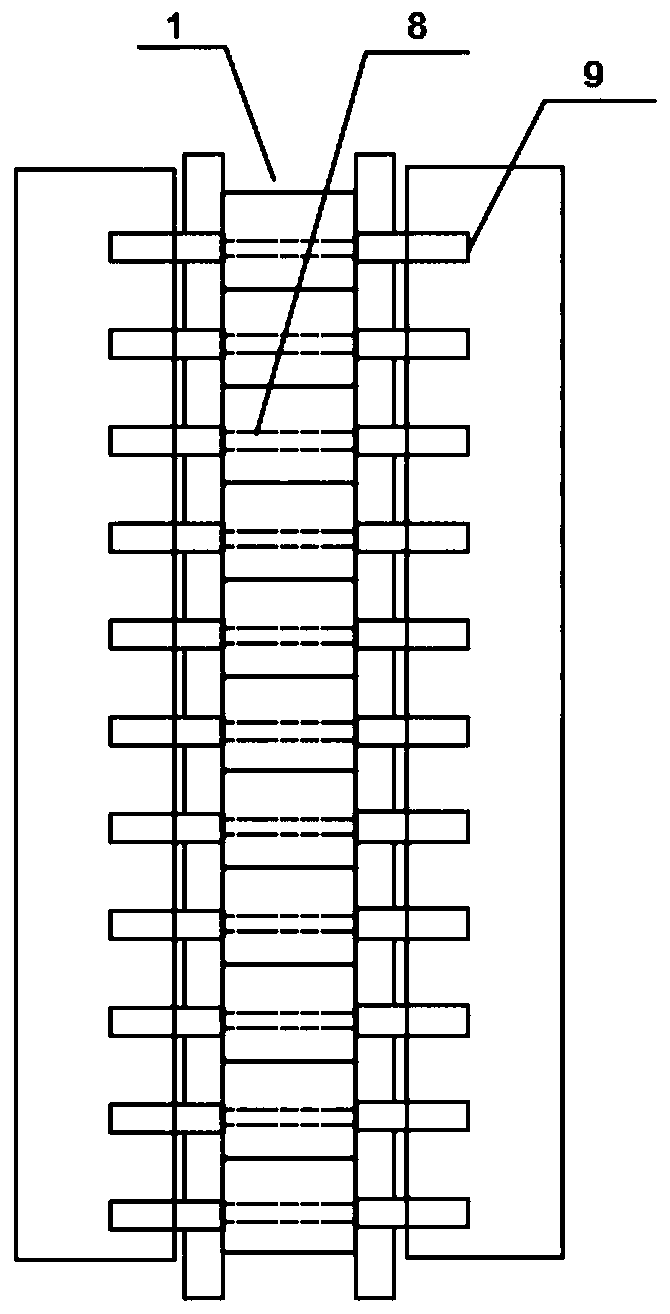

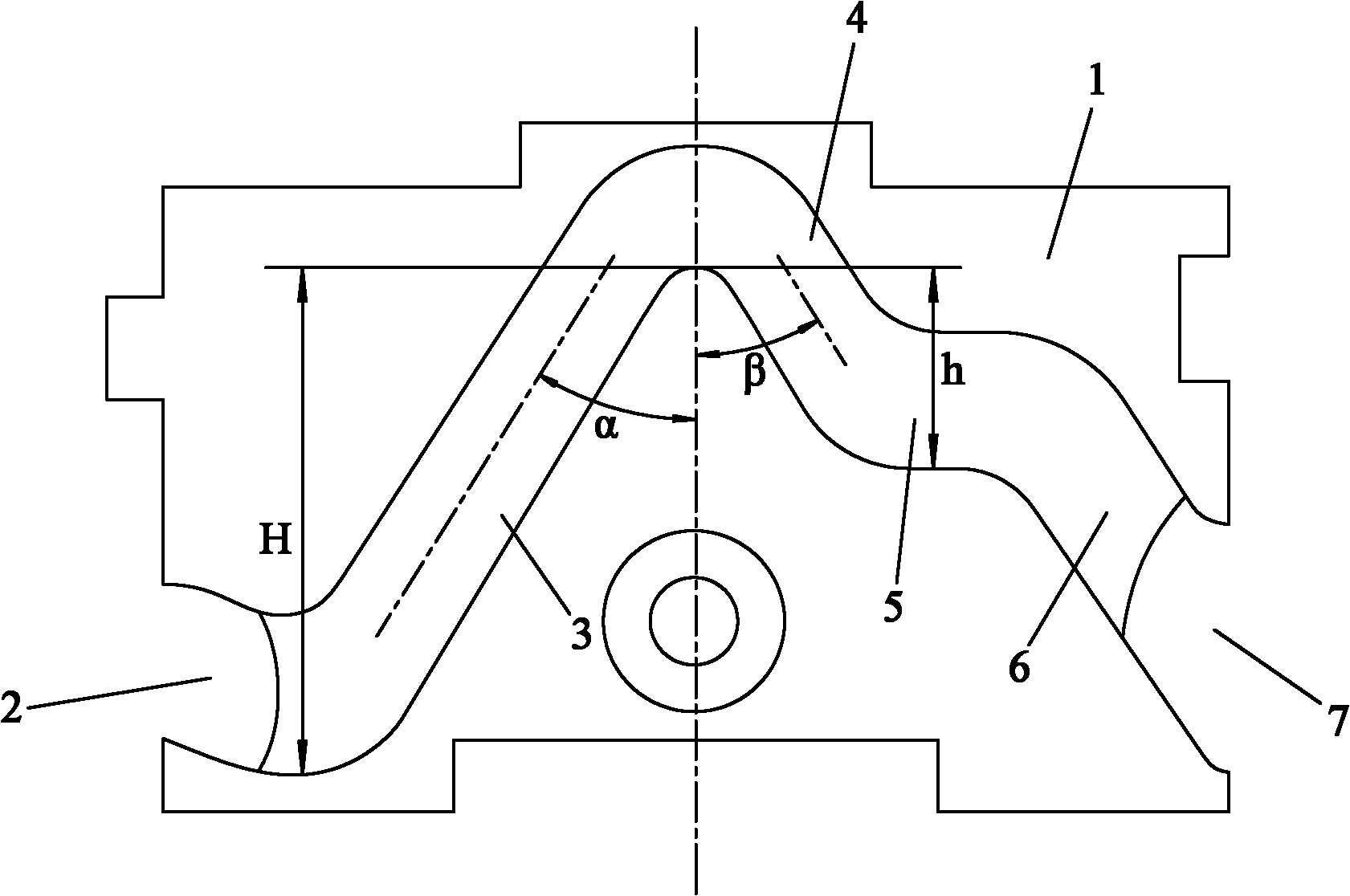

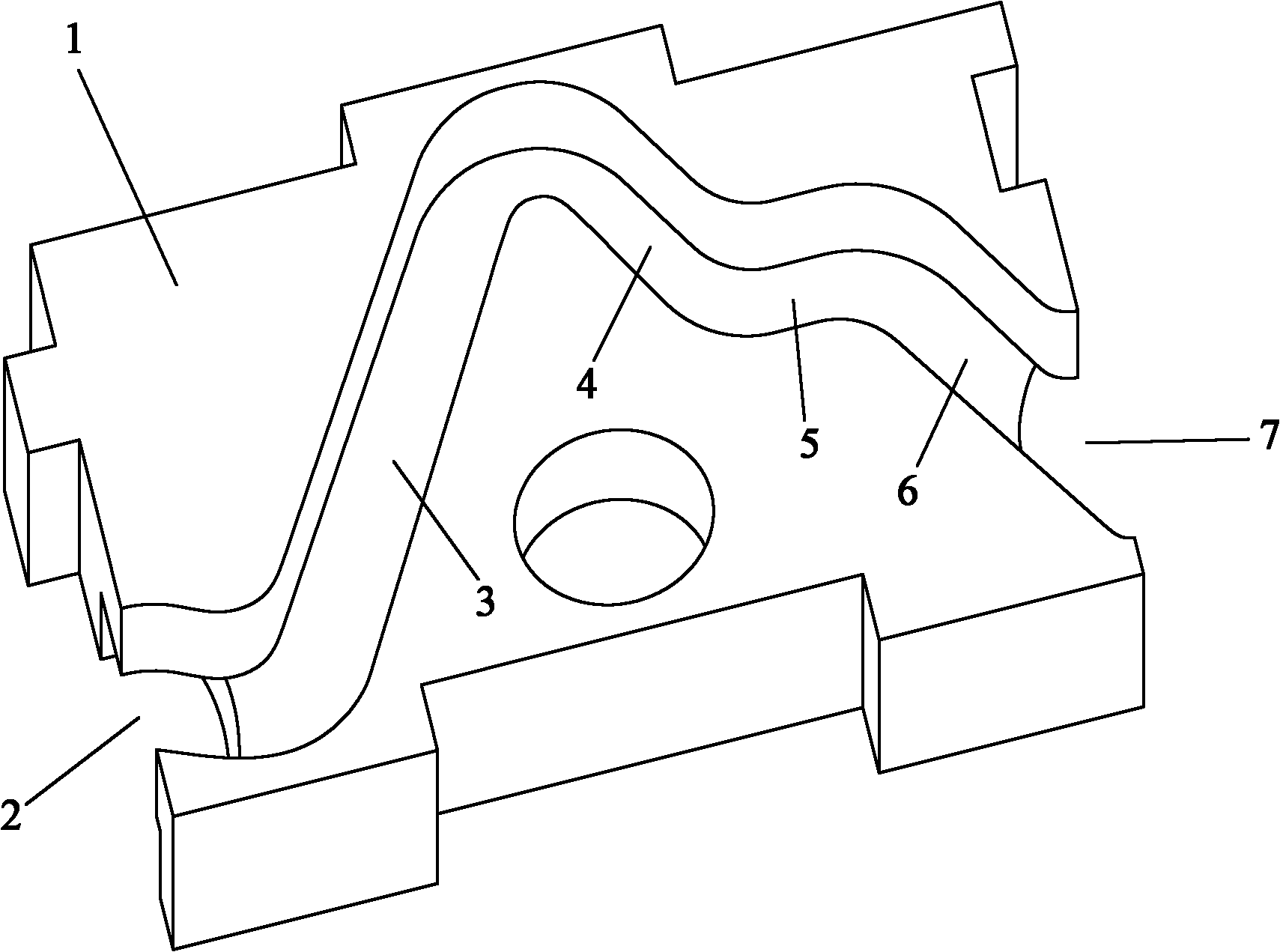

Thick needle triangular block of knitting machine

The invention discloses a thick needle triangular block of a knitting machine. The triangular block body is provided with a knitting guide groove, the knitting guide groove comprises a needle inlet chute section and a return needle chute section, the upper ends of the needle inlet chute section and the return needle chute section are in smooth transition, the lower end of the return needle chute section is connected with a translation groove section, the lower end of the translation groove section is connected with a needle withdrawing chute section, the joints of the return needle chute section and the translation groove section are in smooth transition, and the joints of the translation groove section and the needle withdrawing chute section are also in smooth transition; and the oblique included angle alpha of the needle inlet chute section is 25 to 30 degrees, the oblique included angle beta of the return needle chute section is 25 to 30 degrees, and the height h from the translation groove section to the top of the knitting guide groove is 2 / 5 to 3 / 5 of the height H of the knitting guide groove. By increasing the translation groove section, reasonably setting the height from the translation groove section to the top of the knitting guide groove and matching corresponding knitting processes, the woven fabric has light and thin structure, softness, good air permeability, elasticity and extensibility and low loosening property, is cool to wear, is not easy to stick the skin and is popular among people.

Owner:绍兴维格网络科技有限公司

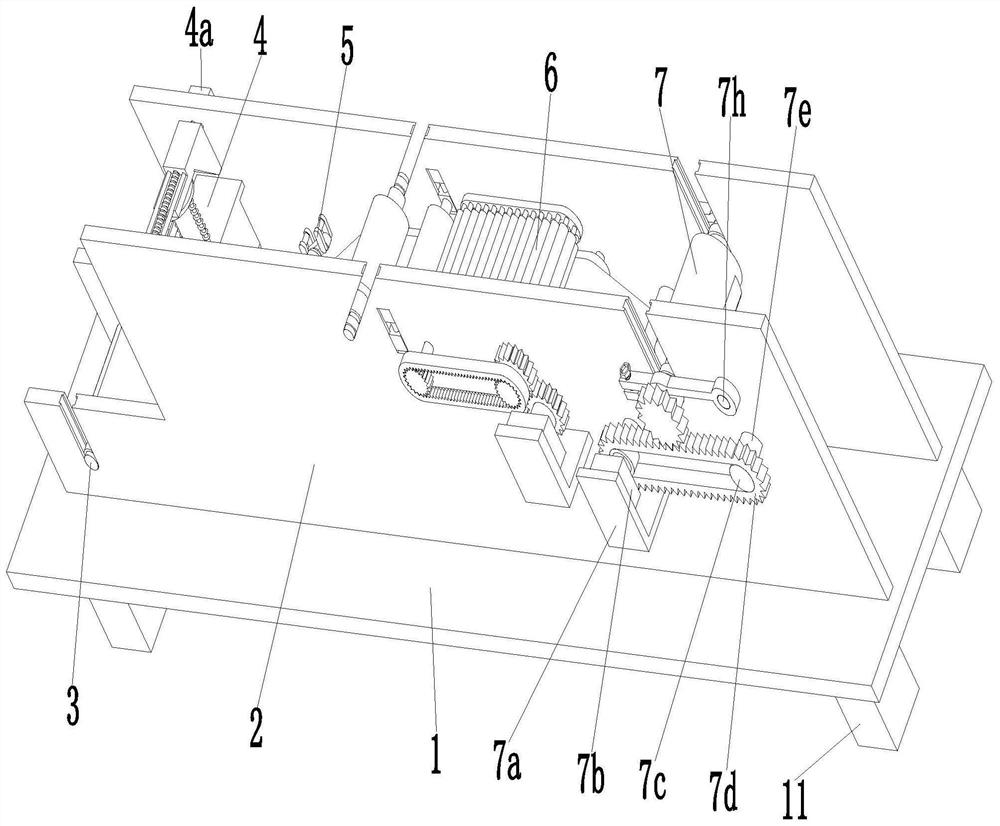

Automatic labeling machine

PendingCN113525841AFully automaticEasy for automatic loadingLabelling machinesLabelling short rigid containersGear wheelControl engineering

The invention relates to the technical field of automatic labeling, in particular to an automatic labeling machine. The automatic labeling machine comprises a base, a feeding table, a discharging table, an automatic feeding and discharging mechanism, an automatic pasting mechanism and an automatic position changing mechanism, the automatic feeding and discharging mechanism comprises a third motor, a first rotating table, a fourth motor and a second rotating table, the automatic pasting mechanism comprises a rotating seat, a fixed support and a position changing table, and the automatic position changing mechanism comprises a position changing motor, a second position changing gear, a contact switch and a rolling wheel. By arranging the automatic feeding and discharging mechanism, automatic feeding of products to be pasted and automatic discharging of pasted products are facilitated, by arranging the automatic pasting mechanism, so that the labels can be automatically pasted on the outer walls of the products, and by arranging the automatic position changing mechanism, so that the device can continuously and automatically paste the labels.

Owner:刘松鑫

Antifog sheet

InactiveCN104842613ANot easy to scratchNot easy to pasteSynthetic resin layered productsAntioxidantExtinction

The invention discloses an antifog sheet, which comprises a base material layer, a metal plastic sheet layer, reflection particles, a decorative film, an extinction film and a silicone oil layer. The base material layer is prepared by blending a PBT material with a PET material and adding a catalyst, a flame retardant and an antioxidant, the metal plastic sheet layer, the reflection particles, the decorative film, the extinction film and the silicone oil layer are disposed on the base material layer surface integratedly in order, and the silicone oil layer is completed by a silicone oil spray system disposed above a coiling apparatus. The antifog sheet provided by the invention has the characteristics of flame retardance, high temperature resistance, oxidation resistance, low production cost, difficult scratching of silicone oil sprayed surface, and reeling part sticking.

Owner:浙江中盛新材料股份有限公司

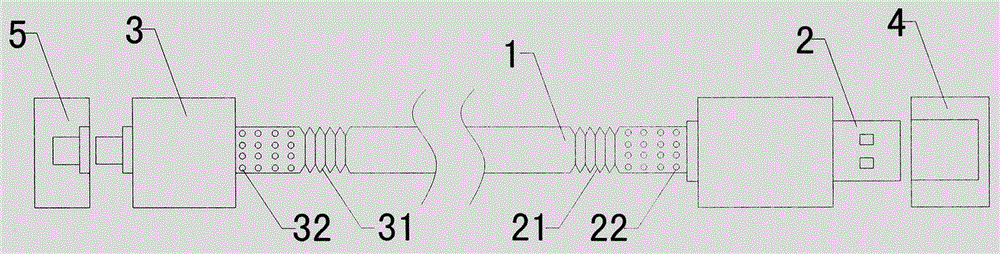

Novel data line

InactiveCN105428908ASolve the problem of not easy to unplug from the chargerExtended service lifeCouplings bases/casesEngineeringUSB

The invention relates to a novel data line. The data line comprises a connection line as well as a USB plug and a charging plug connected to two ends of the connection line, wherein a first extended part is arranged on the side, connected with the connection line, of the USB plug; frictional points are arranged on the surface of the first extended part; a second extended part is arranged on the side, connected with the connection line, of the charging plug; and frictional points are arranged on the surface of the second extended part. Therefore, the problem that the charging plug is pulled out of a mobile phone is solved, the service life of the data line is prolonged, and the use cost is reduced.

Owner:解家凤

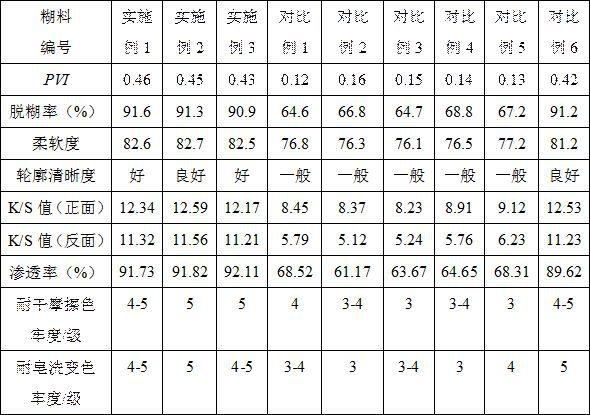

Polyacrylic acid synthetic thickener for reactive dye printing of viscose fabric and preparation method and application of polyacrylic acid synthetic thickener

ActiveCN112411208AIncrease moisture contentNot easy to pasteDyeing processTextile printerPolymer science

The invention relates to a polyacrylic acid synthetic thickener for reactive dye printing of viscose fabric and a preparation method and application of the polyacrylic acid synthetic thickener. The thickener is prepared by the following steps: carrying out a grafting reaction on methacrylic acid and starch to obtain a methacrylic acid grafted starch modified solution, carrying out a polymerizationreaction on the methacrylic acid, the methacrylic acid grafted starch modified solution and 3-methacryloxypropyletris(trimethylsiloxy)silane to obtain a polyacrylic acid aqueous solution, and finallydistilling under reduced pressure conditions. The polyacrylic acid synthetic thickener prepared by the invention is used for reactive dye printing of the viscose fabric; the prepared printed fabric has the characteristics that a de-gelatinization rate is higher than 90%, the softness is good, the contour definition is high, the permeability is higher than 91%, and the color fastness to dry rubbing and the color fastness to soaping are high, and has a good application prospect.

Owner:WUHAN TEXTILE UNIV

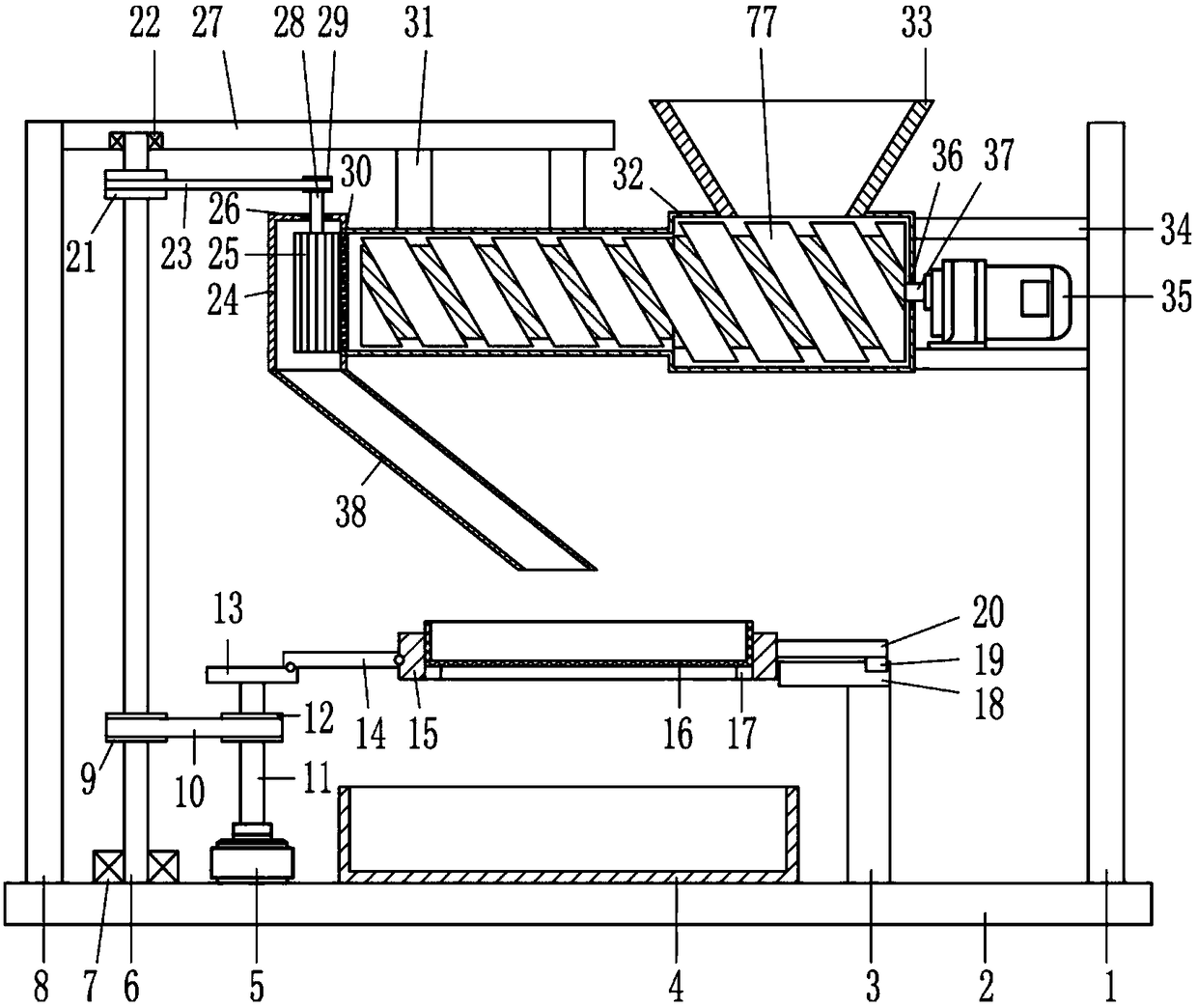

Multifunctional pelletizer for organic fertilizer

InactiveCN109126629AImprove granulation efficiencyExtend the movement timeGranulation by material expressionAgricultural engineeringOrganic manure

The invention belongs to the field of production of organic fertilizers, and particularly relates to a multifunctional pelletizer for an organic fertilizer. By the multifunctional pelletizer for the organic fertilizer, four operations including pelletizing, drying, cooling and sieving can be carried out simultaneously, the pelletizing efficiency of the fertilizer is improved, and the yield of fertilizer particles is ensured. The multifunctional pelletizer for the organic fertilizer comprises a screw extrusion rod, a first mounting plate, an extrusion frame, a feeding hopper, a second connecting plate, a second motor, a fourth bearing block, a fourth rotating shaft, a discharging hopper and the like; the first mounting plate is fixedly connected to a side of a second mounting plate, and a third mounting plate is fixedly connected to another side of the second mounting plate; and a fourth mounting plate is fixedly connected to the top of the third mounting plate. The fertilizer is integrally treated by the four steps of pelletizing, drying, cooling and sieving, and the pelletizing efficiency of the organic fertilizer is improved.

Owner:邹乐文

Pipeline for conveying yellow phosphorus tail gas

InactiveCN108592644AImprove adsorption capacityWill not accumulate and clogWaste heat treatmentInlet channelEngineering

The invention discloses a pipeline for conveying yellow phosphorus tail gas. The pipeline comprises a conveying pipeline, a filtering plate and a separating plate, wherein an air inlet channel is formed inside the left end of the conveying pipeline, a first pressing block is connected to the lower surface of a first pressing rod, a filter plate is located inside a transition cavity, and the frontside surface of a push block is connected with a first movable rod; a second movable rod is connected with a first gear disc, a rotating block is installed on the outer surface of a second gear disc,the upper surface of an ejected plate is connected with a force transmission rod, the separating plate is positioned on the right side of the first pressing rod, and the upper surface of a second pressing block is connected with a second pressing rod; and a rotating shaft is located in the center of a balance frame, and an air outlet channel is formed in the outer portion of the balance frame. Thepipeline for conveying yellow phosphorus tail gas does not need manual intervention, gas can be automatically conveyed, time and labor are saved, and a filtering device is arranged, the yellow phosphorus tail gas is not prone to be attached on the inner surface of the pipeline, and impurities in the tail gas cannot accumulate and block the pipeline.

Owner:贵州开阳川东化工有限公司

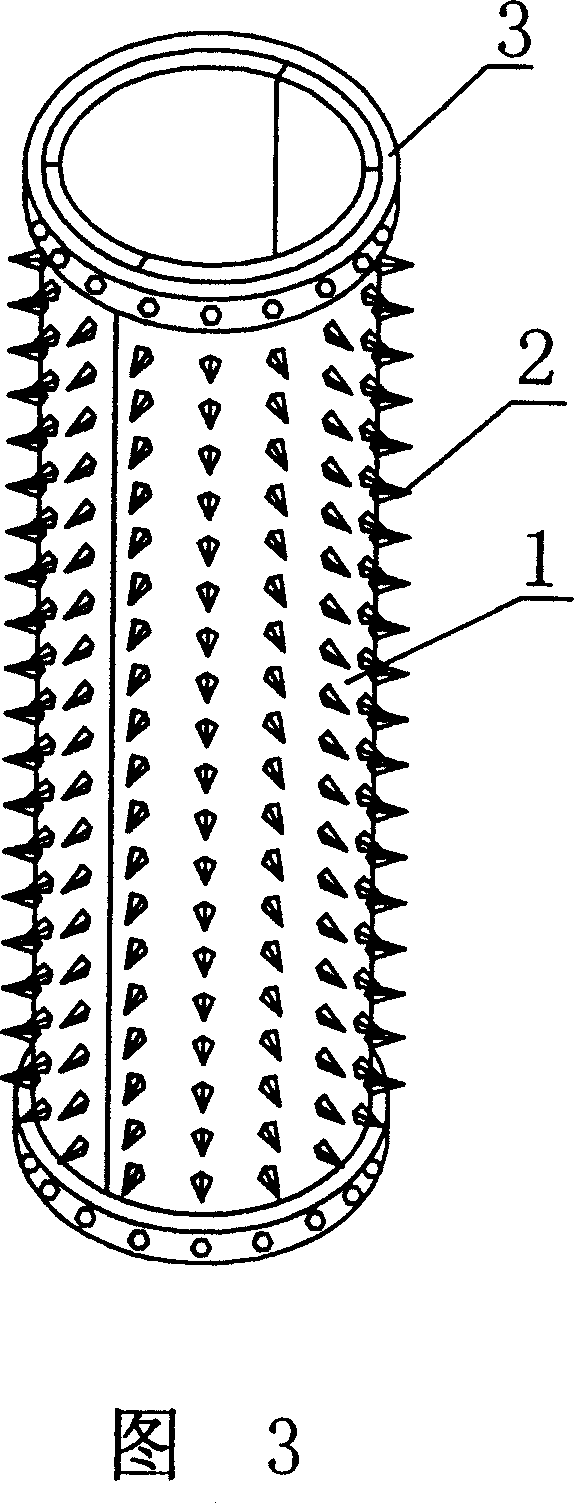

Anti sticking up environmental protective set

InactiveCN101093049AGuaranteed cleanlinessAvoid stickingConstructions elementsEngineeringSurface shape

This invention relates to a stick-proof environmental protection device including a body adaptive to the protection surface of a covered fixity, in which several pin-like or corner-like protruding things for preventing propagation articles from adhering to the body are set on the outer surface of the body to prevent adhesion of things effectively.

Owner:张发胜

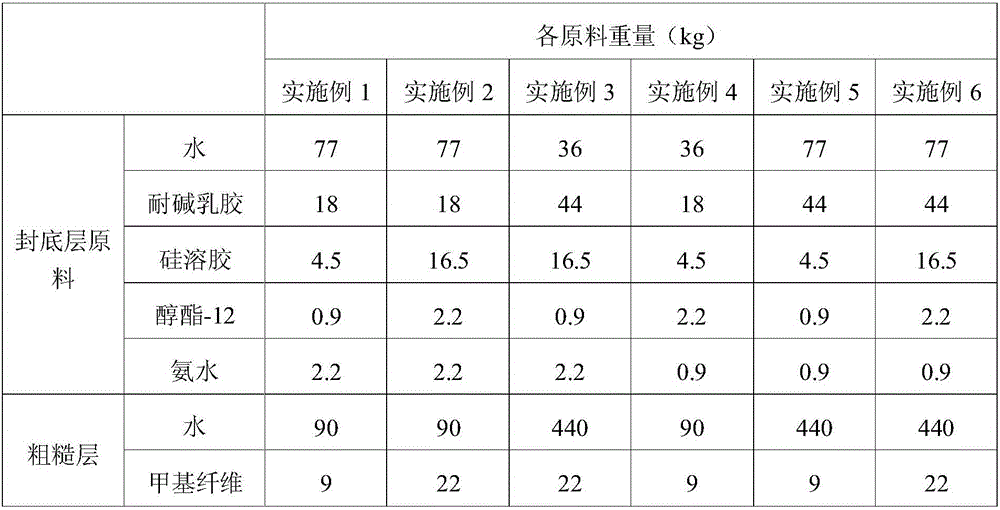

Composite coating and marker

ActiveCN106479233AImprove tear resistanceHigh tear strengthStampsAnti-corrosive paintsCoated surfaceHydrogen

The invention provides a composite coating and a marker. The composite coating comprises a bottom sealing layer and a rough layer, wherein the bottom sealing layer covers a substrate material; the bottom sealing layer is prepared from the raw materials in parts by weight: 36 to 77 parts of water, 0.9 to 2.2 parts of a first pH (Potential of Hydrogen) regulator and 22 to 61 parts of a toughening agent; the rough layer is located at one side, far away from the substrate material, of the bottom sealing layer; the quantity of bulges on the surface of the rough layer is 25 / cm<2> to 45 / cm<2>. The bottom sealing layer has relatively high tear resistance strength so that the tear resistance performance of the whole coating can be obviously improved; an anti-collision marker utilizing the coating has good breakage-proof performance. The quantity of the bulges on the surface of the rough layer is 25 / cm<2> to 45 / cm<2>, so that the surface of the coating has obvious roughness; when the coating is used as the marker, adlets are not easy to stick on the surface of the marker and the adlets stuck on the surface are also very easily removed as a whole. Therefore, the problems of sticking and removing the adlets on the marker can be solved.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

Modified peach gum paste for silk fabric acid dye printing and its preparation method and application

ActiveCN112142869BGood water solubilityHigh molecular weightDyeing processTextile printerPolymer science

The invention relates to a modified peach gum paste for acid dye printing of silk fabrics, a preparation method and application thereof. The paste in the present invention is prepared from peach gum through carboxymethyl modification, sulfonation modification and crosslinking modification. The peach gum paste prepared by the invention is used for acid dye printing of silk fabrics, and the prepared printed fabric has the characteristics of depaste rate higher than 90%, good softness, high contour definition, permeability higher than 86% and dry friction resistance It has the characteristics of high color fastness and soaping color fastness, and has a good application prospect.

Owner:WUHAN TEXTILE UNIV

A plastic pellet granulator

The invention relates to the field of plastic processing, in particular to a plastic granulator and aims to solve the problem of plastic particle adhesion and improve plastic particle size uniformity.The plastic granulator comprises a first mounting plate, a first collecting frame, supporting seats, an air drying frame, a first bearing seat, a first pulley, a first flat belt, a fourth rotating shaft, a third mounting plate and the like. A second mounting plate is fixedly connected to a lateral portion of the first mounting plate, and the air drying frame is fixedly connected to a lateral portion, away from the second mounting plate, of the first mounting plate. The first bearing seat is embedded to a lateral portion of the air drying frame. The plastic granulator has advantages that the plastic particles accumulated after granulation are less prone to adhesion, and the manufactured plastic particles can be screened and classified to guarantee plastic particle uniformity.

Owner:惠州市启达环美科技有限公司

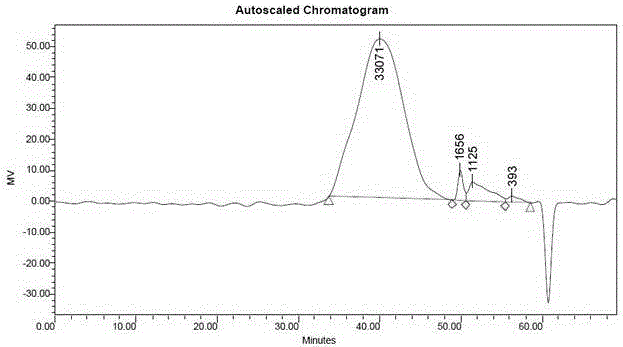

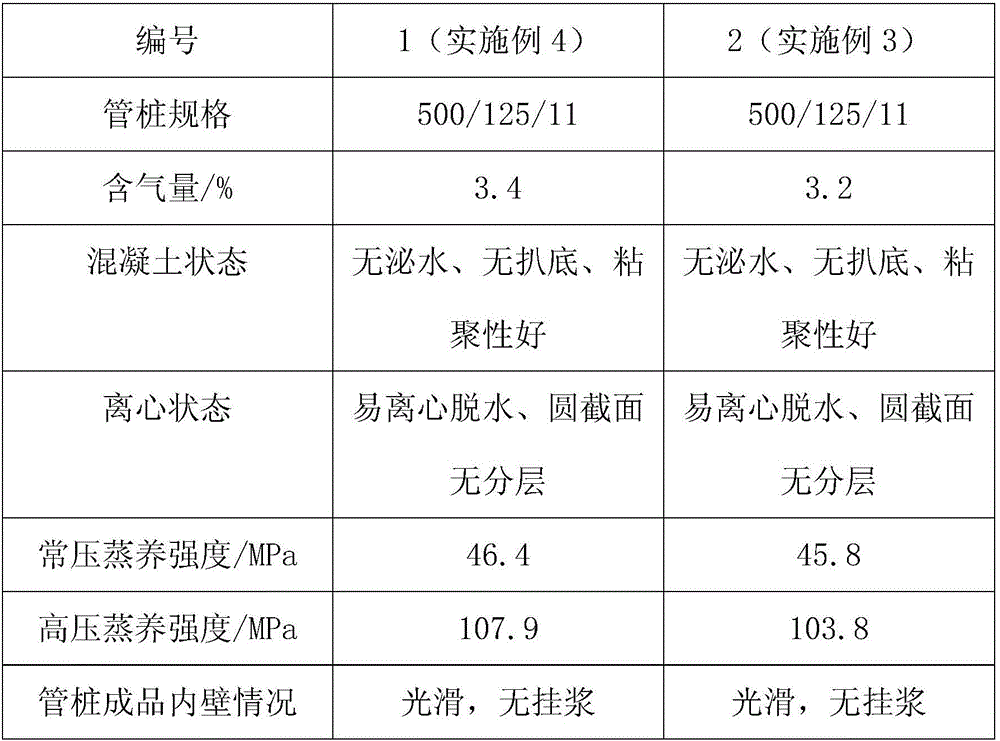

A polycarboxylate water reducer for prestressed high-strength concrete pipe piles and its application

The invention discloses a polycarboxylic acid water reducer for a pre-stressed high-strength concrete pipe pile. The water reducer comprise the following components: methallyl polyoxyethylene ether 2400, isoprenol polyoxyethylene ether 2400, acrylic acid, maleic anhydride, sodium methacryl sulfonate, N-hydroxymethyl acrylamide, a 30% sodium hydroxide solution, a chain transfer agent, an oxidant, a reductant, a water softener and a 30% sodium hydroxide solution used for adjusting the pH value of the solution, wherein the mass ratio of methallyl polyoxyethylene ether 2400 to isoprenol polyoxyethylene ether 2400 is 1:(0.5-2) and the mass ratio of acrylic acid to maleic anhydride is 1:(0-1). The polycarboxylic acid water reducer disclosed by the invention is reliable in quality and when the polycarboxylic acid water reducer is applied in concrete, the concrete has the advantages of low entrained air, short setting time, high strength, good cohesiveness, easiness for centrifugal dehydration and less in possibility of pulp hanging.

Owner:太仓新亚逊生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com