Efficient environment-friendly plastic granulation device

An environmentally friendly and plastic technology, applied in the field of plastic processing, can solve the problems of unfavorable promotion of plastic granulators, uncontrollable cooling effect, single use range, etc., to avoid burning phenomenon, good washing effect, and avoid secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

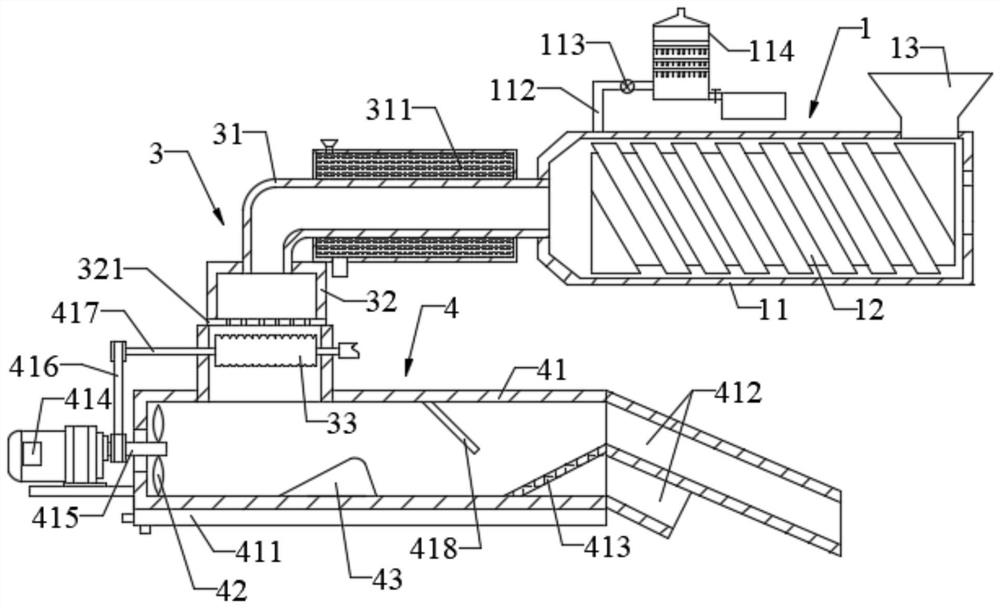

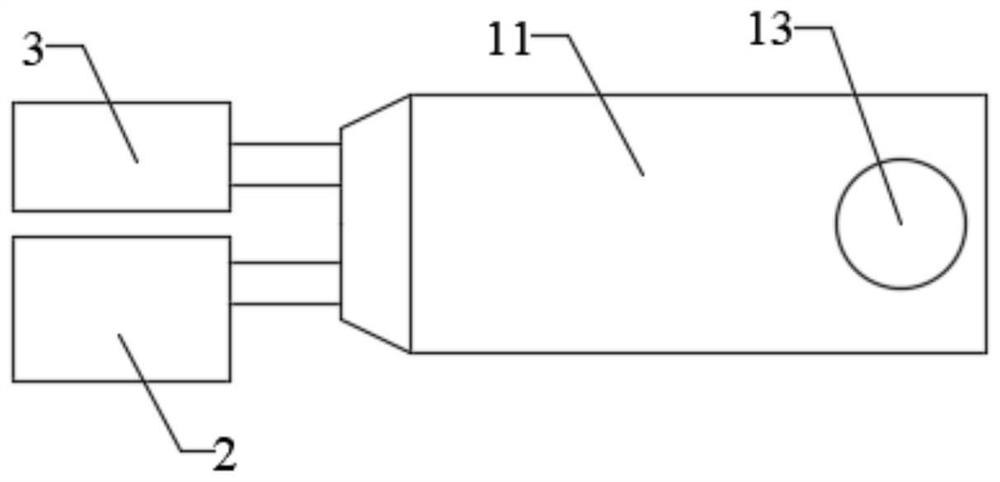

[0055] A high-efficiency and environment-friendly plastic granulator, including a feeding extrusion device 1, a hot cutting device 2, a cold cutting device 3 and a cooling discharge device 4;

[0056] The feeding extrusion device 1 comprises a first extrusion chamber 11, a first extrusion screw 12 and a feed hopper 13, and the feed hopper 13 is arranged on the top of one end of the first extrusion chamber 11, and the first extruder The output screw 12 is rotated and installed in the first extrusion chamber 11. The end of the first extrusion chamber 11 away from the feed hopper 13 is provided with a feeding end 111. The feeding end 111 is funnel-shaped, and the feeding end 111 is funnel-shaped. The end 111 is provided with a hot-cut feeding port and a cold-cut feeding port, and the hot-cut feeding port and the cold-cut feeding port are both provided with sealing valves;

[0057] The hot cutting device 2 includes a feeding barrel 21, a second extrusion screw 22, an extrusion bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com