Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Separation will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DNA coding compound library and compound screening method

ActiveCN110093408ASeparation will notMicrobiological testing/measurementLibrary screeningDna encodingChemistry

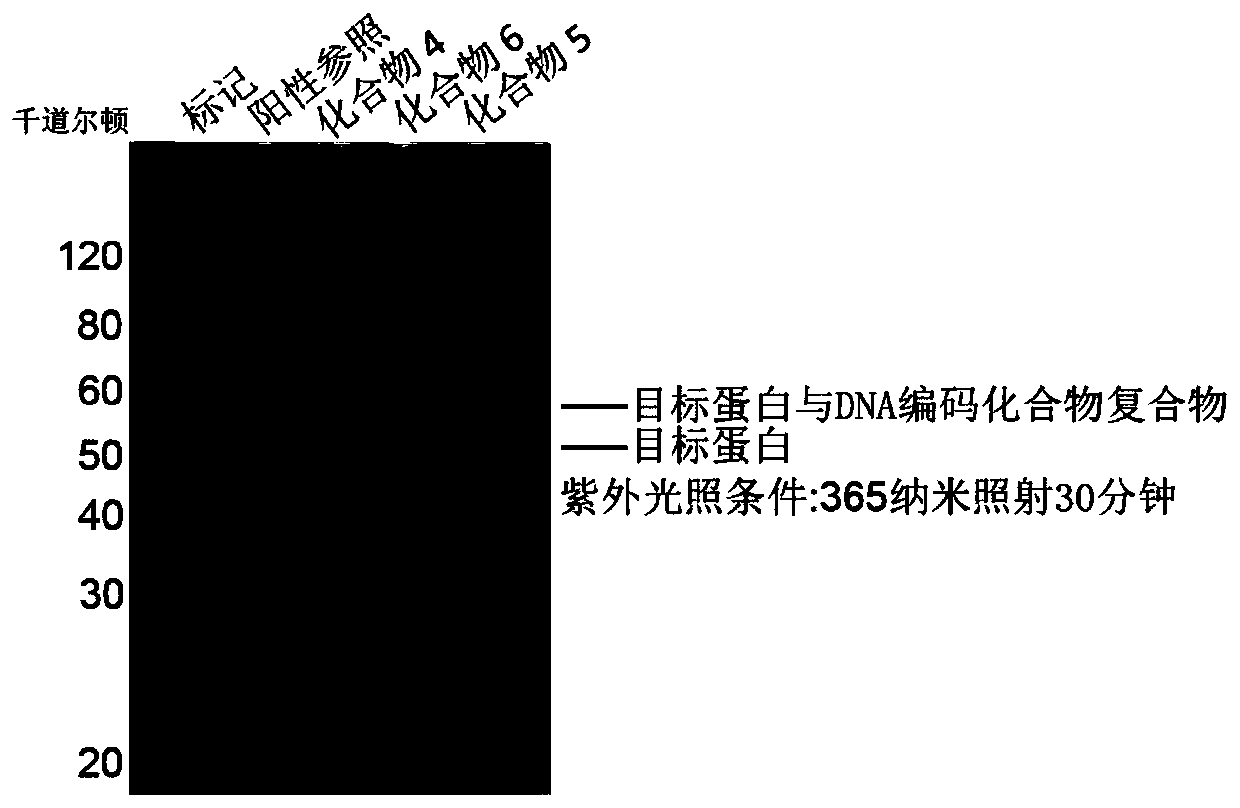

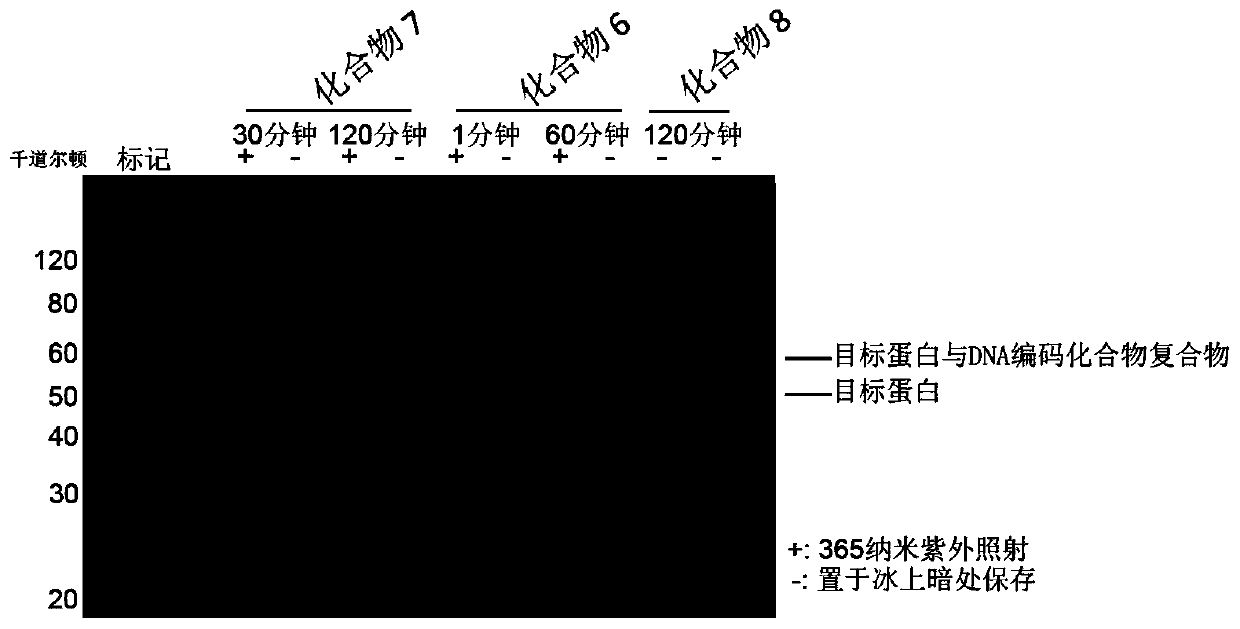

The invention provides a DNA coding compound, a compound library and a compound screening method. Purifying or fixing on target protein is not needed by using the DNA coding compound library to perform screening, so that the DNA coding compound library can be suitable for the screening of complex systems such as non-immobilized protein, cell transmembrane protein and cell lysate. In addition, after the DNA coding compound covalently crosslinks with protein, the protein and DNA label sections are all covalently linked, various separating conditions, such as electrophoretic separation and strongelution conditions, can be tolerated, and the protein and the DNA label sections cannot be separated due to the harsh separating conditions.

Owner:HITGEN INC

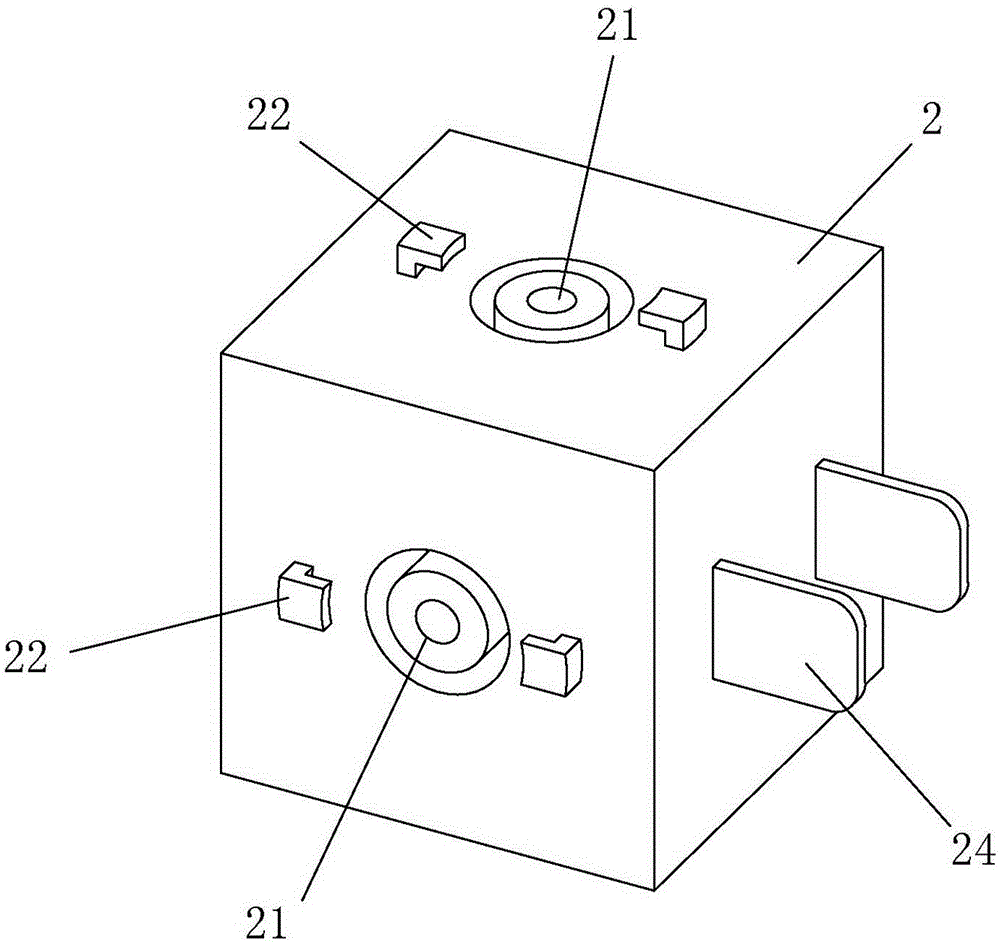

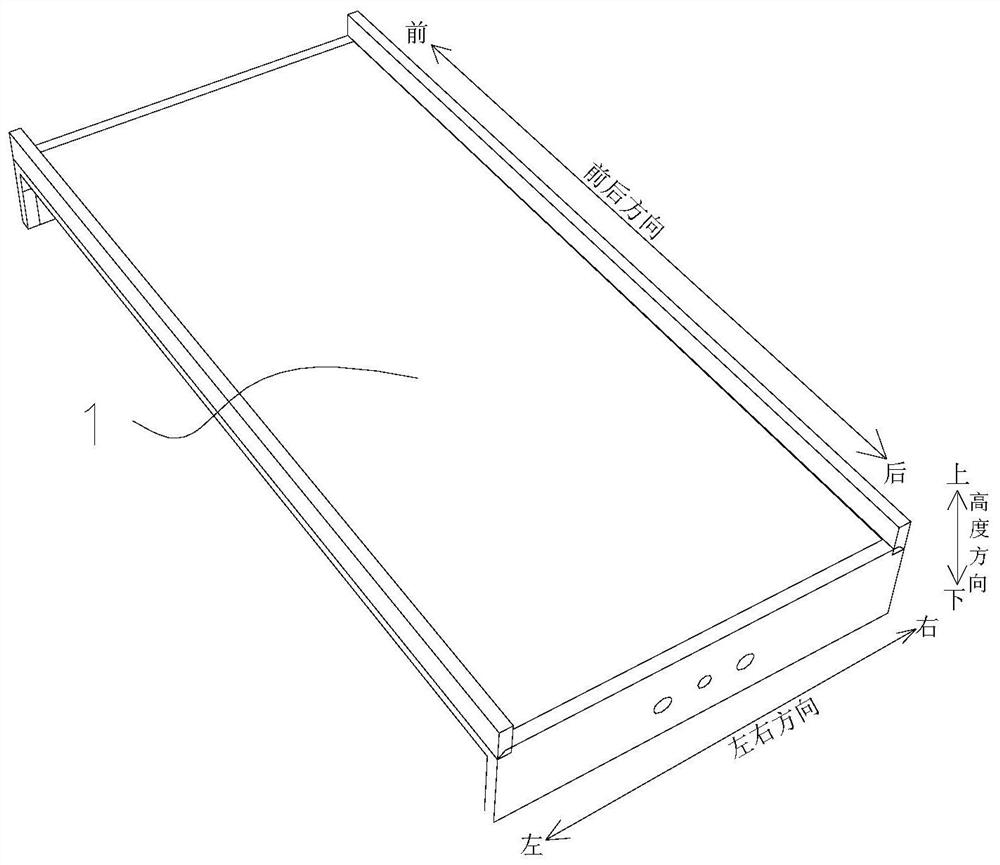

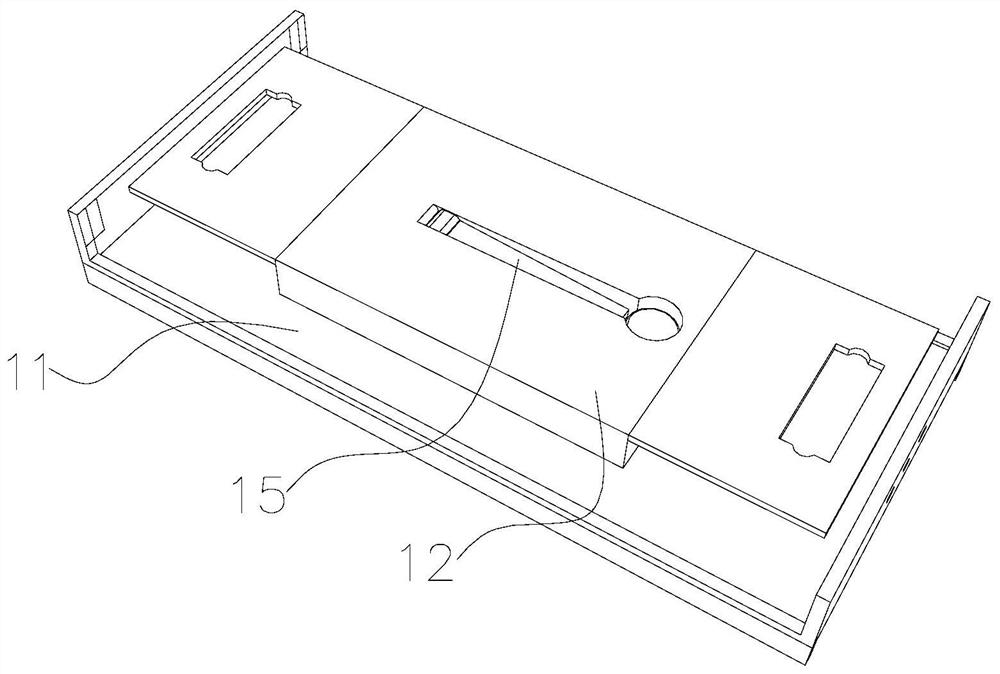

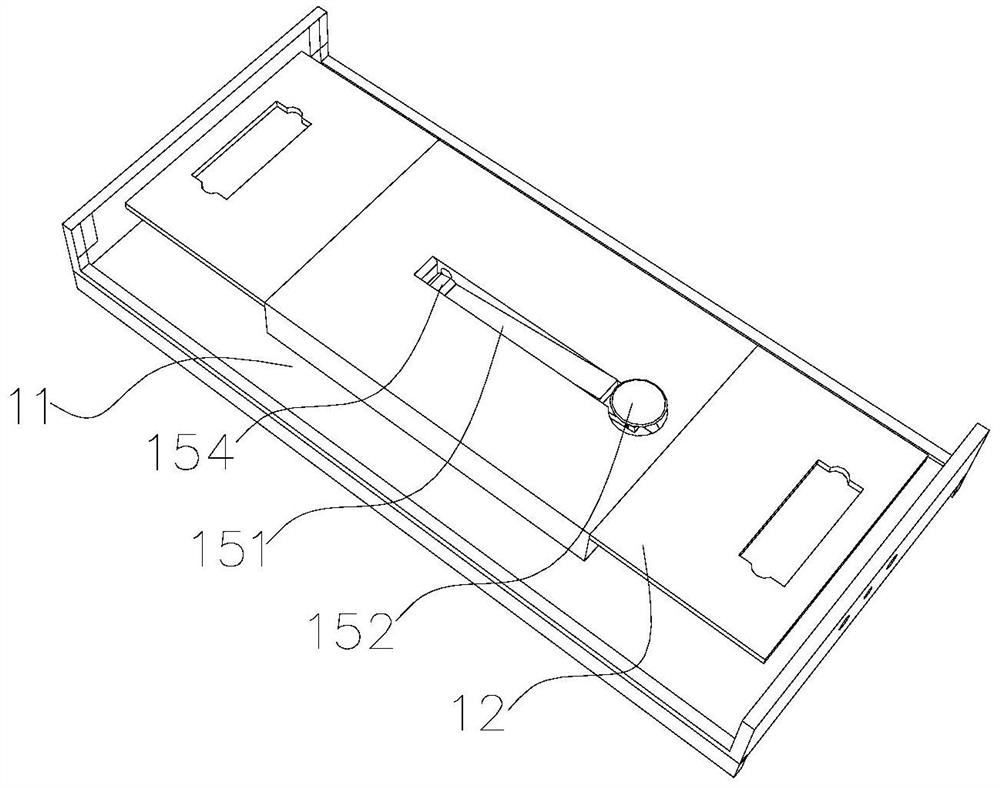

Washing-agent putting box of roller washing machine

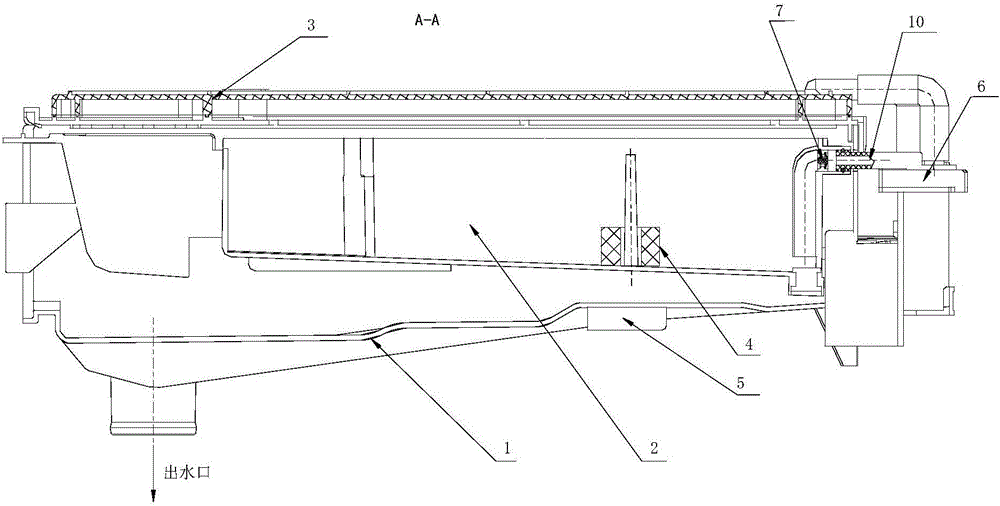

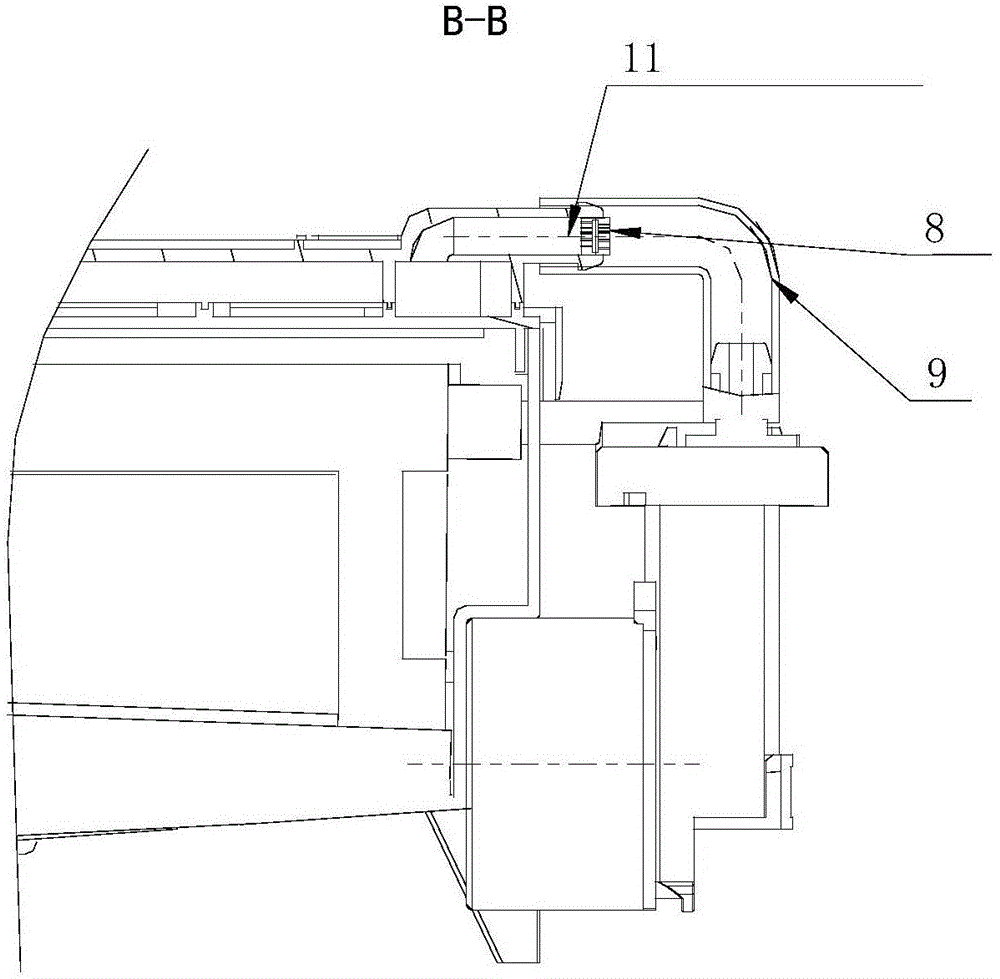

InactiveCN105887423ANo leakage problemStructure optimization and streamliningOther washing machinesTextiles and paperWater dischargeEngineering

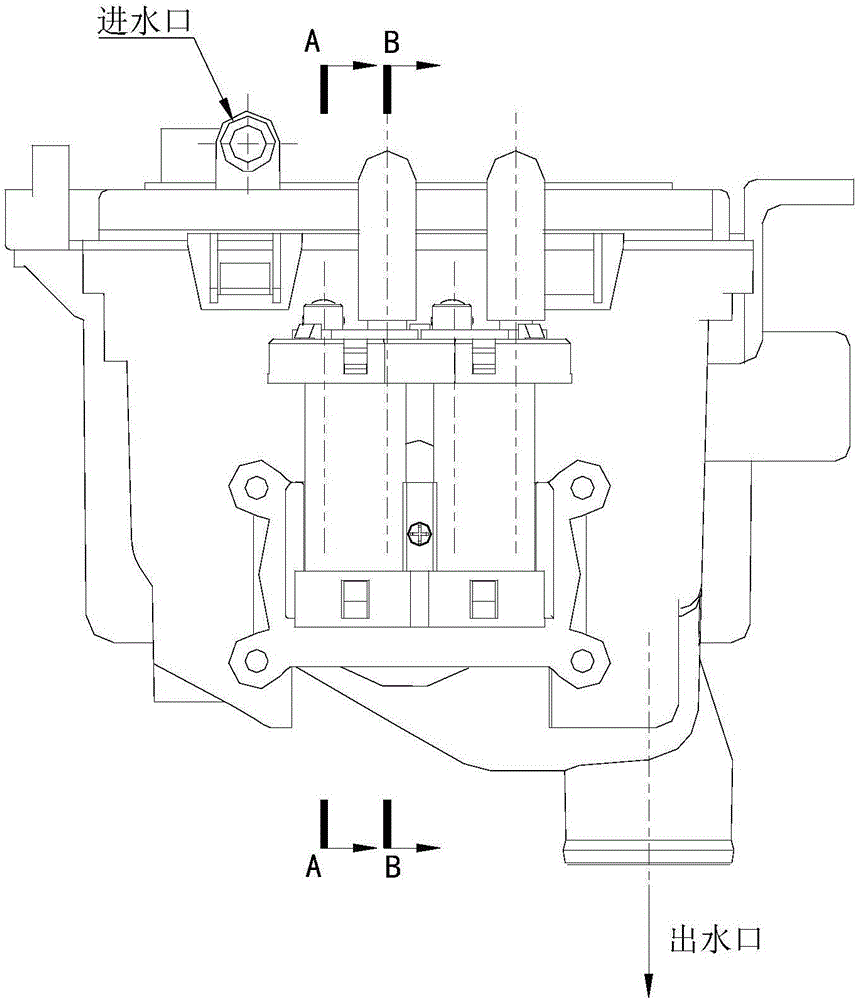

The invention discloses a washing-agent putting box of a roller washing machine. The washing-agent putting box comprises a washing liquid box, a water discharging box, a shower assembly and an automatic putting pump. A liquid inlet is formed in the top of the washing liquid box and connected with the automatic putting pump through a one-way valve, the automatic putting pump is located on the washing liquid box, and puts washing agents into the shower assembly through a liquid conveying pipe. According to the washing-agent putting box of the roller washing machine, the automatic putting pump is arranged at the top of the washing liquid box, the high liquid-inlet mode and the high liquid-outlet mode are adopted, and it is avoided that the large quantity of washing agents are leaked when a drawer box of the washing machine is drawn out; as the putting time of washing liquid of the washing machine is shorter than the water flushing time of the washing machine, after the washing agents are added into the washing machine, water flushing is further continuous, residual washing agents in a washing-agent washing pipe are flushed away through water, and when a water inlet is stopped to conduct water flushing, the liquid conveying pipe reabsorbs part of water in a pump-washing-agent liquid inlet through the negative pressure effect, and it is avoided that the liquid inlet is dried up and plugged.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

High temperature substrate protective structure

ActiveCN101842855AQuality improvementImprove insulation performanceLayered product treatmentSynthetic resin layered productsEnvironmental resistancePolymer coatings

Substrate protective structures, including high performance polymers and polymer coatings from 1 to over 2500 mils thick, are disclosed. The structures protect metal and other surfaces with heat resistant, abrasion resistant, and chemical inert polymers. The structures are applied to the substrate in a manner that provides easy processing of curved and bent surfaces, increased adhesion of metal to polymer, greater resistance to mechanical and thermal stresses that cause cracking and de-lamination, and increased environmental resistance.

Owner:POLYMICS

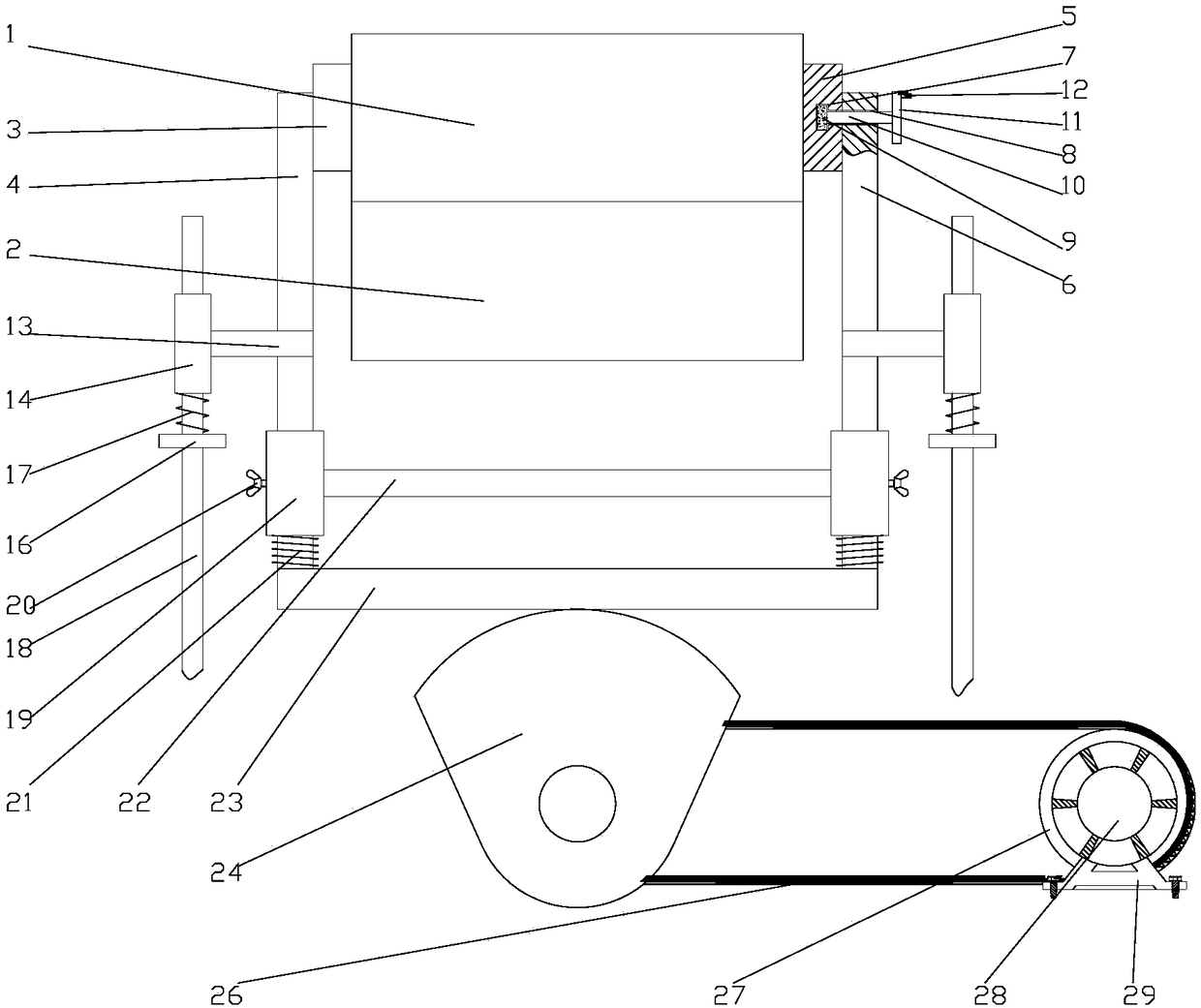

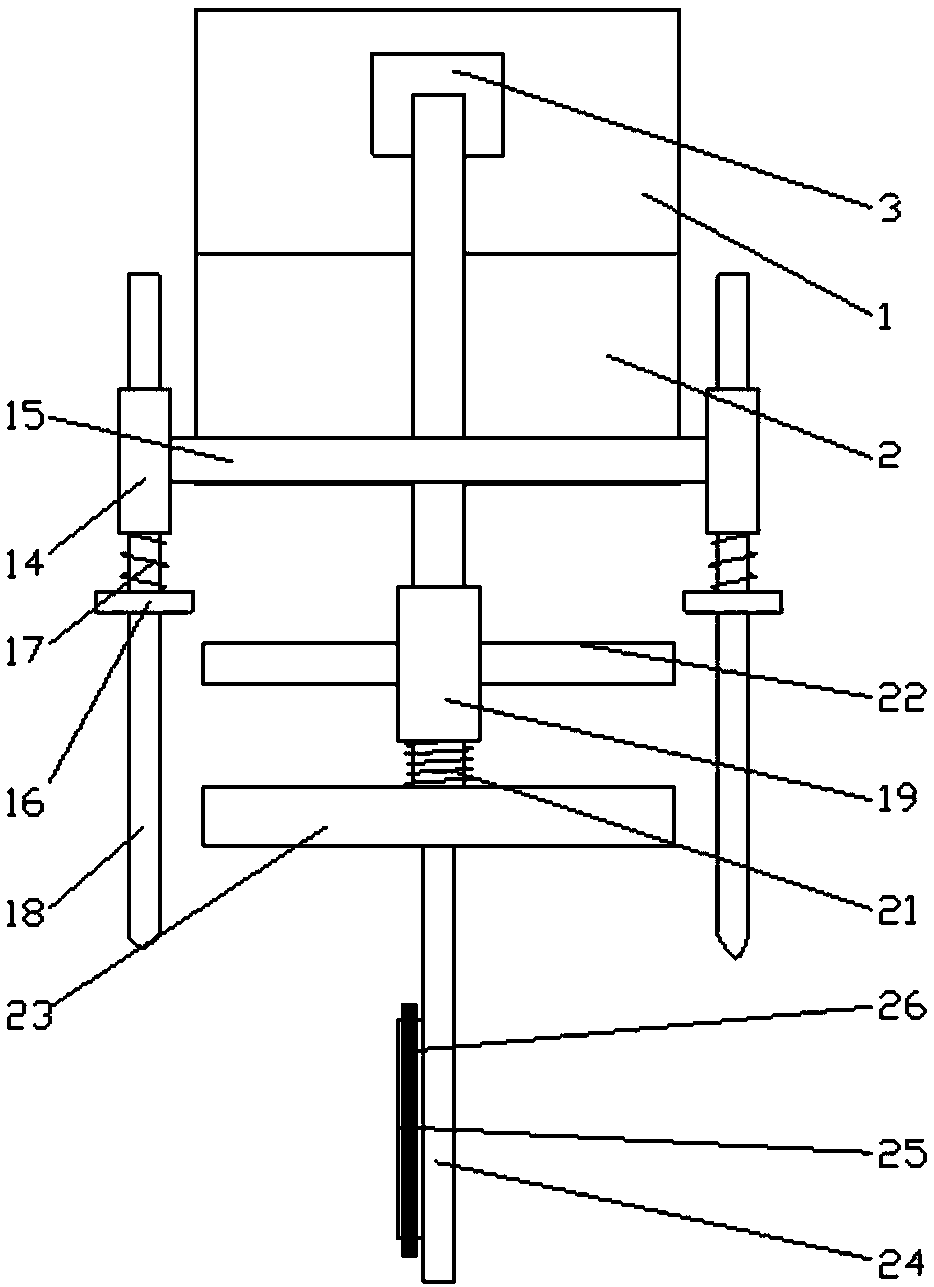

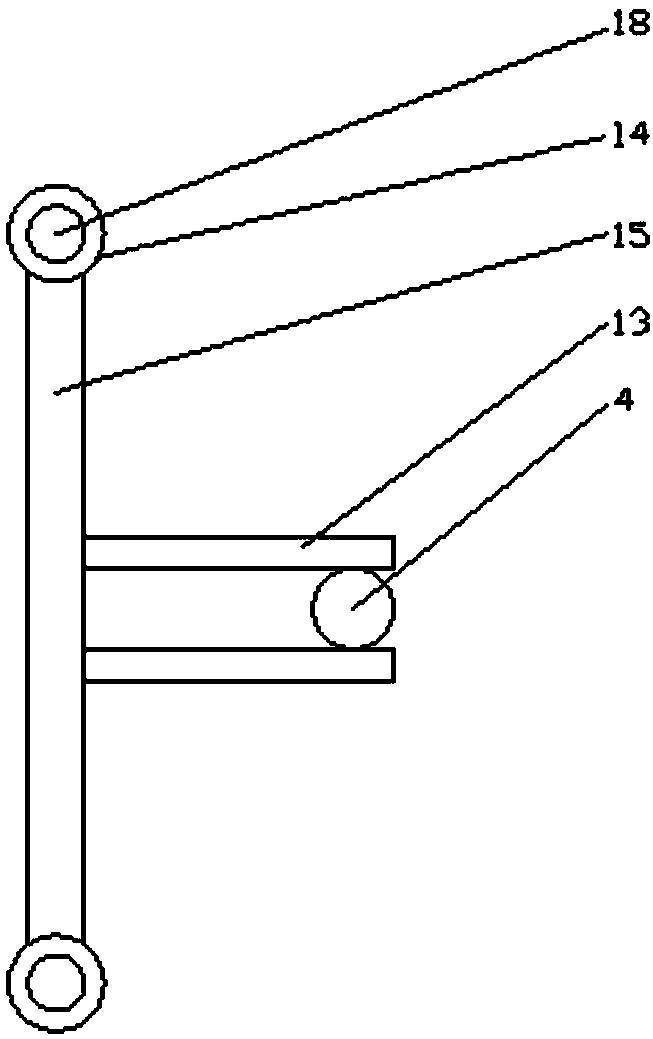

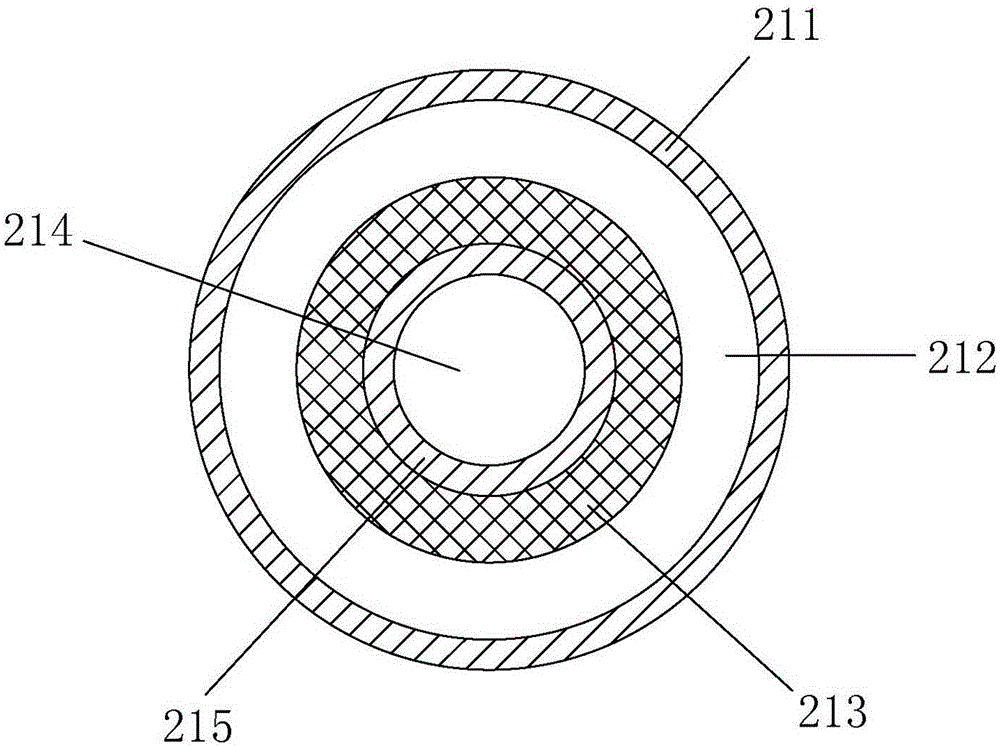

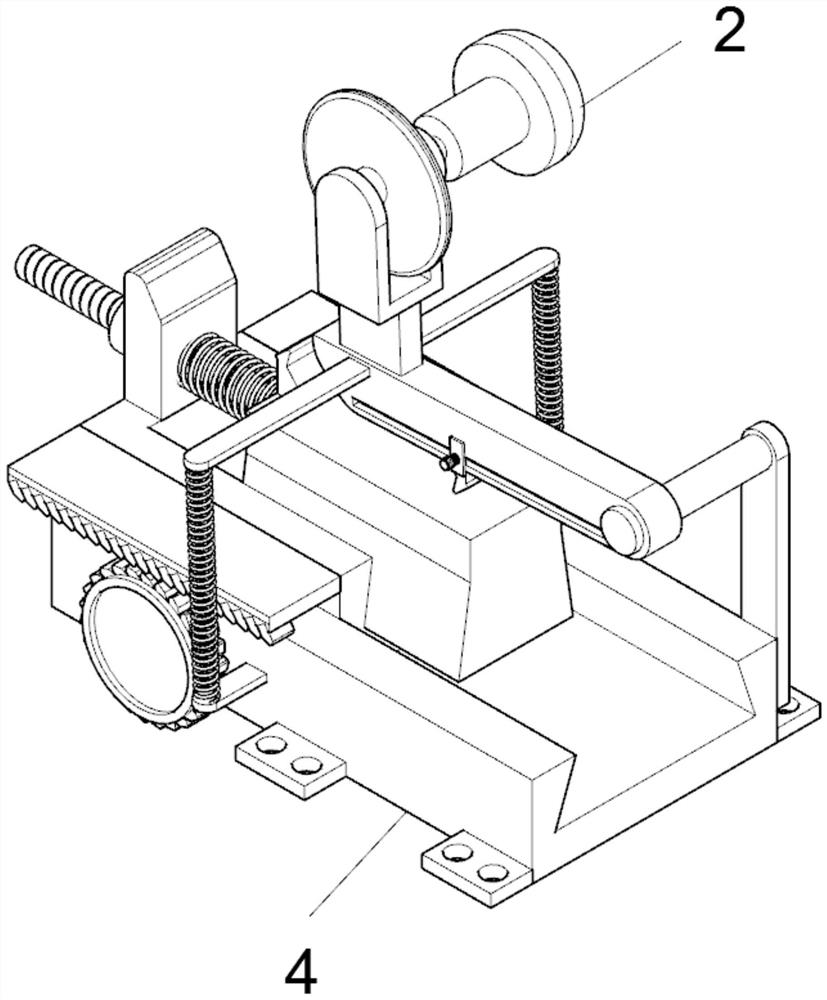

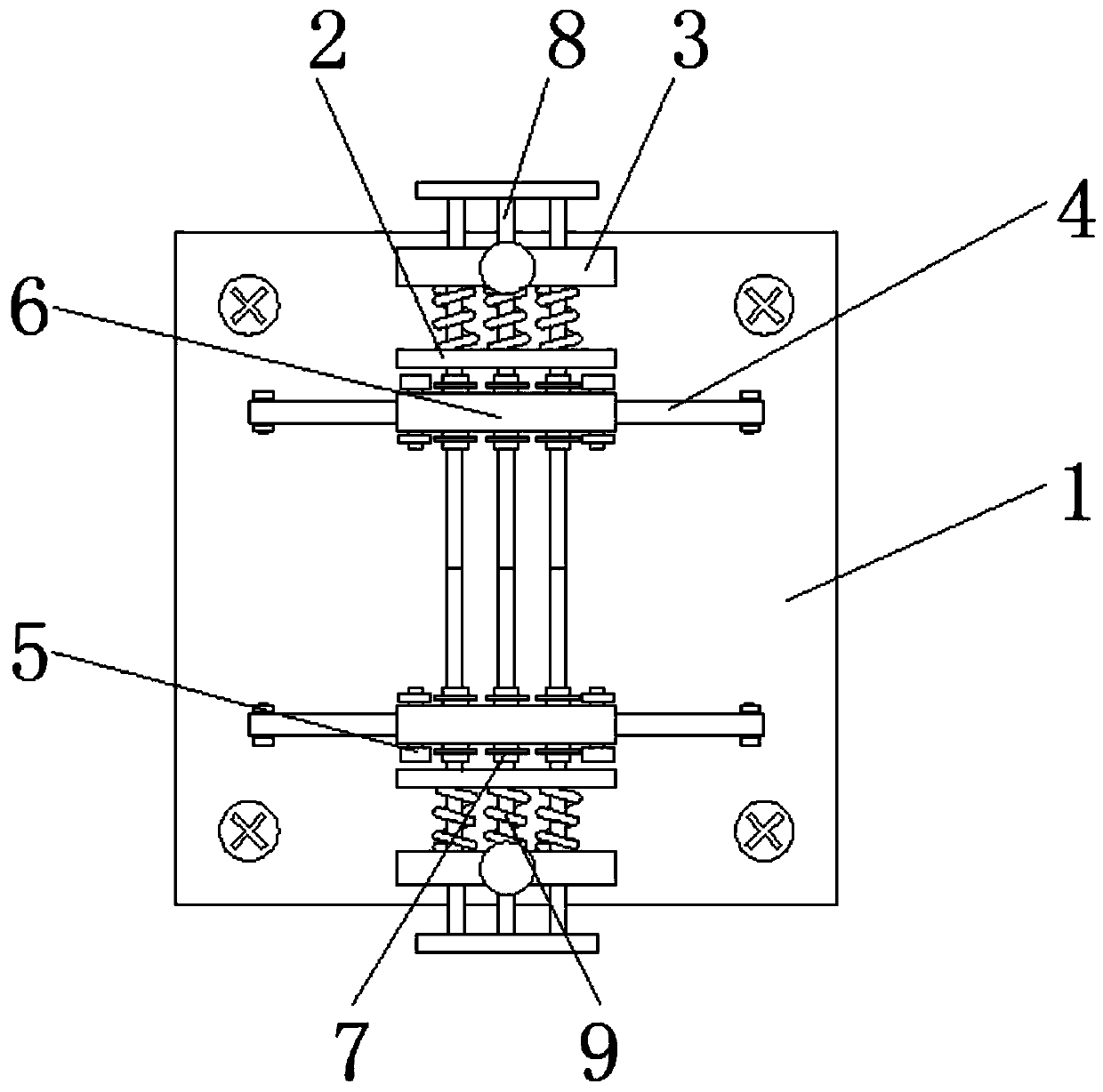

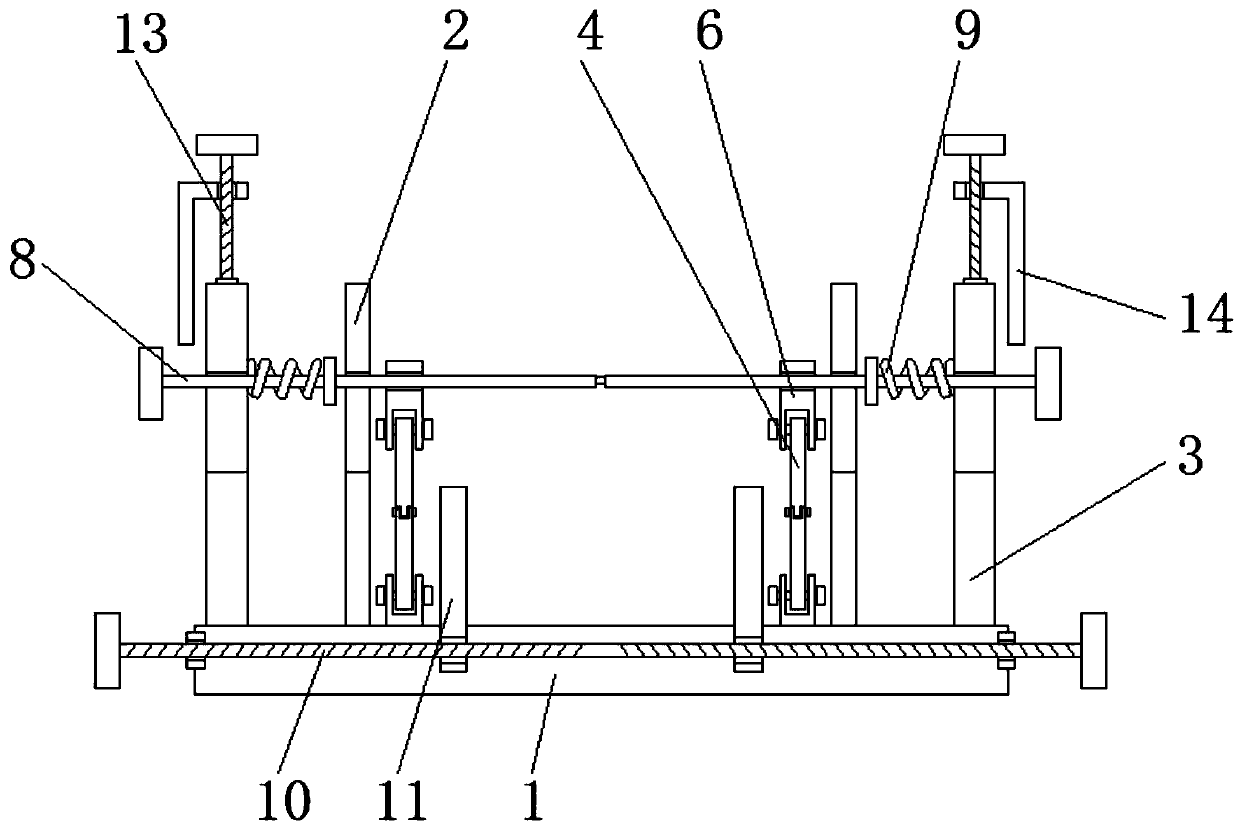

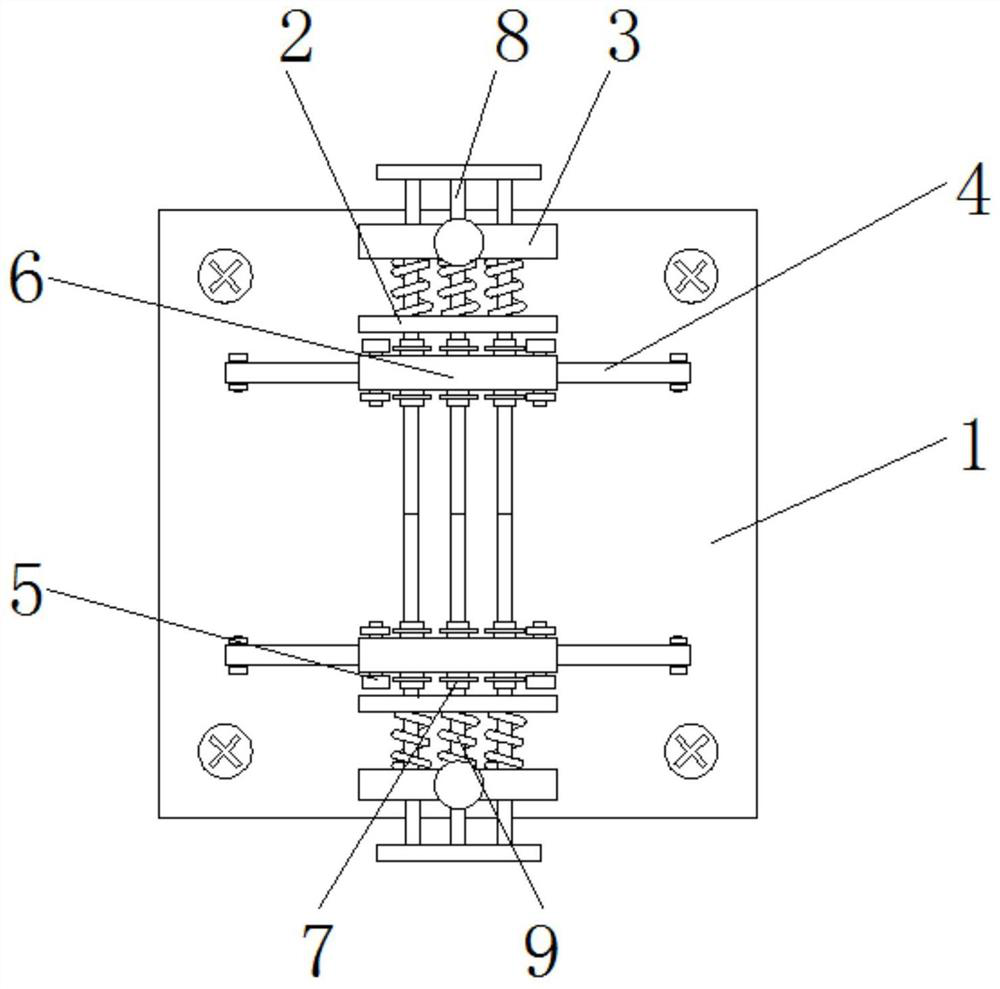

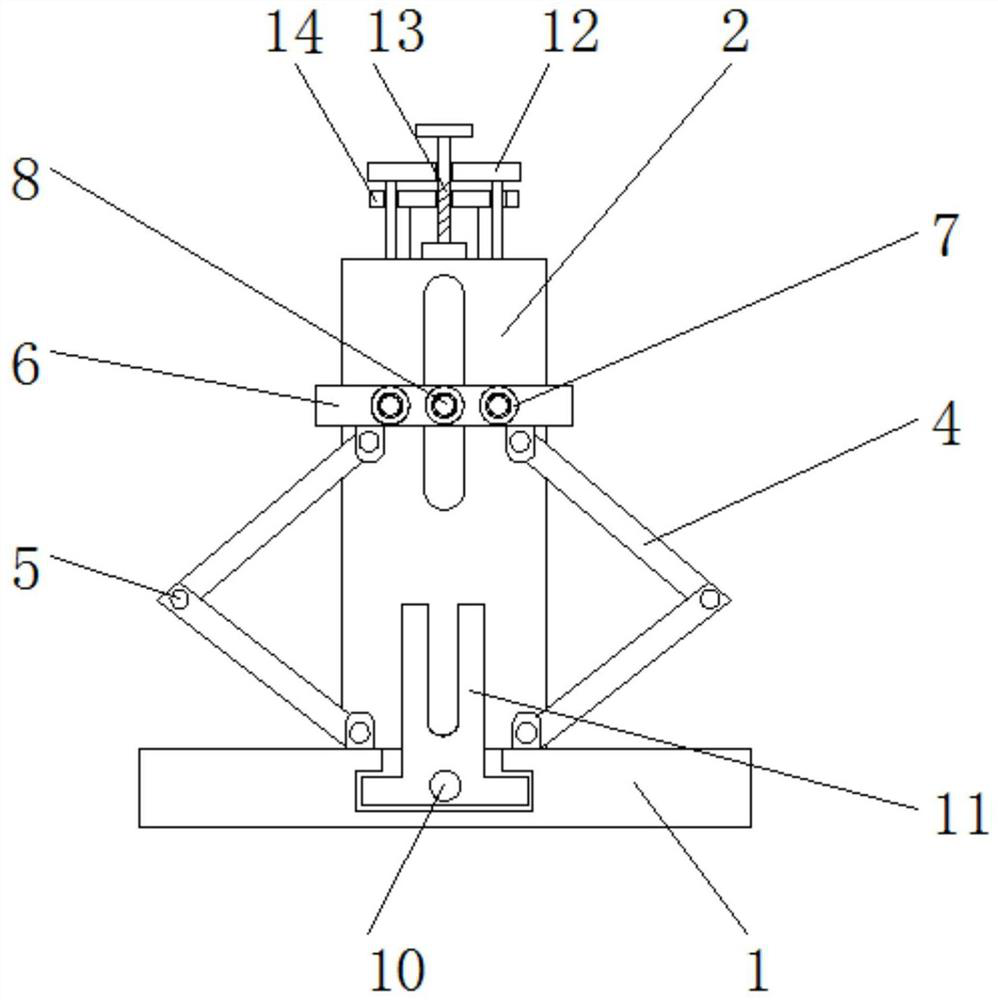

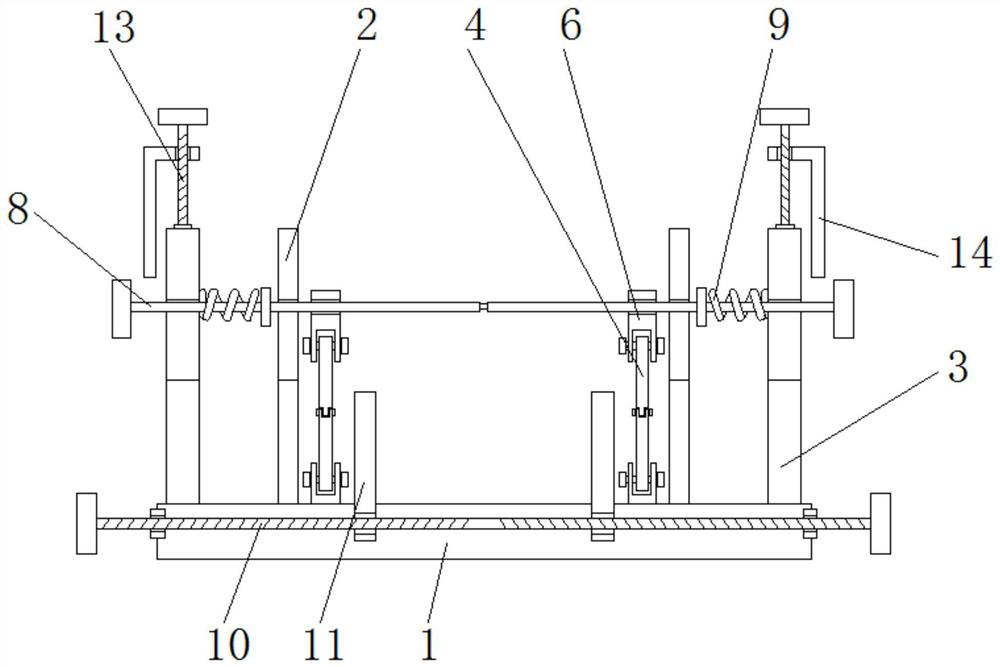

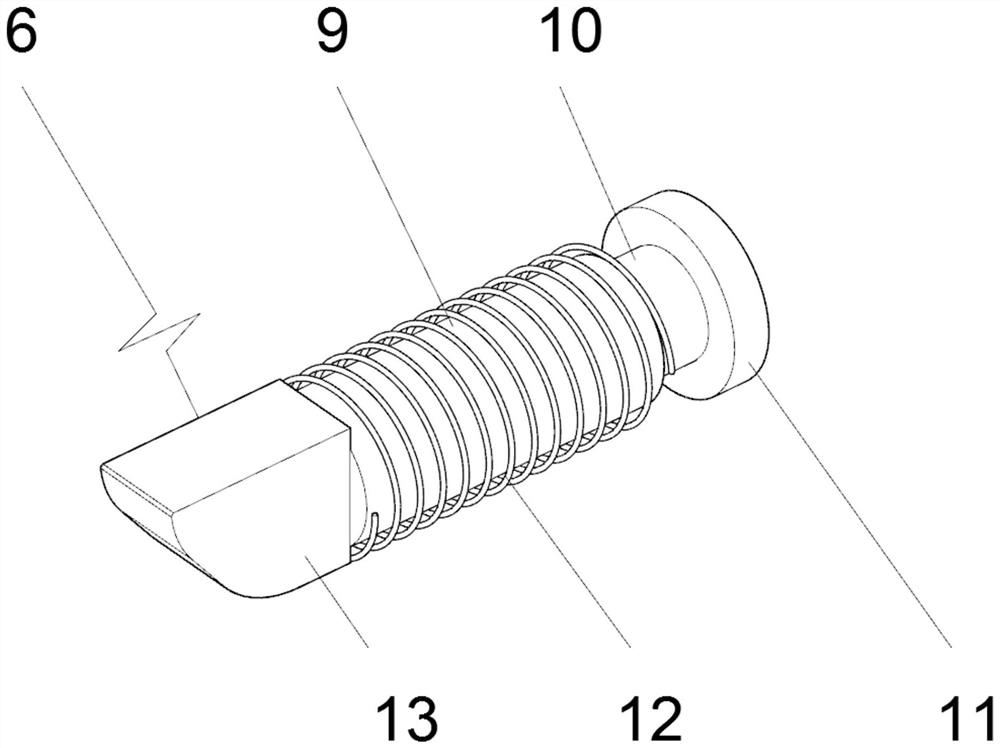

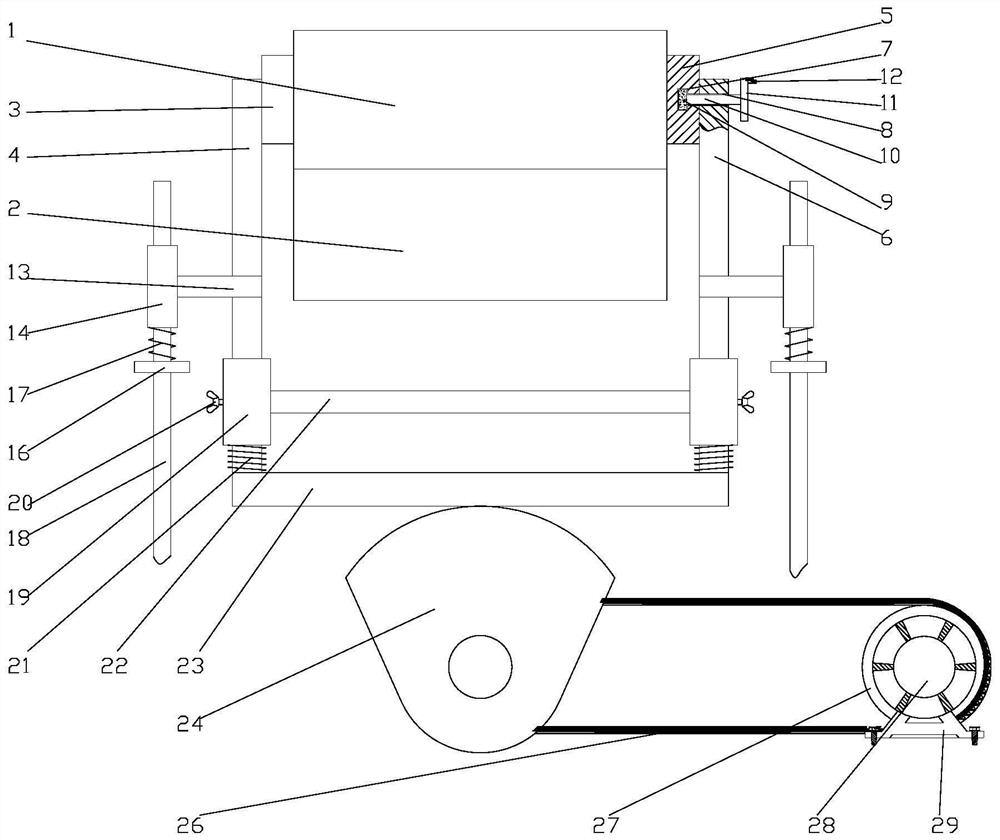

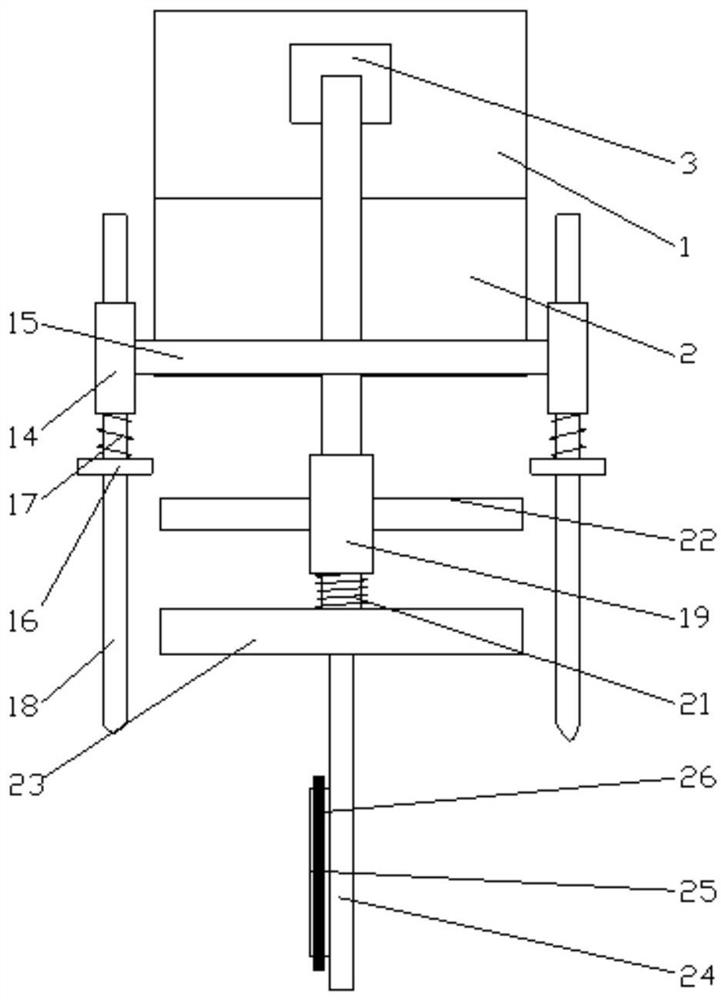

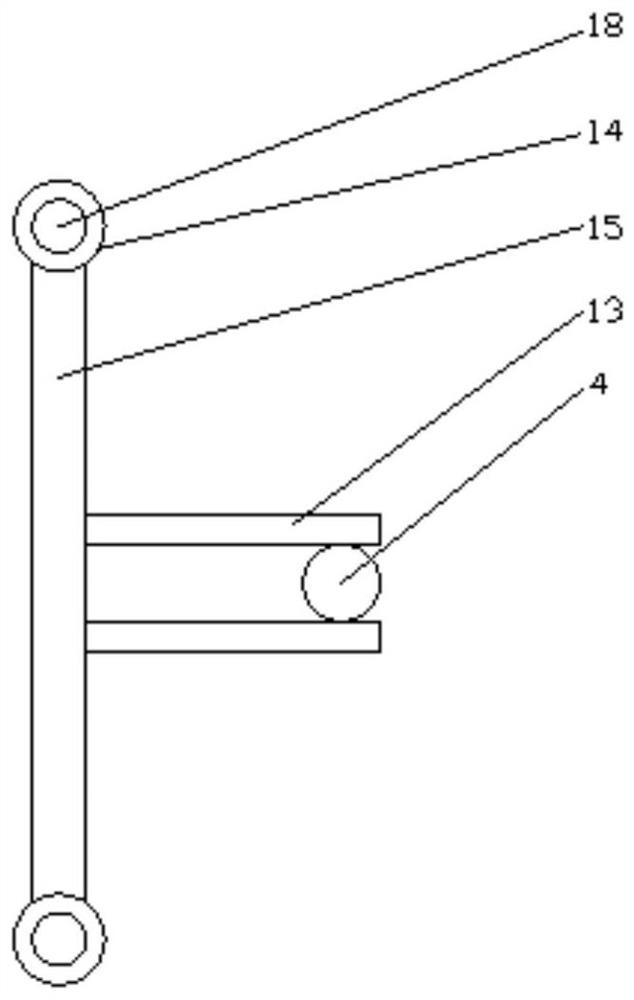

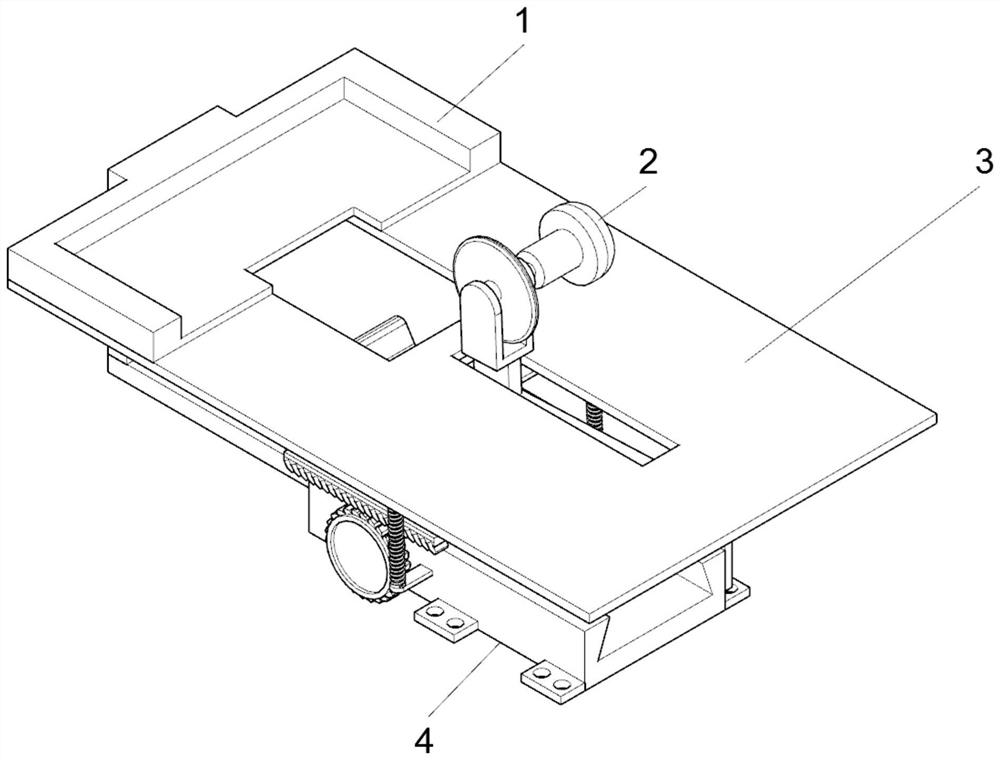

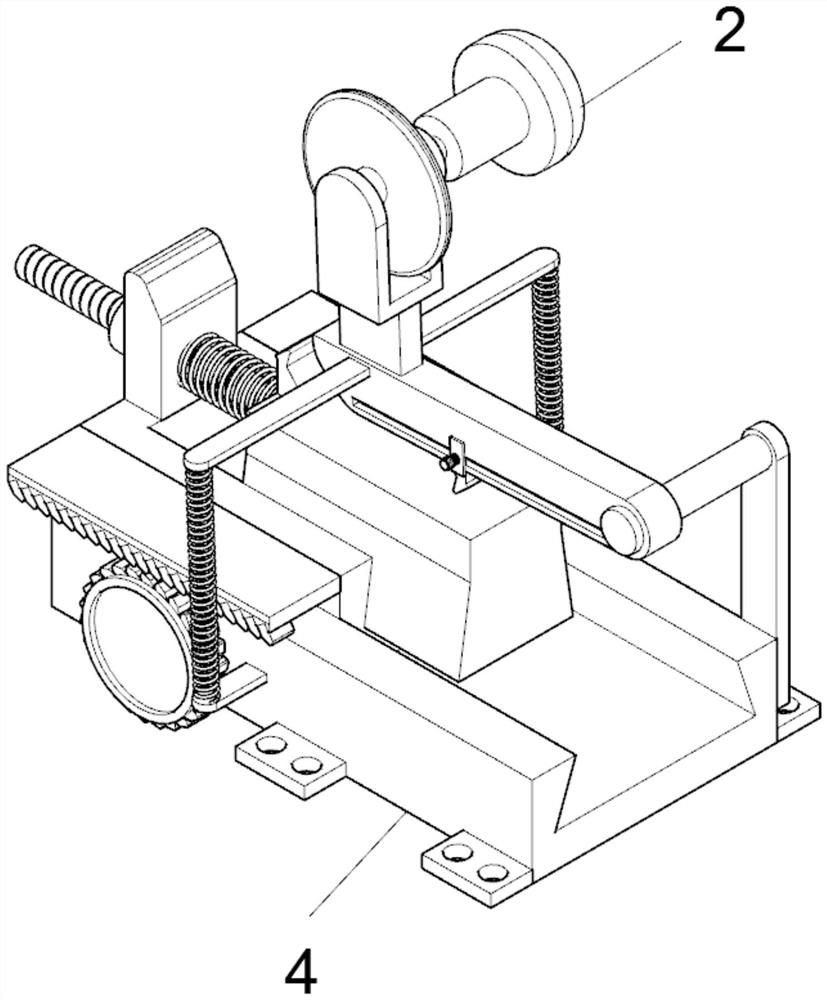

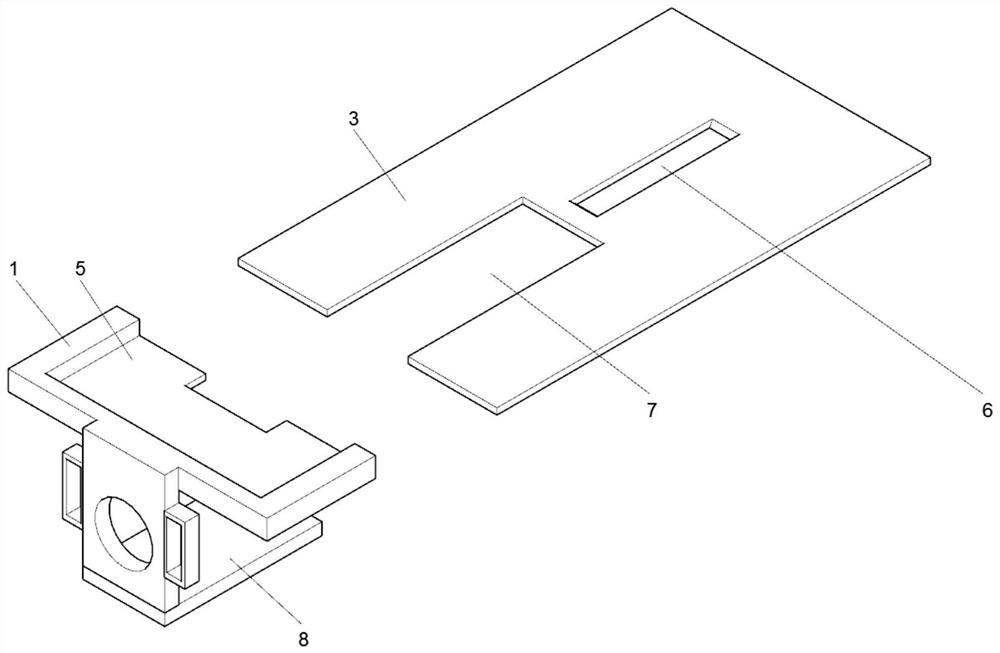

Quick demoulding device for casting

ActiveCN108817360AImprove buffering effectImprove separation efficiencyMould handling equipmentsPass rateEngineering

The invention discloses a quick demoulding device for casting. The quick demoulding device for casting comprises a concave die and a convex die, a right ejector plate is arranged on the right side ofthe concave die, a notch is formed in the right ejector plate, a screw hole is formed in a right upright column, and the notch is communicated with the screw hole. A stop block is placed in the notch,a screw rod is placed on the right side of the stop block, a fixing plate is fixedly welded to the middles of a left upright column and the right upright column, a connection rod is fixedly welded tothe fixing plate, sleeves A are fixedly welded to the front end and the rear end of the connection rod respectively, and guide rails are sleeved with the sleeves A. The bottom of the left upright column and the bottom of the right upright column are fixedly welded to a bottom plate, and a cam is arranged on the bottom of the bottom plate. According to the quick demoulding device, the concave dieis separated from the convex die under the action of inertia, the separation efficiency is high, and a casting piece between the dies cannot be damaged; the die separation efficiency is greatly improved, the casting piece production pass rate is improved, and the quick demoulding device provides an important significance for improving the production efficiency and yield of an enterprise.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

Method for processing phosphorus mud with ultrasonic wave to recycle yellow phosphorus

The invention relates to the technical field of yellow phosphorus production, in particular to a method for processing phosphorus mud with ultrasonic wave to recycle yellow phosphorus. The method for processing the phosphorus with ultrasonic wave mud to recycle yellow phosphorus comprises the following steps of adding water into the phosphorus mud for dilution and stirring, and adjusting the pH of the slurry, processing the obtained the phosphorus mud slurry with ultrasonic wave, and then carrying out heat preservation treatment. According to the method, the device is simple, the purity of the recycled yellow phosphorus is high, no substance causing secondary pollution is introduced, operation is easy, energy consumption is low, and industrialization is easy to achieve.

Owner:湖北省兴发磷化工研究院有限公司

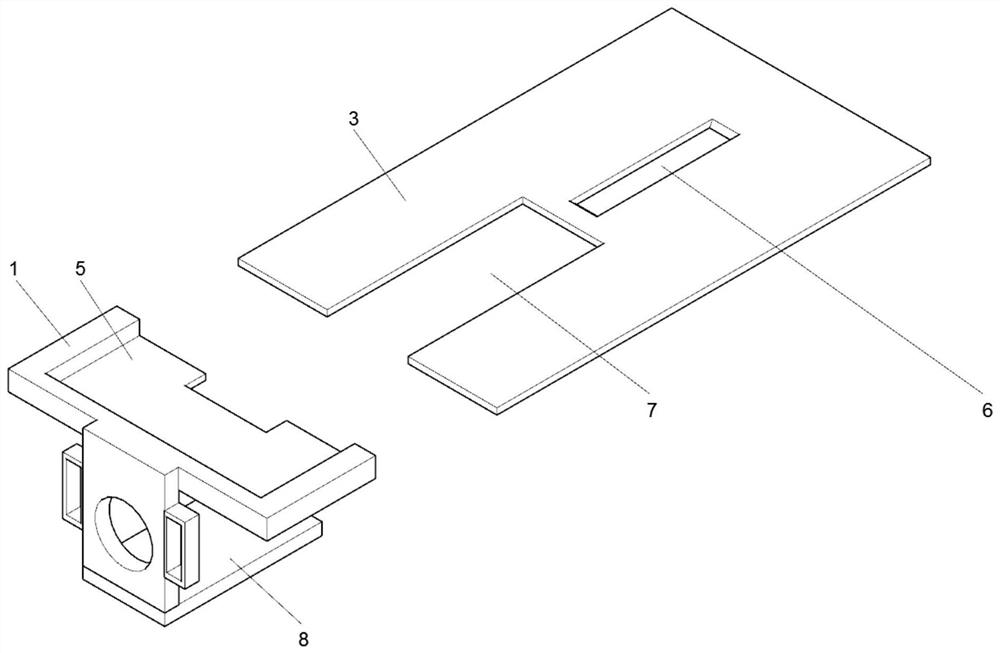

Anti-drop single-jack plug socket

InactiveCN105006688AReduce volumeFirmly connectedCoupling device detailsTwo-part coupling devicesEngineering

The invention relates to a plug socket, and particularly relates to an anti-drop single-jack plug socket. The anti-drop single-jack plug socket comprises a plug and a socket, wherein the plug comprises an insulation base, an insertion column arranged on the insulation base and an insertion piece arranged at the periphery of the insertion column, a clearance is reserved between the insertion column and the insertion piece, the socket is provided with jacks, the insulation base is provided with clamping portions, the periphery of each jack is provided with fixing seats, and the plug and the socket are clamped into an integral whole through the clamping portions and the fixing seats. The anti-drop single-jack plug socket is simple in structure, small in plug size and small in occupied space, reduces the size of the socket, saves materials, and reduces the production cost. Meanwhile, the plug and the socket are firmly connected and not easy to separate, the clamping portions are enabled to be clamped into clamping slots by only rotating a rotating base by a certain angle, and the plug and the socket are not separated by the action of an external force, thereby reducing potential safety hazards in power utilization.

Owner:ZHEJIANG FAST ELEVATOR

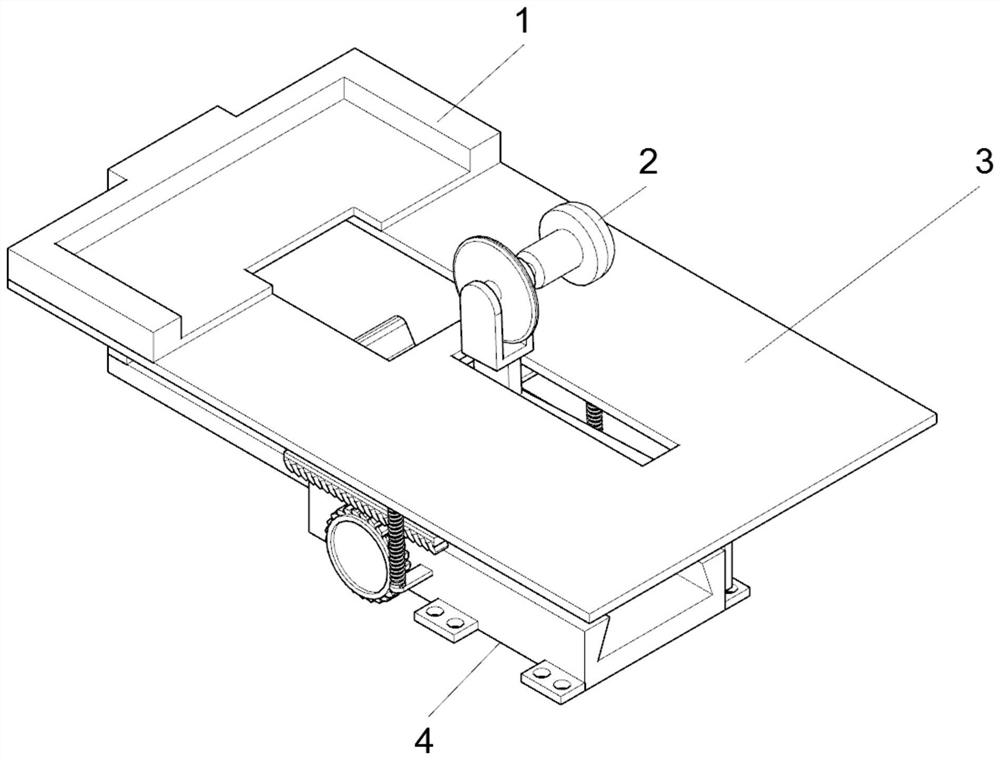

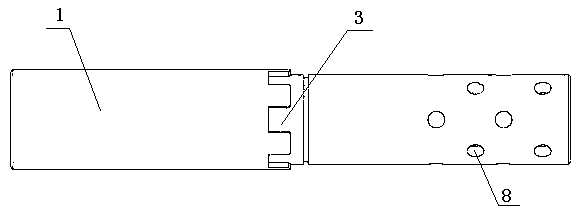

Corrugated paper cutting device with fixed cutting distance, convenience in adjustment and protection function

ActiveCN112009020APop up automaticallySame distanceBox making operationsPaper-makingEngineeringPaper cut

The invention discloses a corrugated paper cutting device with a fixed cutting distance, convenience in adjustment and a protection function. The corrugated paper cutting device comprises a pushing plate and a supporting table, the pushing plate is slidably mounted on the upper portion of one end of the supporting table, a placing clamping groove is formed in the pushing plate, a movable clampinggroove is formed in the middle of the end, close to the pushing plate, of the supporting table in a penetrating manner, a cutting knife groove is formed in the side, away from the pushing plate, of the movable clamping groove and located in the supporting table in a penetrating manner, a connecting plate is fixedly connected to the middle of the outer end of the pushing plate, an adjusting deviceis installed below the supporting table, a cutting protection device is installed above the adjusting device, and a limiting plate is installed in the adjusting device. According to the corrugated paper cutting device, corrugated paper can be rapidly cut in the using process, the cutting distances of the cut corrugated paper are the same, it is guaranteed that the specifications of the cut corrugated paper are the same, an operator can be protected in the using process, and using and adjusting are convenient and rapid.

Owner:云南汇盈环保包装科技有限公司

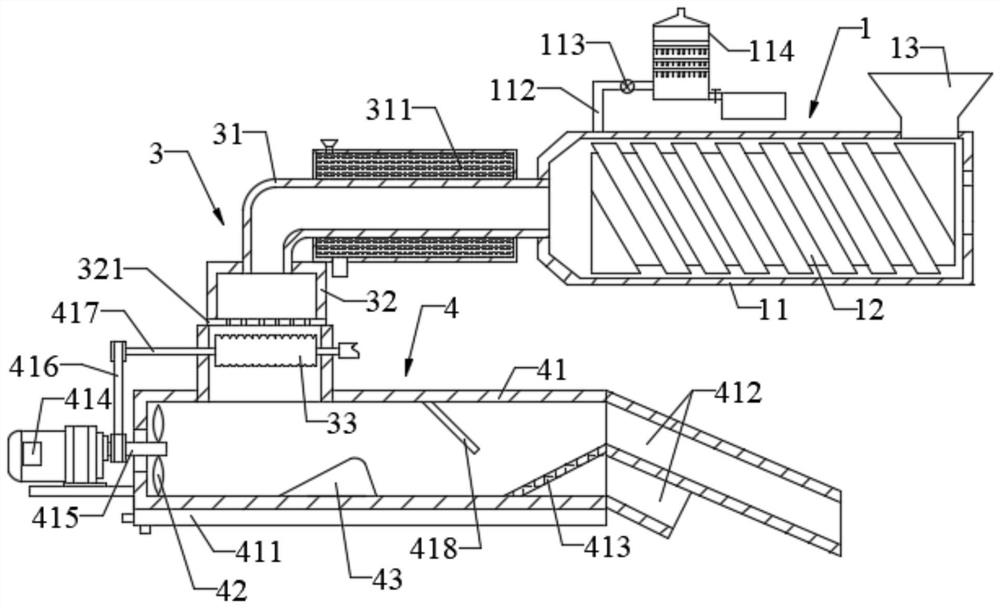

Efficient environment-friendly plastic granulation device

InactiveCN111645221AEasy to pastePaste will notDispersed particle separationDirt cleaningProcess engineeringEnvironmental engineering

The invention relates to the field of plastic processing, in particular to an efficient environment-friendly plastic granulation device. The plastic granulation device comprises a feeding extrusion device, a hot cutting device, a cold cutting device and a cooling discharging device. According to the high-efficiency environment-friendly plastic granulation device, accumulated plastic particles after granulation are not easy to stick together, and the produced plastic particles can be screened and classified to ensure the effect of uniformity of the plastic particles; the cut plastic particles are air-dried by means of wind transportation to ensure that the plastic particles are mutually separated directly and cannot stick together; dual processes of cold cutting and hot cutting are integrated, switching or simultaneous production can be performed according to demands, waste gas is washed by three layers of spray pipes, an adsorption layer can adsorb toxic and harmful gases in the gas, the gas is effectively purified, and pollution is reduced. A waste liquid tank can collect waste liquid generated in the washing process, so that secondary pollution is prevented, and the environment is further protected.

Owner:福建亚通新材料科技股份有限公司

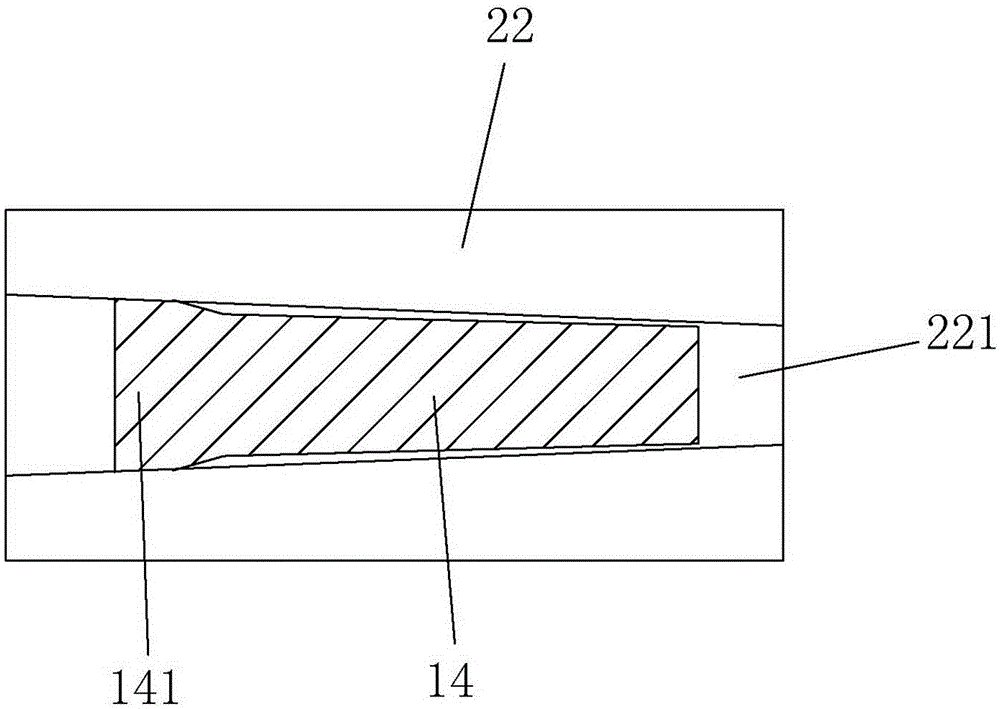

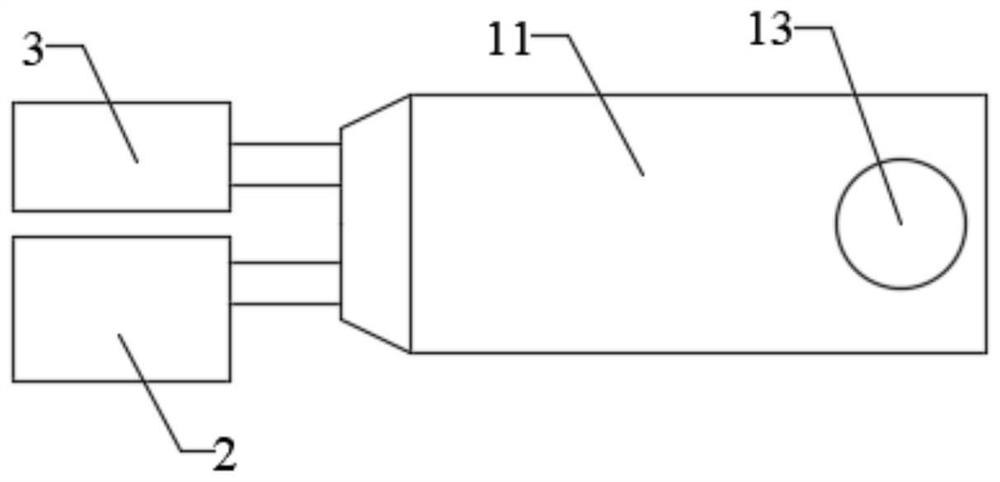

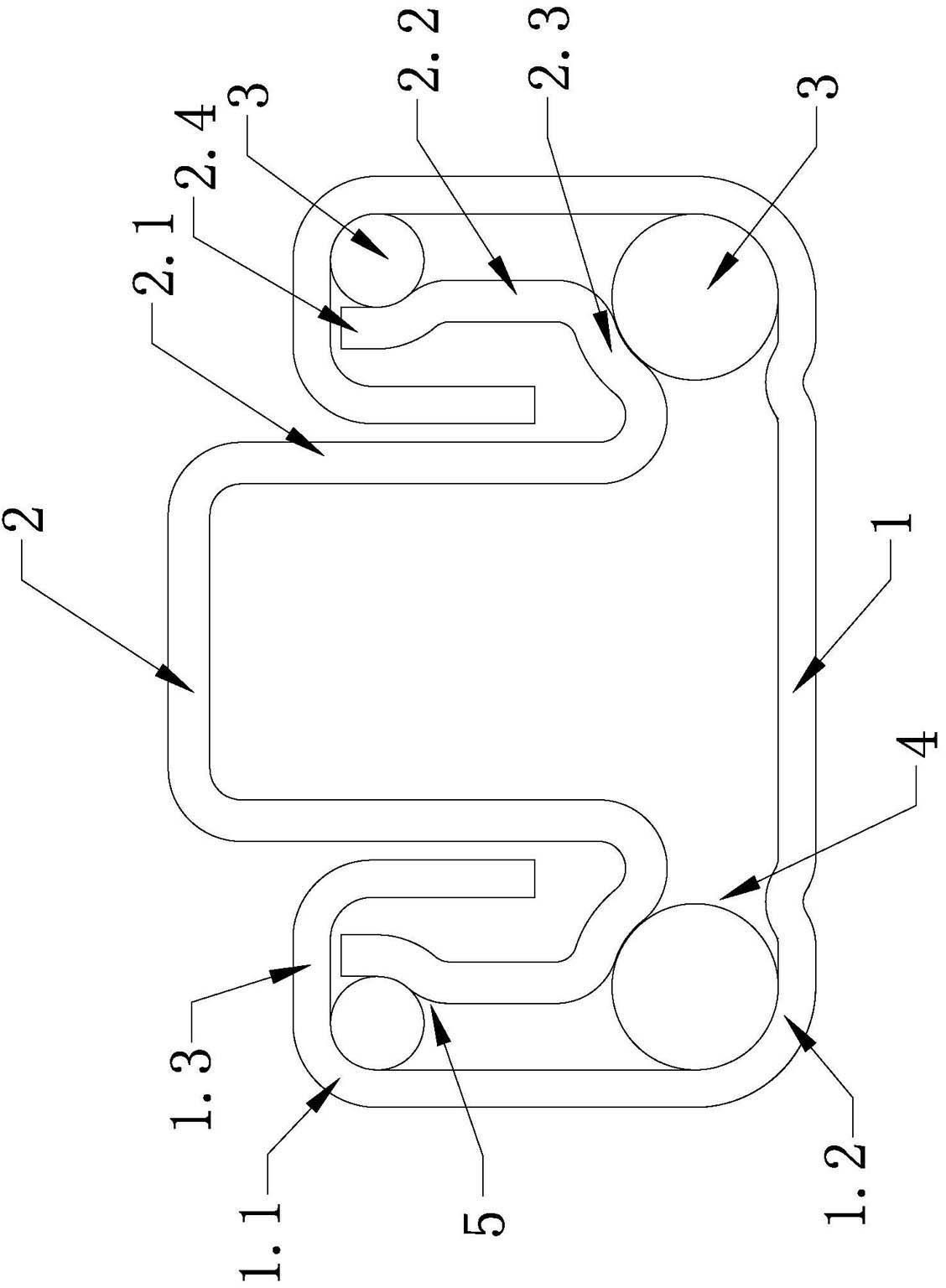

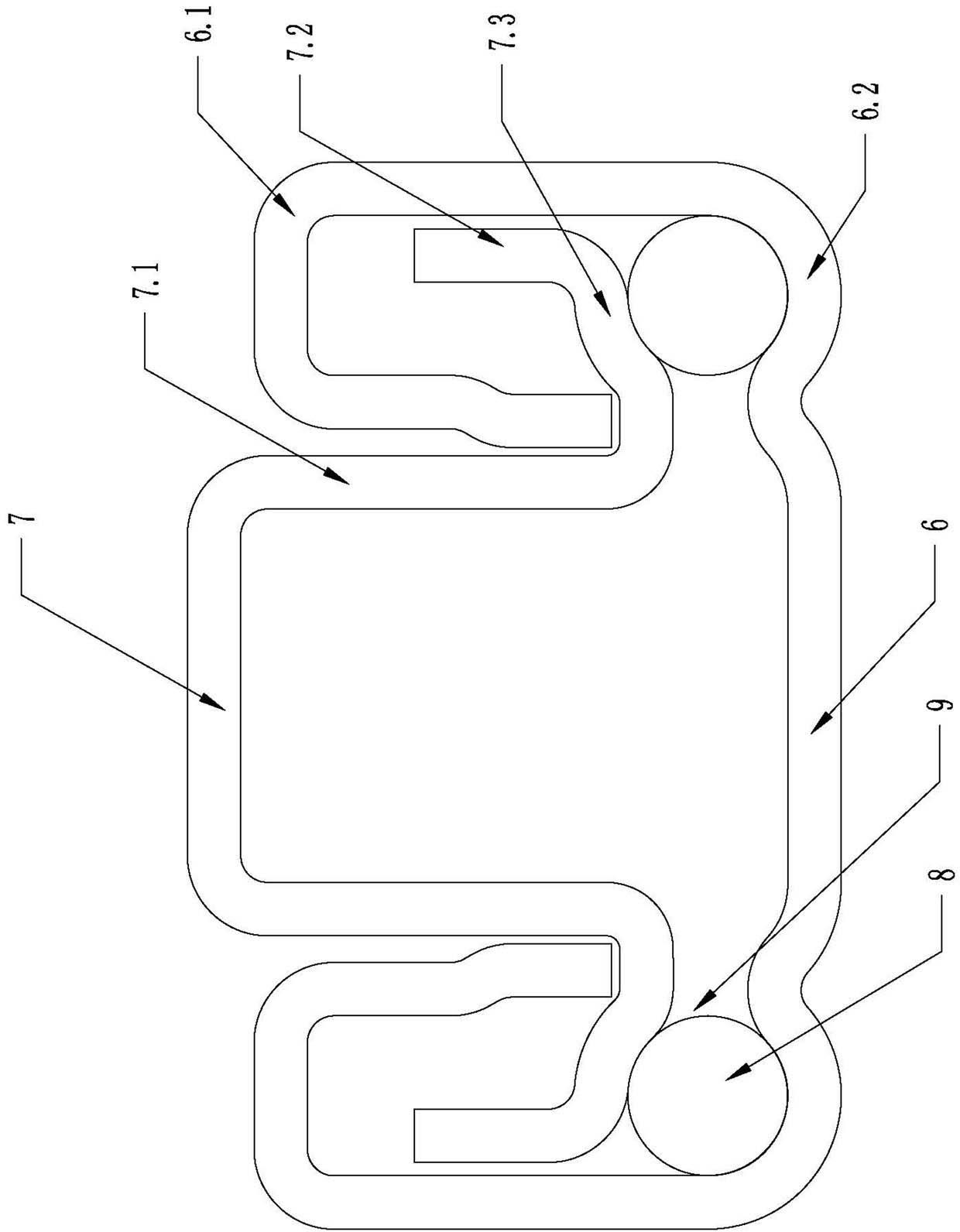

A slide rail for a vehicle seat

The invention relates to a slide rail for a vehicle seat, comprising a slide case, a slide core and steel balls, the lower end of the inner vertical folded wall of the slide core is connected with the lower end of the outer vertical folded wall through an arc-shaped folded wall; the upper and lower ends of the slide shell are respectively There are upper groove-shaped folding wall and lower groove-shaped folding wall; the arc-shaped folding wall of the sliding core and the lower groove-shaped folding wall at the lower end of the sliding case form a lower steel ball channel; steel balls are arranged in the lower steel ball channel; The upper end of the vertical folding wall is an inner bending wall, and the inner bending wall and the upper groove-shaped folding wall at the upper end of the slide case form an upper steel ball channel, and steel balls are arranged in the upper steel ball channel. The invention has the advantage that when the vehicle swings and bumps to give traction force and impact force to the slide rail, the sliding core and the sliding shell can be perfectly combined and move smoothly.

Owner:JIANGYIN FUHUA AUTOMOBILE SEAT

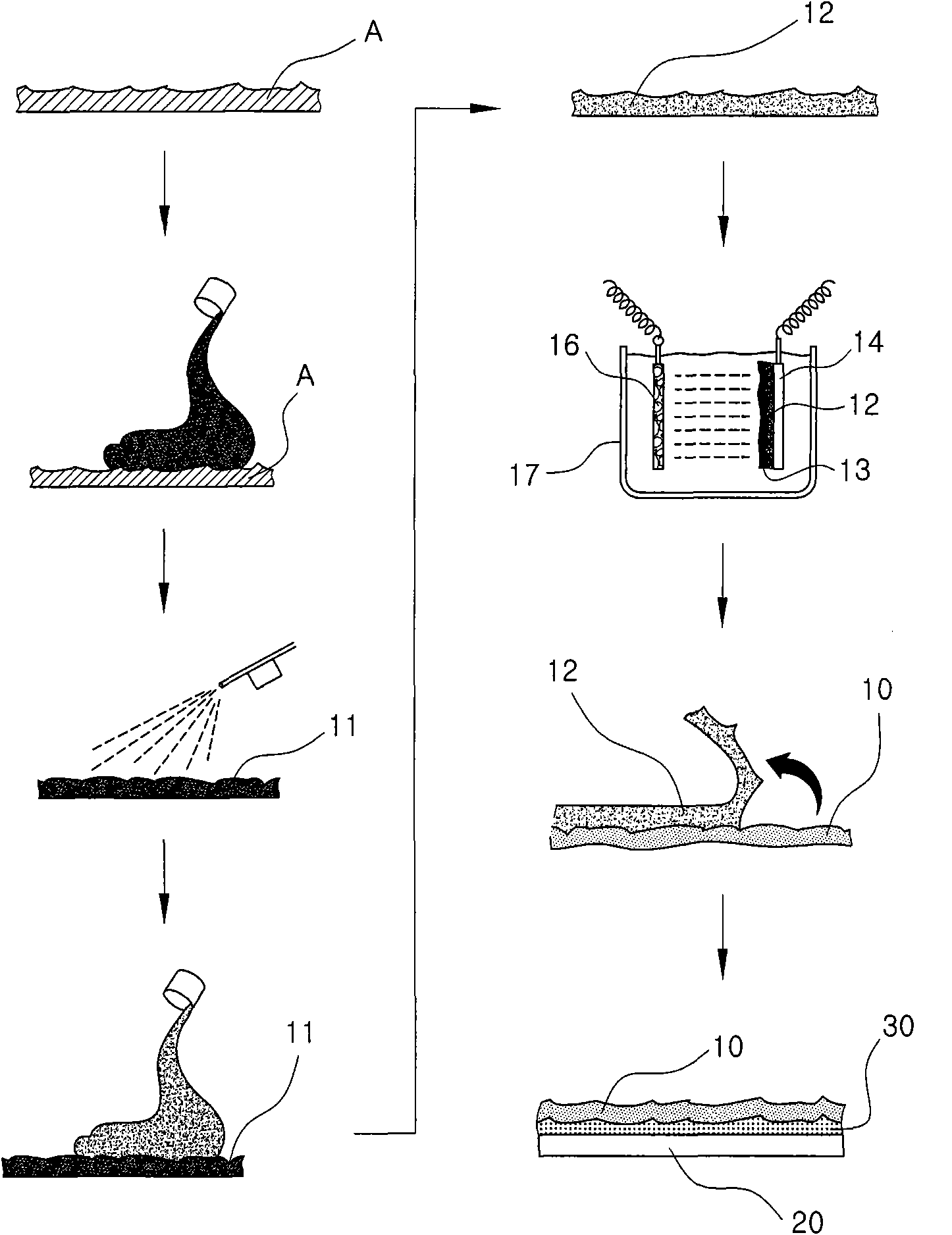

TPR shoe surface modification technology

The invention discloses a TPR shoe surface modification technology. The modification technology comprises the following steps of (1) a TPR shoe surface processing step, in which a TPR specific processing agent is employed to clean the external surface of the shoe and soften the external surface, and the shoe external surface is dried for 10 to 20 minutes, (2) a priming paint spraying step, in which a paint spraying device is employed to spray priming paint to the TPR shoe to form a flat priming paint plane on the external of the TPR shoe, and then the shoe sprayed with the priming paint is dried by 10 to 20 minutes at the temperature of 60 to 70 DEG C, (3) a metal spraying step, in which a spraying device is employed to spray an imitating metal layer on the priming paint, and then the imitating metal layer is dried for 5 to 10 minutes at the temperature of 60 to 70 DEG C, and (4) a spraying device is employed to spray a layer of surface paint on the external surface of the imitating metal layer and then the shoe is dried. The modified shot can be achieved at last. The priming paint is composed of the following components according to weight by parts: 100 parts of base main resin, 10 to 30 parts of hardener, 30 to 80 parts of diluents and 1 to 10 parts of binding agents; and the surface paint is formed by the following components according to weight by parts: 100 parts of surface main resin, 30 to 50 parts of hardener, 50 to 80 parts of diluents and proper pigment. The TPR shoe surface modification technology is characterized by great decorating effect.

Owner:晋江国盛新材料科技有限公司

Lever type magnetic control suction cup window cleaner base

The invention discloses a lever type magnetic control suction cup window cleaner base which comprises a base body and an anti-falling mechanism used for preventing the base from falling, the anti-falling mechanism comprises a rocker arm, a suction cup, an auxiliary magnet and an elastic part, the middle of the rocker arm is hinged to the base body in an up-down overturning mode, and the middle of the rocker arm is hinged to the base body in an up-down overturning mode. One end of the rocker arm is provided with the auxiliary magnet used for being attracted to a magnet on the base opposite to the glass, the other end of the rocker arm is provided with the suction cup used for attracting the glass, and the elastic part used for driving the suction cup on the rocker arm to move downwards to be close to the glass to be cleaned is arranged between the rocker arm and the base body. Through cooperation of the elastic part, the rocker arm and the auxiliary magnet, the suction cup is far away from to-be-wiped glass in the wiping state of the wiping body and can be close to and attracted to the glass only when the suction cup accidentally falls off, the resistance of the window cleaner in the window wiping process cannot be increased, meanwhile, the suction cup cannot leave wiping marks on the glass, the structure is simple, performance is reliable, and the window cleaner can be well prevented from falling off.

Owner:NANAN GAOJIE ELECTRONICS TECH

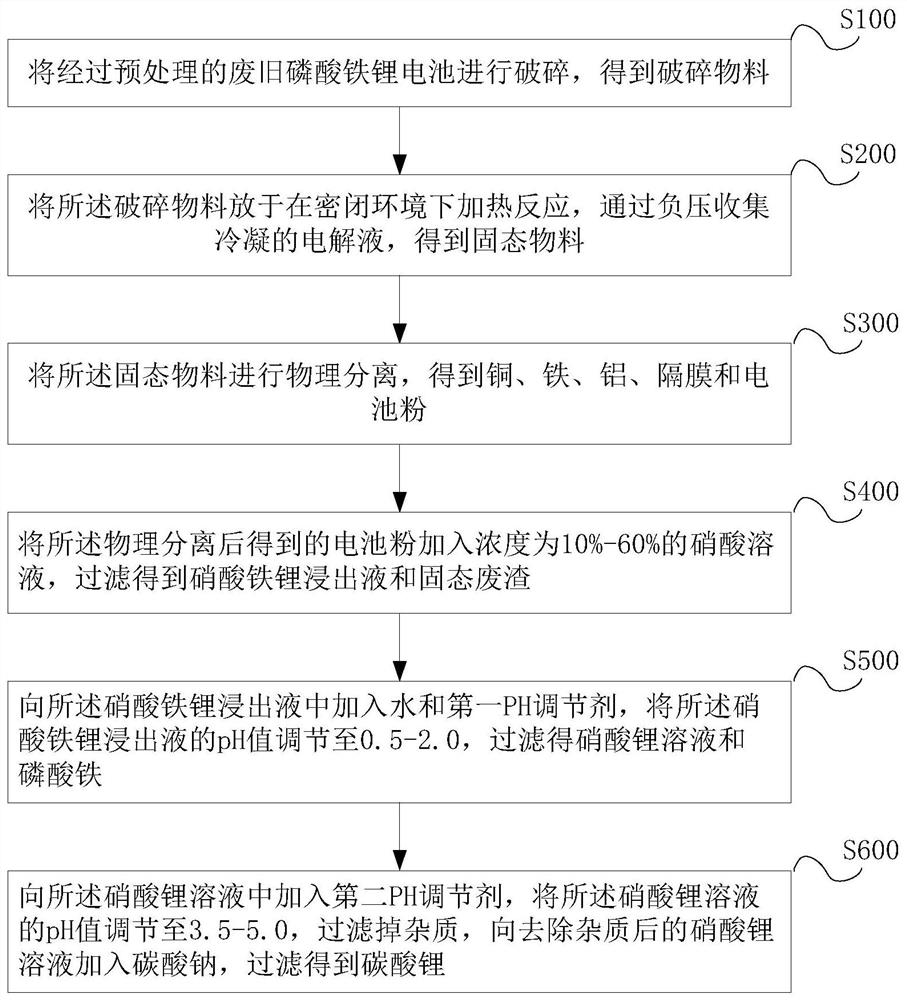

Recovery method of waste lithium iron phosphate battery

PendingCN113937339ASeparation will notAvoid it happening againWaste accumulators reclaimingPhosphorus compoundsElectrolytic agentMetallic aluminum

The invention provides a recovery method of a waste lithium iron phosphate battery. According to the technical scheme, an electrolytic solution in a waste battery is separated and collected in a low-temperature heating mode in closed equipment, and a battery diaphragm cannot be decomposed under the low-temperature heating condition, so that the subsequent recycling of the diaphragm is facilitated while a large amount of toxic and harmful gases such as chlorides, dioxin and the like generated by high-temperature heating are avoided. According to the scheme, by using nitric acid, iron and lithium in a battery positive electrode material lithium iron phosphate are selectively leached, and metal copper, metal iron and metal aluminum are not leached, so that copper, iron and aluminum are effectively separated at a time, wherein the concentrations of copper, aluminum and iron in the leaching solution are all smaller than 0.1 g / L, the leaching rates of iron and lithium in the battery positive electrode material lithium iron phosphate are both larger than 99.2%, and the used nitric acid can be recycled while iron and lithium can be efficiently recycled. According to the method, cation impurity elements are not brought in in the recovery process, the technological process is short, the energy consumption of auxiliary materials is low, the obtained nickel, cobalt, manganese and lithium metal solutions are high in purity, and the recovery rates of nickel, cobalt, manganese and lithium are all larger than 99.0%.

Owner:湖南金凯循环科技股份有限公司

A kind of surface modification process of eva shoe material

ActiveCN106362920BReduce wasteWith metallic effectShoemaking devicesPretreated surfacesEngineeringSurface modification

The invention discloses a surface modification technology for an EVA shoe material. The technology comprises the following steps of firstly, EVA shoe material surface treatment, wherein the outer surface of the shoe material is cleaned through an EVA special treating agent, the outer surface is softened, and drying is conducted for 10 min-20 min; secondly, primer spraying, wherein primer spraying is conducted on the EVA shoe material through a spraying device, accordingly a layer of flat primer plane is formed on the outer portion of the EVA shoe material, drying is conducted for 20 min-30 min in the environment with the temperature ranging from 60 DEG C to 70 DEG C, and the primer comprises, by weight, 100 parts of bottom host crystals, 30-80 parts of boiled oil water and 1-10 parts of binding agents; thirdly, metal spraying, wherein a metal simulating layer is sprayed to the primer through the spraying device, and drying is conducted for 5 min in the environment with the temperature ranging from 60 DEG C to 70 DEG C; and fourthly, finish coating spraying, wherein a layer of finish coating is then sprayed to the outside of the metal simulating layer through the spraying device, the modified shoe material is obtained after drying, and the finish coating comprises, by weight, 100 parts of face host crystals, 20-50 parts of hardening agents, 30-60 parts of boiled oil water and a proper amount of pigment. The surface modification technology has the beneficial effect that the decoration effect is good.

Owner:晋江国盛新材料科技有限公司

A kind of surface modification technology of nylon shoe material

The invention discloses a surface finishing process of a nylon shoe material. The surface finishing process comprises the following steps: (1), nylon shoe material surface treatment: utilizing a nylon special treatment agent to clean the outer surface of a shoe material and soften the outer surface, and drying for 10-20 minutes; (2), primer spraying: utilizing a spraying device to spray a primer on the nylon shoe material so as to form a layer of smooth primer plane on the exterior of the nylon shoe material, and drying at 60-70 DEG C for 10-20 minutes, wherein the primer is prepared from 100 parts by weight of primer main agent, 10-20 parts by weight of hardening agent, 60-100 parts by weight of diluent and 1-10 parts by weight of binding agent; (3), metal spraying and plating: utilizing the spraying device to spray a metal-imitating layer on the primer, and drying at 60-70 DEG C for 5-10 minutes; and (4), finishing coat spraying: utilizing the spraying device to spray a layer of finishing coat on the exterior of the metal-imitating layer, and drying for 30-50 minutes, thereby obtaining the finished shoe material, wherein the finishing coat is prepared from 100 parts by weight of finishing coat main agent, 60-80 parts by weight of hardening agent, 60-100 parts by weight of diluent and the balance of pigments. The surface finishing process of the nylon shoe material has the characteristics of good decoration effect.

Owner:晋江国盛新材料科技有限公司

Coal mining clamping sheet beneficial for reducing friction force

ActiveCN109681200AEasy to install and disassembleEasy to fixSlitting machinesEngineeringFriction force

The invention discloses a coal mining clamping sheet beneficial for reducing friction force. The coal mining clamping sheet beneficial for reducing the friction force comprises a base, supports and clamping blocks, wherein first fixing boards and second fixing boards are installed on the base, the first fixing boards are located on the inner sides of the second fixing boards, push rods are arranged on the inner sides of the first fixing boards, rotating shafts are installed on the push rods, the push rods are connected with the base and movable boards through the rotating shafts, the middle portions of the movable boards are connected with sleeves in a penetrated mode, outer walls of movable rods are connected with elastic parts, a first screw is connected with the base in a penetrating mode, the supports are fixed above the second fixing boards, the clamping blocks are connected with the supports and the outer walls of second screws, and the clamping blocks are located above the movable rod. According to the coal mining clamping sheet beneficial for reducing the friction force, dismounting and mounting of a cable are convenient, installation of the clamping sheet does not consumemuch time, and fixing of the cable is firm, so that the situation that the cable slides in a device to cause wear of the cable is avoided.

Owner:GUIZHOU UNIV

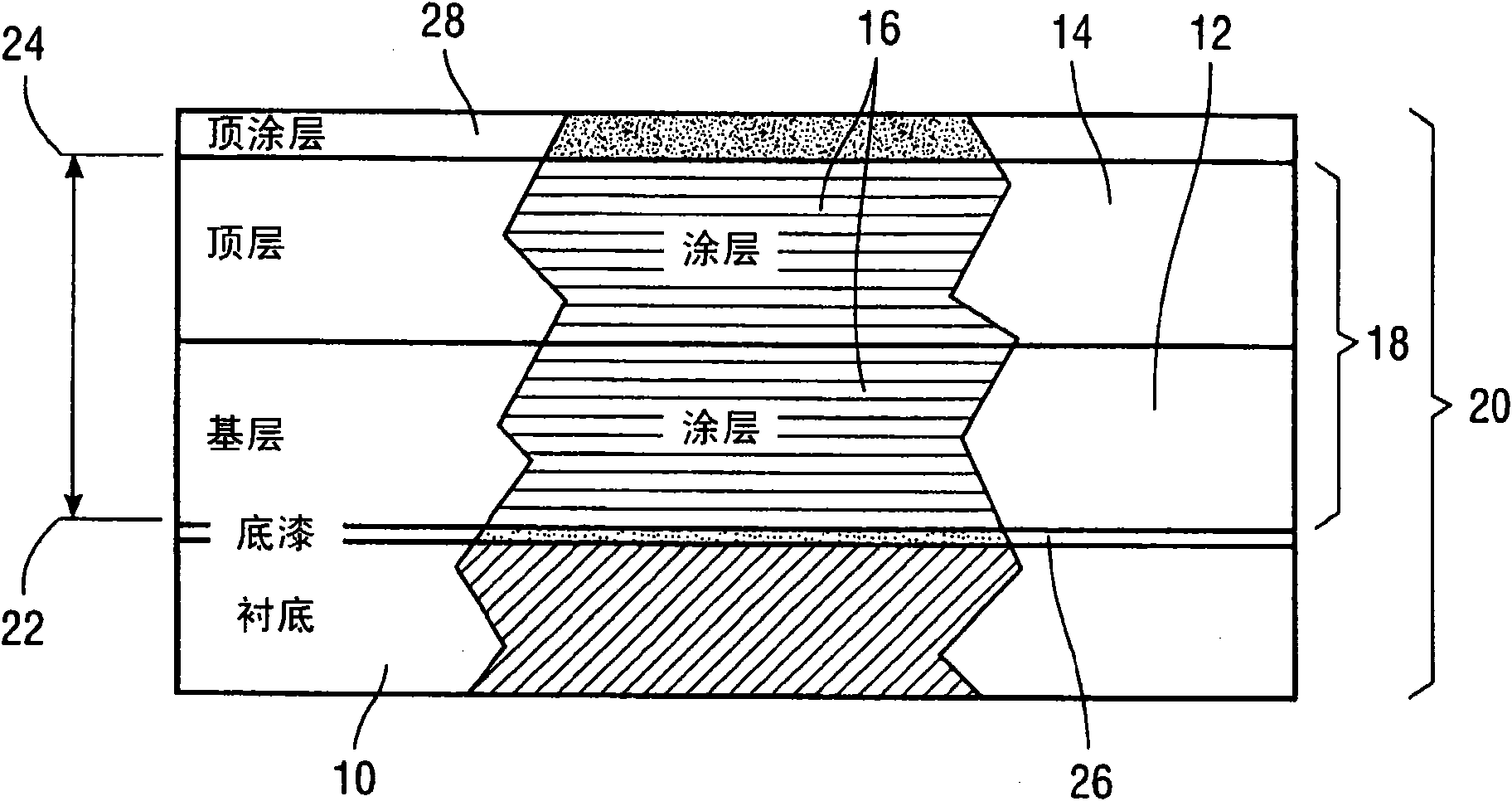

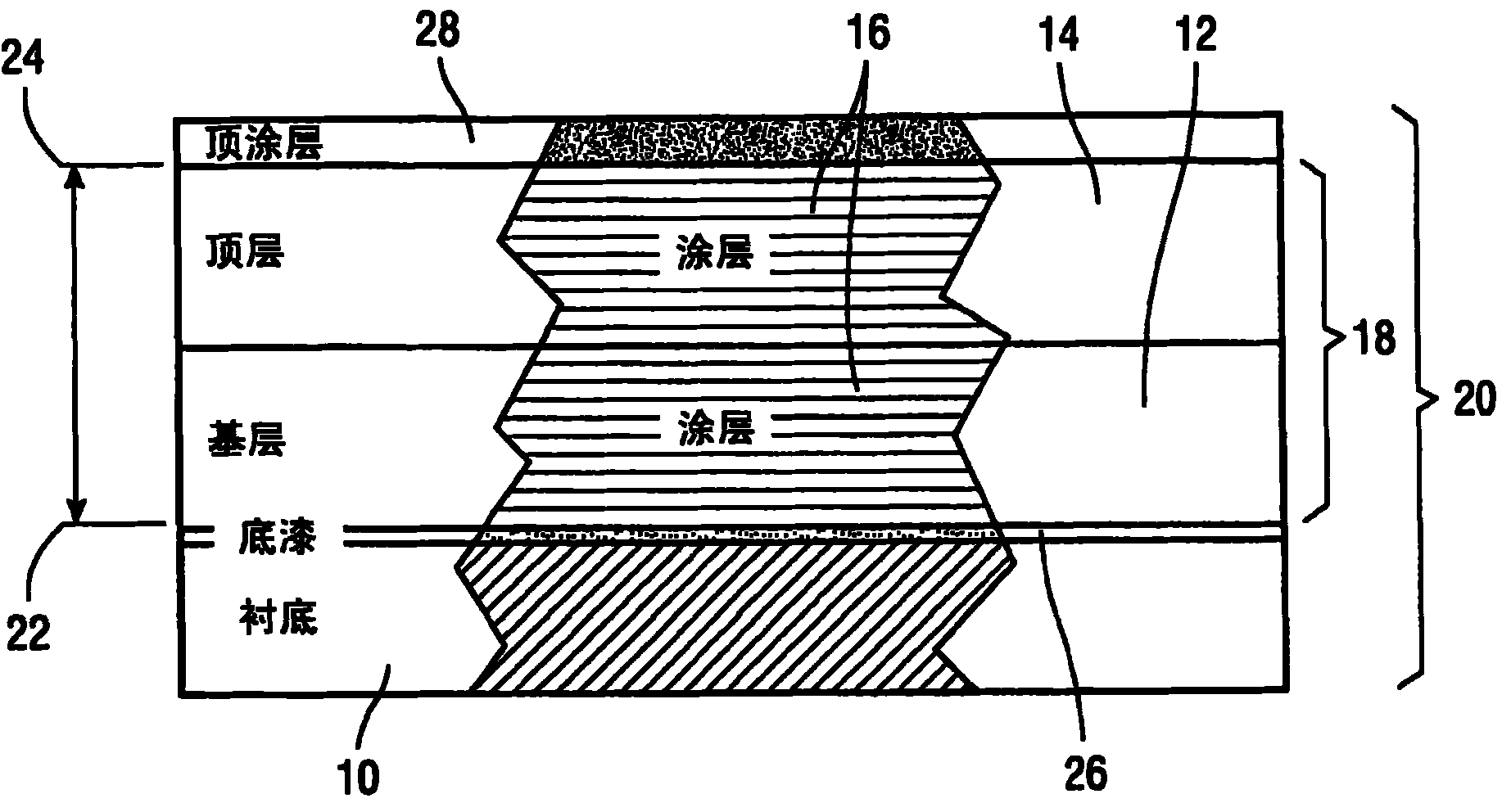

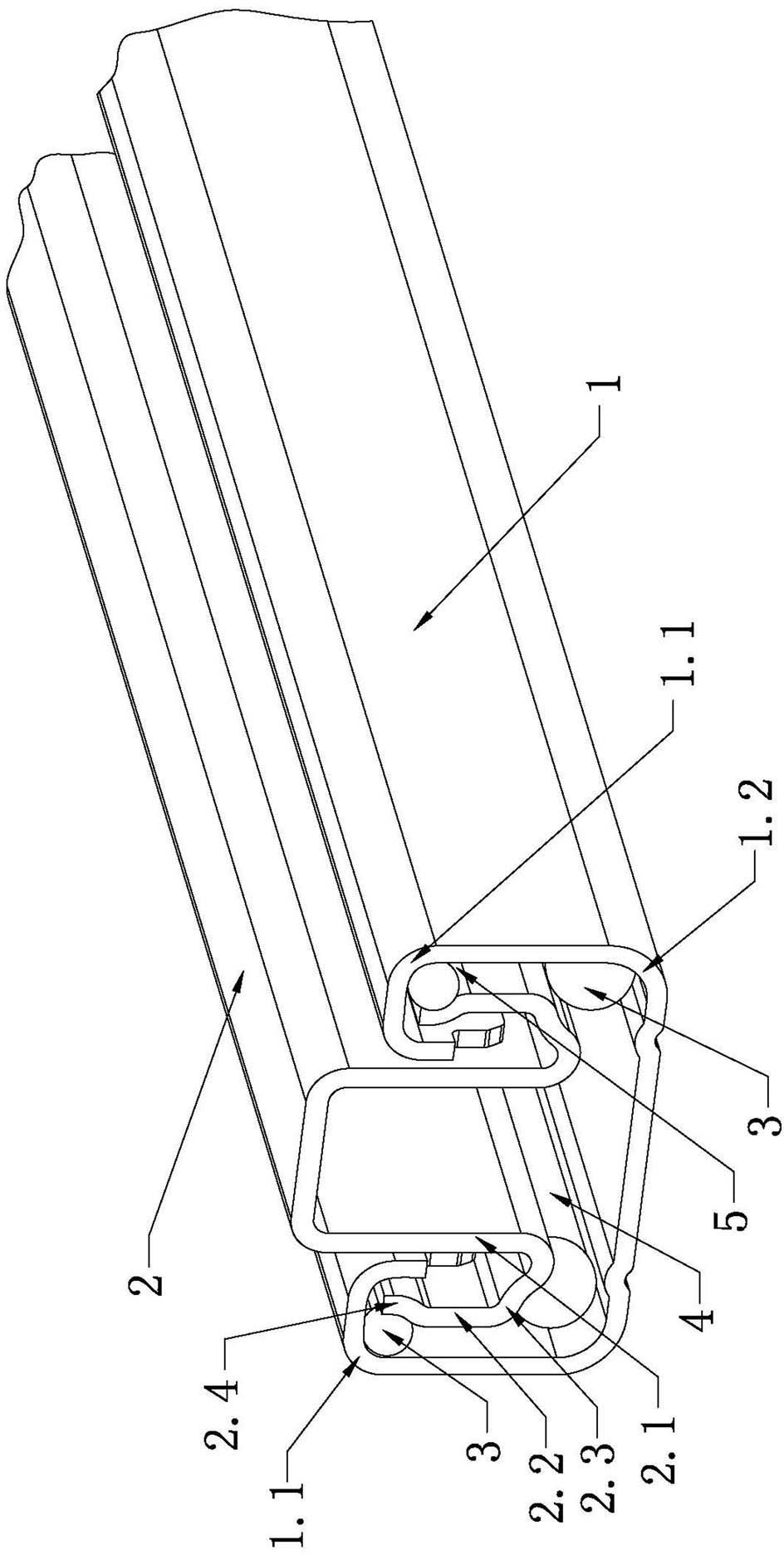

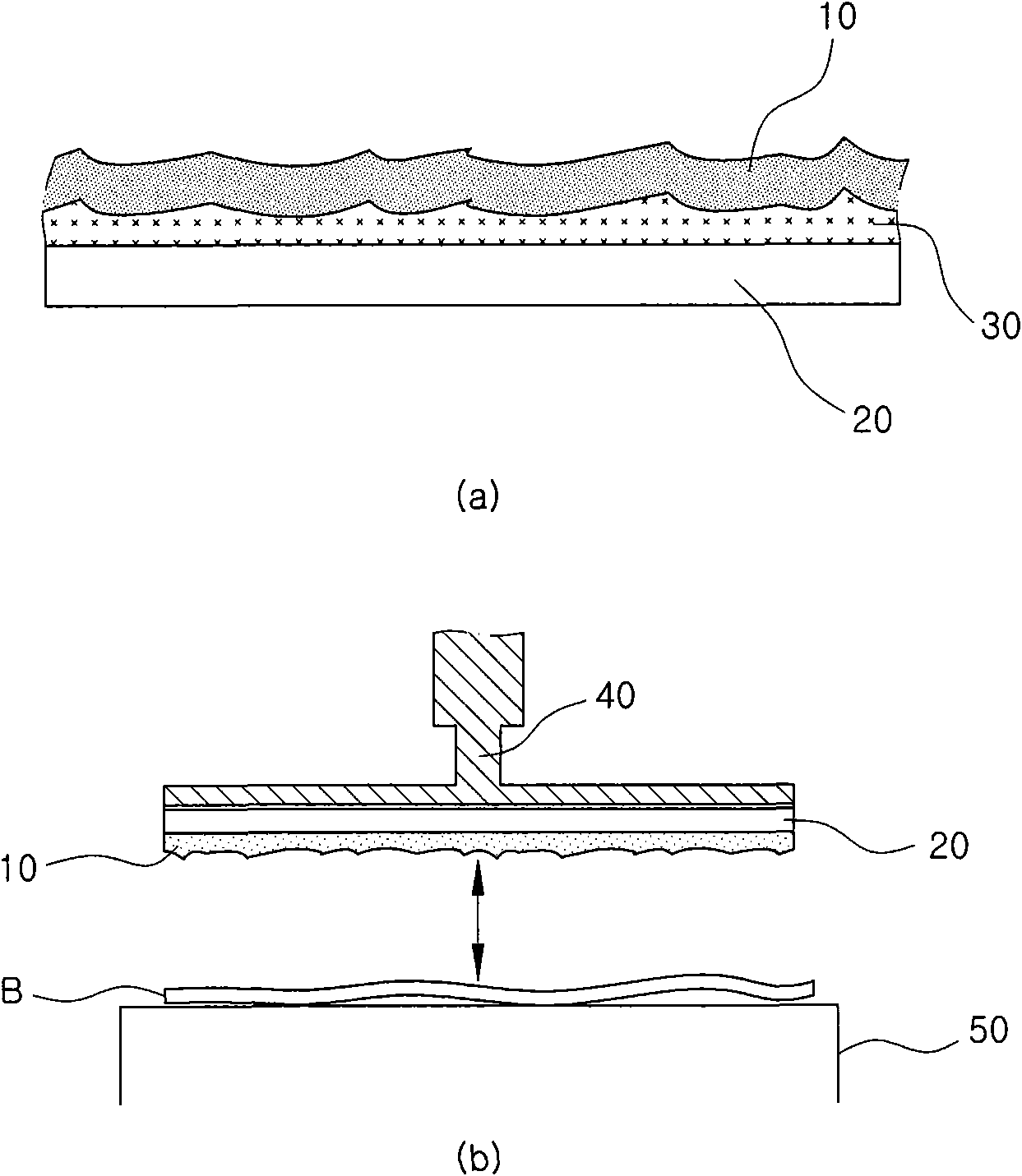

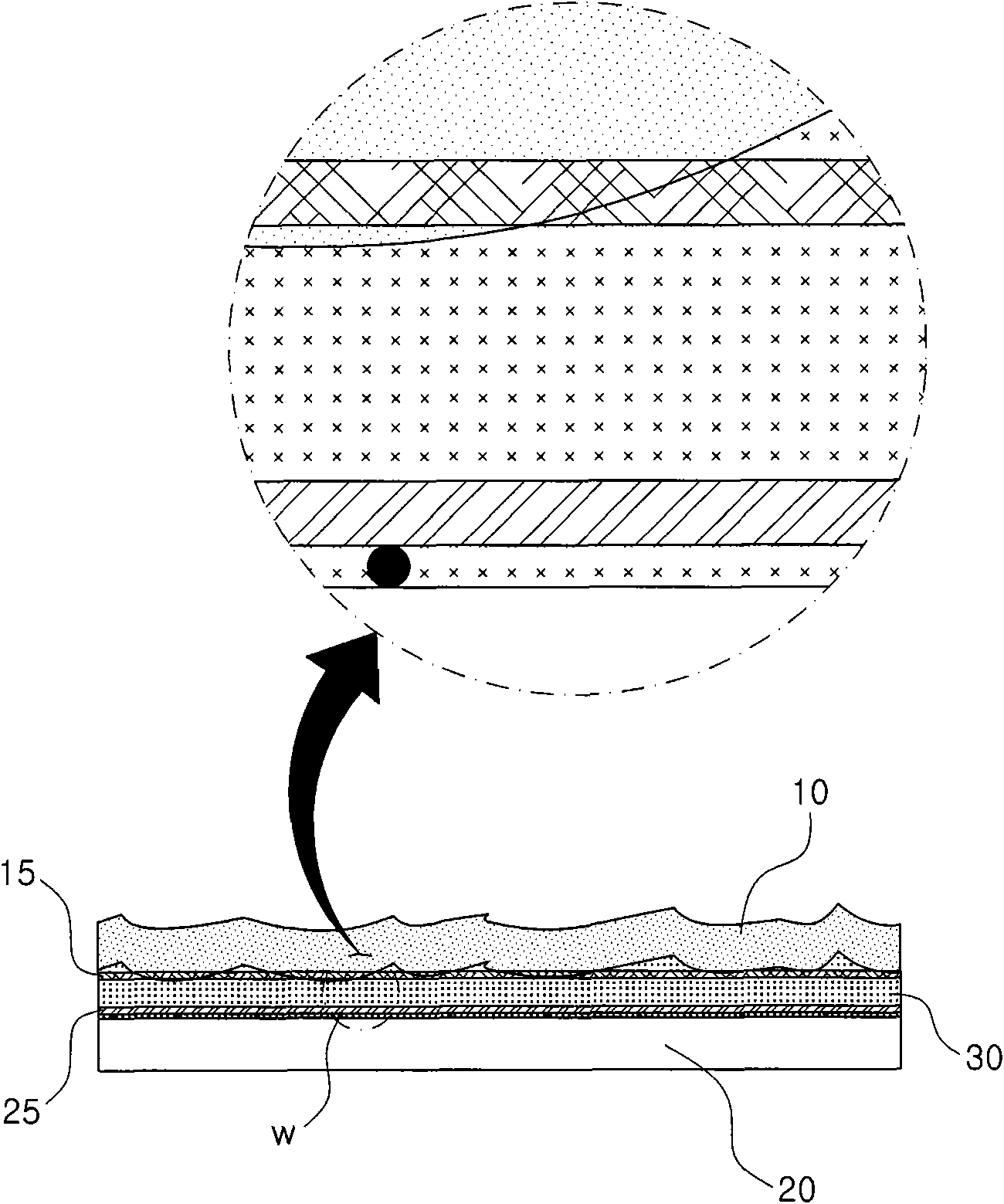

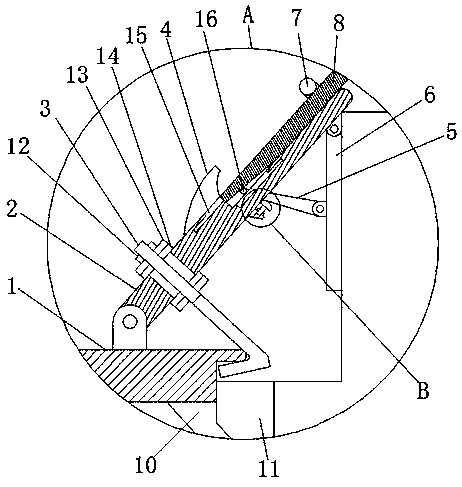

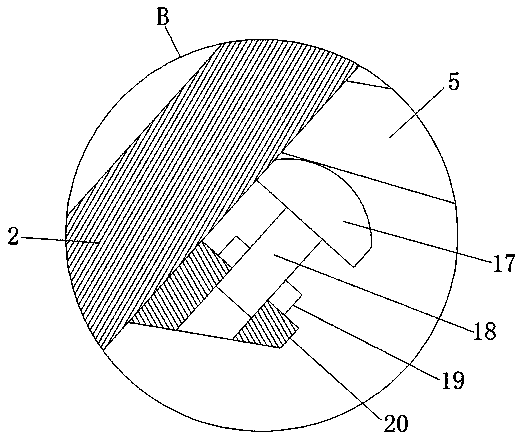

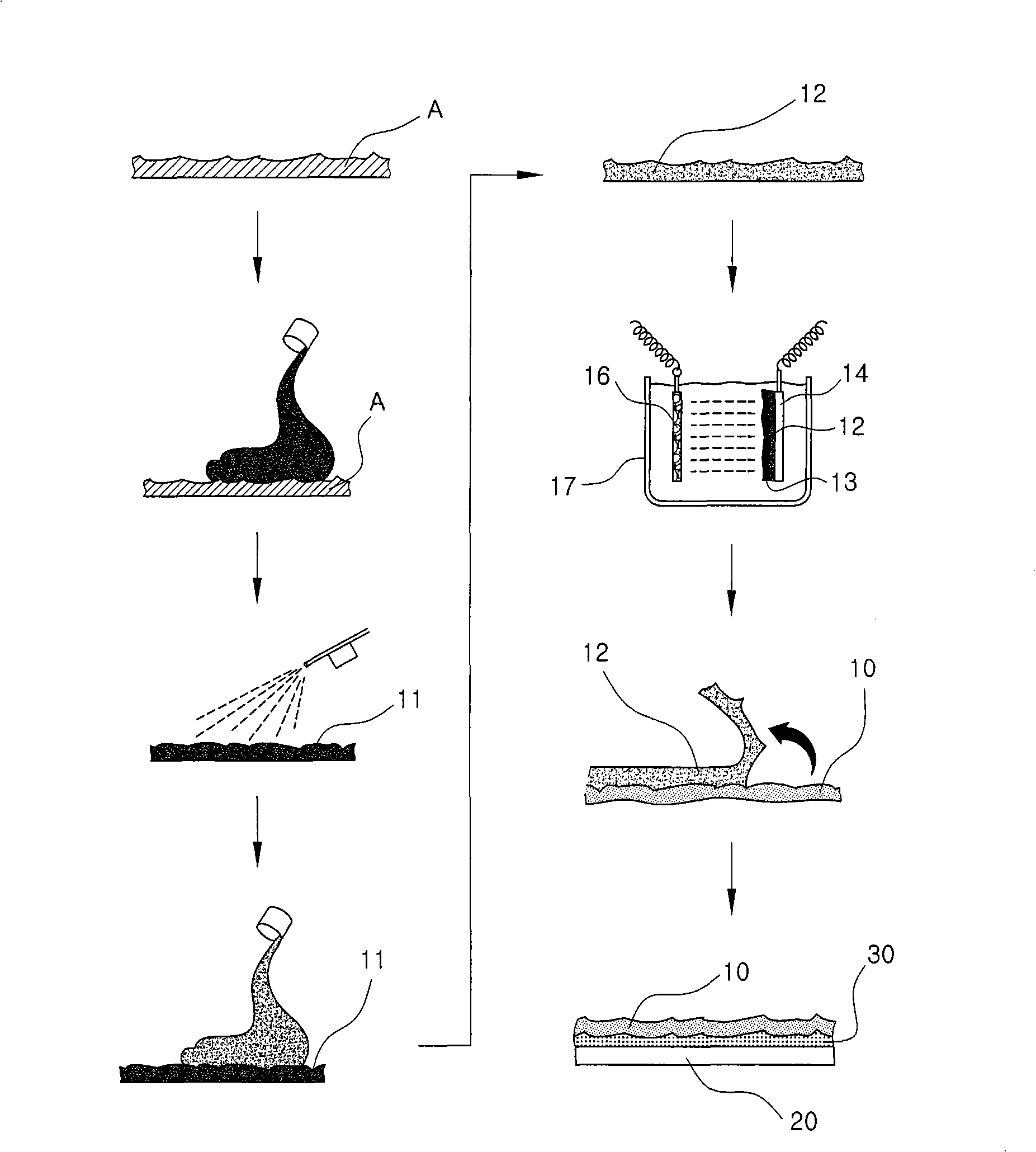

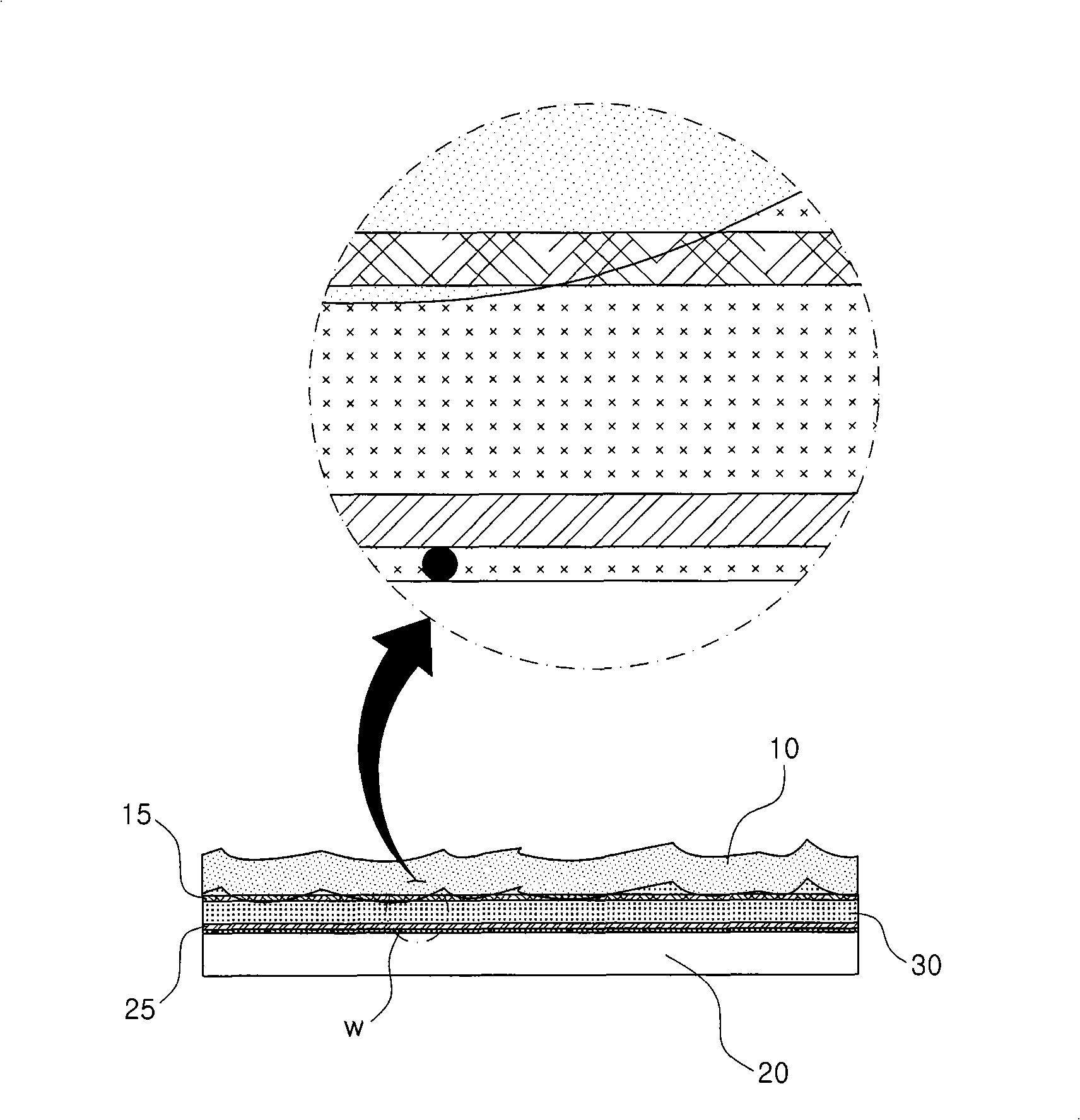

Electroplated embossing plate and the manufacturing method of the same

InactiveCN101831511AAvoid separationSeparation will notLeather surface mechanical treatmentElectroforming processesAdhesiveEngineering

The invention relates to an electroplated embossing plate and the manufacturing method of the same. The electroplated embossing plate comprises: a plating plate (10) capable of forming a leather master mask (A) pattern to be embossed by diaglyph; a mesh structure (15) adhered on the back of the plating plate (10) and forming a plating layer (13) thereon; a support iron plate (20) adhered on the back of the plating plate (10); a metal net (25) welded on the adhering surface of the support iron plate (20); and an adhesive layer (30) for adhering the plating plate (10) and the support iron plate(20) together after hardening the adhesive impregnated into the mesh structure (15) and the metal net (25). The manufacturing method corresponds with the structure of the electroplated embossing plate. Thus the adhesive is impregnated into the mesh structure integrated with the plating plate and the metal net welded with the support iron plate and then hardened, so as to integrate the adhesive layer, the mesh structure with the metal net; even thought the embossing plate is used for a long time, the plating plate is not separated from the support iron plate with increased endurance life.

Owner:玄正淳

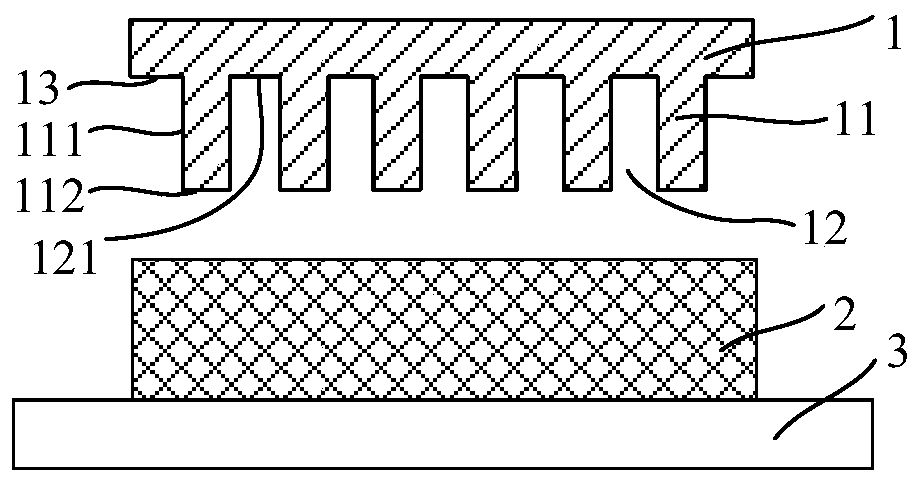

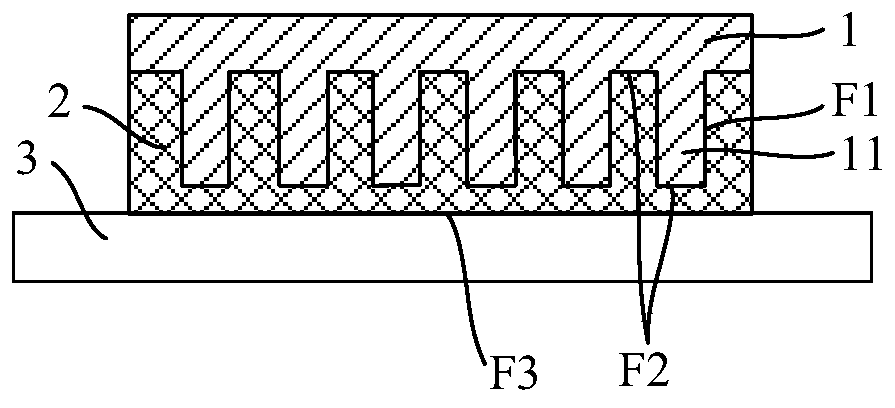

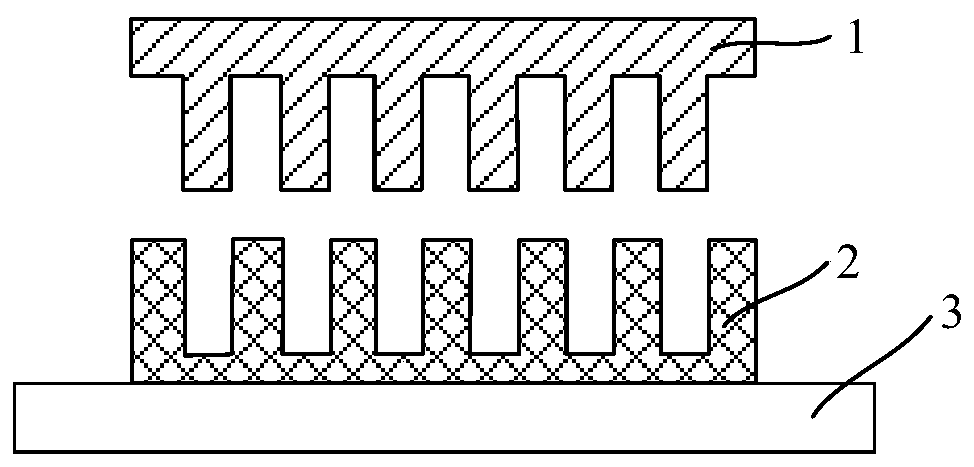

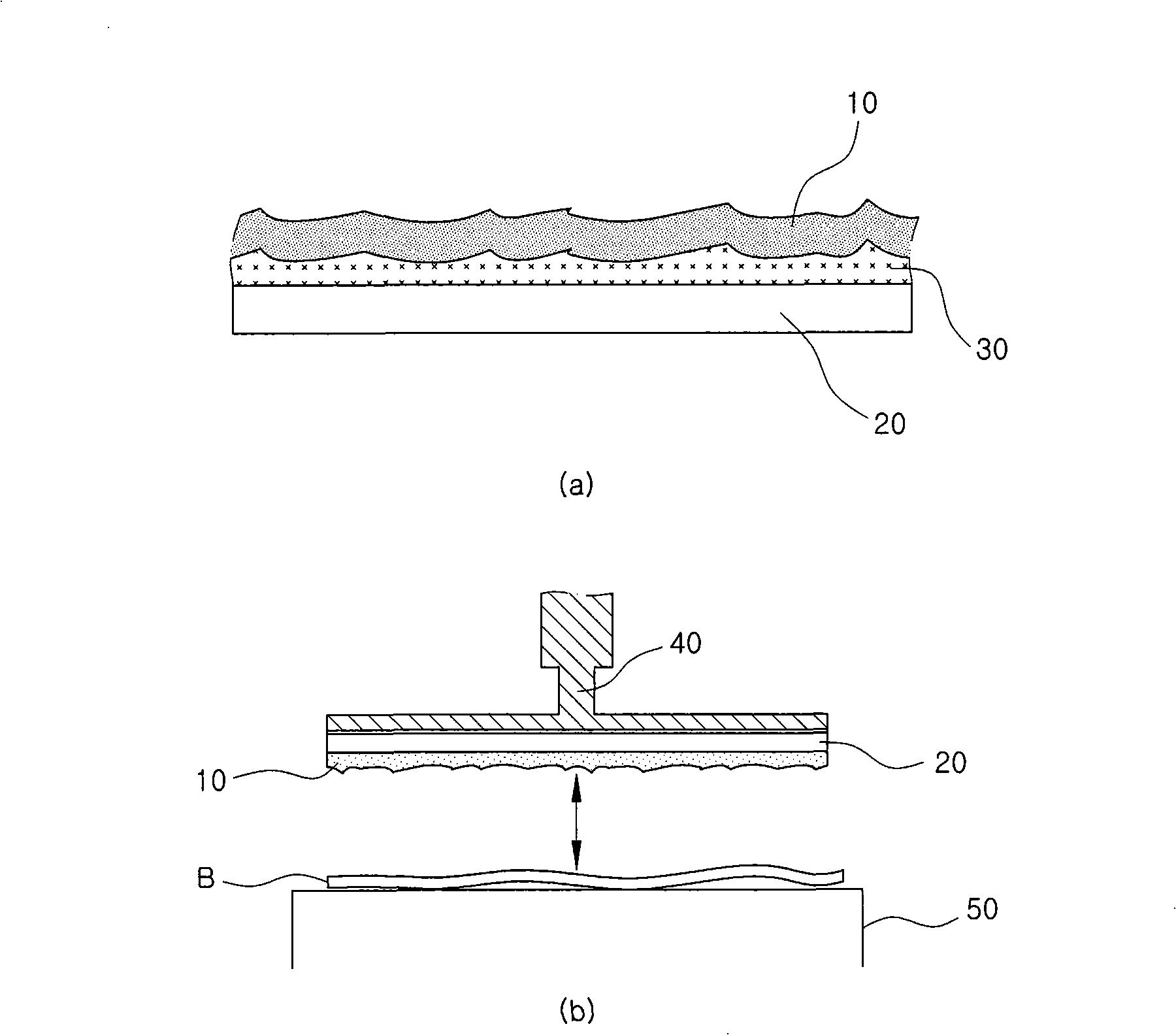

Nanoimprint template, manufacturing method and demolding method thereof

ActiveCN111562719ASeparation will notSeparation will not makePhotomechanical apparatusAdhesiveStructural engineering

The invention discloses a nanoimprint template and a manufacturing method and demolding method thereof. The nanoimprint template includes a first template and a second template. The first template isprovided with an impressing pattern, and the impressing pattern comprises a plurality of impressing columns arranged at intervals and grooves located between the adjacent impressing columns. Wherein second template is provided with a filling pattern, the groove of the first template is filled with the filling pattern, so that the first template and the second template are embedded, and the impressing column penetrates through the second template. The nanoimprint template can reduce the risk that imprint adhesive is separated from the imprint substrate.

Owner:BOE TECH GRP CO LTD

A kind of splint used in coal mining that is beneficial to reduce friction

ActiveCN109681200BEasy to install and disassembleEasy to fixSlitting machinesMining engineeringStructural engineering

The invention discloses a splint for coal mine exploitation which is beneficial to reduce friction, which comprises a base, a bracket and a clamping block. A first fixing plate and a second fixing plate are installed on the base, and the first fixing plate is located on the second fixing plate. The inner side of the first fixed plate is provided with a push rod, the push rod is equipped with a rotating shaft, and the push rod is connected to the base and the movable plate through the rotating shaft, and the middle part of the movable plate is connected with a sleeve. The outer wall of the movable rod is connected with an elastic member, the base is connected with a first screw rod, the bracket is fixed above the second fixed plate, and the clamping block is connected to the bracket and the outer wall of the second screw rod , and the block is located above the movable rod. The splint is used in coal mine development that is conducive to reducing friction. The disassembly and installation of the cable is convenient, and it will not take too much time to install the splint. The fixing of the cable is relatively firm. The cable will not slide inside the device, causing the wire cable wear.

Owner:GUIZHOU UNIV

A kind of surface modification technology of rubber shoe material

The invention discloses a rubber shoe material surface finishing process. The rubber shoe material surface finishing process comprises the following steps that 1, rubber shoe material surface treatment is performed: a treating agent special for rubber is adopted to clean the outer surface of a shoe material and make the outer surface become soft, and drying is performed for 10-20 minutes; 2, primer spraying is performed: a spraying device is adopted to spray a primer on the rubber shoe material, a layer of flat primer plane is formed on the outside of the rubber shoe material, and then drying is performed in an environment of 60-70 DEG C for 10-20 minutes; the primer is prepared from, by weight, 100 parts of main bottom agent, 20-30 parts of hardener, 30-50 parts of diluent and 1-10 parts of binder; 3, metal spraying is performed: the spraying device is adopted to spray an imitated metal layer on the primer, and then drying is performed in an environment of 60-70 DEG C for 5-10 minutes; 4, finish paint spraying is performed: the spraying device is adopted to spray a layer of finish paint on the outside of the imitated metal layer, and then drying is performed for 30-50 minutes to obtain the finished shoe material, wherein the finish paint is prepared from, by weight, 100 parts of main face agent, 20-30 parts of hardener, 30-50 parts of diluent and a proper amount of pigments. The rubber shoe material surface finishing process has the advantage of being good in ornamental effect.

Owner:晋江国盛新材料科技有限公司

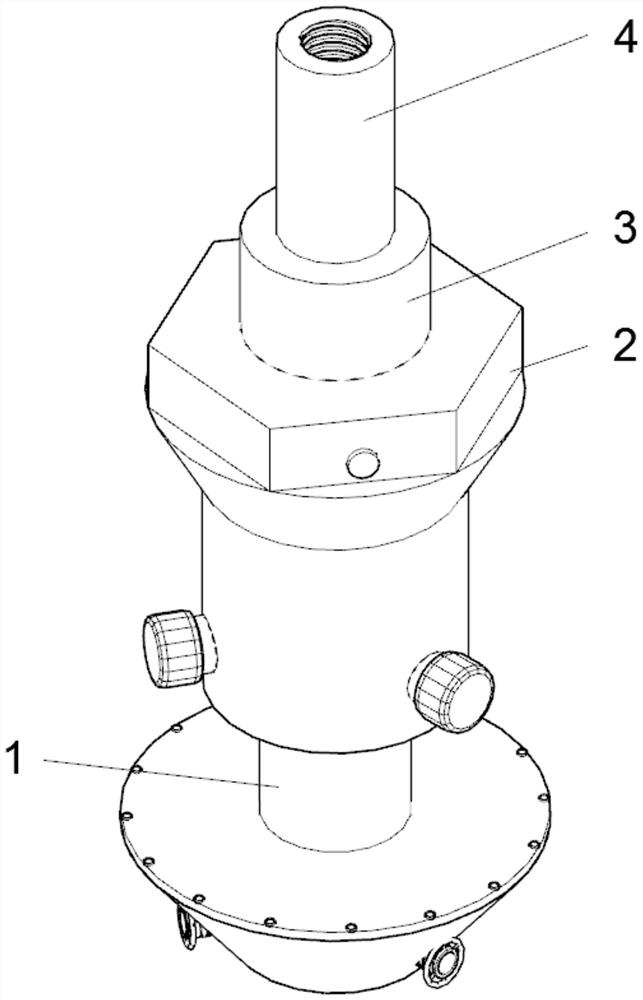

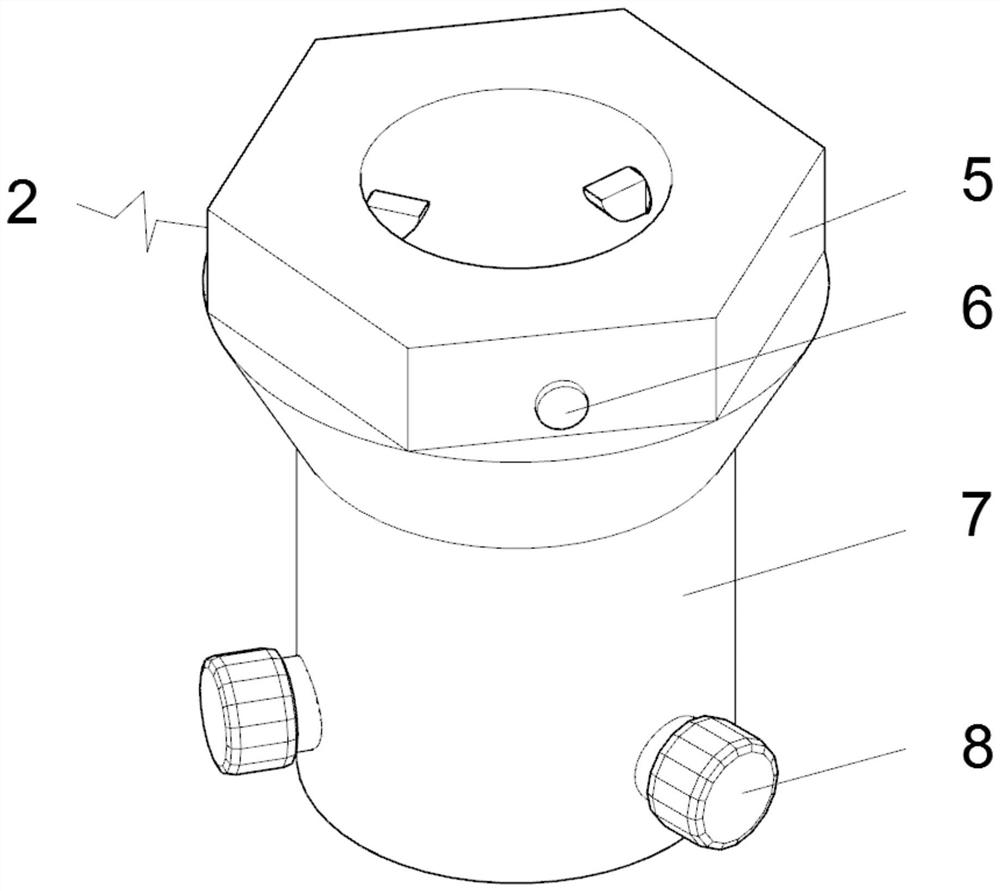

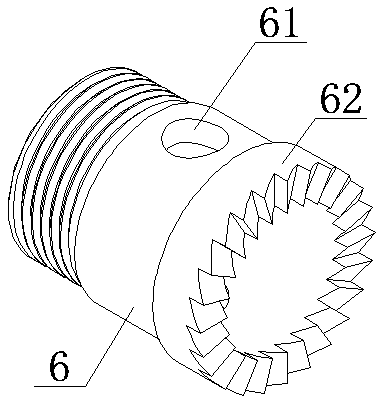

Sewage cleaning device for sewage pipeline maintenance

ActiveCN111622340AQuick changeQuick slide separationSewer cleaningMechanical engineeringThreaded rod

The invention discloses a sewage cleaning device for sewage pipeline maintenance. The sewage cleaning device comprises a fixing mechanism, wherein a fastening column is mounted at the bottom of the fixing mechanism, a fixing column is fixedly connected to the upper end of the fastening column, three adjusting pieces are uniformly installed on the fixing column, the three adjusting pieces are distributed in a triangular distribution manner, and fastening pin bodies are uniformly and movably inserted into the bottom end of the fastening column; and an adjusting connecting pipe is fixedly connected to the upper end surface of the fixing column, a connecting threaded rod is fixedly connected to the middle of the upper end face of the adjusting connecting pipe, a first adjusting column is mounted in the middle of the adjusting piece, the front end of the first adjusting column is fixedly connected with a supporting block, and the tail end of the first adjusting column is fixedly connected with a second adjusting column. According to the sewage cleaning device, the sewage at a sewage discharge pipe of the maintenance position can be quickly and conveniently cleaned in the use process, and the device can be adjusted and replaced quickly in the use process, so that an operator is in contact with the sewage to the minimum degree.

Owner:广东省九建建设集团有限公司

A kind of surface modification process of shoe material substrate

The invention discloses a shoe sole material surface decoration technology comprising the following steps of (1) processing the surface of the shoe sole material, (2) spraying base paint, (3) spraying metal, (4) spraying surface paint. In the first step, a processing agent corresponding to material of the external surface of a visible part in the sole material; the external surface of the visible part of the sole material is cleaned and softened, and then dried for 10 to 20 mins; in the second step, the sole material is spayed via a spraying device, so a flat base paint plane can be formed on the external part of the sole material, and then the base paint layer is dried for 20 to 30 mins at the temperature of 60 to 70 DEG C; in the third step, a metal-like layer is sprayed on the base paint layer via the spraying device and then the base paint layer is dried for 5 mins at the temperature of 60 to 70 DEG C; and in the fourth step, surface paint is sprayed on the metal-like layer via the spraying device and then dried to acquire decorated shoe sole material. The decoration layer can be directly formed on the external surface of the sole material, so a characteristic of great decorating effect can be achieved.

Owner:晋江国盛新材料科技有限公司

A quick demoulding device for casting

ActiveCN108817360BImprove buffering effectImprove separation efficiencyMould handling equipmentsStructural engineeringCam

The invention discloses a rapid demoulding device for casting, comprising a concave die and a convex die. A right top plate is arranged on the right side of the concave die, a notch is machined inside the right top plate, and a screw hole is machined on the right column. , the slot is communicated with the screw hole, a stop is placed inside the slot, a screw is placed on the right side of the stop, the fixing plate is welded and fixed in the middle of the left and right columns, and the fixing plate A connecting rod is welded and fixed on the upper part, and a sleeve A is welded and fixed at the front and rear ends of the connecting rod respectively, and the sleeve A is sleeved on the guide rail; the bottom ends of the left column and the right column are welded and fixed to the bottom plate, and the bottom plate is welded and fixed. The bottom is provided with a cam. The present invention utilizes inertia to separate the die and the punch, the separation efficiency is high, and the castings in the die are not damaged, the efficiency of die separation is greatly improved, and the production qualification rate of the castings is also improved, which is beneficial to improving the efficiency of enterprises. It is of great significance to improve production efficiency and improve the yield rate of enterprises.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

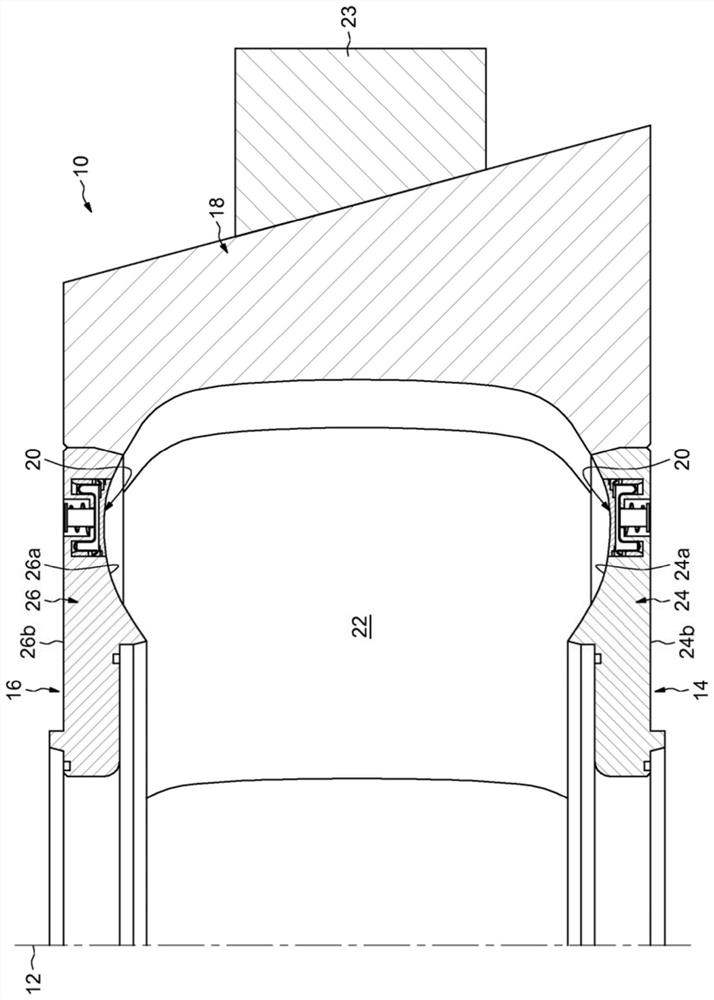

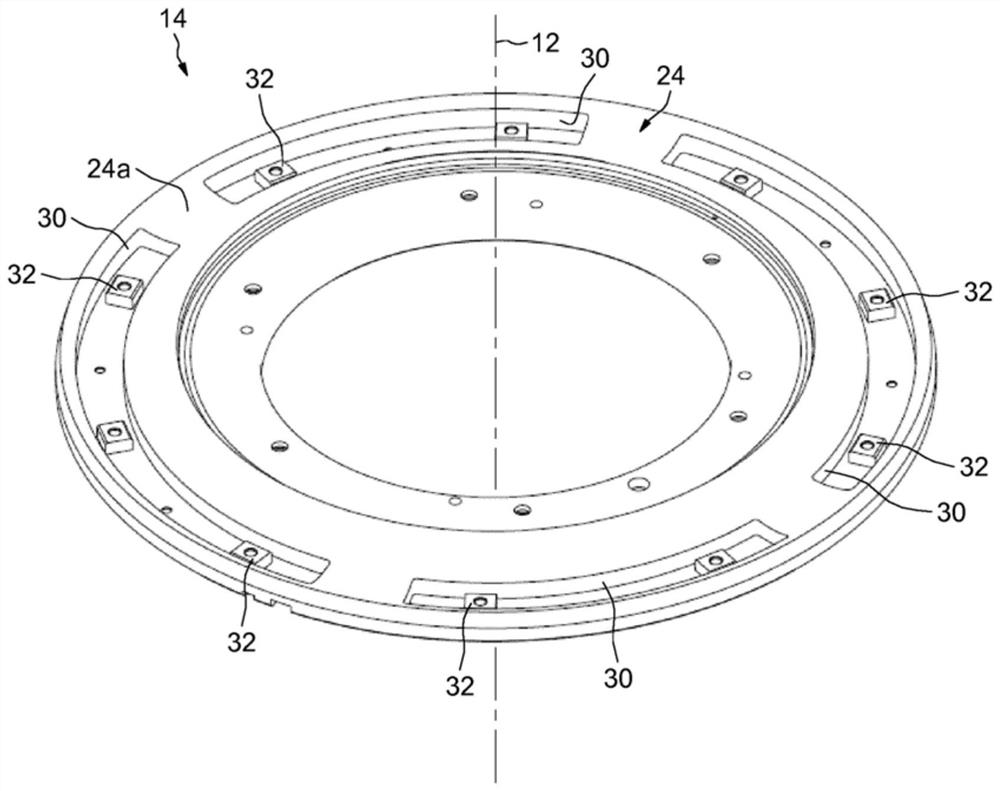

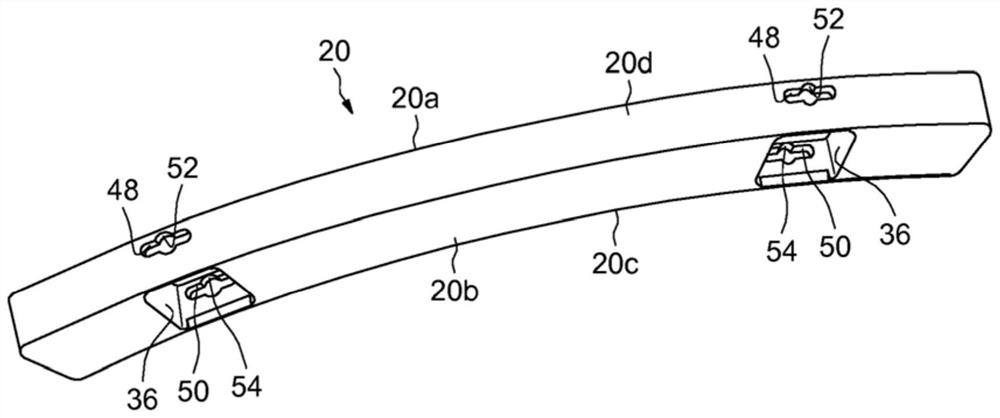

Mold elements for tire molds including removable inserts

ActiveCN110177680BEasy to dismantleQuick installationTyresSecuring devicesEngineeringMechanical engineering

The mold element (14) comprises a main body (24), at least one insert (20), and at least one fixing device, the main body (24) being provided with all or part of one of a sidewall or a tread suitable for molding a tire a molding face (24a), at least one recess (30) formed in the molding face, said insert (20) being accommodated in said recess, said fixing means adapted to remove said insert Fixed to the main body, said insert is provided with an inner molding surface comprising marking means adapted to mold a pattern on the tyre.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

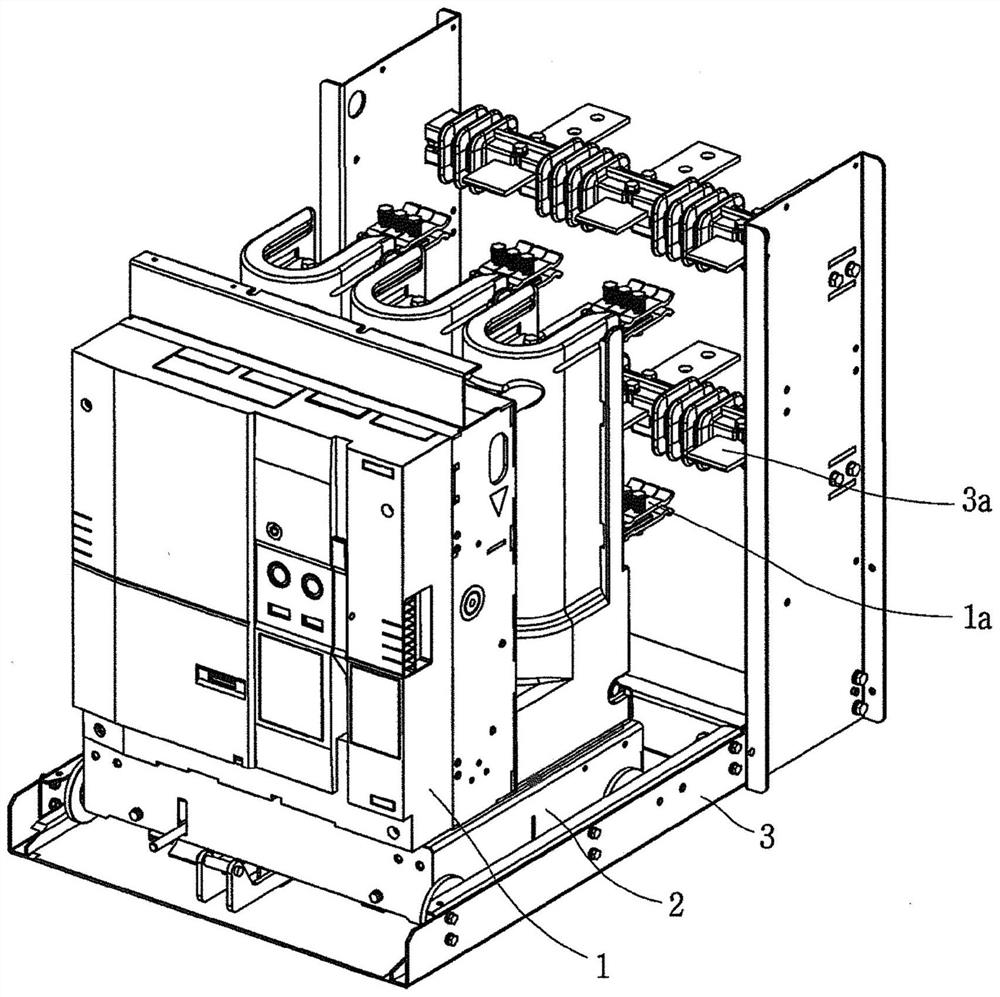

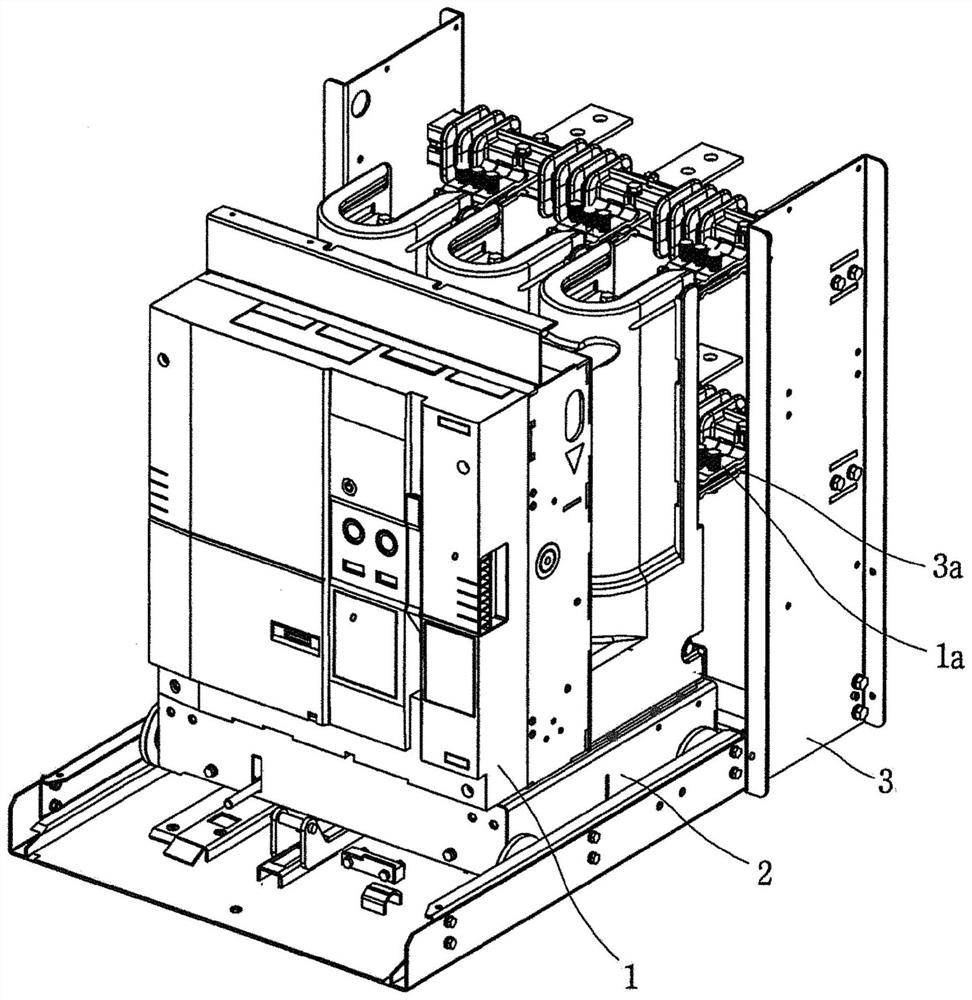

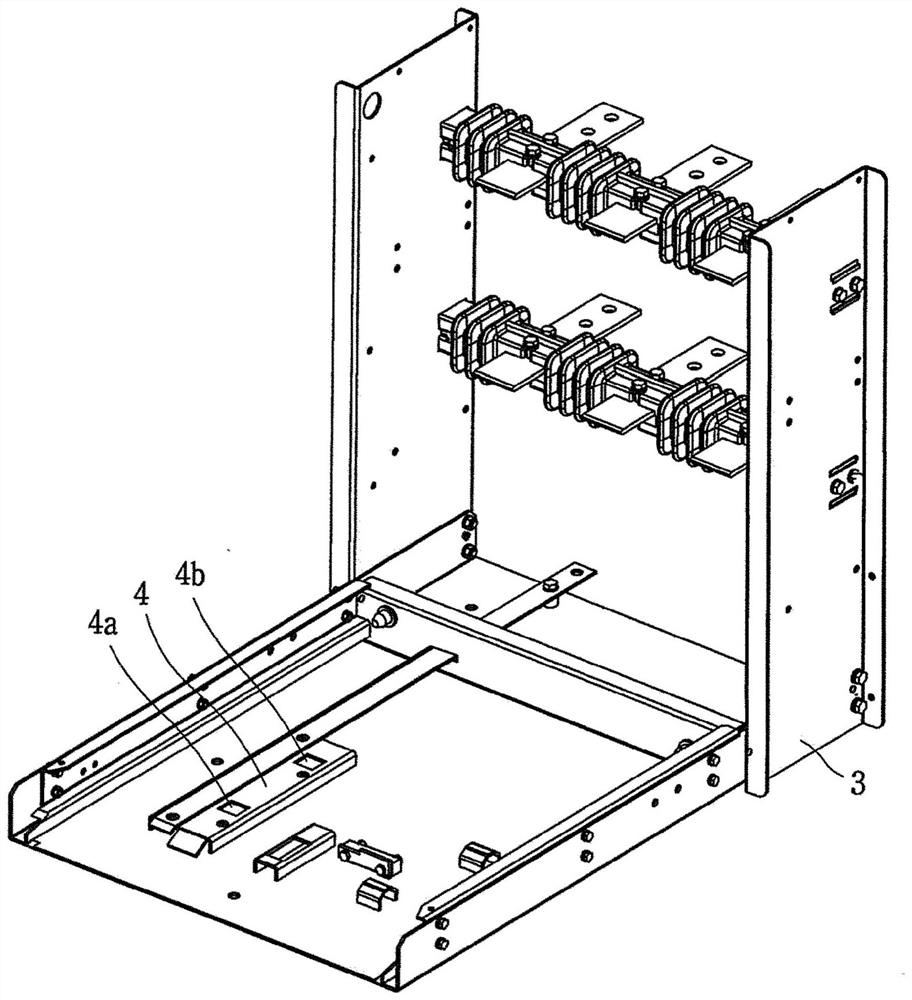

Plug interlocking device of circuit breaker

PendingCN114730677ASimple compositionSeparation will notSwitchgear with withdrawable carriageHigh-tension/heavy-dress switchesStructural engineeringControl line

Owner:LS电气株式会社

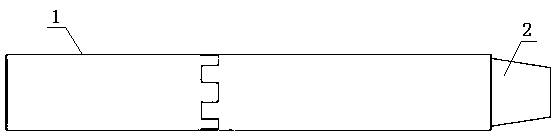

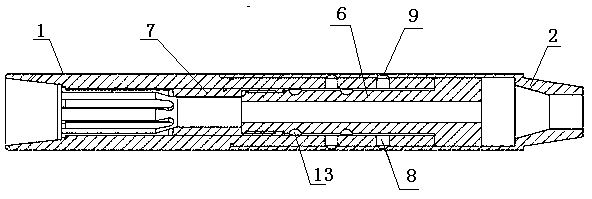

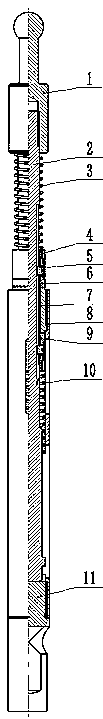

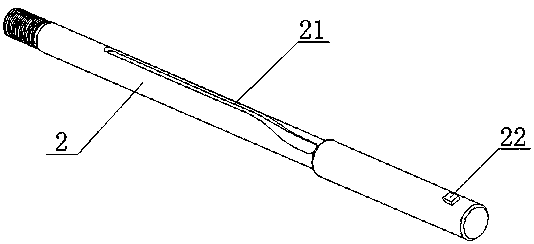

A coiled tubing string hydraulic breaking device

The invention relates to a coiled tubing tubular column hydraulic breakage device. A plurality of hole channels are formed in the lower end of an upper tubular column, adjacent two lines of hole channels formed in an interlacing mode and a ball is arranged in each hole channel; concave holes are formed in the inner wall of a lower contact, the upper tubular column inserts into the lower contact and each hole channel of the upper tubular column corresponds to each concave hole of the lower contact in a one-to-one mode; the lower end of a chuck is connected with a supporting piston in a threading mode and the chunk and the supporting piston are located in the cavity formed by the upper tubular column and the lower contact; the chuck communicates with the supporting piston by respective center passageway; chuck jaws are arranged on the upper portion of the chuck, a clamping shoulder is formed at the upper end of each chuck jaw correspondingly and chunk jaws are clamped on a boss of the upper tubular column by the clamping shoulder; a piston shoulder of the supporting piston is clamped at the lower end opening of the upper tubular column; sliding grooves are formed in the external wallof the supporting piston and a pit is formed in each sliding groove correspondingly; when the piston shoulder moves to a circular bead of the upper tubular column, the pits of the sliding grooves correspond to hole channels of the upper tubular column in a one-to-one mode. A repeating shaking shock can be borne and is prevented from separating prematurely and the chuck is not out of operation prematurely.

Owner:NORTHEAST GASOLINEEUM UNIV

A cutting device for corrugated paper with fixed cutting distance, convenient adjustment and protective function

ActiveCN112009020BPop up automaticallySame distanceBox making operationsPaper-makingStructural engineeringElectrical and Electronics engineering

The invention discloses a cutting device for corrugated paper with a fixed cutting distance, convenient adjustment and protection function, which comprises a push plate and a support table, the push plate is slidably installed on the upper part of one end of the support table, and the inside of the push plate is opened with a A card slot is placed, and a moving card slot is opened through the middle of one end of the support table close to the push plate. The middle part of the end is fixedly connected with a connecting plate, an adjustment device is installed under the support platform, a cutting protection device is installed above the adjustment device, and a limiting plate is installed in the adjustment device. The device can quickly cut corrugated paper in the process of use, and the cutting distance of the cut corrugated paper is the same, which ensures the same specification of the cut corrugated paper, and can protect the operator during use, and the use and adjustment are convenient and quick.

Owner:云南汇盈环保包装科技有限公司

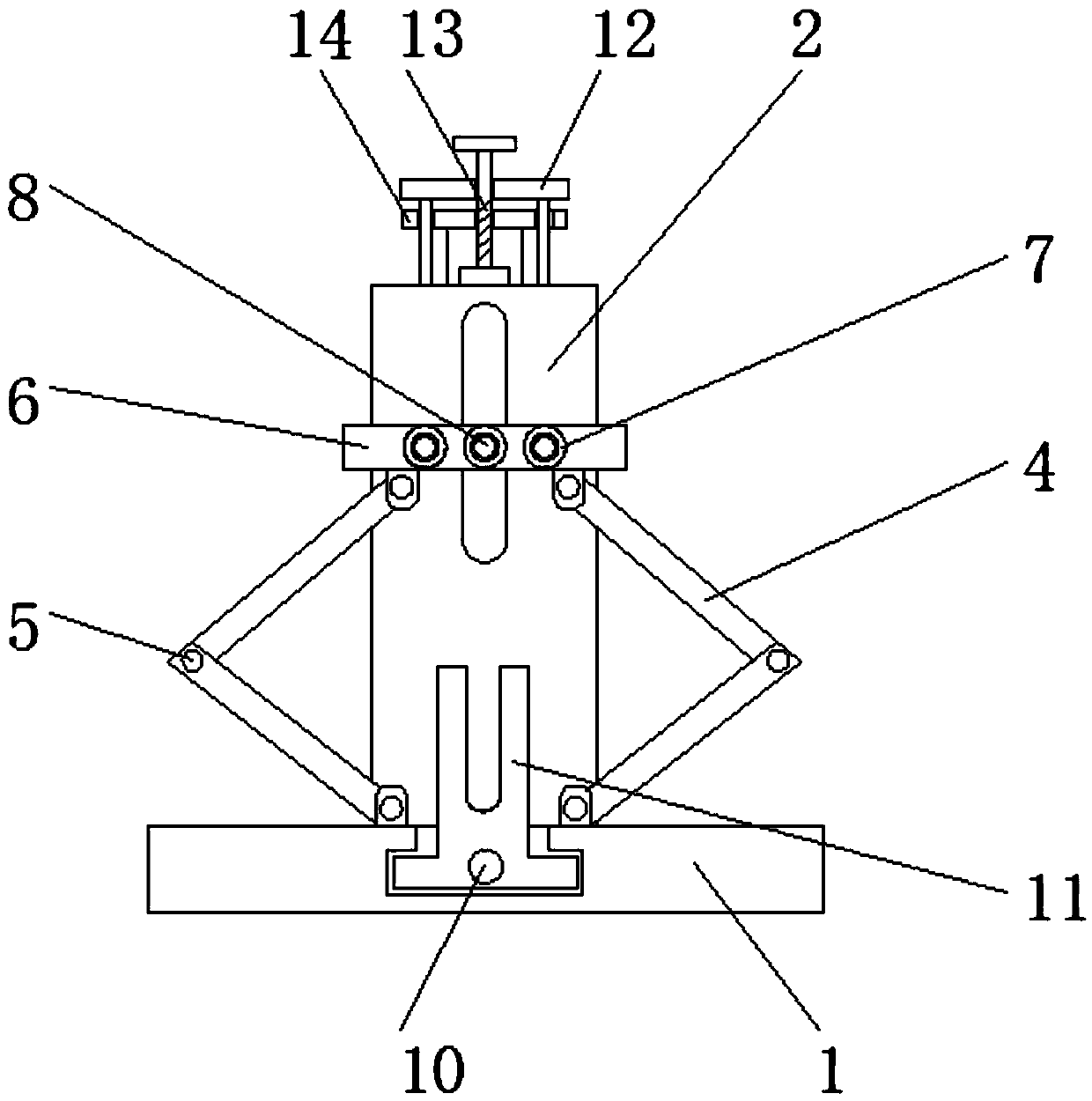

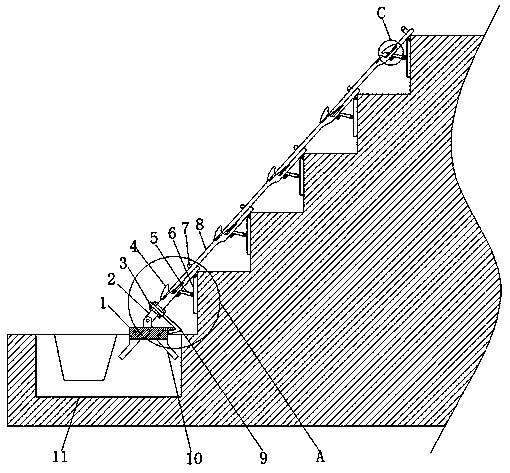

Combined connecting device for cutting transition section

The invention belongs to the technical field of roadbed transition sections, and especially relates to a cutting transition section combined connecting device. For the problems that a cutting transition section is easy to slide, an existing device is not convenient to install and cannot be suitable for all cutting heights, the following scheme is completed: the device comprises a base, a first fixing rod is rotationally connected to the top end of the base, a first groove is formed in the top end of the first fixing rod, a second fixing rod is arranged at the position, at the first groove, ofthe first fixing rod, and supporting plates are rotationally connected to the top ends of the first fixing rod and the second fixing rod. A threaded column drives the supporting block to ascend, the supporting block is in contact with a supporting column, the supporting column is rotated to drive the connecting rod to move upwards, the connecting rod enables the second fixing rod to rotate throughthe slope opening of the second fixing rod, then the connecting rod forms a lever through supporting of the fixing shaft and the second fixing rod to apply force to the road cutting, finally the roadcutting is fixed through the supporting plate and the supporting column on the second fixing rod, and landslide is avoided.

Owner:HUBEI UNIV OF TECH

Electroplated embossing plate and the manufacturing method of the same

InactiveCN101831511BAvoid separationSeparation will notLeather surface mechanical treatmentElectroforming processesAdhesiveEngineering

The invention relates to an electroplated embossing plate and the manufacturing method of the same. The electroplated embossing plate comprises: a plating plate (10) capable of forming a leather master mask (A) pattern to be embossed by diaglyph; a mesh structure (15) adhered on the back of the plating plate (10) and forming a plating layer (13) thereon; a support iron plate (20) adhered on the back of the plating plate (10); a metal net (25) welded on the adhering surface of the support iron plate (20); and an adhesive layer (30) for adhering the plating plate (10) and the support iron plate(20) together after hardening the adhesive impregnated into the mesh structure (15) and the metal net (25). The manufacturing method corresponds with the structure of the electroplated embossing plate. Thus the adhesive is impregnated into the mesh structure integrated with the plating plate and the metal net welded with the support iron plate and then hardened, so as to integrate the adhesive layer, the mesh structure with the metal net; even thought the embossing plate is used for a long time, the plating plate is not separated from the support iron plate with increased endurance life.

Owner:玄正淳

Well testing steel wire releasing tool

PendingCN108487872ASimple construction and applicationSimple construction applicationBorehole/well accessoriesEngineering

Owner:YANCHENG QINGLONG MACHINERY

A kind of surface modification process of tpr shoe material

The invention discloses a TPR shoe surface modification technology. The modification technology comprises the following steps of (1) a TPR shoe surface processing step, in which a TPR specific processing agent is employed to clean the external surface of the shoe and soften the external surface, and the shoe external surface is dried for 10 to 20 minutes, (2) a priming paint spraying step, in which a paint spraying device is employed to spray priming paint to the TPR shoe to form a flat priming paint plane on the external of the TPR shoe, and then the shoe sprayed with the priming paint is dried by 10 to 20 minutes at the temperature of 60 to 70 DEG C, (3) a metal spraying step, in which a spraying device is employed to spray an imitating metal layer on the priming paint, and then the imitating metal layer is dried for 5 to 10 minutes at the temperature of 60 to 70 DEG C, and (4) a spraying device is employed to spray a layer of surface paint on the external surface of the imitating metal layer and then the shoe is dried. The modified shot can be achieved at last. The priming paint is composed of the following components according to weight by parts: 100 parts of base main resin, 10 to 30 parts of hardener, 30 to 80 parts of diluents and 1 to 10 parts of binding agents; and the surface paint is formed by the following components according to weight by parts: 100 parts of surface main resin, 30 to 50 parts of hardener, 50 to 80 parts of diluents and proper pigment. The TPR shoe surface modification technology is characterized by great decorating effect.

Owner:晋江国盛新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com