Anti-drop single-jack plug socket

A plug and socket, anti-falling technology, applied in the direction of two-part connection devices, electrical components, coupling devices, etc., can solve problems such as plugs cannot be inserted smoothly, equipment cannot operate normally, and the area occupied by the jack is large, so as to reduce power consumption Potential safety hazards, material saving, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

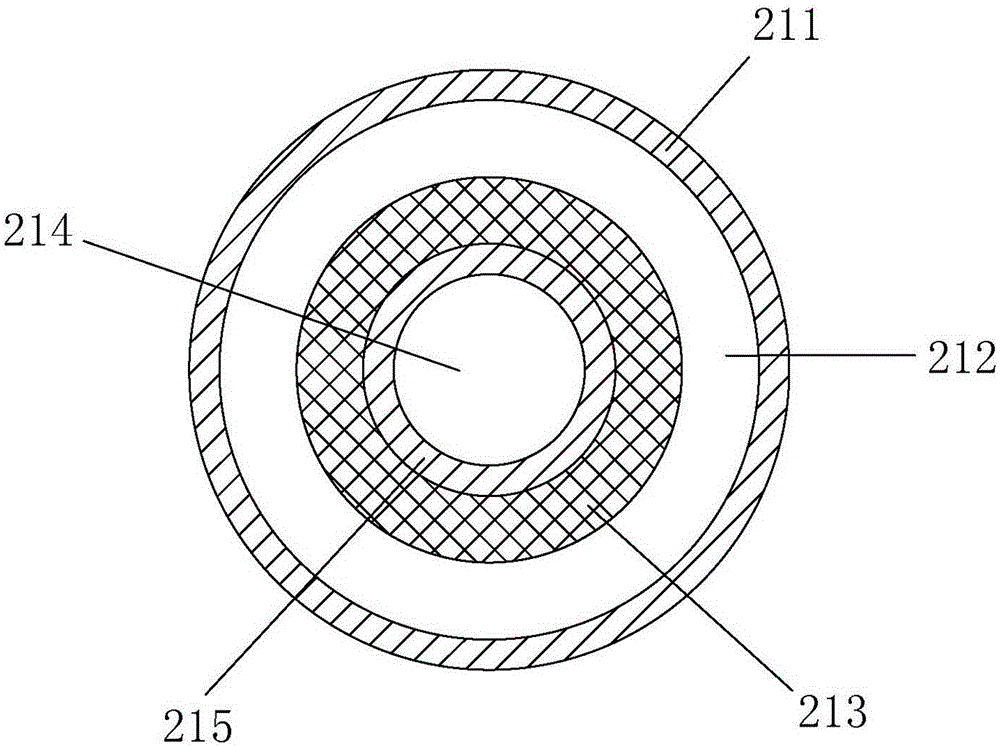

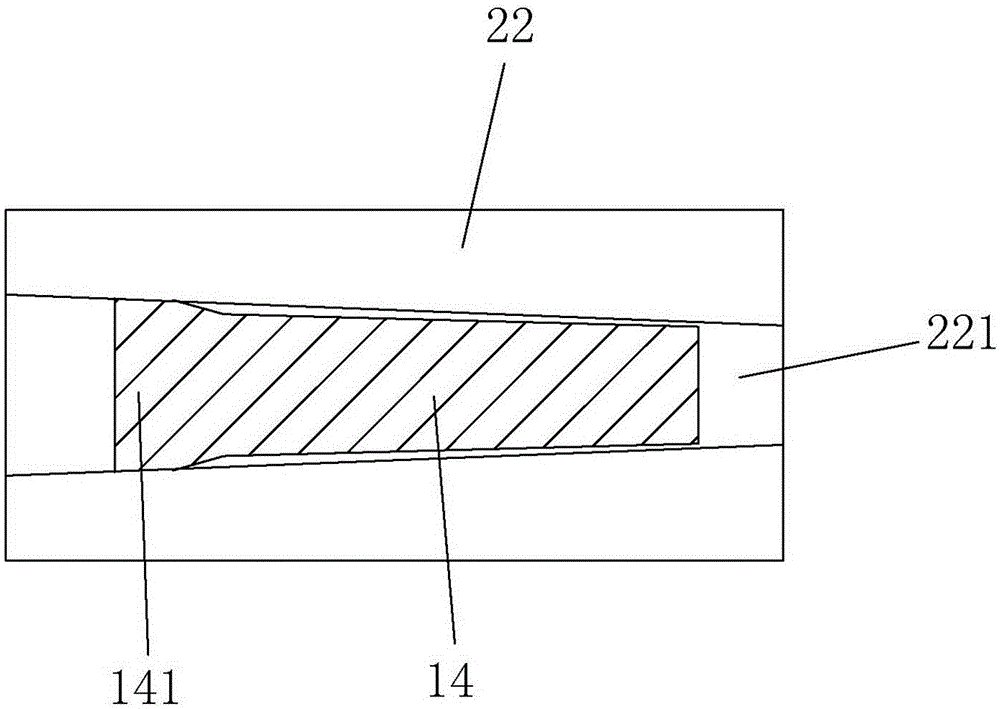

[0019] Embodiment 1: as Figure 1 to Figure 3 As shown, an anti-falling single-hole plug and socket includes a plug 1 and a socket 2. The plug 1 includes an insulating seat 11, a post 12 arranged on the insulating seat 11, and an insert 13 arranged on the periphery of the post 12. The post A gap is provided between 12 and the insertion piece 13, and the insertion post 12 and the insertion piece 12 are respectively connected with wires. The insulating base 11 is provided with a power switch 15 , and the power switch 15 controls the contact or disconnection of the inserting column 12 or the inserting piece 13 with the wire in the insulating base 11 . The socket 2 is an in-line socket with jacks 21 arranged on the socket 2 along a straight line, and a switch button 23 is provided at one end of the socket 2 . The side wall of the socket 21 is provided with an outer conductive piece 211, and an insulating column 213 is arranged in the middle of the jack 21. A slot 212 for insertin...

Embodiment 2

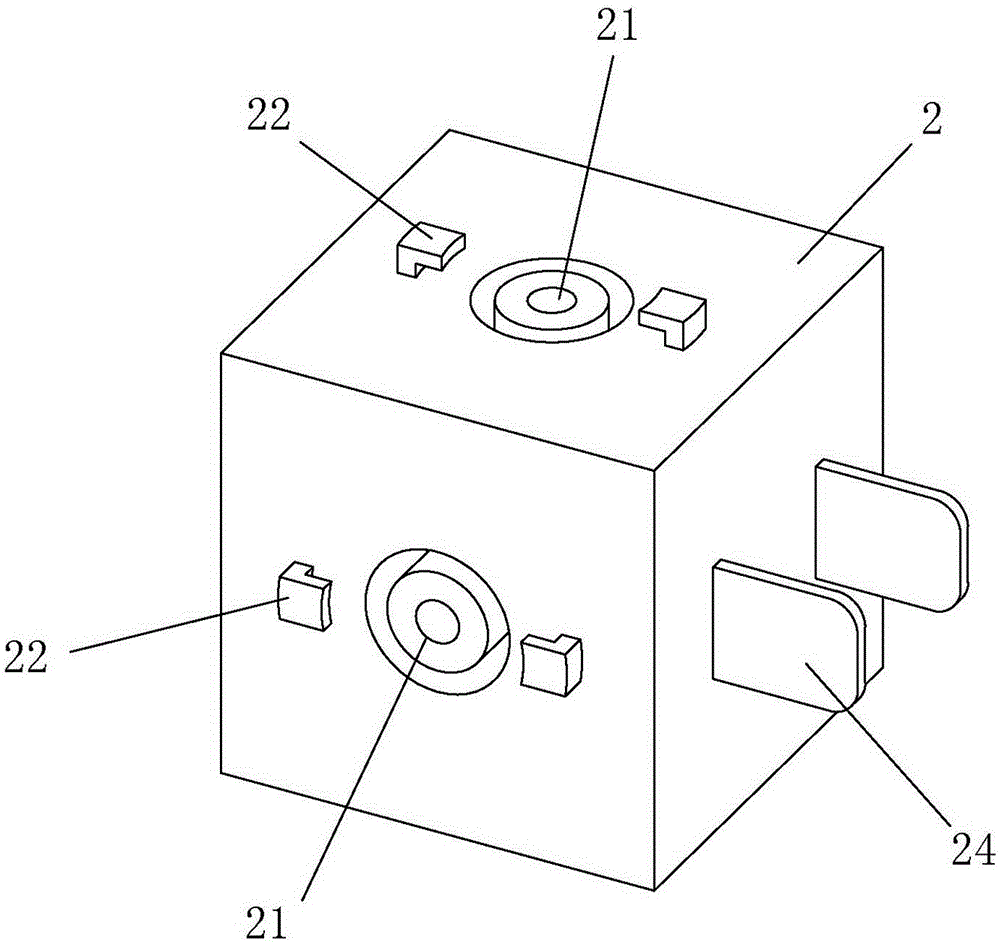

[0020] Embodiment 2: as Figure 4 As shown, the difference from the above embodiment is that the socket 2 is a cube structure, the four end faces of the socket 2 are provided with jacks 21, the fifth end face of the socket 2 is provided with a conductive part 24, and the sixth end face is provided with a conductive part 24. A connection hole matching the conductive part 24 is provided, so that any number of sockets 2 can be connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com