Washing-agent putting box of roller washing machine

A technology for a detergent delivery box and a drum washing machine is applied in the field of washing machines, which can solve the problems of long pipelines, detergent leakage, and high product cost, and achieve the effect of streamlining and optimizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

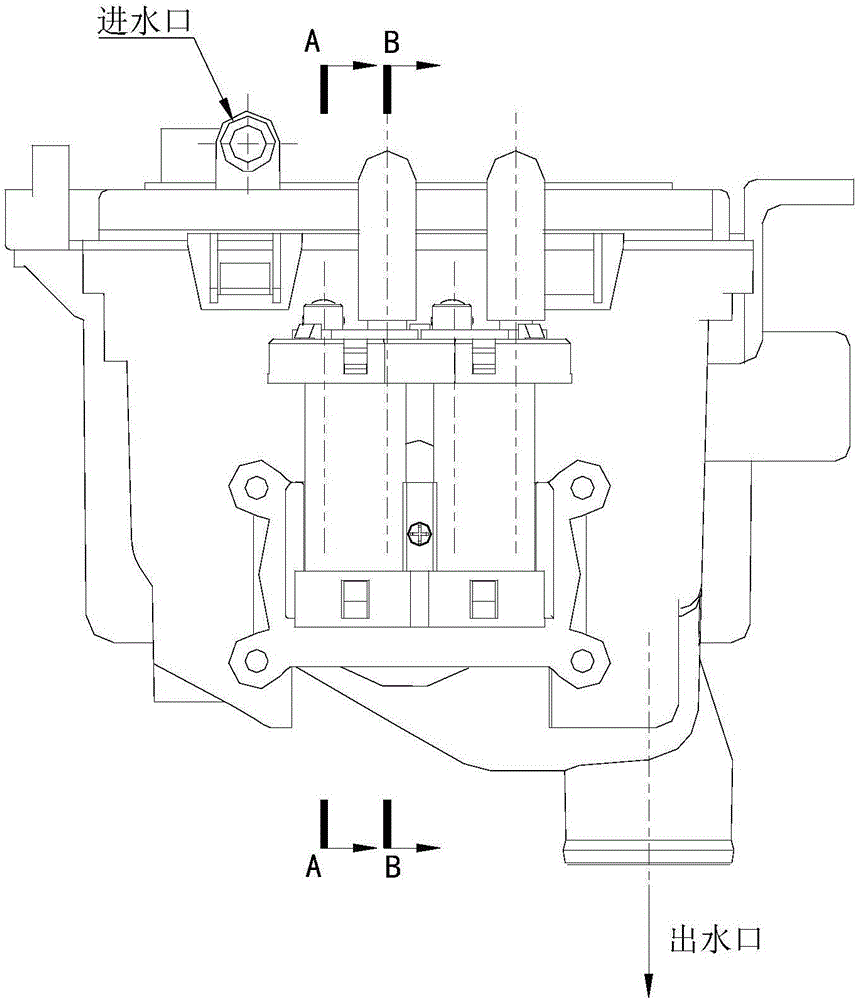

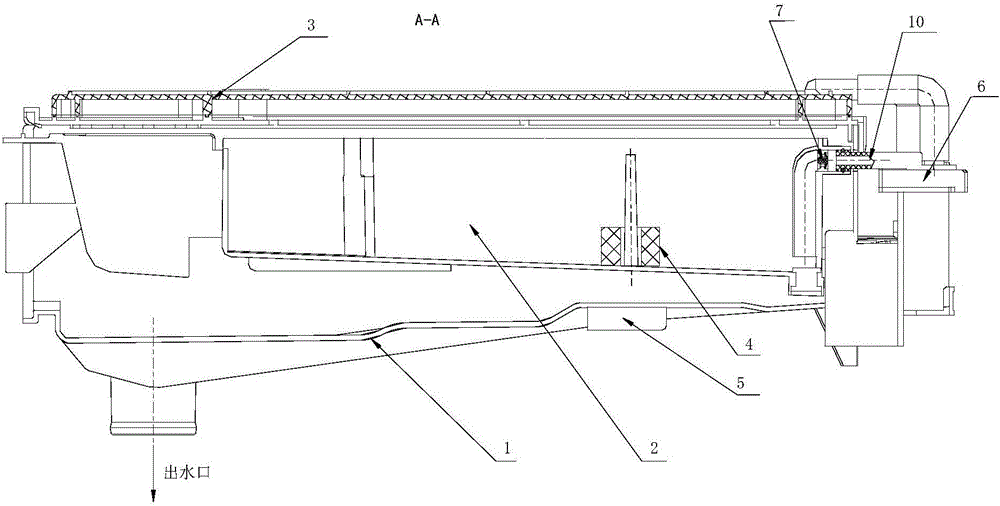

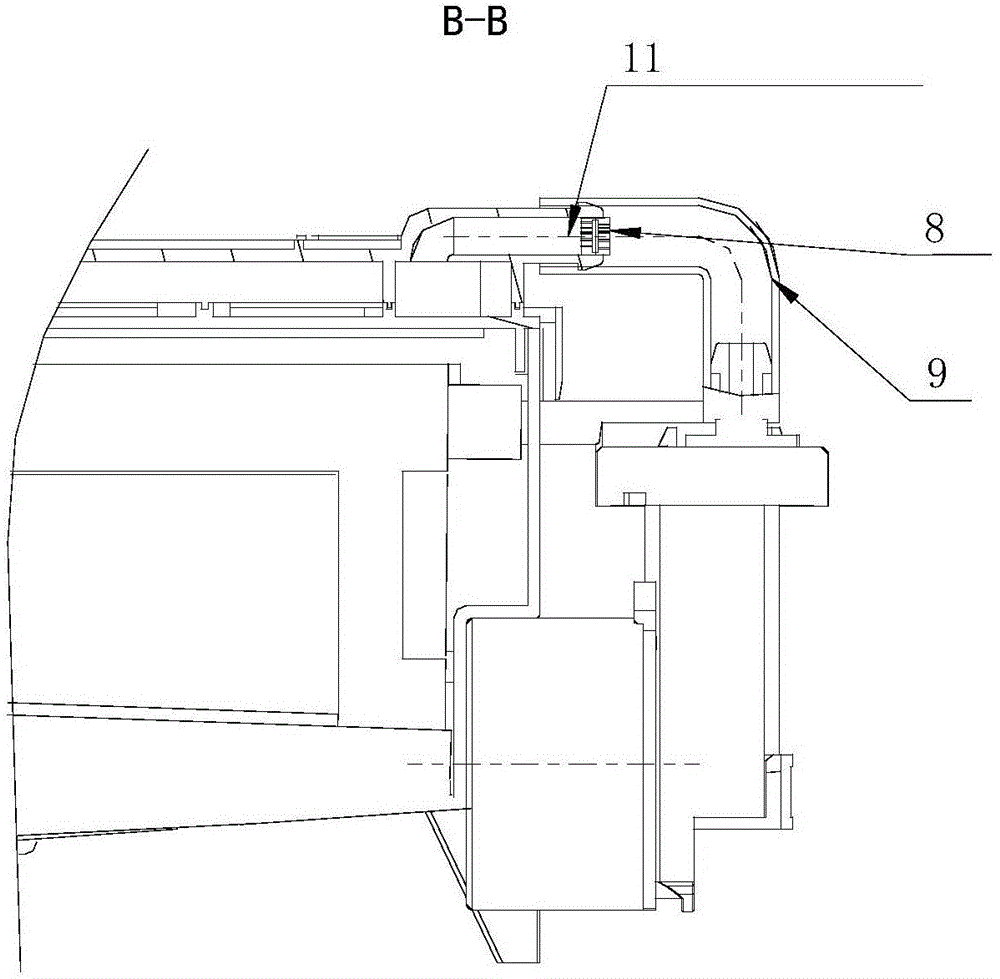

[0016] Such as Figure 1 to Figure 3 As shown, the detergent delivery box of the drum washing machine of the present invention includes a washing solution box 2 containing laundry detergent, softener or disinfectant, a lower water box 1 and an automatic delivery pump 6, and the top of the washing solution box 2 is provided with an internal Pipeline, the liquid inlet 10 of the internal pipeline is connected with the automatic feeding pump 6 through the check valve 7, the internal pipeline draws liquid from the bottom of the washing liquid box, the automatic feeding pump 6 is installed on the lower water box 1, and the automatic feeding pump 6 is preferred It is a piston pump with high self-priming capacity. The automatic delivery pump 6 injects detergent into the shower assembly 3 located on the top of the drain box 1 through the infusion tube 9. The shower assembly 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com